ACURA NSX 1991 Service Repair Manual

Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 751 of 1640

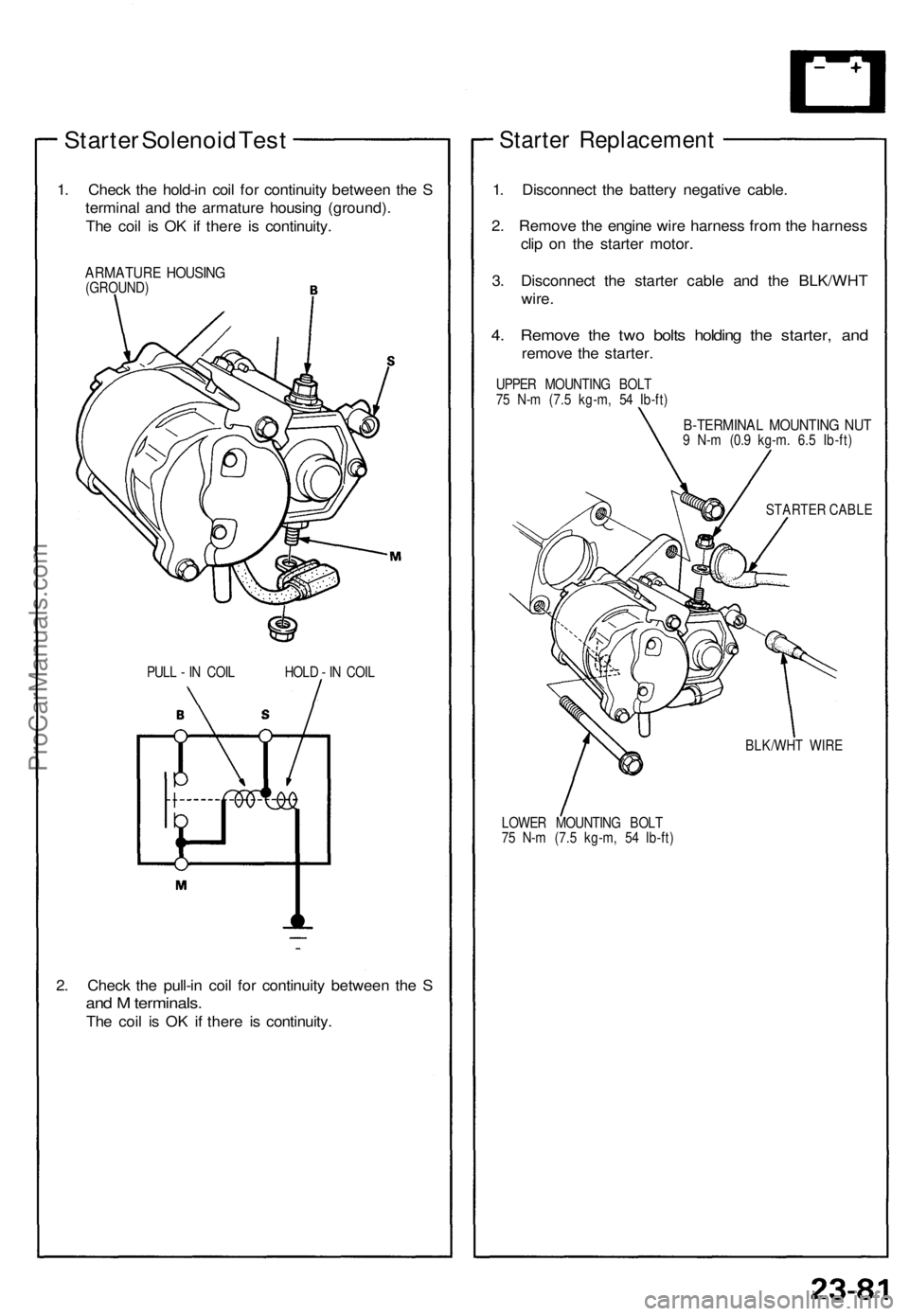

Starter Solenoid Test

1. Check the hold-in coil for continuity between the S

terminal and the armature housing (ground).

The coil is OK if there is continuity.

ARMATURE HOUSING

(GROUND)

PULL - IN COIL HOLD - IN COIL

2. Check the pull-in coil for continuity between the S

and M terminals.

The coil is OK if there is continuity.

Starter Replacement

1. Disconnect the battery negative cable.

2. Remove the engine wire harness from the harness

clip on the starter motor.

3. Disconnect the starter cable and the BLK/WHT

wire.

4. Remove the two bolts holding the starter, and

remove the starter.

UPPER MOUNTING BOLT

75 N-m (7.5 kg-m, 54 Ib-ft)

B-TERMINAL MOUNTING NUT

9 N-m (0.9 kg-m. 6.5 Ib-ft)

STARTER CABLE

LOWER MOUNTING BOLT

75 N-m (7.5 kg-m, 54 Ib-ft)

BLK/WHT WIREProCarManuals.com

Page 752 of 1640

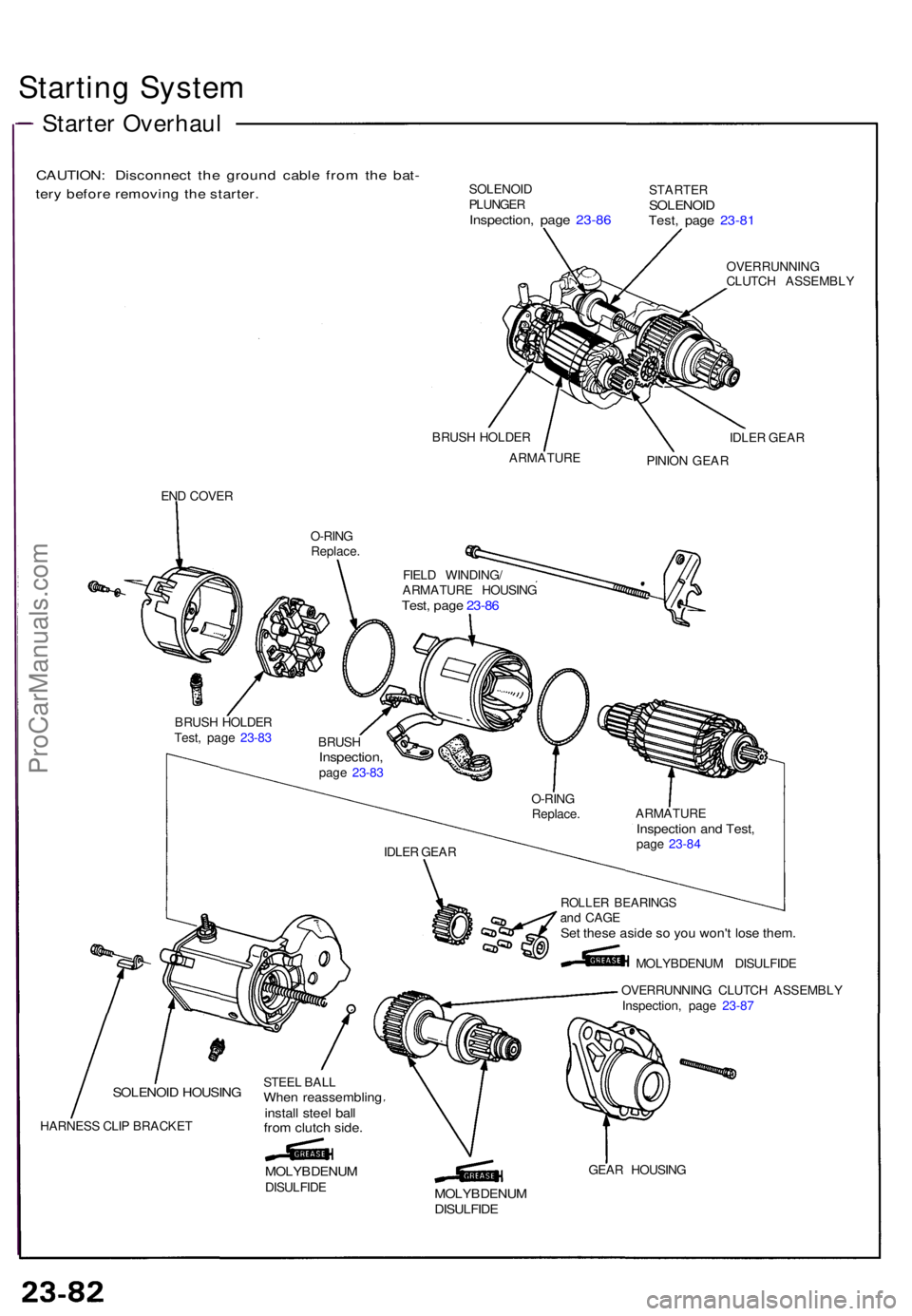

Starting Syste m

CAUTION : Disconnec t th e groun d cabl e fro m th e bat -

tery befor e removin g th e starter .SOLENOI D

PLUNGE R

Inspection , pag e 23-8 6

STARTE RSOLENOI DTest, pag e 23-8 1

OVERRUNNIN G

CLUTC H ASSEMBL Y

BRUS H HOLDE R

ARMATUR E IDLE

R GEA R

PINIO N GEA R

EN D COVE R

O-RING

Replace .

FIELD WINDING /

ARMATUR E HOUSIN G

Test, pag e 23-8 6

IDLE R GEA R

SOLENOI D HOUSIN G

HARNES S CLI P BRACKE T STEE

L BAL L

When reassemblin ginstall stee l bal lfrom clutc h side .

MOLYBDENU MDISULFIDE

ROLLER BEARING Sand CAG ESet thes e asid e s o yo u won' t los e them .

MOLYBDENU M DISULFID E

OVERRUNNIN G CLUTC H ASSEMBL Y

Inspection , pag e 23-8 7

GEA R HOUSIN G

MOLYBDENU MDISULFIDE

Starter Overhau l

BRUSH HOLDE R

Test , pag e 23-8 3

BRUSH

Inspection ,page 23-8 3

ARMATURE

Inspection an d Test ,page 23-8 4

O-RIN

G

Replace .

ProCarManuals.com

Page 753 of 1640

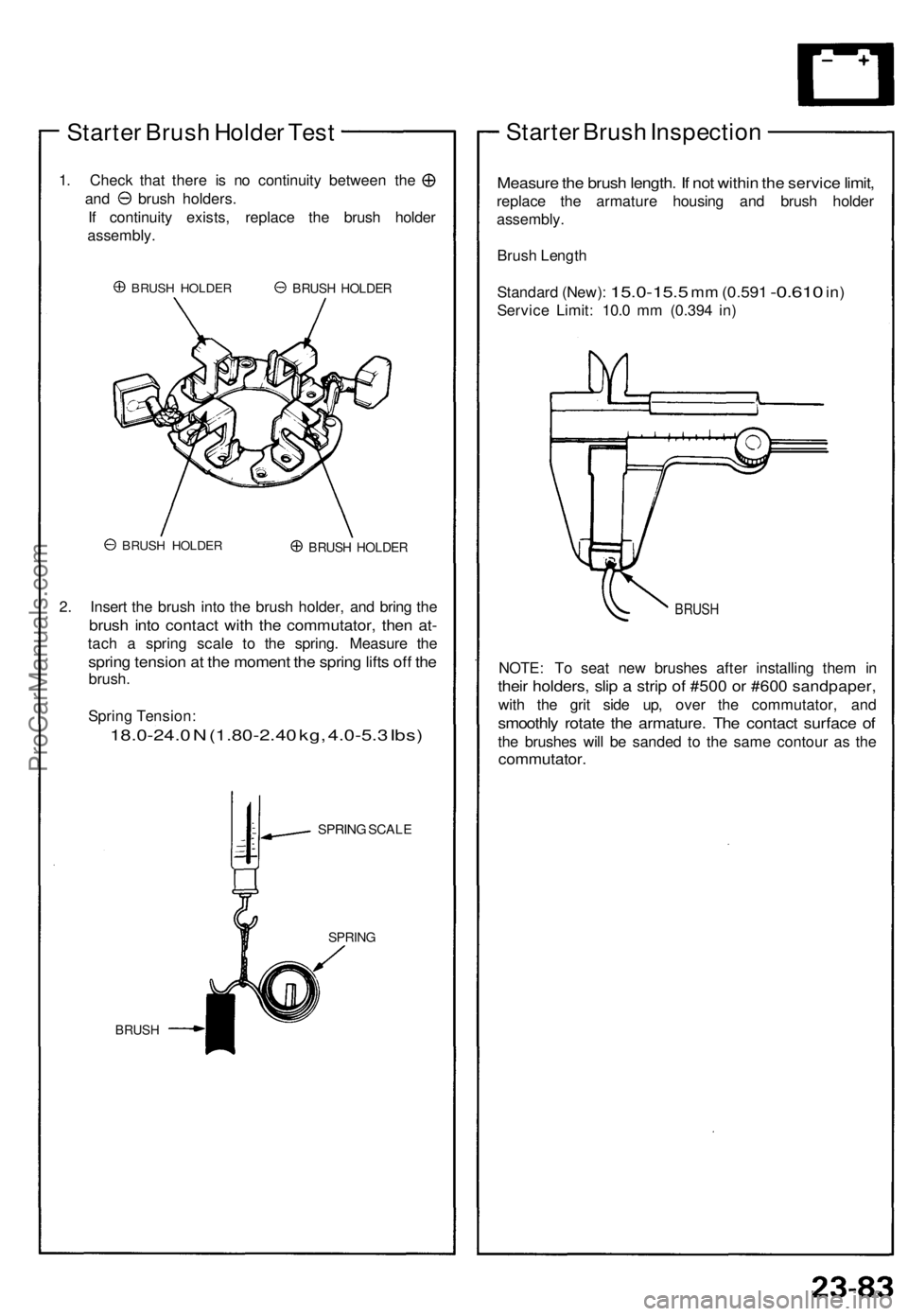

Starter Brush Holder Test

1. Check that there is no continuity between the

and brush holders.

If continuity exists, replace the brush holder

assembly.

BRUSH HOLDER

BRUSH HOLDER

BRUSH HOLDER

2. Insert the brush into the brush holder, and bring the

brush into contact with the commutator, then at-

tach a spring scale to the spring. Measure the

spring tension at the moment the spring lifts off the

brush.

Spring Tension:

18.0-24.0 N (1.80-2.40 kg, 4.0-5.3 Ibs)

SPRING SCALE

BRUSH

SPRING

Starter Brush Inspection

Measure the brush length. If not within the service limit,

replace the armature housing and brush holder

assembly.

Brush Length

Standard (New):

15.0-15.5

mm

(0.591

-0.610

in)

Service Limit: 10.0 mm (0.394 in)

BRUSH

NOTE: To seat new brushes after installing them in

their holders, slip a strip of #500 or #600 sandpaper,

with the grit side up, over the commutator, and

smoothly rotate the armature. The contact surface of

the brushes will be sanded to the same contour as the

commutator.

BRUSH HOLDERProCarManuals.com

Page 754 of 1640

Starting System

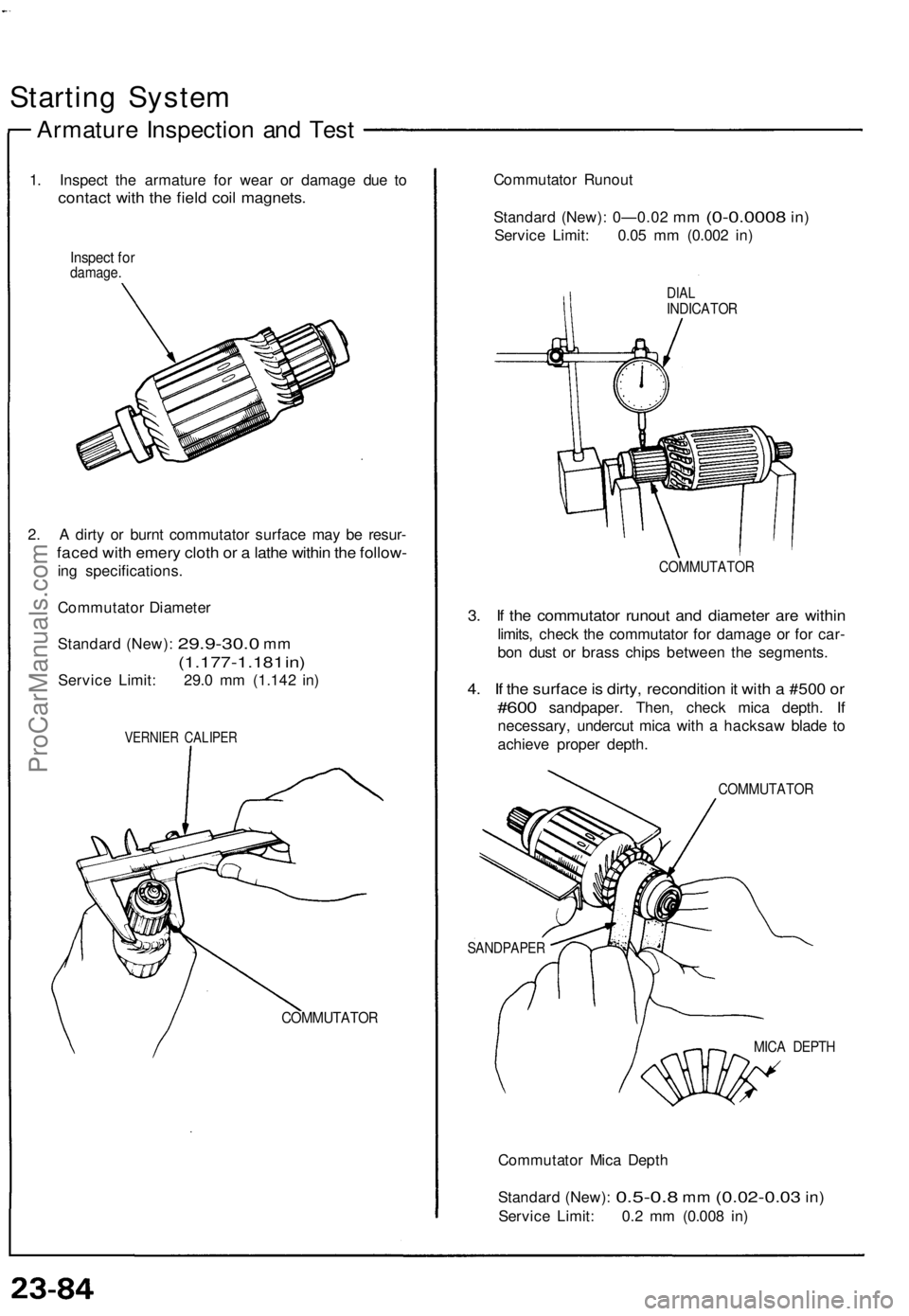

Armature Inspection and Test

1. Inspect the armature for wear or damage due to

contact with the field coil magnets.

Inspect for

damage.

2. A dirty or burnt commutator surface may be resur-

faced with emery cloth or a lathe within the follow-

ing specifications.

Commutator Diameter

Standard (New):

29.9-30.0

mm

(1.177-1.181 in)

Service Limit: 29.0 mm (1.142 in)

VERNIER CALIPER

COMMUTATOR

Commutator Runout

Standard (New): 0—0.02

mm

(0-0.0008

in)

Service Limit: 0.05 mm (0.002 in)

DIAL

INDICATOR

COMMUTATOR

3. If the commutator runout and diameter are within

limits, check the commutator for damage or for car-

bon dust or brass chips between the segments.

4. If the surface is dirty, recondition it with a #500 or

#600

sandpaper. Then, check mica depth.

If

necessary, undercut mica with a hacksaw blade to

achieve proper depth.

COMMUTATOR

SANDPAPER

MICA DEPTH

Commutator Mica Depth

Standard (New):

0.5-0.8

mm

(0.02-0.03

in)

Service Limit: 0.2 mm (0.008 in)ProCarManuals.com

Page 755 of 1640

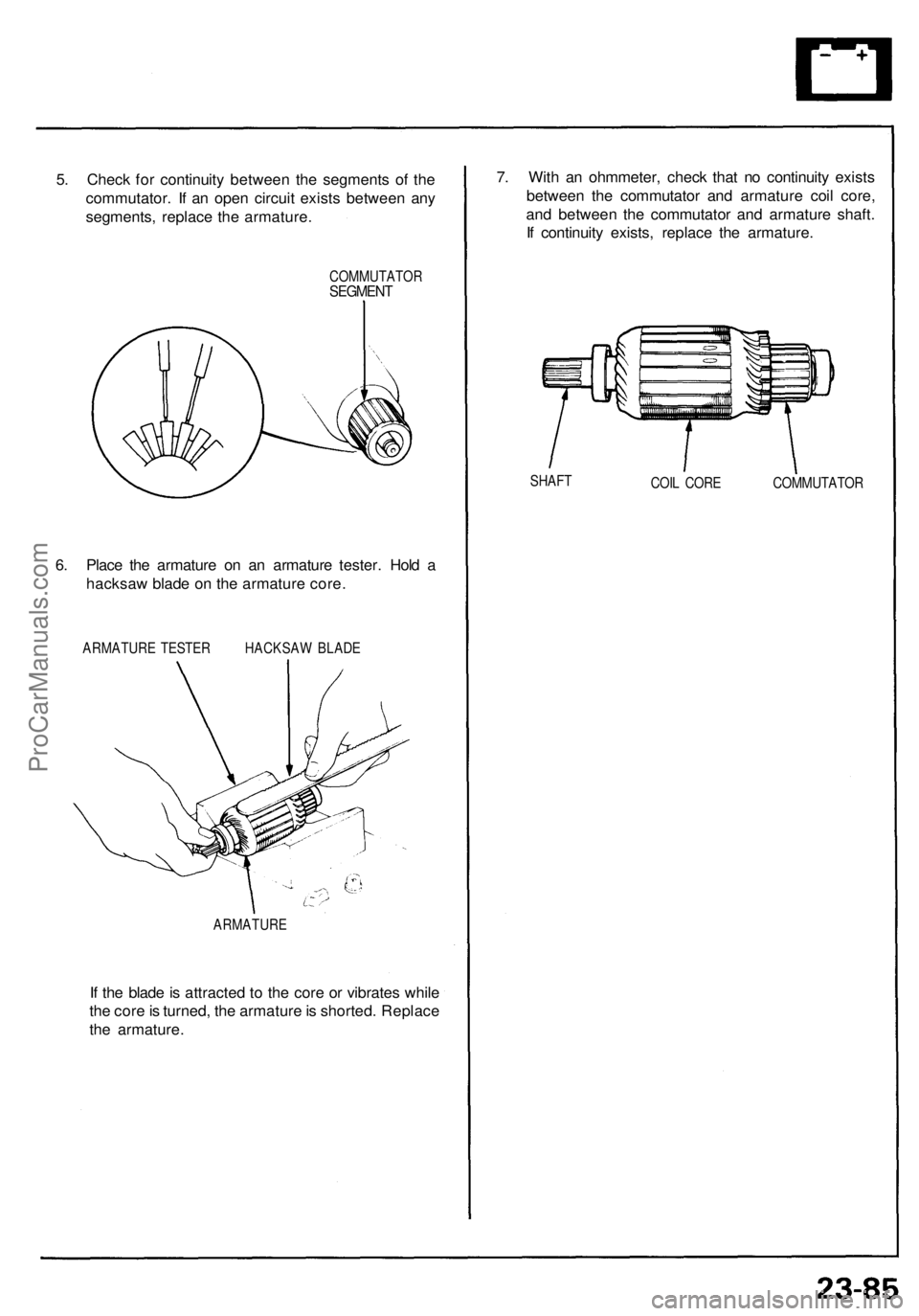

5. Check for continuity between the segments of the

commutator. If an open circuit exists between any

segments, replace the armature.

COMMUTATOR

SEGMENT

6. Place the armature on an armature tester. Hold a

hacksaw blade on the armature core.

ARMATURE TESTER

HACKSAW BLADE

ARMATURE

If the blade is attracted to the core or vibrates while

the core is turned, the armature is shorted. Replace

the armature.

7. With an ohmmeter, check that no continuity exists

between the commutator and armature coil core,

and between the commutator and armature shaft.

If continuity exists, replace the armature.

SHAFT

COIL CORE COMMUTATORProCarManuals.com

Page 756 of 1640

Starting System

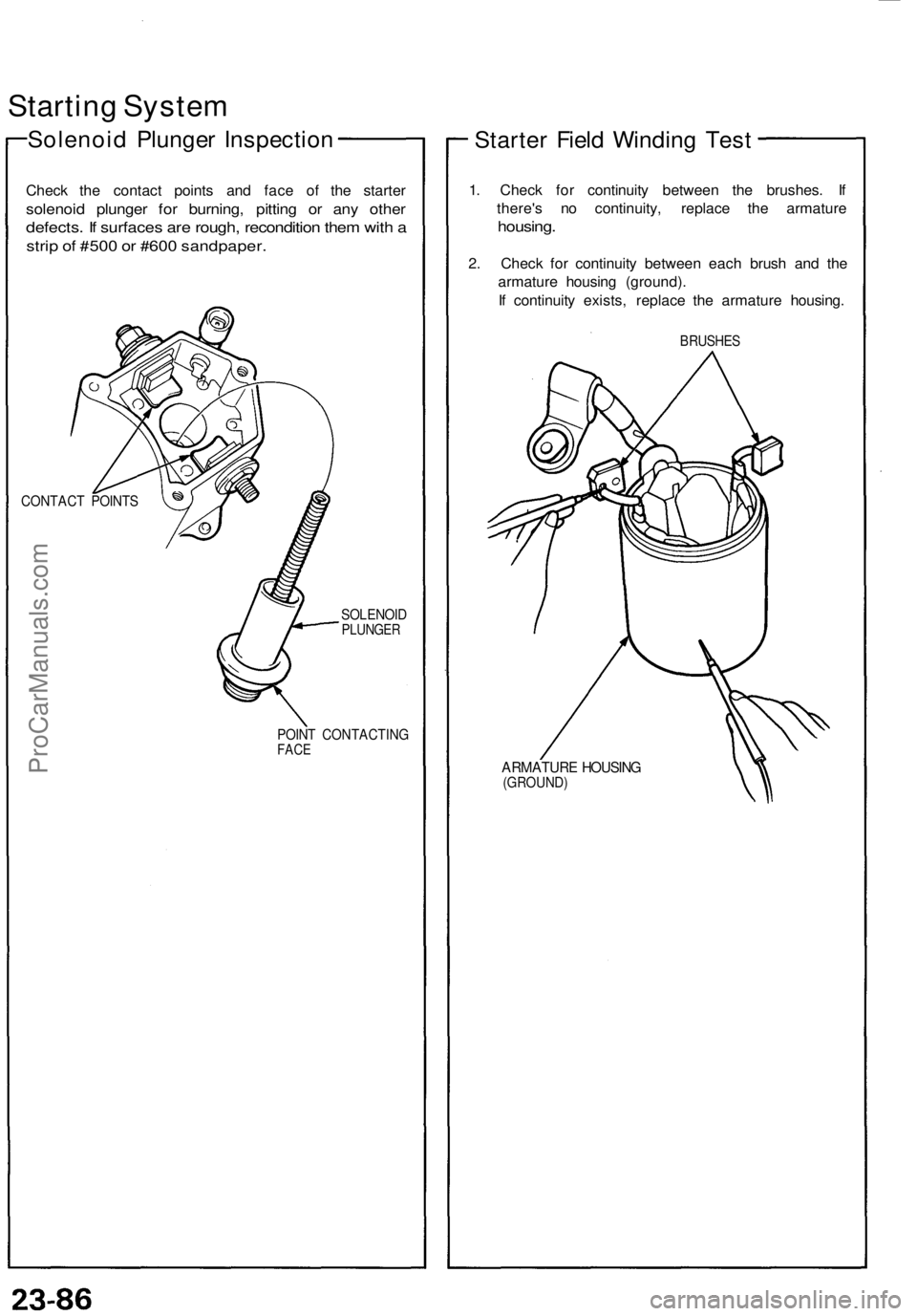

Solenoid Plunger Inspection

Check the contact points and face of the starter

solenoid plunger for burning, pitting or any other

defects. If surfaces are rough, recondition them with a

strip of #500 or #600 sandpaper.

CONTACT POINTS

SOLENOID

PLUNGER

POINT CONTACTING

FACE

Starter Field Winding Test

1. Check for continuity between the brushes. If

there's no continuity, replace the armature

housing.

2. Check for continuity between each brush and the

armature housing (ground).

If continuity exists, replace the armature housing.

BRUSHES

ARMATURE HOUSING

(GROUND)ProCarManuals.com

Page 757 of 1640

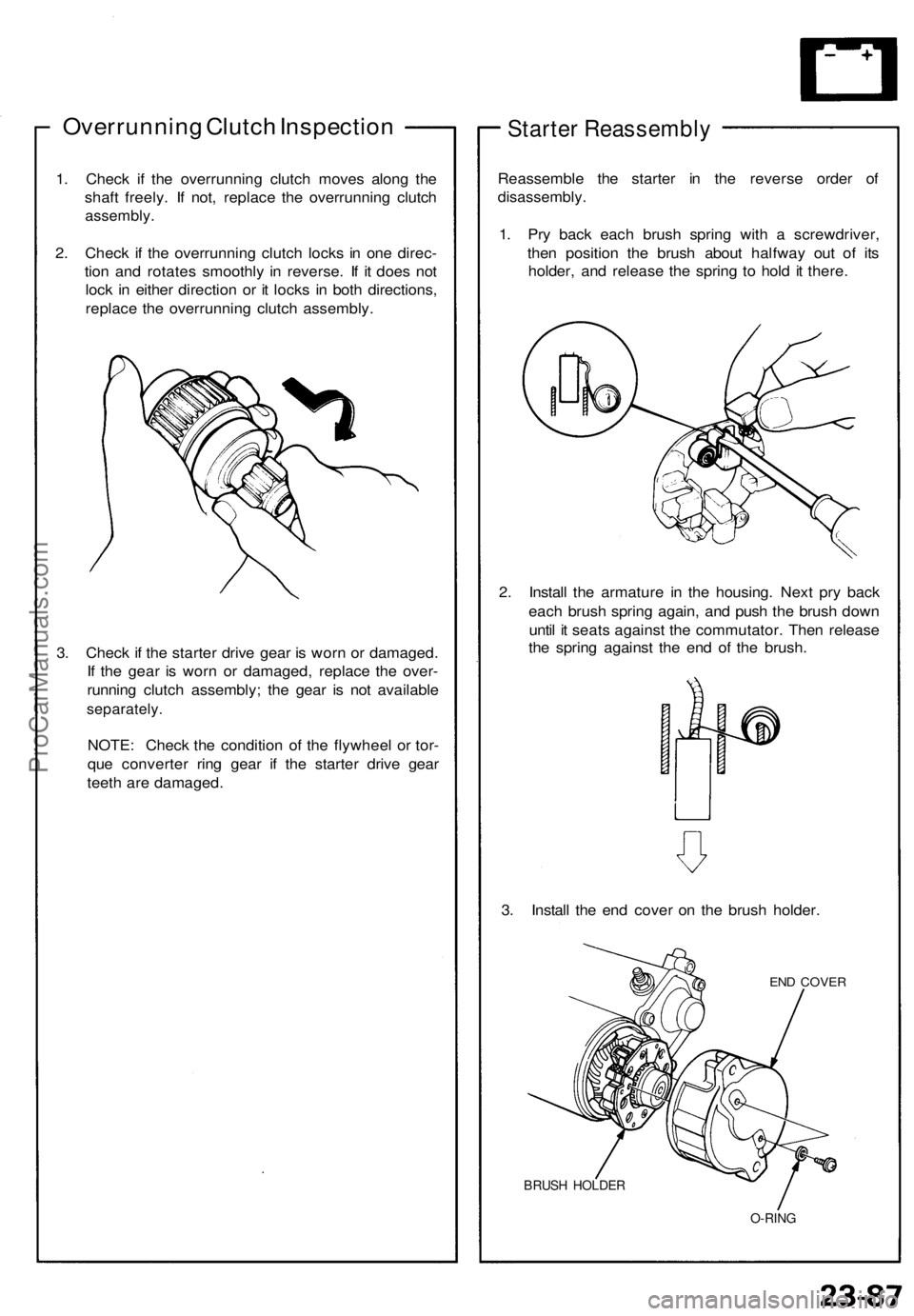

Overrunning Clutc h Inspectio n

1. Chec k i f th e overrunnin g clutc h move s alon g th e

shaf t freely . I f not , replac e th e overrunnin g clutc h

assembly .

2. Chec k i f th e overrunnin g clutc h lock s i n on e direc -

tio n an d rotate s smoothl y i n reverse . I f i t doe s no t

loc k i n eithe r directio n o r i t lock s i n bot h directions ,

replac e th e overrunnin g clutc h assembly .

3 . Chec k i f th e starte r driv e gea r i s wor n o r damaged .

I f th e gea r i s wor n o r damaged , replac e th e over -

runnin g clutc h assembly ; th e gea r i s no t availabl e

separately .

NOTE: Chec k th e conditio n o f th e flywhee l o r tor -

qu e converte r rin g gea r i f th e starter drive gea r

teet h ar e damaged .

Starter Reassembl y

Reassembl e th e starter in th e revers e orde r o f

disassembly .

1. Pr y bac k eac h brus h sprin g wit h a screwdriver ,

the n positio n th e brus h abou t halfwa y ou t o f it s

holder , an d releas e th e sprin g t o hol d i t there .

2 . Instal l th e armatur e i n th e housing . Nex t pr y bac k

eac h brus h sprin g again , an d pus h th e brus h dow n

unti l i t seat s agains t th e commutator . The n releas e

th e sprin g agains t th e en d o f th e brush .

3 . Instal l th e en d cove r o n th e brus h holder .

END COVE R

BRUSH HOLDE R

O-RING

ProCarManuals.com

Page 758 of 1640

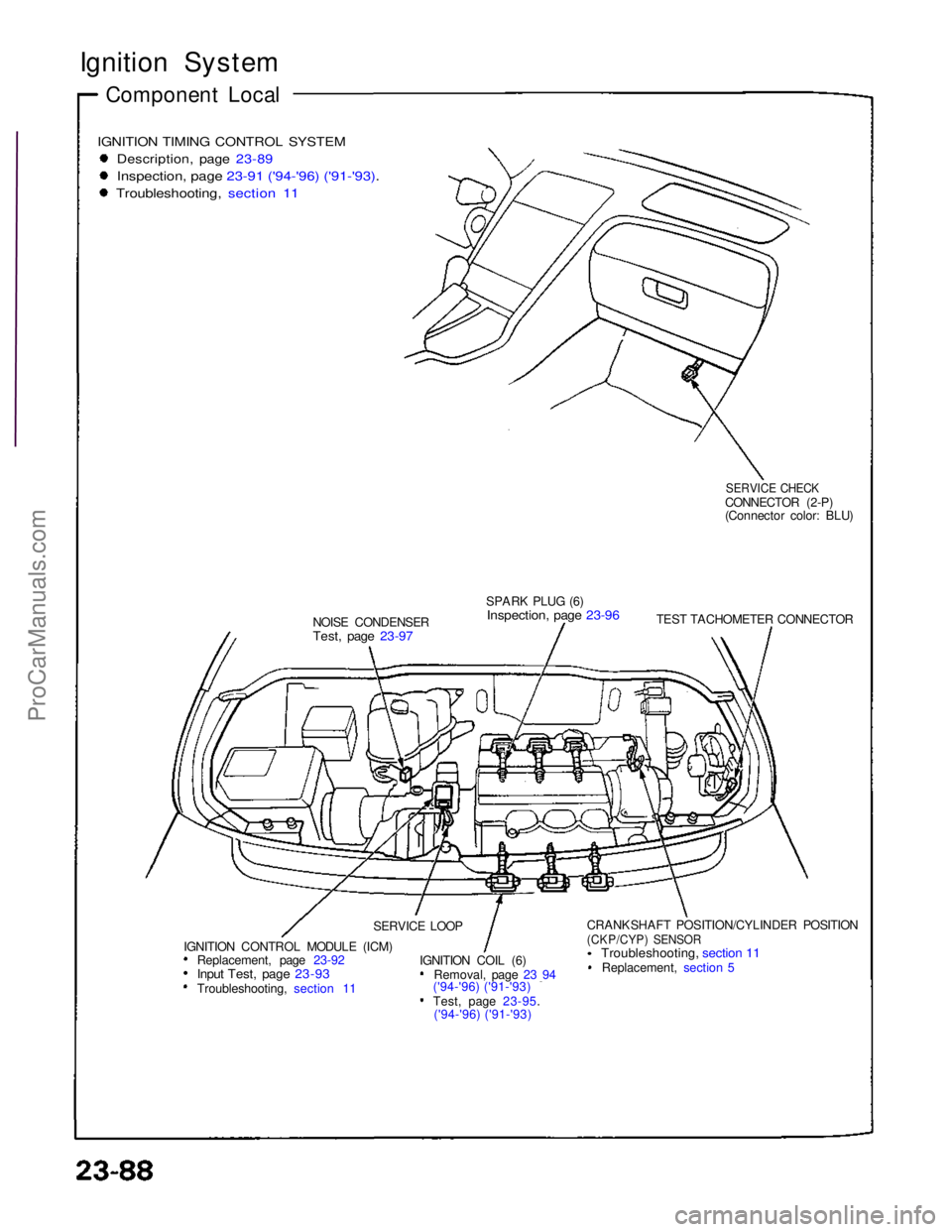

Ignition System

Component Local

IGNITION TIMING CONTROL SYSTEM

Description, page 23-89

Inspection, page 23-91 ('94-'96) ('91-'93).

Troubleshooting, section 11

NOISE CONDENSER

Test, page 23-97

SPARK PLUG (6)

Inspection, page 23-96

TEST TACHOMETER CONNECTOR

SERVICE CHECK

CONNECTOR (2-P)

(Connector color: BLU)

CRANKSHAFT POSITION/CYLINDER POSITION

(CKP/CYP) SENSOR

Troubleshooting, section 11

Replacement, section 5

IGNITION COIL (6)

Removal, page 23 94

('94-'96) ('91-'93) Test, page 23-95.

('94-'96) ('91-'93)

IGNITION CONTROL MODULE (ICM)

Replacement, page 23-92

Input Test, page 23-93

Troubleshooting, section 11

SERVICE LOOP

ProCarManuals.com

Page 759 of 1640

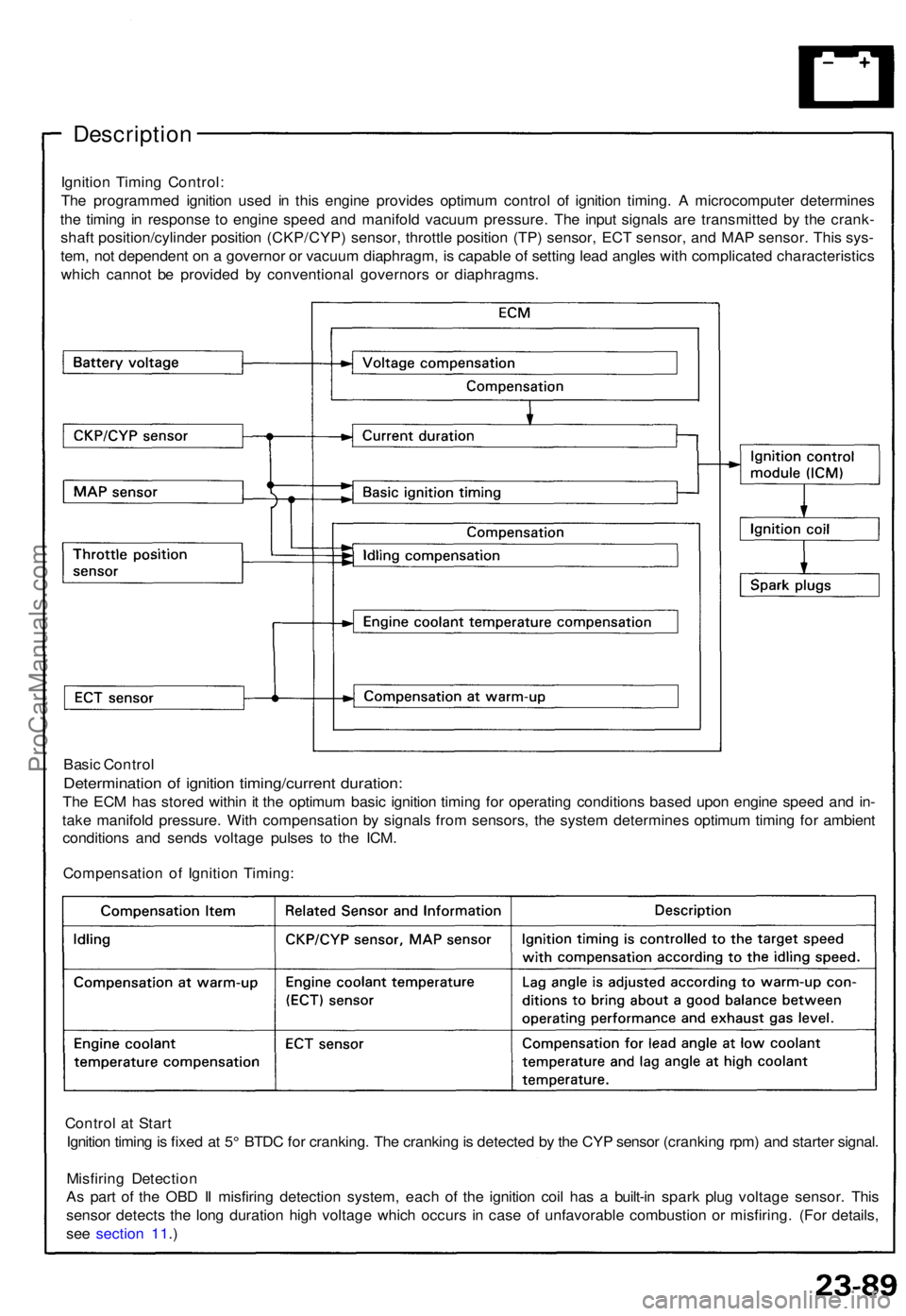

Control a t Star t

Ignitio n timin g is fixe d a t 5 ° BTD C fo r cranking . Th e crankin g is detecte d b y th e CY P senso r (crankin g rpm ) an d starte r signal .

Misfirin g Detectio n

A s par t o f th e OB D II misfirin g detectio n system , eac h o f th e ignitio n coi l ha s a built-i n spar k plu g voltag e sensor . Thi s

senso r detect s th e lon g duratio n hig h voltag e whic h occur s i n cas e o f unfavorabl e combustio n o r misfiring . (Fo r details ,

se e sectio n 11 .)

Compensatio

n o f Ignitio n Timing :

Basi

c Contro l

Determinatio n o f ignitio n timing/curren t duration :

The EC M ha s store d withi n it th e optimu m basi c ignitio n timin g fo r operatin g condition s base d upo n engin e spee d an d in -

tak e manifol d pressure . Wit h compensatio n b y signal s fro m sensors , th e syste m determine s optimu m timin g fo r ambien t

condition s an d send s voltag e pulse s t o th e ICM .

Ignitio

n Timin g Control :

Th e programme d ignitio n use d i n thi s engin e provide s optimu m contro l o f ignitio n timing . A microcompute r determine s

th e timin g i n respons e t o engin e spee d an d manifol d vacuu m pressure . Th e inpu t signal s ar e transmitte d b y th e crank -

shaf t position/cylinde r positio n (CKP/CYP ) sensor , throttl e positio n (TP ) sensor , EC T sensor , an d MA P sensor . Thi s sys -

tem , no t dependen t o n a governo r o r vacuu m diaphragm , i s capabl e o f settin g lea d angle s wit h complicate d characteristic s

whic h canno t b e provide d b y conventiona l governor s o r diaphragms .

Description

ProCarManuals.com

Page 760 of 1640

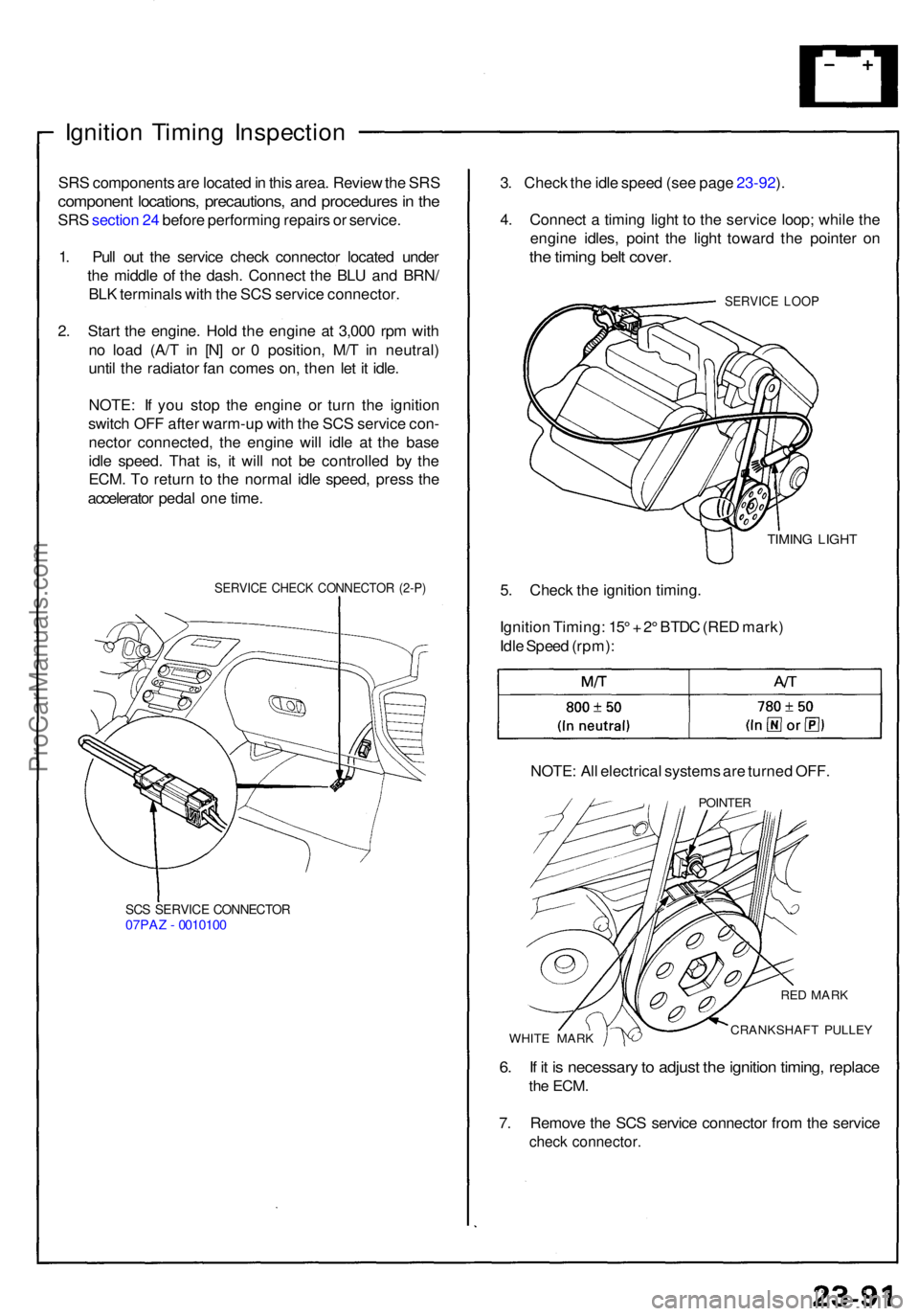

Ignition Timin g Inspectio n

SRS component s ar e locate d in thi s area . Revie w th e SR S

componen t locations , precautions , an d procedure s in th e

SR S sectio n 24 befor e performin g repair s o r service .

1 . Pul l ou t th e servic e chec k connecto r locate d unde r

th e middl e o f th e dash . Connec t th e BL U an d BRN /

BL K terminal s wit h th e SC S servic e connector .

2 . Star t th e engine . Hol d th e engin e a t 3,00 0 rp m wit h

n o loa d (A/ T i n [N ] o r 0 position , M/ T i n neutral )

unti l th e radiato r fa n come s on , the n le t i t idle .

NOTE : I f yo u sto p th e engin e o r tur n th e ignitio n

switc h OF F afte r warm-u p wit h th e SC S servic e con -

necto r connected , th e engin e wil l idl e a t th e bas e

idl e speed . Tha t is , i t wil l no t b e controlle d b y th e

ECM . T o retur n t o th e norma l idl e speed , pres s th e

accelerato r peda l on e time .

SERVIC E CHEC K CONNECTO R (2-P )

SCS SERVIC E CONNECTO R07PAZ - 001010 0

3. Chec k th e idl e spee d (se e pag e 23-92 ).

4 . Connec t a timin g ligh t t o th e servic e loop ; whil e th e

engin e idles , poin t th e ligh t towar d th e pointe r o n

the timin g bel t cover .

SERVIC E LOO P

TIMIN G LIGH T

5. Chec k th e ignitio n timing .

Ignitio n Timing : 15 ° + 2° BTD C (RE D mark )

Idl e Spee d (rpm) :

NOTE : Al l electrica l system s ar e turne d OFF .

POINTE R

WHITE MAR K

RED MAR K

CRANKSHAF T PULLE Y

6. I f i t i s necessar y to adjus t th e ignitio n timing , replac e

the ECM .

7. Remov e th e SC S servic e connecto r fro m th e servic e

check connector .

ProCarManuals.com