ACURA NSX 1997 Service Repair Manual

Manufacturer: ACURA, Model Year: 1997,

Model line: NSX,

Model: ACURA NSX 1997

Pages: 1503, PDF Size: 57.08 MB

ACURA NSX 1997 Service Repair Manual

NSX 1997

ACURA

ACURA

https://www.carmanualsonline.info/img/32/56989/w960_56989-0.png

ACURA NSX 1997 Service Repair Manual

Trending: width, headlight bulb, child lock, power steering fluid, climate control, transmission fluid, AUX

Page 1391 of 1503

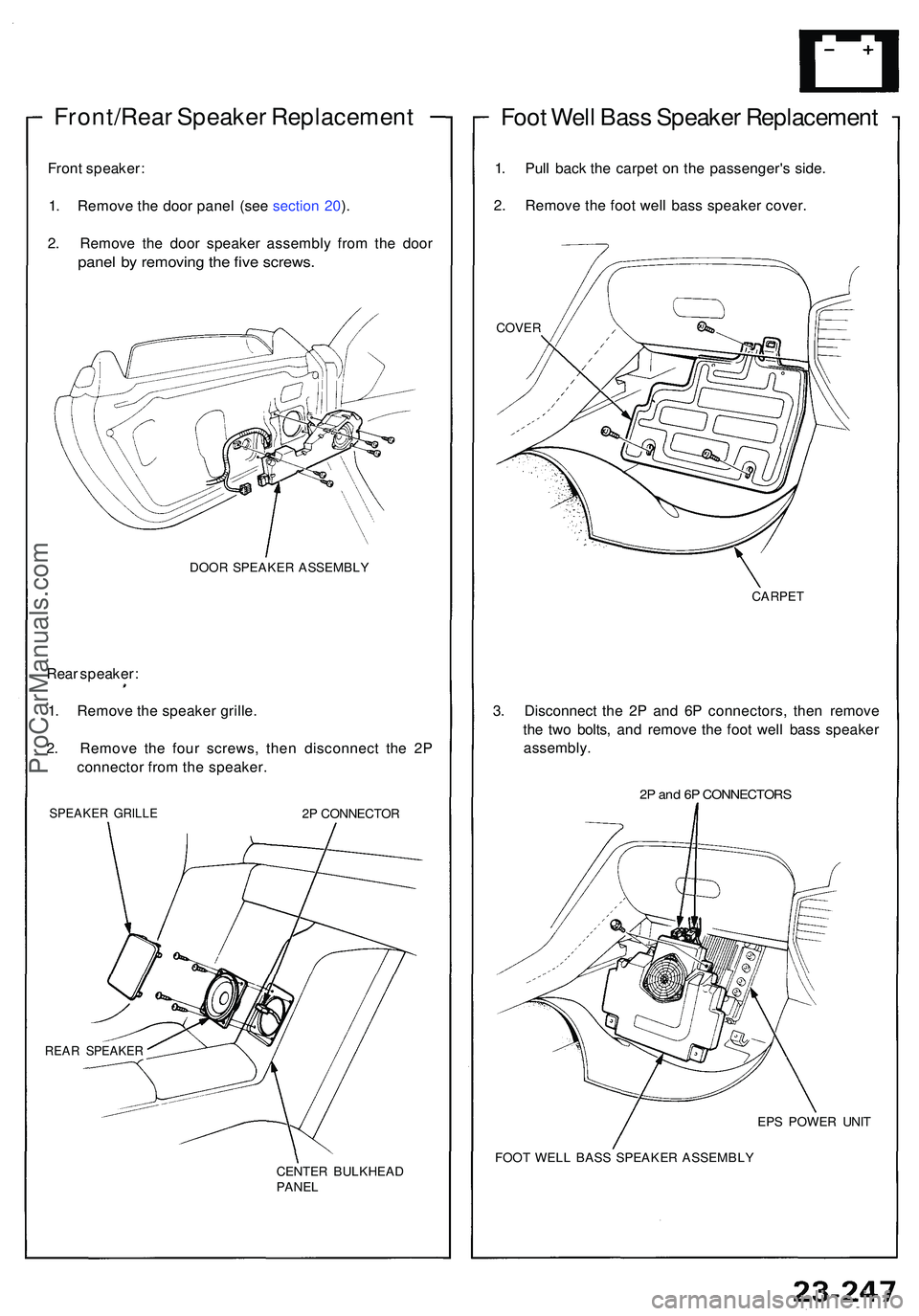

Front/Rear Speake r Replacemen t

Front speaker :

1 . Remov e th e doo r pane l (se e sectio n 20 ).

2 . Remov e th e doo r speake r assembl y fro m th e doo r

panel b y removin g th e fiv e screws .

DOOR SPEAKE R ASSEMBL Y

Rear speaker :

1 . Remov e th e speake r grille .

2 . Remov e th e fou r screws , the n disconnec t th e 2 P

connecto r fro m th e speaker .

SPEAKE R GRILL E2P CONNECTO R

REAR SPEAKE R

CENTER BULKHEA DPANEL

Foot Wel l Bas s Speake r Replacemen t

1. Pul l bac k th e carpe t o n th e passenger' s side .

2 . Remov e th e foo t wel l bass speake r cover .

COVER

CARPE T

3. Disconnec t th e 2 P an d 6 P connectors , the n remov e

th e tw o bolts , an d remov e th e foo t wel l bas s speake r

assembly .

2P an d 6 P CONNECTOR S

EPS POWE R UNI T

FOO T WEL L BAS S SPEAKE R ASSEMBL Y

ProCarManuals.com

Page 1392 of 1503

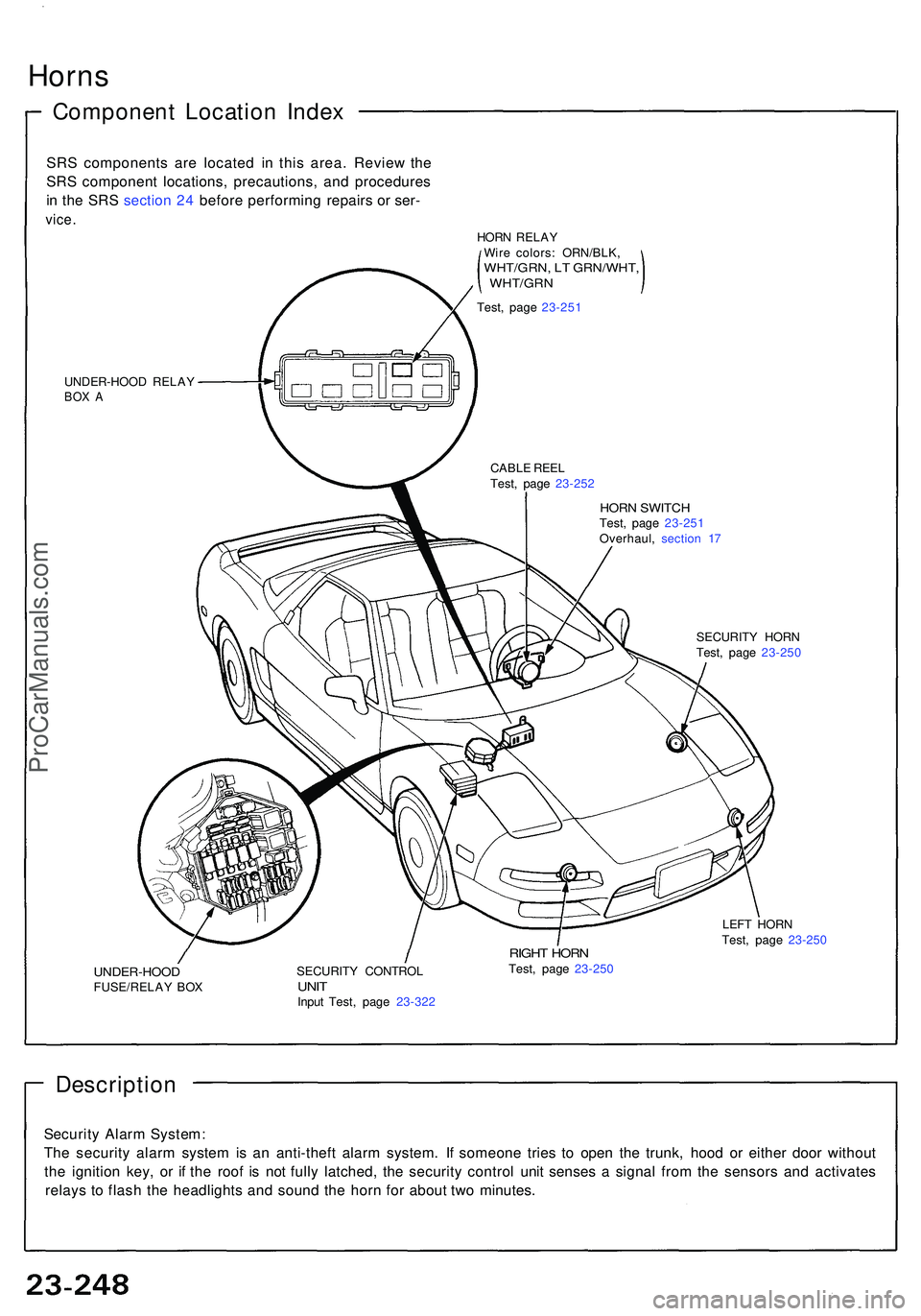

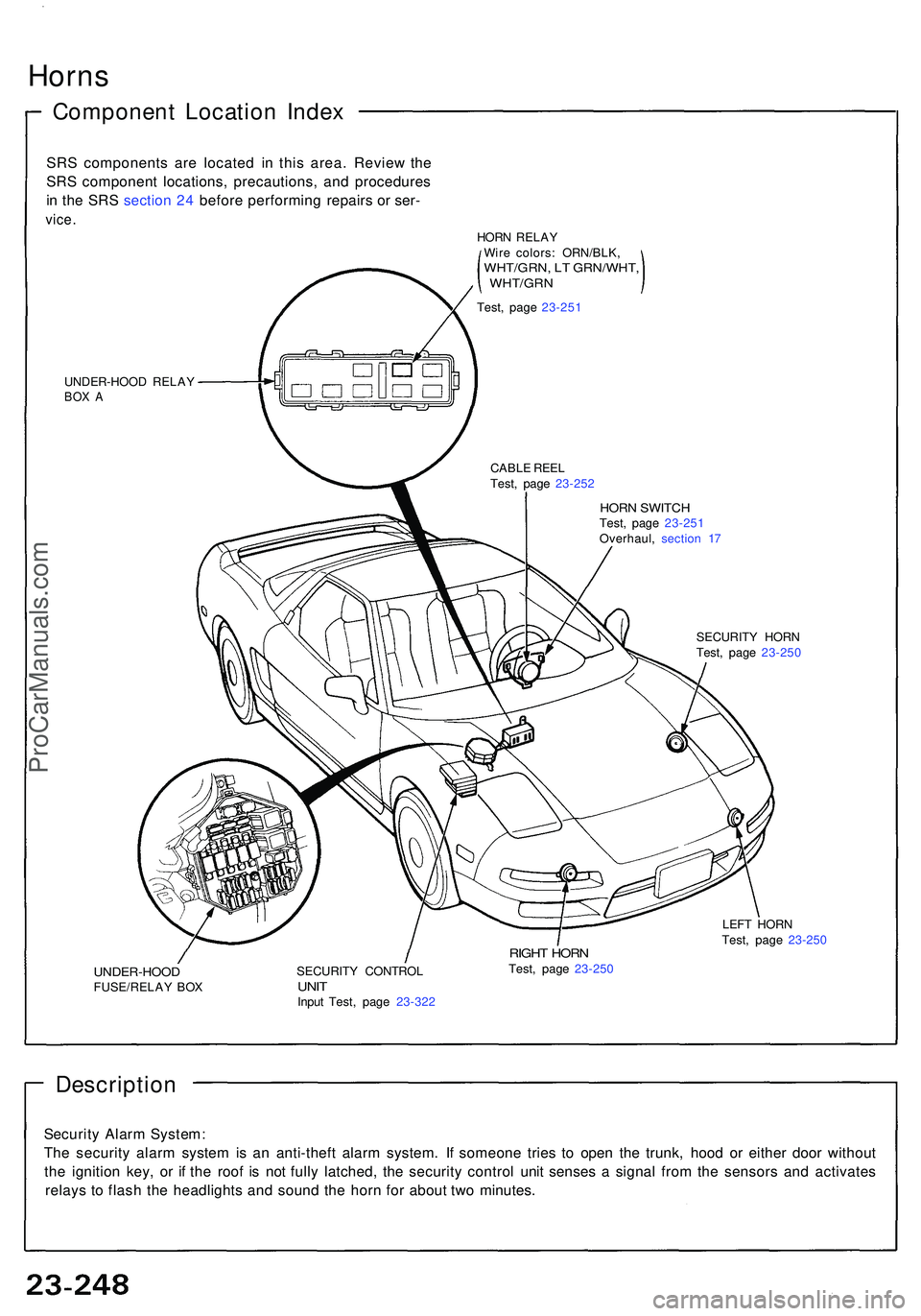

Horns

Componen t Locatio n Inde x

SRS component s ar e locate d i n thi s area . Revie w th e

SR S componen t locations , precautions , an d procedure s

i n th e SR S sectio n 24 befor e performin g repair s o r ser -

vice .

UNDER-HOO D RELA YBOX A

HOR N SWITC HTest, pag e 23-25 1

Overhaul , sectio n 1 7

CABL

E REE L

Test , pag e 23-25 2

SECURITY HOR N

Test , pag e 23-25 0

UNDER-HOO DFUSE/RELAY BO X SECURIT

Y CONTRO LUNITInpu t Test , pag e 23-32 2

RIGHT HOR NTest, pag e 23-25 0 LEF

T HOR N

Test , pag e 23-25 0

Descriptio n

Security Alar m System :

Th e securit y alar m syste m is a n anti-thef t alar m system . I f someon e trie s t o ope n th e trunk , hoo d o r eithe r doo r withou t

th e ignitio n key , o r i f th e roo f i s no t full y latched , th e securit y contro l uni t sense s a signa l fro m th e sensor s an d activate s

relay s t o flas h th e headlight s an d soun d th e hor n fo r abou t tw o minutes .

HORN RELA Y

Wir e colors : ORN/BLK ,

WHT/GRN, L T GRN/WHT ,, WHT/GR N

Test, pag e 23-25 1

ProCarManuals.com

Page 1393 of 1503

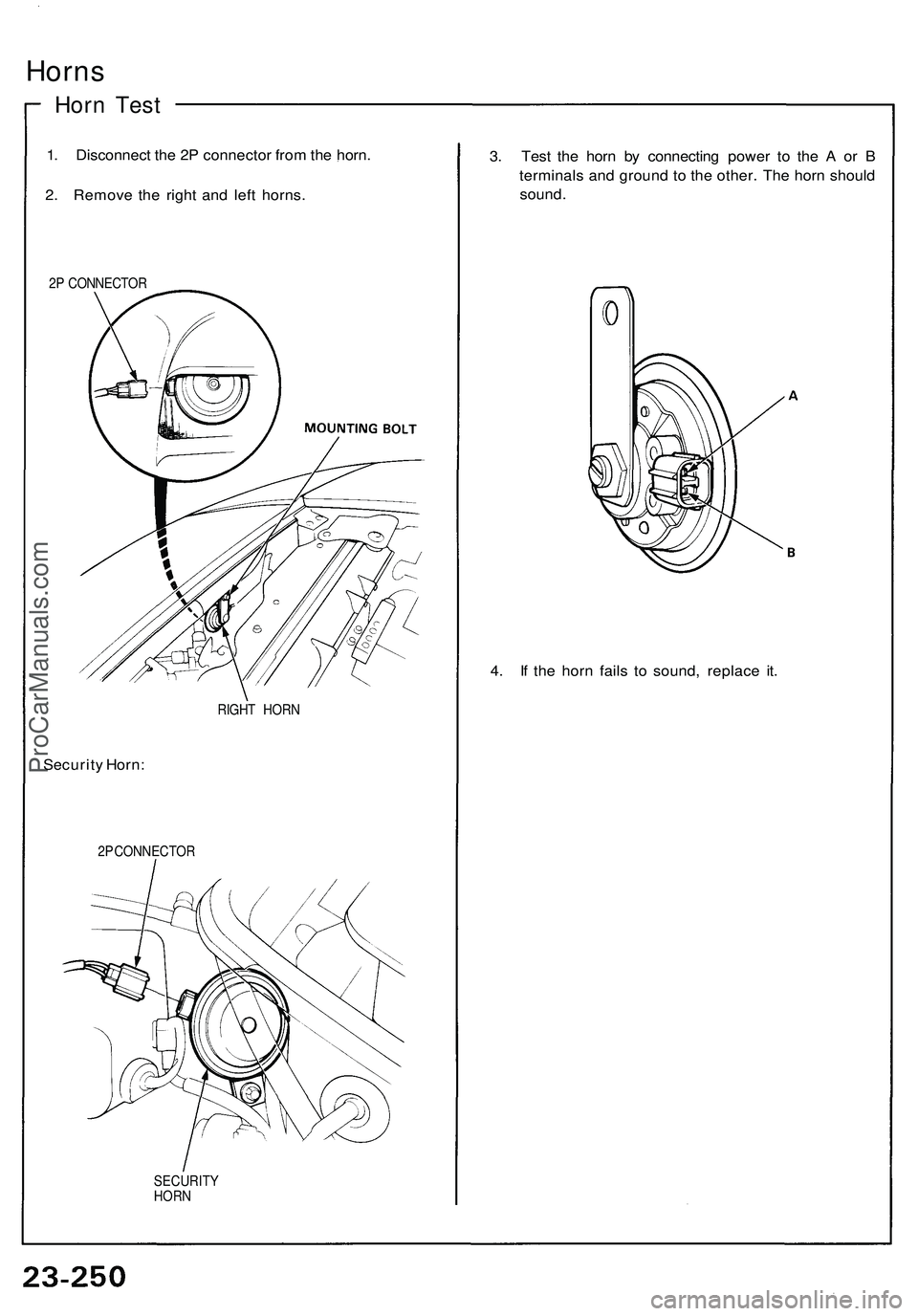

Horns

Horn Tes t

1. Disconnec t th e 2 P connecto r fro m th e horn .

2 . Remov e th e righ t an d lef t horns .

2P CONNECTO R

RIGHT HOR N

Securit y Horn :

2P CONNECTO R

SECURITYHORN

3. Tes t th e hor n b y connectin g powe r t o th e A or B

terminal s an d groun d t o th e other . Th e hor n shoul d

sound .

4 . I f th e hor n fail s t o sound , replac e it .

ProCarManuals.com

Page 1394 of 1503

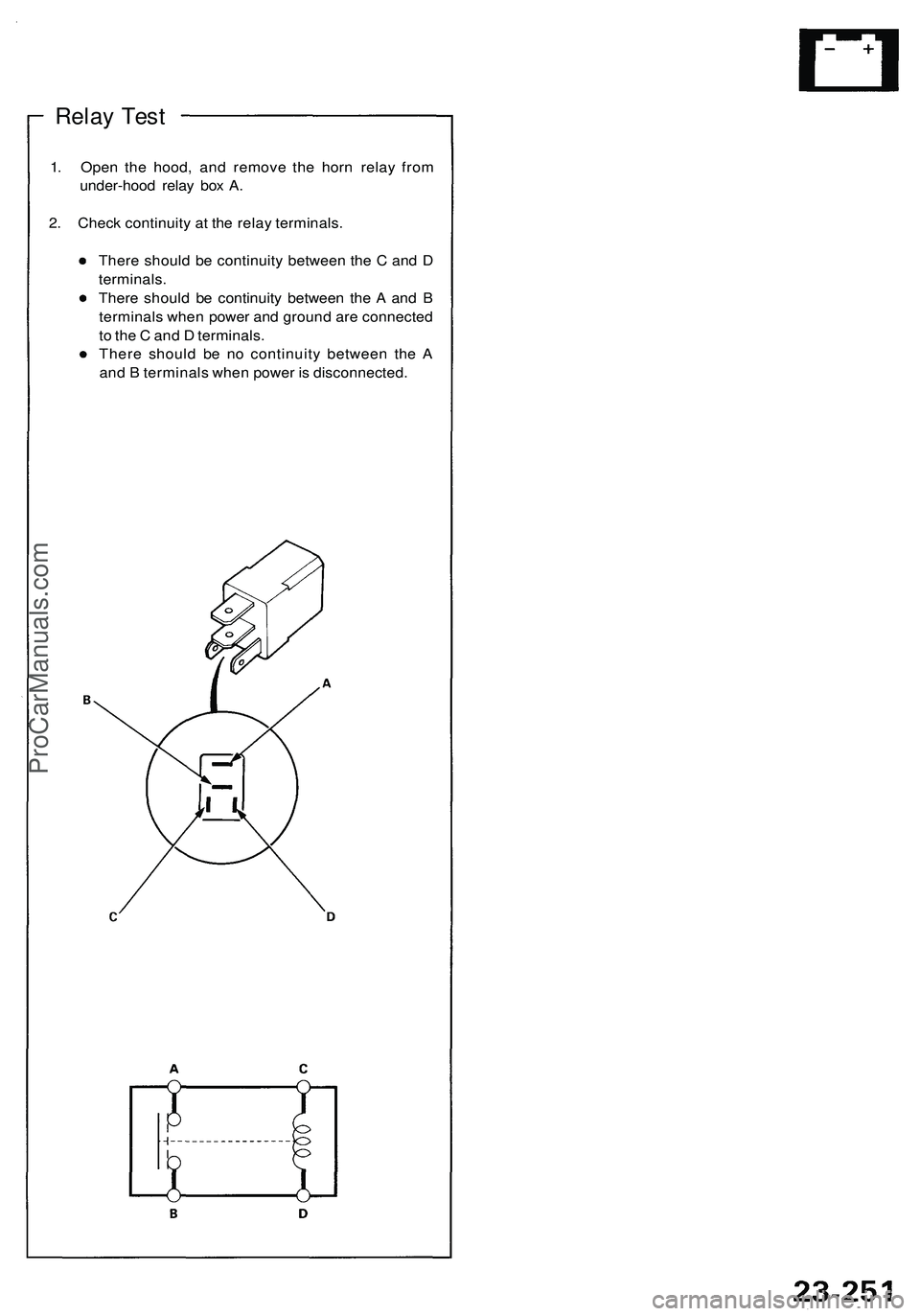

Relay Test

1. Open the hood, and remove the horn relay from

under-hood relay box A.

2. Check continuity at the relay terminals.

There should be continuity between the C and D

terminals.

There should be continuity between the A and B

terminals when power and ground are connected

to the C and D terminals.

There should be no continuity between the A

and B terminals when power is disconnected.ProCarManuals.com

Page 1395 of 1503

Switch Tes t

SRS component s ar e locate d i n thi s area . Revie w th e

SR S componen t locations , precautions , an d procedure s

i n th e SR S sectio n 24 befor e performin g repair s o r ser -

vice .

1. Disconnec t th e batter y negativ e cable , the n discon -

nec t th e positiv e cable .

2 . Mak e sur e th e wheel s ar e turne d straigh t ahead .

3 . Remov e th e dashboar d lowe r cover .

4 . Instal l th e shor t connector s o n th e airba g an d seat -

bel t tensione r connector s (se e sectio n 24 ).

(cont'd )

ProCarManuals.com

Page 1396 of 1503

Horns

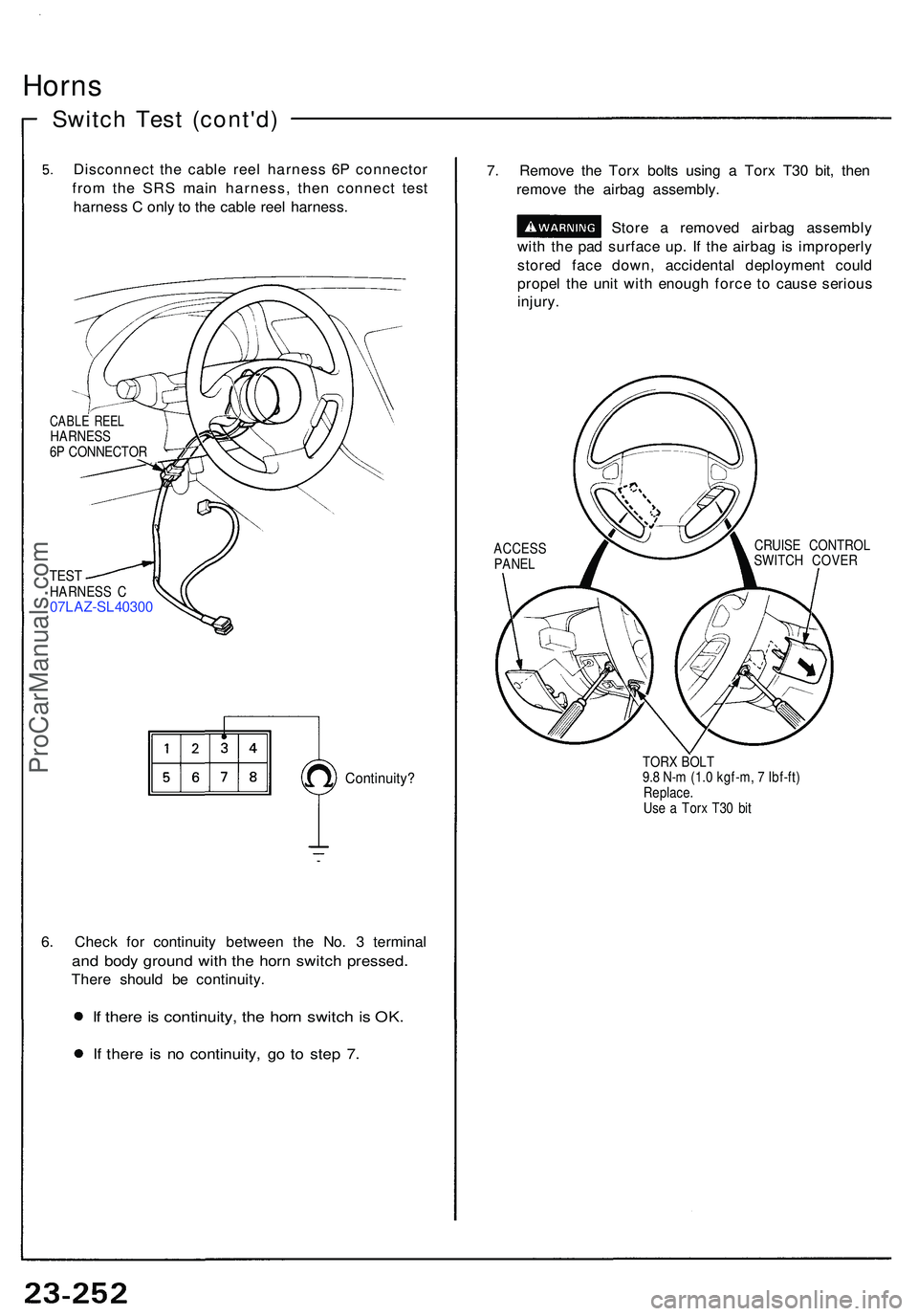

Switc h Tes t (cont'd )

Disconnec t th e cabl e ree l harnes s 6 P connecto r

fro m th e SR S mai n harness , the n connec t tes t

harnes s C onl y t o th e cabl e ree l harness .

CABLE REE LHARNES S

6 P CONNECTO R

TESTHARNES S C07LAZ-SL4030 0

Continuity?

6. Chec k fo r continuit y betwee n th e No . 3 termina l

and bod y groun d wit h th e hor n switc h pressed .

There shoul d b e continuity .

If ther e is continuity , th e hor n switc h is OK .

If ther e i s n o continuity , g o t o ste p 7 .

7. Remov e th e Tor x bolt s usin g a Tor x T3 0 bit , the n

remov e th e airba g assembly .

Stor e a remove d airba g assembl y

wit h th e pa d surfac e up . I f th e airba g is improperl y

store d fac e down , accidenta l deploymen t coul d

prope l th e uni t wit h enoug h forc e t o caus e seriou s

injury .

ACCES S

PANE L CRUIS

E CONTRO L

SWITC H COVE R

TOR X BOL T

9. 8 N- m (1. 0 kgf-m , 7 Ibf-ft )

Replace .Use a Tor x T3 0 bi t

ProCarManuals.com

Page 1397 of 1503

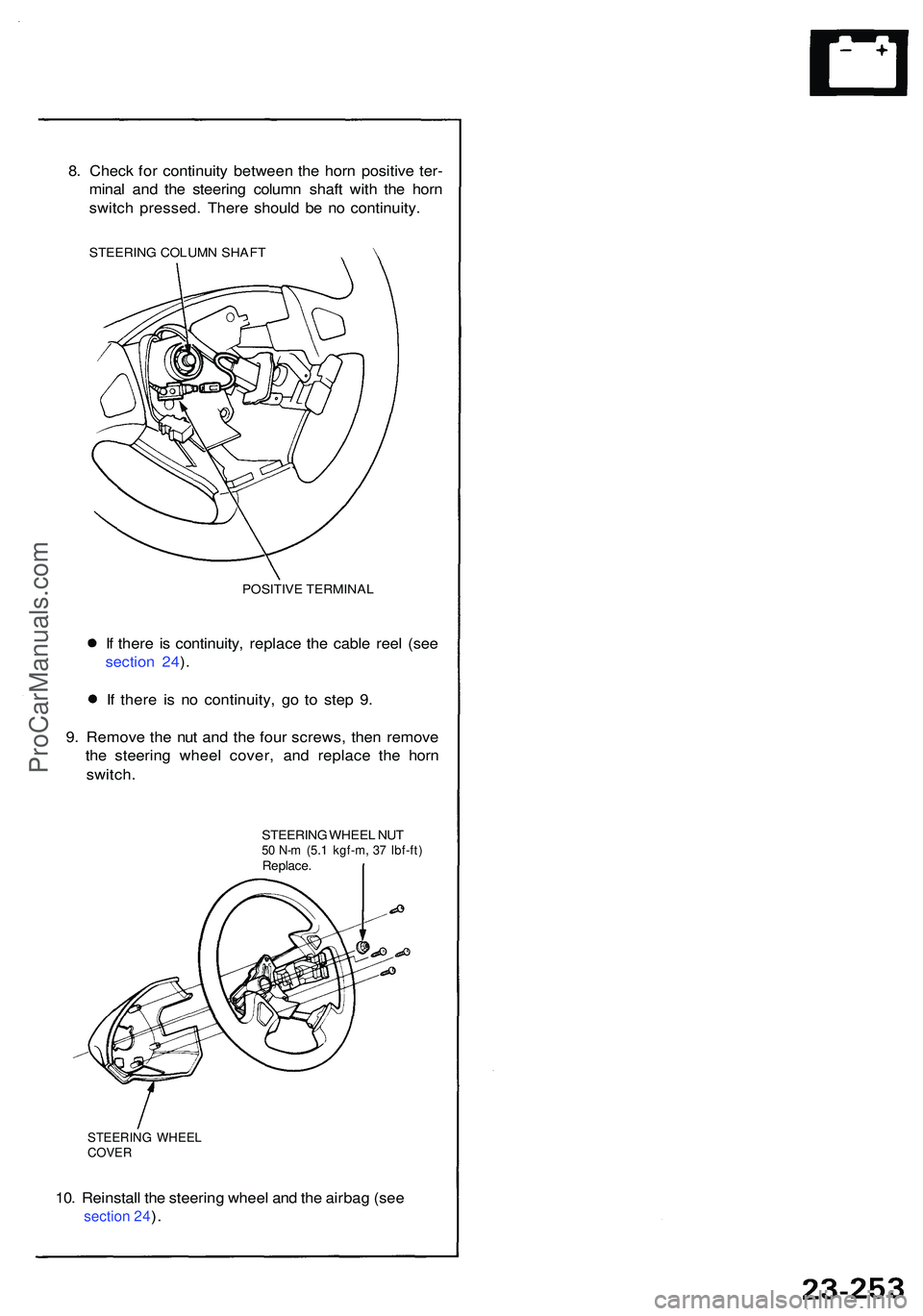

8. Chec k fo r continuit y betwee n th e hor n positiv e ter -

mina l an d th e steerin g colum n shaf t with the hor n

switc h pressed . Ther e shoul d b e n o continuity .

STEERING COLUM N SHAF T

POSITIV E TERMINA L

If ther e i s continuity , replac e th e cabl e ree l (se e

sectio n 24 ).

I f ther e i s n o continuity , g o t o ste p 9 .

9 . Remov e th e nu t an d th e fou r screws , the n remov e

th e steerin g whee l cover , an d replac e th e hor n

switch .

STEERIN G WHEE L NU T50 N- m (5. 1 kgf-m , 3 7 Ibf-ft )Replace .

STEERIN G WHEE LCOVER

10. Reinstal l th e steerin g whee l an d th e airba g (se e

sectio n 24).

ProCarManuals.com

Page 1398 of 1503

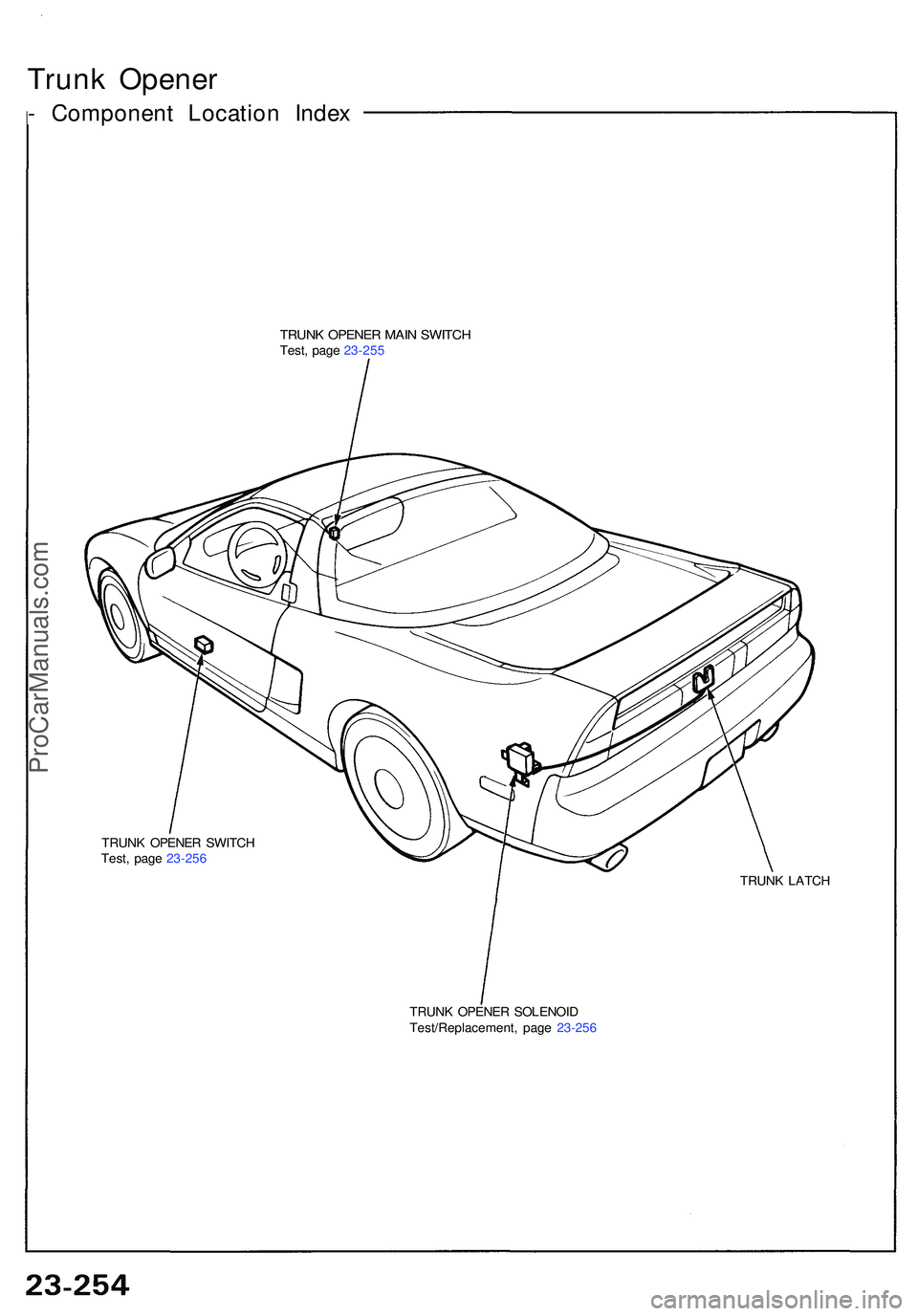

Trunk Opene r

- Componen t Locatio n Inde x

TRUN K OPENE R MAI N SWITC HTest, pag e 23-25 5

TRUN K OPENE R SWITC H

Test , pag e 23-25 6

TRUNK LATC H

TRUN K OPENE R SOLENOI D

Test/Replacement , pag e 23-25 6

ProCarManuals.com

Page 1399 of 1503

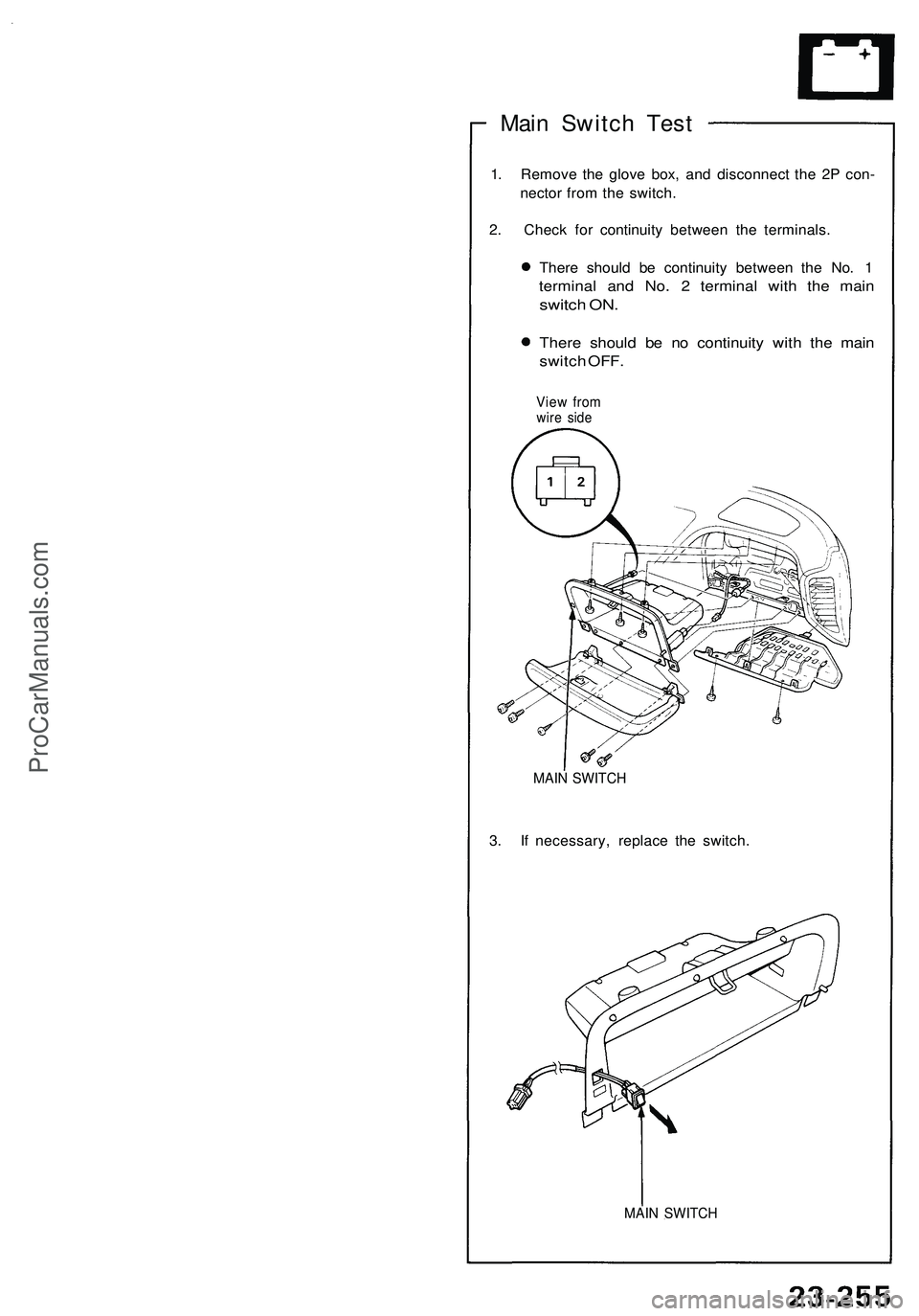

Main Switch Test

1. Remove the glove box, and disconnect the 2P con-

nector from the switch.

2. Check for continuity between the terminals.

There should be continuity between the No. 1

terminal and No. 2 terminal with the main

switch ON.

There should be no continuity with the main

switch OFF.

View from

wire side

MAIN SWITCH

3. If necessary, replace the switch.

MAIN SWITCHProCarManuals.com

Page 1400 of 1503

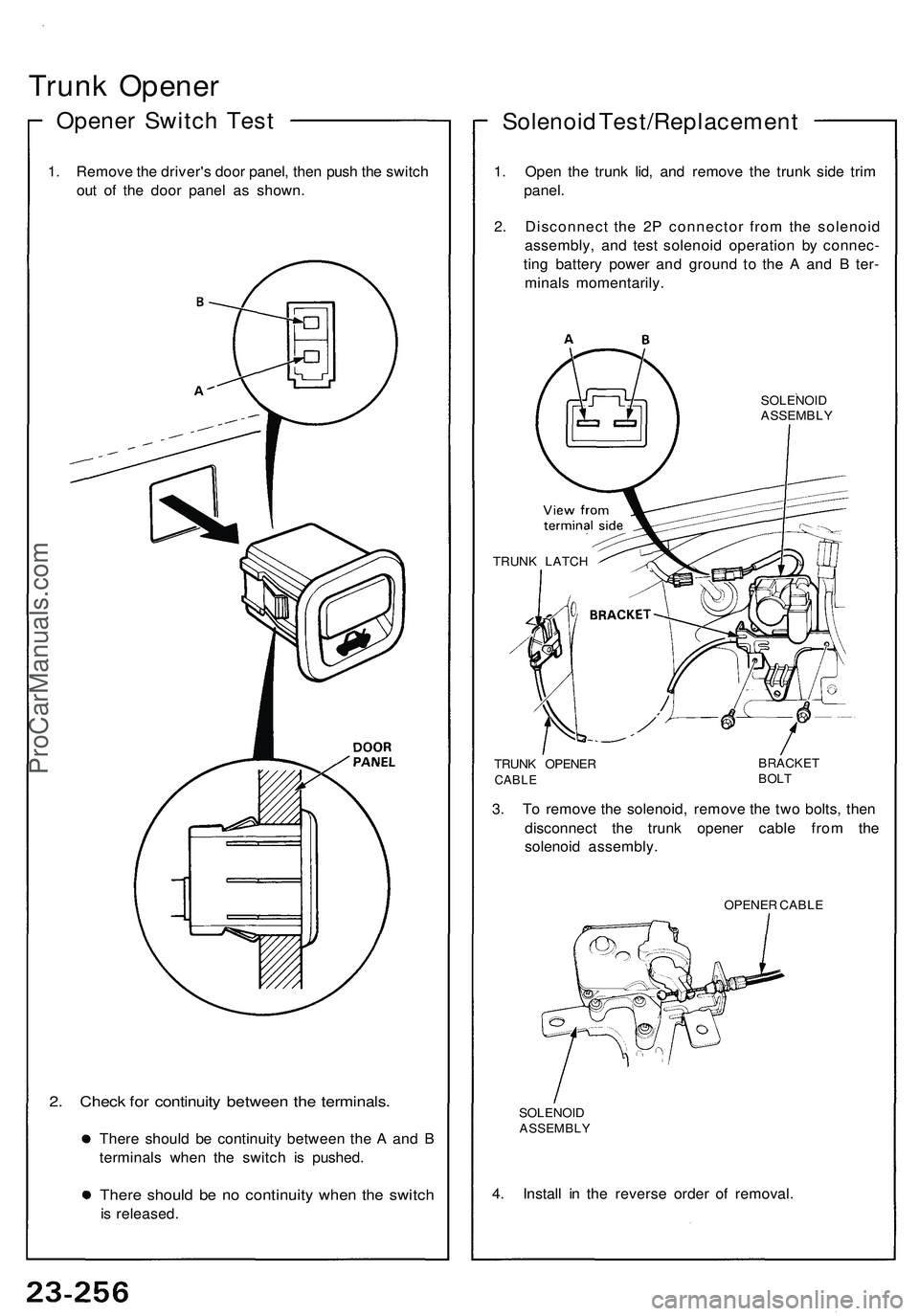

Trunk Opener

Opener Switch Test

1. Remove the driver's door panel, then push the switch

out of the door panel as shown.

2. Check for continuity between the terminals.

There should be continuity between the A and B

terminals when the switch is pushed.

There should be no continuity when the switch

is released.

Solenoid Test/Replacement

1. Open the trunk lid, and remove the trunk side trim

panel.

2. Disconnect the 2P connector from the solenoid

assembly, and test solenoid operation by connec-

ting battery power and ground to the A and B ter-

minals momentarily.

SOLENOID

ASSEMBLY

TRUNK LATCH

TRUNK OPENER

CABLE

BRACKET

BOLT

3. To remove the solenoid, remove the two bolts, then

disconnect the trunk opener cable from the

solenoid assembly.

OPENER CABLE

SOLENOID

ASSEMBLY

4. Install in the reverse order of removal.ProCarManuals.com

Trending: air bleeding, rear view mirror, height adjustment, jump start terminals, engine overheat, clutch, spark plugs replace