engine ACURA NSX 1991 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 1126 of 1640

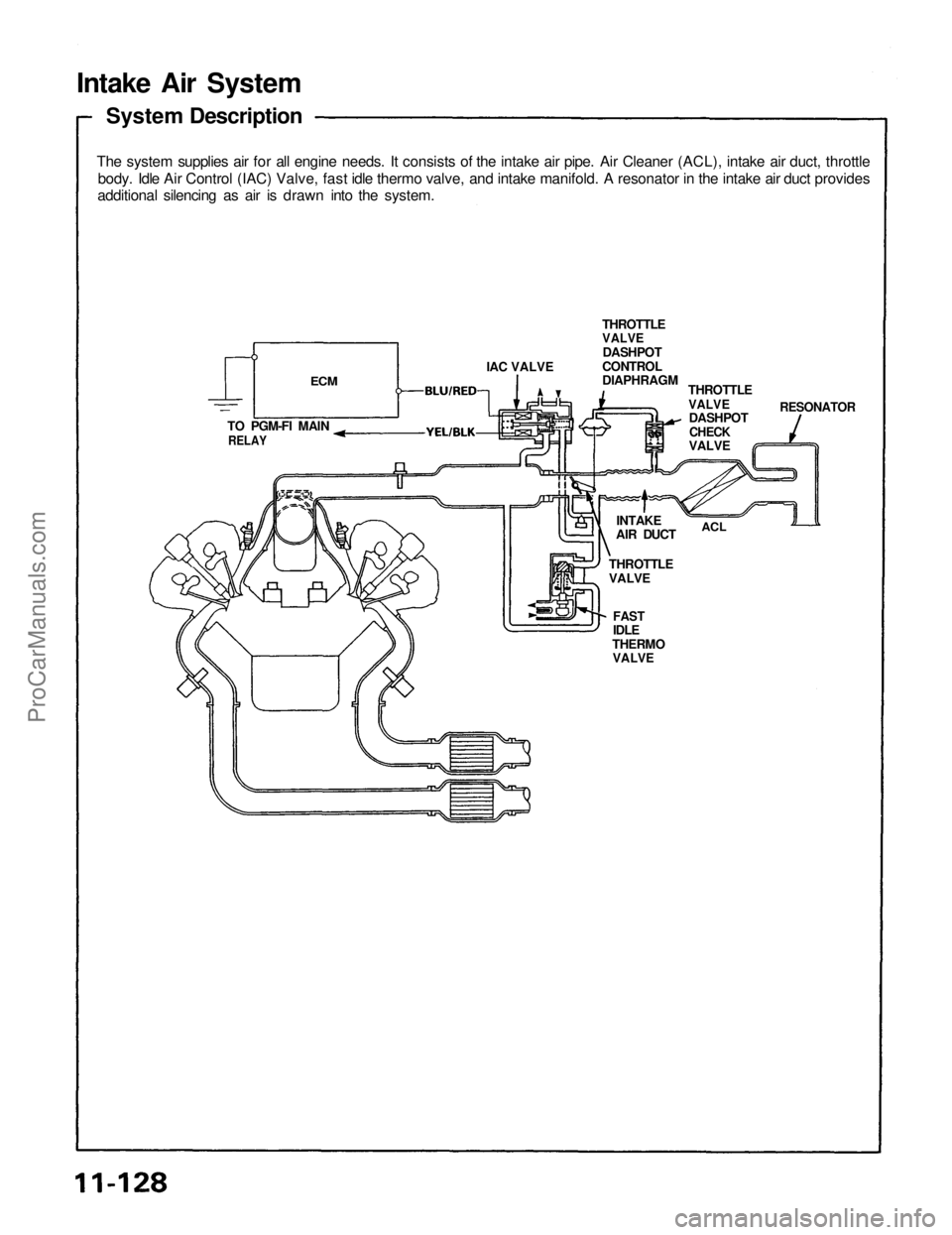

Intake Air System

System Description

The system supplies air for all engine needs. It consists of the intake air pipe. Air Cleaner (ACL), intake air duct, throttle

body. Idle Air Control (IAC) Valve, fast idle thermo valve, and intake manifold. A resonator in the intake air duct provides

additional silencing as air is drawn into the system.

FAST

IDLE

THERMO

VALVE

ECM

IAC VALVE

TO PGM-FI MAIN

RELAY

THROTTLE

VALVE

INTAKE

AIR DUCT

ACL

THROTTLE

VALVE

DASHPOT

CONTROL

DIAPHRAGM

THROTTLE

VALVE

RESONATOR

DASHPOT

CHECK

VALVEProCarManuals.com

Page 1128 of 1640

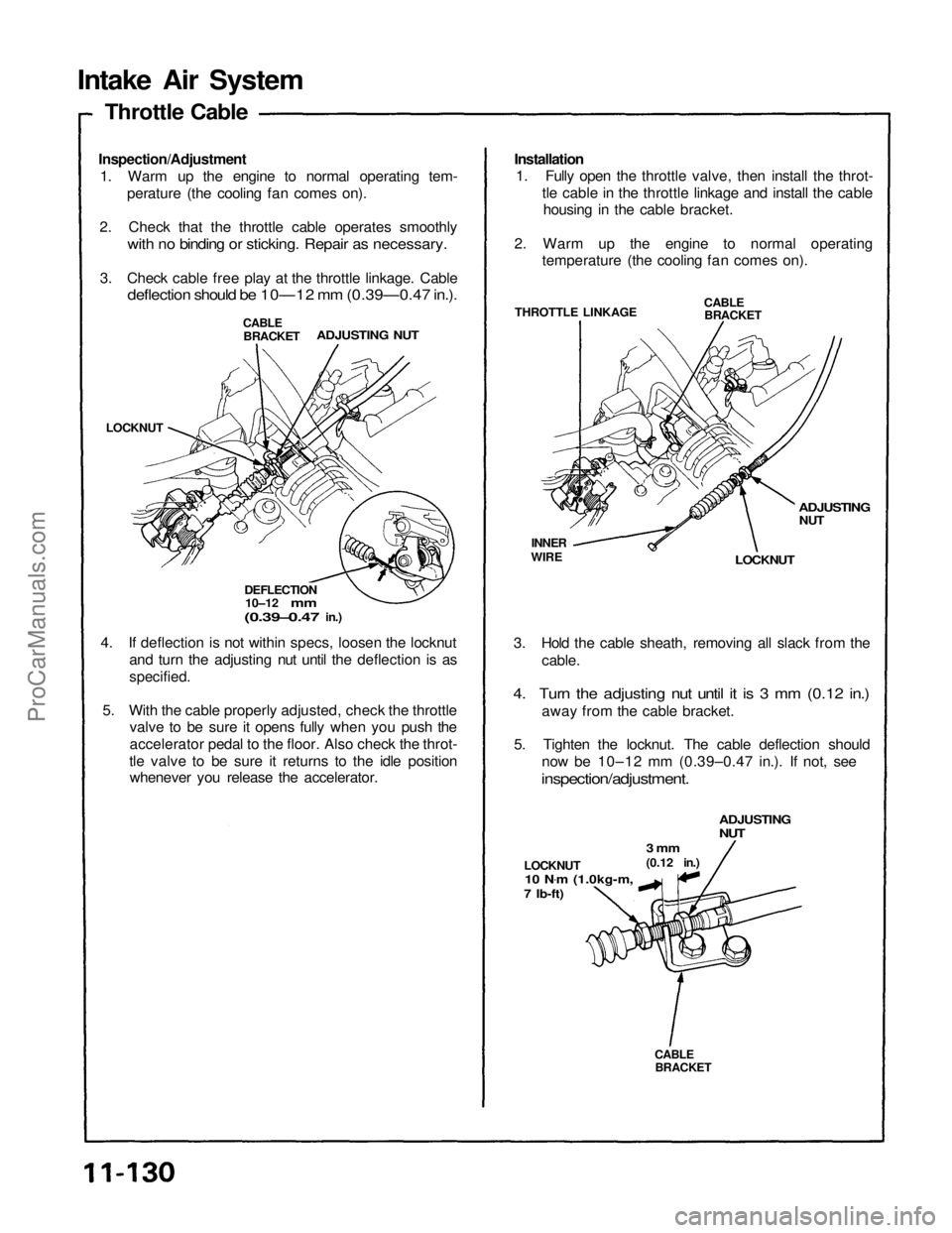

Intake Air System

Inspection/Adjustment

1. Warm up the engine to normal operating tem- perature (the cooling fan comes on).

2. Check that the throttle cable operates smoothly

with no binding or sticking. Repair as necessary.

3. Check cable free play at the throttle linkage. Cable

deflection should be 10—12 mm (0.39—0.47 in.).

Installation

1. Fully open the throttle valve, then install the throt-

tle cable in the throttle linkage and install the cablehousing in the cable bracket.

2. Warm up the engine to normal operating temperature (the cooling fan comes on).

4. If deflection is not within specs, loosen the locknut and turn the adjusting nut until the deflection is as

specified.

5. With the cable properly adjusted, check the throttle valve to be sure it opens fully when you push the

accelerator pedal to the floor. Also check the throt-

tle valve to be sure it returns to the idle position whenever you release the accelerator. 3. Hold the cable sheath, removing all slack from the

cable.

4. Turn the adjusting nut until it is 3 mm (0.12 in.)

away from the cable bracket.

5. Tighten the locknut. The cable deflection should now be 10–12 mm (0.39–0.47 in.). If not, see

inspection/adjustment.

CABLE

BRACKET

LOCKNUT

10 N .

m (1.0kg-m,

7 Ib-ft)

3 mm

(0.12 in.)

ADJUSTING

NUT

DEFLECTION

10–12

mm

(0.39–0.47

in.)

ADJUSTING NUT

CABLE

BRACKET

LOCKNUT

INNER

WIRE

THROTTLE LINKAGE

LOCKNUT

ADJUSTING

NUT

CABLE

BRACKET

Throttle CableProCarManuals.com

Page 1134 of 1640

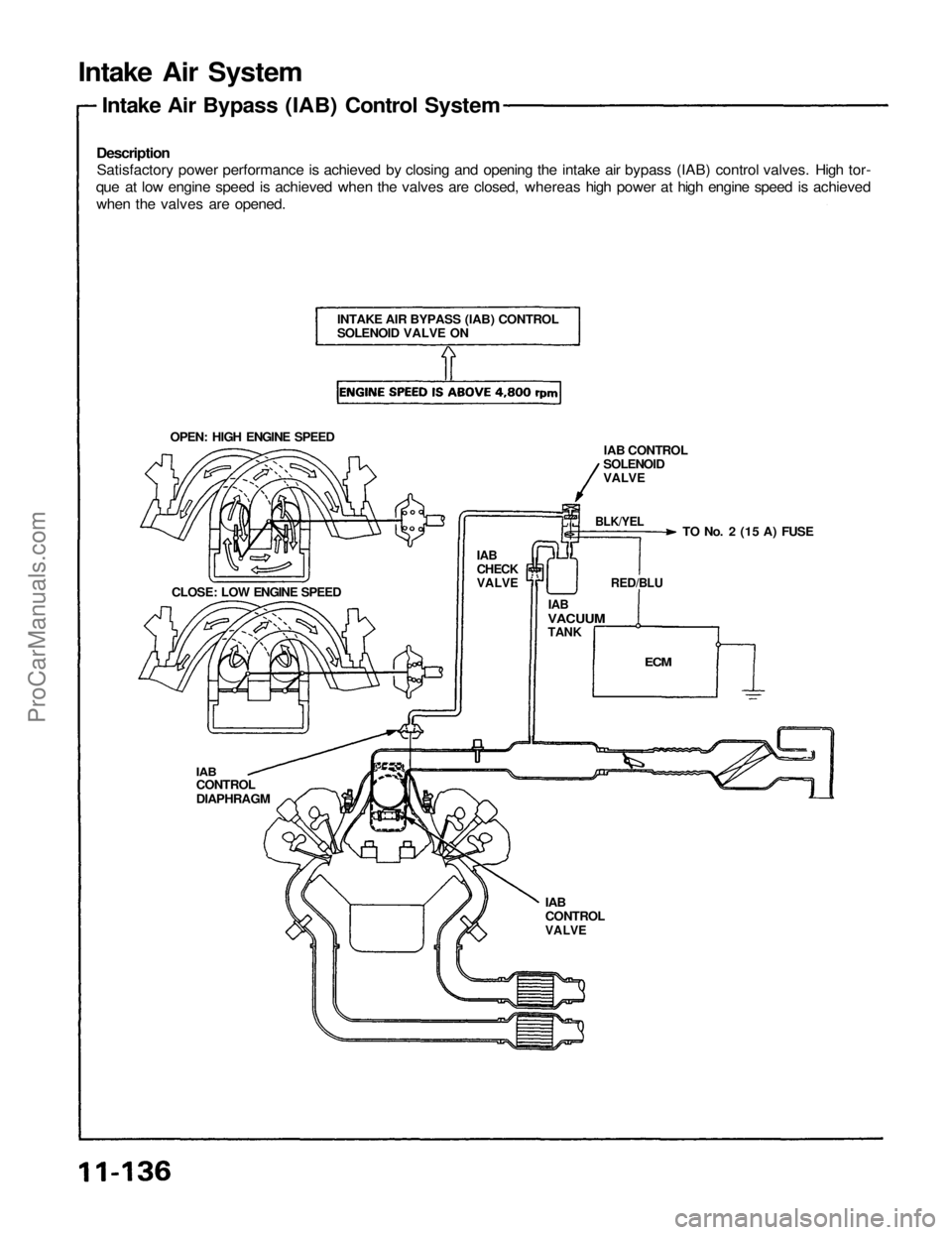

Intake Air System

Description

Satisfactory power performance is achieved by closing and opening the intake air bypass (IAB) control valves. High tor-

que at low engine speed is achieved when the valves are closed, whereas high power at high engine speed is achieved

when the valves are opened.

Intake Air Bypass (IAB) Control System

OPEN: HIGH ENGINE SPEED

INTAKE AIR BYPASS (IAB) CONTROL

SOLENOID VALVE ON

IAB

CHECK

VALVE

CLOSE: LOW ENGINE SPEED

IAB

CONTROL

DIAPHRAGM

IAB

CONTROL

VALVE

ECM

IAB

VACUUM

TANK

IAB CONTROL

SOLENOID

VALVE

TO No. 2 (15 A) FUSE

BLK/YEL

RED/BLUProCarManuals.com

Page 1141 of 1640

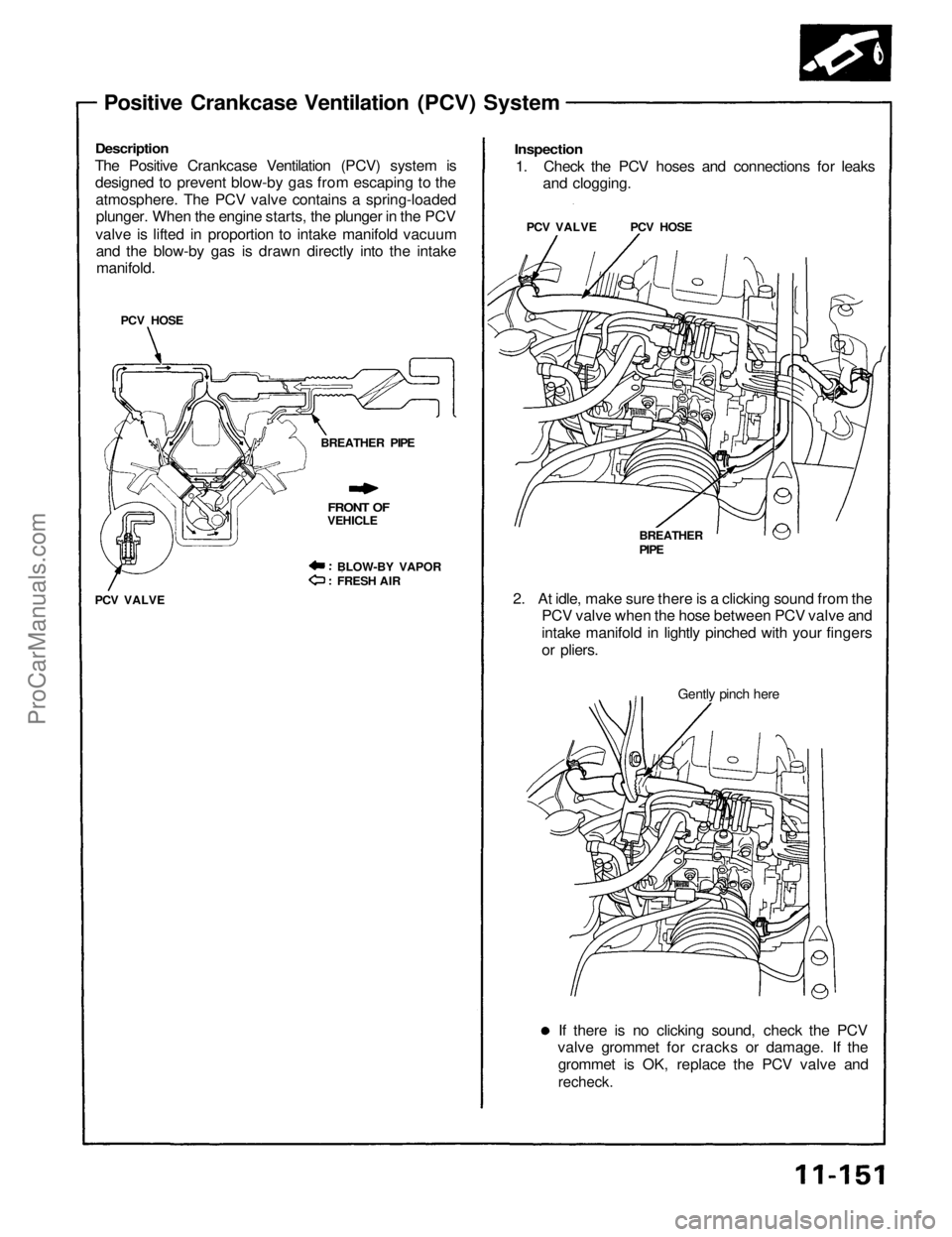

Positive Crankcase Ventilation (PCV) System

Description

The Positive Crankcase Ventilation (PCV) system is

designed to prevent blow-by gas from escaping to the

atmosphere. The PCV valve contains a spring-loaded

plunger. When the engine starts, the plunger in the PCV

valve is lifted in proportion to intake manifold vacuum

and the blow-by gas is drawn directly into the intake

manifold.

PCV HOSE

BREATHER PIPE

FRONT OF

VEHICLE

BLOW-BY VAPOR

FRESH AIR

PCV VALVE

If there is no clicking sound, check the PCV

valve grommet for cracks or damage. If the

grommet is OK, replace the PCV valve and

recheck.

Gently pinch here

2. At idle, make sure there is a clicking sound from the

PCV valve when the hose between PCV valve and

intake manifold in lightly pinched with your fingers

or pliers.

BREATHER

PIPE

PCV VALVE PCV HOSE

Inspection

1. Check the PCV hoses and connections for leaks

and clogging.ProCarManuals.com

Page 1142 of 1640

Emission Control System

Description

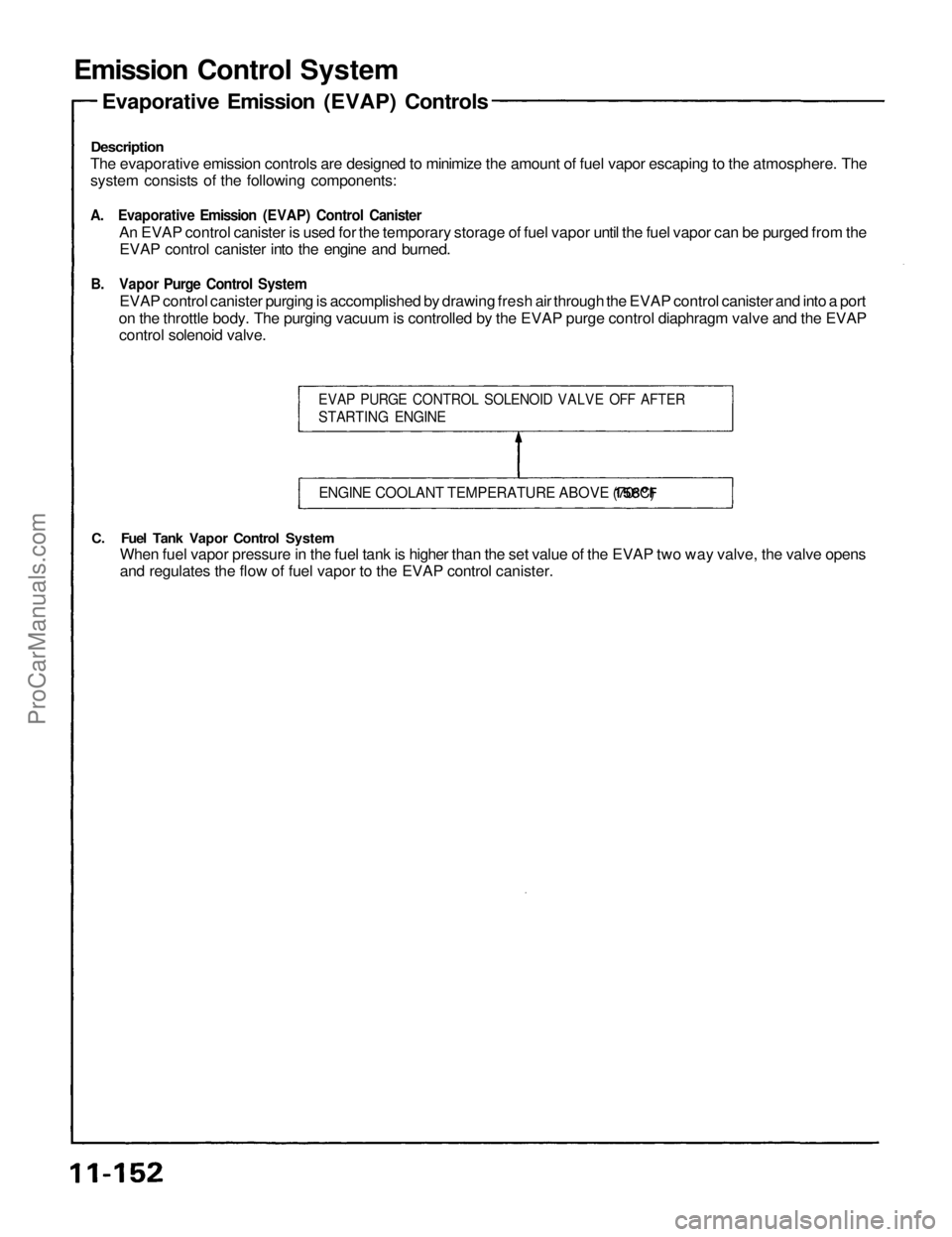

The evaporative emission controls are designed to minimize the amount of fuel vapor escaping to the atmosphere. The

system consists of the following components:

A. Evaporative Emission (EVAP) Control Canister

An EVAP control canister is used for the temporary storage of fuel vapor until the fuel vapor can be purged from the

EVAP control canister into the engine and burned.

B. Vapor Purge Control System

EVAP control canister purging is accomplished by drawing fresh air through the EVAP control canister and into a port

on the throttle body. The purging vacuum is controlled by the EVAP purge control diaphragm valve and the EVAP

control solenoid valve.

C. Fuel Tank Vapor Control System

When fuel vapor pressure in the fuel tank is higher than the set value of the EVAP two way valve, the valve opens

and regulates the flow of fuel vapor to the EVAP control canister.

EVAP PURGE CONTROL SOLENOID VALVE OFF AFTER

STARTING ENGINE

ENGINE COOLANT TEMPERATURE ABOVE

158°F

(70°C)

Evaporative Emission (EVAP) ControlsProCarManuals.com

Page 1150 of 1640

Transmission Assembly

Removal (cont'd)

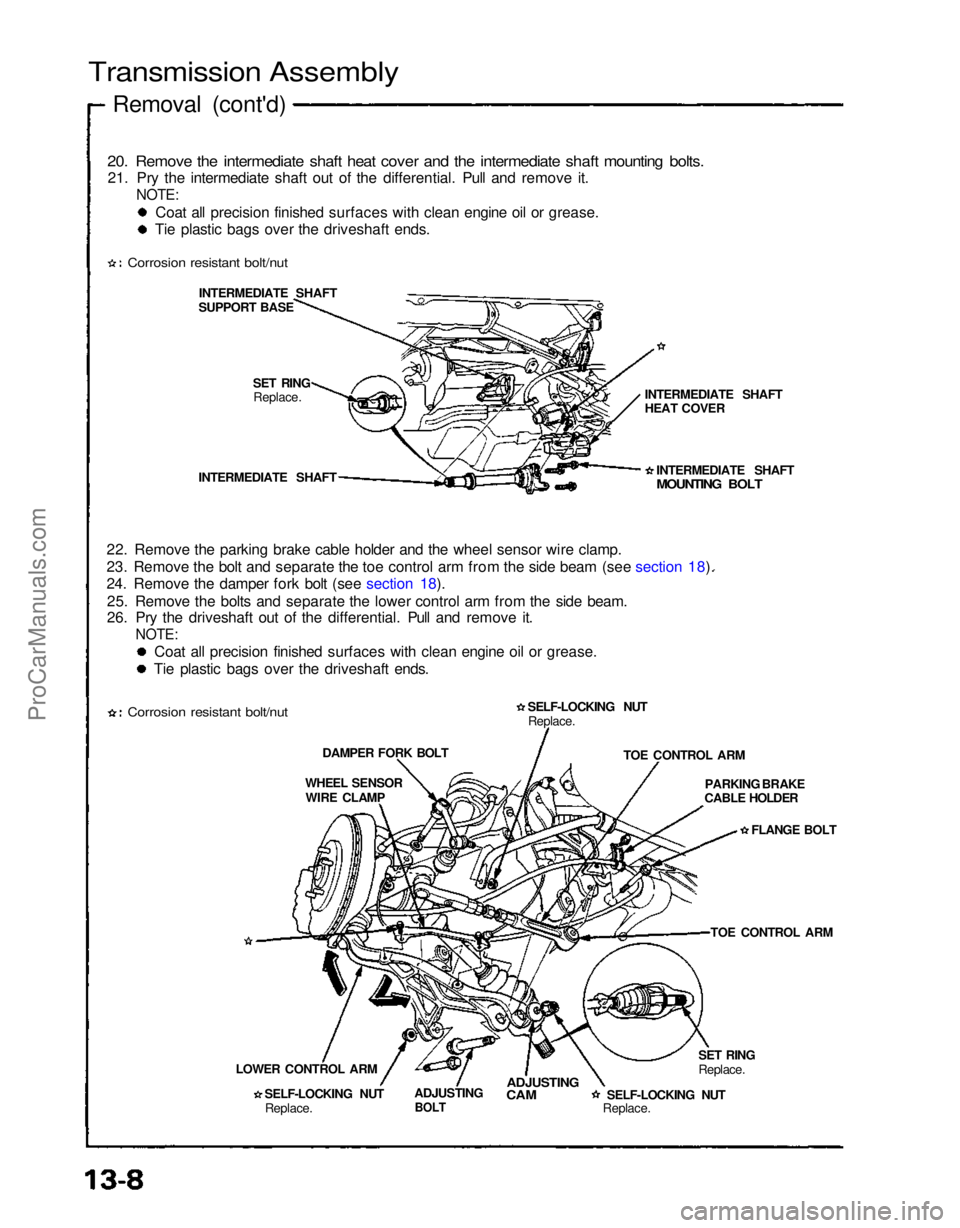

20. Remove the intermediate shaft heat cover and the intermediate shaft mounting bolts.

21. Pry the intermediate shaft out of the differential. Pull and remove it.

NOTE:

Coat all precision finished surfaces with clean engine oil or grease.

Tie plastic bags over the driveshaft ends.

Corrosion resistant bolt/nut

INTERMEDIATE SHAFT

SUPPORT BASE

SET RINGReplace.

INTERMEDIATE SHAFT

22. Remove the parking brake cable holder and the wheel sensor wire clamp.

23. Remove the bolt and separate the toe control arm from the side beam (see section 18).

24. Remove the damper fork bolt (see section 18). 25. Remove the bolts and separate the lower control arm from the side beam.

26. Pry the driveshaft out of the differential. Pull and remove it.

NOTE:

Coat all precision finished surfaces with clean engine oil or grease.

Tie plastic bags over the driveshaft ends.

Corrosion resistant bolt/nut

DAMPER FORK BOLT

WHEEL SENSOR WIRE CLAMP

LOWER CONTROL ARM SELF-LOCKING NUTReplace. ADJUSTING

BOLT

ADJUSTING

CAM

SELF-LOCKING NUT

Replace.SET RING

Replace.TOE CONTROL ARM

PARKING BRAKE

CABLE HOLDER

FLANGE BOLT

TOE CONTROL ARM

SELF-LOCKING NUT

Replace. INTERMEDIATE SHAFT

MOUNTING BOLT

INTERMEDIATE SHAFT

HEAT COVERProCarManuals.com

Page 1151 of 1640

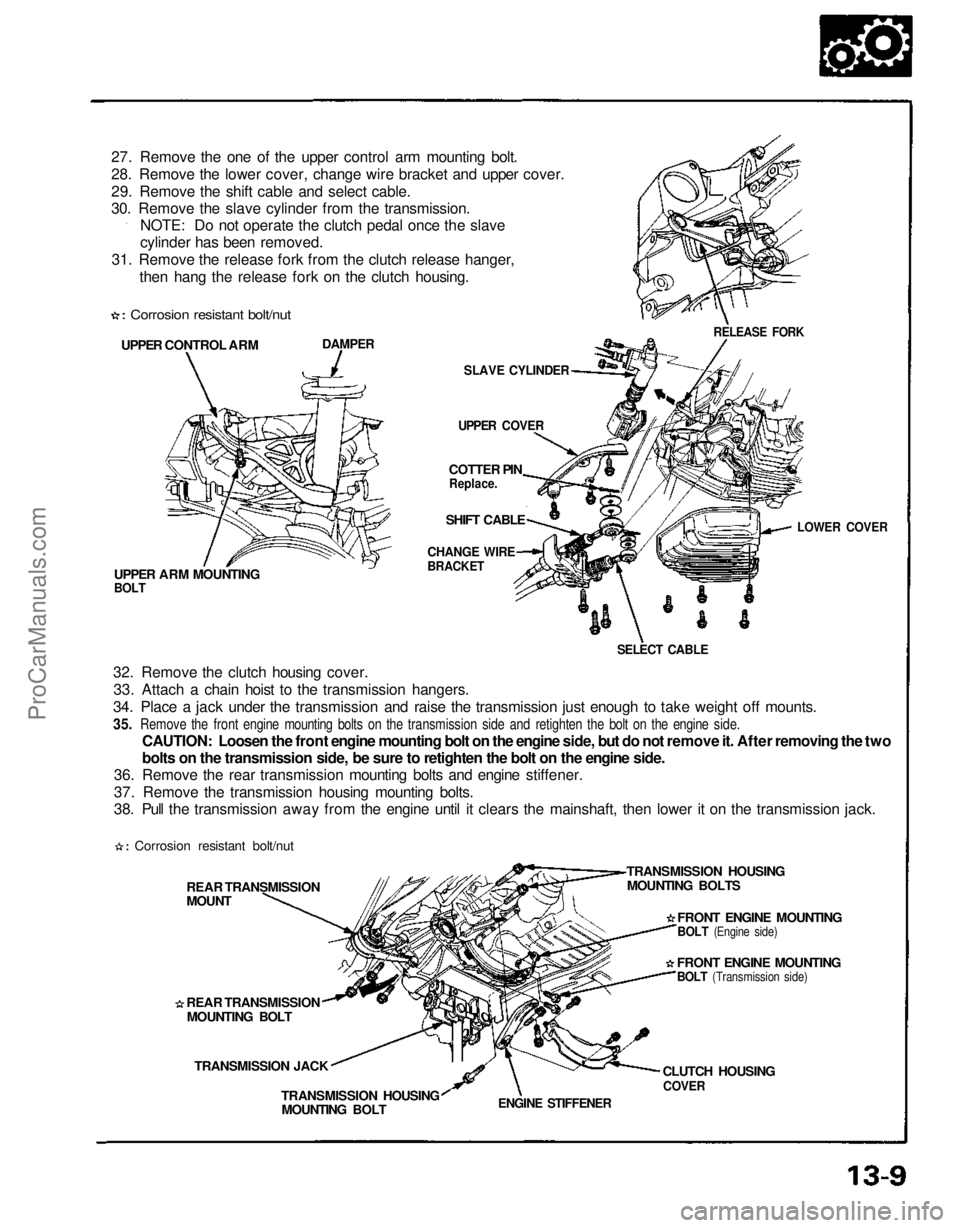

27. Remove the one of the upper control arm mounting bolt.

28. Remove the lower cover, change wire bracket and upper cover.

29. Remove the shift cable and select cable.

30. Remove the slave cylinder from the transmission.

NOTE: Do not operate the clutch pedal once the slave

cylinder has been removed.

31. Remove the release fork from the clutch release hanger, then hang the release fork on the clutch housing.

UPPER CONTROL ARM

DAMPER

SLAVE CYLINDER

UPPER COVER

UPPER ARM MOUNTING

BOLT

32. Remove the clutch housing cover. 33. Attach a chain hoist to the transmission hangers.

34. Place a jack under the transmission and raise the transmission just enough to take weight off mounts.

35. Remove the front engine mounting bolts on the transmission side and retighten the bolt on the engine side.

CAUTION: Loosen the front engine mounting bolt on the engine side, but do not remove it. After removing the two

bolts on the transmission side, be sure to retighten the bolt on the engine side.

36. Remove the rear transmission mounting bolts and engine stiffener.

37. Remove the transmission housing mounting bolts.

38. Pull the transmission away from the engine until it clears the mainshaft, then lower it on the transmission jack.

REAR TRANSMISSION

MOUNT

REAR TRANSMISSIONMOUNTING BOLT

TRANSMISSION JACK TRANSMISSION HOUSINGMOUNTING BOLT

ENGINE STIFFENER

CLUTCH HOUSING

COVER

TRANSMISSION HOUSING

MOUNTING BOLTS

FRONT ENGINE MOUNTING

BOLT

(Engine side)

FRONT ENGINE MOUNTING

BOLT

(Transmission side)

RELEASE FORK

COTTER PIN

Replace.

SHIFT CABLE

CHANGE WIRE

BRACKET

SELECT CABLE

LOWER COVER

Corrosion resistant bolt/nut

Corrosion resistant bolt/nutProCarManuals.com

Page 1160 of 1640

Transmission Assembly

Installation

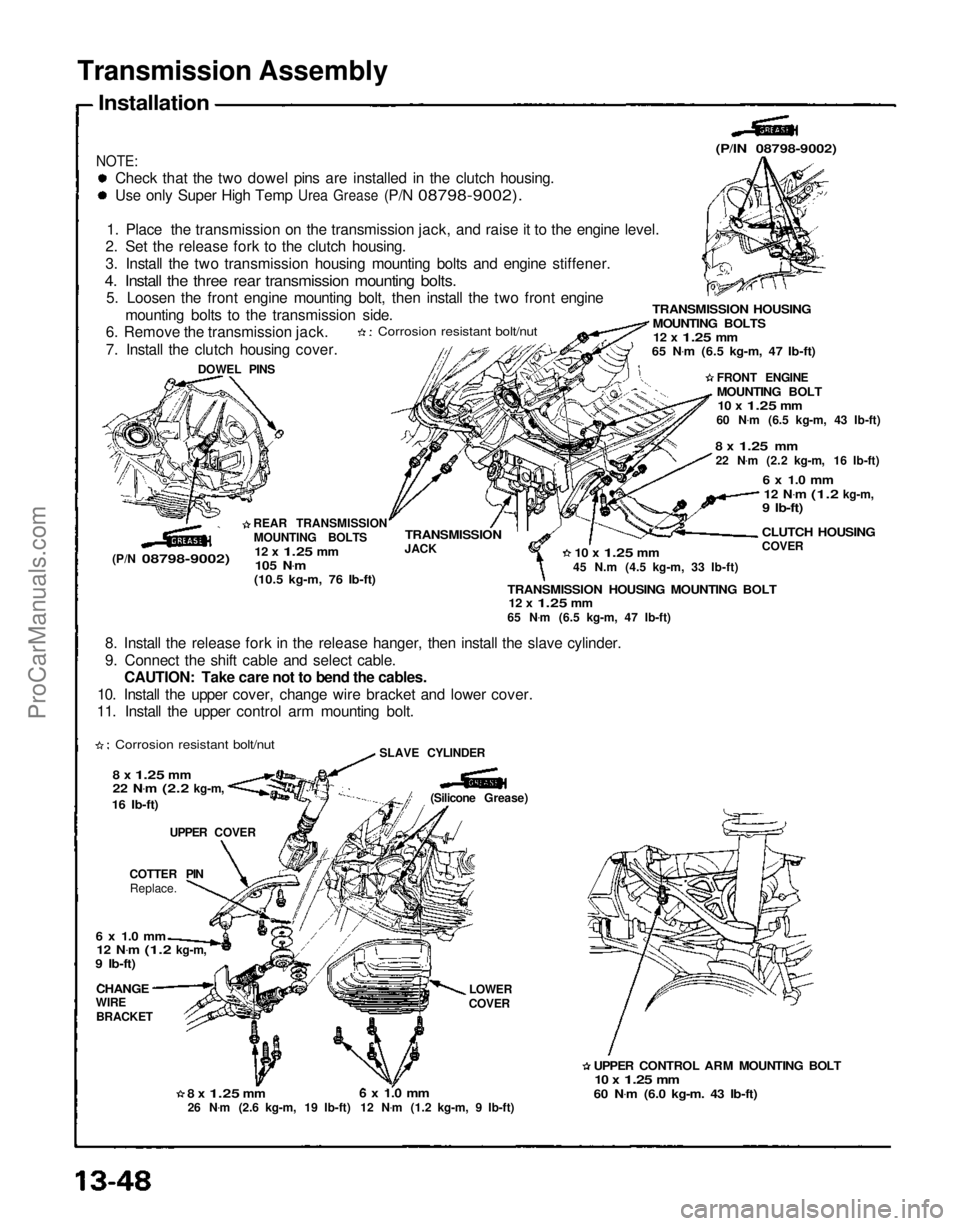

NOTE:

Check that the two dowel pins are installed in the clutch housing.

Use

only Super High Temp

Urea

Grease

(P/N

08798-9002).

1. Place the transmission on the transmission jack, and raise it to the engine level.

2. Set the release fork to the clutch housing.

3. Install the two transmission housing mounting bolts and engine stiffener.

4. Install the three rear transmission mounting bolts.

5. Loosen the front engine mounting bolt, then install the two front engine

mounting bolts to the transmission side.

6. Remove the transmission jack.

7. Install the clutch housing cover.

Corrosion resistant bolt/nut

DOWEL PINS

(P/N

08798-9002)

REAR TRANSMISSION

MOUNTING BOLTS

12 x

1.25

mm

105 N .

m

(10.5 kg-m, 76 Ib-ft)

(P/lN 08798-9002)

TRANSMISSION HOUSING

MOUNTING BOLTS

12 x

1.25

mm

65 N .

m (6.5 kg-m, 47 Ib-ft)

FRONT ENGINE

MOUNTING BOLT

10 x

1.25

mm

60 N .

m (6.5 kg-m, 43 Ib-ft)

8 x

1.25

mm

22 N .

m (2.2 kg-m, 16 Ib-ft)

6 x 1.0 mm

12 N .

m

(1.2

kg-m,

9 Ib-ft)

CLUTCH HOUSING

COVER

10 x

1.25

mm

45 N.m (4.5 kg-m, 33 Ib-ft)

TRANSMISSION HOUSING MOUNTING BOLT

12 x

1.25

mm

65 N .

m (6.5 kg-m, 47 Ib-ft)

TRANSMISSION

JACK

8. Install the release fork in the release hanger, then install the slave cylinder.

9. Connect the shift cable and select cable. CAUTION: Take care not to bend the cables.

10. Install the upper cover, change wire bracket and lower cover.

11. Install the upper control arm mounting bolt.

Corrosion resistant bolt/nut

8 x

1.25

mm

22 N .

m

(2.2

kg-m,

16 Ib-ft)

UPPER COVER

COTTER PIN Replace.

6 x 1.0 mm

12 N .

m

(1.2

kg-m,

9 Ib-ft)

CHANGE

WIRE

BRACKET

8 x

1.25

mm

26 N .

m (2.6 kg-m, 19 Ib-ft)

6 x 1.0 mm

12 N .

m (1.2 kg-m, 9 Ib-ft) LOWER

COVER

UPPER CONTROL ARM MOUNTING BOLT

10 x

1.25

mm

60 N .

m (6.0 kg-m. 43 Ib-ft)

(Silicone Grease)

SLAVE CYLINDERProCarManuals.com

Page 1165 of 1640

Description

The automatic transmission is a combination of a 3-element torque converter and a triple-shaft electronically controlled

automatic transmission which provides 4 speeds forward and 1 in reverse. The entire unit is positioned in line with the

engine.

TORQUE CONVERTER, GEARS AND CLUTCHES

The torque converter consists of a pump, turbine and stator, assembled in a single unit.

They are connected to the engine crankshaft so they turn together as a unit as the engine turns.

Around the outside of the torque converter is a ring gear which meshes with the starter pinion when the engine is being

started. The entire torque converter assembly serves as a flywheel while transmitting power to the transmission mainshaft.

The transmission has three parallel shafts, the mainshaft, the countershaft, and the secondary shaft. The mainshaft is

in line with the engine crankshaft.

The mainshaft includes the clutches for 1st, and 4th, and gears for 3rd, 4th, Reverse and 1st (3rd gear is integral with

the mainshaft, while reverse gear is integral with 4th gear).

The countershaft includes the clutches for 1st-Hold and 3rd, and gears for 2nd, 3rd, 4th, Reverse and 1st.

The secondary shaft includes the 2nd clutch and gears for 2nd and 3rd.

The 4th and reverse gears can be locked to the countershaft at its center, providing 4th gear or Reverse, depending on

which way the selector is moved.

The gears on the mainshaft and secondary shaft are in constant mesh with those on the countershaft.

When certain combinations of gears in the transmission are engaged by clutches, power is transmitted from the main-

shaft to the countershaft to provide , , , and

ELECTRONIC CONTROL

The electronic control system consists of the Transmission Control Module (TCM), sensors, a linear solenoid and 4

solenoid valves. Shifting and lock-up are electronically controlled for comfortable driving under all conditions.

The TCM is located on the insulator center bulkhead, behind the driver's seat.

HYDRAULIC CONTROL

The valve bodies include the main valve body, secondary valve body, servo body, regulator valve body, throttle valve

body, lock-up valve body and the 2nd accumulator body.

They are bolted to the torque converter housing as an assembly.

The main valve body contains the manual valve, 1-2 shift valve, 2-3 shift valve, 3-4 shift valve, relief valve, one-way

relief valve and oil pump gears.

The secondary valve body contains the 3-2 kick-down valve, CPC (clutch pressure control) valve, 2nd orifice control

valve, 3rd orifice control valve, modulator valve, 4th exhaust valve, servo control valve, 2nd exhaust valve and 4-3 kick-

down valve.

The servo body contains the accumulator pistons and servo valve. The throttle valve body includes the throttle valve B

which is bolted onto the servo body.

The regulator valve body contains the pressure regulator valve, lock-up control valve and cooler relief valve. Fluid from

the regulator passes through the manual valve to the various control valves.

The lock-up valve body contains the lock-up timing B valve and lock-up shift valve. The 2nd accumulator body contains

the accumulator pistons and limited slip differential (LSD) relief valve.

The torque converter check valve is located in the torque converter housing, under the main valve body.

The 1st, 1st-hold, 3rd and 4th clutches receive oil from their respective feed pipes.

SHIFT CONTROL MECHANISM

Input from various sensors located throughout the car determines which shift control solenoid valve the TCM will ac-

tivate. Activating a shift control solenoid valve changes modulator pressure, causing a shift valve to move. This

pressurizes a line to one of the clutches, engaging that clutch and its corresponding gear.

LOCK-UP MECHANISM

In position and position in 2nd, 3rd and 4th, pressurized fluid is drained from the back of the torque converter

through an oil passage, causing the lock-up piston to be held, against the torque converter cover. As this takes place, the

mainshaft rotates at the same speed as the engine crankshaft. Together with hydraulic control, the TCM optimizes the

timing of the lock-up mechaism.

The lock-up valves control the range of lock-up according to lock-up control solenoid valves A and B, and throttle valve B.

When lock-up control solenoid valves A and B activate, modulator pressure changes. The lock-up control solenoid valves

A and B are mounted on the torque converter housing, and are controlled by the TCM.

(cont'd)ProCarManuals.com

Page 1166 of 1640

REVERSE,

Description

(cont'd)

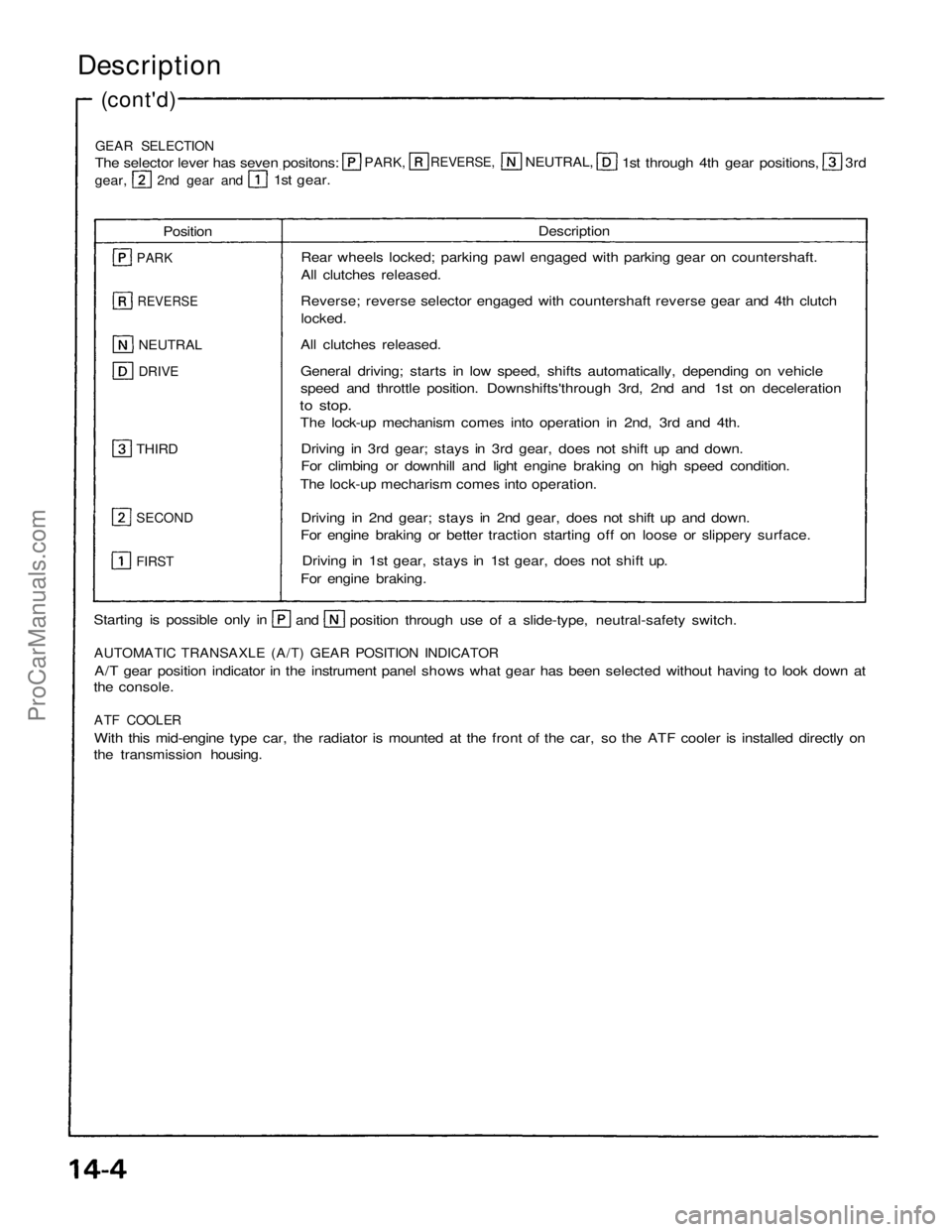

AUTOMATIC TRANSAXLE (A/T) GEAR POSITION INDICATOR

A/T gear position indicator in the instrument panel shows what gear has been selected without having to look down at

the console.

ATF COOLER

With this mid-engine type car, the radiator is mounted at the front of the car, so the ATF cooler is installed directly on

the transmission housing. Position

Description

PARK

REVERSE

NEUTRAL

DRIVE

THIRD

SECOND

FIRST

Rear wheels locked; parking pawl engaged with parking gear on countershaft.

All clutches released.

Reverse; reverse selector engaged with countershaft reverse gear and 4th clutch locked.

All clutches released.

General driving; starts in low speed, shifts automatically, depending on vehicle

speed and throttle position. Downshifts'through 3rd, 2nd and 1st on deceleration

to stop.

The lock-up mechanism comes into operation in 2nd, 3rd and 4th.

Driving in 3rd gear; stays in 3rd gear, does not shift up and down.

For climbing or downhill and light engine braking on high speed condition.

The lock-up mecharism comes into operation.

Driving in 2nd gear; stays in 2nd gear, does not shift up and down.

For engine braking or better traction starting off on loose or slippery surface.

Driving in 1st gear, stays in 1st gear, does not shift up.

For engine braking.

GEAR SELECTION

The selector lever has seven positons:

PARK,

NEUTRAL,

1st through 4th gear positions,

3rd

gear,

2nd gear and

1st gear.

Starting is possible only in

and

position through use of a slide-type, neutral-safety switch.

ProCarManuals.com