ACURA NSX 1991 Service Repair Manual

Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 721 of 1640

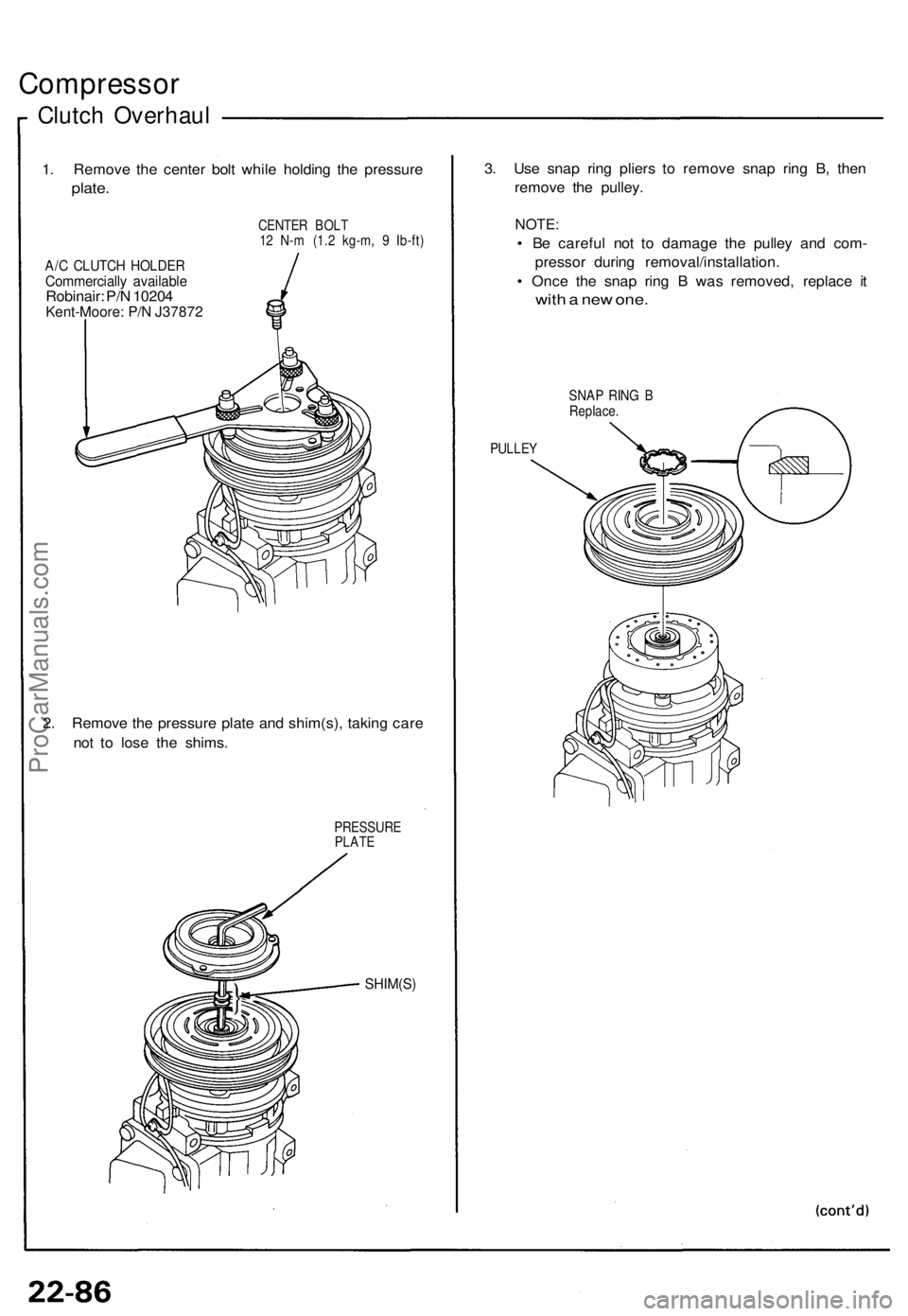

Compressor

Clutch Overhaul

1. Remove the center bolt while holding the pressure

plate.

CENTER BOLT

12 N-m (1.2 kg-m, 9 Ib-ft)

A/C CLUTCH HOLDER

Commercially available

Robinair: P/N 10204

Kent-Moore: P/N J37872

2. Remove the pressure plate and shim(s), taking care

not to lose the shims.

PRESSURE

PLATE

SHIM(S)

3. Use snap ring pliers to remove snap ring B, then

remove the pulley.

NOTE:

• Be careful not to damage the pulley and com-

pressor during removal/installation.

• Once the snap ring B was removed, replace it

with a new one.

SNAP RING B

Replace.

PULLEYProCarManuals.com

Page 722 of 1640

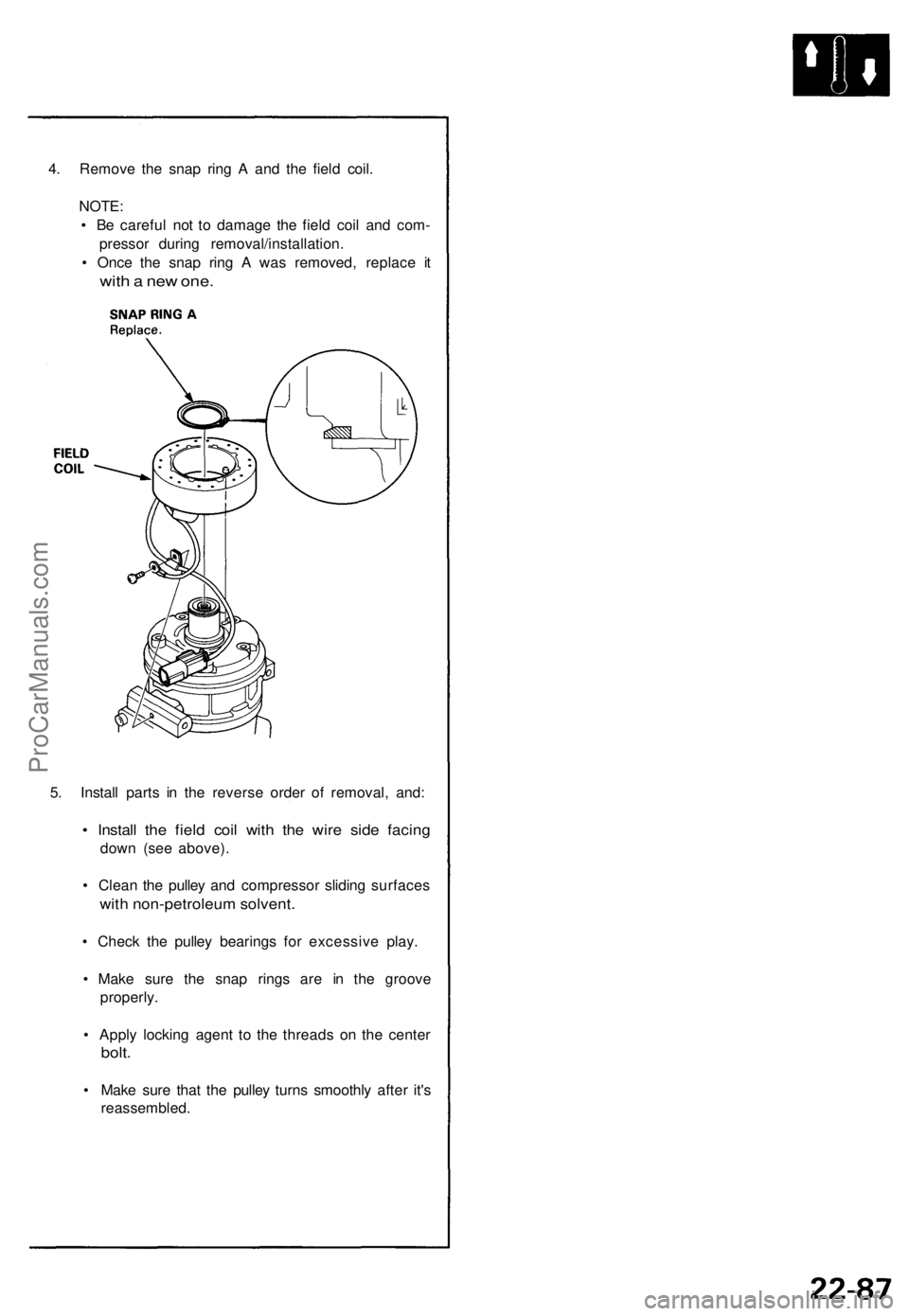

4. Remove the snap ring A and the field coil.

NOTE:

• Be careful not to damage the field coil and com-

pressor during removal/installation.

• Once the snap ring A was removed, replace it

with a new one.

5. Install parts in the reverse order of removal, and:

• Install the field coil with the wire side facing

down (see above).

• Clean the pulley and compressor sliding surfaces

with non-petroleum solvent.

• Check the pulley bearings for excessive play.

• Make sure the snap rings are in the groove

properly.

• Apply locking agent to the threads on the center

bolt.

• Make sure that the pulley turns smoothly after it's

reassembled.ProCarManuals.com

Page 723 of 1640

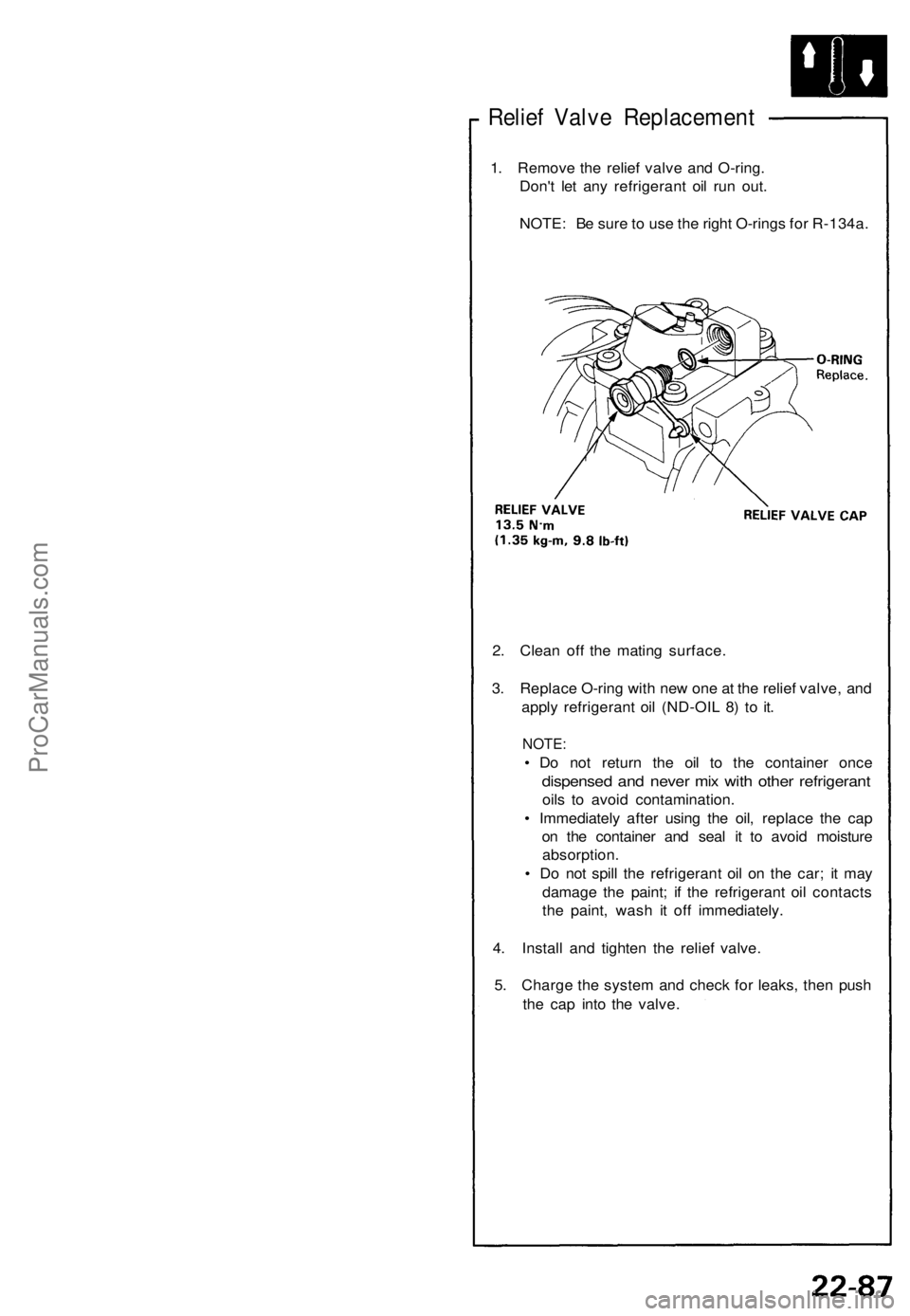

Relief Valve Replacement

1. Remove the relief valve and O-ring.

Don't let any refrigerant oil run out.

NOTE: Be sure to use the right O-rings for R-134a.

2. Clean off the mating surface.

3. Replace O-ring with new one at the relief valve, and

apply refrigerant oil (ND-OIL 8) to it.

NOTE:

• Do not return the oil to the container once

dispensed and never mix with other refrigerant

oils to avoid contamination.

• Immediately after using the oil, replace the cap

on the container and seal it to avoid moisture

absorption.

• Do not spill the refrigerant oil on the car; it may

damage the paint; if the refrigerant oil contacts

the paint, wash it off immediately.

4. Install and tighten the relief valve.

5. Charge the system and check for leaks, then push

the cap into the valve.ProCarManuals.com

Page 724 of 1640

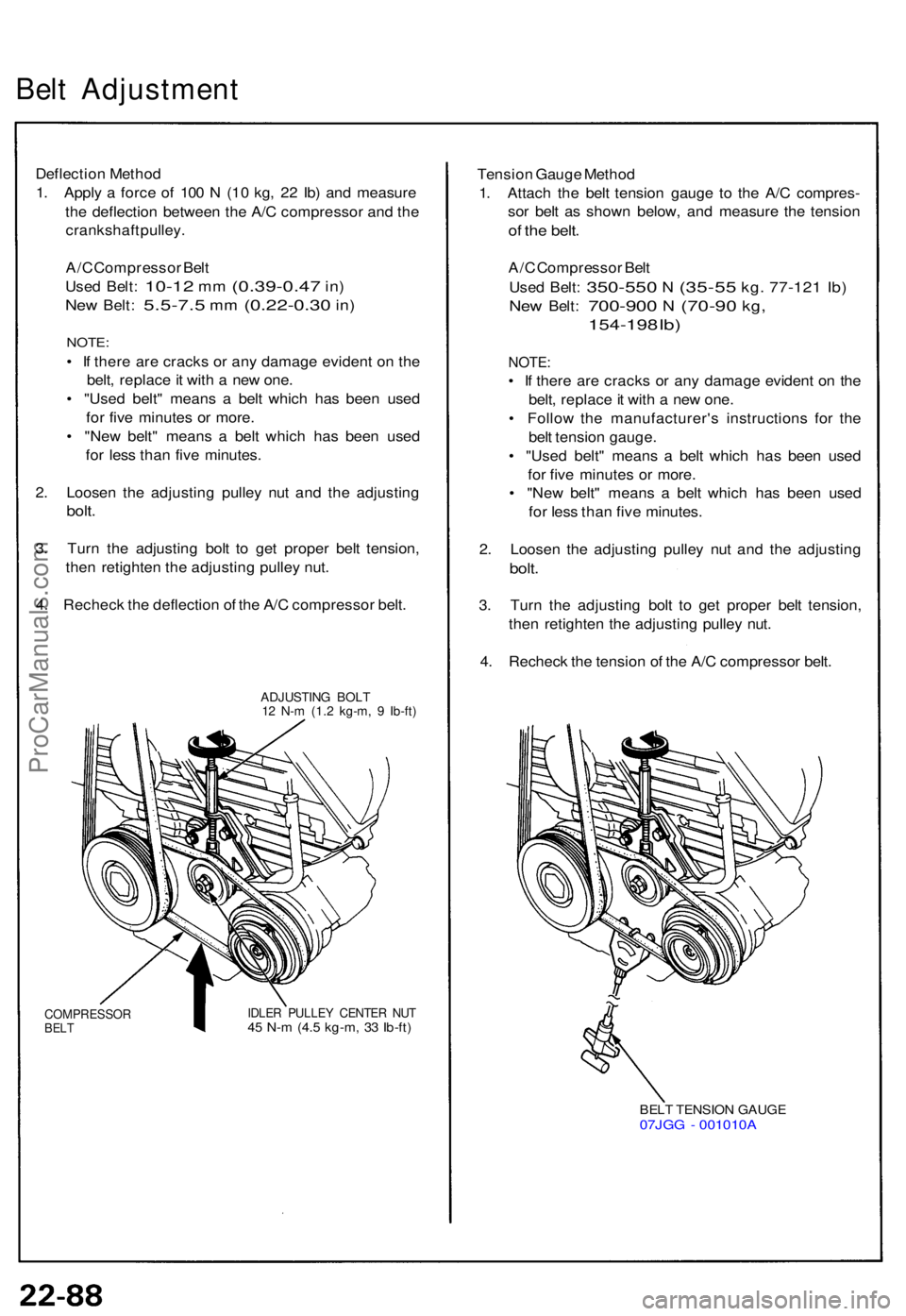

Belt Adjustmen t

Deflection Metho d

1 . Appl y a forc e o f 10 0 N (1 0 kg , 2 2 Ib ) an d measur e

th e deflectio n betwee n th e A/ C compresso r an d th e

crankshaf t pulley .

A/ C Compresso r Bel t

Use d Belt :

10-1 2 mm (0.39-0.4 7 in)

Ne w Belt : 5.5-7. 5 mm (0.22-0.3 0 in)

NOTE :

• I f ther e ar e crack s o r an y damag e eviden t o n th e

belt , replac e it wit h a ne w one .

• "Use d belt " mean s a bel t whic h ha s bee n use d

fo r fiv e minute s o r more .

• "Ne w belt " mean s a bel t whic h ha s bee n use d

fo r les s tha n fiv e minutes .

2 . Loose n th e adjustin g pulle y nu t an d th e adjustin g

bolt.

3. Tur n th e adjustin g bol t t o ge t prope r bel t tension ,

the n retighte n th e adjustin g pulle y nut .

4 . Rechec k th e deflectio n o f th e A/ C compresso r belt .

ADJUSTIN G BOL T12 N- m (1. 2 kg-m , 9 Ib-ft )

COMPRESSO RBELTIDLE R PULLE Y CENTE R NU T45 N- m (4. 5 kg-m , 3 3 Ib-ft )

Tensio n Gaug e Metho d

1 . Attac h th e bel t tensio n gaug e t o th e A/ C compres -

so r bel t a s show n below , an d measur e th e tensio n

of th e belt .

A/C Compresso r Bel t

Use d Belt :

350-55 0 N (35-55 kg. 77-12 1 Ib)

New Belt : 700-90 0 N (70-90 kg,

154-19 8 Ib )

NOTE :

• I f ther e ar e crack s o r an y damag e eviden t o n th e

belt , replac e it wit h a ne w one .

• Follo w th e manufacturer' s instruction s fo r th e

bel t tensio n gauge .

• "Use d belt " mean s a bel t whic h ha s bee n use d

fo r fiv e minute s o r more .

• "Ne w belt " mean s a bel t whic h ha s bee n use d

fo r les s tha n fiv e minutes .

2 . Loose n th e adjustin g pulley nut an d th e adjustin g

bolt.

3. Tur n th e adjustin g bol t t o ge t prope r bel t tension ,

the n retighte n th e adjustin g pulle y nut .

4 . Rechec k th e tensio n o f th e A/ C compresso r belt .

BEL T TENSIO N GAUG E07JGG - 001010 A

ProCarManuals.com

Page 725 of 1640

A/C System Service

Evacuation

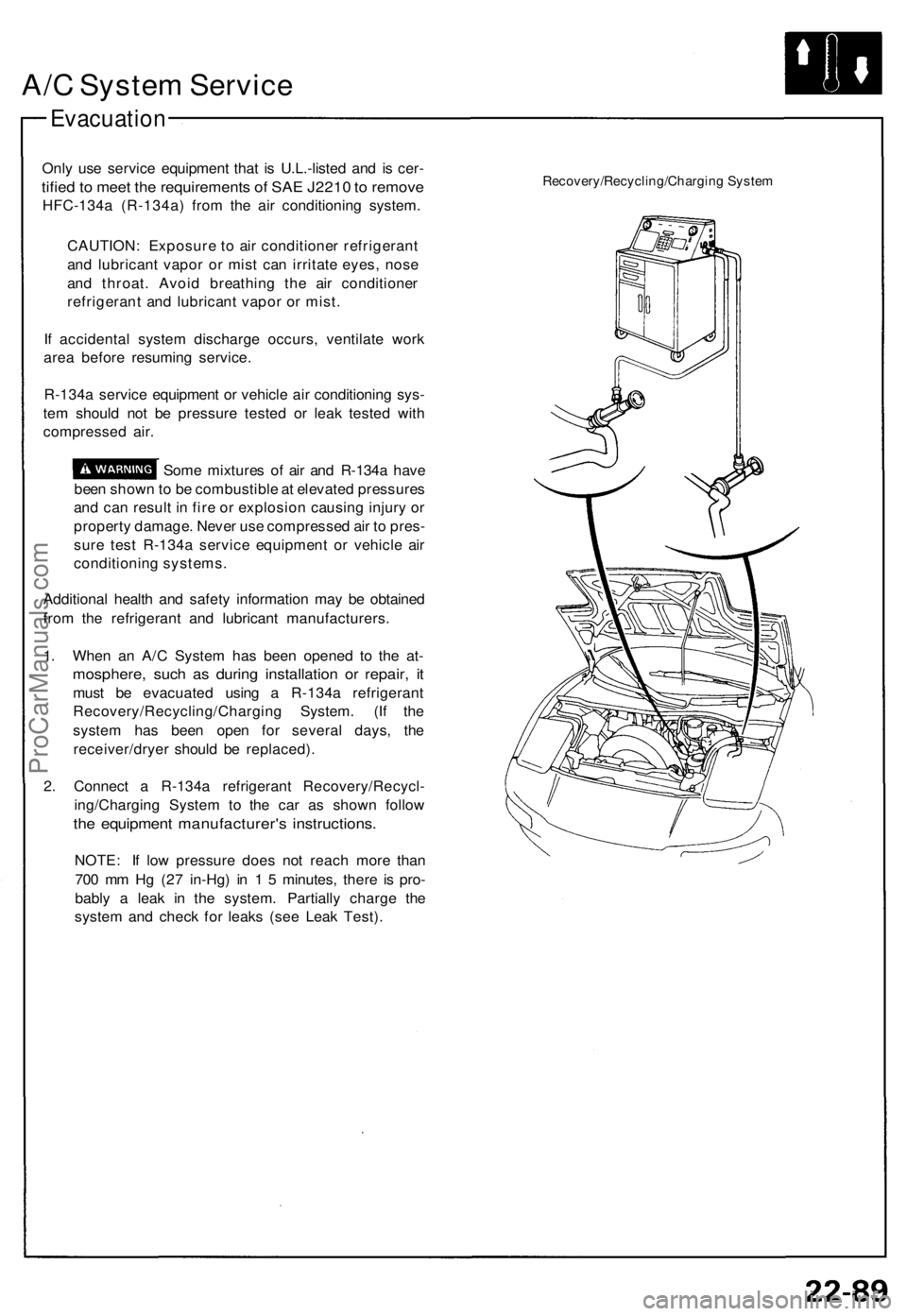

Only use service equipment that is U.L.-listed and is cer-

tified to meet the requirements of SAE J2210 to remove

HFC-134a (R-134a) from the air conditioning system.

CAUTION: Exposure to air conditioner refrigerant

and lubricant vapor or mist can irritate eyes, nose

and throat. Avoid breathing the air conditioner

refrigerant and lubricant vapor or mist.

If accidental system discharge occurs, ventilate work

area before resuming service.

R-134a service equipment or vehicle air conditioning sys-

tem should not be pressure tested or leak tested with

compressed air.

Some mixtures of air and R-134a have

been shown to be combustible at elevated pressures

and can result in fire or explosion causing injury or

property damage. Never use compressed air to pres-

sure test R-134a service equipment or vehicle air

conditioning systems.

Additional health and safety information may be obtained

from the refrigerant and lubricant manufacturers.

1. When an A/C System has been opened to the at-

mosphere, such as during installation or repair, it

must be evacuated using a R-134a refrigerant

Recovery/Recycling/Charging System. (If the

system has been open for several days, the

receiver/dryer should be replaced).

2. Connect a R-134a refrigerant Recovery/Recycl-

ing/Charging System to the car as shown follow

the equipment manufacturer's instructions.

NOTE: If low pressure does not reach more than

700 mm Hg (27 in-Hg) in 1 5 minutes, there is pro-

bably a leak in the system. Partially charge the

system and check for leaks (see Leak Test).

Recovery/Recycling/Charging SystemProCarManuals.com

Page 726 of 1640

A/C Syste m Servic e

Leak Tes t

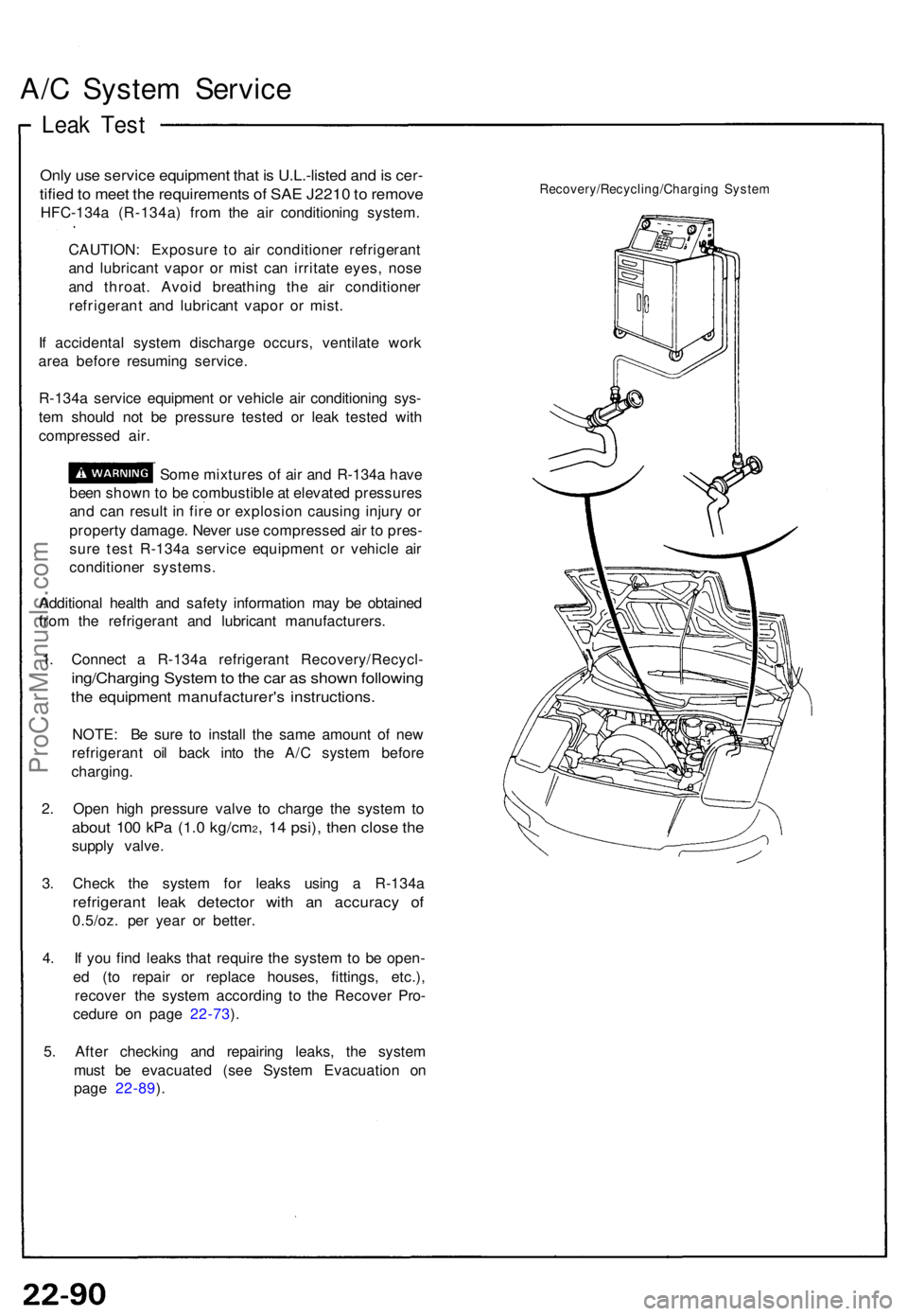

Only us e servic e equipmen t tha t i s U.L.-liste d an d is cer -

tified to mee t th e requirement s o f SA E J221 0 to remov e

HFC-134 a (R-134a ) fro m th e ai r conditionin g system .

CAUTION : Exposur e t o ai r conditione r refrigeran t

an d lubrican t vapo r o r mis t ca n irritat e eyes , nos e

an d throat . Avoi d breathin g th e ai r conditione r

refrigeran t an d lubrican t vapo r o r mist .

I f accidenta l syste m discharg e occurs , ventilat e wor k

are a befor e resumin g service .

R-134 a servic e equipmen t o r vehicl e ai r conditionin g sys -

te m shoul d no t b e pressur e teste d o r lea k teste d wit h

compresse d air .

Som e mixture s o f ai r an d R-134 a hav e

bee n show n to b e combustibl e a t elevate d pressure s

an d ca n resul t i n fir e o r explosio n causin g injur y o r

propert y damage . Neve r us e compresse d ai r t o pres -

sur e tes t R-134 a servic e equipmen t o r vehicl e ai r

conditione r systems.

Additiona l healt h an d safet y informatio n ma y b e obtaine d

fro m th e refrigeran t an d lubrican t manufacturers .

1 . Connec t a R-134 a refrigeran t Recovery/Recycl -

ing/Charging Syste m to th e ca r a s show n followin g

the equipmen t manufacturer' s instructions .

NOTE: B e sur e t o instal l th e sam e amoun t o f ne w

refrigeran t oi l bac k int o th e A/ C syste m befor e

charging .

2 . Ope n hig h pressur e valv e t o charg e th e syste m to

abou t 10 0 kP a (1. 0 kg/cm2, 1 4 psi) , the n clos e th e

suppl y valve .

3 . Chec k th e syste m fo r leak s usin g a R-134 a

refrigeran t lea k detecto r wit h a n accurac y o f

0.5/oz . pe r yea r o r better .

4 . I f yo u fin d leak s tha t requir e th e syste m to b e open -

e d (t o repai r o r replac e houses , fittings , etc.) ,

recove r th e syste m accordin g t o th e Recove r Pro -

cedur e o n pag e 22-73 ).

5 . Afte r checkin g an d repairin g leaks , th e syste m

mus t b e evacuate d (se e Syste m Evacuatio n o n

pag e 22-89 ).

Recovery/Recycling/Chargin g Syste m

ProCarManuals.com

Page 727 of 1640

Charging

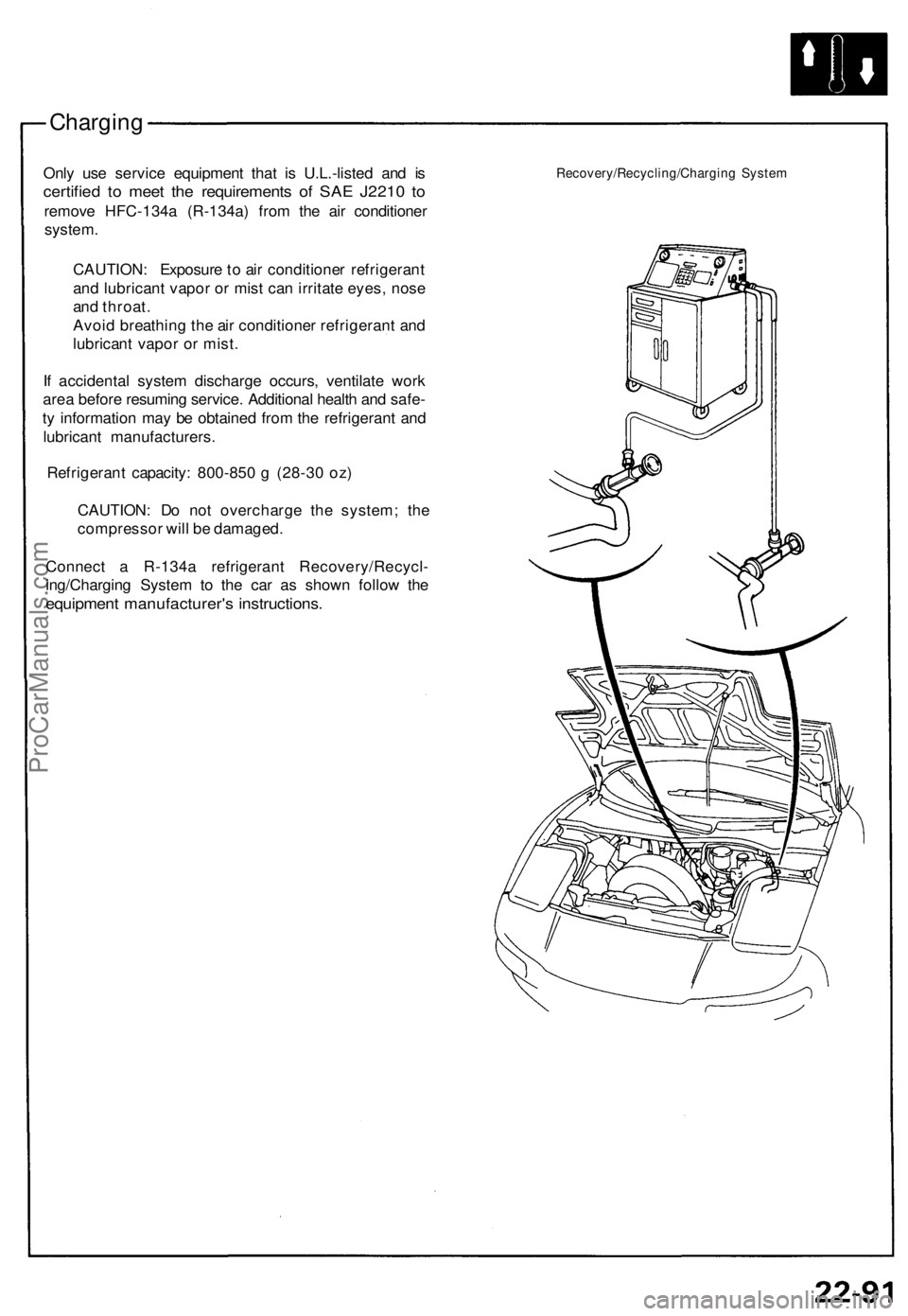

Only us e servic e equipmen t tha t i s U.L.-liste d an d i s

certifie d t o mee t th e requirement s o f SA E J221 0 t o

remov e HFC-134 a (R-134a ) fro m th e ai r conditione r

system .

CAUTION : Exposur e t o ai r conditione r refrigeran t

an d lubrican t vapo r o r mis t ca n irritat e eyes , nos e

an d throat .

Avoi d breathin g th e ai r conditione r refrigeran t an d

lubrican t vapo r o r mist .

I f accidenta l syste m discharg e occurs , ventilat e wor k

are a befor e resumin g service . Additiona l healt h an d safe -

t y informatio n ma y b e obtaine d fro m th e refrigeran t an d

lubrican t manufacturers .

Refrigeran t capacity : 800-85 0 g (28-3 0 oz )

CAUTION : D o no t overcharg e th e system ; th e

compresso r wil l b e damaged .

Connec t a R-134 a refrigeran t Recovery/Recycl -

ing/Chargin g Syste m to th e ca r a s show n follo w th e

equipmen t manufacturer' s instructions .

Recovery/Recycling/Chargin g Syste m

ProCarManuals.com

Page 728 of 1640

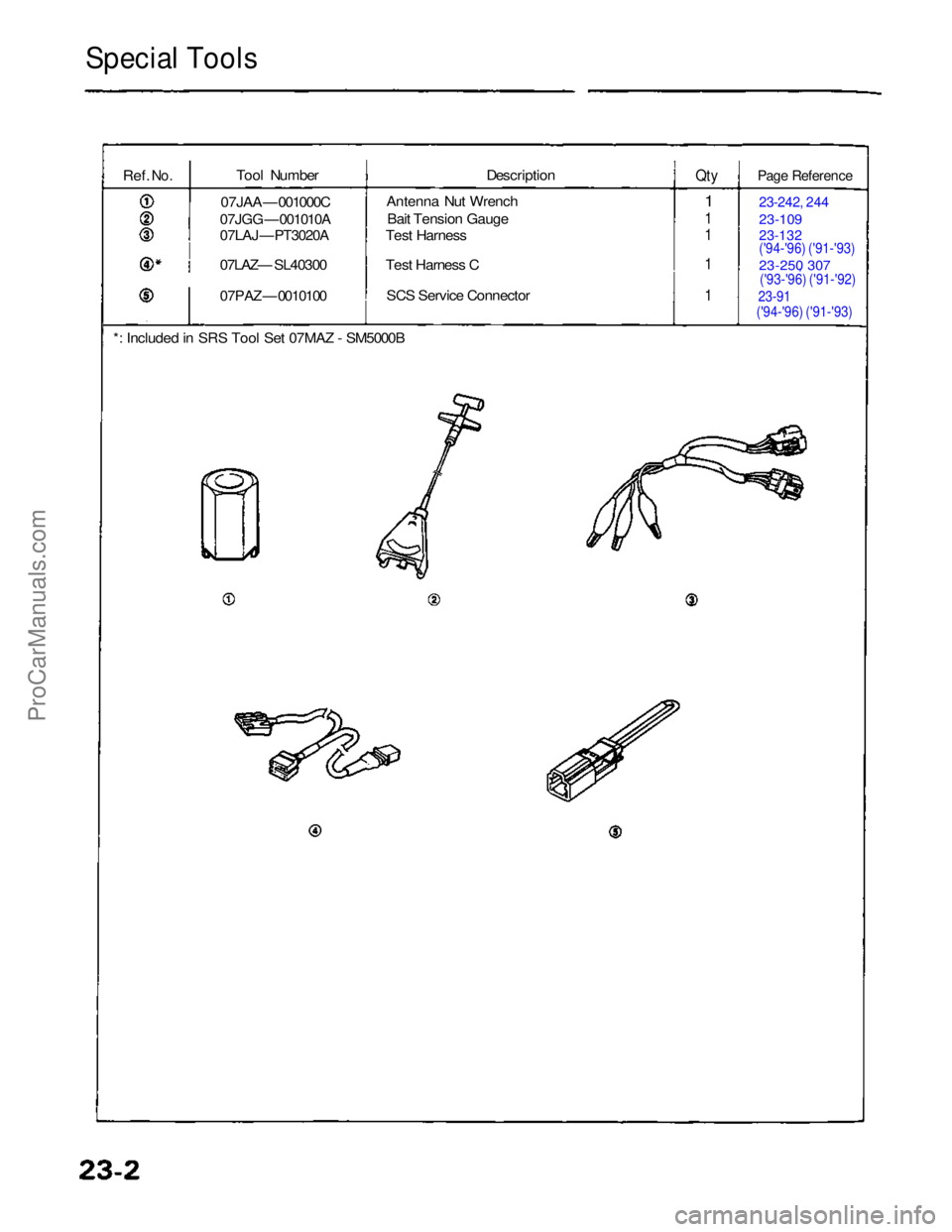

Special Tools

Ref.

No.

Tool Number

07JAA — 001000C

07JGG — 001010A

07LAJ — PT3020A

07LAZ— SL40300

07PAZ — 0010100

Description

Antenna Nut Wrench Bait Tension Gauge

Test Harness

Test Harness C

SCS Service Connector

Qty

1

1

1

1

1

Page Reference

23-242, 244

23-109

23-132('94-'96) ('91-'93)

23-250, 307('93-'96) ('91-'92)

23-91

('94-'96) ('91-'93)

*: Included in SRS Tool Set 07MAZ - SM5000B

ProCarManuals.com

Page 729 of 1640

Troubleshooting

Tips and Precautions

Before Troubleshooting

• Check applicable fuses in the appropriate fuse box.

• Check the battery for damage, state of charge, and

clean and tight connections.

• Check the alternator belt tension.

CAUTION:

• Do not quick-charge a battery unless the battery

ground cable has been disconnected.

Otherwise you will damage the alternator

diodes.

• Do not attempt to crank the engine with the bat-

tery ground cable loosely connected or you will

severely damage the wiring.

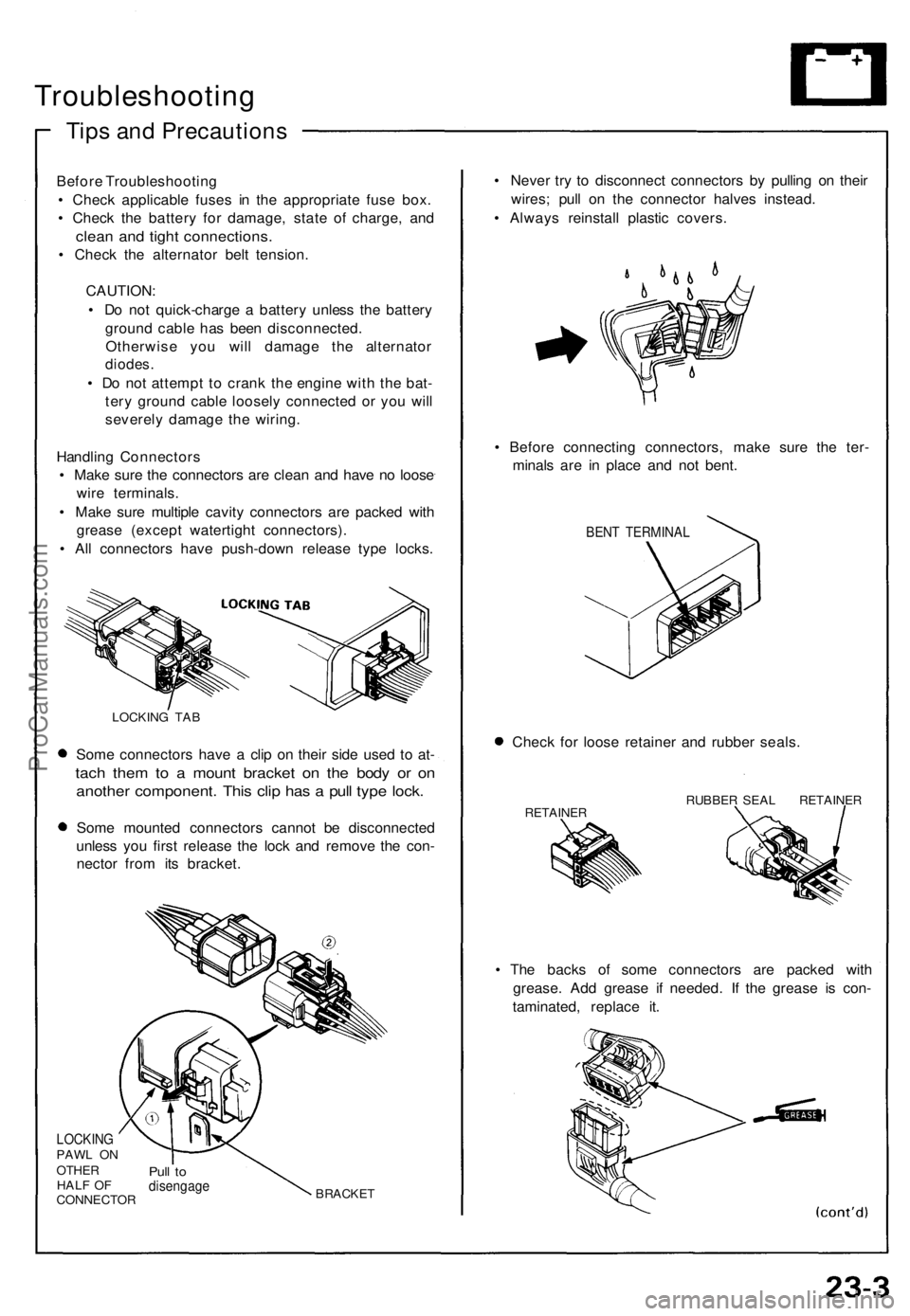

Handling Connectors

• Make sure the connectors are clean and have no loose

wire terminals.

• Make sure multiple cavity connectors are packed with

grease (except watertight connectors).

• All connectors have push-down release type locks.

LOCKING TAB

Some connectors have a clip on their side used to at-

tach them to a mount bracket on the body or on

another component. This clip has a pull type lock.

Some mounted connectors cannot be disconnected

unless you first release the lock and remove the con-

nector from its bracket.

LOCKING

PAWL ON

OTHER

HALF OF

CONNECTOR

Pull to

disengage

BRACKET

• Never try to disconnect connectors by pulling on their

wires; pull on the connector halves instead.

• Always reinstall plastic covers.

• Before connecting connectors, make sure the ter-

minals are in place and not bent.

BENT TERMINAL

Check for loose retainer and rubber seals.

RETAINER

RUBBER SEAL RETAINER

• The backs of some connectors are packed with

grease. Add grease if needed. If the grease is con-

taminated, replace it.ProCarManuals.com

Page 730 of 1640

Troubleshooting

Tips and Precautions

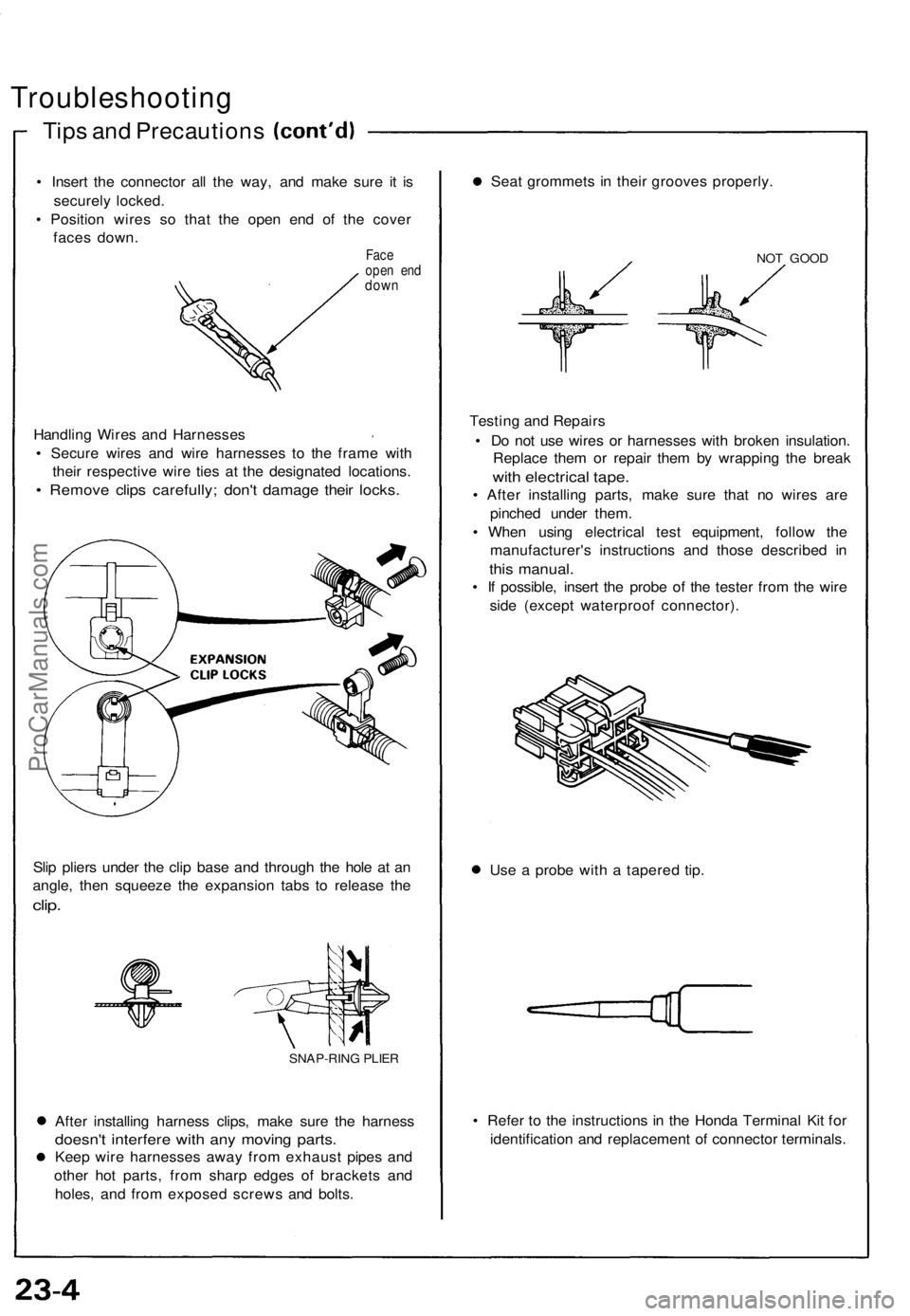

• Insert the connector all the way, and make sure it is

securely locked.

• Position wires so that the open end of the cover

faces down.

Face

open end

down

Handling Wires and Harnesses

• Secure wires and wire harnesses to the frame with

their respective wire ties at the designated locations.

• Remove clips carefully; don't damage their locks.

Slip pliers under the clip base and through the hole at an

angle, then squeeze the expansion tabs to release the

clip.

SNAP-RING PLIER

After installing harness clips, make sure the harness

doesn't interfere with any moving parts.

Keep wire harnesses away from exhaust pipes and

other hot parts, from sharp edges of brackets and

holes, and from exposed screws and bolts.

Seat grommets in their grooves properly.

NOT GOOD

Testing and Repairs

• Do not use wires or harnesses with broken insulation.

Replace them or repair them by wrapping the break

with electrical tape.

• After installing parts, make sure that no wires are

pinched under them.

• When using electrical test equipment, follow the

manufacturer's instructions and those described in

this manual.

• If possible, insert the probe of the tester from the wire

side (except waterproof connector).

Use a probe with a tapered tip.

• Refer to the instructions in the Honda Terminal Kit for

identification and replacement of connector terminals.ProCarManuals.com