ACURA NSX 1997 Service Repair Manual

Manufacturer: ACURA, Model Year: 1997,

Model line: NSX,

Model: ACURA NSX 1997

Pages: 1503, PDF Size: 57.08 MB

ACURA NSX 1997 Service Repair Manual

NSX 1997

ACURA

ACURA

https://www.carmanualsonline.info/img/32/56989/w960_56989-0.png

ACURA NSX 1997 Service Repair Manual

Trending: seat adjustment, fuse, alternator belt, cooling, engine overheat, battery, service reset

Page 1421 of 1503

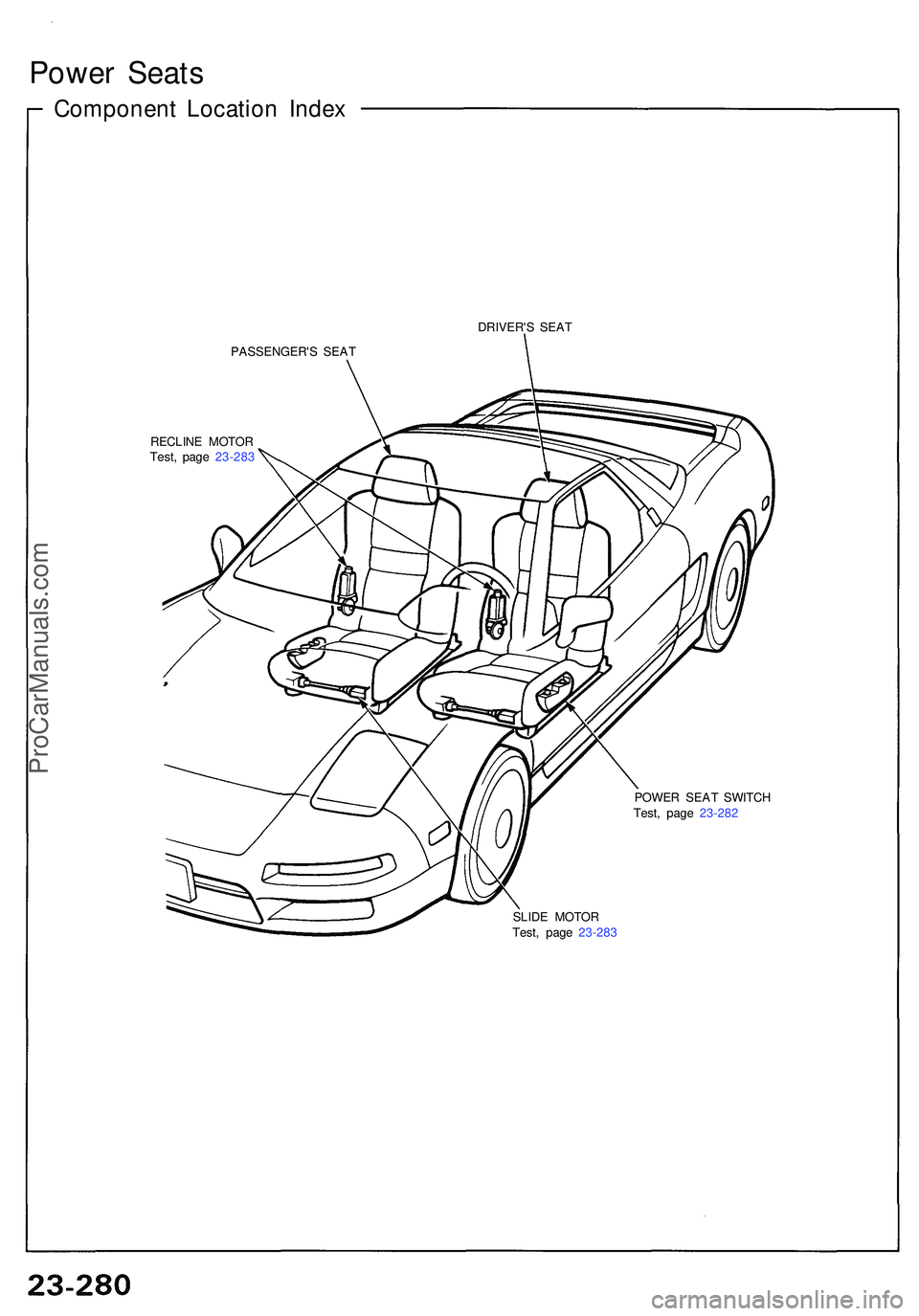

Power Seat s

Componen t Locatio n Inde x

PASSENGER' S SEA T

RECLIN E MOTO R

Test , pag e 23-28 3 DRIVER'

S SEA T

POWER SEA T SWITC H

Test , pag e 23-28 2

SLID E MOTO R

Test , pag e 23-28 3

ProCarManuals.com

Page 1422 of 1503

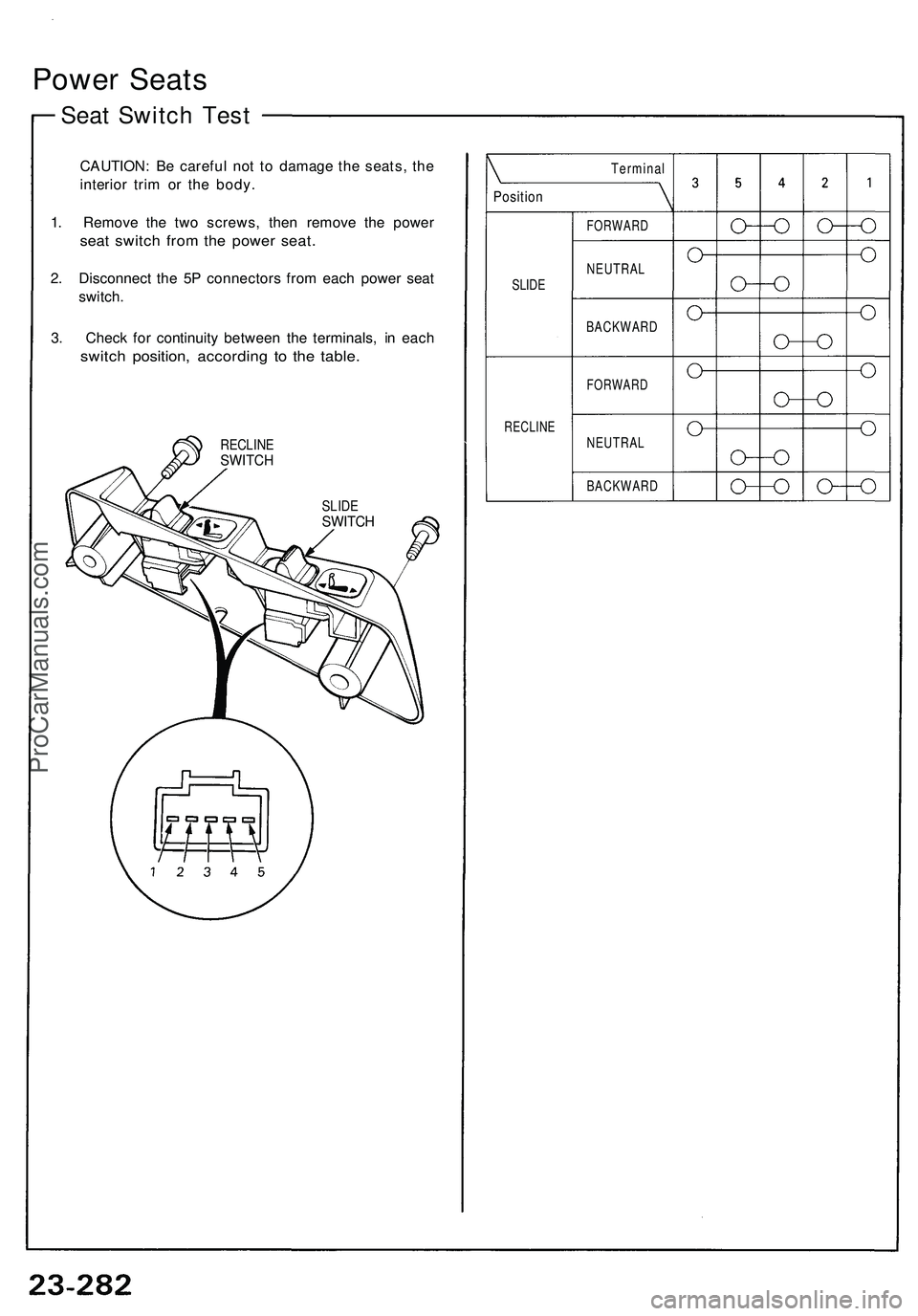

Power Seats

Seat Switch Test

CAUTION: Be careful not to damage the seats, the

interior trim or the body.

1. Remove the two screws, then remove the power

seat switch from the power seat.

2. Disconnect the 5P connectors from each power seat

switch.

3. Check for continuity between the terminals, in each

switch position, according to the table.

RECLINE

SWITCH

SLIDE

SWITCH

SLIDE

RECLINE

Position

Terminal

FORWARD

NEUTRAL

BACKWARD

FORWARD

NEUTRAL

BACKWARDProCarManuals.com

Page 1423 of 1503

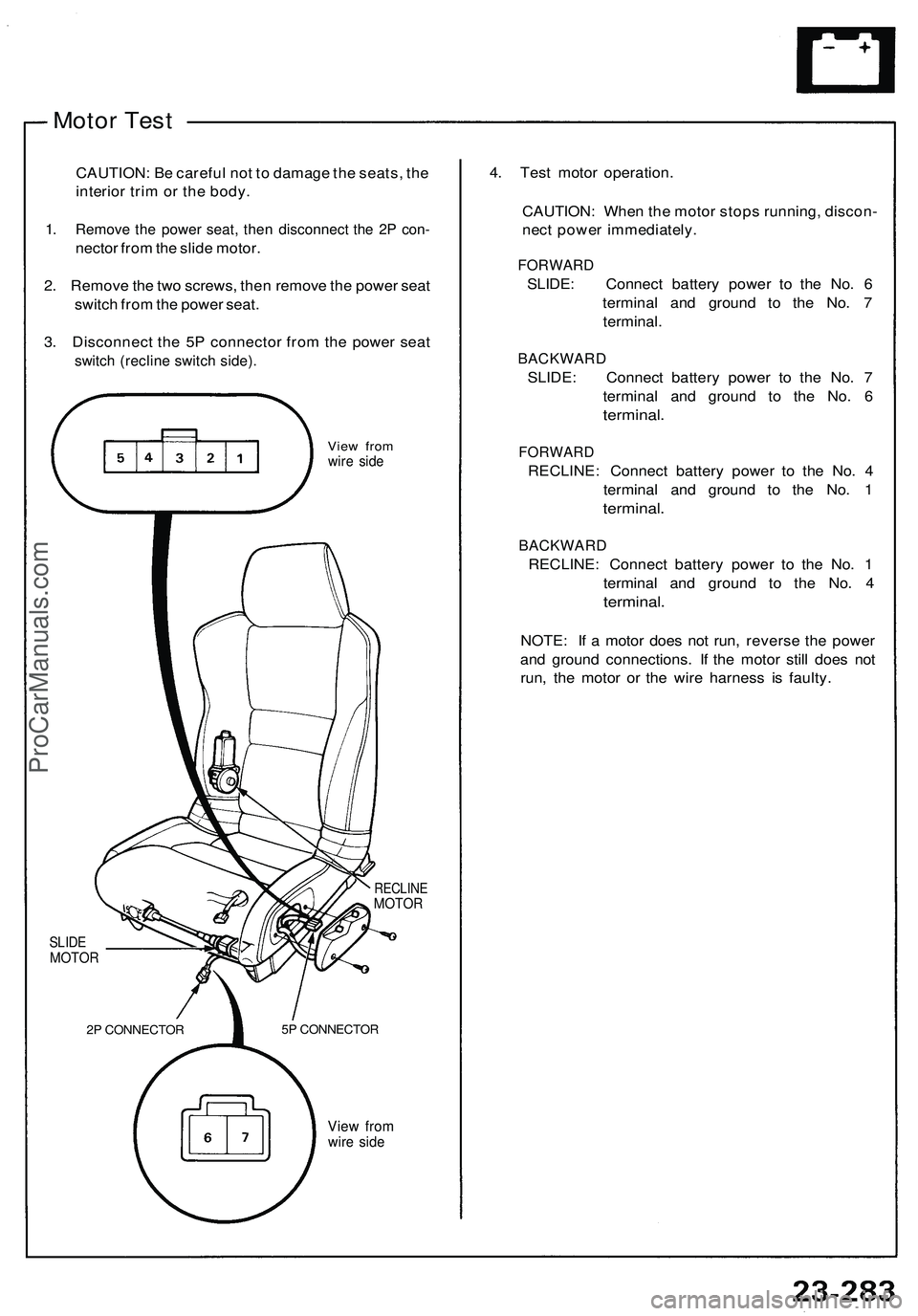

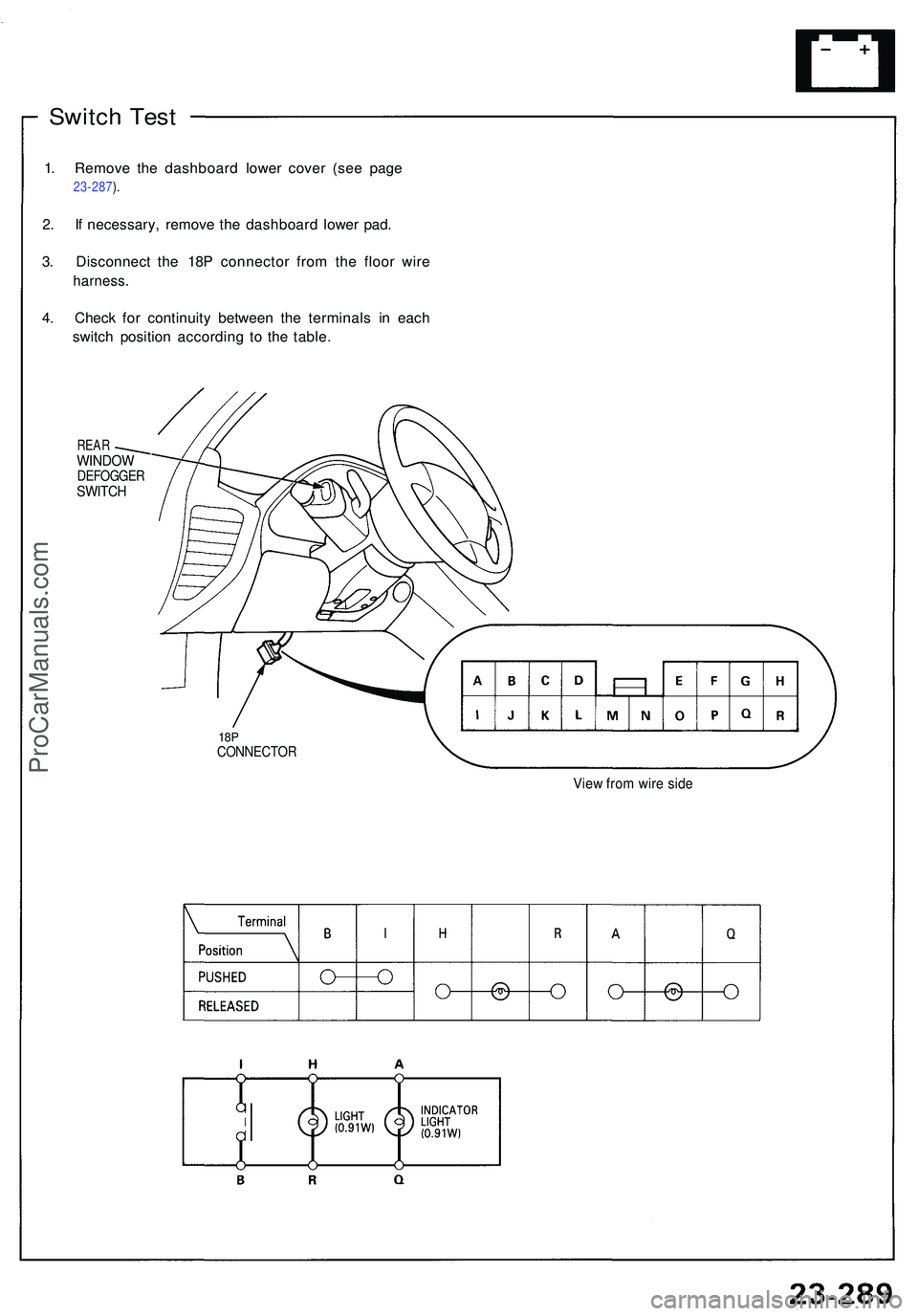

Motor Test

CAUTION: Be careful not to damage the seats, the

interior trim or the body.

1. Remove the power seat, then disconnect the 2P con-

nector from the slide motor.

2. Remove the two screws, then remove the power seat

switch from the power seat.

3. Disconnect the 5P connector from the power seat

switch (recline switch side).

View from

wire side

RECLINE

MOTOR

SLIDE

MOTOR

View from

wire side

4. Test motor operation.

CAUTION: When the motor stops running, discon-

nect power immediately.

FORWARD

SLIDE: Connect battery power to the No. 6

terminal and ground to the No. 7

terminal.

BACKWARD

SLIDE: Connect battery power to the No. 7

terminal and ground to the No. 6

terminal.

FORWARD

RECLINE: Connect battery power to the No. 4

terminal and ground to the No. 1

terminal.

BACKWARD

RECLINE: Connect battery power to the No. 1

terminal and ground to the No. 4

terminal.

NOTE: If a motor does not run, reverse the power

and ground connections. If the motor still does not

run, the motor or the wire harness is faulty.

2P CONNECTOR

5P CONNECTORProCarManuals.com

Page 1424 of 1503

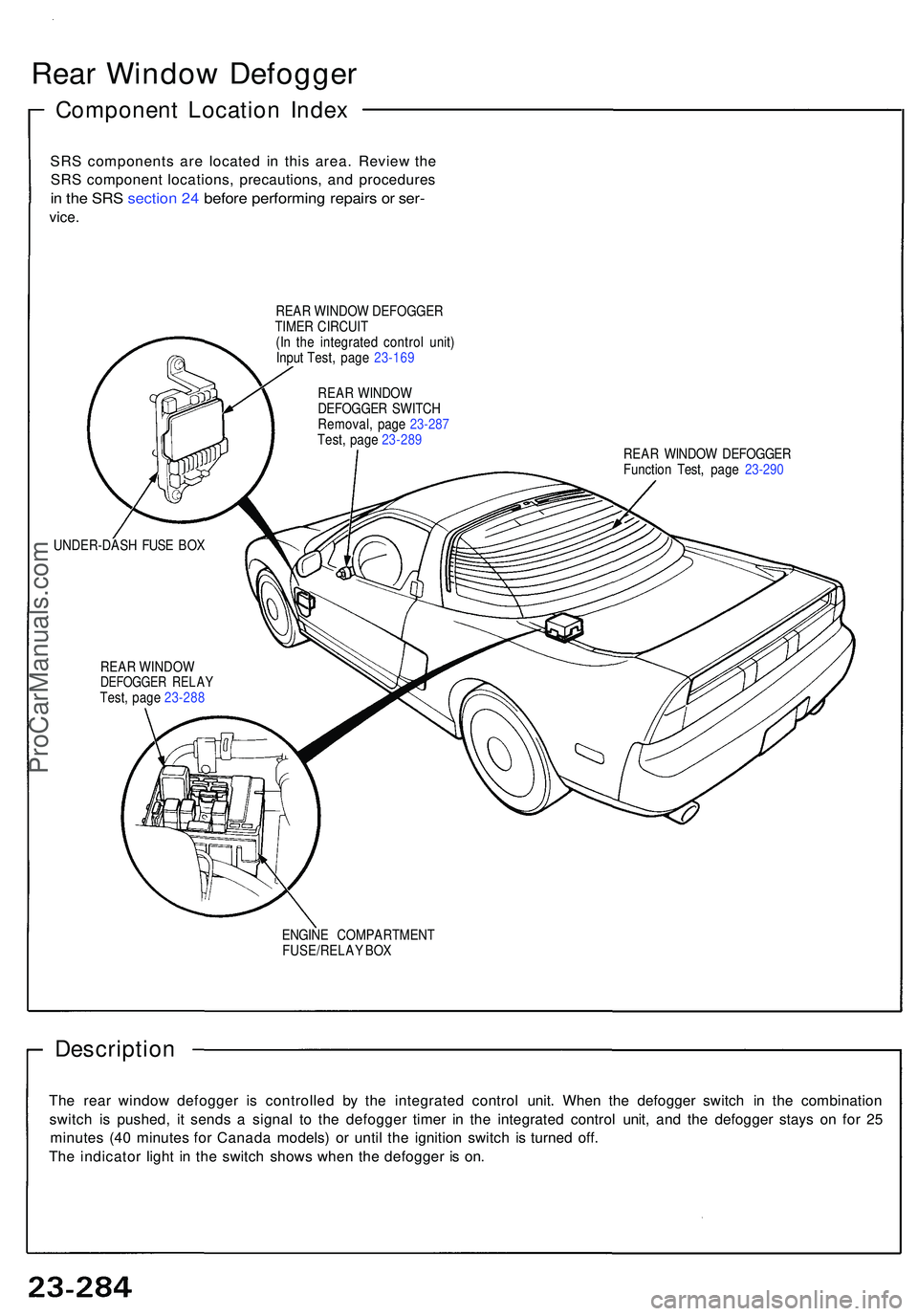

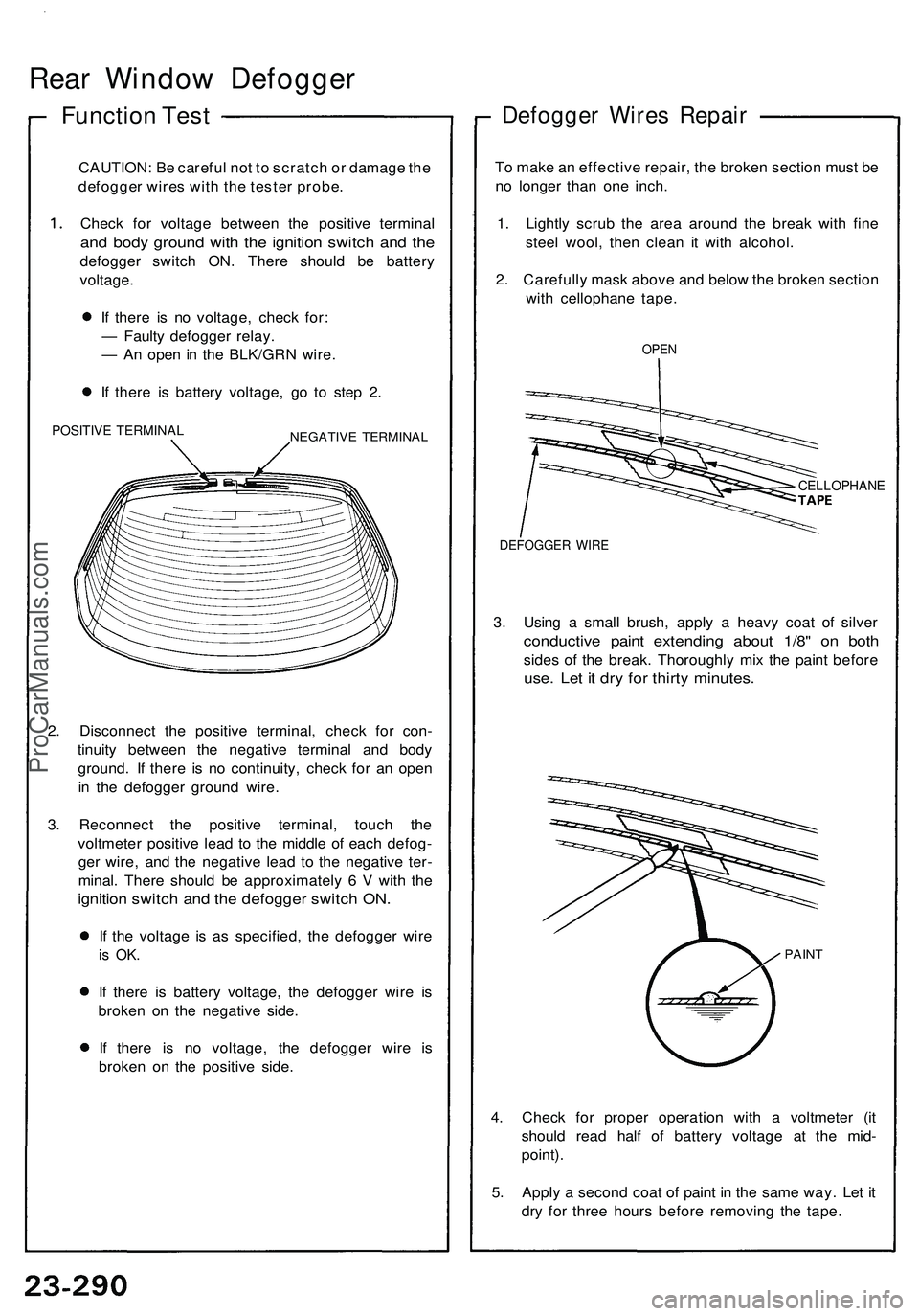

Rear Windo w Defogge r

Componen t Locatio n Inde x

SRS component s ar e locate d i n thi s area . Revie w th e

SR S componen t locations , precautions , an d procedure s

in th e SR S sectio n 24 befor e performin g repair s o r ser -

vice .

REA R WINDO W DEFOGGE R

TIME R CIRCUI T

(I n th e integrate d contro l unit )

Inpu t Test , pag e 23-16 9

REAR WINDO W DEFOGGE R

Functio n Test , pag e 23-29 0

UNDER-DAS H FUS E BO X REA

R WINDO W

DEFOGGE R SWITC H

Removal , pag e 23-28 7

Test , pag e 23-28 9

REA R WINDO W

DEFOGGE R RELA YTest, pag e 23-28 8

ENGINE COMPARTMEN T

FUSE/RELA Y BO X

Descriptio n

The rea r windo w defogge r i s controlle d b y th e integrate d contro l unit . Whe n th e defogge r switc h i n th e combinatio n

switc h i s pushed , i t send s a signa l t o th e defogge r time r i n th e integrate d contro l unit , an d th e defogge r stay s o n fo r 2 5

minute s (4 0 minute s fo r Canad a models ) o r unti l th e ignitio n switc h i s turne d off .

Th e indicato r ligh t i n th e switc h show s whe n th e defogge r i s on .

ProCarManuals.com

Page 1425 of 1503

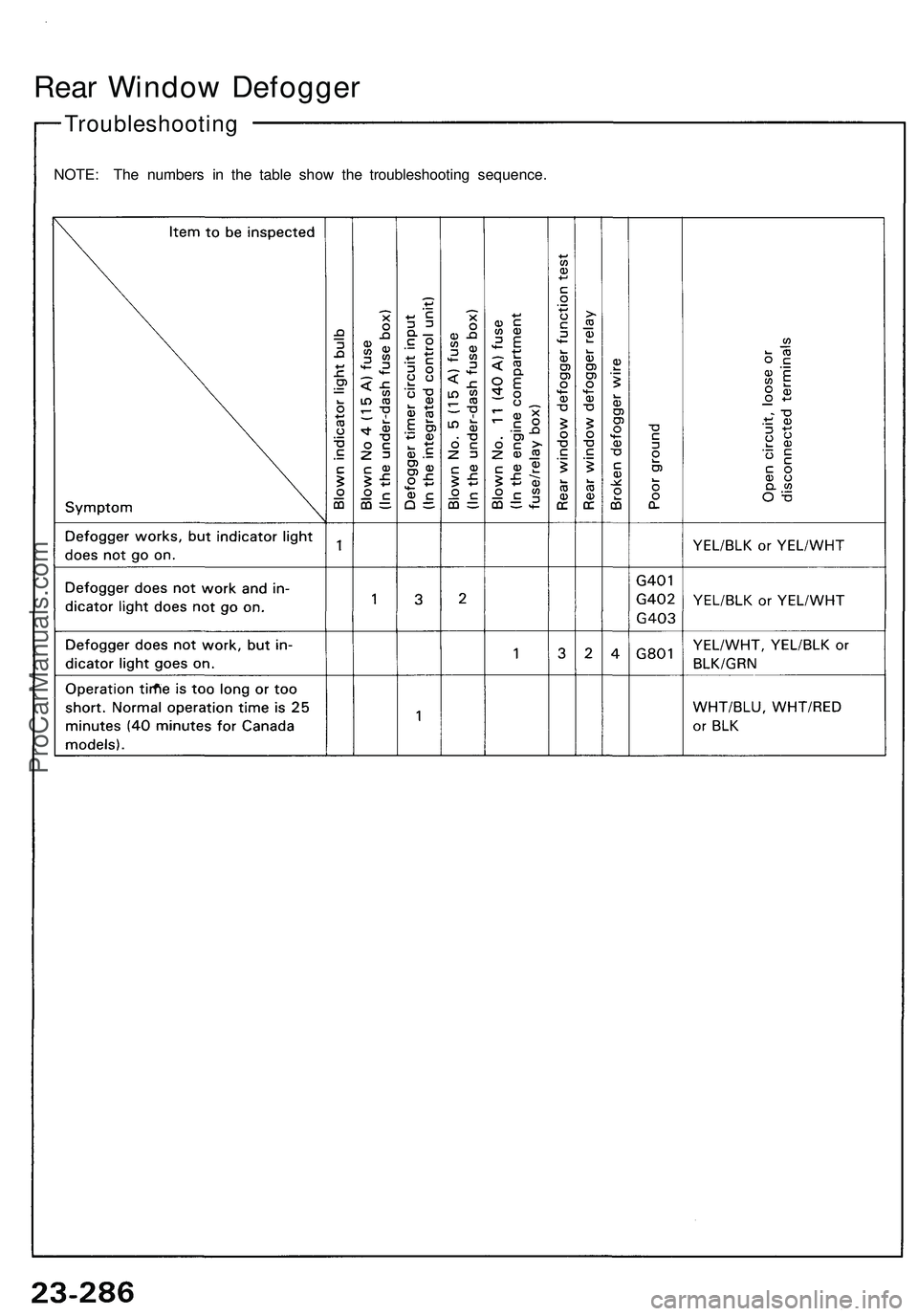

Rear Window Defogger

Troubleshooting

NOTE: The numbers in the table show the troubleshooting sequence.ProCarManuals.com

Page 1426 of 1503

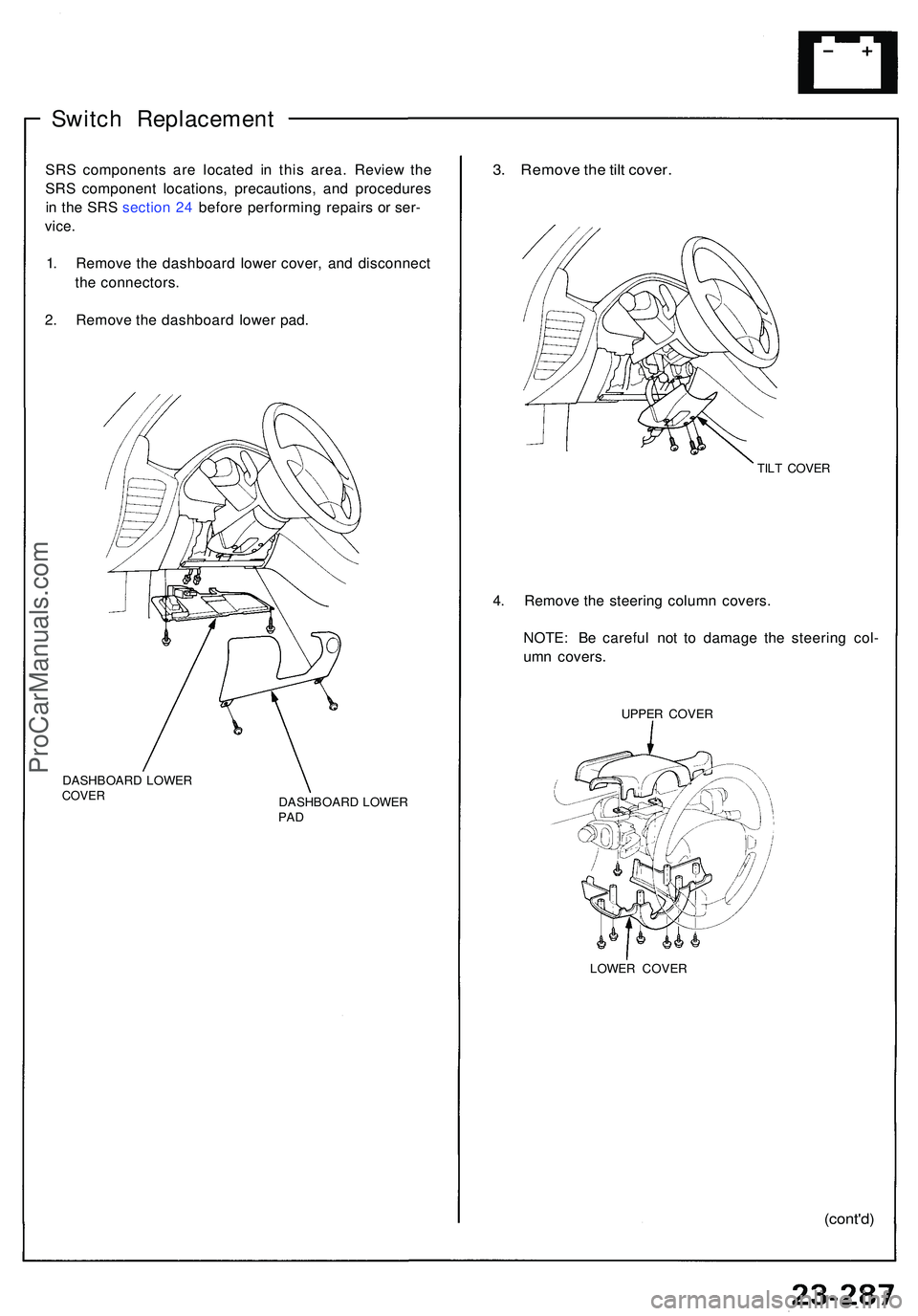

Switch Replacemen t

SRS component s ar e locate d i n thi s area . Revie w th e

SR S componen t locations , precautions , an d procedure s

i n th e SR S sectio n 24 befor e performin g repair s o r ser -

vice .

1. Remov e th e dashboar d lowe r cover , an d disconnec t

th e connectors .

2 . Remov e th e dashboar d lowe r pad .

DASHBOAR D LOWE RCOVERDASHBOAR D LOWE RPAD

3. Remov e th e til t cover .

TILT COVE R

4. Remov e th e steerin g colum n covers .

NOTE : B e carefu l no t t o damag e th e steerin g col -

um n covers .

UPPER COVE R

LOWE R COVE R

(cont'd)

ProCarManuals.com

Page 1427 of 1503

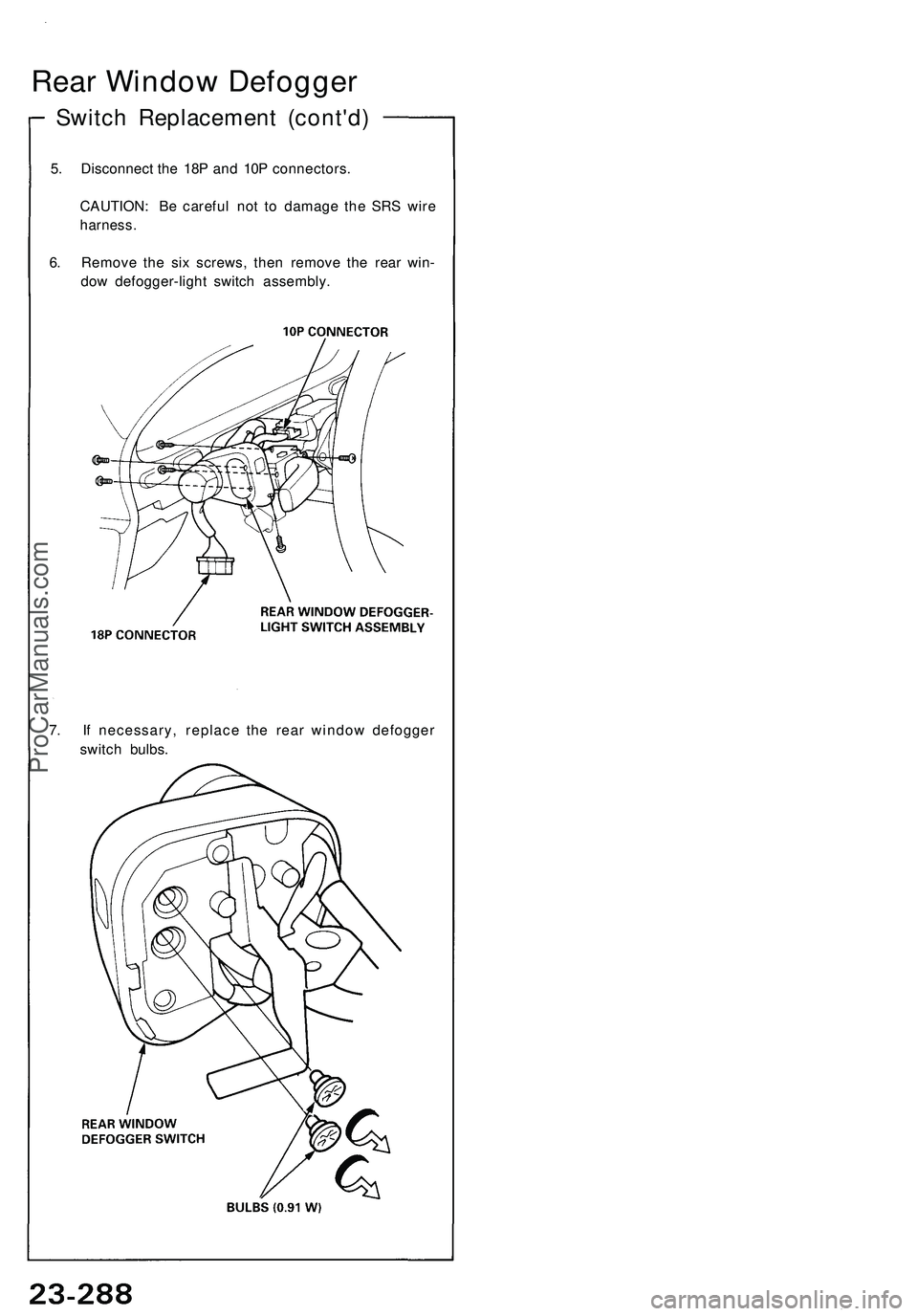

Switch Replacement (cont'd)

Rear Window Defogger

5. Disconnect the 18P and 10P connectors.

CAUTION: Be careful not to damage the SRS wire

harness.

6. Remove the six screws, then remove the rear win-

dow defogger-light switch assembly.

7. If necessary, replace the rear window defogger

switch bulbs.ProCarManuals.com

Page 1428 of 1503

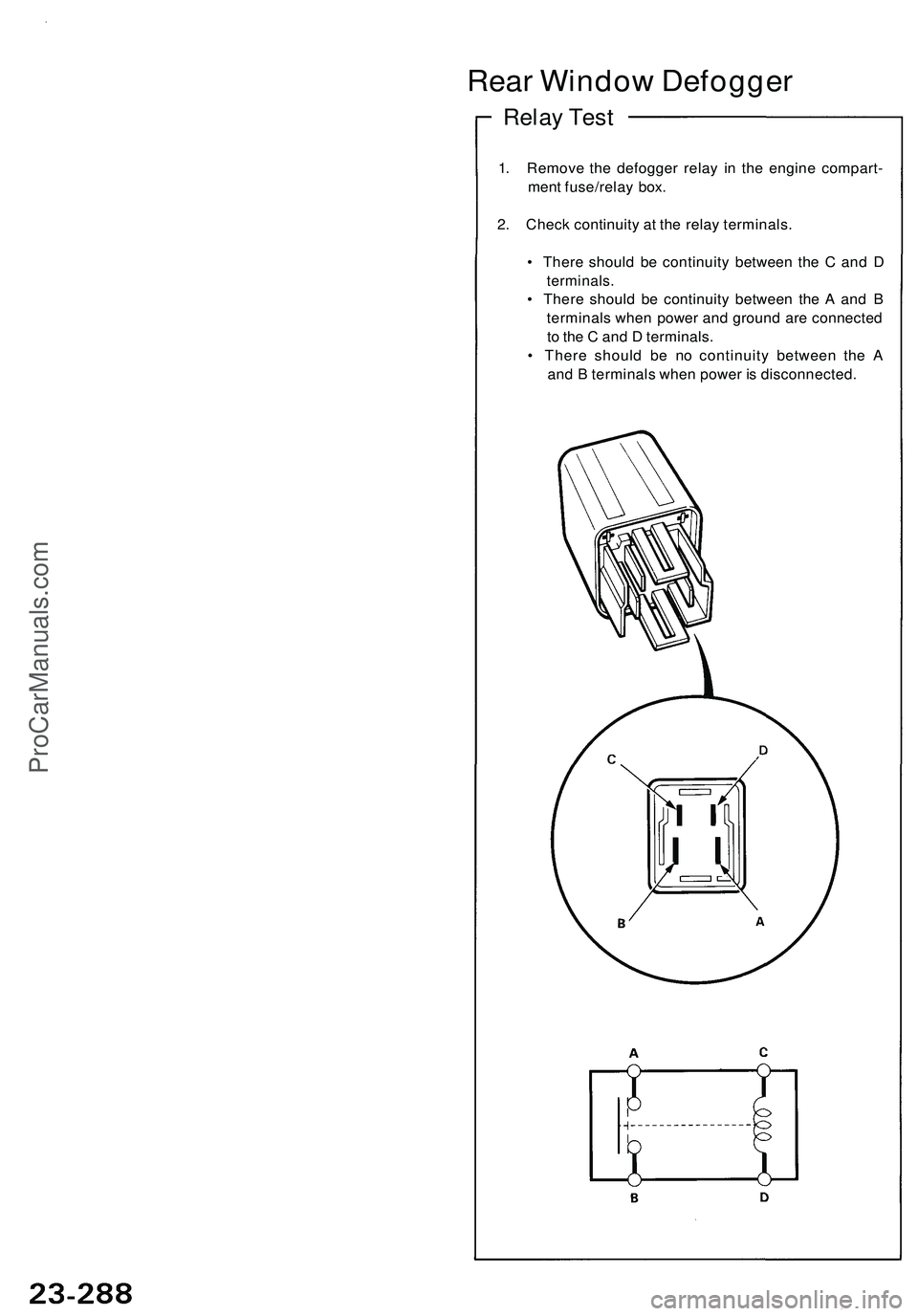

Rear Windo w Defogge r

Relay Tes t

1. Remov e th e defogge r rela y i n th e engin e compart -

men t fuse/rela y box .

2 . Chec k continuit y a t th e rela y terminals .

• Ther e shoul d b e continuit y betwee n th e C an d D

terminals .

• Ther e shoul d b e continuit y betwee n th e A an d B

terminal s whe n powe r an d groun d ar e connecte d

t o th e C an d D terminals .

• Ther e shoul d b e n o continuit y betwee n th e A

an d B terminal s whe n powe r i s disconnected .

ProCarManuals.com

Page 1429 of 1503

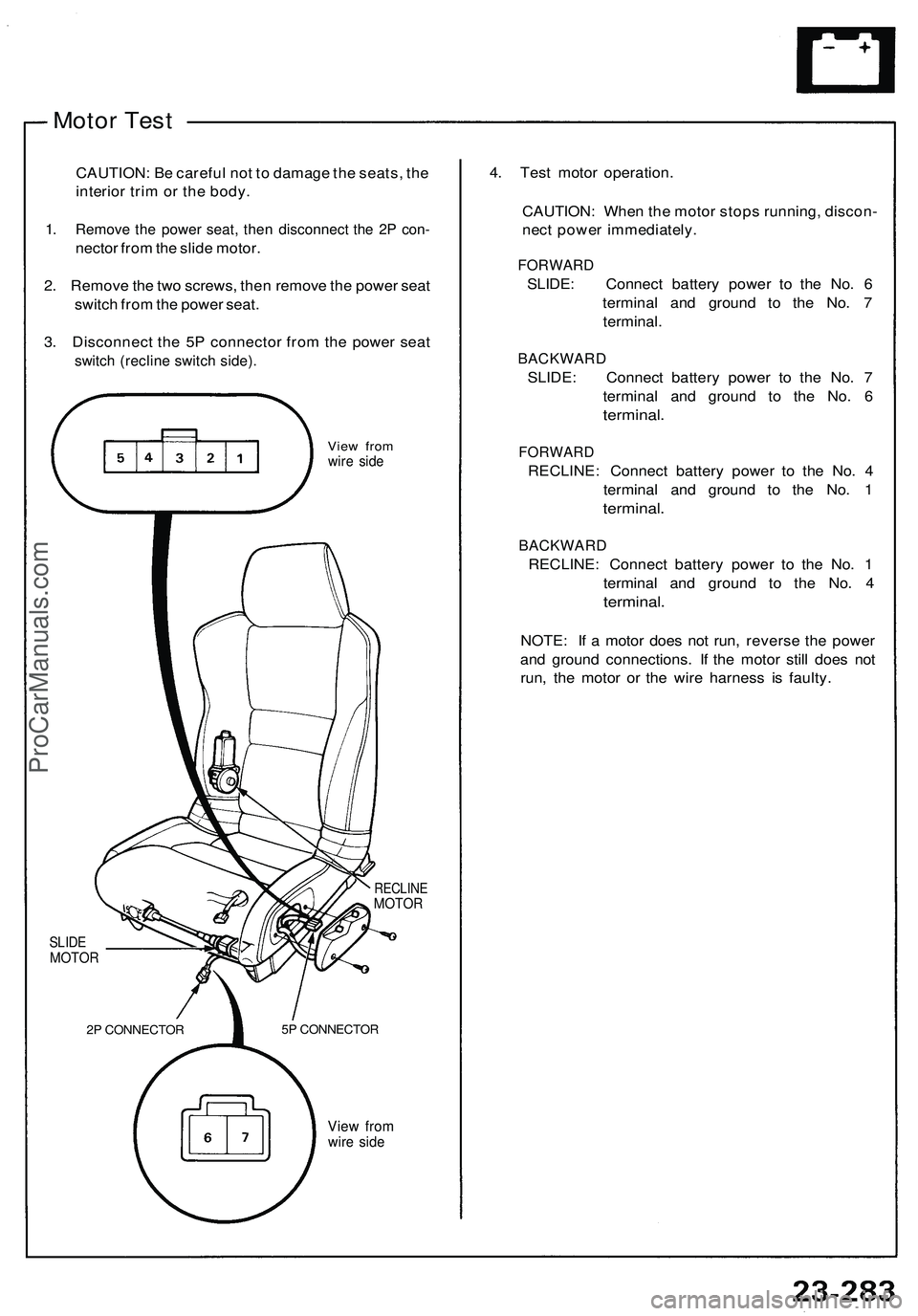

Switch Tes t

1. Remov e th e dashboar d lowe r cove r (se e pag e

23-287 ).

2 . I f necessary , remov e th e dashboar d lowe r pad .

3 . Disconnec t th e 18 P connecto r fro m th e floo r wir e

harness .

4. Chec k fo r continuit y betwee n th e terminal s i n eac h

switc h positio n accordin g t o th e table .

REARWINDO WDEFOGGE RSWITCH

18PCONNECTO R

View fro m wir e sid e

ProCarManuals.com

Page 1430 of 1503

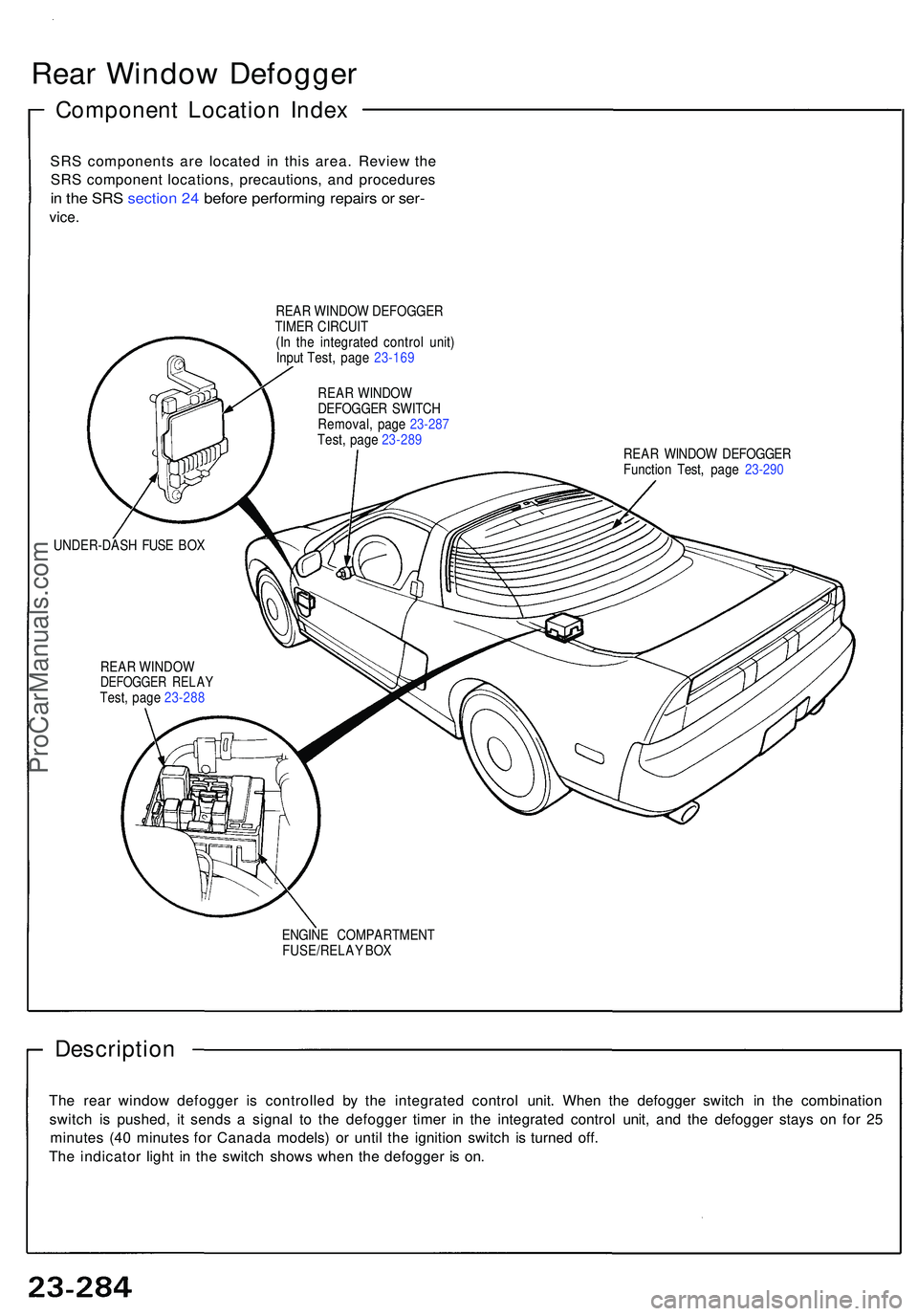

Rear Window Defogger

Function Test

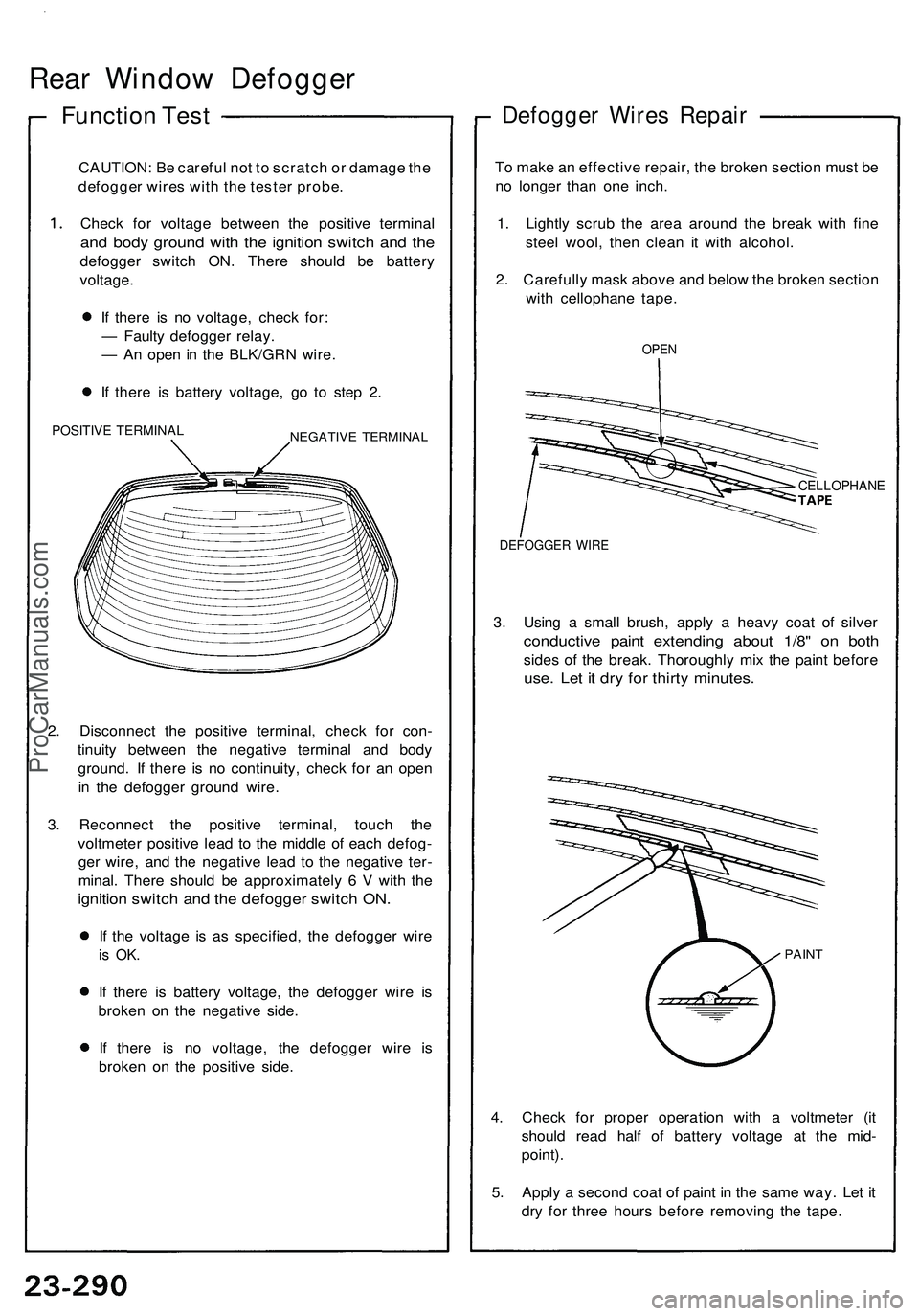

CAUTION: Be careful not to scratch or damage the

defogger wires with the tester probe.

Check for voltage between the positive terminal

and body ground with the ignition switch and the

defogger switch ON. There should be battery

voltage.

If there is no voltage, check for:

— Faulty defogger relay.

— An open in the BLK/GRN wire.

If there is battery voltage, go to step 2.

POSITIVE TERMINAL

NEGATIVE TERMINAL

2. Disconnect the positive terminal, check for con-

tinuity between the negative terminal and body

ground. If there is no continuity, check for an open

in the defogger ground wire.

3. Reconnect the positive terminal, touch the

voltmeter positive lead to the middle of each defog-

ger wire, and the negative lead to the negative ter-

minal. There should be approximately 6 V with the

ignition switch and the defogger switch ON.

If the voltage is as specified, the defogger wire

is OK.

If there is battery voltage, the defogger wire is

broken on the negative side.

If there is no voltage, the defogger wire is

broken on the positive side.

Defogger Wires Repair

To make an effective repair, the broken section must be

no longer than one inch.

1. Lightly scrub the area around the break with fine

steel wool, then clean it with alcohol.

2. Carefully mask above and below the broken section

with cellophane tape.

OPEN

CELLOPHANE

DEFOGGER WIRE

3. Using a small brush, apply a heavy coat of silver

conductive paint extending about 1/8" on both

sides of the break. Thoroughly mix the paint before

use. Let it dry for thirty minutes.

PAINT

4. Check for proper operation with a voltmeter (it

should read half of battery voltage at the mid-

point).

5. Apply a second coat of paint in the same way. Let it

dry for three hours before removing the tape.ProCarManuals.com

Trending: airbag, oil, coolant temperature, spark plugs, differential, length, dashboard warning lights