ACURA NSX 1997 Service Repair Manual

Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 1431 of 1503

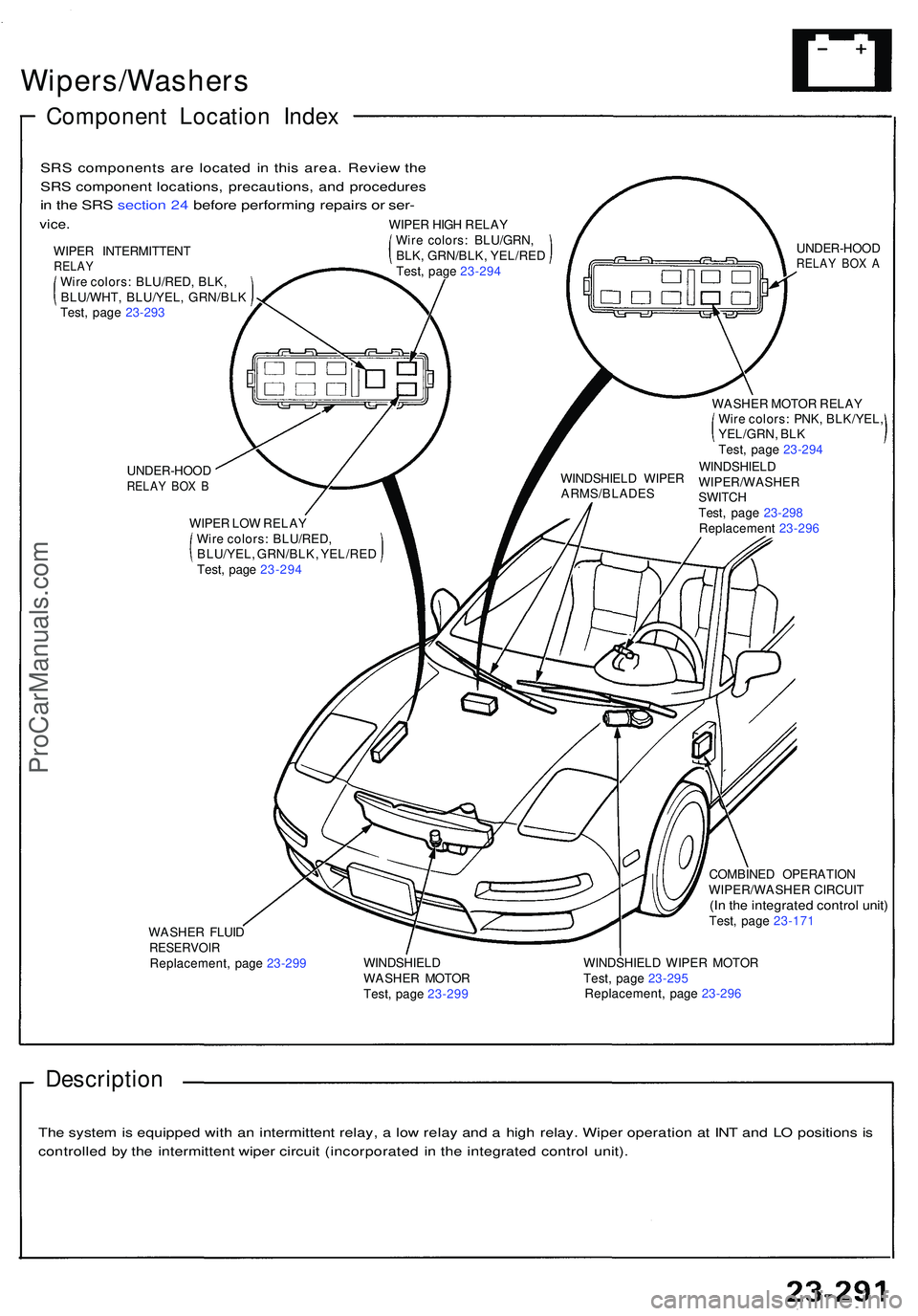

Wipers/Washers

Component Locatio n Inde x

UNDER-HOO DRELAY BO X B

WIPE R LO W RELA Y

Wir e colors : BLU/RED ,

BLU/YEL , GRN/BLK , YEL/RE D

Test , pag e 23-29 4 WASHE

R MOTO R RELA Y

Wir e colors : PNK , BLK/YEL ,

YEL/GRN , BL K

Test , pag e 23-29 4

WINDSHIEL D

WIPER/WASHE R

SWITC H

Test , pag e 23-29 8

Replacemen t 23-29 6

WINDSHIEL

D WIPE R

ARMS/BLADE S UNDER-HOO

D

RELAY BO X A

WASHE R FLUI DRESERVOI RReplacement , pag e 23-29 9 COMBINE

D OPERATIO N

WIPER/WASHE R CIRCUI T

(In th e integrate d contro l unit )Test , pag e 23-17 1

WINDSHIEL D

WASHE R MOTO R

Test , pag e 23-29 9 WINDSHIEL

D WIPE R MOTO R

Test , pag e 23-29 5

Replacement , pag e 23-29 6

Descriptio n

The syste m is equippe d wit h a n intermitten t relay , a lo w rela y an d a hig h relay . Wipe r operatio n a t IN T an d L O position s i s

controlle d b y th e intermitten t wipe r circui t (incorporate d i n th e integrate d contro l unit) .

SR

S component s ar e locate d i n thi s area . Revie w th e

SR S componen t locations , precautions , an d procedure s

in th e SR S sectio n 24 befor e performin g repair s o r ser -

vice .

WIPE R INTERMITTEN TRELAYWire colors : BLU/RED , BLK ,

BLU/WHT , BLU/YEL , GRN/BL K

Test, pag e 23-29 3 WIPE

R HIG H RELA Y

Wir e colors : BLU/GRN ,

BLK , GRN/BLK , YEL/RE D

Test , pag e 23-29 4

ProCarManuals.com

Page 1432 of 1503

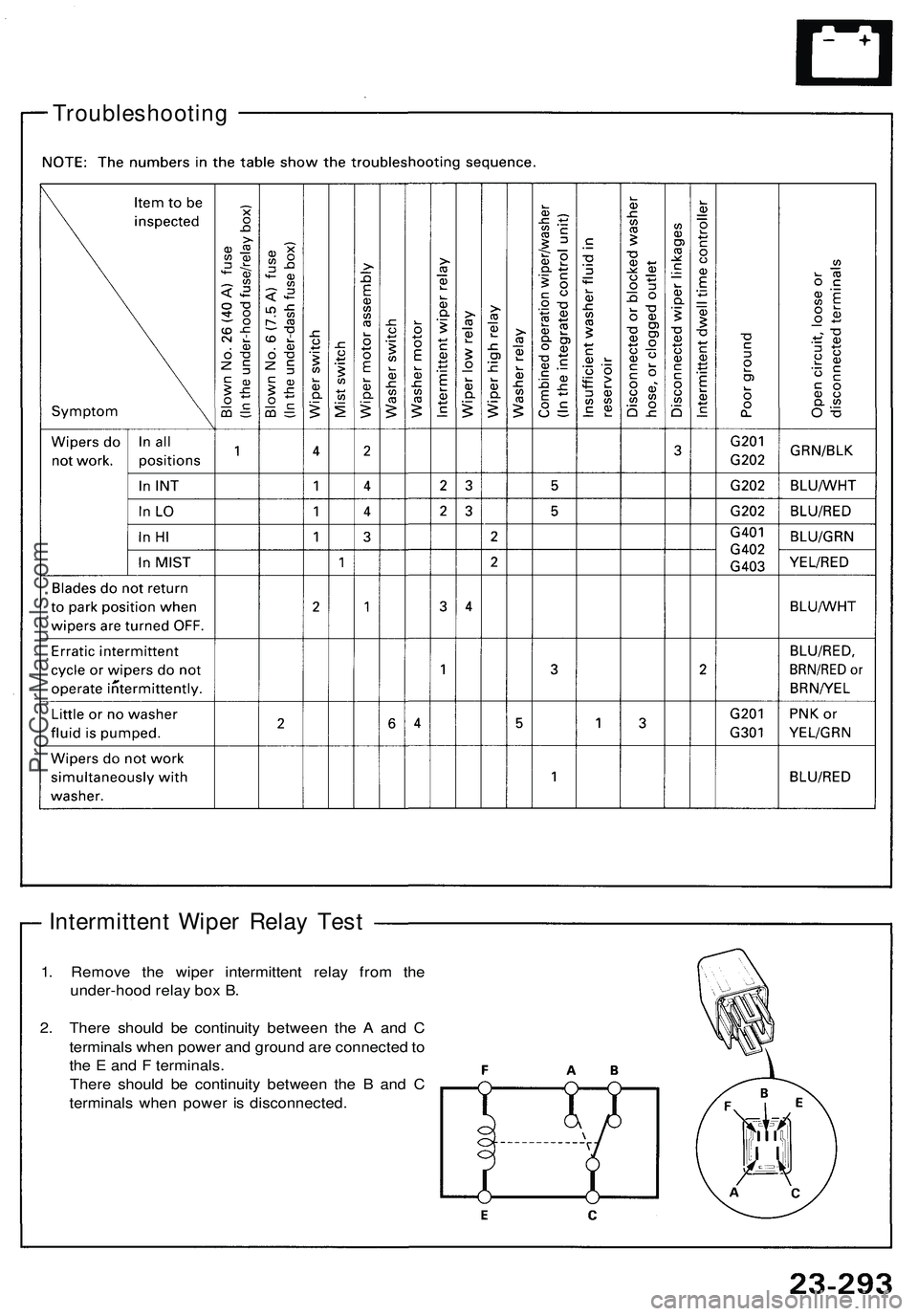

1. Remove the wiper intermittent relay from the

under-hood relay box B.

2. There should be continuity between the A and C

terminals when power and ground are connected to

the E and F terminals.

There should be continuity between the B and C

terminals when power is disconnected.

Troubleshooting

Intermittent Wiper Relay TestProCarManuals.com

Page 1433 of 1503

Wiper/Washer

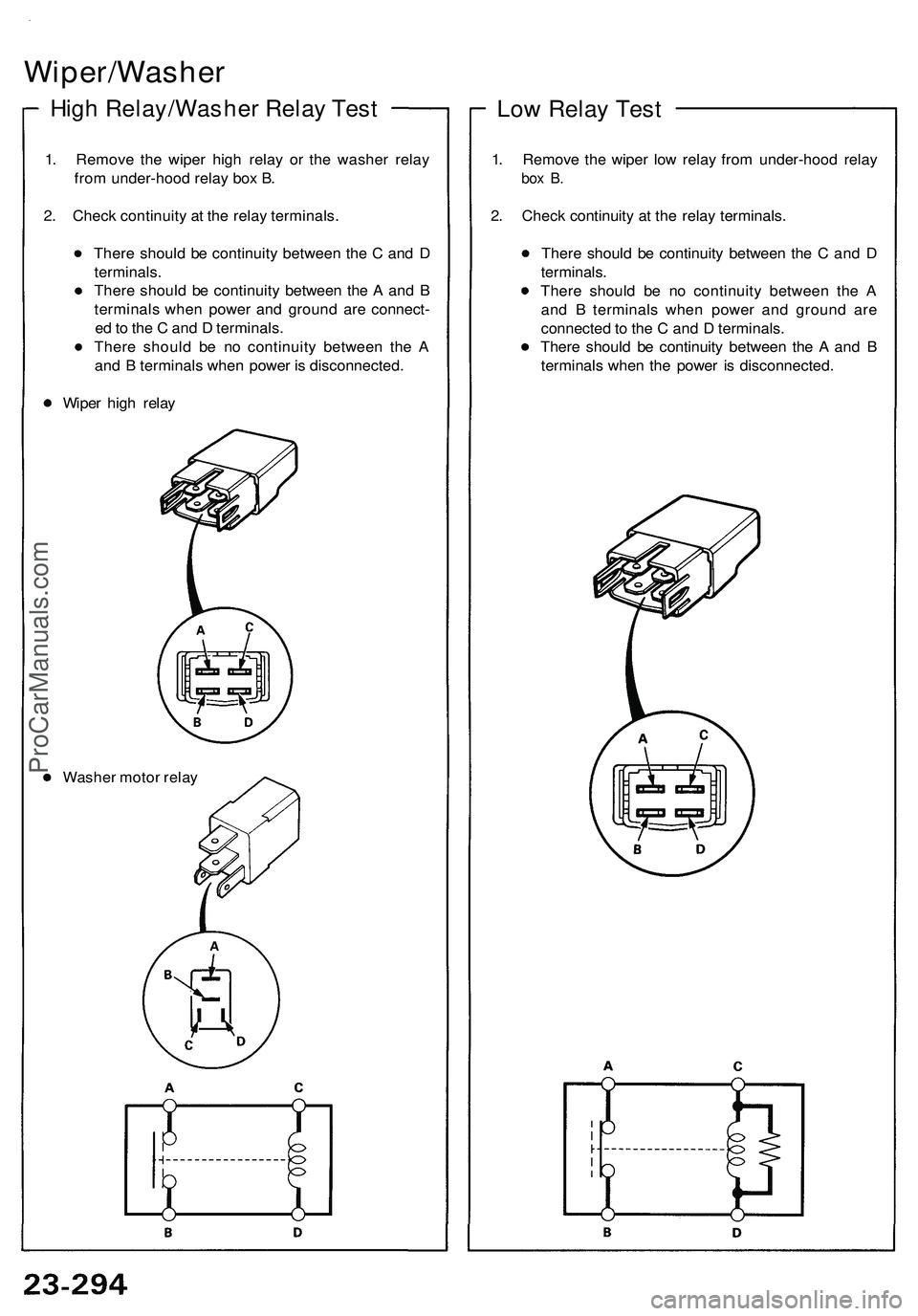

High Relay/Washer Relay Test

1. Remove the wiper high relay or the washer relay

from under-hood relay box B.

2. Check continuity at the relay terminals.

There should be continuity between the C and D

terminals.

There should be continuity between the A and B

terminals when power and ground are connect-

ed to the C and D terminals.

There should be no continuity between the A

and B terminals when power is disconnected.

Wiper high relay

Washer motor relay

Low Relay Test

1. Remove the wiper low relay from under-hood relay

box B.

2. Check continuity at the relay terminals.

There should be continuity between the C and D

terminals.

There should be no continuity between the A

and B terminals when power and ground are

connected to the C and D terminals.

There should be continuity between the A and B

terminals when the power is disconnected.ProCarManuals.com

Page 1434 of 1503

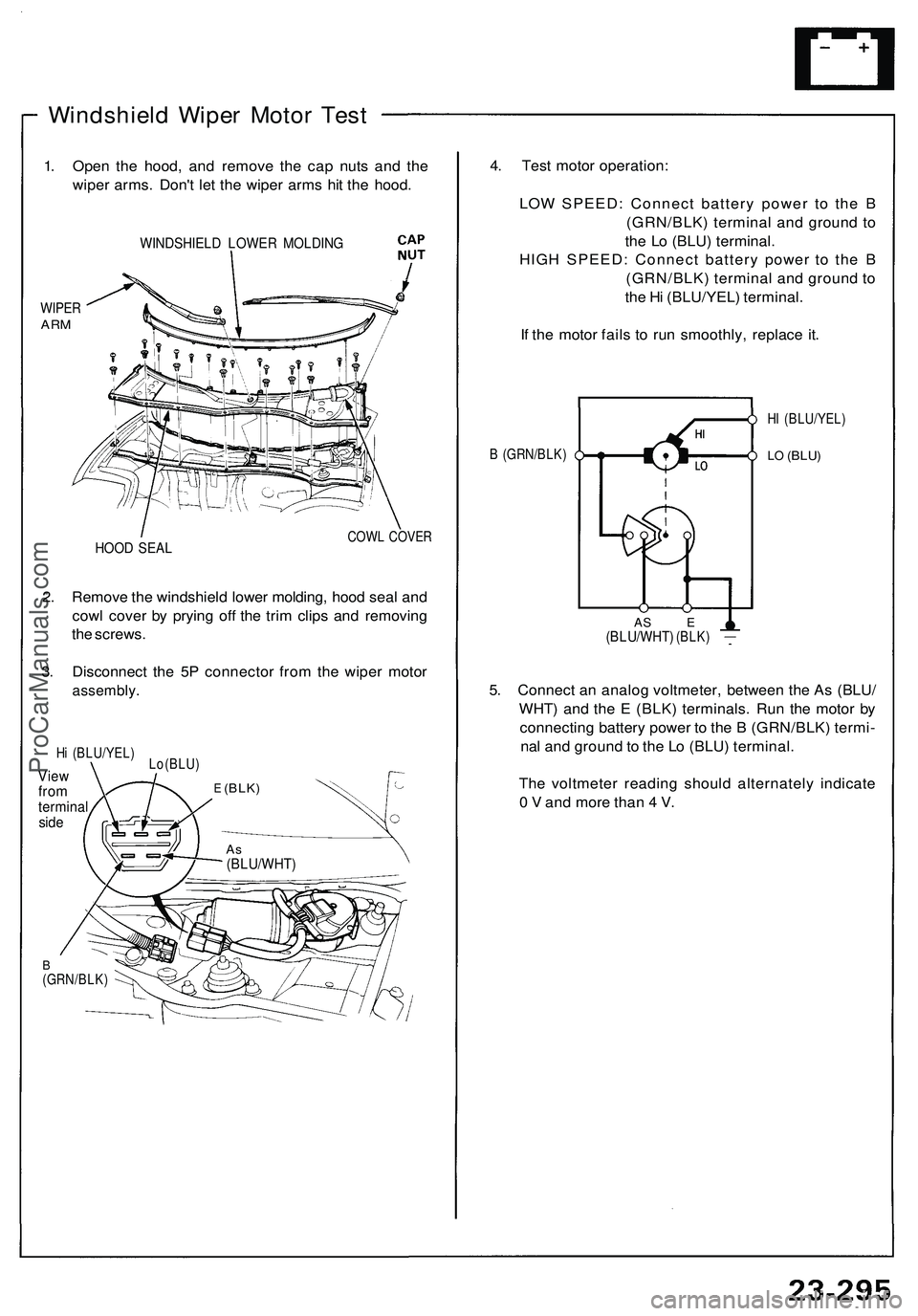

Windshield Wiper Motor Test

1. Open the hood, and remove the cap nuts and the

wiper arms. Don't let the wiper arms hit the hood.

WINDSHIELD LOWER MOLDING

WIPER

ARM

HOOD SEAL

COWL COVER

2. Remove the windshield lower molding, hood seal and

cowl cover by prying off the trim clips and removing

the screws.

3. Disconnect the 5P connector from the wiper motor

assembly.

Hi (BLU/YEL)

View

from

terminal

side

Lo(BLU)

B

(GRN/BLK)

4. Test motor operation:

LOW SPEED: Connect battery power to the B

(GRN/BLK) terminal and ground to

the Lo (BLU) terminal.

HIGH SPEED: Connect battery power to the B

(GRN/BLK) terminal and ground to

the Hi (BLU/YEL) terminal.

If the motor fails to run smoothly, replace it.

5. Connect an analog voltmeter, between the As (BLU/

WHT) and the E (BLK) terminals. Run the motor by

connecting battery power to the B (GRN/BLK) termi-

nal and ground to the Lo (BLU) terminal.

The voltmeter reading should alternately indicate

0 V and more than 4 V.

B (GRN/BLK)

HI (BLU/YEL)

LO

(BLU)

AS E

(BLU/WHT)

(BLK)

E

(BLK)

As

(BLU/WHT)ProCarManuals.com

Page 1435 of 1503

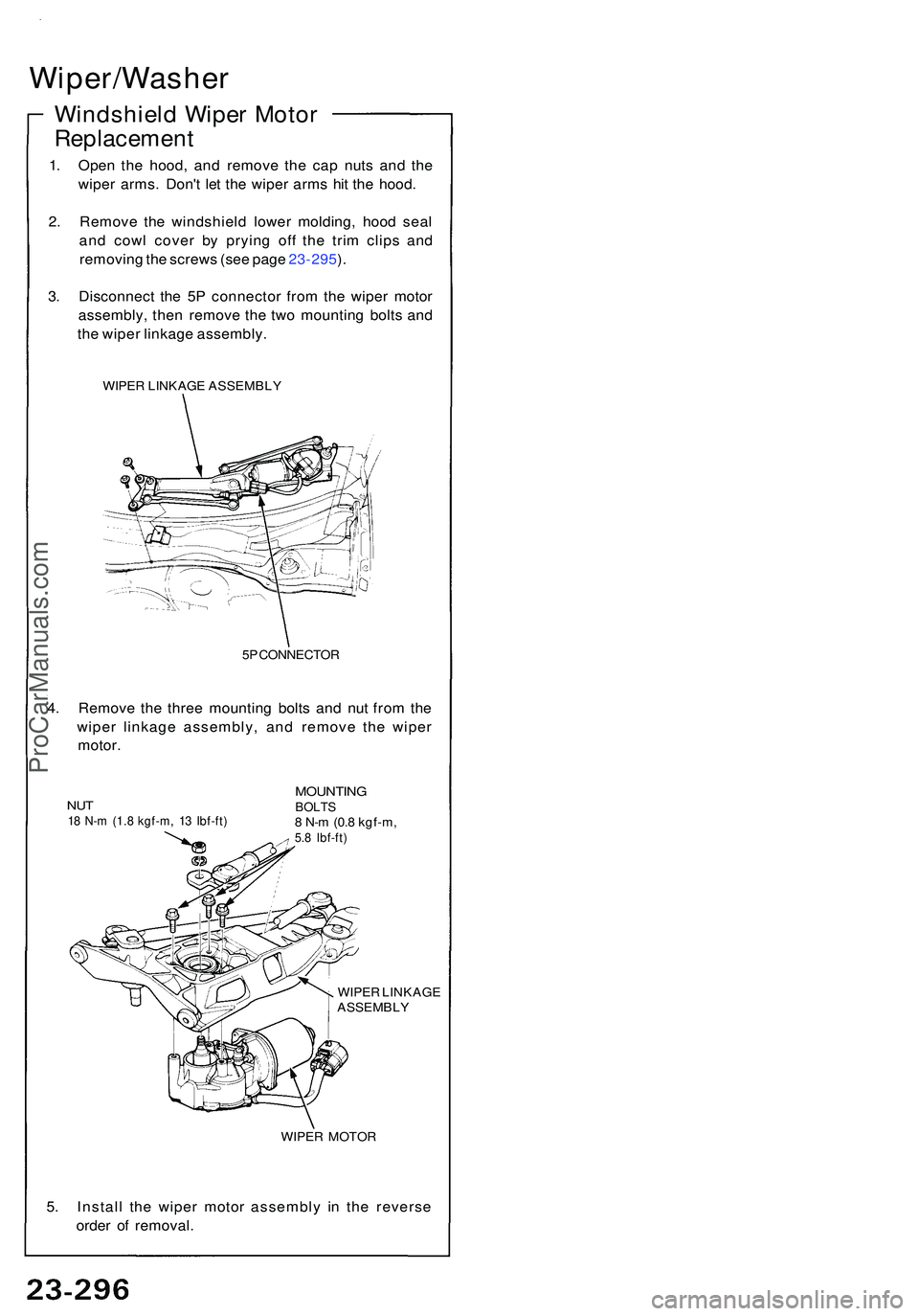

Wiper/Washer

Windshield Wipe r Moto r

Replacemen t

1. Ope n th e hood , an d remov e th e ca p nut s an d th e

wipe r arms . Don' t le t th e wipe r arm s hi t th e hood .

2 . Remov e th e windshiel d lowe r molding , hoo d sea l

an d cow l cove r b y pryin g of f th e tri m clip s an d

removin g th e screw s (se e pag e 23-295 ).

3 . Disconnec t th e 5 P connecto r fro m th e wipe r moto r

assembly , the n remov e th e tw o mountin g bolt s an d

th e wipe r linkag e assembly .

WIPER LINKAG E ASSEMBL Y

5 P CONNECTO R

4. Remov e th e thre e mountin g bolt s an d nu t fro m th e

wipe r linkag e assembly , an d remov e th e wipe r

motor .

NUT18 N- m (1. 8 kgf-m , 1 3 Ibf-ft )

MOUNTIN GBOLTS8 N- m (0. 8 kgf-m ,5.8 Ibf-ft )

WIPER LINKAG E

ASSEMBL Y

WIPE R MOTO R

5. Instal l th e wipe r moto r assembl y i n th e revers e

orde r o f removal .

ProCarManuals.com

Page 1436 of 1503

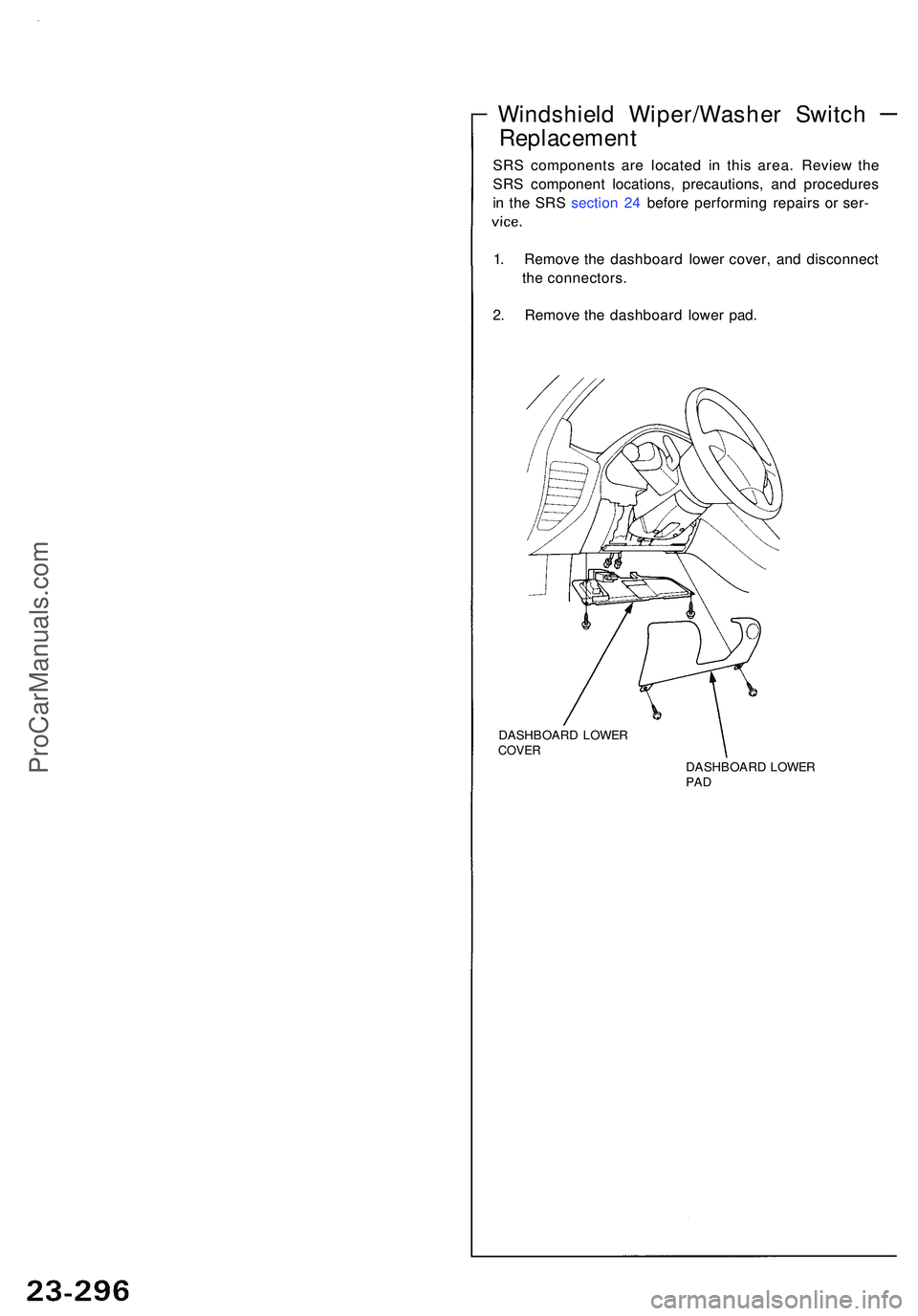

Windshield Wiper/Washe r Switc h

Replacemen t

SRS component s ar e locate d i n thi s area . Revie w th e

SR S componen t locations , precautions , an d procedure s

i n th e SR S sectio n 24 befor e performin g repair s o r ser -

1 . Remov e th e dashboar d lowe r cover , an d disconnec t

th e connectors .

2 . Remov e th e dashboar d lowe r pad .

DASHBOAR D LOWE RCOVERDASHBOAR D LOWE RPAD

ProCarManuals.com

Page 1437 of 1503

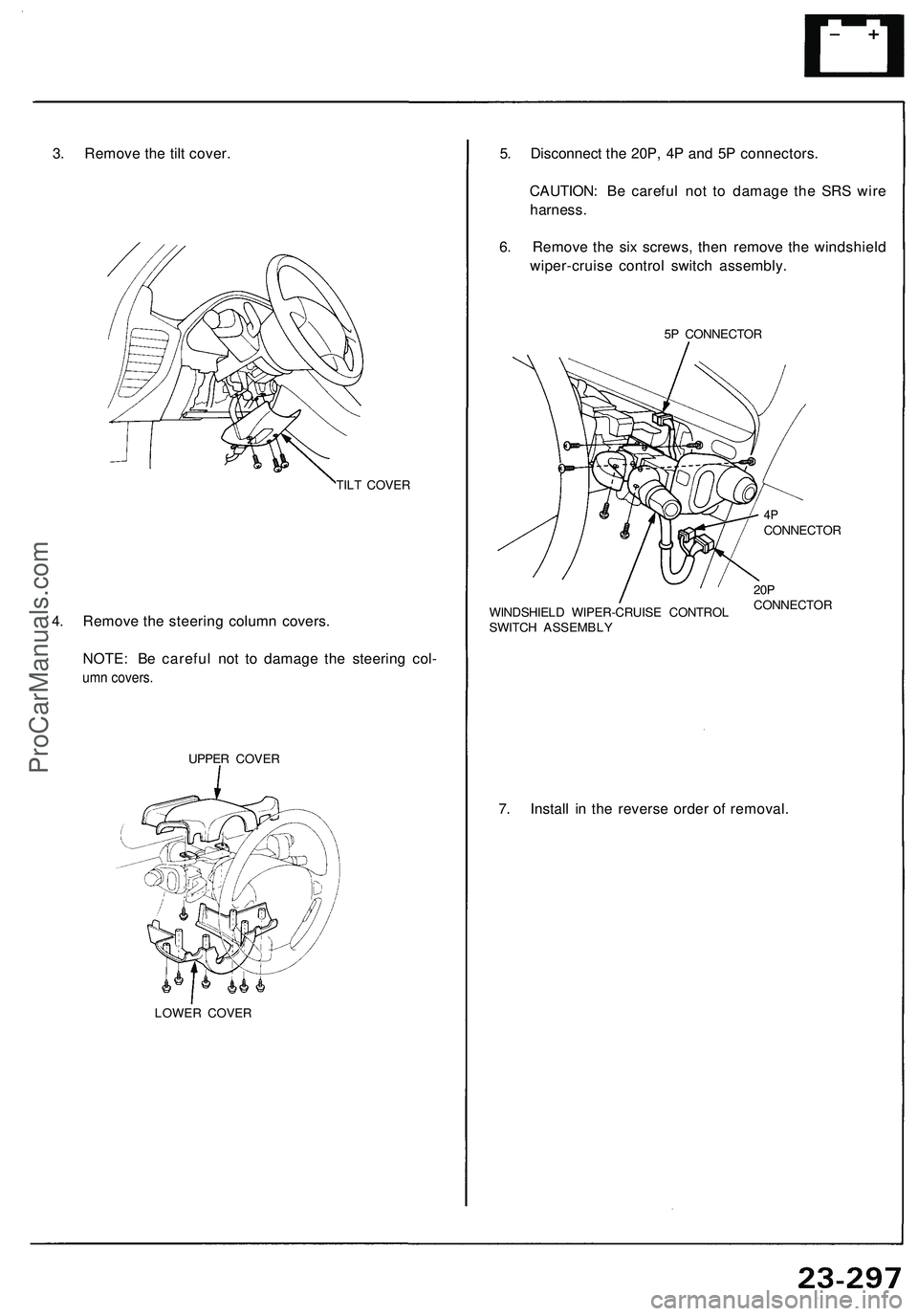

3. Remov e th e til t cover .

TILT COVE R

4. Remov e th e steerin g colum n covers .

NOTE : B e carefu l no t t o damag e th e steerin g col -

umn covers.

UPPE R COVE R

LOWE R COVE R

5. Disconnec t th e 20P , 4 P an d 5 P connectors .

CAUTION : B e carefu l no t t o damag e th e SR S wir e

harness .

6 . Remov e th e si x screws , the n remov e th e windshiel d

wiper-cruis e contro l switc h assembly .

5P CONNECTO R

WINDSHIEL D WIPER-CRUIS E CONTRO L

SWITC H ASSEMBL Y

4PCONNECTO R

20PCONNECTO R

7. Instal l i n th e revers e orde r o f removal .

ProCarManuals.com

Page 1438 of 1503

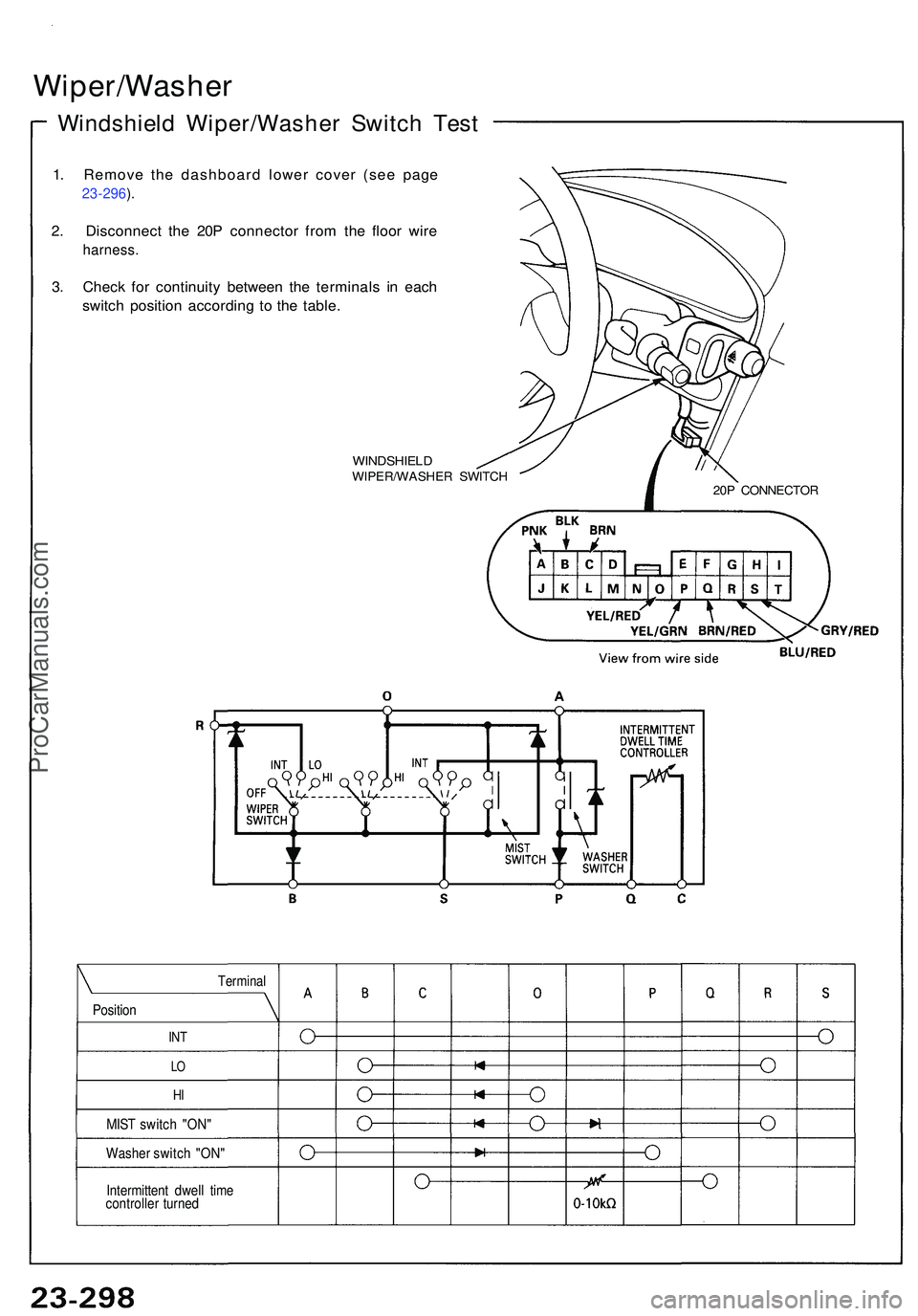

Wiper/Washer

Windshield Wiper/Washe r Switc h Tes t

1. Remov e th e dashboar d lowe r cove r (se e pag e

23-296 ).

2 . Disconnec t th e 20 P connecto r fro m th e floo r wir e

harness .

3. Chec k fo r continuit y betwee n th e terminal s i n eac h

switc h positio n accordin g t o th e table .

WINDSHIEL DWIPER/WASHE R SWITC H

20P CONNECTO R

Intermittent dwel l tim e

controlle r turne d

Positio n

Termina l

INT

LO

H I

MIS T switc h "ON "

Washe r switc h "ON "

ProCarManuals.com

Page 1439 of 1503

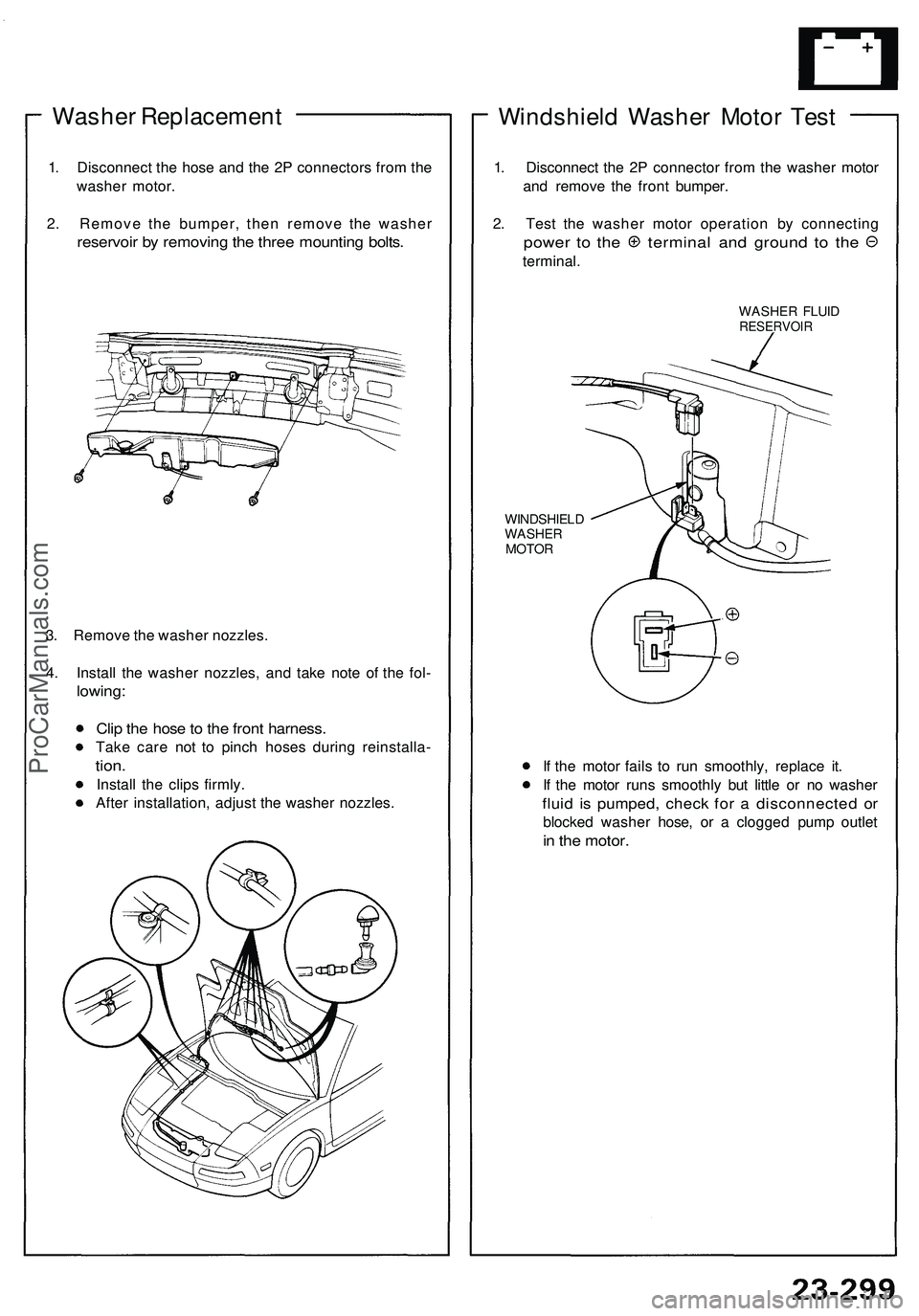

Washer Replacement

1. Disconnect the hose and the 2P connectors from the

washer motor.

2. Remove the bumper, then remove the washer

reservoir by removing the three mounting bolts.

3. Remove the washer nozzles.

4. Install the washer nozzles, and take note of the fol-

lowing:

Clip the hose to the front harness.

Take care not to pinch hoses during reinstalla-

tion.

Install the clips firmly.

After installation, adjust the washer nozzles.

Windshield Washer Motor Test

1. Disconnect the 2P connector from the washer motor

and remove the front bumper.

2. Test the washer motor operation by connecting

power to the terminal and ground to the

terminal.

WASHER FLUID

RESERVOIR

WINDSHIELD

WASHER

MOTOR

If the motor fails to run smoothly, replace it.

If the motor runs smoothly but little or no washer

fluid is pumped, check for a disconnected or

blocked washer hose, or a clogged pump outlet

in the motor.ProCarManuals.com

Page 1440 of 1503

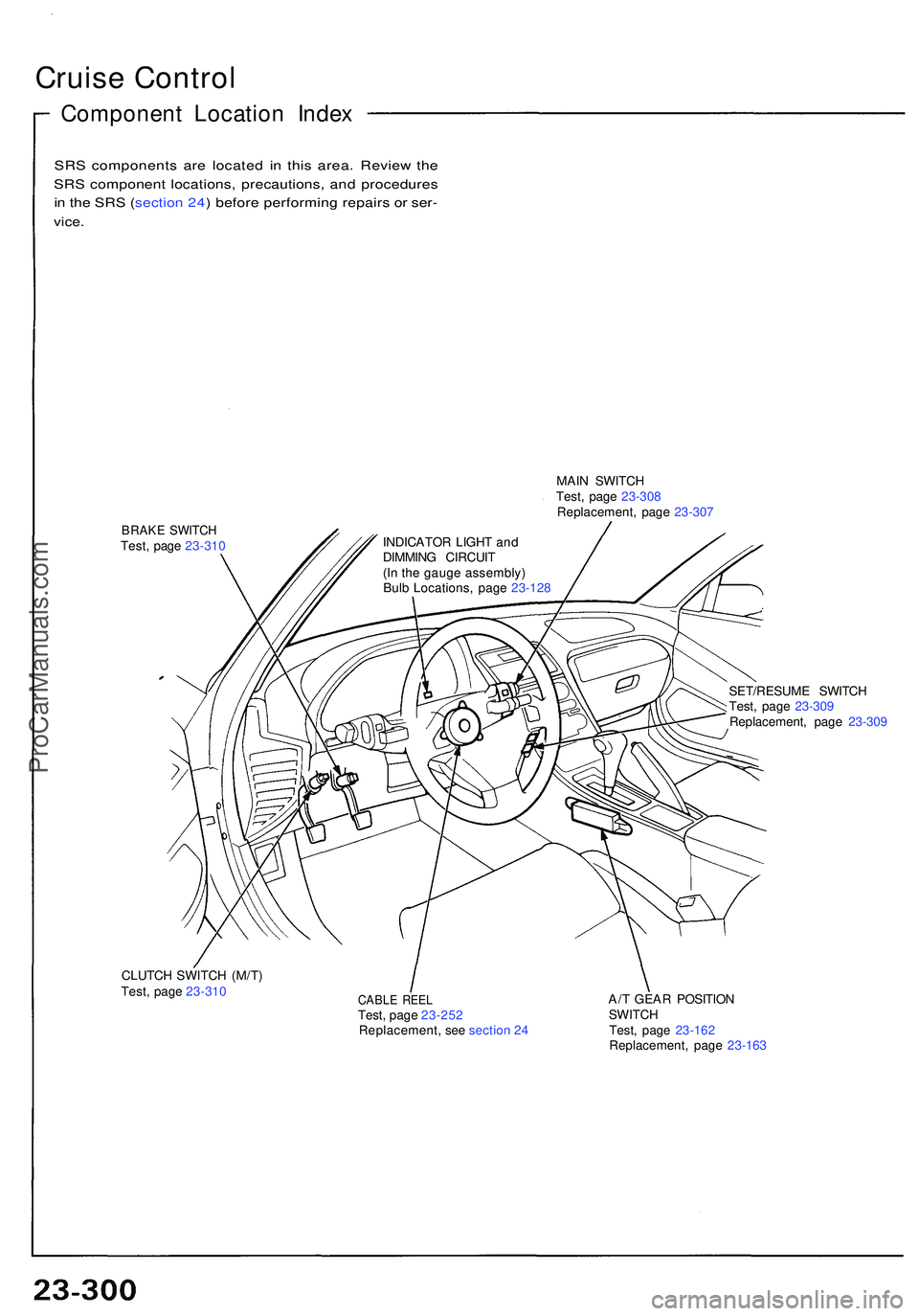

Cruise Contro l

Componen t Locatio n Inde x

SRS component s ar e locate d i n thi s area . Revie w th e

SR S componen t locations , precautions , an d procedure s

i n th e SR S (sectio n 24 ) befor e performin g repair s o r ser -

vice .

MAIN SWITC H

Test , pag e 23-30 8

Replacement , pag e 23-30 7

BRAK E SWITC HTest, pag e 23-31 0

SET/RESUME SWITC H

Test , pag e 23-30 9

Replacement , pag e 23-30 9

CLUTC H SWITC H (M/T )

Test , pag e 23-31 0

CABL E REE LTest, pag e 23-25 2

Replacement , se e sectio n 2 4 A/

T GEA R POSITIO N

SWITC H

Test , page 23-162Replacement , pag e 23-16 3

INDICATO

R LIGH T an d

DIMMIN G CIRCUI T

(I n th e gaug e assembly )

Bul b Locations , pag e 23-12 8

ProCarManuals.com