ACURA NSX 1997 Service Repair Manual

Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 521 of 1503

Engine Coolant Refilling and Bleeding

CAUTION: When pouring engine coolant, be sure to

shut the relay box lid and not let coolant spill on the

electrical parts or the paint. If any coolant spills, rinse it

off immediately.

NOTE:

• Perform this maintenance when the engine is cool.

• Before replacing the coolant, turn the ignition ON,

slowly turn the climate control temperature knob to

90° and turn off the ignition. This will allow the

coolant in the heater to drain out with the rest of the

system.

1. Open the hood, the rear window and the engine

cover.

2. Remove the cover protecting the water pipes and

shift cables on the underside of the car.

3. Before removing the expansion tank cap, first

loosen the cap to lower pressure.

CAUTION: Do not remove the expansion tank cap

when engine is hot. The coolant is under pressure

and may blow out and scald you. Open the cap

slowly when the engine is cool.

4. Loosen the drain plug in the bottom of the radiator,

and drain the coolant.

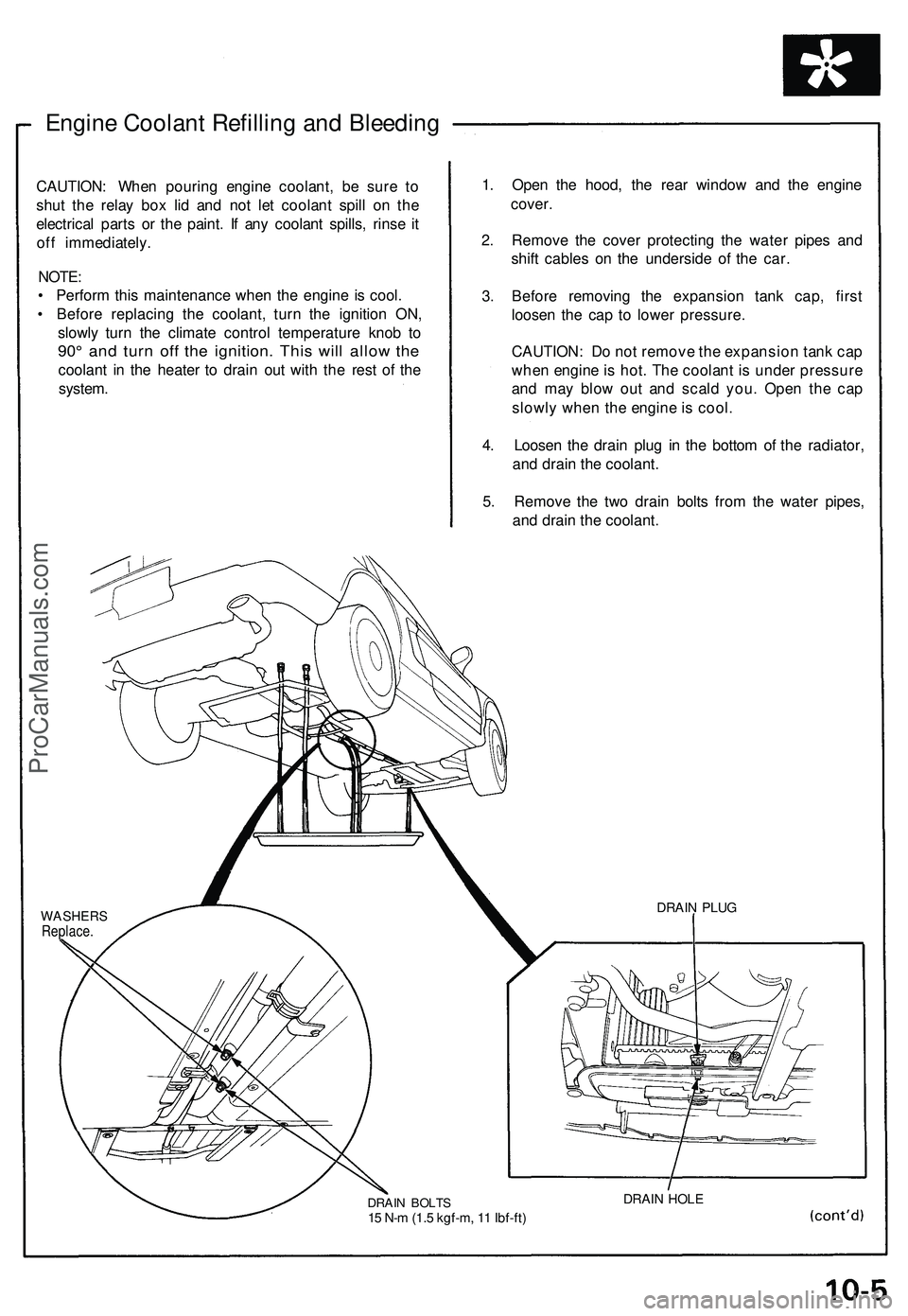

5. Remove the two drain bolts from the water pipes,

and drain the coolant.

WASHERS

Replace.

DRAIN BOLTS

15 N-m (1.5 kgf-m, 11 Ibf-ft)

DRAIN HOLE

DRAIN PLUGProCarManuals.com

Page 522 of 1503

Radiator

Engine Coolan t Refillin g an d Bleedin g (cont'd)

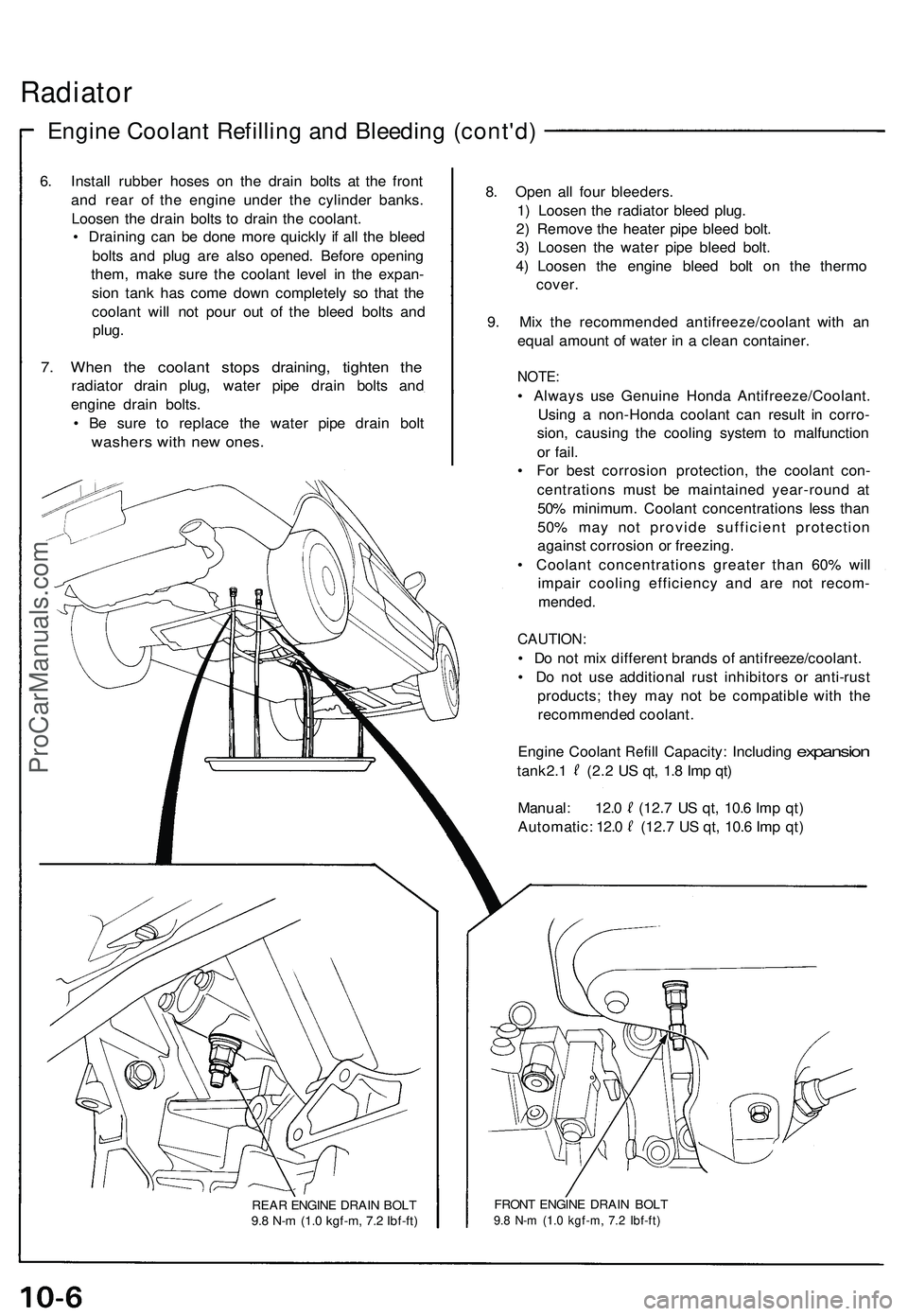

6. Instal l rubbe r hose s o n th e drai n bolt s a t th e fron t

an d rea r o f th e engin e unde r th e cylinde r banks .

Loose n th e drai n bolt s t o drai n th e coolant .

• Drainin g ca n b e don e mor e quickl y i f al l th e blee d

bolt s an d plu g ar e als o opened . Befor e openin g

them , mak e sur e th e coolan t leve l i n th e expan -

sio n tan k ha s com e dow n completel y s o tha t th e

coolan t wil l no t pou r ou t o f th e blee d bolt s an d

plug .

7. Whe n th e coolan t stop s draining , tighte n th e

radiato r drai n plug , wate r pip e drai n bolt s an d

engin e drai n bolts .

• B e sur e t o replac e th e wate r pip e drai n bol t

washer s wit h ne w ones .

REAR ENGIN E DRAI N BOL T

9. 8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )

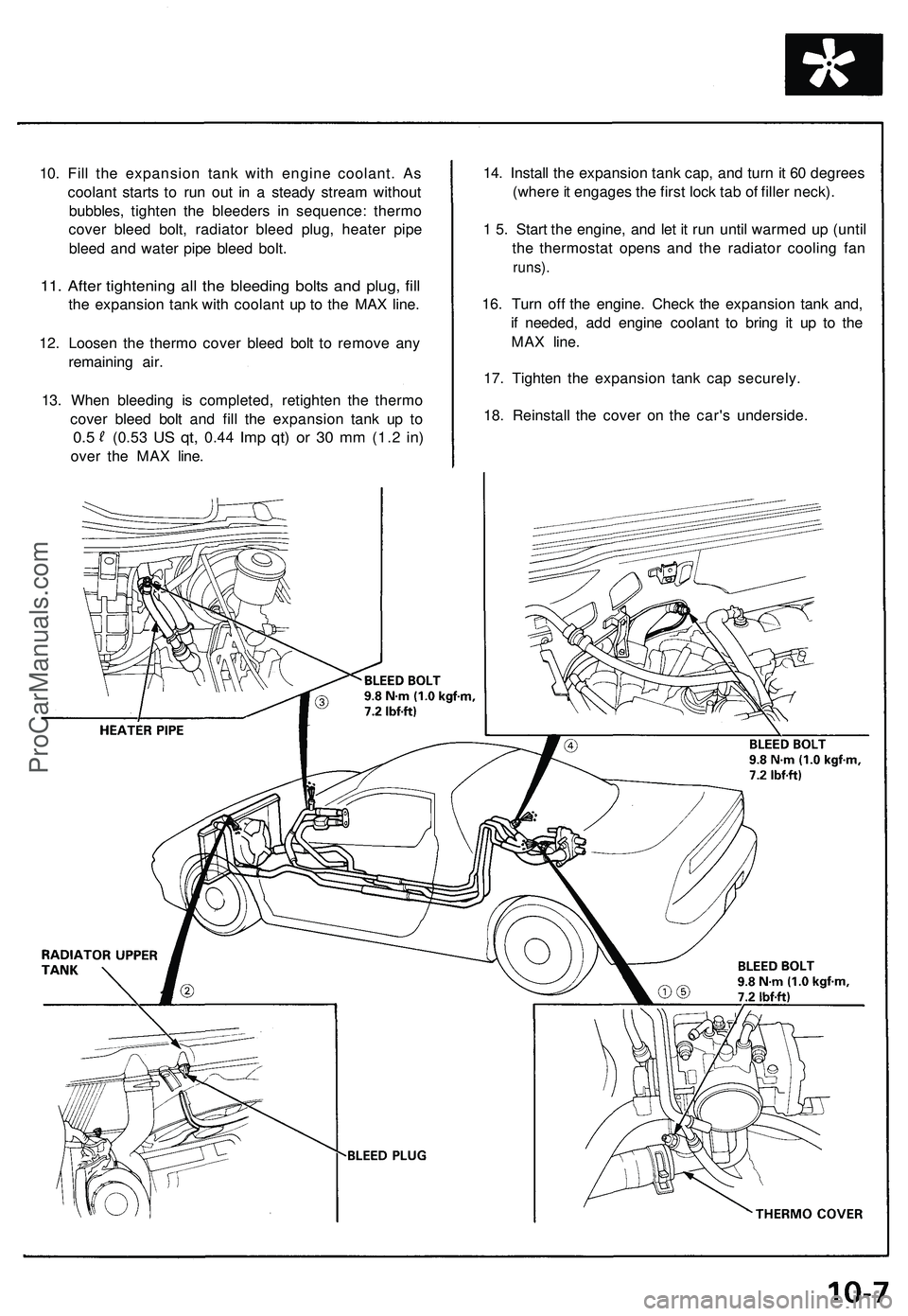

8. Ope n al l fou r bleeders .

1 ) Loose n th e radiato r blee d plug .

2 ) Remov e th e heate r pip e blee d bolt .

3 ) Loose n th e wate r pip e blee d bolt .

4 ) Loose n th e engin e blee d bol t o n th e therm o

cover .

9 . Mi x th e recommende d antifreeze/coolan t wit h a n

equa l amoun t o f wate r i n a clea n container .

NOTE:

• Alway s us e Genuin e Hond a Antifreeze/Coolant .

Usin g a non-Hond a coolan t ca n resul t i n corro -

sion , causin g th e coolin g syste m to malfunctio n

o r fail .

• Fo r bes t corrosio n protection , th e coolan t con -

centration s mus t b e maintaine d year-roun d a t

50 % minimum . Coolan t concentration s les s tha n

50 % ma y no t provid e sufficien t protectio n

agains t corrosio n o r freezing .

• Coolan t concentration s greate r tha n 60 % wil l

impai r coolin g efficienc y an d ar e no t recom -

mended .

CAUTION :

• D o no t mi x differen t brand s o f antifreeze/coolant .

• D o no t us e additiona l rus t inhibitor s o r anti-rus t

products ; the y ma y no t b e compatibl e wit h th e

recommende d coolant .

Engin e Coolan t

Refill Capacity : Includin g expansion

tank 2. 1 (2. 2 U S qt , 1. 8 Im p qt )

Manual : 12. 0 (12. 7 U S qt , 10. 6 Im p qt )

Automatic : 12. 0 (12. 7 U S qt , 10. 6 Im p qt )

FRON T ENGIN E DRAI N BOL T9.8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )

ProCarManuals.com

Page 523 of 1503

10. Fill the expansion tank with engine coolant. As

coolant starts to run out in a steady stream without

bubbles, tighten the bleeders in sequence: thermo

cover bleed bolt, radiator bleed plug, heater pipe

bleed and water pipe bleed bolt.

11. After tightening all the bleeding bolts and plug, fill

the expansion tank with coolant up to the MAX line.

12. Loosen the thermo cover bleed bolt to remove any

remaining air.

13. When bleeding is completed, retighten the thermo

cover bleed bolt and fill the expansion tank up to

0.5

(0.53

US qt,

0.44

Imp qt) or 30 mm

(1.2

in)

over the MAX line.

14. Install the expansion tank cap, and turn it 60 degrees

(where it engages the first lock tab of filler neck).

1 5. Start the engine, and let it run until warmed up (until

the thermostat opens and the radiator cooling fan

runs).

16. Turn off the engine. Check the expansion tank and,

if needed, add engine coolant to bring it up to the

MAX line.

17. Tighten the expansion tank cap securely.

18. Reinstall the cover on the car's underside.ProCarManuals.com

Page 524 of 1503

Expansion Tan k

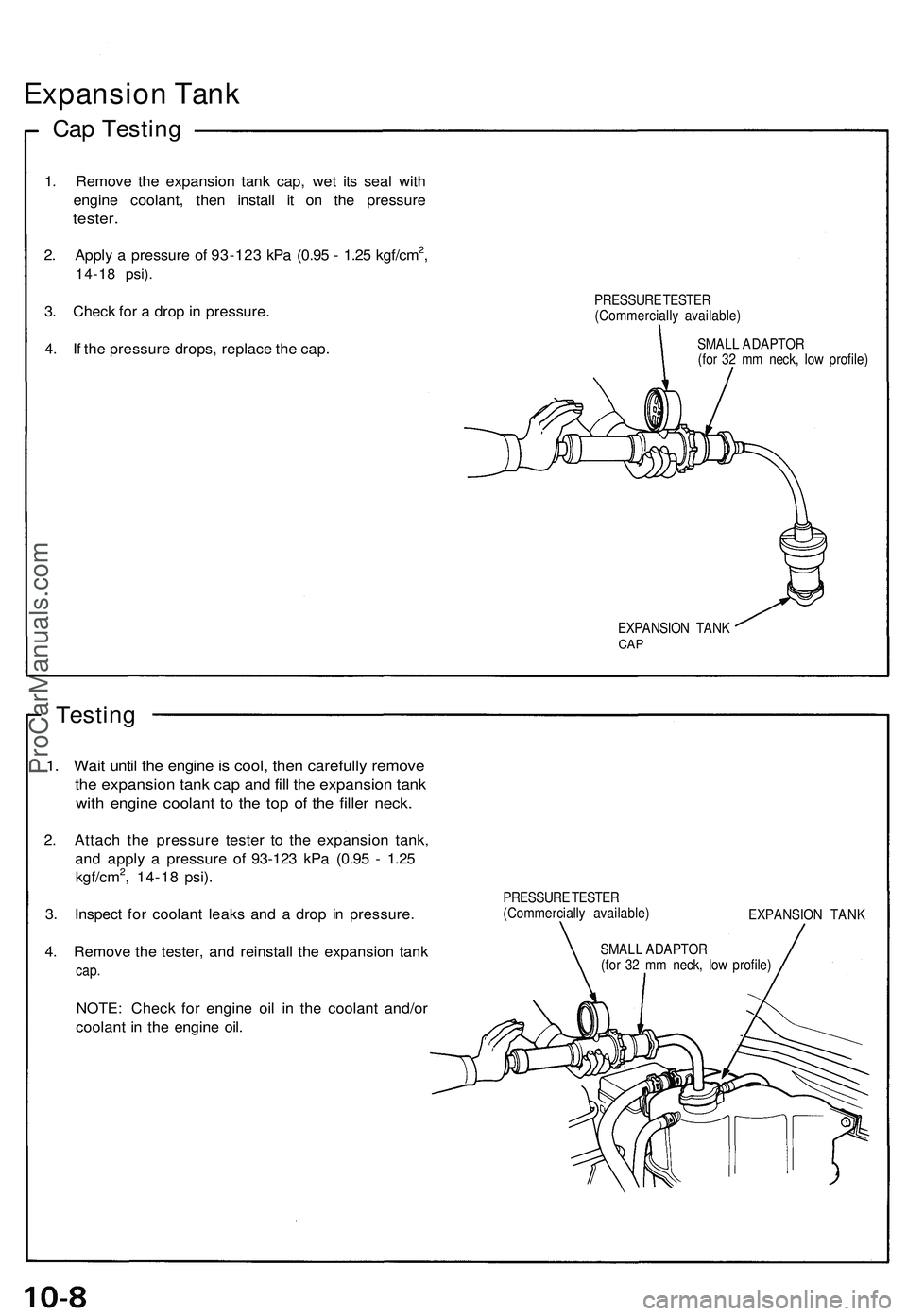

Cap Testin g

1. Remov e th e expansio n tan k cap , we t it s sea l wit h

engin e coolant , the n instal l i t o n th e pressur e

tester.

2. Appl y a pressur e o f 93-12 3 kP a (0.9 5 - 1.2 5 kgf/cm2,

14-1 8 psi) .

3. Chec k fo r a dro p in pressure .

4 . I f th e pressur e drops , replac e th e cap .PRESSUR E TESTE R

(Commerciall y available )

SMAL L ADAPTO R

(fo r 3 2 m m neck , lo w profile )

EXPANSIO N TAN K

CAP

Testin g

1. Wai t unti l th e engin e is cool , the n carefull y remov e

the expansio n tan k ca p an d fil l th e expansio n tan k

with engin e coolan t t o th e to p of the fille r neck .

2. Attac h th e pressur e teste r t o th e expansio n tank ,

an d appl y a pressur e o f 9 3-12 3 kP a (0.9 5 - 1.2 5

kgf/cm

2, 14-1 8 psi) .

3 . Inspec t fo r coolan t leak s an d a dro p i n pressure .

4 . Remov e th e tester , an d reinstal l th e expansio n tan k

cap.

NOTE : Chec k fo r engin e oi l i n th e coolan t and/o r

coolan t i n th e engin e oil .

PRESSUR E TESTE R

(Commerciall y available )

EXPANSION TAN K

SMAL L ADAPTO R

(fo r 3 2 m m neck , lo w profile )

ProCarManuals.com

Page 525 of 1503

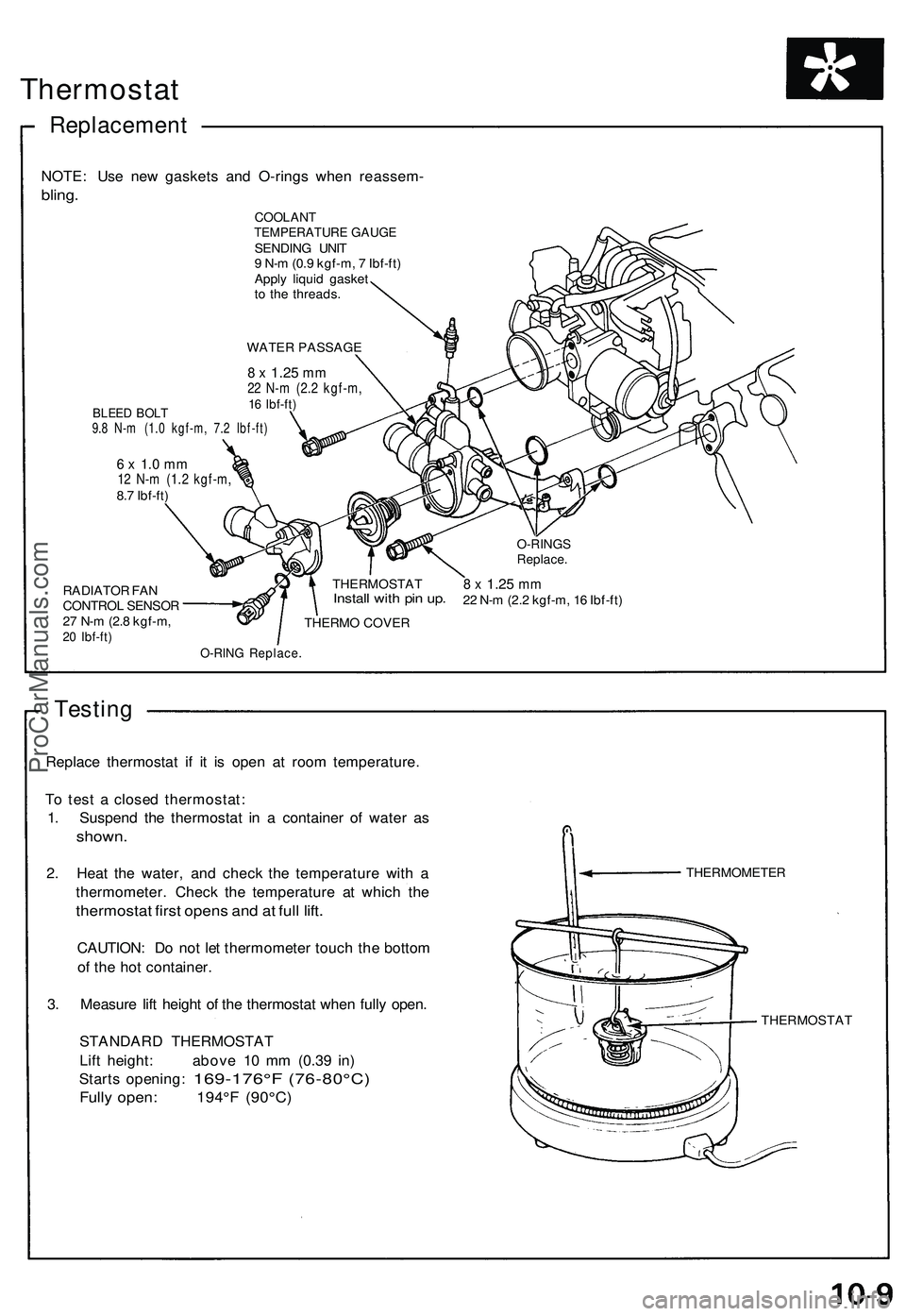

Thermostat

Replacemen t

NOTE: Us e ne w gasket s an d O-ring s whe n reassem -

bling.

COOLAN TTEMPERATUR E GAUG ESENDIN G UNI T

9 N- m (0. 9 kgf-m , 7 Ibf-ft )

Appl y liqui d gaske t

t o th e threads .

WATE R PASSAG E

BLEED BOL T9.8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,16 Ibf-ft )

RADIATO R FA N

CONTRO L SENSO R

2 7 N- m (2. 8 kgf-m ,

20 Ibf-ft )

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,8.7 Ibf-ft )

THERMOSTAT

Install wit h pi n up .

THERM O COVE R

8 x 1.2 5 mm22 N- m (2. 2 kgf-m , 1 6 Ibf-ft )

O-RIN G Replace .

Testing

Replac e thermosta t i f i t i s ope n a t roo m temperature .

T o tes t a close d thermostat :

1 . Suspen d th e thermosta t i n a containe r o f wate r a s

shown .

2. Hea t th e water , an d chec k th e temperatur e wit h a

thermometer . Chec k th e temperatur e a t whic h th e

thermosta t firs t open s an d a t ful l lift .

CAUTION : D o no t le t thermomete r touc h th e botto m

o f th e ho t container .

3 . Measur e lif t heigh t o f th e thermosta t whe n full y open .

STANDAR D THERMOSTA T

Lif t height : abov e 1 0 m m (0.3 9 in )

Start s opening :

169-176° F (76-80°C)

Fully open : 194° F (90°C )

THERMOMETE R

THERMOSTA T

O-RINGSReplace .

ProCarManuals.com

Page 526 of 1503

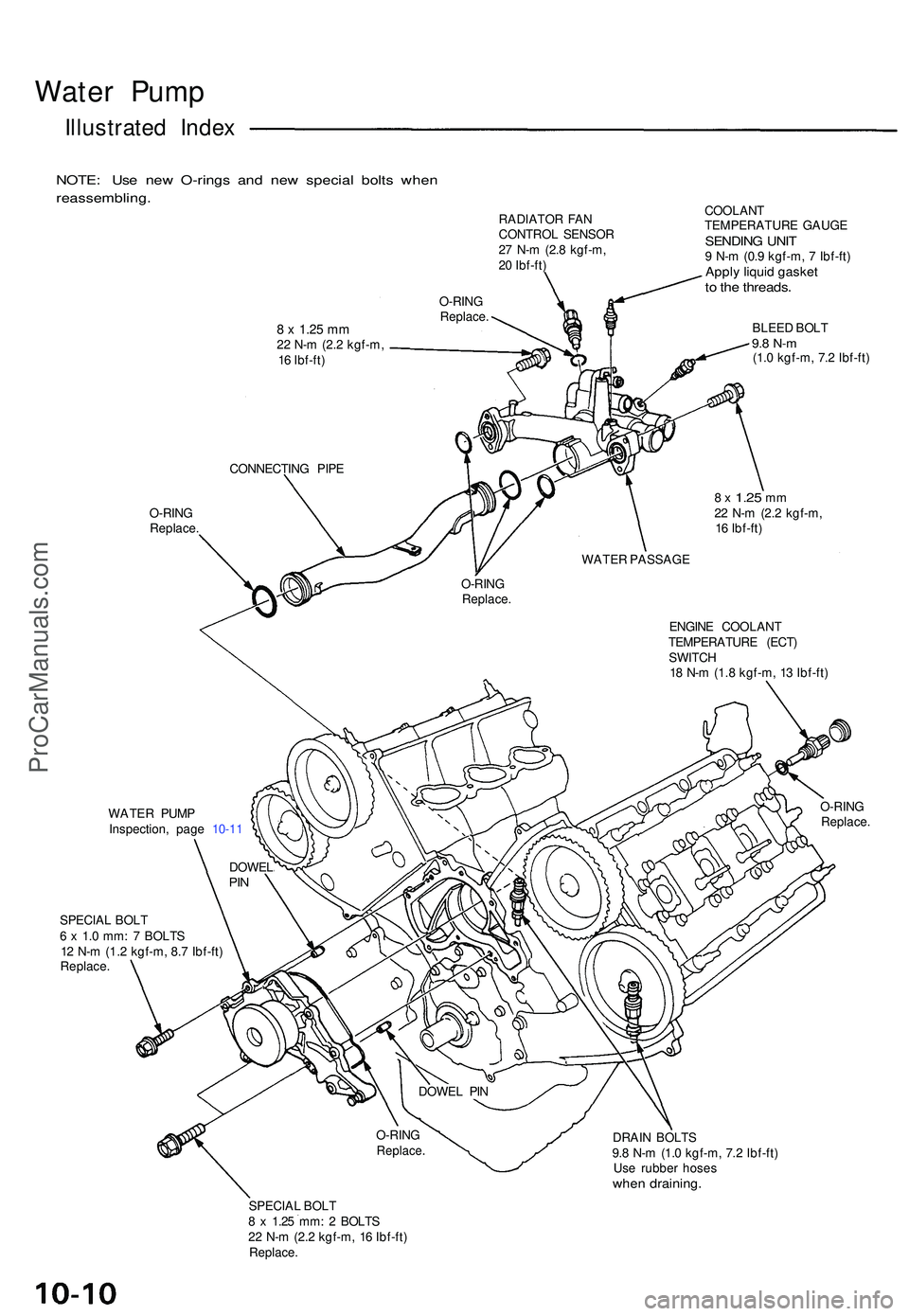

Water Pum p

Illustrate d Inde x

NOTE : Us e ne w O-ring s an d ne w specia l bolt s whe n

reassembling .

RADIATOR FA N

CONTRO L SENSO R

2 7 N- m (2. 8 kgf-m ,

2 0 Ibf-ft )

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft ) O-RIN

G

Replace .

O-RING

Replace . COOLAN

T

TEMPERATUR E GAUG E

SENDIN G UNI T9 N- m (0. 9 kgf-m , 7 Ibf-ft )Apply liqui d gaske tto th e threads .

BLEED BOL T9.8 N- m(1.0 kgf-m , 7. 2 Ibf-ft )

CONNECTIN G PIP E

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

WATE R PASSAG E

O-RIN G

Replace .

ENGINE COOLAN T

TEMPERATUR E (ECT )

SWITC H

1 8 N- m (1. 8 kgf-m , 1 3 Ibf-ft )

WATE R PUM P

Inspection , pag e 10-1 1 O-RIN

G

Replace .

SPECIAL BOL T

6 x 1. 0 mm : 7 BOLT S

1 2 N- m (1.2 kgf-m , 8. 7 Ibf-ft )

Replace .

DRAIN BOLT S

9. 8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )

Us e rubbe r hose s

when draining .

SPECIAL BOL T

8 x 1.2 5 mm : 2 BOLT S

2 2 N- m (2. 2 kgf-m , 1 6 Ibf-ft )

Replace .

DOWELPIN

DOWE L PI N

O-RIN G

Replace .

ProCarManuals.com

Page 527 of 1503

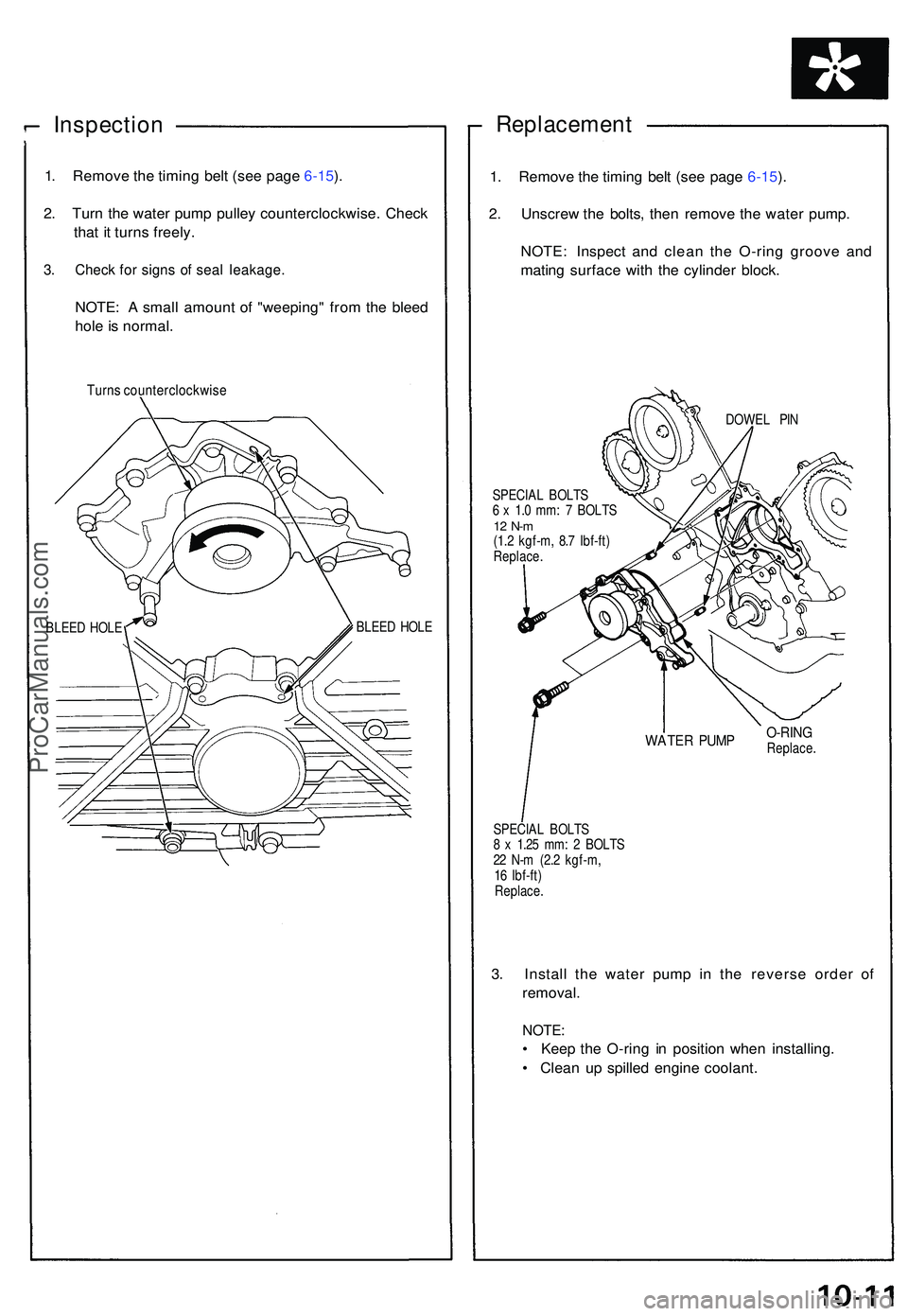

Inspection

1. Remov e th e timin g bel t (se e pag e 6-15 ).

2 . Tur n th e wate r pum p pulle y counterclockwise . Chec k

tha t i t turn s freely .

3. Chec k fo r sign s o f sea l leakage .

NOTE: A smal l amoun t o f "weeping " fro m th e blee d

hol e is normal .

Turns counterclockwis e

BLEED HOL E BLEE

D HOL E

Replacemen t

1. Remov e th e timin g bel t (se e pag e 6-15 ).

2 . Unscre w th e bolts , the n remov e th e wate r pump .

NOTE : Inspec t an d clea n th e O-rin g groov e an d

matin g surfac e wit h th e cylinde r block .

DOWE L PI N

SPECIA L BOLT S

6 x 1. 0 mm : 7 BOLT S

12 N- m(1.2 kgf-m , 8. 7 Ibf-ft )

Replace .

O-RINGReplace .

SPECIA L BOLT S

8 x 1.2 5 mm : 2 BOLT S

2 2 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

Replace .

3. Instal l th e wate r pum p i n th e revers e orde r o f

removal .

NOTE:

• Kee p th e O-rin g i n positio n whe n installing .

• Clea n u p spille d engin e coolant .

WATER PUM P

ProCarManuals.com

Page 528 of 1503

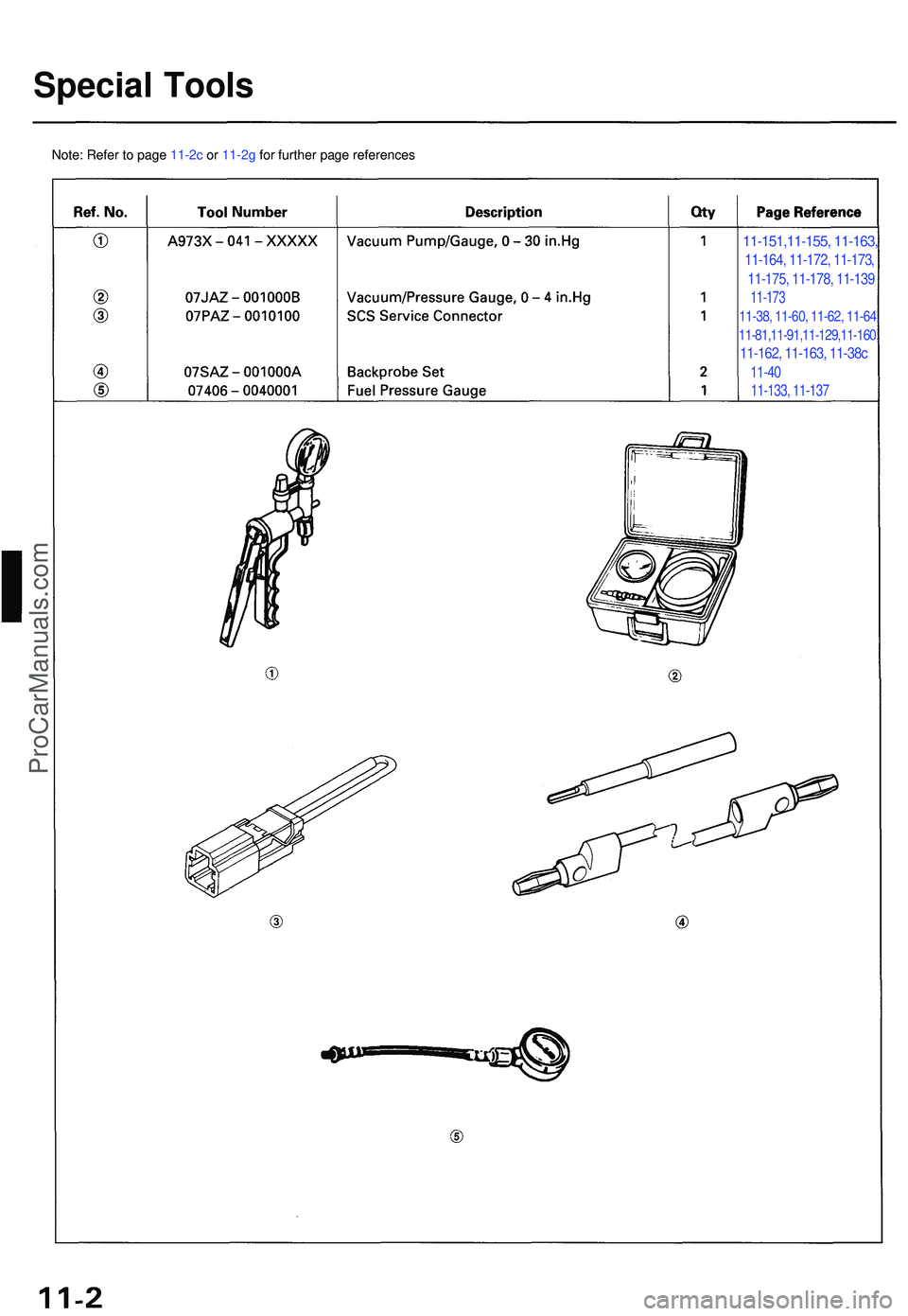

Special Tool s

11-151,11-155, 11-163,

11-164, 11-172, 11-173,

11-175, 11-178, 11-139

11-173

11-38, 11-60, 11-62, 11-64,

11-81,11-91,11-129,11-160,

11-162, 11-163, 11-38c

11-40

11-133, 11-137

Note: Refer to page 11-2c or 11-2g for further page references

ProCarManuals.com

Page 529 of 1503

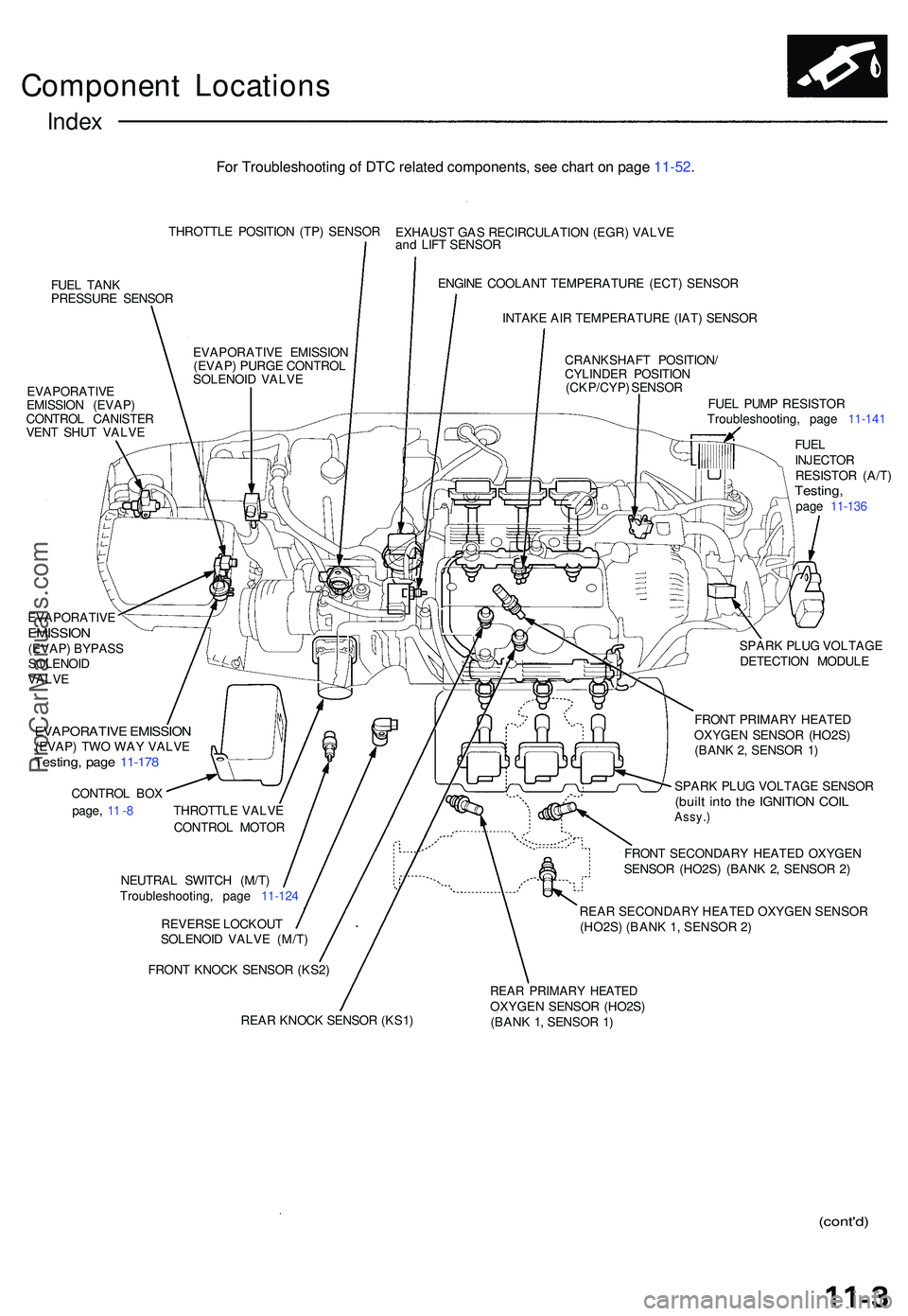

Component Location s

Index

THROTTL E POSITIO N (TP ) SENSO R

FUE L TAN K

PRESSUR E SENSO R

EVAPORATIV E

EMISSIO N (EVAP )

CONTRO L CANISTE R

VEN T SHU T VALV E EXHAUS

T GA S RECIRCULATIO N (EGR ) VALV E

an d LIF T SENSO R

ENGIN E COOLAN T TEMPERATUR E (ECT ) SENSO R

INTAK E AI R TEMPERATUR E (IAT ) SENSO R

CRANKSHAF T POSITION /

CYLINDE R POSITIO N

(CKP/CYP ) SENSO R

FUEL PUM P RESISTO R

Troubleshooting , pag e 11-14 1

FUE L

INJECTO R

RESISTO R (A/T )

Testing ,page 11-13 6

EVAPORATIV

E EMISSIO N

(EVAP ) PURG E CONTRO L

SOLENOI D VALV E

EVAPORATIV E

EMISSION(EVAP) BYPAS S

SOLENOI D

VALV E

EVAPORATIV E EMISSIO N(EVAP) TW O WA Y VALV ETesting , pag e 11-17 8

CONTRO L BO X

page , 1 1 -8 THROTTL E VALV E

CONTRO L MOTO R

NEUTRA L SWITC H (M/T )

Troubleshooting , pag e 11-12 4

REVERS E LOCKOU T

SOLENOI D VALV E (M/T )

FRON T KNOC K SENSO R (KS2 ) SPAR

K PLU G VOLTAG E

DETECTIO N MODUL E

FRON T PRIMAR Y HEATE D

OXYGEN SENSOR (HO2S )

(BAN K 2 , SENSO R 1 )

SPAR K PLU G VOLTAG E SENSO R(built int o th e IGNITIO N COI LAssy. )

FRONT SECONDAR Y HEATE D OXYGE N

SENSO R (HO2S ) (BAN K 2 , SENSO R 2 )

REAR SECONDARY HEATED OXYGEN SENSOR (HO2S) (BANK 1, SENSOR 2)

REA R KNOC K SENSO R (KS1 )

REAR PRIMAR Y HEATE DOXYGEN SENSO R (HO2S )

(BAN K 1 , SENSO R 1 )

(cont'd )

For Troubleshooting of DTC related components, see chart on page 11-52.

ProCarManuals.com

Page 530 of 1503

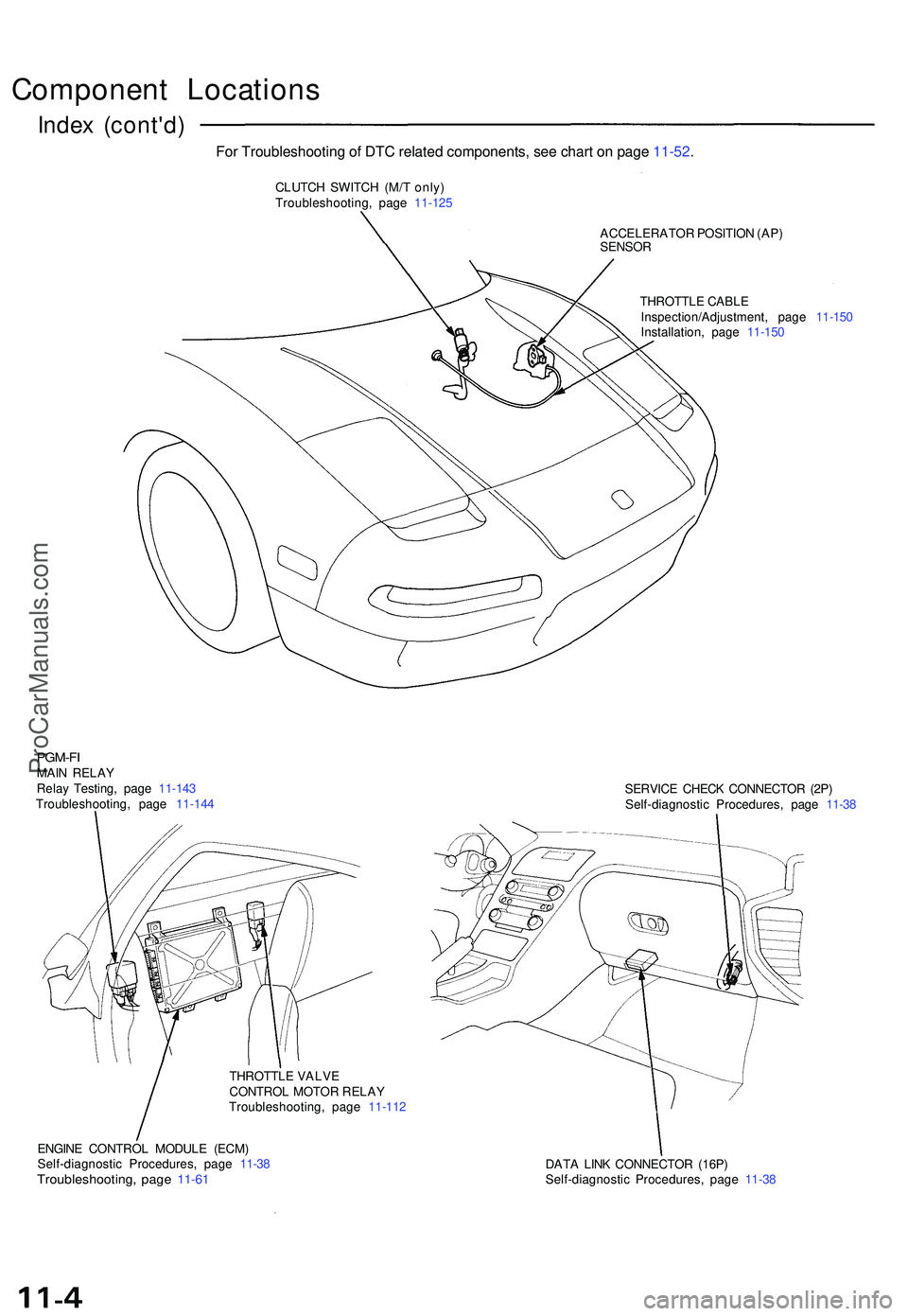

Component Location s

Index (cont'd )

CLUTCH SWITC H (M/ T only )

Troubleshooting , pag e 11-12 5

ACCELERATOR POSITIO N (AP )

SENSO R

THROTTL E CABL E

Inspection/Adjustment , pag e 11-15 0

Installation , pag e 11-15 0

PGM-FIMAIN RELA Y

Rela y Testing , pag e 11-14 3

Troubleshooting , pag e 11-14 4 SERVIC

E CHEC K CONNECTO R (2P )

Self-diagnosti c Procedures , pag e 11-3 8

THROTTL E VALV E

CONTRO L MOTO R RELA Y

Troubleshooting , pag e 11-11 2

ENGIN E CONTRO L MODUL E (ECM )

Self-diagnosti c Procedures , pag e 11-3 8

Troubleshooting , pag e 11-6 1DAT A LIN K CONNECTO R (16P )

Self-diagnosti c Procedures , pag e 11-3 8

For Troubleshooting of DTC related components, see chart on page 11-52.

ProCarManuals.com