ACURA NSX 1991 Service Repair Manual

Manufacturer: ACURA, Model Year: 1991, Model line: NSX, Model: ACURA NSX 1991Pages: 1640, PDF Size: 60.48 MB

Page 741 of 1640

Under-dash Fus e Bo x

Removal/Installatio n

SRS component s ar e locate d in thi s area . Revie w th e SR S

componen t locations , precautions , an d procedure s in th e

SR S sectio n 24 befor e performin g repair s o r service .

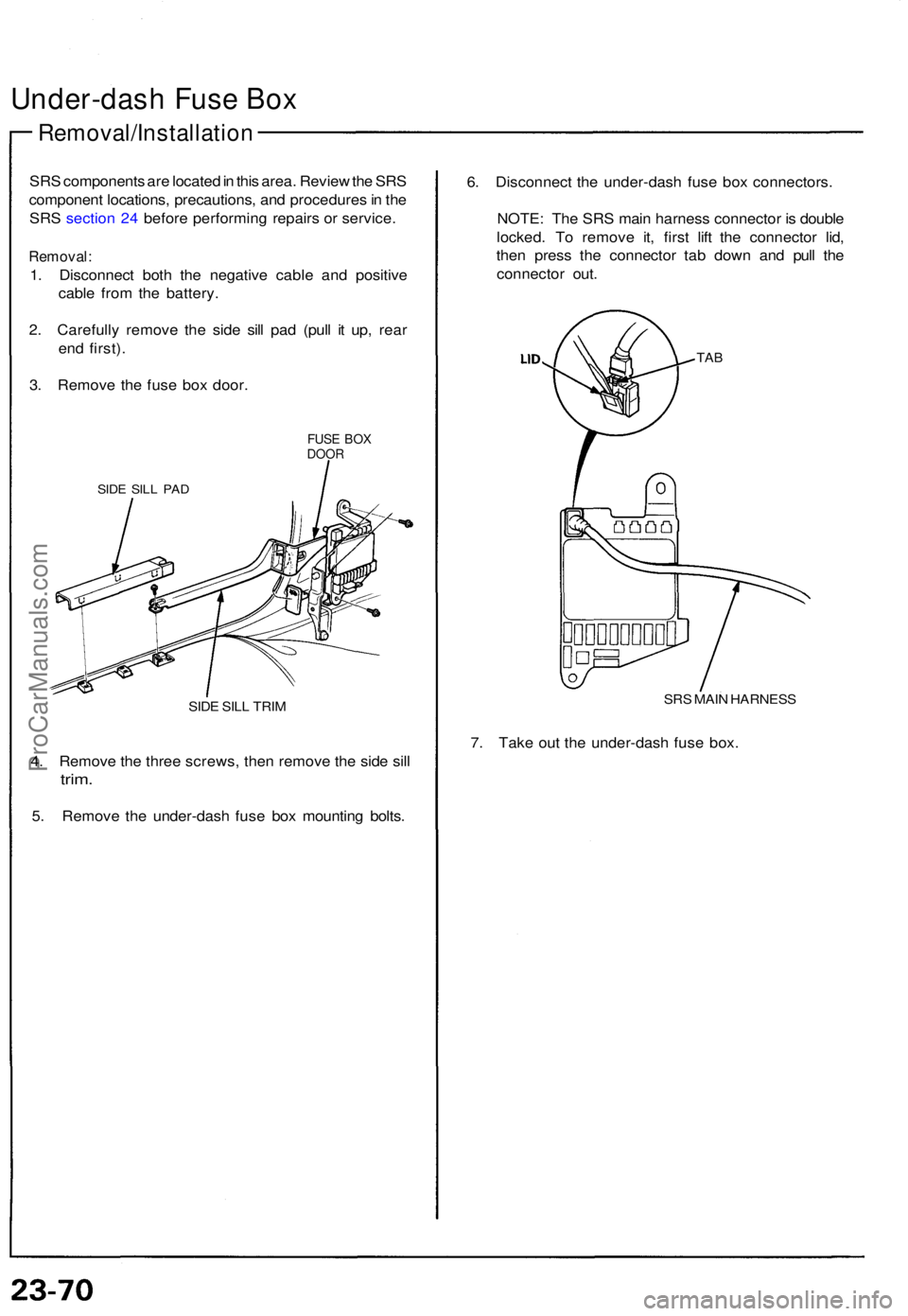

Removal :

1. Disconnec t bot h th e negativ e cabl e an d positiv e

cabl e fro m th e battery .

2 . Carefull y remov e th e sid e sil l pa d (pul l i t up , rea r

en d first) .

3 . Remov e th e fus e bo x door .

FUSE BO XDOO R

SIDE SIL L PA D

SIDE SIL L TRI M

4. Remov e th e thre e screws , the n remov e th e sid e sil l

trim .

5. Remov e th e under-das h fus e bo x mountin g bolts . 6

. Disconnec t th e under-das h fus e bo x connectors .

NOTE : Th e SR S mai n harnes s connecto r i s doubl e

locked . T o remov e it , firs t lif t th e connecto r lid ,

the n pres s th e connecto r ta b dow n an d pul l th e

connecto r out .

TAB

SR S MAI N HARNES S

7. Tak e ou t th e under-das h fus e box .

ProCarManuals.com

Page 742 of 1640

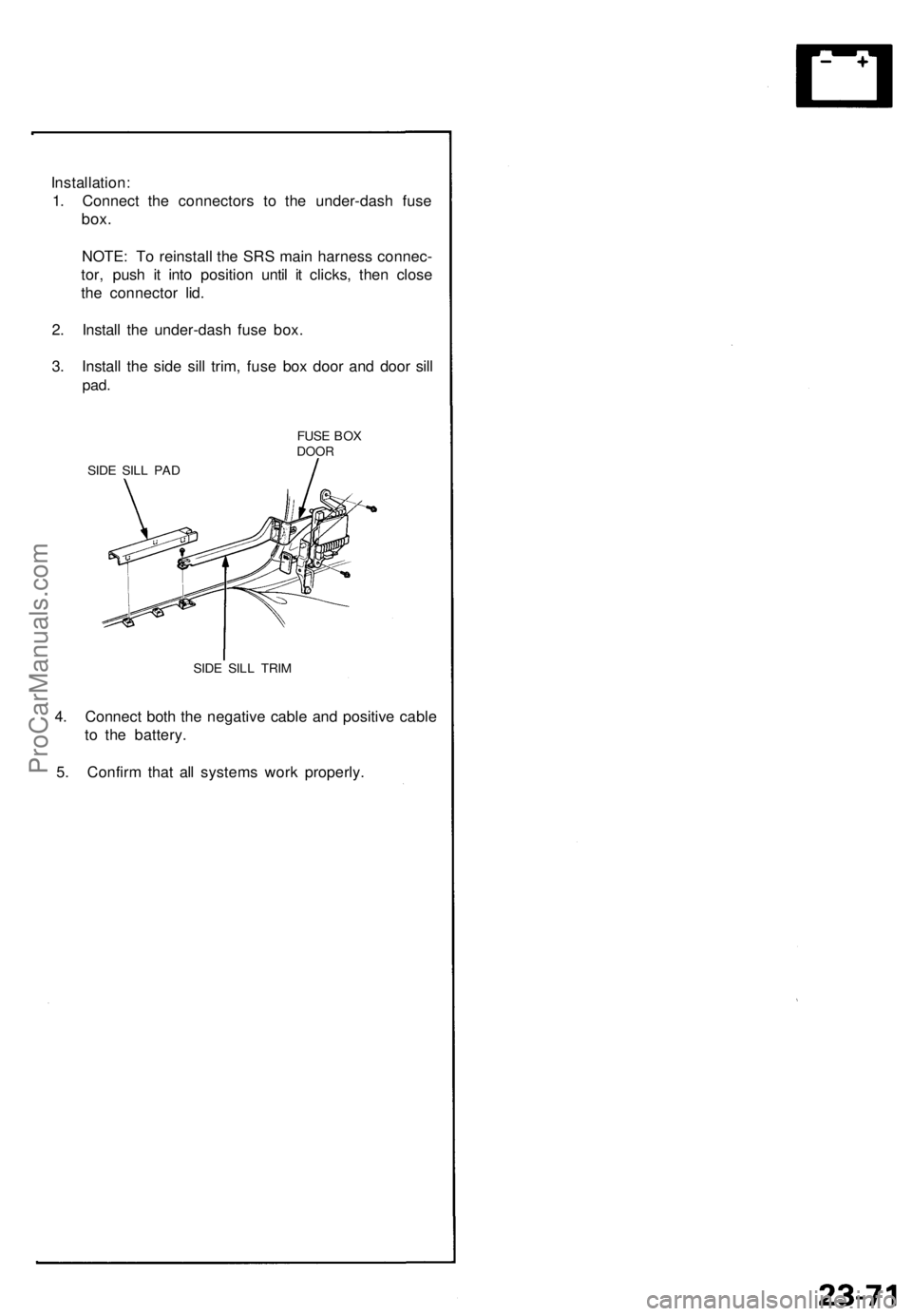

Installation:

1. Connect the connectors to the under-dash fuse

box.

NOTE: To reinstall the SRS main harness connec-

tor, push it into position until it clicks, then close

the connector lid.

2. Install the under-dash fuse box.

3. Install the side sill trim, fuse box door and door sill

pad.

FUSE BOX

DOOR

SIDE SILL PAD

SIDE SILL TRIM

4. Connect both the negative cable and positive cable

to the battery.

5. Confirm that all systems work properly.ProCarManuals.com

Page 743 of 1640

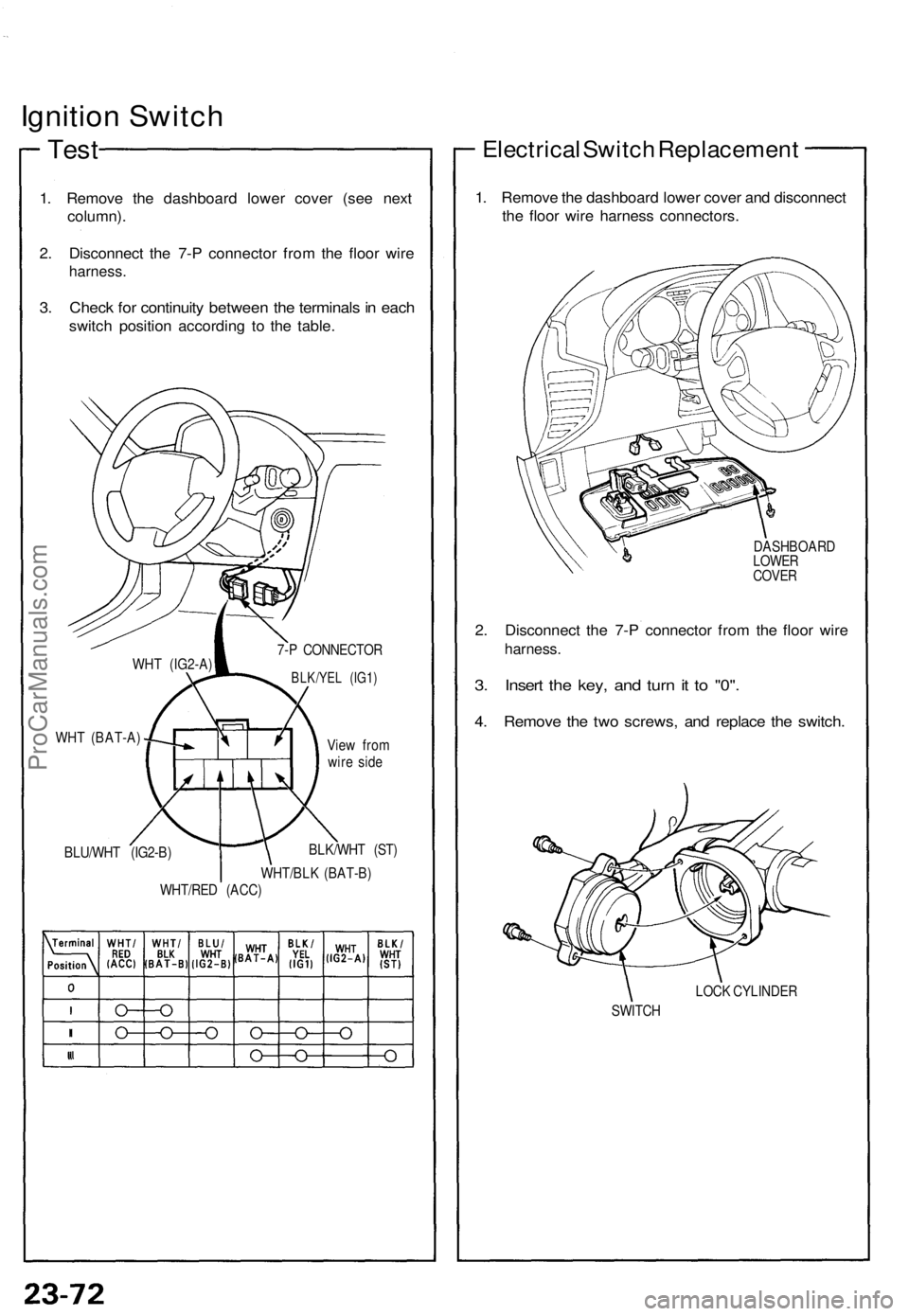

Ignition Switc h

Test

1. Remov e th e dashboar d lowe r cove r (se e nex t

column) .

2 . Disconnec t th e 7- P connecto r fro m th e floo r wir e

harness .

3. Chec k fo r continuit y betwee n th e terminal s in eac h

switc h positio n accordin g t o th e table.

WHT (BAT-A )

BLU/WH T (IG2-B ) Vie

w fro m

wir e sid e

BLK/WH T (ST )

WHT/BL K (BAT-B )

WHT/RE D (ACC )

Electrica l Switc h Replacemen t

1. Remov e th e dashboar d lowe r cove r an d disconnec t

th e floo r wir e harnes s connectors .

DASHBOAR D

LOWE R

COVE R

2. Disconnec t th e 7- P connecto r fro m th e floo r wir e

harness .

3. Inser t th e key , an d tur n it t o "0" .

4. Remov e th e tw o screws , an d replac e th e switch .

LOCK CYLINDE R

SWITC H

WHT

(IG2-A ) 7-

P CONNECTO R

BLK/YEL (IG1)

ProCarManuals.com

Page 744 of 1640

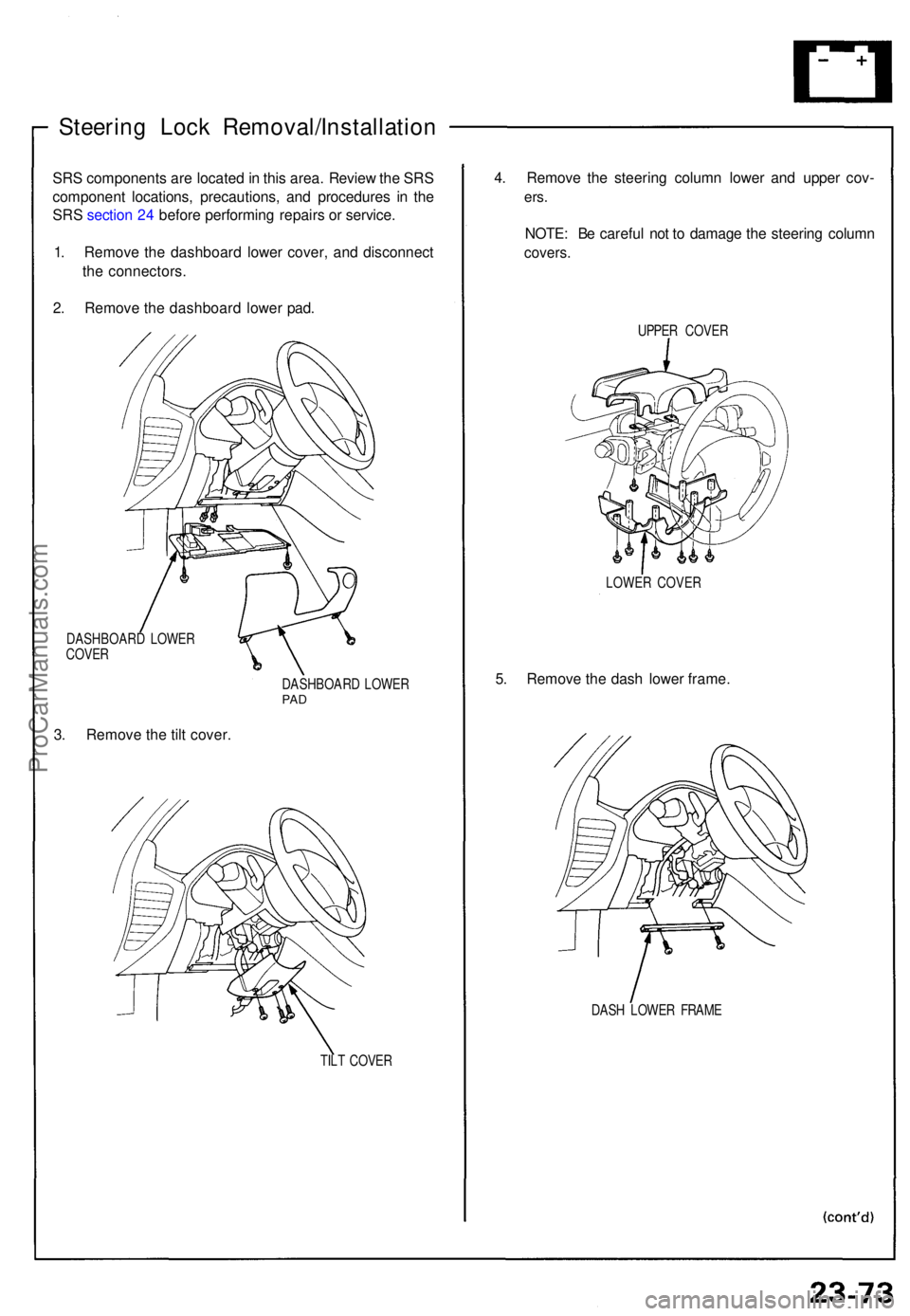

Steering Loc k Removal/Installatio n

SRS component s ar e locate d in thi s area . Revie w th e SR S

componen t locations , precautions , an d procedure s i n th e

SR S sectio n 24 befor e performin g repair s o r service .

1 . Remov e th e dashboar d lowe r cover , an d disconnec t

th e connectors .

2 . Remov e th e dashboar d lowe r pad .

DASHBOAR D LOWE R

COVE R

3. Remov e th e til t cover .

DASHBOAR D LOWE RPAD

TIL T COVE R

4. Remov e th e steerin g colum n lowe r an d uppe r cov -

ers.

NOTE : B e carefu l no t t o damag e th e steerin g colum n

covers.

UPPER COVE R

LOWE R COVE R

5. Remov e th e das h lowe r frame .

DASH LOWE R FRAM E

ProCarManuals.com

Page 745 of 1640

Ignition Switch

Steering Lock Removal/Installation

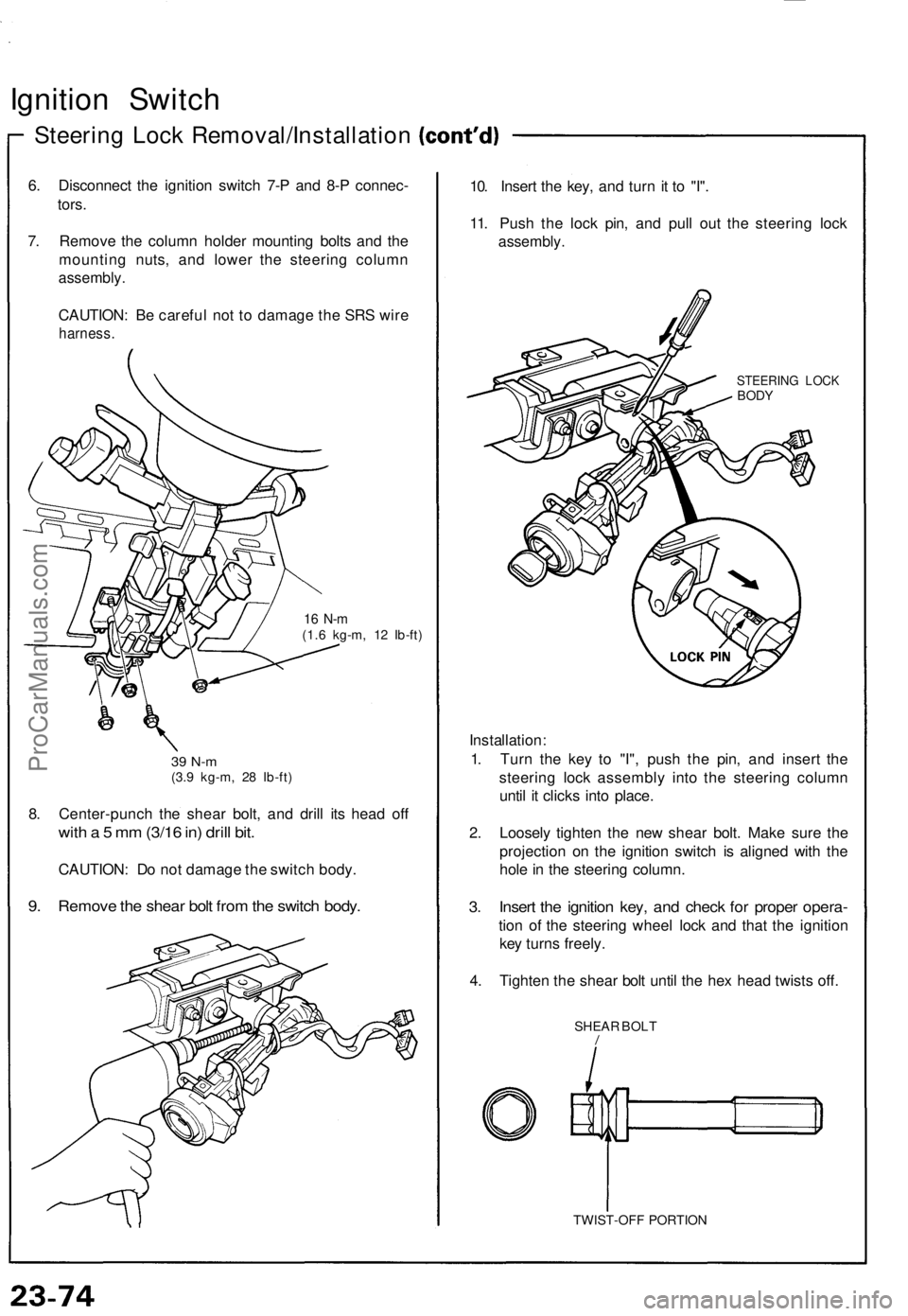

6. Disconnect the ignition switch 7-P and 8-P connec-

tors.

7. Remove the column holder mounting bolts and the

mounting nuts, and lower the steering column

assembly.

CAUTION: Be careful not to damage the SRS wire

harness.

16 N-m

(1.6 kg-m, 12 Ib-ft)

39 N-m

(3.9 kg-m, 28 Ib-ft)

8. Center-punch the shear bolt, and drill its head off

with a 5 mm (3/16 in) drill bit.

CAUTION: Do not damage the switch body.

9. Remove the shear bolt from the switch body.

10. Insert the key, and turn it to "I".

11. Push the lock pin, and pull out the steering lock

assembly.

STEERING LOCK

BODY

Installation:

1. Turn the key to "I", push the pin, and insert the

steering lock assembly into the steering column

until it clicks into place.

2. Loosely tighten the new shear bolt. Make sure the

projection on the ignition switch is aligned with the

hole in the steering column.

3. Insert the ignition key, and check for proper opera-

tion of the steering wheel lock and that the ignition

key turns freely.

4. Tighten the shear bolt until the hex head twists off.

SHEAR BOLT

/

TWIST-OFF PORTIONProCarManuals.com

Page 746 of 1640

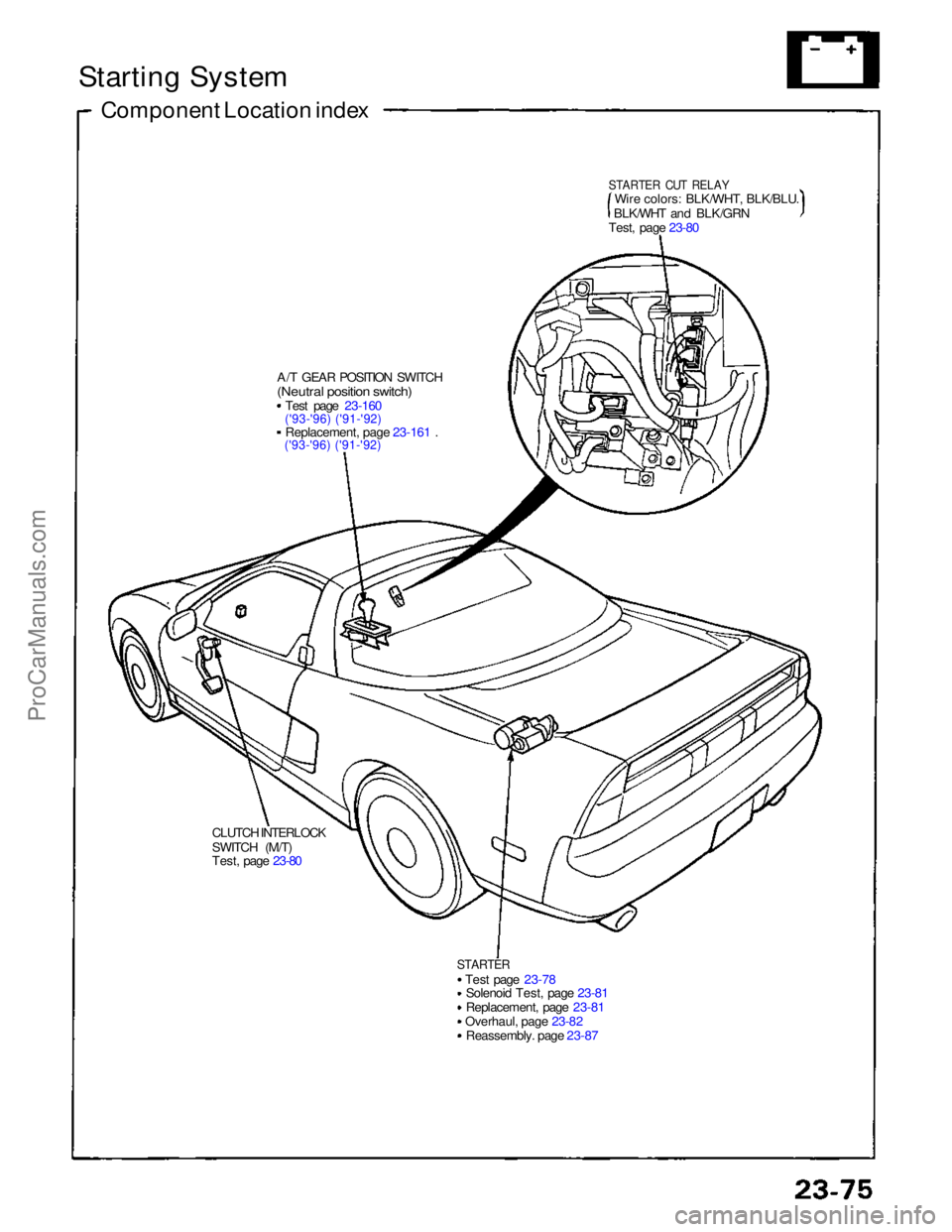

Starting System

Component Location index

A/T GEAR POSITION SWITCH

(Neutral position switch)

Test page 23-160

('93-'96) ('91-'92)

Replacement, page 23-161 .

('93-'96) ('91-'92)

CLUTCH INTERLOCK

SWITCH (M/T)

Test, page 23-80

STARTER

Test page 23-78Solenoid Test, page 23-81

Replacement, page 23-81

Overhaul, page 23-82 Reassembly. page 23-87

STARTER CUT RELAY

Wire colors: BLK/WHT, BLK/BLU.

BLK/WHT and BLK/GRN

Test, page 23-80ProCarManuals.com

Page 747 of 1640

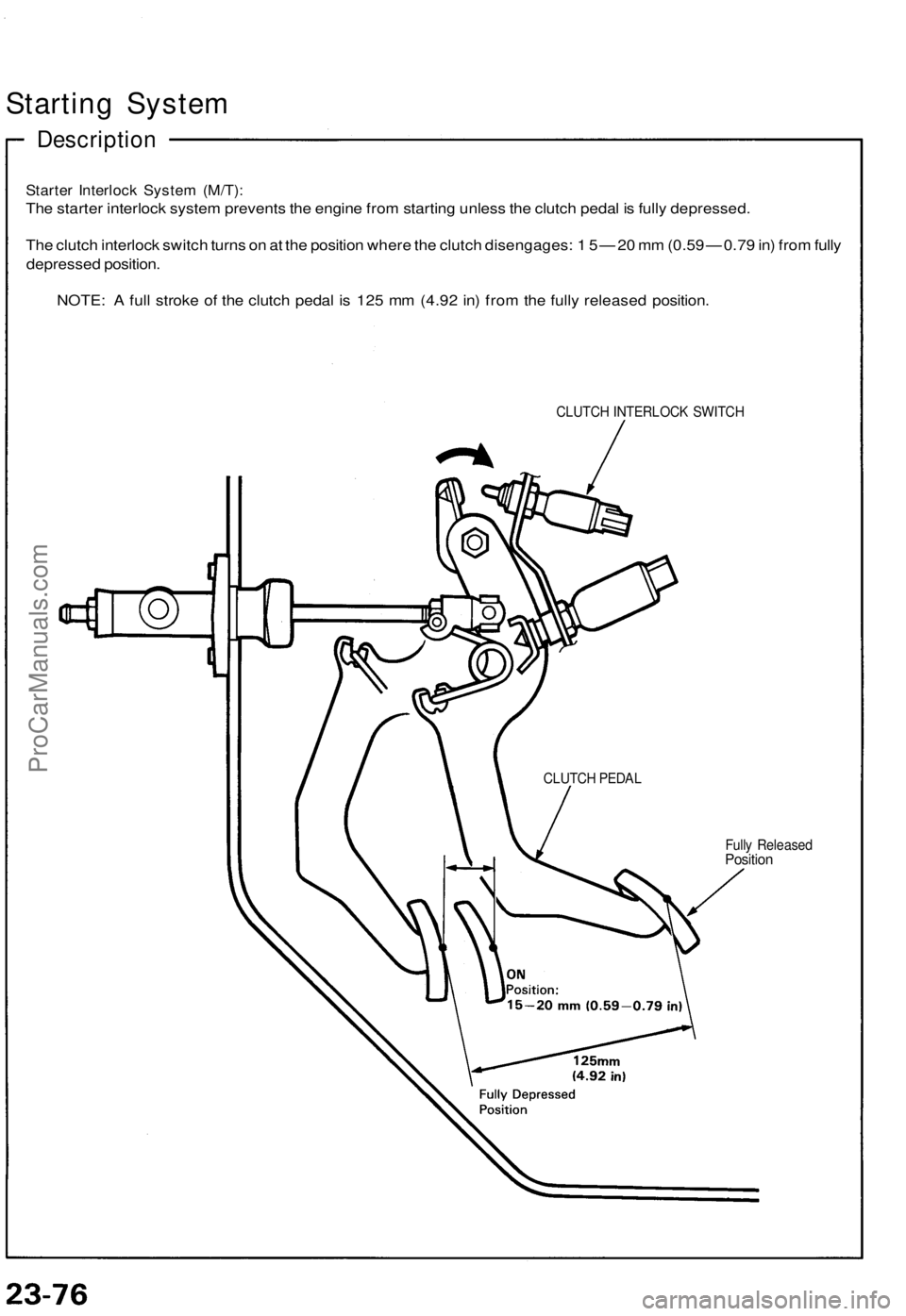

Starting System

Description

Starter Interlock System (M/T):

The starter interlock system prevents the engine from starting unless the clutch pedal is fully depressed.

The clutch interlock switch turns on at the position where the clutch disengages: 1 5 — 20 mm (0.59 — 0.79 in) from fully

depressed position.

NOTE: A full stroke of the clutch pedal is 125 mm (4.92 in) from the fully released position.

CLUTCH INTERLOCK SWITCH

Fully Released

Position

CLUTCH PEDALProCarManuals.com

Page 748 of 1640

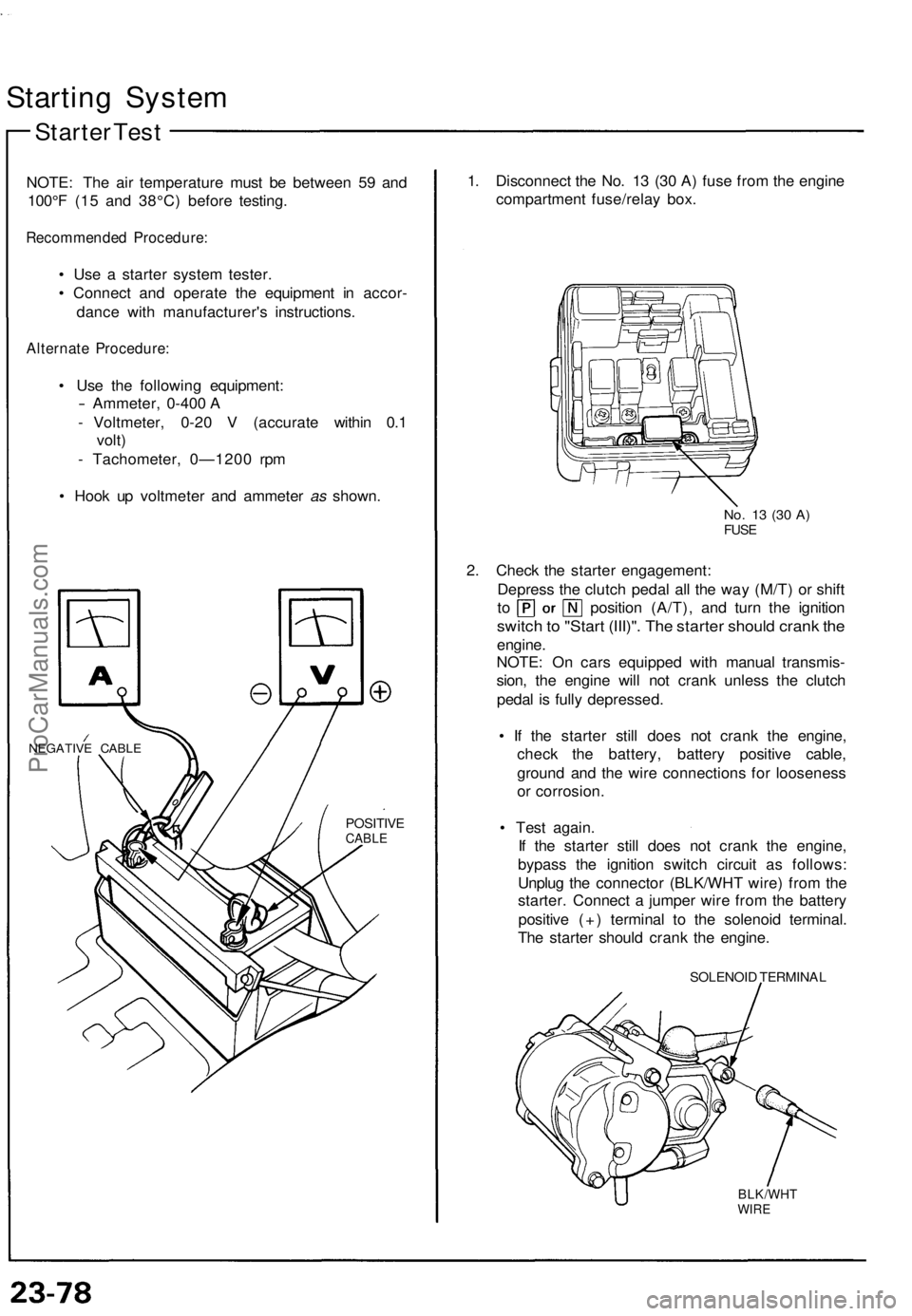

Starting Syste m

Starter Tes t

NOTE : Th e ai r temperatur e mus t b e betwee n 5 9 an d

100° F (1 5 an d 38°C ) befor e testing .

Recommende d Procedure :

• Us e a starte r syste m tester .

• Connec t an d operat e th e equipmen t i n accor -

danc e wit h manufacturer' s instructions .

Alternate Procedure :

• Us e th e followin g equipment :

- Ammeter, 0-400 A

- Voltmeter , 0-2 0 V (accurat e withi n 0. 1

volt )

- Tachometer , 0—120 0 rp m

• Hoo k u p voltmete r an d ammete r as shown .

NEGATIV E CABL E

POSITIV ECABLE

1. Disconnec t th e No . 1 3 (3 0 A ) fus e fro m th e engin e

compartmen t fuse/rela y box .

No. 1 3 (3 0 A )FUS E

2. Chec k th e starte r engagement :

Depres s th e clutc h peda l al l th e wa y (M/T ) o r shif t

to positio n (A/T) , an d tur n th e ignitio n

switch to "Star t (III)" . Th e starte r shoul d cran k th e

engine .

NOTE : O n car s equippe d wit h manua l transmis -

sion , th e engin e wil l no t cran k unles s th e clutc h

peda l i s full y depressed .

• I f th e starte r stil l doe s no t cran k th e engine ,

chec k th e battery , batter y positiv e cable ,

groun d an d th e wir e connection s fo r loosenes s

o r corrosion .

• Tes t again .

I f th e starte r stil l doe s no t cran k th e engine ,

bypas s th e ignitio n switc h circui t a s follows :

Unplu g th e connecto r (BLK/WH T wire ) fro m th e

starter . Connec t a jumpe r wir e fro m th e batter y

positiv e (+ ) termina l t o th e solenoi d terminal .

Th e starte r shoul d cran k th e engine .

SOLENOI D TERMINA L

BLK/WHTWIRE

ProCarManuals.com

Page 749 of 1640

- I f th e starte r stil l doe s no t cran k th e engine ,

remov e th e starte r an d diagnos e it s interna l

problems .

- I f th e starte r crank s th e engine , chec k fo r a n

ope n i n th e BLK/WH T wir e an d connector s be -

twee n th e starte r an d ignitio n switch . Chec k th e

ignitio n switch .

On car s wit h automati c transmission , chec k th e

A/ T gea r positio n switc h (neutra l positio n

switch ) an d connector .

O n car s with manua l transmission , chec k th e

starte r cu t relay , clutc h interloc k switc h an d

connectors .

NOTE : Chec k th e No . 2 9 (5 0 A ) fus e an d th e

starte r cu t relay , an d inspec t th e securit y alar m

system .

3 . Chec k fo r wea r o r damage :

Th e starte r shoul d cran k th e engin e smoothl y an d

steadily .

If th e starte r engages , bu t crank s th e engin e er -

ratically , remov e th e starte r motor . Inspec t th e

starter , driv e gea r an d flywhee l rin g gea r fo r

damage .

Check th e driv e gea r overrunnin g clutc h fo r bindin g

or slippin g whe n th e armatur e i s rotated with th e

driv e gea r held . Replac e th e gear s i f damaged .

4 . Chec k crankin g voltag e an d curren t draw :

Voltag e shoul d b e n o les s tha n 8. 5 volts .

Curren t shoul d b e n o mor e tha n 35 0 amperes .

I f voltag e i s to o low , o r curren t dra w to o high ,

chec k for :

• Lo w battery .

• Ope n circui t i n starte r armatur e commutato r

segments .

• Starte r armatur e dragging .

• Shorte d armatur e winding .

• Excessiv e dra g i n engine . 5

. Chec k crankin g rpm :

Engin e spee d durin g crankin g shoul d b e abov e 10 0

rpm .

If spee d i s to o low , chec k for :

Loos e batter y o r starte r terminals .

Excessivel y wor n starte r brushes .

Ope n circui t i n commutato r segments .

Dirt y o r damage d helica l splin e o r driv e gear .

Defectiv e driv e gea r overrunnin g clutch .

6 . Chec k th e starte r disengagement :

Depres s th e clutc h peda l al l th e wa y (M/T ) o r shif t

to positio n (A/T) , tur n th e ignitio n switc h

to "Star t (III) " an d releas e to O N (II) .

The starter drive gea r shoul d disengag e fro m th e

flywhee l rin g gear .

I f th e driv e gea r hang s u p o n th e flywhee l rin g gear ,

check :

• Solenoi d plunge r an d switc h fo r malfunction .

• Driv e gea r assembl y fo r dir t o r damage d over -

runnin g clutch .

ProCarManuals.com

Page 750 of 1640

Starting Syste m

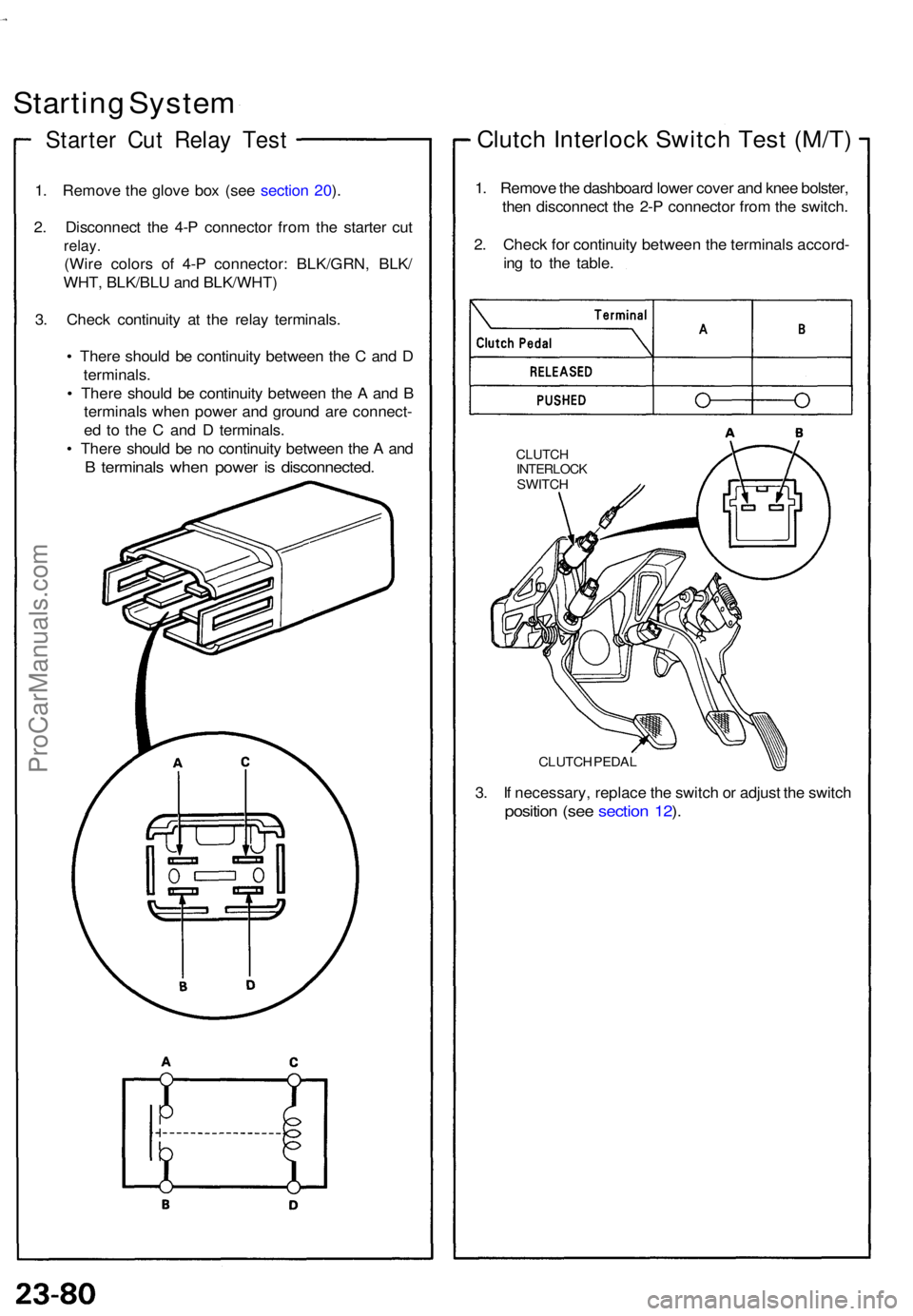

Starte r Cu t Rela y Tes t

1. Remov e th e glov e bo x (se e sectio n 20 ).

2 . Disconnec t th e 4- P connecto r fro m th e starte r cu t

relay .

(Wire color s of 4- P connector : BLK/GRN , BLK /

WHT , BLK/BL U an d BLK/WHT )

3 . Chec k continuit y a t th e rela y terminals .

• Ther e shoul d b e continuit y betwee n th e C an d D

terminals .

• Ther e shoul d b e continuit y betwee n th e A an d B

terminal s whe n powe r an d groun d ar e connect -

e d t o th e C an d D terminals .

• Ther e shoul d b e n o continuit y betwee n th e A an d

B terminal s whe n powe r i s disconnected .

Clutch Interloc k Switc h Tes t (M/T )

1. Remov e th e dashboar d lowe r cove r an d kne e bolster ,

the n disconnec t th e 2- P connecto r fro m th e switch .

2 . Chec k fo r continuit y betwee n th e terminal s accord -

in g t o th e table .

CLUTC HINTERLOC KSWITCH

CLUTC H PEDA L

3. I f necessary , replac e th e switc h o r adjus t th e switc h

positio n (se e sectio n 12 ).

ProCarManuals.com