ACURA NSX 1997 Service Repair Manual

Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 491 of 1503

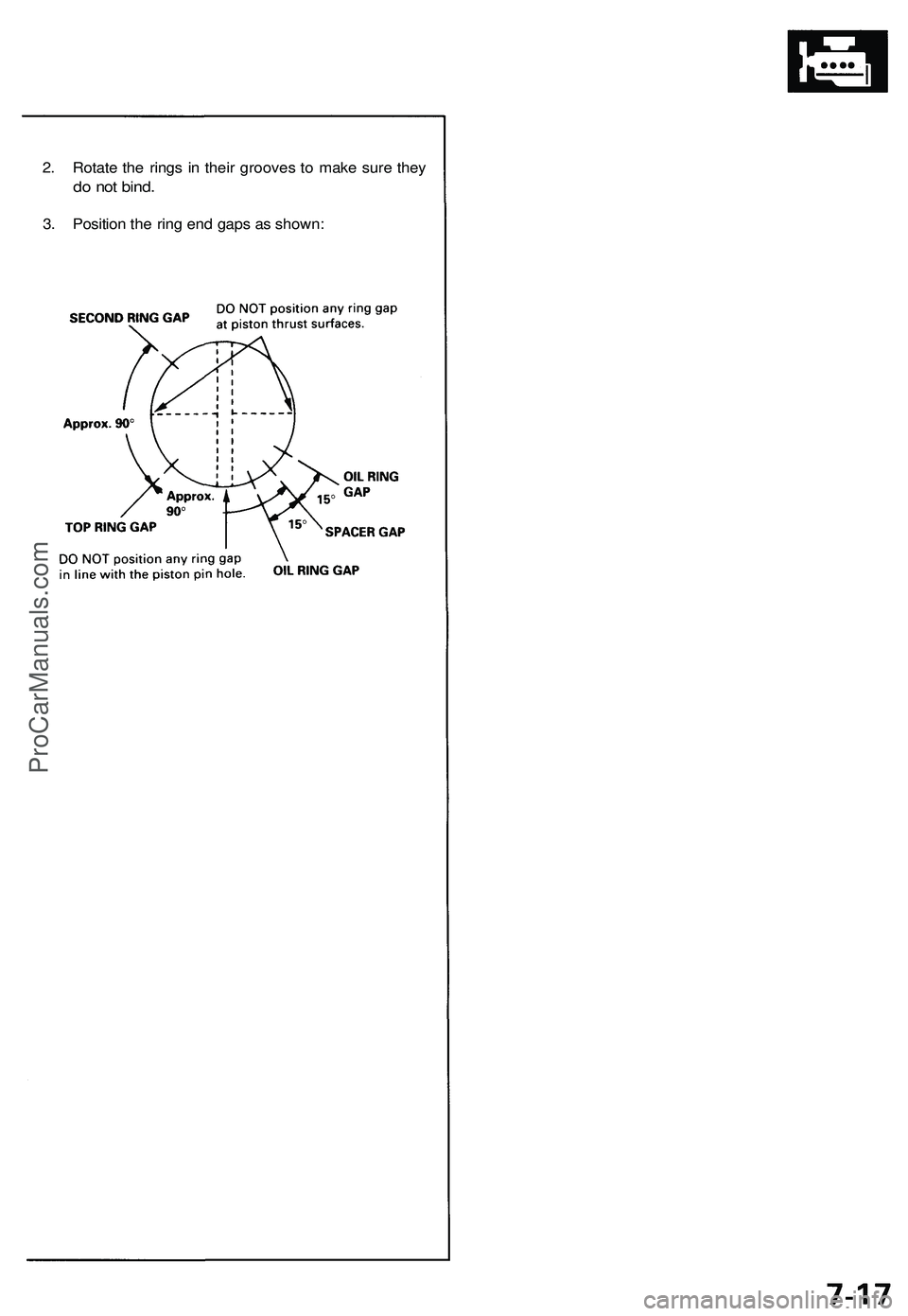

2. Rotate the rings in their grooves to make sure they

do not bind.

3. Position the ring end gaps as shown:ProCarManuals.com

Page 492 of 1503

Piston/Connecting

Rod Assemblie s

Installation

Before installin g th e piston , appl y a coa t o f

engin e oi l t o th e rin g groove s an d cylinde r

bores.

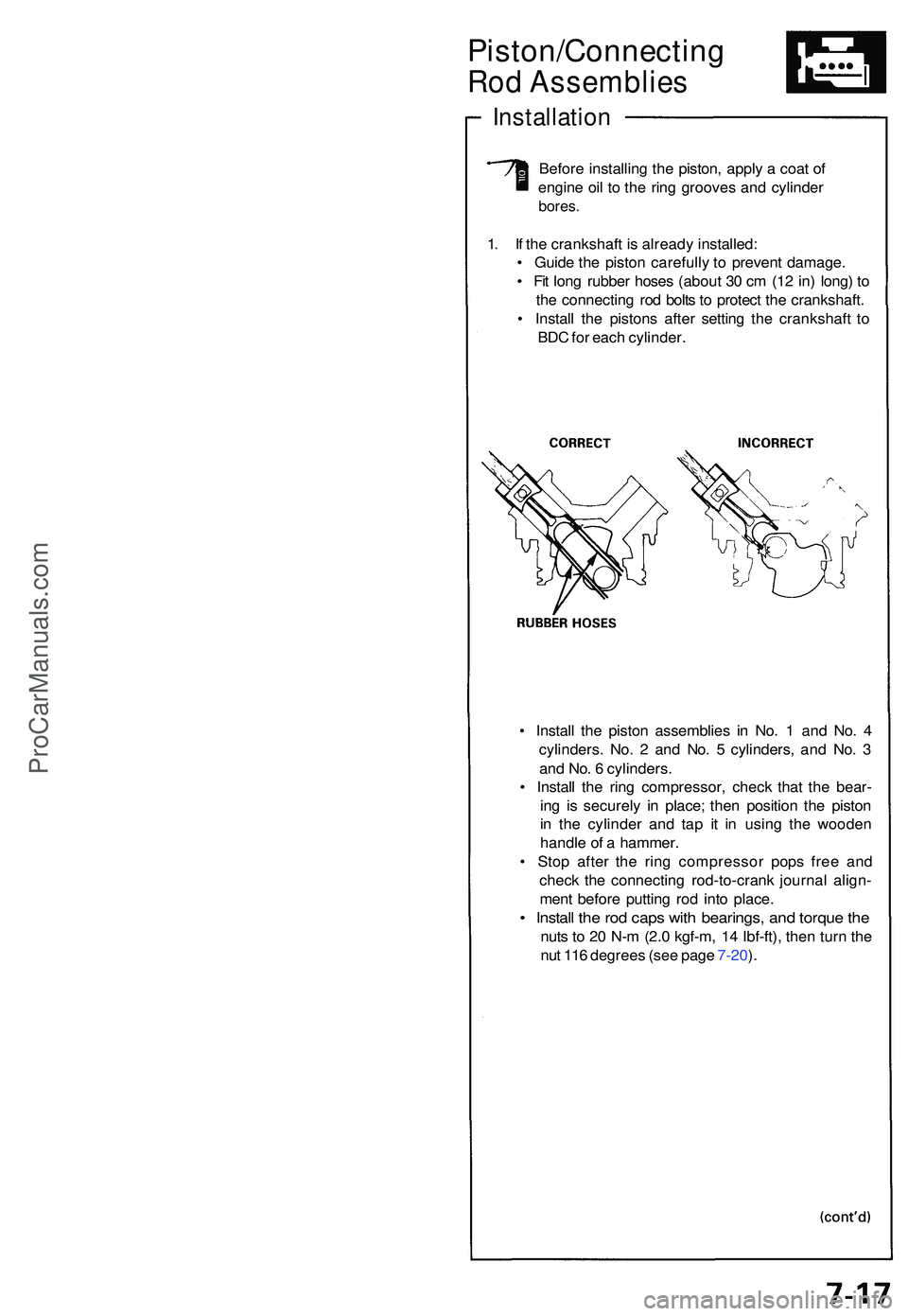

1. I f th e crankshaf t i s alread y installed :

• Guid e th e pisto n carefull y t o preven t damage .

• Fi t lon g rubbe r hose s (abou t 3 0 c m (1 2 in ) long ) t o

th e connectin g ro d bolt s t o protec t th e crankshaft .

• Instal l th e piston s afte r settin g th e crankshaf t t o

BD C fo r eac h cylinder .

• Instal l th e pisto n assemblie s i n No . 1 an d No . 4

cylinders . No . 2 an d No . 5 cylinders , an d No . 3

an d No . 6 cylinders .

• Instal l th e rin g compressor , chec k tha t th e bear -

in g i s securel y i n place ; the n positio n th e pisto n

i n th e cylinde r an d ta p i t i n usin g th e woode n

handl e o f a hammer .

• Sto p afte r th e rin g compresso r pop s fre e an d

chec k th e connectin g rod-to-cran k journa l align -

men t befor e puttin g ro d int o place .

• Instal l th e ro d cap s wit h bearings , an d torqu e th e

nut s t o 2 0 N- m (2. 0 kgf-m , 1 4 Ibf-ft) , the n tur n th e

nu t 11 6 degree s (se e pag e 7-20 ).

ProCarManuals.com

Page 493 of 1503

Piston/Connecting Ro d

Assemblie s

Installation (cont'd )

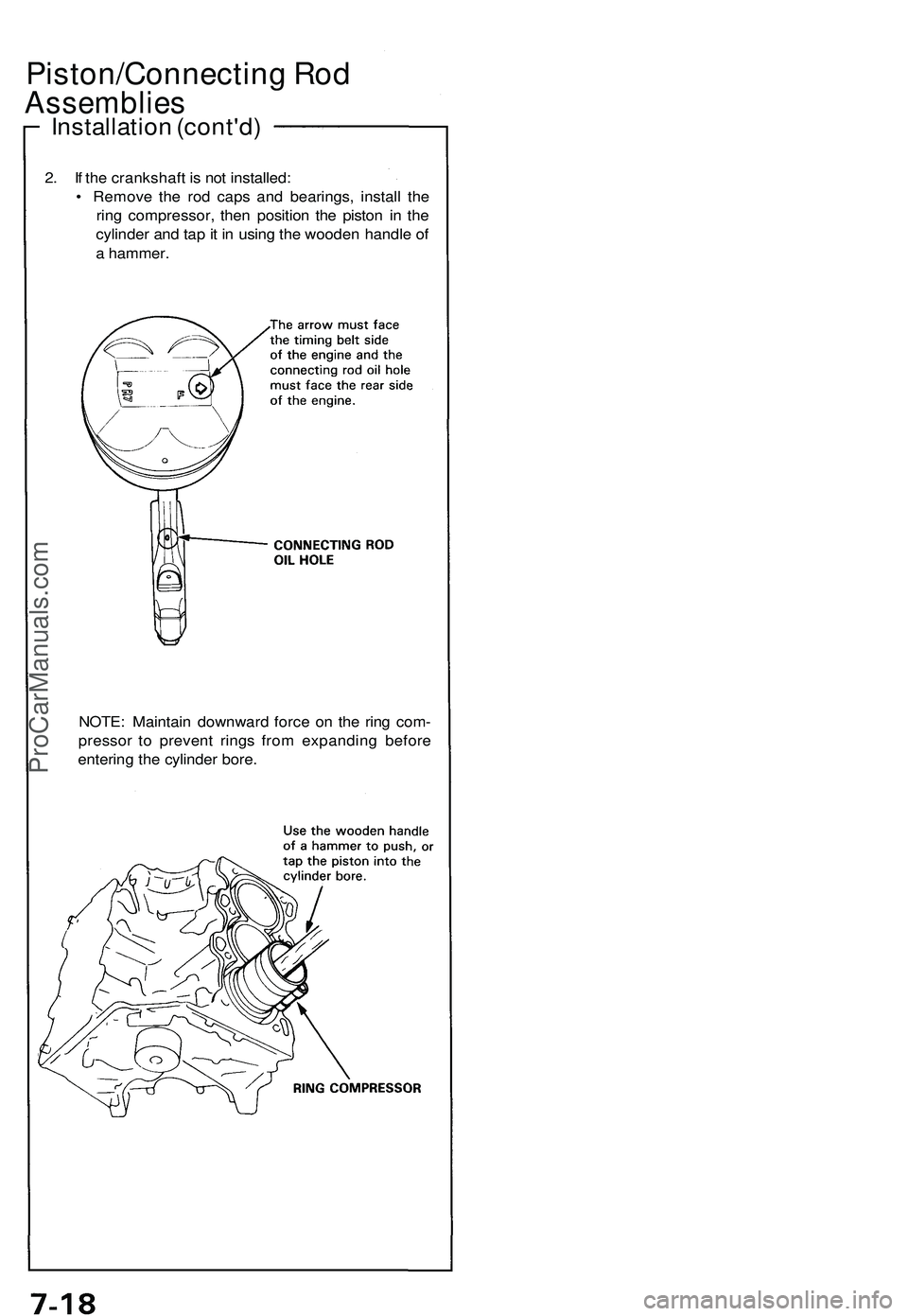

2. I f th e crankshaf t i s no t installed :

• Remov e th e ro d cap s an d bearings , instal l th e

rin g compressor , the n positio n th e pisto n i n th e

cylinde r an d ta p it i n usin g th e woode n handl e o f

a hammer.

NOTE : Maintai n downwar d forc e o n th e rin g com -

presso r t o preven t ring s fro m expandin g befor e

enterin g th e cylinde r bore .

ProCarManuals.com

Page 494 of 1503

NOTE: Refe r t o pag e 8- 9 fo r installatio n o f th e oi l

pum p sid e oi l seal .

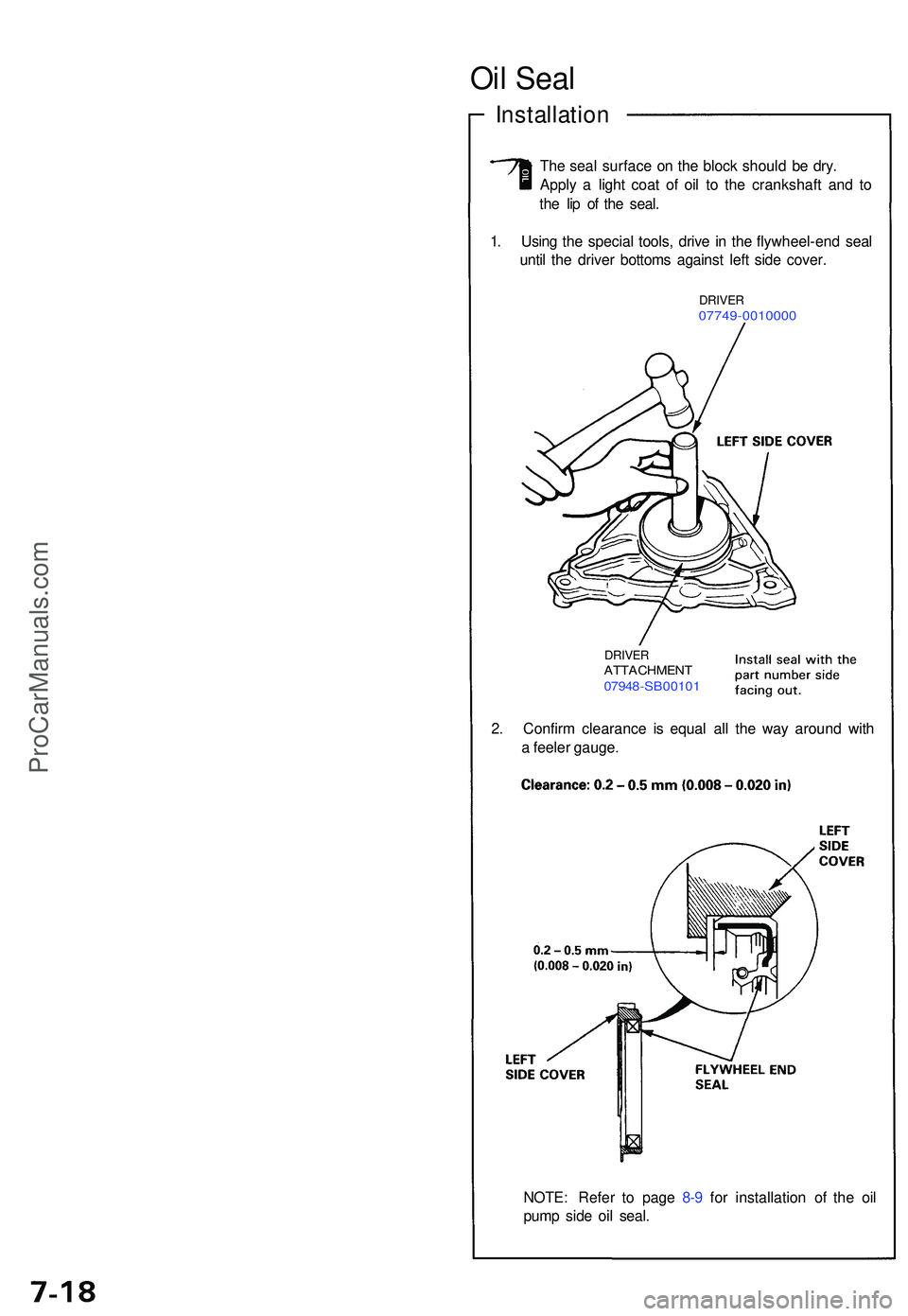

2

. Confir m clearanc e i s equa l al l th e wa y aroun d wit h

a feele r gauge .

DRIVERATTACHMEN T07948-SB0010 1

1. Usin g th e specia l tools , driv e i n th e flywheel-en d sea l

unti l th e drive r bottom s agains t lef t sid e cover .

DRIVE R07749-001000 0

The sea l surfac e o n th e bloc k shoul d b e dry .

Appl y a ligh t coa t o f oi l t o th e crankshaf t an d t o

th e li p o f th e seal .

Oil Sea l

Installatio n

ProCarManuals.com

Page 495 of 1503

Crankshaft

Installation

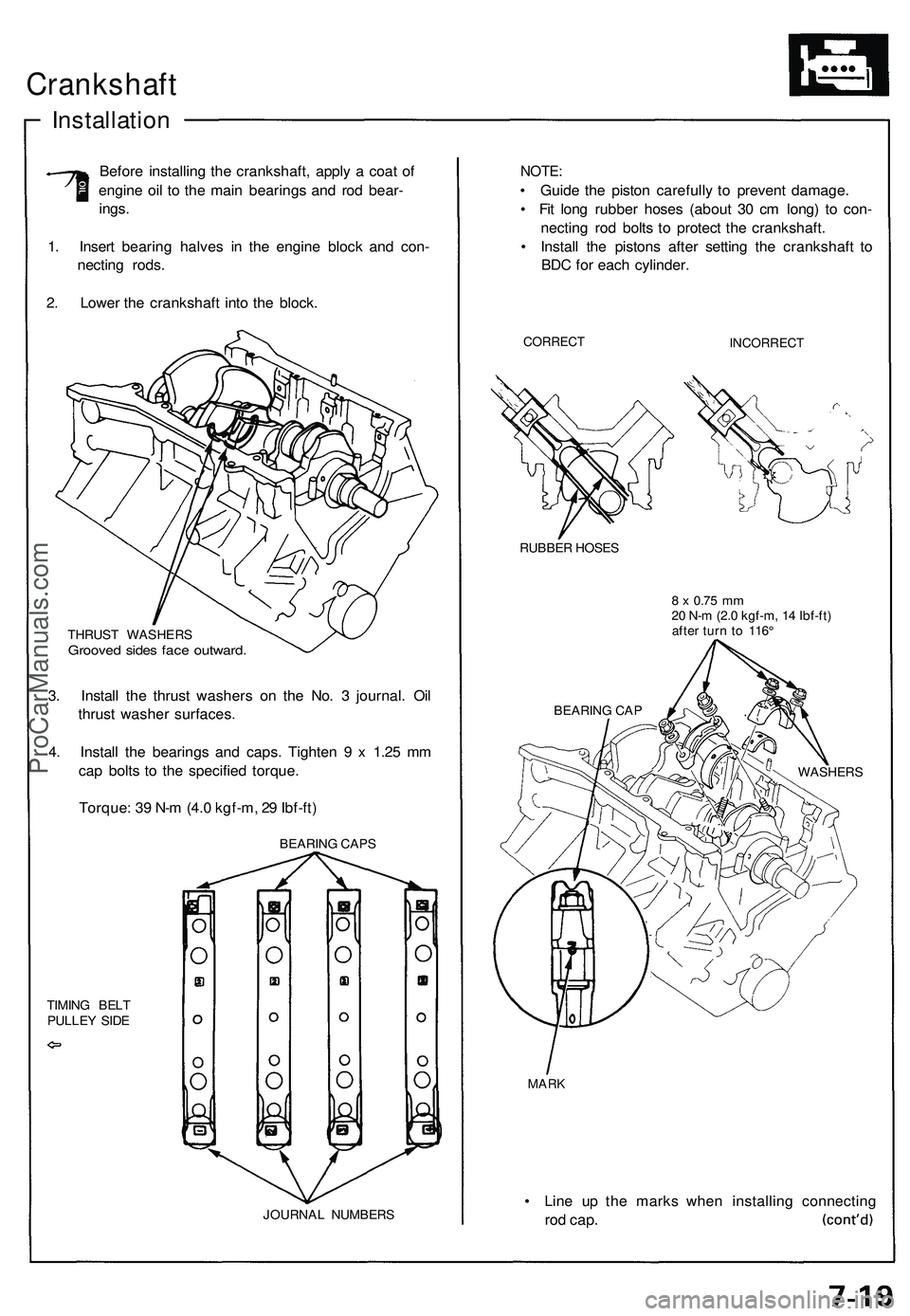

Before installing the crankshaft, apply a coat of

engine oil to the main bearings and rod bear-

ings.

1. Insert bearing halves in the engine block and con-

necting rods.

2. Lower the crankshaft into the block.

THRUST WASHERS

Grooved sides face outward.

3. Install the thrust washers on the No. 3 journal. Oil

thrust washer surfaces.

4. Install the bearings and caps. Tighten 9 x 1.25 mm

cap bolts to the specified torque.

Torque: 39 N-m (4.0 kgf-m, 29 Ibf-ft)

TIMING BELT

PULLEY SIDE

JOURNAL NUMBERS

NOTE:

• Guide the piston carefully to prevent damage.

• Fit long rubber hoses (about 30 cm long) to con-

necting rod bolts to protect the crankshaft.

• Install the pistons after setting the crankshaft to

BDC for each cylinder.

CORRECT

INCORRECT

RUBBER HOSES

8 x

0.75

mm

20 N-m (2.0 kgf-m, 14 Ibf-ft)

after turn to 116°

MARK

• Line up the marks when installing connecting

rod

cap.

BEARING CAP

WASHERS

BEARING CAPSProCarManuals.com

Page 496 of 1503

Crankshaft

Installation (cont'd )

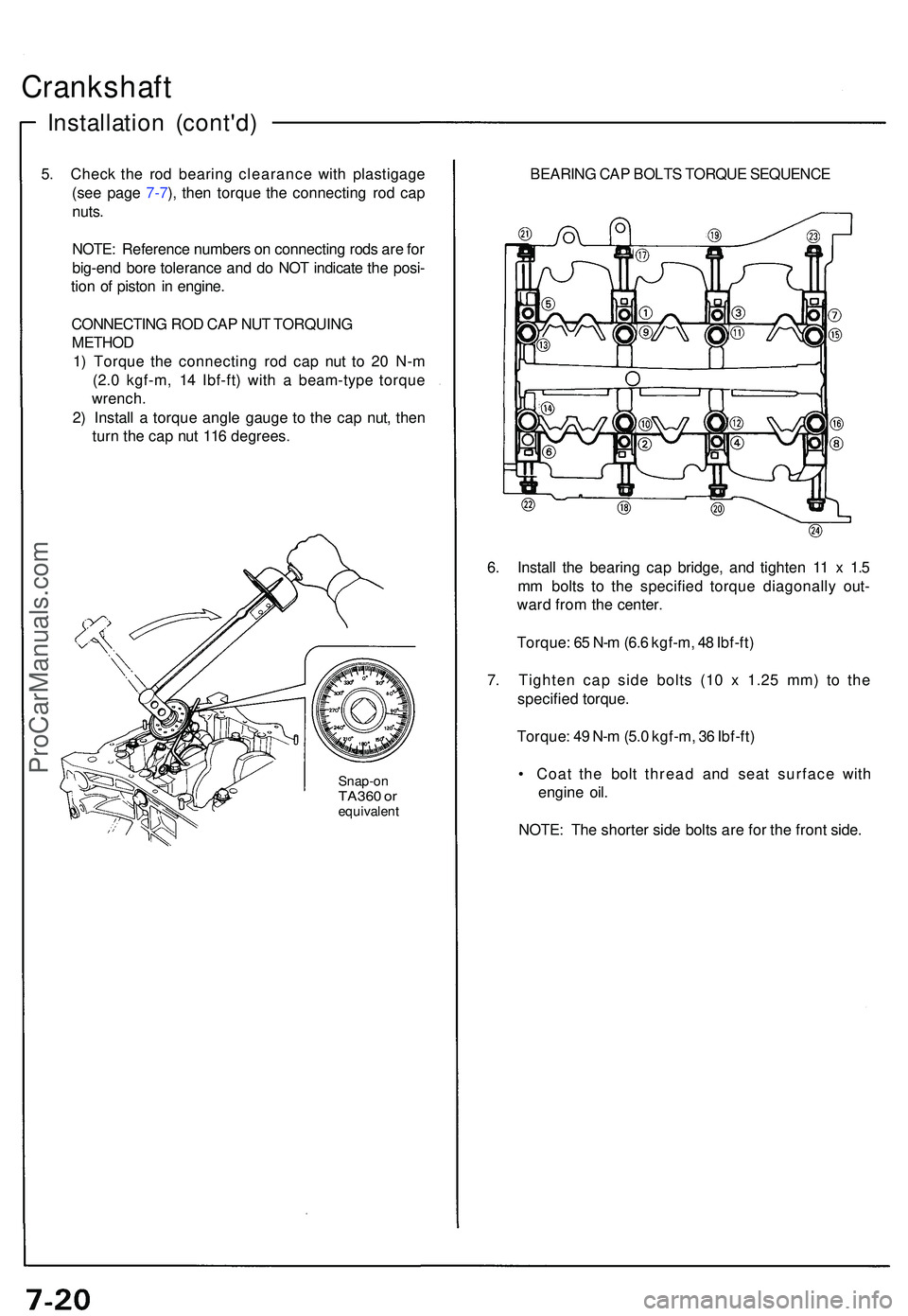

5. Chec k th e ro d bearin g clearanc e wit h plastigag e

(se e pag e 7-7 ), the n torqu e th e connectin g ro d ca p

nuts .

NOTE : Referenc e number s o n connectin g rod s ar e fo r

big-en d bor e toleranc e an d d o NO T indicat e th e posi -

tio n o f pisto n i n engine .

CONNECTIN G RO D CA P NU T TORQUIN G

METHO D

1 ) Torqu e th e connectin g ro d ca p nu t t o 2 0 N- m

(2. 0 kgf-m , 1 4 Ibf-ft ) wit h a beam-typ e torqu e

wrench .

2 ) Instal l a torqu e angl e gaug e t o th e ca p nut , the n

tur n th e ca p nu t 11 6 degrees .

Snap-onTA360 o requivalen t

BEARING CAP BOLTS TORQUE SEQUENCE

6 . Instal l th e bearin g ca p bridge , an d tighte n 1 1 x 1. 5

m m bolt s t o th e specifie d torqu e diagonall y out -

war d fro m th e center .

Torque : 6 5 N- m (6. 6 kgf-m , 4 8 Ibf-ft )

7 . Tighte n ca p sid e bolt s (1 0 x 1.2 5 mm ) t o th e

specifie d torque .

Torque : 4 9 N- m (5. 0 kgf-m , 3 6 Ibf-ft )

• Coa t th e bol t threa d an d sea t surfac e wit h

engin e oil .

NOTE : Th e shorte r sid e bolt s ar e fo r th e fron t side .

ProCarManuals.com

Page 497 of 1503

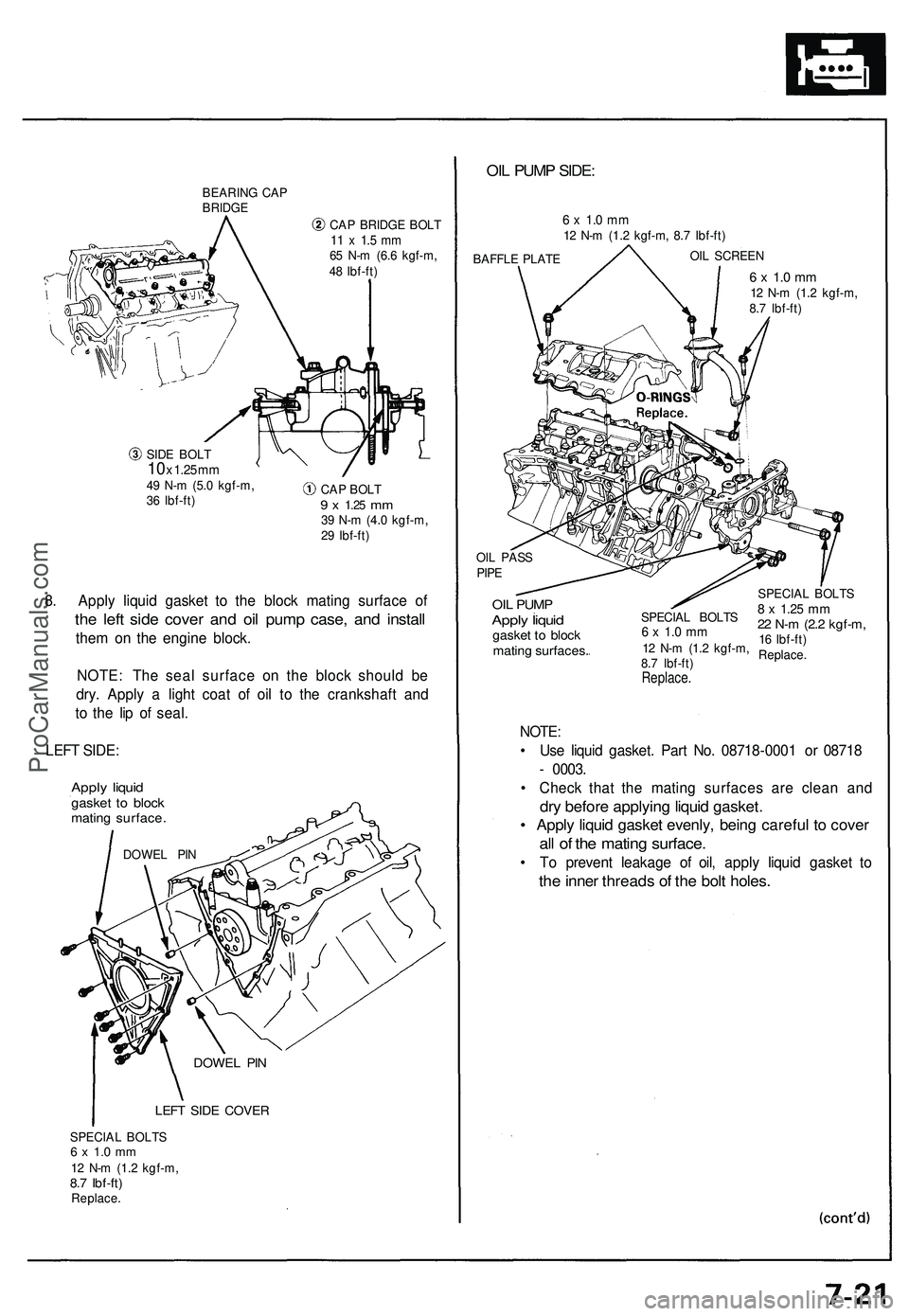

BEARING CA P

BRIDG E

CAP BRIDG E BOL T

11 x 1. 5 m m65 N- m (6. 6 kgf-m ,

4 8 Ibf-ft )

SID E BOL T

10 x 1.2 5 m m49 N- m (5. 0 kgf-m ,

3 6 Ibf-ft ) CA

P BOL T

9 x 1.2 5 mm39 N- m (4. 0 kgf-m ,

2 9 Ibf-ft )

8. Appl y liqui d gaske t t o th e bloc k matin g surfac e o f

the lef t sid e cove r an d oi l pum p case , an d instal l

them o n th e engine block.

NOTE : Th e sea l surfac e o n th e bloc k shoul d b e

dry . Appl y a ligh t coa t o f oi l t o th e crankshaf t an d

t o th e li p o f seal .

LEF T SIDE :

Apply liqui dgaske t t o bloc kmatin g surface .

LEFT SID E COVE R

SPECIA L BOLT S6 x 1. 0 m m12 N- m (1. 2 kgf-m ,8.7 Ibf-ft )Replace .

OIL PUM P SIDE :

6 x 1. 0 m m12 N- m (1. 2 kgf-m , 8. 7 Ibf-ft )

BAFFL E PLAT E OI

L SCREE N

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

OI L PAS S

PIPE

OIL PUM PApply liqui dgaske t t o bloc k

matin g surfaces .

NOTE:

SPECIA L BOLT S6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

Replace .

SPECIAL BOLT S8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,16 Ibf-ft )

Replace .

• Us e liqui d gasket . Par t No . 0871 8-000 1 o r 0871 8

- 0003 .

• Chec k tha t th e matin g surface s ar e clea n an d

dry befor e applyin g liqui d gasket .

• Appl y liqui d gaske t evenly , bein g carefu l t o cove r

all o f th e matin g surface .

• T o preven t leakag e o f oil , appl y liqui d gaske t t o

th e inne r thread s o f th e bol t holes .

DOWE L PI N

DOWE L PI N

ProCarManuals.com

Page 498 of 1503

Crankshaft

Installation (cont'd )

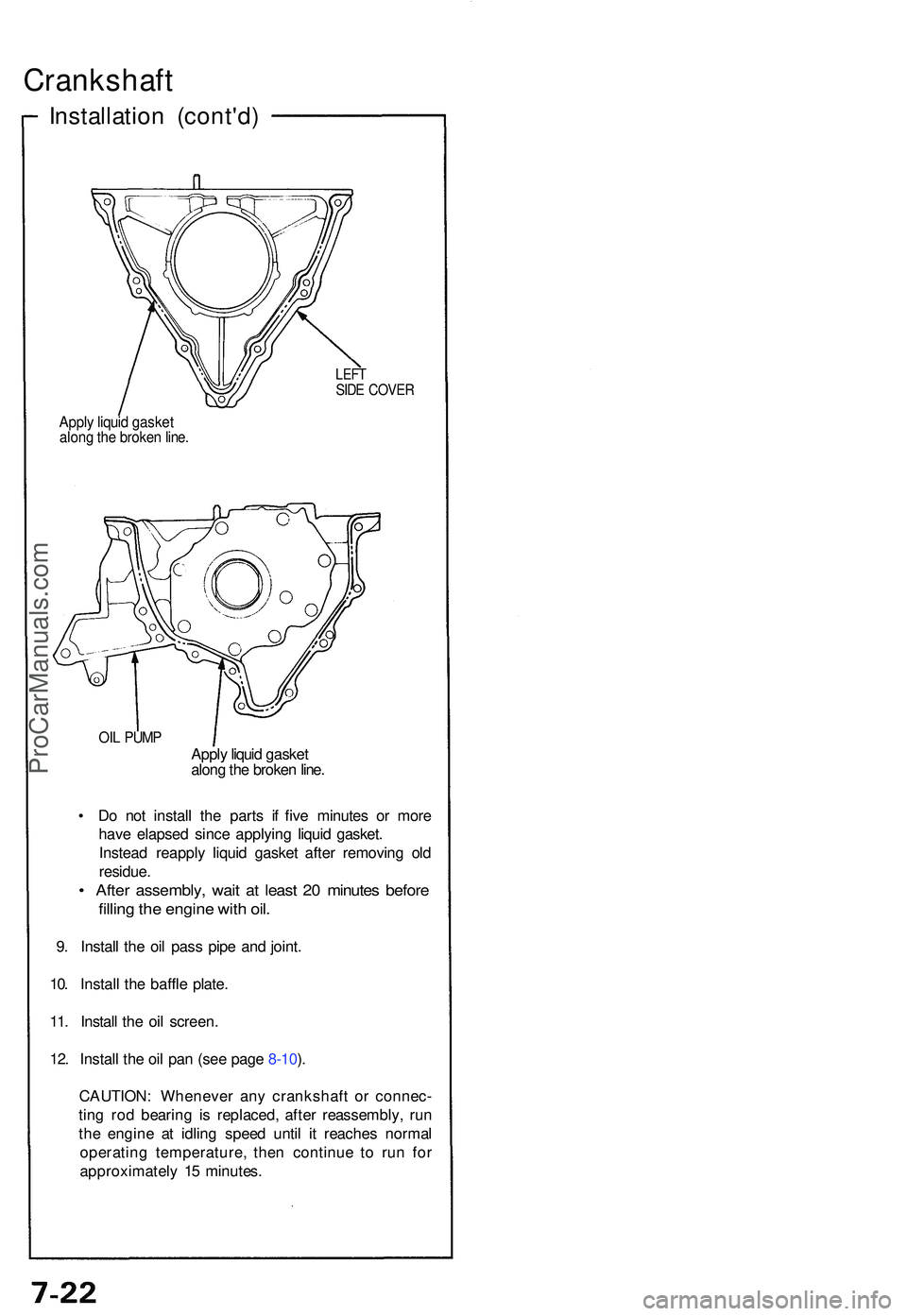

LEFTSIDE COVE R

Apply liqui d gaske talong th e broke n line .

OIL PUM PApply liqui d gaske t

alon g th e broke n line .

• D o no t instal l th e part s i f fiv e minute s o r mor e

hav e elapse d sinc e applyin g liqui d gasket .

Instea d reappl y liqui d gaske t afte r removin g ol d

residue .

• Afte r assembly , wai t a t leas t 2 0 minute s befor e

filling th e engin e wit h oil .

9. Instal l th e oi l pas s pip e an d joint .

10 . Instal l th e baffl e plate .

11 . Instal l th e oi l screen .

12 . Instal l th e oi l pa n (se e pag e 8-10 ).

CAUTION : Wheneve r an y crankshaf t o r connec -

tin g ro d bearin g i s replaced , afte r reassembly , ru n

th e engin e a t idlin g spee d unti l i t reache s norma l

operatin g temperature , the n continu e t o ru n fo r

approximatel y 1 5 minutes .

ProCarManuals.com

Page 499 of 1503

Special Tool s

8-9

8- 5

ProCarManuals.com

Page 500 of 1503

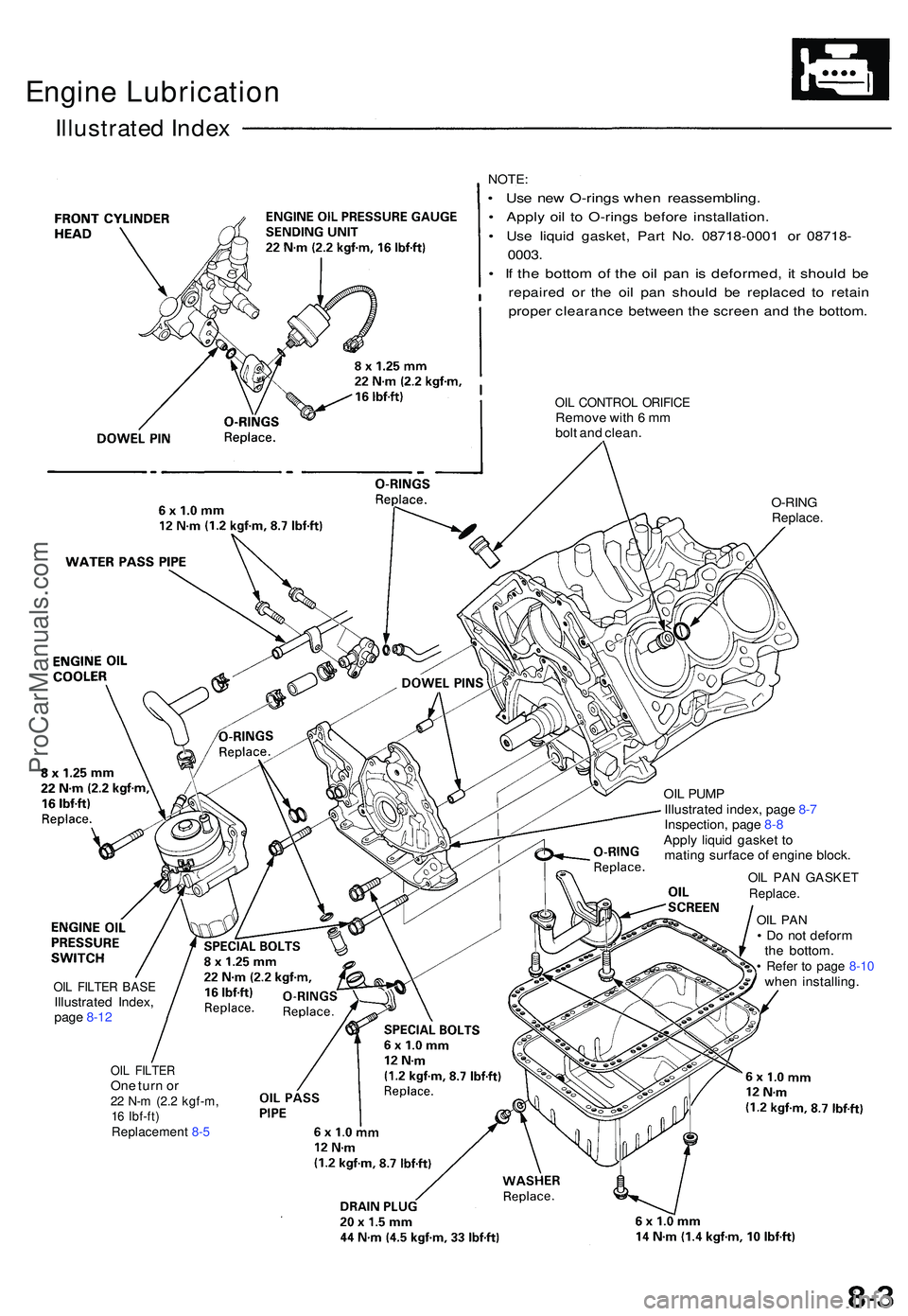

Engine Lubricatio n

Illustrated Index

NOTE:

• Us e ne w O-ring s whe n reassembling .

• Appl y oi l t o O-ring s befor e installation .

• Us e liqui d gasket , Par t No . 0871 8-000 1 o r 0871 8-

0003 .

• I f th e botto m o f th e oi l pa n i s deformed , i t shoul d b e

repaire d o r th e oi l pa n shoul d b e replace d t o retai n

prope r clearanc e betwee n th e scree n an d th e bottom .

OIL CONTRO L ORIFIC ERemove wit h 6 m m

bol t an d clean .

O-RIN GReplace .

OIL FILTE R BAS EIllustrate d Index ,

pag e 8-1 2

OIL FILTE ROne tur n o r22 N- m (2. 2 kgf-m ,16 Ibf-ft )Replacemen t 8- 5

OI L PUM P

Illustrate d index , pag e 8- 7

Inspection , pag e 8 -8

Appl y liqui d gaske t t o

matin g surfac e o f engin e block .

OIL PA N GASKE TReplace.

OIL PA N• D o no t defor m

th e bottom .

• Refe r t o pag e 8-1 0whe n installing .

ProCarManuals.com