ACURA NSX 1991 Service Repair Manual

Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 761 of 1640

Ignition Syste m

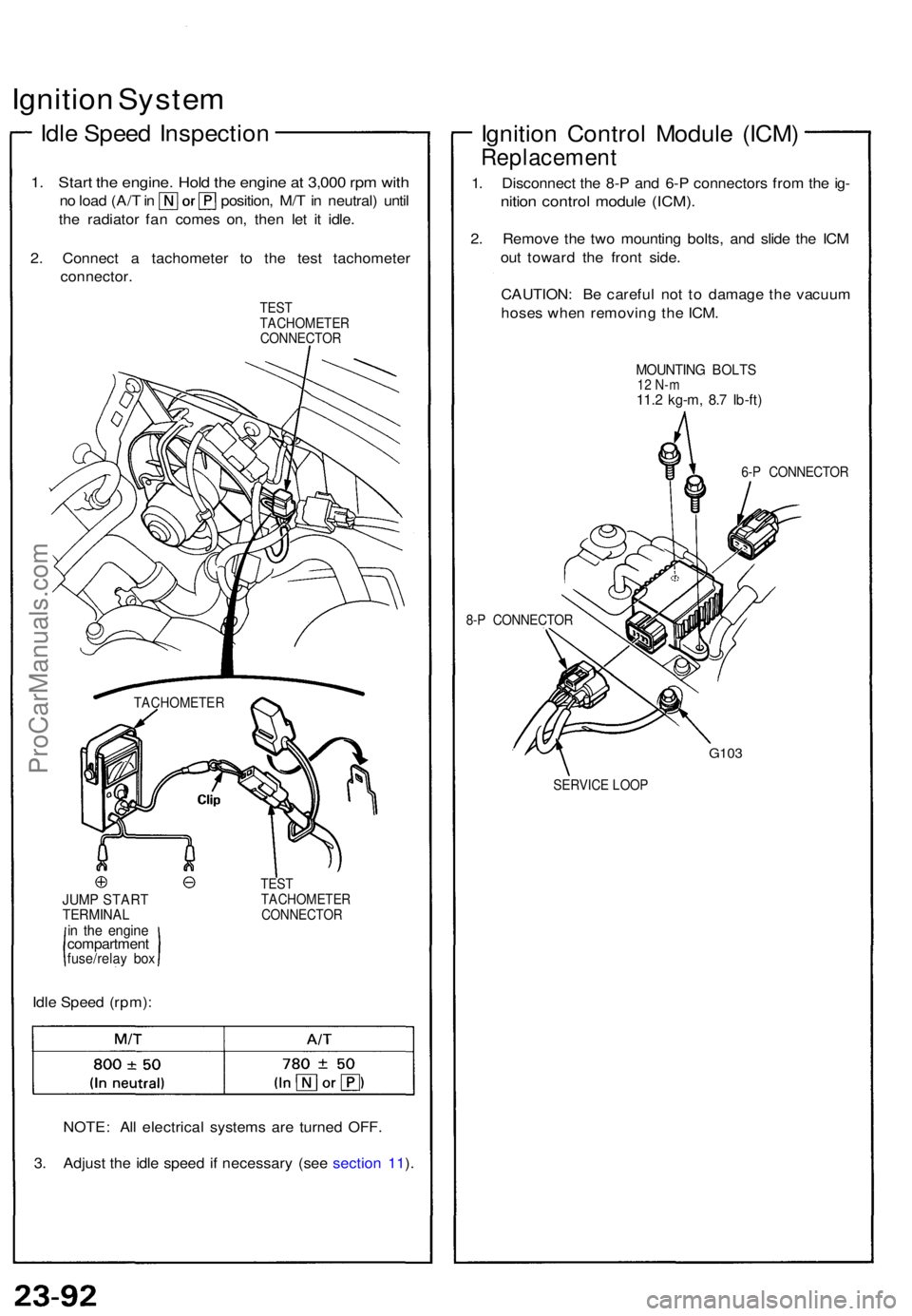

Idle Spee d Inspectio n

1. Star t th e engine . Hol d th e engin e a t 3,00 0 rp m wit h

no loa d (A/ T in position , M/ T in neutral ) unti l

th e radiator fan come s on , the n le t i t idle .

2 . Connec t a tachomete r t o th e tes t tachomete r

connector .

TEST

TACHOMETE R

CONNECTO R

JUMP STAR TTERMINA Lin th e engin ecompartmen tfuse/relay bo x

Idle Spee d (rpm) :

TEST

TACHOMETE R

CONNECTO R

NOTE: Al l electrica l system s ar e turne d OFF .

3 . Adjus t th e idl e spee d i f necessar y (se e sectio n 11 ).

Ignitio n Contro l Modul e (ICM )

Replacemen t

1. Disconnec t th e 8- P an d 6- P connector s fro m th e ig -

nitio n contro l modul e (ICM) .

2. Remov e th e tw o mountin g bolts , an d slid e th e IC M

ou t towar d th e fron t side .

CAUTION : B e carefu l no t t o damag e th e vacuu m

hose s whe n removin g th e ICM .

MOUNTIN G BOLT S12 N- m11.2 kg-m , 8. 7 Ib-ft )

6-P CONNECTO R

8- P CONNECTO R

G103

SERVIC E LOO P

TACHOMETE

R

ProCarManuals.com

Page 762 of 1640

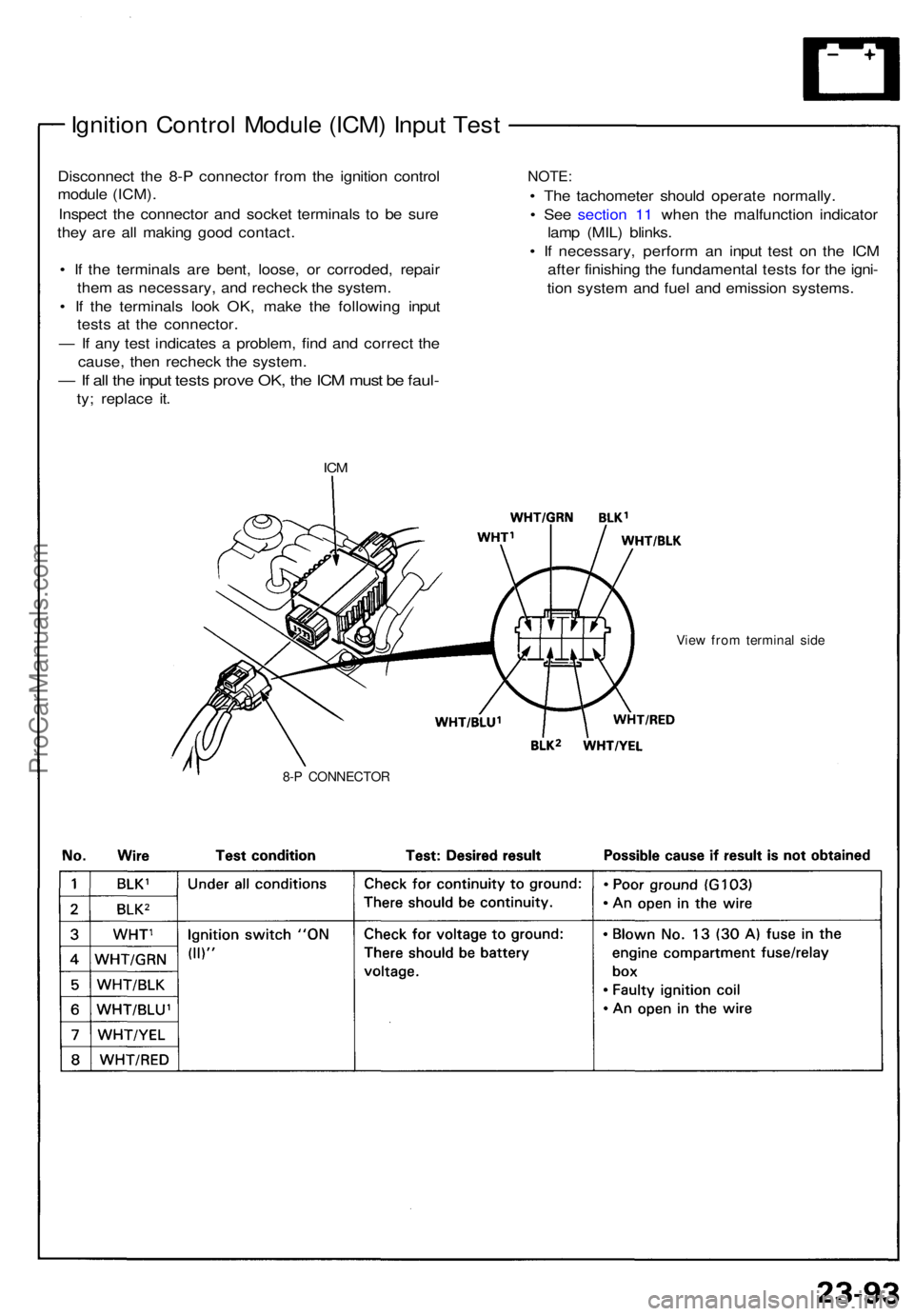

Ignition Contro l Modul e (ICM ) Inpu t Tes t

Disconnec t th e 8- P connecto r fro m th e ignitio n contro l

modul e (ICM) .

Inspec t th e connecto r an d socke t terminal s t o b e sur e

the y ar e al l makin g goo d contact .

• I f th e terminal s ar e bent , loose , o r corroded , repai r

the m a s necessary , an d rechec k th e system .

• I f th e terminal s loo k OK , mak e th e followin g inpu t

test s a t th e connector .

— If an y tes t indicate s a problem , fin d an d correc t th e

cause , the n rechec k th e system .

— If al l th e inpu t test s prov e OK , th e IC M mus t b e faul -

ty; replac e it .

IC M

NOTE :

• Th e tachomete r shoul d operat e normally .

• Se e sectio n 1 1 whe n th e malfunctio n indicato r

lam p (MIL ) blinks .

• I f necessary , perfor m a n inpu t tes t o n th e IC M

afte r finishin g th e fundamenta l test s fo r th e igni -

tio n syste m an d fue l an d emissio n systems .

View fro m termina l sid e

8-P CONNECTO R

ProCarManuals.com

Page 763 of 1640

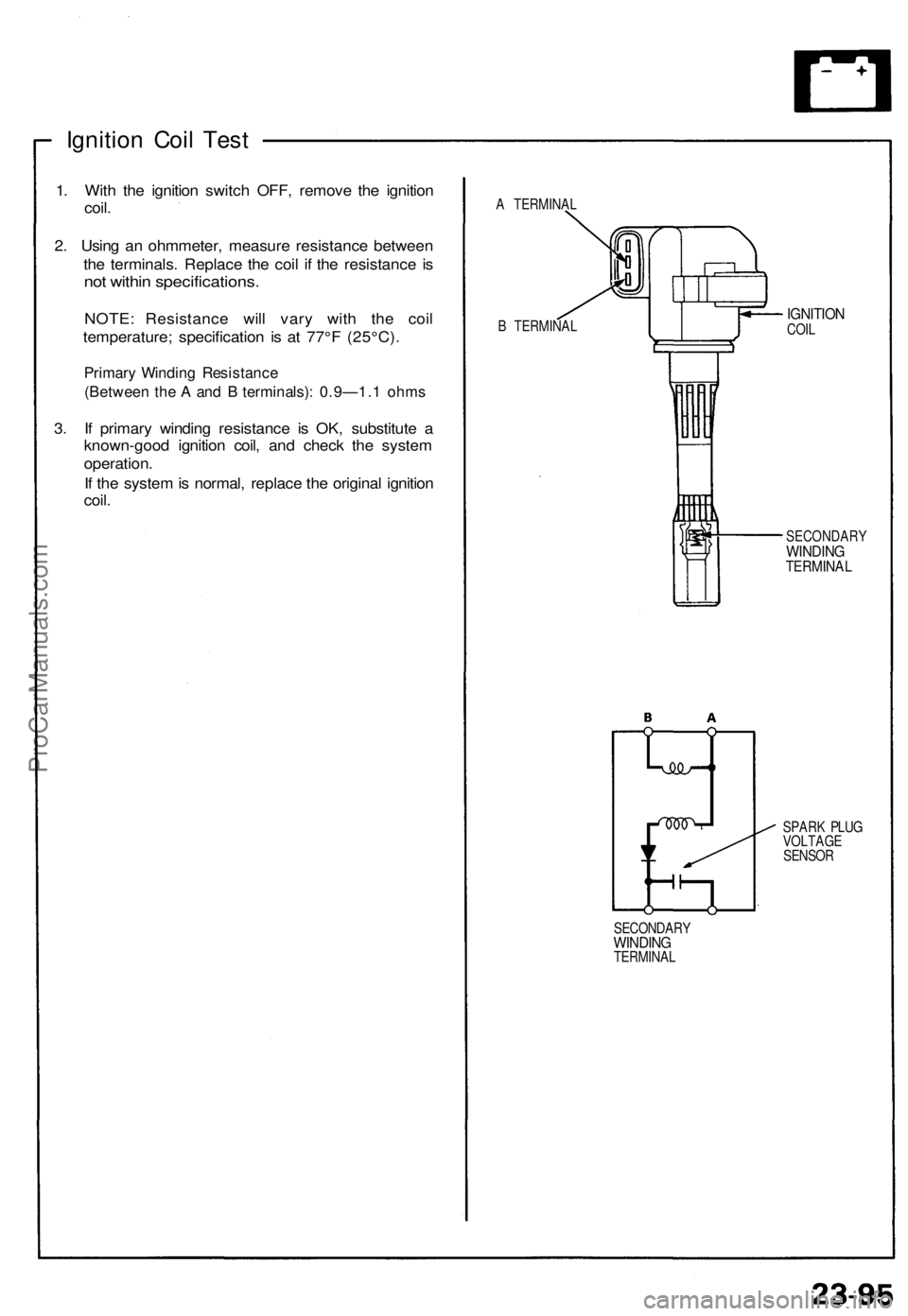

Ignition Coil Test

1. With the ignition switch OFF, remove the ignition

coil.

2. Using an ohmmeter, measure resistance between

the terminals. Replace the coil if the resistance is

not within specifications.

NOTE: Resistance will vary with the coil

temperature; specification is at 77°F (25°C).

Primary Winding Resistance

(Between the A and B terminals): 0.9—1.1 ohms

3. If primary winding resistance is OK, substitute a

known-good ignition coil, and check the system

operation.

If the system is normal, replace the original ignition

coil.

A TERMINAL

B TERMINAL

IGNITION

COIL

SECONDARY

WINDING

TERMINAL

SPARK PLUG

VOLTAGE

SENSOR

SECONDARY

WINDING

TERMINALProCarManuals.com

Page 764 of 1640

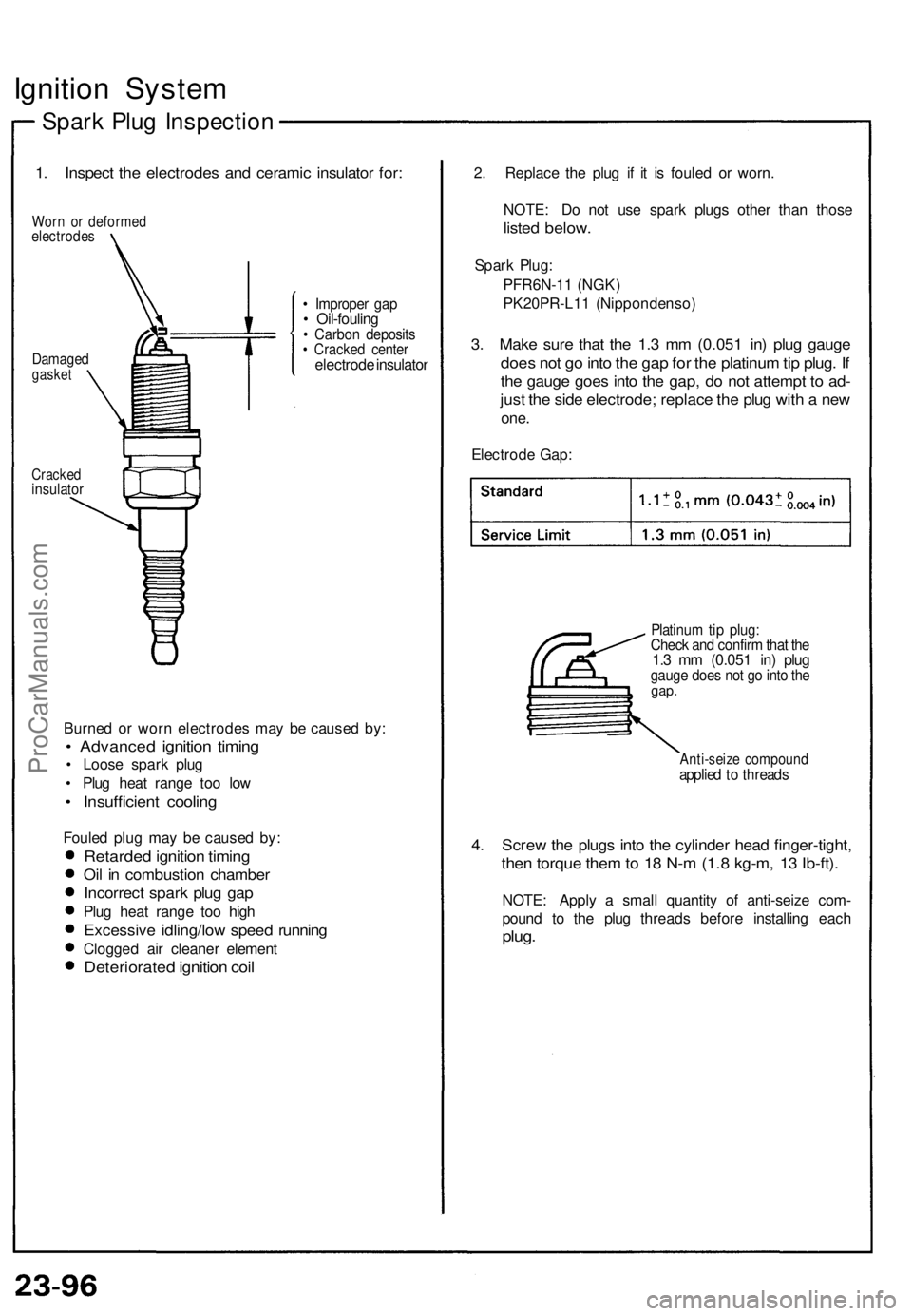

Ignition System

Spark Plug Inspection

1. Inspect the electrodes and ceramic insulator for:

Worn or deformed

electrodes

Damaged

gasket

• Improper gap

• Oil-fouling

• Carbon deposits

• Cracked center

electrode insulator

Cracked

insulator

Burned or worn electrodes may be caused by:

• Advanced ignition timing

• Loose spark plug

• Plug heat range too low

• Insufficient cooling

Fouled plug may be caused by:

Retarded ignition timing

Oil in combustion chamber

Incorrect spark plug gap

Plug heat range too high

Excessive idling/low speed running

Clogged air cleaner element

Deteriorated ignition coil

2. Replace the plug if it is fouled or worn.

NOTE: Do not use spark plugs other than those

listed below.

Spark Plug:

PFR6N-11 (NGK)

PK20PR-L11 (Nippondenso)

3. Make sure that the 1.3 mm (0.051 in) plug gauge

does not go into the gap for the platinum tip plug. If

the gauge goes into the gap, do not attempt to ad-

just the side electrode; replace the plug with a new

one.

Electrode Gap:

Platinum tip plug:

Check and confirm that the

1.3 mm (0.051 in) plug

gauge does not go into the

gap.

Anti-seize compound

applied to threads

4. Screw the plugs into the cylinder head finger-tight,

then torque them to 18 N-m (1.8 kg-m, 13 Ib-ft).

NOTE: Apply a small quantity of anti-seize com-

pound to the plug threads before installing each

plug.ProCarManuals.com

Page 765 of 1640

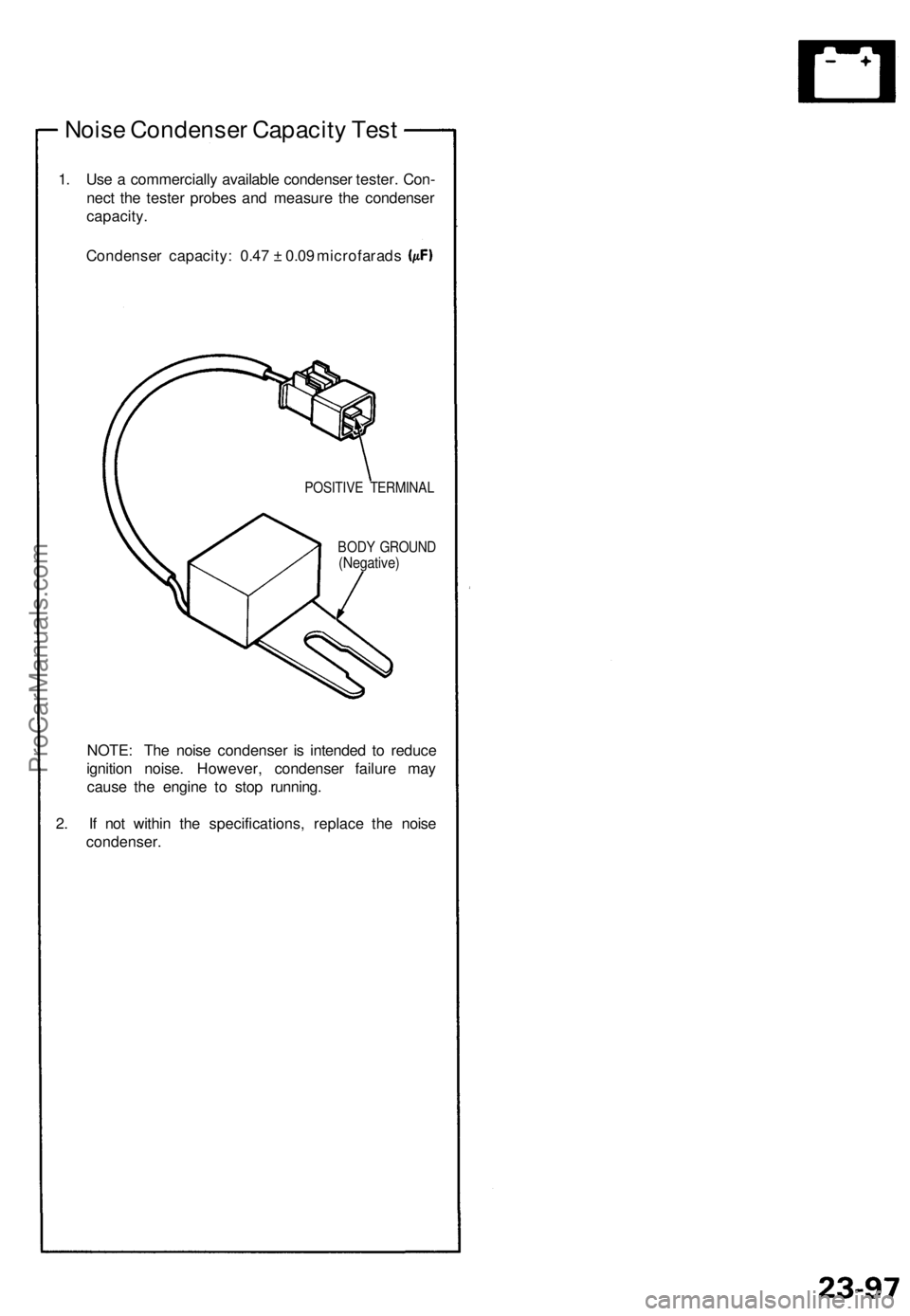

Noise Condenser Capacity Test

1. Use a commercially available condenser tester. Con-

nect the tester probes and measure the condenser

capacity.

Condenser capacity: 0.47 ± 0.09 microfarads

POSITIVE TERMINAL

BODY GROUND

(Negative)

NOTE: The noise condenser is intended to reduce

ignition noise. However, condenser failure may

cause the engine to stop running.

2. If not within the specifications, replace the noise

condenser.ProCarManuals.com

Page 766 of 1640

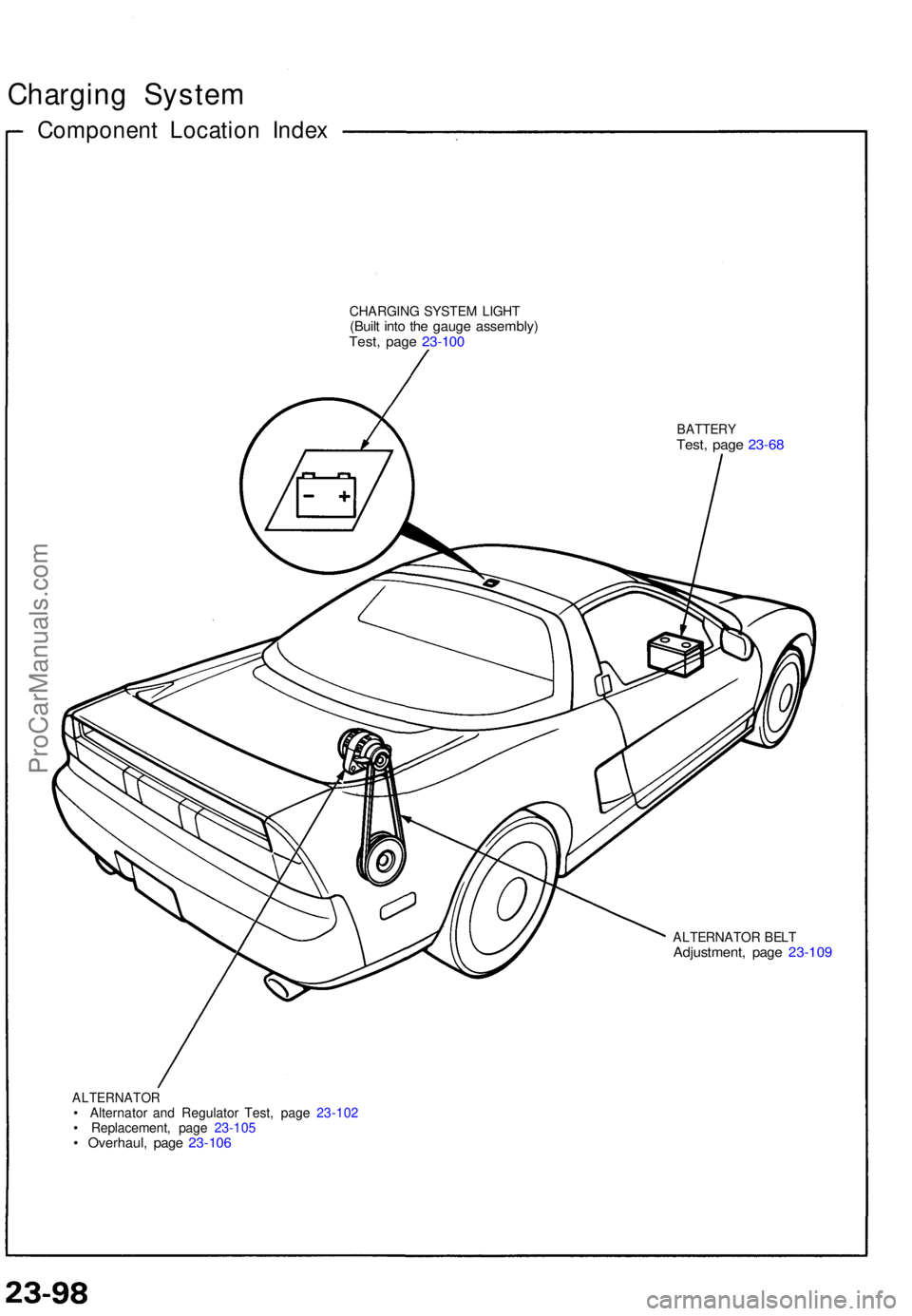

Charging Syste m

Componen t Locatio n Inde x

CHARGIN G SYSTE M LIGH T(Built int o th e gaug e assembly )Test, pag e 23-10 0

BATTER YTest, pag e 23-6 8

ALTERNATO R BEL TAdjustment , pag e 23-10 9

ALTERNATO R• Alternato r an d Regulato r Test , pag e 23-10 2

• Replacement , pag e 23-10 5

• Overhaul , pag e 23-10 6

ProCarManuals.com

Page 767 of 1640

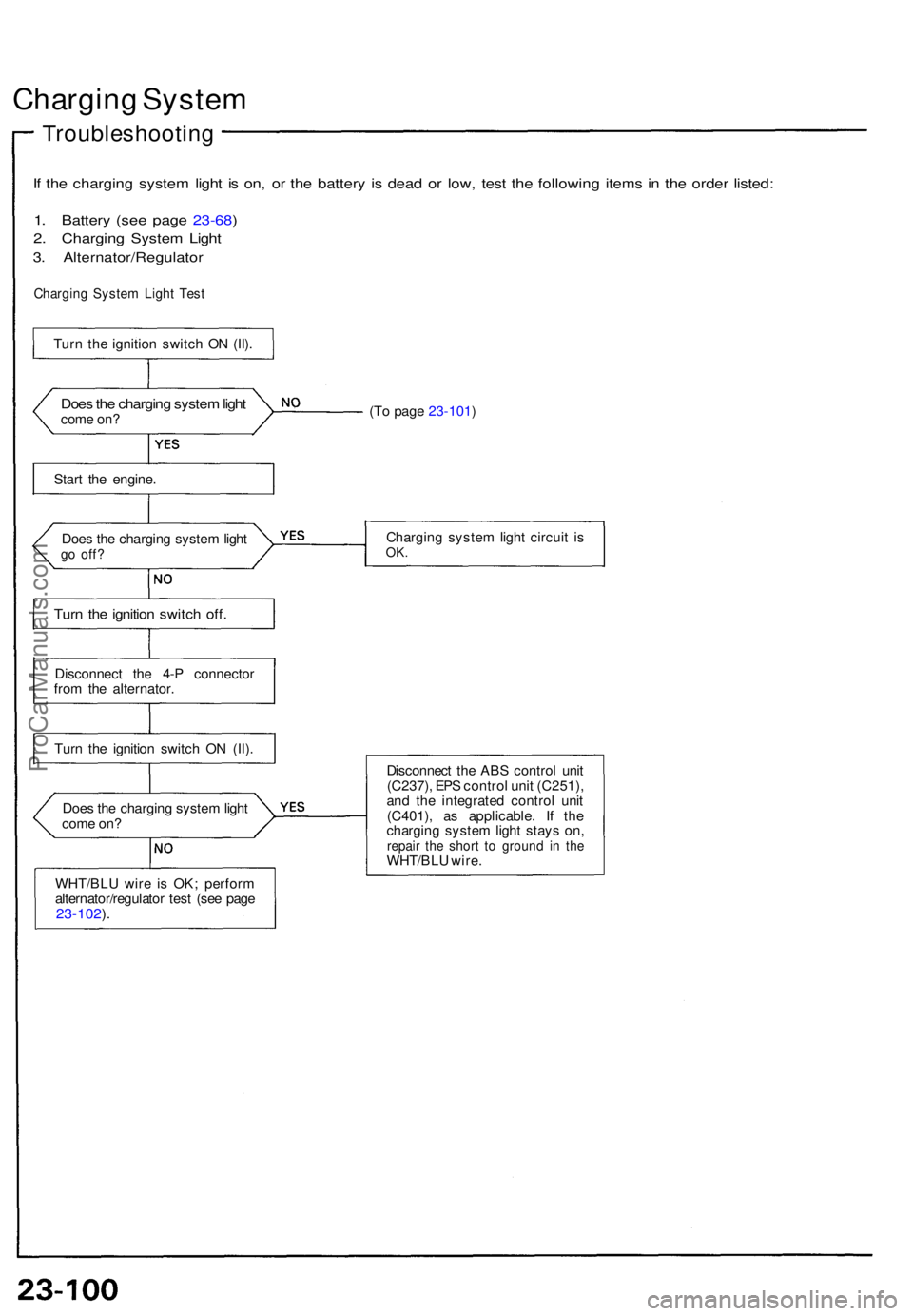

Charging Syste m

Troubleshootin g

If th e chargin g syste m ligh t i s on , o r th e batter y i s dea d o r low , tes t th e followin g item s i n th e orde r listed :

1. Batter y (se e pag e 23-68 )

2. Chargin g Syste m Ligh t

3. Alternator/Regulato r

Charging Syste m Ligh t Tes t

Does th e chargin g syste m ligh tcom e on ?

Star t th e engine .

Doe s th e chargin g syste m ligh t

go off ?

Turn th e ignitio n switc h off .

Disconnec t th e 4- P connecto r

fro m th e alternator .

Tur n th e ignitio n switc h O N (II) .

WHT/BL U wir e i s OK ; perfor m

alternator/regulato r tes t (se e pag e

23-102 ).

Doe s th e chargin g syste m ligh t

com e on ? (T

o pag e 23-101 )

Chargin g syste m ligh t circui t i s

OK .

Disconnec t th e AB S contro l uni t

(C237) , EP S contro l uni t (C251) ,

an d th e integrate d contro l uni t

(C401) , a s applicable . I f th e

chargin g syste m ligh t stay s on ,

repai r th e shor t t o groun d i n th eWHT/BL U wire .

Tur

n th e ignitio n switc h O N (II) .

ProCarManuals.com

Page 768 of 1640

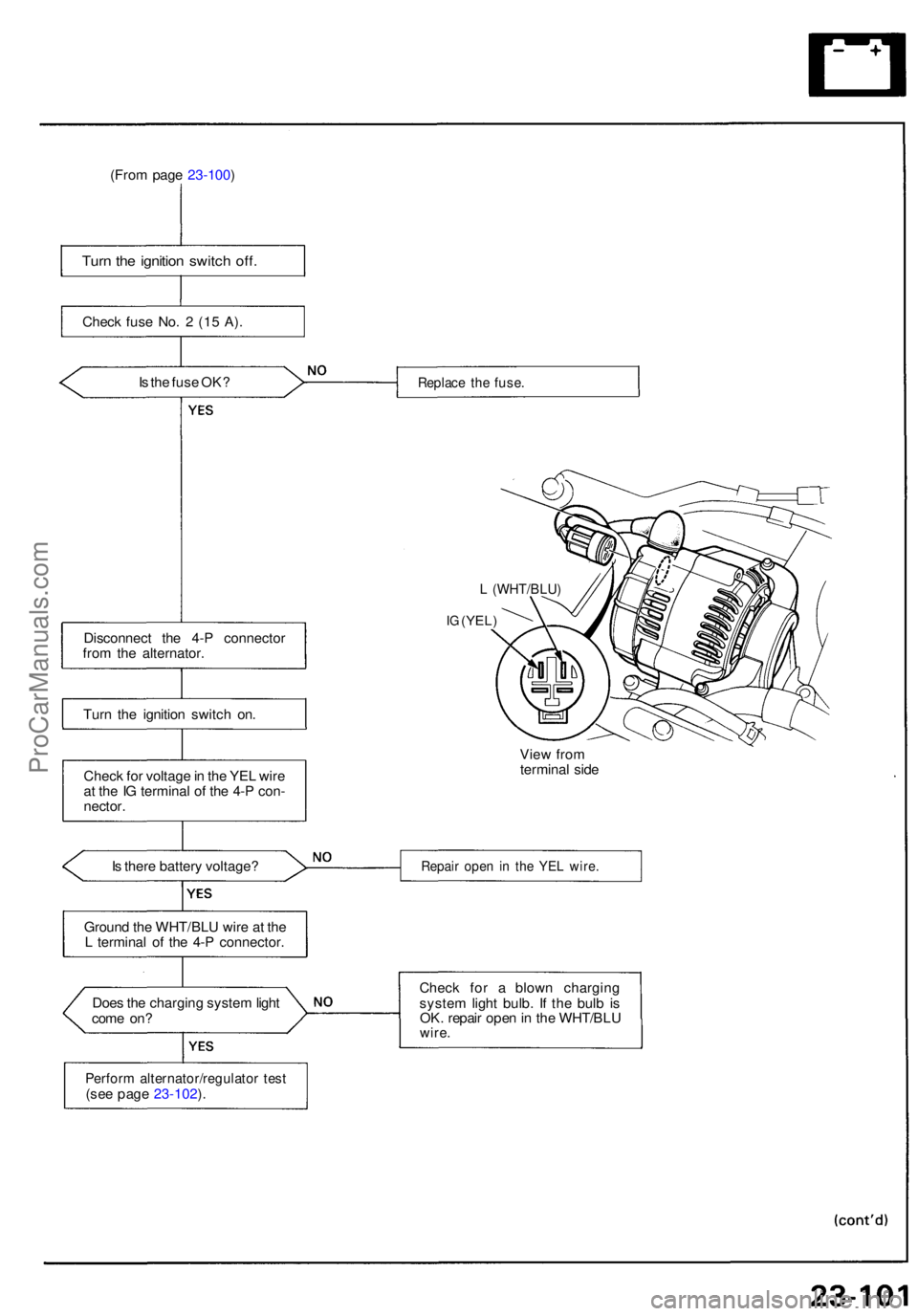

(From pag e 23-100 )

Turn th e ignitio n switc h off .

Chec k fus e No . 2 (1 5 A) .

I s th e fus e OK ?

Disconnec t th e 4- P connecto r

fro m th e alternator .

Tur n th e ignitio n switc h on .

Chec k fo r voltag e in th e YE L wir e

a t th e IG termina l o f th e 4- P con -

nector .

I s ther e batter y voltage ?

Groun d th e WHT/BL U wire at th e

L termina l o f th e 4- P connector .

Doe s th e chargin g syste m ligh t

com e on ?

Perfor m alternator/regulato r tes t(see pag e 23-102 ).

Replac e th e fuse .

L (WHT/BLU )

IG (YEL )

View fro m

termina l sid e

Repai r ope n i n th e YE L wire .

Check fo r a blow n chargin g

syste m ligh t bulb . I f th e bul b is

OK . repai r ope n in th e WHT/BL U

wire.

ProCarManuals.com

Page 769 of 1640

Charging System

Troubleshooting

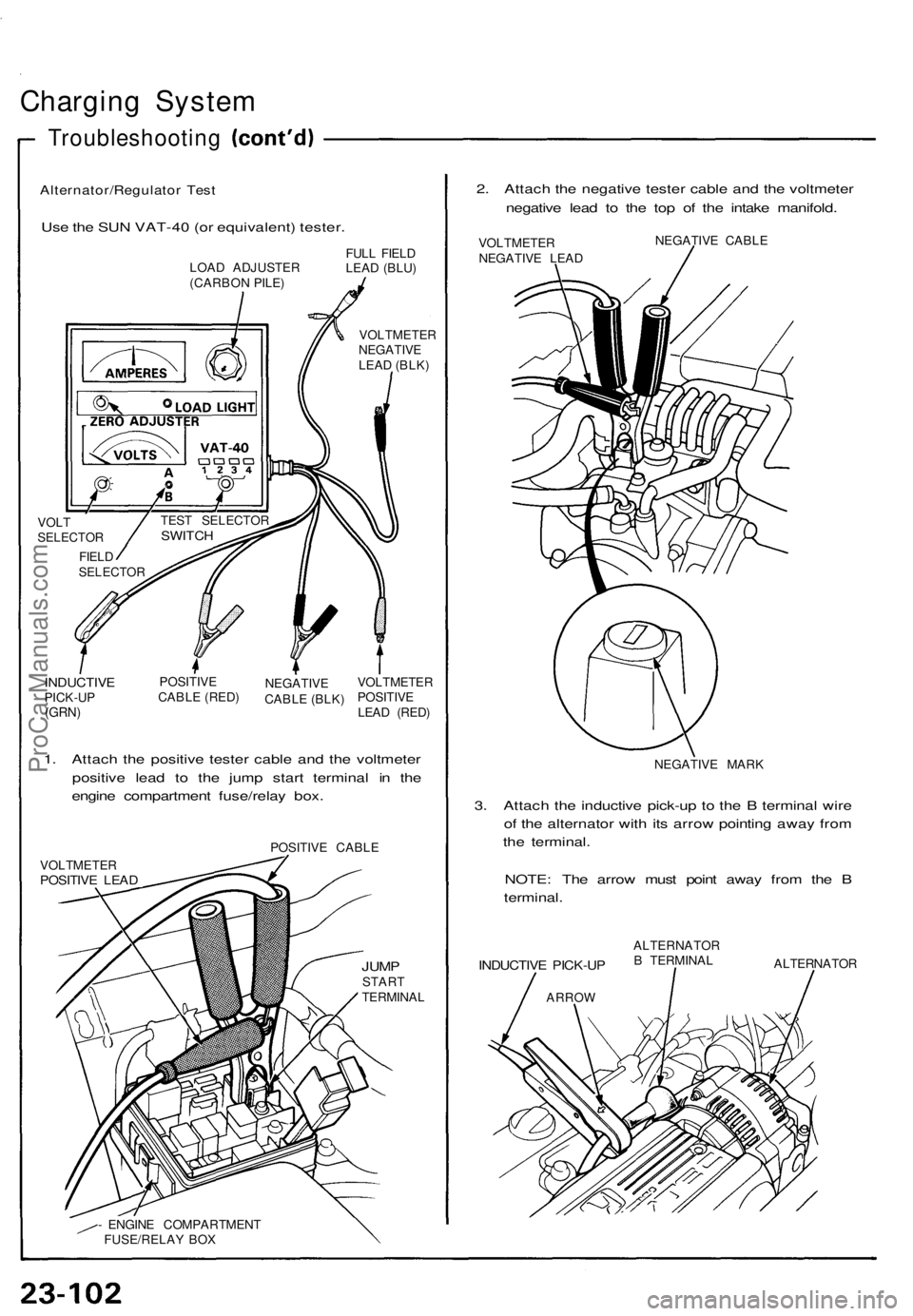

Alternator/Regulator Test

Use the SUN VAT-40 (or equivalent) tester.

2. Attach the negative tester cable and the voltmeter

negative lead to the top of the intake manifold.

LOAD ADJUSTER

(CARBON PILE)

FULL FIELD

LEAD (BLU)

VOLTMETER

NEGATIVE

LEAD (BLK)

VOLT

SELECTOR

FIELD

SELECTOR

INDUCTIVE

PICK-UP

(GRN)

POSITIVE

CABLE (RED)

NEGATIVE

CABLE (BLK)

VOLTMETER

POSITIVE

LEAD (RED)

1. Attach the positive tester cable and the voltmeter

positive lead to the jump start terminal in the

engine compartment fuse/relay box.

POSITIVE CABLE

VOLTMETER

POSITIVE LEAD

JUMP

START

TERMINAL

- ENGINE COMPARTMENT

FUSE/RELAY BOX

VOLTMETER

NEGATIVE LEAD

NEGATIVE CABLE

NEGATIVE MARK

3. Attach the inductive pick-up to the B terminal wire

of the alternator with its arrow pointing away from

the terminal.

NOTE: The arrow must point away from the B

terminal.

INDUCTIVE PICK-UP

ARROW

ALTERNATOR

B TERMINAL

ALTERNATOR

TEST SELECTOR

SWITCHProCarManuals.com

Page 770 of 1640

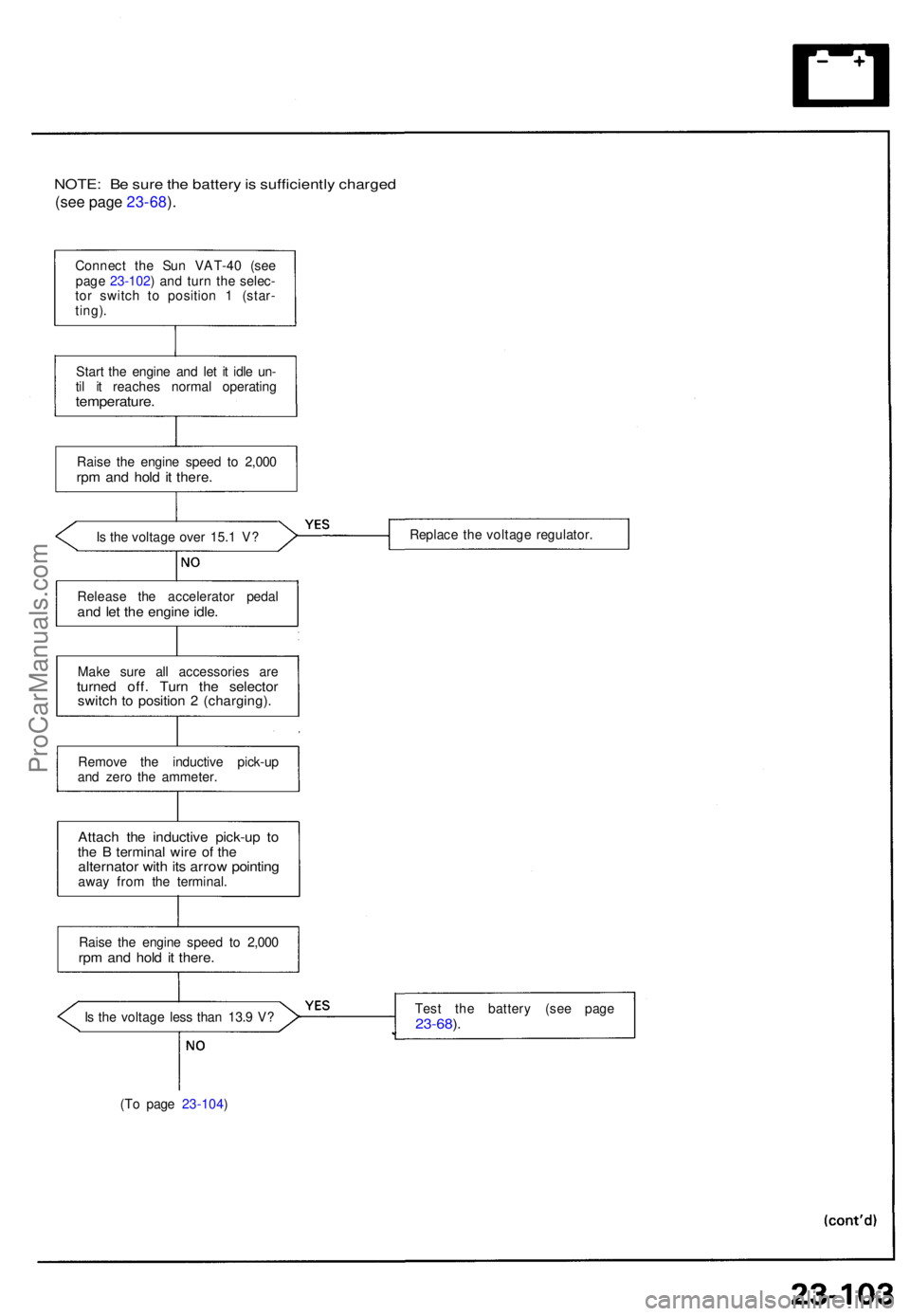

NOTE: B e sur e th e batter y is sufficientl y charge d

(see pag e 23-68 ).

Connec t th e Su n VAT-4 0 (se e

pag e 23-102 ) an d tur n th e selec -

to r switc h t o positio n 1 (star -

ting) .

Star t th e engin e an d le t i t idl e un -

ti l i t reache s norma l operatin g

temperature .

Raise th e engin e spee d t o 2,00 0rpm an d hol d i t there .

Is th e voltag e ove r 15. 1 V ?

Releas e th e accelerato r peda l

and le t th e engin e idle .

Mak e sur e al l accessorie s ar eturne d off . Tur n th e selecto rswitch t o positio n 2 (charging) .

Remove th e inductiv e pick-u p

an d zer o th e ammeter .

Attach th e inductiv e pick-u p t oth e B termina l wir e o f th ealternato r wit h it s arro w pointin gaway fro m th e terminal .

Rais e th e engin e spee d t o 2,00 0

rpm an d hol d i t there .

Is th e voltag e les s tha n 13. 9 V ?

(T o pag e 23-104 ) Replac

e th e voltag e regulator .

Tes t th e batter y (se e pag e23-68).

ProCarManuals.com