ACURA NSX 1991 Service Repair Manual

Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 791 of 1640

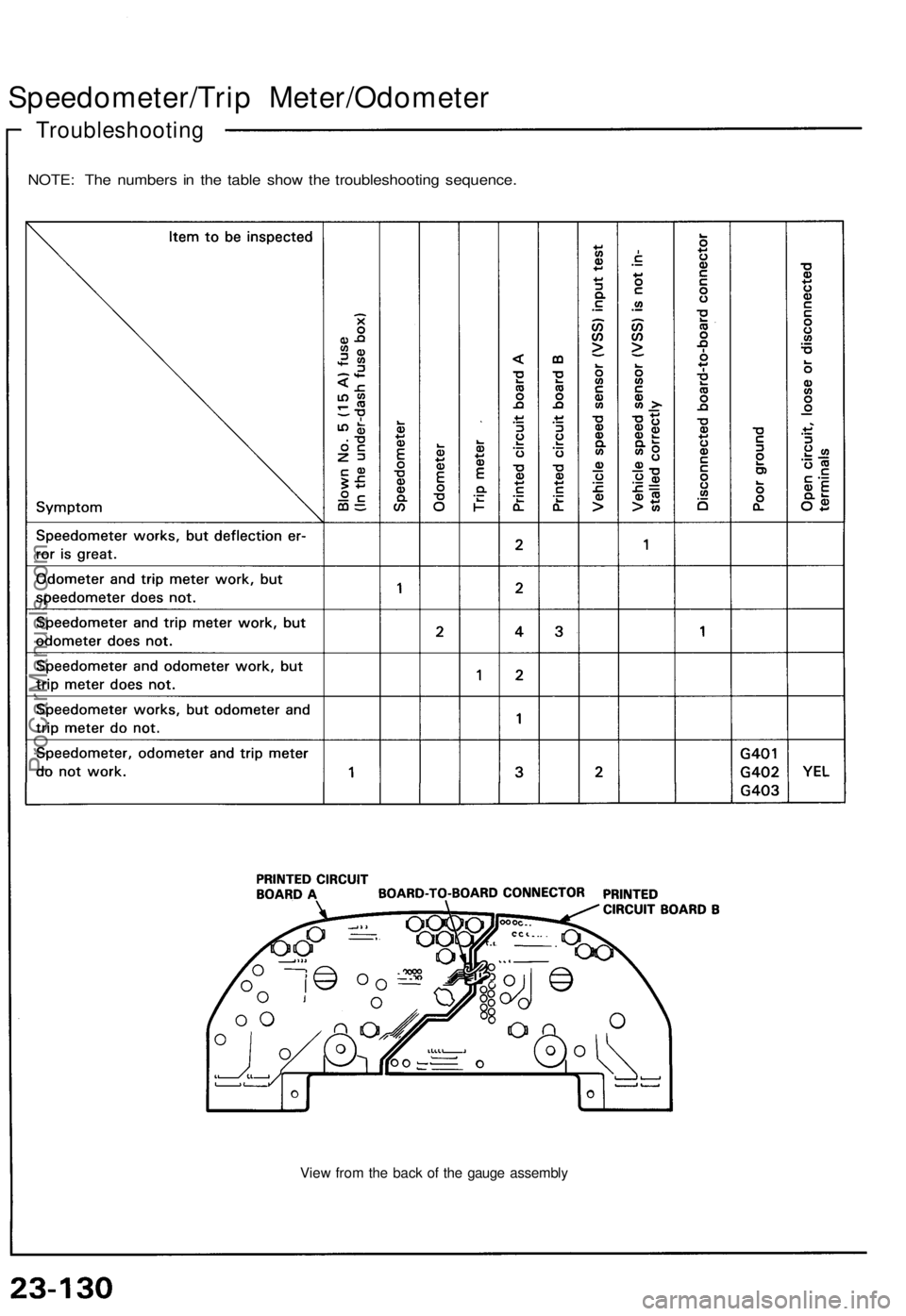

Speedometer/Trip Meter/Odometer

Troubleshooting

NOTE: The numbers in the table show the troubleshooting sequence.

View from the back of the gauge assemblyProCarManuals.com

Page 792 of 1640

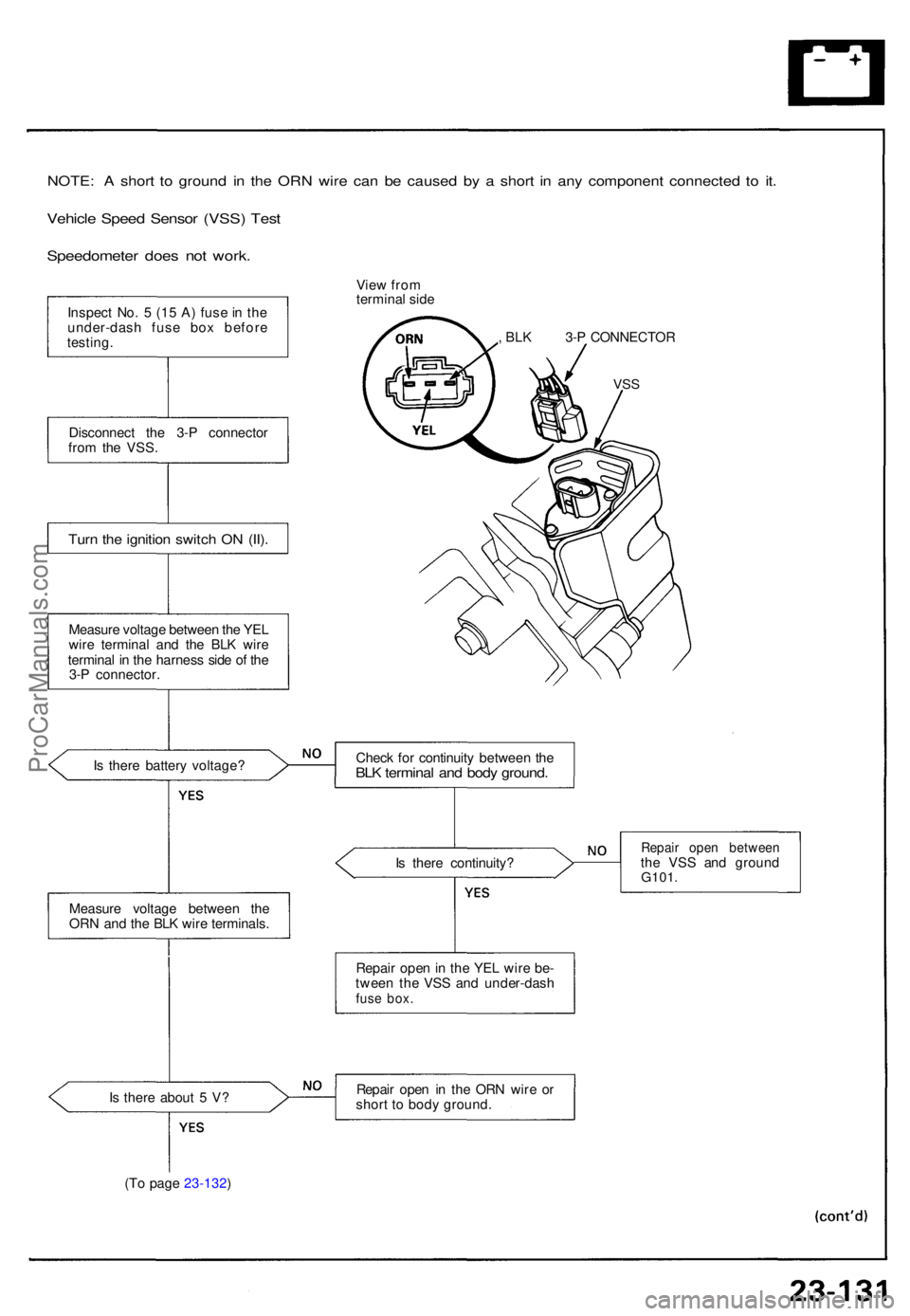

NOTE: A shor t t o groun d i n th e OR N wir e ca n b e cause d b y a shor t i n an y componen t connecte d t o it .

Vehicl e Spee d Senso r (VSS ) Tes t

Speedomete r doe s no t work.

Inspec t No . 5 (1 5 A ) fus e in th e

under-das h fus e bo x befor e

testing .

Disconnec t th e 3- P connecto r

fro m th e VSS .

Turn th e ignitio n switc h O N (II) .

Measur e voltag e betwee n th e YE L

wir e termina l an d th e BL K wir e

termina l i n th e harnes s sid e o f th e

3- P connector .

I s ther e batter y voltage ?

Measur e voltag e betwee n th e

OR N an d th e BL K wir e terminals .

I s ther e abou t 5 V ?

(T o page 23-132 ) Vie

w fro m

termina l sid e

, BL K 3- P CONNECTO R

VSS

Is ther e continuity ?

Repai r ope n in th e OR N wir e o r

shor t t o bod y ground .Repair ope n betwee nthe VS S an d groun dG101.

Repai r ope n in th e YE L wir e be -

twee n th e VS S an d under-das h

fuse box .

Chec k fo r continuit y betwee n th eBLK termina l an d bod y ground .

ProCarManuals.com

Page 793 of 1640

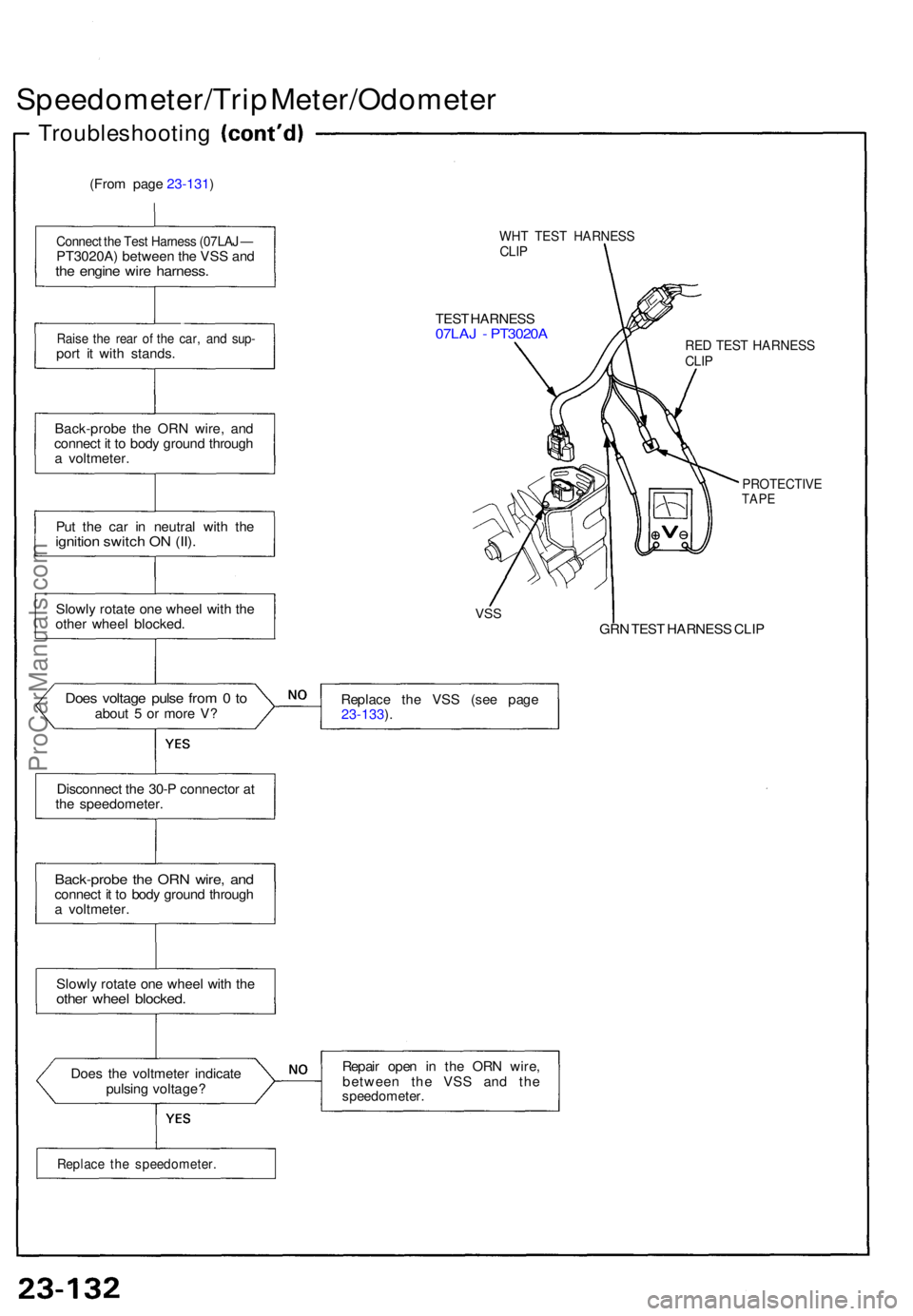

Speedometer/Trip Meter/Odomete r

Troubleshooting

(From page 23-131 )

Connec t th e Tes t Harnes s (07LA J —PT3020A ) betwee n th e VS S an dthe engin e wir e harness .

Raise th e rea r o f th e car , an d sup -port i t wit h stands .

Back-prob e th e OR N wire , an d

connec t i t t o bod y groun d throug h

a voltmeter .

Pu t th e ca r i n neutra l wit h th e

ignitio n switc h O N (II) .

Slowl y rotat e on e whee l wit h th e

othe r whee l blocked .

Does voltag e puls e fro m 0 toabou t 5 or mor e V ?

Disconnec t th e 30- P connecto r a t

th e speedometer .

Back-probe th e OR N wire , an dconnec t i t t o bod y groun d throug h

a voltmeter .

Slowl y rotat e on e whee l wit h th e

othe r whee l blocked .

Does th e voltmete r indicat e

pulsin g voltage ?

WHT TES T HARNES SCLIP

TES T HARNES S07LAJ - PT3020 ARED TES T HARNES SCLIP

PROTECTIV ETAPE

VSSGR N TES T HARNES S CLI P

Replac e th e VS S (se e pag e

23-133 ).

Repai r ope n i n th e OR N wire ,

betwee n th e VS S an d th e

speedometer .

Replace th e speedometer .

ProCarManuals.com

Page 794 of 1640

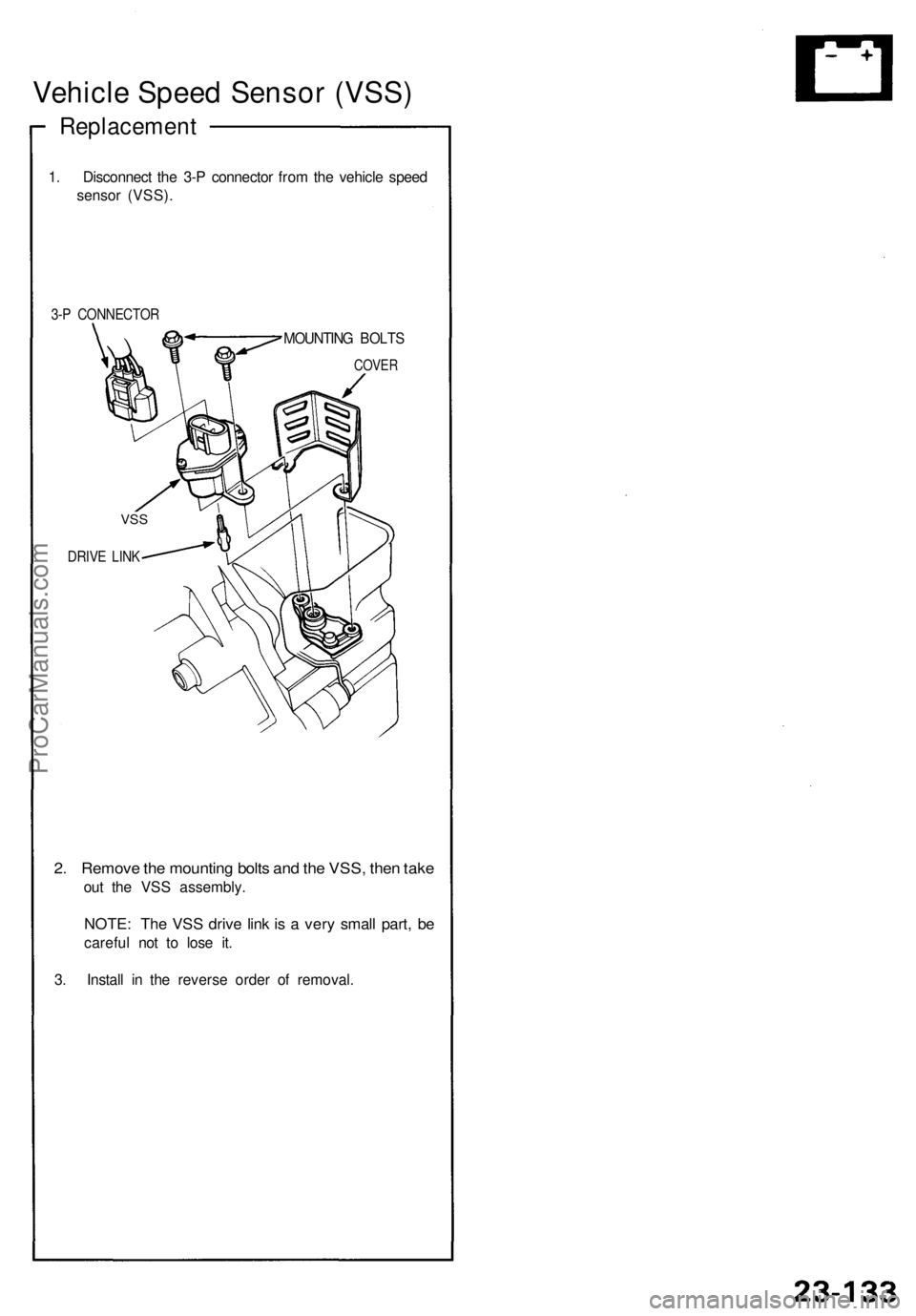

Vehicle Speed Sensor (VSS)

Replacement

1. Disconnect the 3-P connector from the vehicle speed

sensor (VSS).

3-P CONNECTOR

MOUNTING BOLTS

2. Remove the mounting bolts and the VSS, then take

out the VSS assembly.

NOTE: The VSS drive link is a very small part, be

careful not to lose it.

3. Install in the reverse order of removal.

COVER

VSS

DRIVE LINKProCarManuals.com

Page 795 of 1640

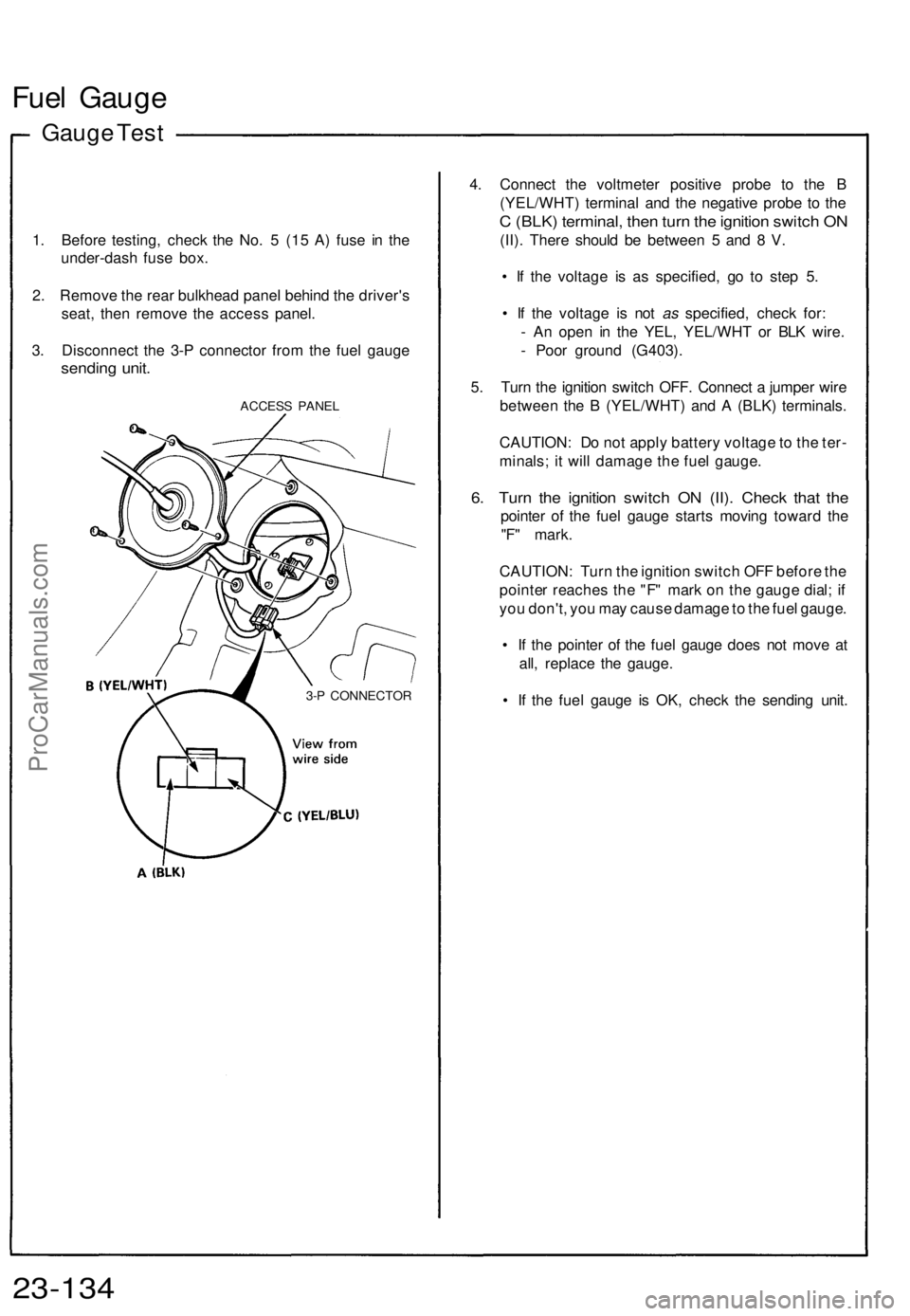

Fuel Gaug e

Gauge Tes t

1. Befor e testing , chec k th e No . 5 (1 5 A ) fus e i n th e

under-das h fus e box .

2 . Remov e th e rea r bulkhea d pane l behin d th e driver' s

seat , the n remov e th e acces s panel .

3 . Disconnec t th e 3- P connecto r fro m th e fue l gaug e

sendin g unit .

ACCES S PANE L

4. Connec t th e voltmete r positiv e prob e t o th e B

(YEL/WHT ) termina l an d th e negativ e prob e t o th e

C (BLK ) terminal , the n tur n th e ignitio n switc h O N

(II) . Ther e shoul d b e betwee n 5 an d 8 V .

• I f th e voltag e i s a s specified , g o t o ste p 5 .

• I f th e voltag e i s no t as specified , chec k for :

- A n ope n i n th e YEL , YEL/WH T o r BL K wire .

- Poo r groun d (G403) .

5 . Tur n th e ignitio n switc h OFF . Connec t a jumpe r wir e

betwee n th e B (YEL/WHT ) an d A (BLK ) terminals .

CAUTION : D o no t appl y batter y voltag e to th e ter -

minals ; i t wil l damag e th e fue l gauge .

6. Tur n th e ignitio n switc h O N (II) . Chec k tha t th e

pointe r o f th e fue l gaug e start s movin g towar d th e

"F " mark .

CAUTION : Tur n th e ignitio n switc h OF F befor e th e

pointe r reache s th e "F " mar k o n th e gaug e dial ; i f

yo u don't , yo u ma y caus e damag e to th e fue l gauge .

• I f th e pointe r o f th e fue l gaug e doe s no t mov e a t

all , replac e th e gauge .

• I f th e fue l gaug e i s OK , chec k th e sendin g unit .

23-13 4

3-P CONNECTO R

ProCarManuals.com

Page 796 of 1640

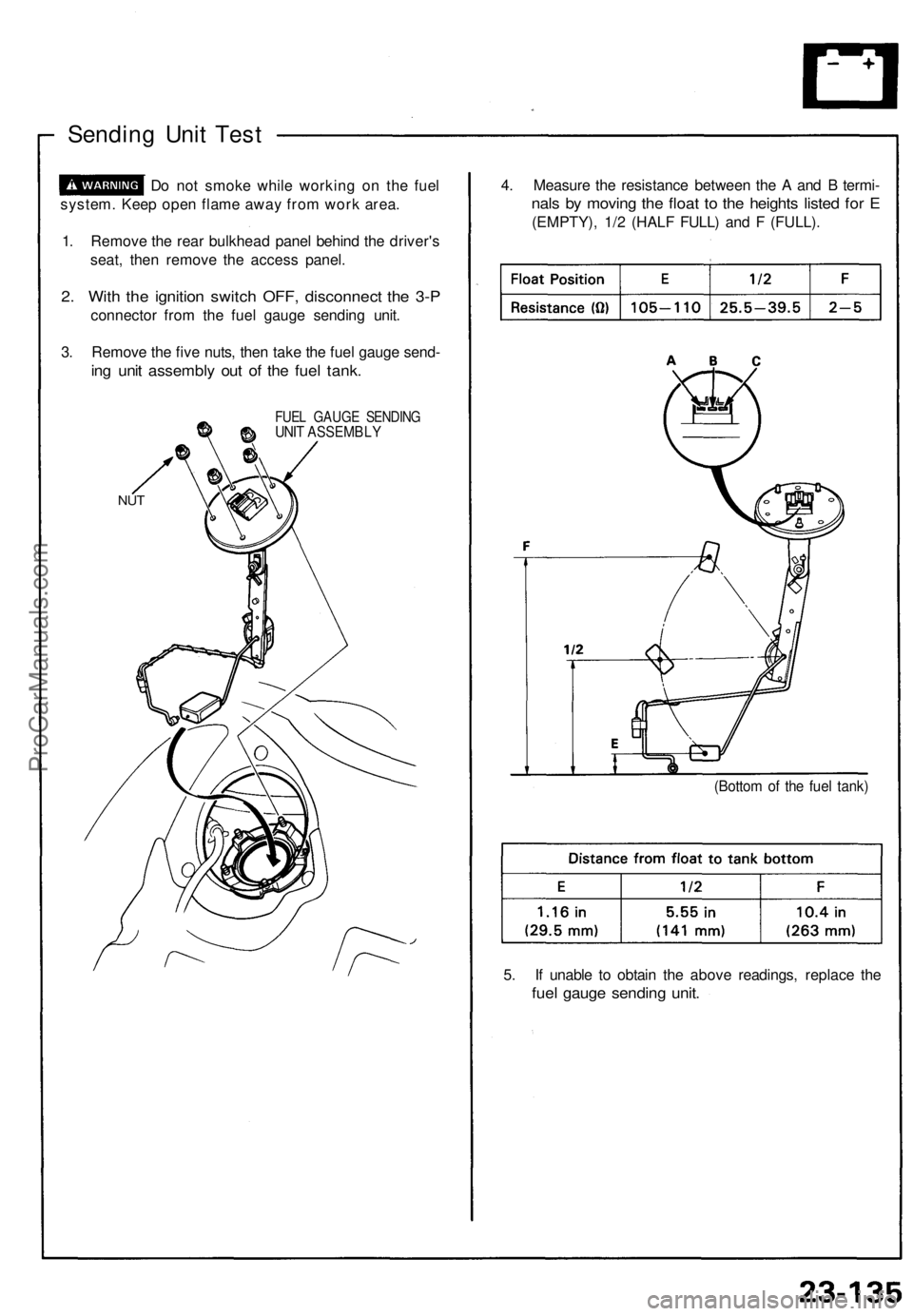

Sending Unit Test

Do not smoke while working on the fuel

system. Keep open flame away from work area.

1. Remove the rear bulkhead panel behind the driver's

seat, then remove the access panel.

2. With the ignition switch OFF, disconnect the 3-P

connector from the fuel gauge sending unit.

3. Remove the five nuts, then take the fuel gauge send-

ing unit assembly out of the fuel tank.

FUEL GAUGE SENDING

UNIT ASSEMBLY

NUT

4. Measure the resistance between the A and B termi-

nals by moving the float to the heights listed for E

(EMPTY), 1/2 (HALF FULL) and F (FULL).

(Bottom of the fuel tank)

5. If unable to obtain the above readings, replace the

fuel gauge sending unit.ProCarManuals.com

Page 797 of 1640

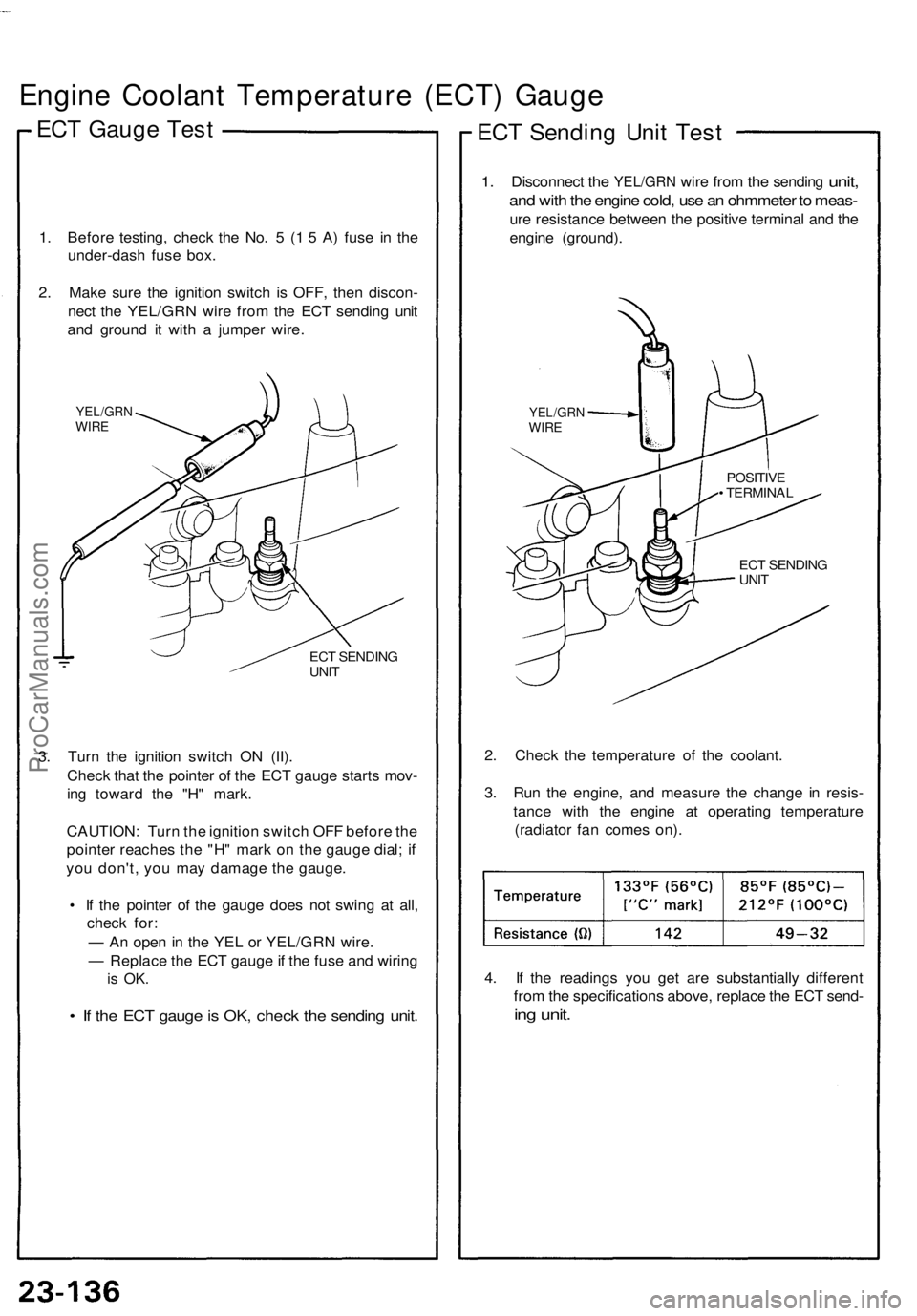

Engine Coolan t Temperatur e (ECT ) Gaug e

ECT Gaug e Tes t

1. Befor e testing , chec k th e No . 5 (1 5 A ) fus e i n th e

under-das h fus e box .

2 . Mak e sur e th e ignitio n switc h i s OFF , the n discon -

nec t th e YEL/GR N wir e fro m th e EC T sendin g uni t

an d groun d i t wit h a jumpe r wire .

YEL/GR NWIRE

ECT SENDIN G

UNI T

3. Tur n th e ignitio n switc h O N (II) .

Chec k tha t th e pointe r o f th e EC T gaug e start s mov -

in g towar d th e "H " mark .

CAUTION : Tur n th e ignitio n switc h OF F befor e th e

pointe r reache s th e "H " mar k o n th e gaug e dial ; i f

yo u don't , yo u ma y damag e th e gauge .

• I f th e pointe r o f th e gaug e doe s no t swin g a t all ,

chec k for :

— A n ope n in th e YE L o r YEL/GR N wire .

— Replac e th e EC T gaug e if th e fus e an d wirin g

is OK .

• I f th e EC T gaug e is OK , chec k th e sendin g unit .

ECT Sendin g Uni t Tes t

1. Disconnec t the YEL/GR N wire fro m the sendin g unit,

and wit h th e engin e cold , us e a n ohmmete r t o meas -

ure resistanc e betwee n th e positiv e termina l an d th e

engin e (ground) .

2 . Chec k th e temperatur e o f th e coolant .

3 . Ru n th e engine , an d measur e th e chang e i n resis -

tanc e wit h th e engin e a t operatin g temperatur e

(radiato r fa n come s on) .

4 . I f th e reading s yo u ge t ar e substantiall y differen t

fro m th e specification s above , replac e th e EC T send -

ing unit .

YEL/GR NWIRE

POSITIV E

• TERMINA L

EC T SENDIN G

UNI T

ProCarManuals.com

Page 798 of 1640

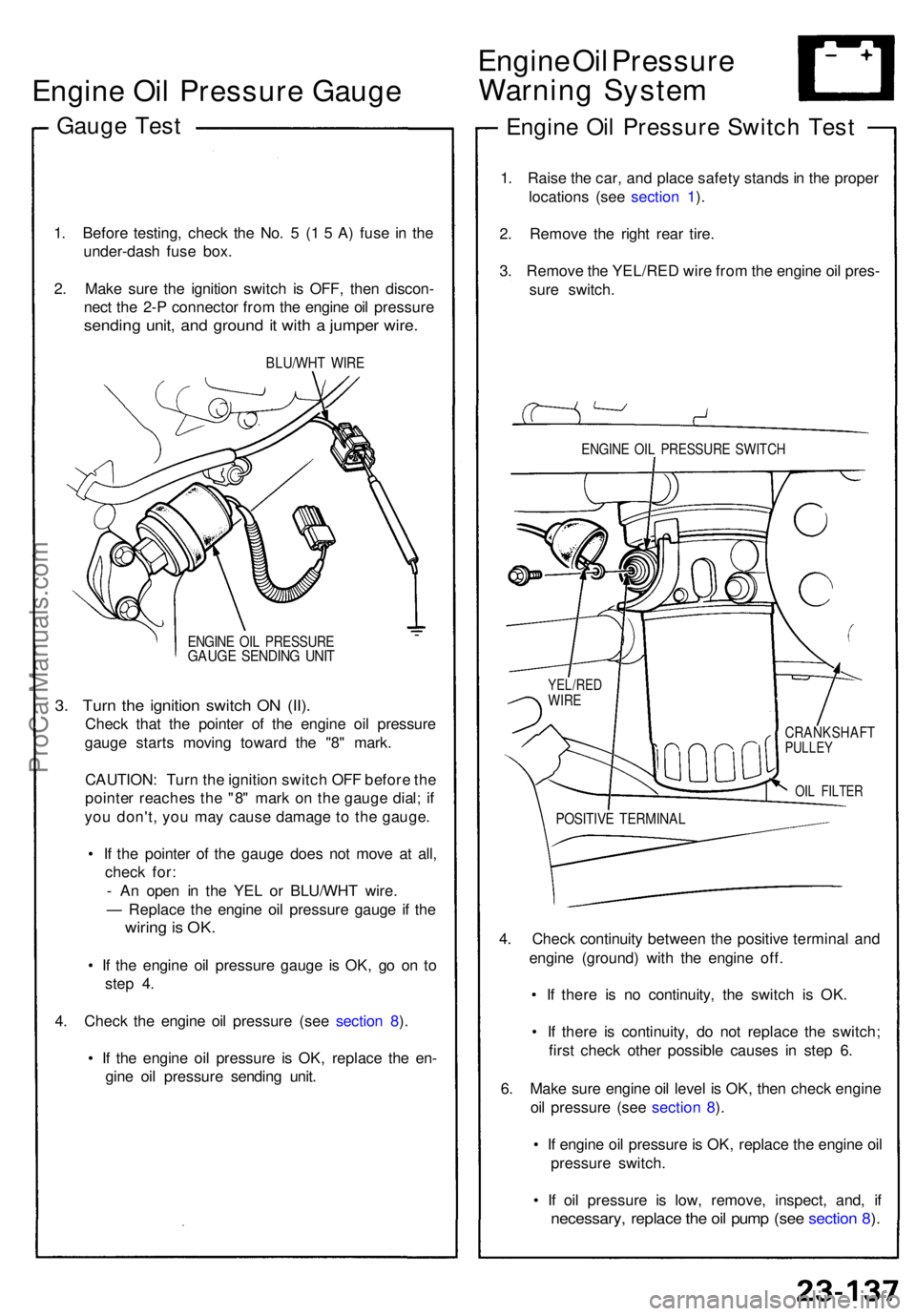

Engine Oi l Pressur e Gaug e

Gauge Tes t

1. Befor e testing , chec k th e No . 5 (1 5 A ) fus e i n th e

under-das h fus e box .

2 . Mak e sur e th e ignitio n switc h i s OFF , the n discon -

nec t th e 2- P connecto r fro m th e engin e oi l pressur e

sending unit , an d groun d it wit h a jumpe r wire .

BLU/WH T WIR E

ENGIN E OI L PRESSUR EGAUGE SENDIN G UNI T

3. Tur n th e ignitio n switc h O N (II) .

Chec k tha t th e pointe r o f th e engin e oi l pressur e

gaug e start s movin g towar d th e "8 " mark .

CAUTION : Tur n th e ignitio n switc h OF F befor e th e

pointe r reache s th e "8 " mar k o n th e gaug e dial ; i f

yo u don't , yo u ma y caus e damag e t o th e gauge .

• I f th e pointe r o f th e gaug e doe s no t mov e a t all ,

chec k for :

- A n ope n i n th e YE L o r BLU/WH T wire .

— Replac e th e engin e oi l pressur e gaug e i f th e

wirin g is OK .

• I f th e engin e oi l pressur e gaug e i s OK , g o o n t o

ste p 4 .

4 . Chec k th e engin e oi l pressur e (se e sectio n 8 ).

• I f th e engin e oi l pressur e i s OK , replac e th e en -

gin e oi l pressur e sendin g unit .

Engin e Oi l Pressur e

Warnin g Syste m

Engine Oi l Pressur e Switc h Tes t

1. Rais e th e car , an d plac e safet y stand s in th e prope r

location s (se e sectio n 1 ).

2 . Remov e th e righ t rea r tire .

3 . Remov e th e YEL/RE D wir e fro m th e engin e oi l pres -

sur e switch .

ENGINE OI L PRESSUR E SWITC H

CRANKSHAF TPULLEY

4. Chec k continuit y betwee n th e positiv e termina l an d

engin e (ground ) wit h th e engin e off .

• I f ther e i s n o continuity , th e switc h i s OK .

• I f ther e i s continuity , d o no t replac e th e switch ;

firs t chec k othe r possibl e cause s i n ste p 6 .

6 . Mak e sur e engin e oi l leve l i s OK , the n chec k engine

oi l pressur e (se e sectio n 8 ).

• I f engin e oi l pressur e is OK , replac e th e engin e oi l

pressur e switch .

• I f oi l pressur e i s low , remove , inspect , and , i f

necessary , replac e th e oi l pum p (se e sectio n 8 ).

YEL/RE DWIRE

POSITIV E TERMINA L

OIL FILTE R

ProCarManuals.com

Page 799 of 1640

Brake Warnin g Syste m

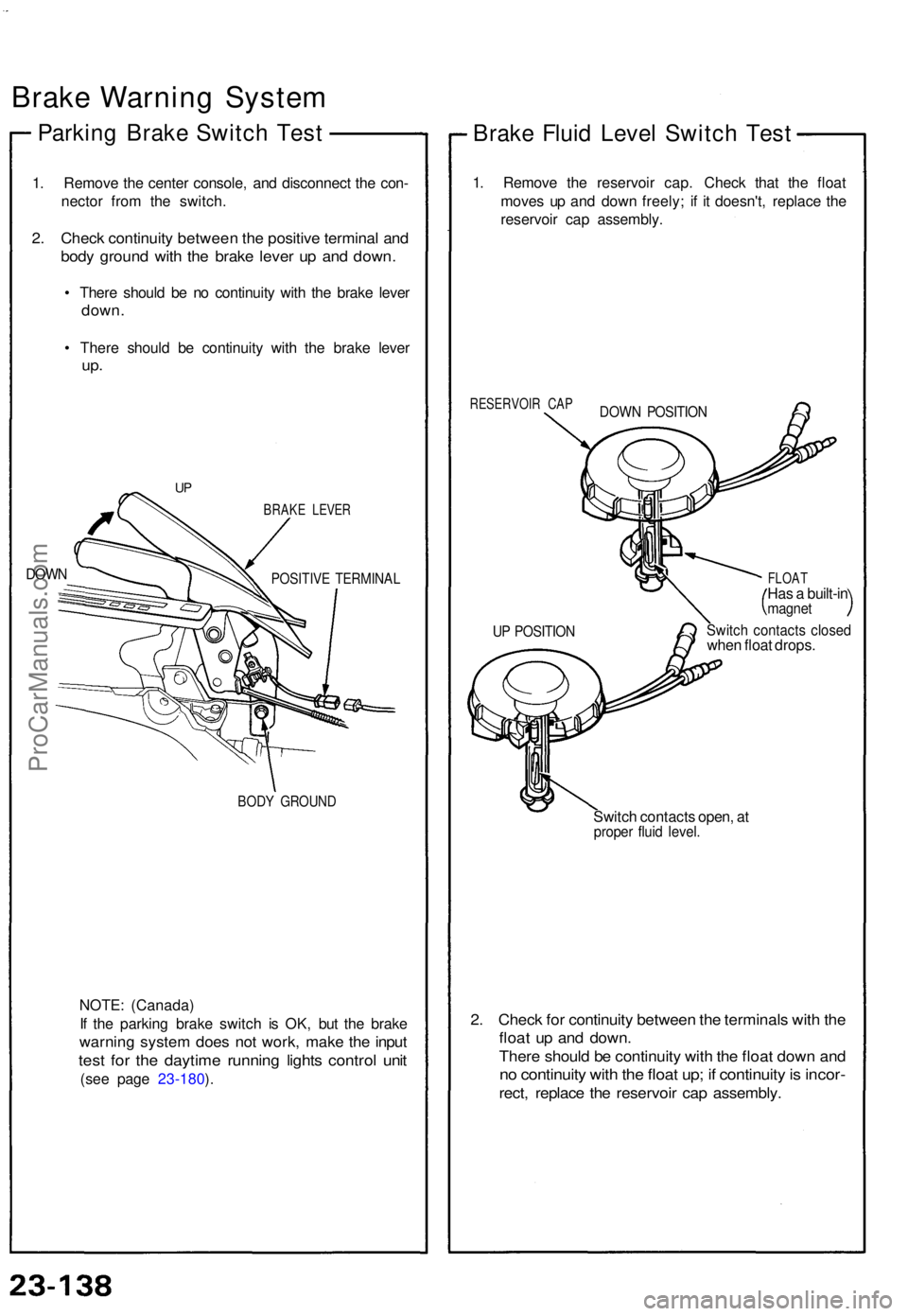

Parking Brak e Switc h Tes t

1. Remov e th e cente r console , an d disconnec t th e con -

necto r fro m th e switch .

2. Chec k continuit y betwee n th e positiv e termina l an d

bod y groun d wit h th e brak e leve r u p an d down .

• Ther e shoul d b e n o continuit y wit h th e brak e leve r

down .

• Ther e shoul d b e continuit y wit h th e brak e leve r

up.

DOW N

BRAK E LEVE R

POSITIV E TERMINA L

BODY GROUN D

NOTE: (Canada )

I f th e parkin g brak e switc h i s OK , bu t th e brak e

warnin g syste m doe s no t work , mak e th e inpu t

test fo r th e daytim e runnin g light s contro l uni t

(see pag e 23-180 ).

Brak e Flui d Leve l Switc h Tes t

1. Remov e th e reservoi r cap . Chec k tha t th e floa t

move s u p an d dow n freely ; i f i t doesn't , replac e th e

reservoi r ca p assembly .

RESERVOI R CA P

FLOAT

Has a built-i nmagne t

Switch contact s close dwhen floa t drops .

Switc h contact s open , a t

prope r flui d level .

2. Chec k fo r continuit y betwee n th e terminal s wit h th e

floa t u p an d down .

There shoul d b e continuit y wit h th e floa t dow n an d

no continuit y wit h th e floa t up ; i f continuit y is incor -

rect, replac e th e reservoi r ca p assembly .

UP POSITIO N

DOWN POSITIO N

UP

ProCarManuals.com

Page 800 of 1640

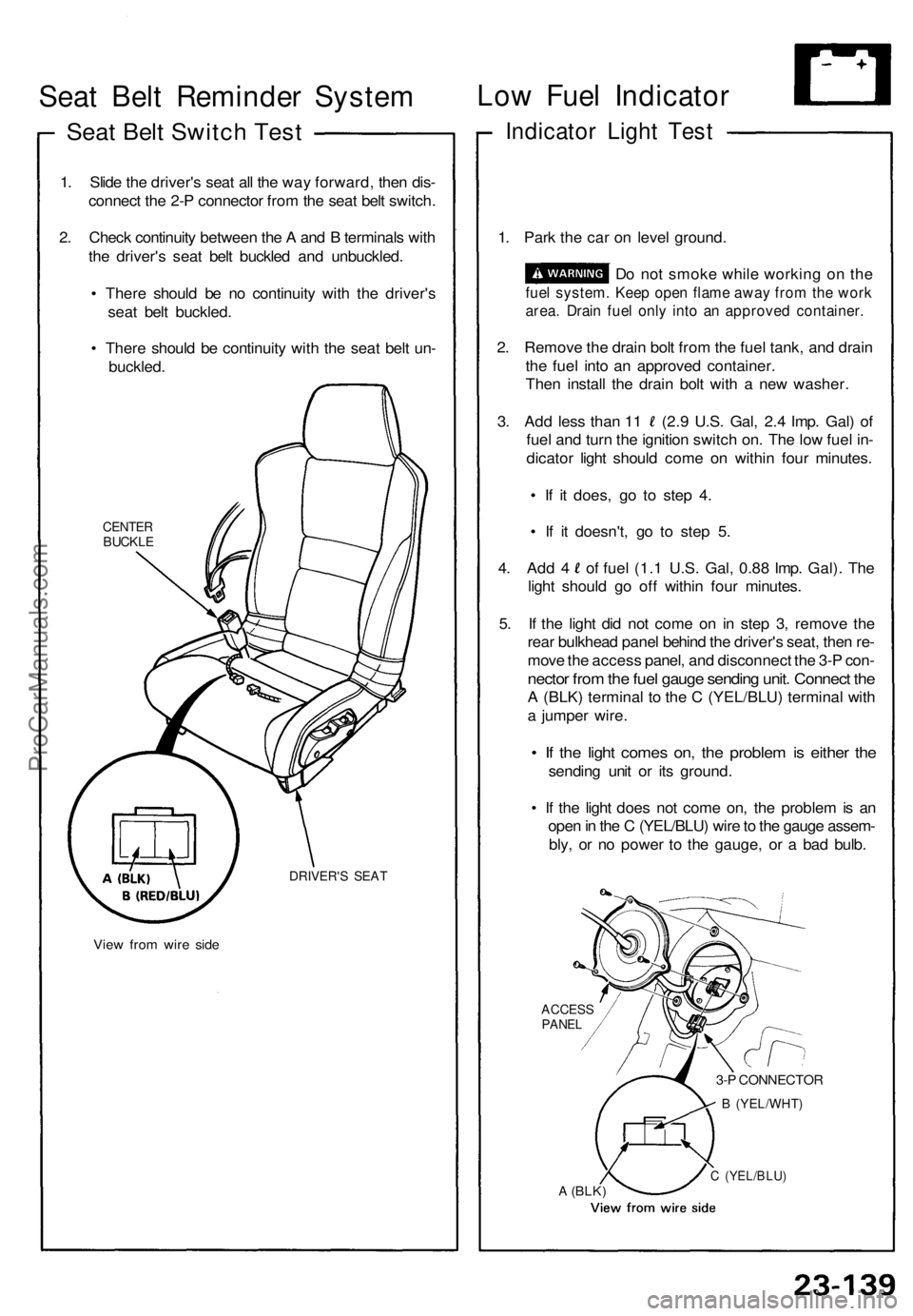

Seat Bel t Reminde r Syste m

Seat Bel t Switc h Tes t

1. Slid e th e driver' s sea t al l th e wa y forward , the n dis -

connec t th e 2- P connecto r fro m th e sea t bel t switch .

2 . Chec k continuit y betwee n th e A an d B terminal s wit h

th e driver' s sea t bel t buckle d an d unbuckled .

• Ther e shoul d b e n o continuit y wit h th e driver' s

sea t bel t buckled .

• Ther e shoul d b e continuit y wit h th e sea t bel t un -

buckled .

CENTERBUCKL E

DRIVER' S SEA T

View fro m wir e sid e

Low Fue l Indicato r

Indicator Ligh t Tes t

1. Par k th e ca r o n leve l ground .

D o no t smok e whil e workin g o n th e

fue l system . Kee p ope n flam e awa y fro m th e wor k

area. Drai n fue l onl y int o a n approve d container .

2. Remov e th e drai n bol t fro m th e fue l tank , an d drai n

th e fue l int o a n approve d container .

The n instal l th e drai n bol t wit h a ne w washer .

3. Ad d les s tha n 1 1 (2. 9 U.S . Gal , 2. 4 Imp . Gal ) o f

fue l an d tur n th e ignitio n switc h on . Th e lo w fue l in -

dicato r ligh t shoul d com e o n withi n fou r minutes .

• I f i t does , g o t o ste p 4 .

• I f i t doesn't , g o t o ste p 5 .

4. Ad d 4 o f fue l (1. 1 U.S . Gal , 0.8 8 Imp . Gal) . Th e

ligh t shoul d g o of f withi n fou r minutes .

5 . I f th e ligh t di d no t com e o n i n ste p 3 , remov e th e

rea r bulkhea d pane l behin d th e driver' s seat , the n re -

mov e th e acces s panel , an d disconnec t th e 3- P con -

necto r fro m th e fue l gaug e sendin g unit . Connec t th e

A (BLK ) termina l t o th e C (YEL/BLU ) termina l wit h

a jumpe r wire .

• I f th e ligh t come s on , th e proble m is eithe r th e

sendin g uni t o r it s ground .

• I f th e ligh t doe s no t com e on , th e proble m is a n

ope n in th e C (YEL/BLU ) wir e to th e gaug e assem -

bly , o r n o powe r t o th e gauge , o r a ba d bulb .

ACCES SPANEL

3-P CONNECTO R

B (YEL/WHT )

A (BLK)C (YEL/BLU )

ProCarManuals.com