sensor ACURA NSX 1997 Service Manual PDF

[x] Cancel search | Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 1013 of 1503

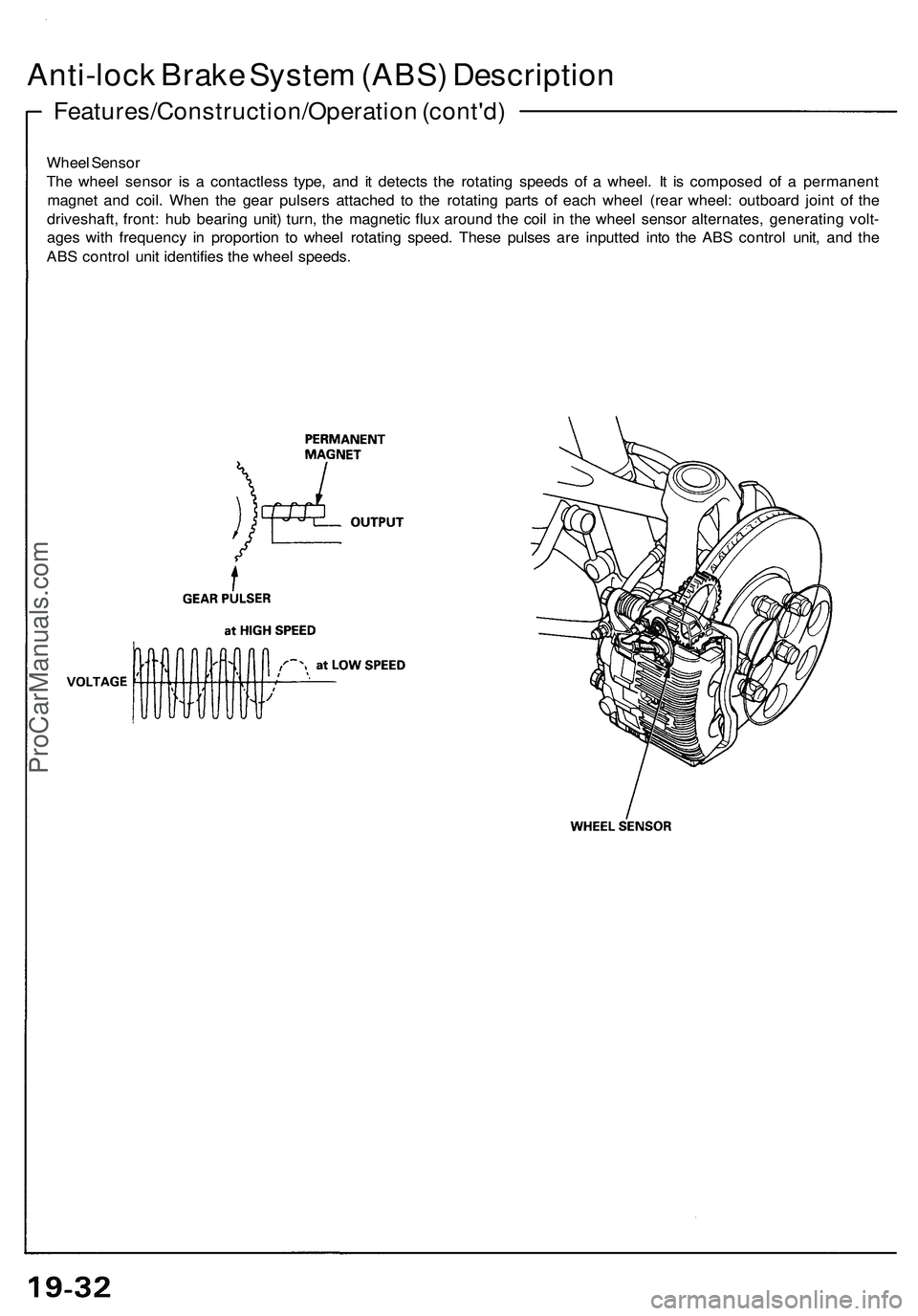

Wheel Sensor

The wheel sensor is a contactless type, and it detects the rotating speeds of a wheel. It is composed of a permanent

magnet and coil. When the gear pulsers attached to the rotating parts of each wheel (rear wheel: outboard joint of the

driveshaft, front: hub bearing unit) turn, the magnetic flux around the coil in the wheel sensor alternates, generating volt-

ages with frequency in proportion to wheel rotating speed. These pulses are inputted into the ABS control unit, and the

ABS control unit identifies the wheel speeds.

Features/Construction/Operation (cont'd)

Anti-lock Brake System (ABS) DescriptionProCarManuals.com

Page 1014 of 1503

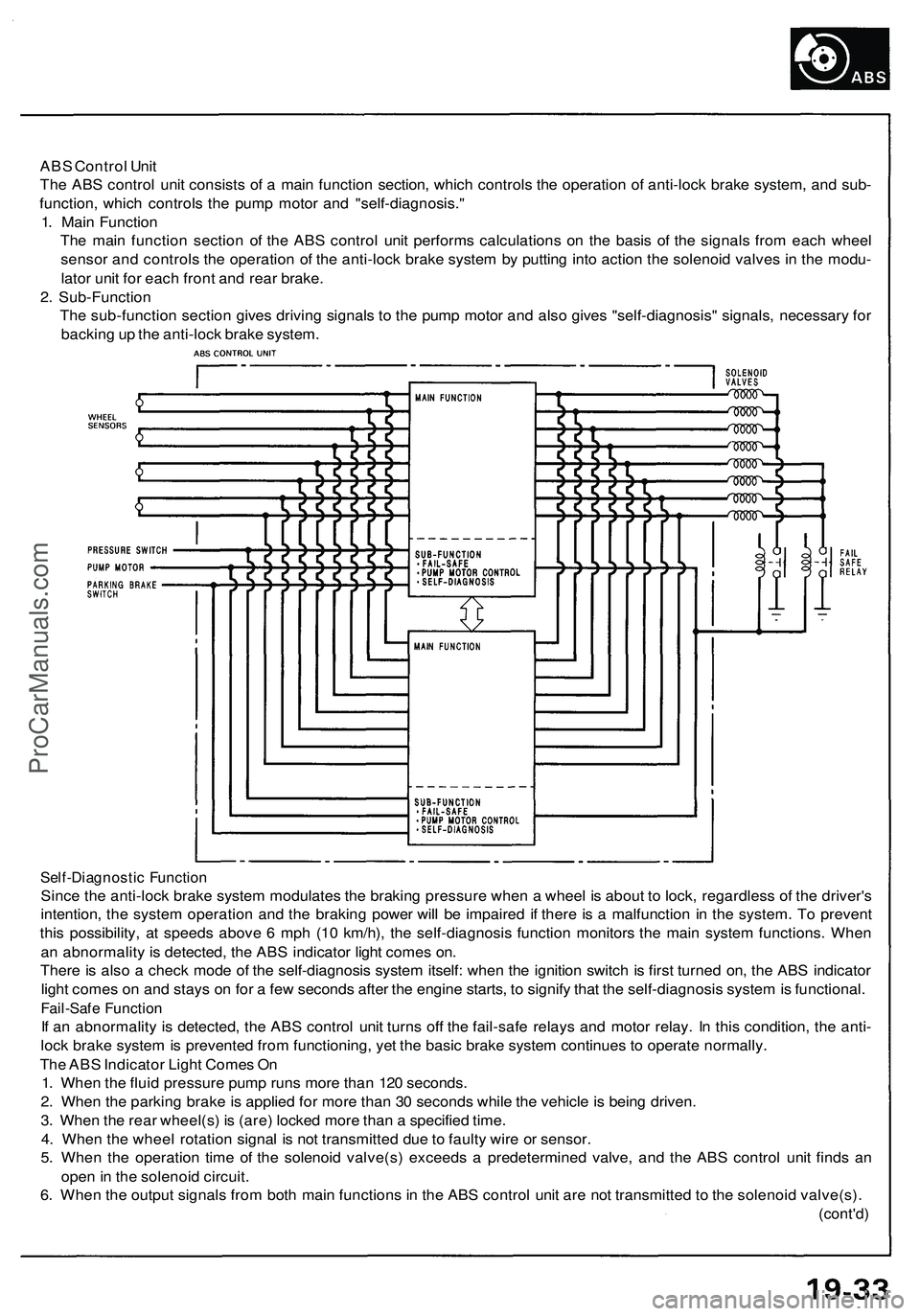

ABS Control Unit

The ABS control unit consists of a main function section, which controls the operation of anti-lock brake system, and sub-

function, which controls the pump motor and "self-diagnosis."

1. Main Function

The main function section of the ABS control unit performs calculations on the basis of the signals from each wheel

sensor and controls the operation of the anti-lock brake system by putting into action the solenoid valves in the modu-

lator unit for each front and rear brake.

2. Sub-Function

The sub-function section gives driving signals to the pump motor and also gives "self-diagnosis" signals, necessary for

backing up the anti-lock brake system.

Self-Diagnostic Function

Since the anti-lock brake system modulates the braking pressure when a wheel is about to lock, regardless of the driver's

intention, the system operation and the braking power will be impaired if there is a malfunction in the system. To prevent

this possibility, at speeds above 6 mph (10 km/h), the self-diagnosis function monitors the main system functions. When

an abnormality is detected, the ABS indicator light comes on.

There is also a check mode of the self-diagnosis system itself: when the ignition switch is first turned on, the ABS indicator

light comes on and stays on for a few seconds after the engine starts, to signify that the self-diagnosis system is functional.

Fail-Safe Function

If an abnormality is detected, the ABS control unit turns off the fail-safe relays and motor relay. In this condition, the anti-

lock brake system is prevented from functioning, yet the basic brake system continues to operate normally.

The ABS Indicator Light Comes On

1. When the fluid pressure pump runs more than 120 seconds.

2. When the parking brake is applied for more than 30 seconds while the vehicle is being driven.

3. When the rear wheel(s) is (are) locked more than a specified time.

4. When the wheel rotation signal is not transmitted due to faulty wire or sensor.

5. When the operation time of the solenoid valve(s) exceeds a predetermined valve, and the ABS control unit finds an

open in the solenoid circuit.

6. When the output signals from both main functions in the ABS control unit are not transmitted to the solenoid valve(s).

(cont'd)ProCarManuals.com

Page 1016 of 1503

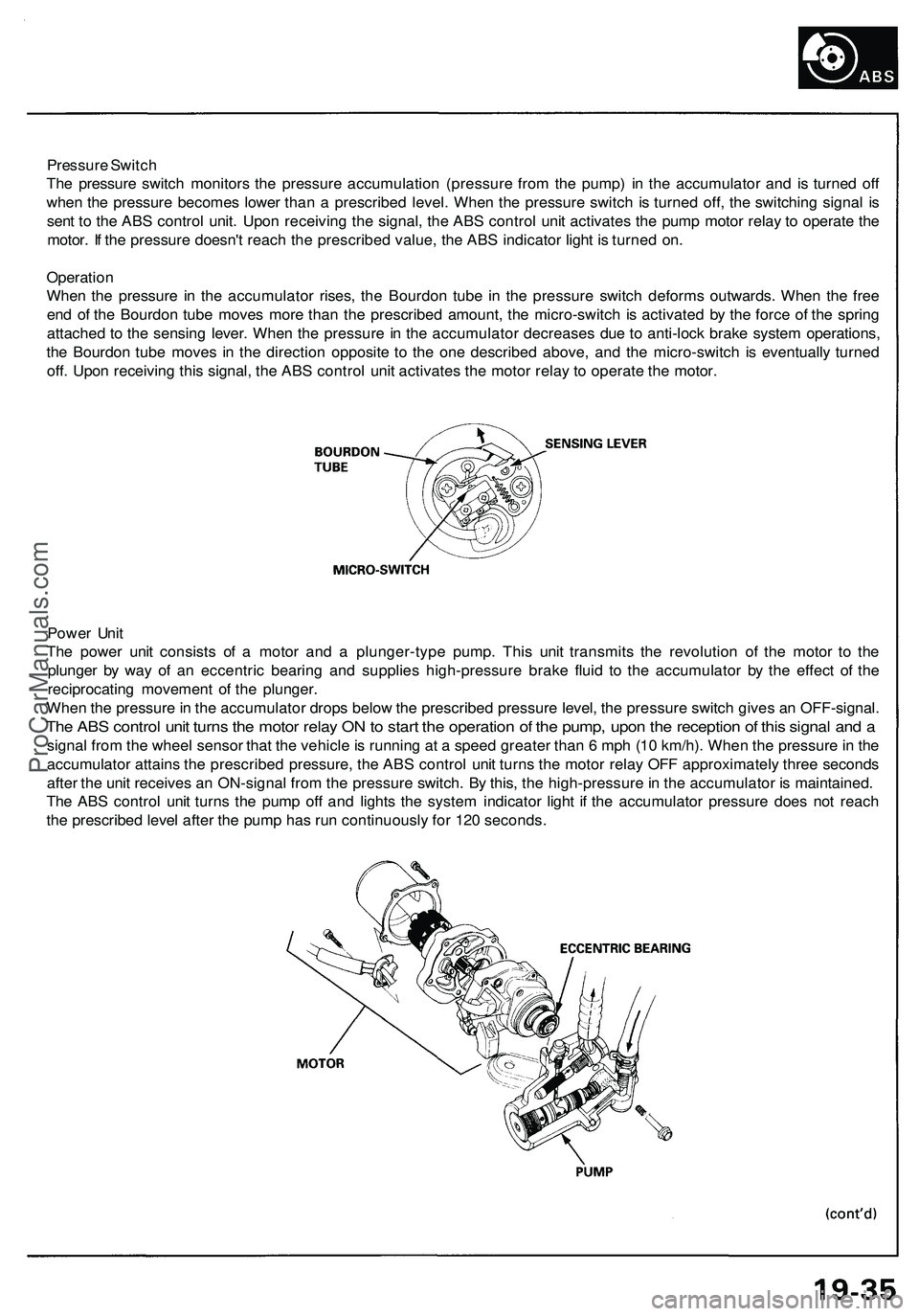

Pressure Switch

The pressure switch monitors the pressure accumulation (pressure from the pump) in the accumulator and is turned off

when the pressure becomes lower than a prescribed level. When the pressure switch is turned off, the switching signal is

sent to the ABS control unit. Upon receiving the signal, the ABS control unit activates the pump motor relay to operate the

motor. If the pressure doesn't reach the prescribed value, the ABS indicator light is turned on.

Operation

When the pressure in the accumulator rises, the Bourdon tube in the pressure switch deforms outwards. When the free

end of the Bourdon tube moves more than the prescribed amount, the micro-switch is activated by the force of the spring

attached to the sensing lever. When the pressure in the accumulator decreases due to anti-lock brake system operations,

the Bourdon tube moves in the direction opposite to the one described above, and the micro-switch is eventually turned

off. Upon receiving this signal, the ABS control unit activates the motor relay to operate the motor.

Power Unit

The power unit consists of a motor and a plunger-type pump. This unit transmits the revolution of the motor to the

plunger by way of an eccentric bearing and supplies high-pressure brake fluid to the accumulator by the effect of the

reciprocating movement of the plunger.

When the pressure in the accumulator drops below the prescribed pressure level, the pressure switch gives an OFF-signal.

The ABS control unit turns the motor relay ON to start the operation of the pump, upon the reception of this signal and a

signal from the wheel sensor that the vehicle is running at a speed greater than 6 mph (10 km/h). When the pressure in the

accumulator attains the prescribed pressure, the ABS control unit turns the motor relay OFF approximately three seconds

after the unit receives an ON-signal from the pressure switch. By this, the high-pressure in the accumulator is maintained.

The ABS control unit turns the pump off and lights the system indicator light if the accumulator pressure does not reach

the prescribed level after the pump has run continuously for 120 seconds.ProCarManuals.com

Page 1030 of 1503

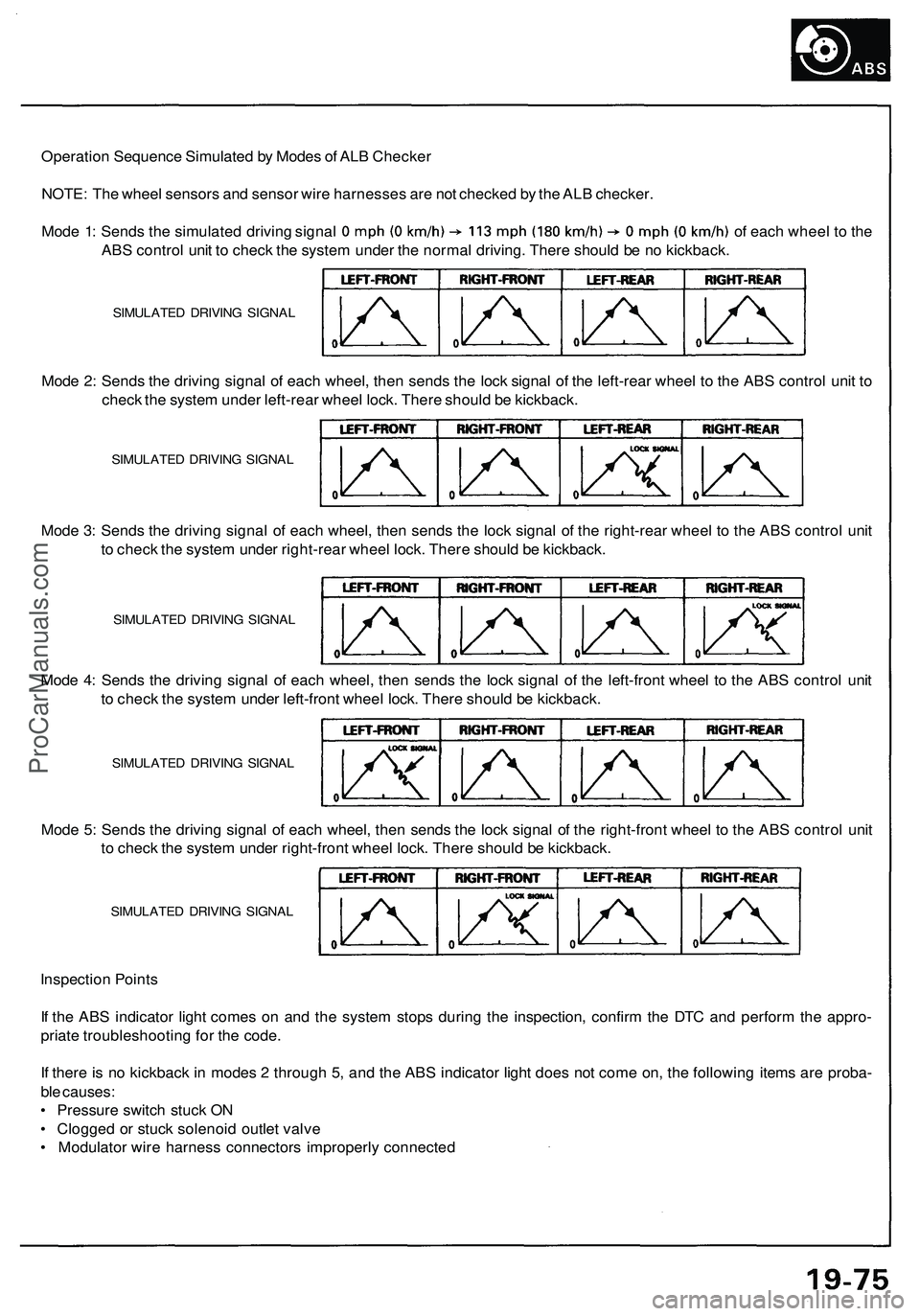

Operation Sequence Simulated by Modes of ALB Checker

NOTE: The wheel sensors and sensor wire harnesses are not checked by the ALB checker.

Mode 1: Sends the simulated driving signal of each wheel to the

ABS control unit to check the system under the normal driving. There should be no kickback.

Mode 2: Sends the driving signal of each wheel, then sends the lock signal of the left-rear wheel to the ABS control unit to

check the system under left-rear wheel lock. There should be kickback.

Mode 3: Sends the driving signal of each wheel, then sends the lock signal of the right-rear wheel to the ABS control unit

to check the system under right-rear wheel lock. There should be kickback.

Mode 4: Sends the driving signal of each wheel, then sends the lock signal of the left-front wheel to the ABS control unit

to check the system under left-front wheel lock. There should be kickback.

Mode 5: Sends the driving signal of each wheel, then sends the lock signal of the right-front wheel to the ABS control unit

to check the system under right-front wheel lock. There should be kickback.

Inspection Points

If the ABS indicator light comes on and the system stops during the inspection, confirm the DTC and perform the appro-

priate troubleshooting for the code.

If there is no kickback in modes 2 through 5, and the ABS indicator light does not come on, the following items are proba-

ble causes:

• Pressure switch stuck ON

• Clogged or stuck solenoid outlet valve

• Modulator wire harness connectors improperly connected

SIMULATED DRIVING SIGNAL

SIMULATED DRIVING SIGNAL

SIMULATED DRIVING SIGNAL

SIMULATED DRIVING SIGNAL

SIMULATED DRIVING SIGNALProCarManuals.com

Page 1041 of 1503

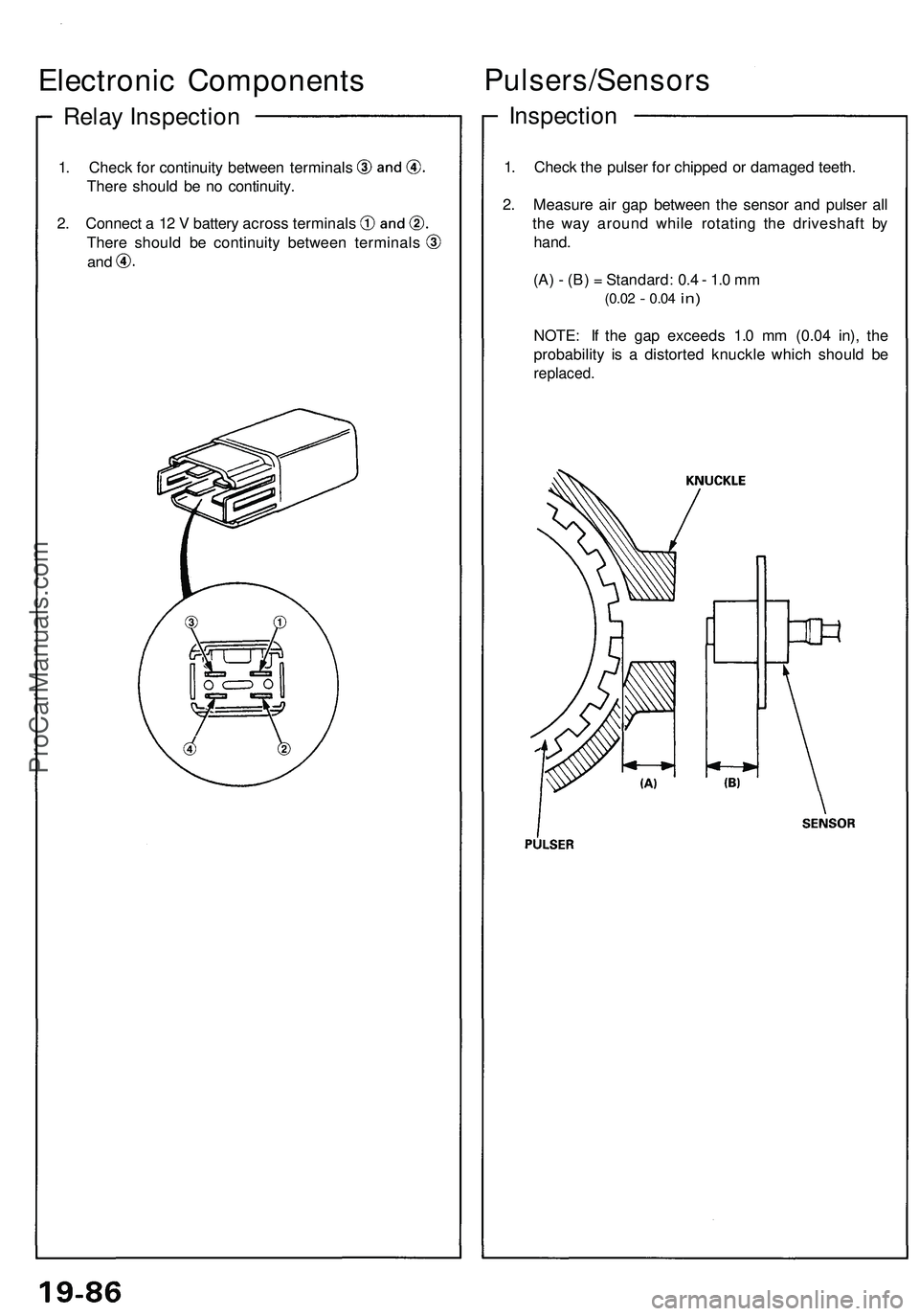

Relay Inspection

Electronic Components

1. Check for continuity between terminals

There should be no continuity.

2. Connect a 12 V battery across terminals

There should be continuity between terminals

and

Inspection

Pulsers/Sensors

1. Check the pulser for chipped or damaged teeth.

2. Measure air gap between the sensor and pulser all

the way around while rotating the driveshaft by

hand.

(A) - (B) = Standard: 0.4 - 1.0 mm

(0.02

-

0.04

in)

NOTE: If the gap exceeds 1.0 mm (0.04 in), the

probability is a distorted knuckle which should be

replaced.ProCarManuals.com

Page 1042 of 1503

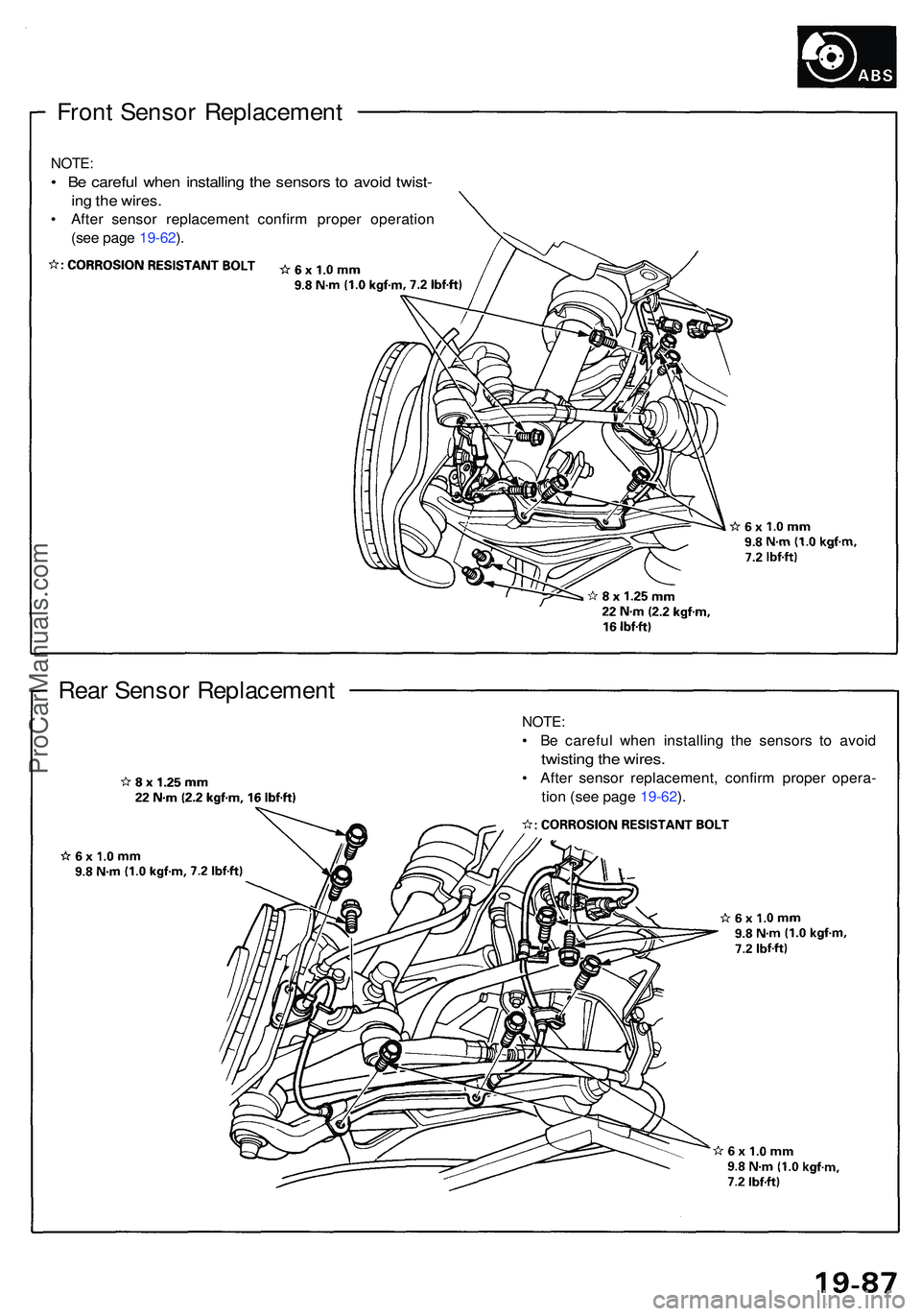

NOTE:

• B e carefu l whe n installin g th e sensor s t o avoi d twist -

ing th e wires .

• Afte r senso r replacemen t confir m prope r operatio n

(se e pag e 19-62 ).

Fron t Senso r Replacemen t

Rea r Senso r Replacemen t

NOTE:

• B e carefu l whe n installin g th e sensor s t o avoi d

twistin g th e wires .

• Afte r senso r replacement , confir m prope r opera -

tio n (se e pag e 19-62 ).

ProCarManuals.com

Page 1045 of 1503

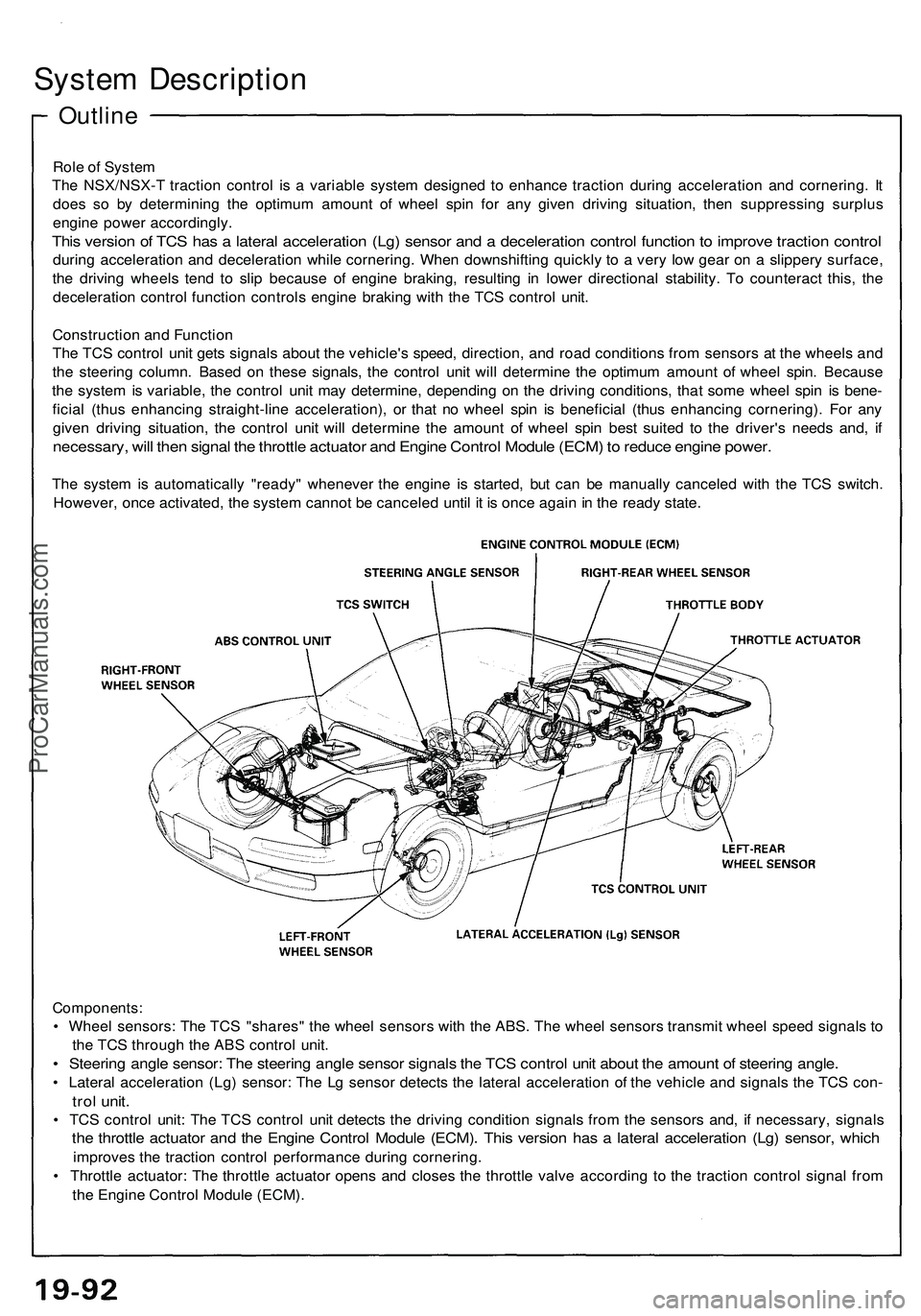

Outline

System Description

Role of System

The NSX/NSX-T traction control is a variable system designed to enhance traction during acceleration and cornering. It

does so by determining the optimum amount of wheel spin for any given driving situation, then suppressing surplus

engine power accordingly.

This version of TCS has a lateral acceleration (Lg) sensor and a deceleration control function to improve traction control

during acceleration and deceleration while cornering. When downshifting quickly to a very low gear on a slippery surface,

the driving wheels tend to slip because of engine braking, resulting in lower directional stability. To counteract this, the

deceleration control function controls engine braking with the TCS control unit.

Construction and Function

The TCS control unit gets signals about the vehicle's speed, direction, and road conditions from sensors at the wheels and

the steering column. Based on these signals, the control unit will determine the optimum amount of wheel spin. Because

the system is variable, the control unit may determine, depending on the driving conditions, that some wheel spin is bene-

ficial (thus enhancing straight-line acceleration), or that no wheel spin is beneficial (thus enhancing cornering). For any

given driving situation, the control unit will determine the amount of wheel spin best suited to the driver's needs and, if

necessary, will then signal the throttle actuator and Engine Control Module (ECM) to reduce engine power.

The system is automatically "ready" whenever the engine is started, but can be manually canceled with the TCS switch.

However, once activated, the system cannot be canceled until it is once again in the ready state.

Components:

• Wheel sensors: The TCS "shares" the wheel sensors with the ABS. The wheel sensors transmit wheel speed signals to

the TCS through the ABS control unit.

• Steering angle sensor: The steering angle sensor signals the TCS control unit about the amount of steering angle.

• Lateral acceleration (Lg) sensor: The Lg sensor detects the lateral acceleration of the vehicle and signals the TCS con-

trol unit.

• TCS control unit: The TCS control unit detects the driving condition signals from the sensors and, if necessary, signals

the throttle actuator and the Engine Control Module (ECM). This version has a lateral acceleration (Lg) sensor, which

improves the traction control performance during cornering.

• Throttle actuator: The throttle actuator opens and closes the throttle valve according to the traction control signal from

the Engine Control Module (ECM).ProCarManuals.com

Page 1046 of 1503

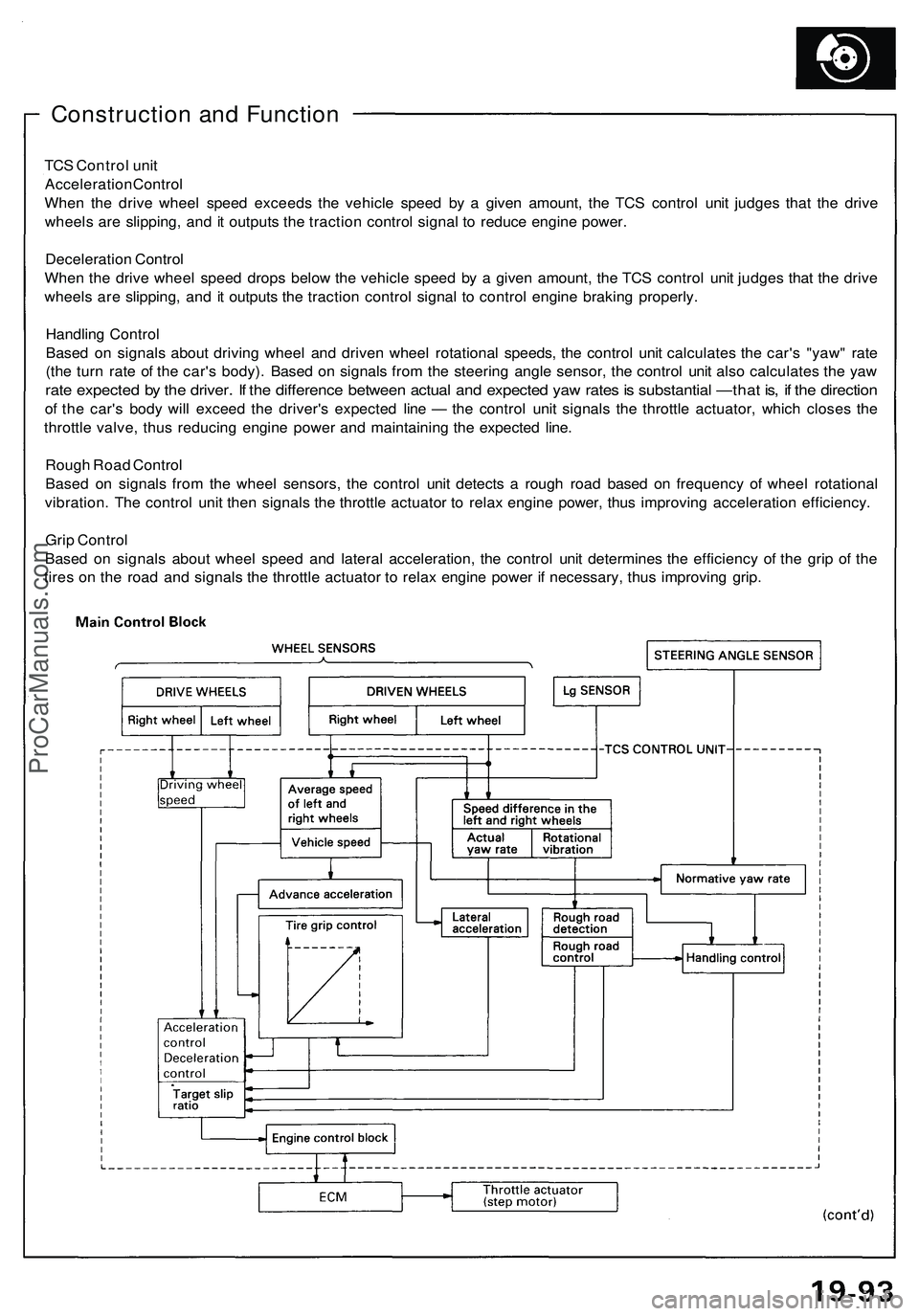

Construction and Function

TCS Control unit

Acceleration Control

When the drive wheel speed exceeds the vehicle speed by a given amount, the TCS control unit judges that the drive

wheels are slipping, and it outputs the traction control signal to reduce engine power.

Deceleration Control

When the drive wheel speed drops below the vehicle speed by a given amount, the TCS control unit judges that the drive

wheels are slipping, and it outputs the traction control signal to control engine braking properly.

Handling Control

Based on signals about driving wheel and driven wheel rotational speeds, the control unit calculates the car's "yaw" rate

(the turn rate of the car's body). Based on signals from the steering angle sensor, the control unit also calculates the yaw

rate expected by the driver. If the difference between actual and expected yaw rates is substantial —that is, if the direction

of the car's body will exceed the driver's expected line — the control unit signals the throttle actuator, which closes the

throttle valve, thus reducing engine power and maintaining the expected line.

Rough Road Control

Based on signals from the wheel sensors, the control unit detects a rough road based on frequency of wheel rotational

vibration. The control unit then signals the throttle actuator to relax engine power, thus improving acceleration efficiency.

Grip Control

Based on signals about wheel speed and lateral acceleration, the control unit determines the efficiency of the grip of the

tires on the road and signals the throttle actuator to relax engine power if necessary, thus improving grip.ProCarManuals.com

Page 1047 of 1503

Construction and Function (cont'd)

System Description

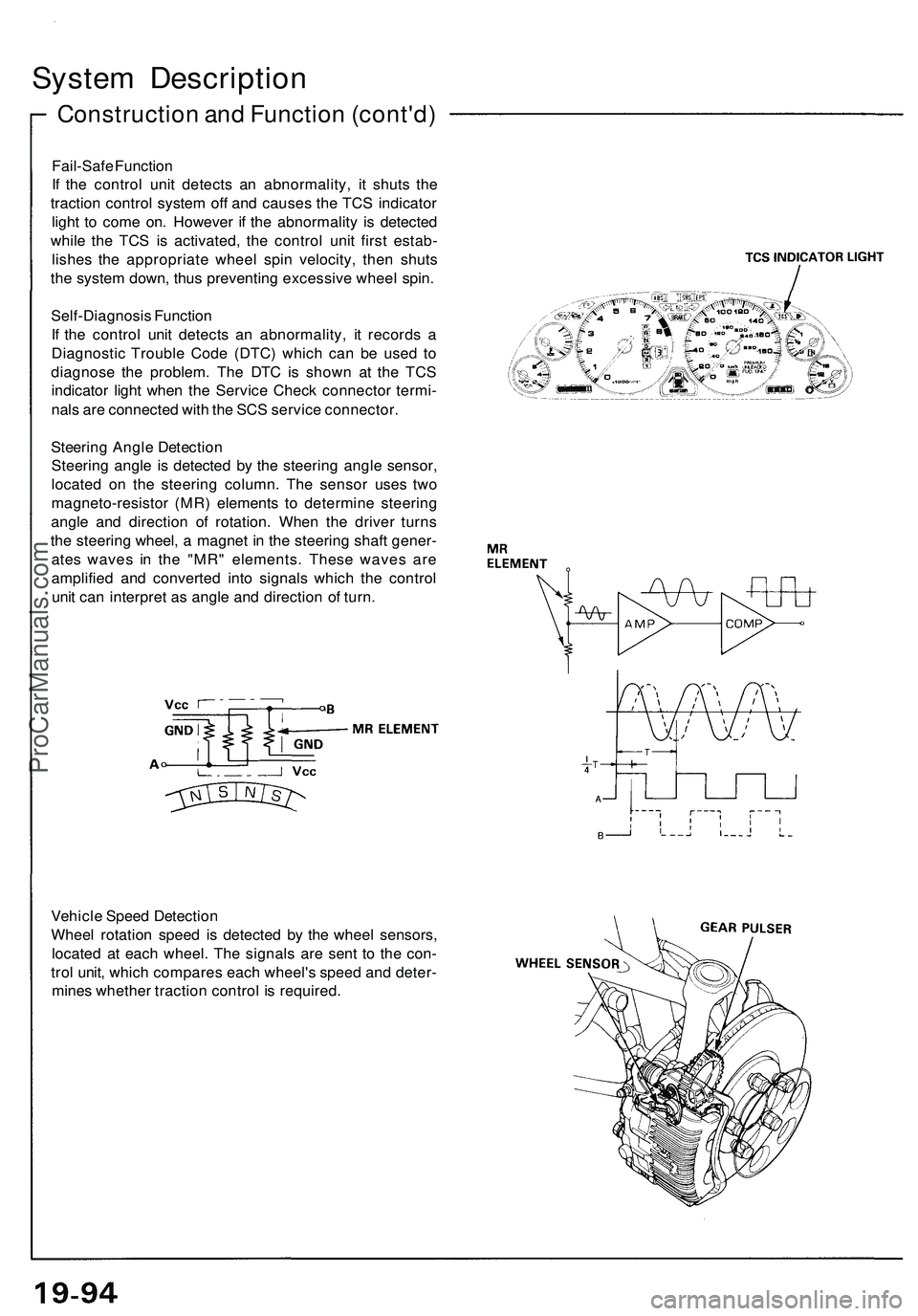

Fail-Safe Function

If the control unit detects an abnormality, it shuts the

traction control system off and causes the TCS indicator

light to come on. However if the abnormality is detected

while the TCS is activated, the control unit first estab-

lishes the appropriate wheel spin velocity, then shuts

the system down, thus preventing excessive wheel spin.

Self-Diagnosis Function

If the control unit detects an abnormality, it records a

Diagnostic Trouble Code (DTC) which can be used to

diagnose the problem. The DTC is shown at the TCS

indicator light when the Service Check connector termi-

nals are connected with the SCS service connector.

Steering Angle Detection

Steering angle is detected by the steering angle sensor,

located on the steering column. The sensor uses two

magneto-resistor (MR) elements to determine steering

angle and direction of rotation. When the driver turns

the steering wheel, a magnet in the steering shaft gener-

ates waves in the "MR" elements. These waves are

amplified and converted into signals which the control

unit can interpret as angle and direction of turn.

Vehicle Speed Detection

Wheel rotation speed is detected by the wheel sensors,

located at each wheel. The signals are sent to the con-

trol unit, which compares each wheel's speed and deter-

mines whether traction control is required.ProCarManuals.com

Page 1048 of 1503

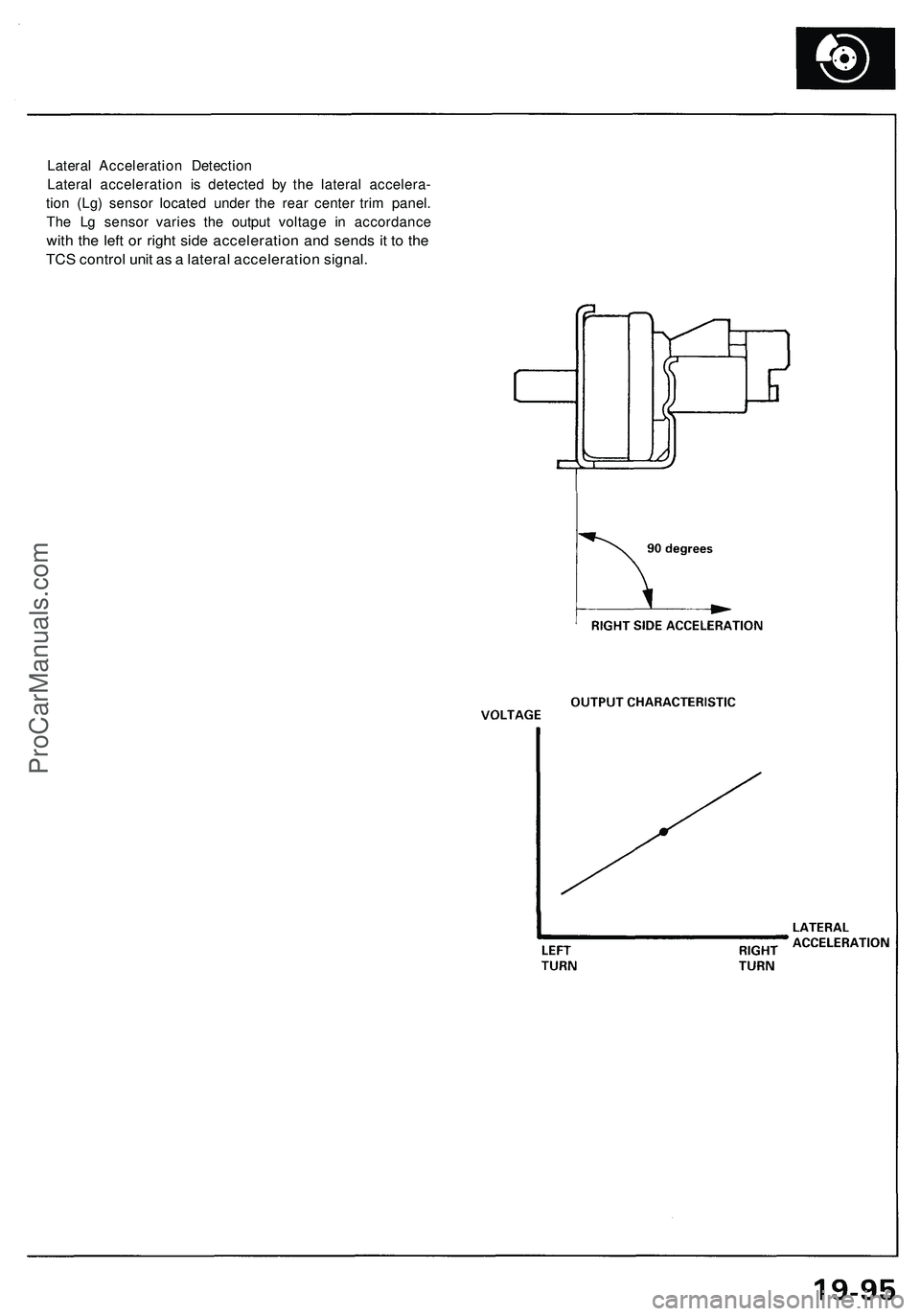

Lateral Acceleration Detection

Lateral acceleration is detected by the lateral accelera-

tion (Lg) sensor located under the rear center trim panel.

The Lg sensor varies the output voltage in accordance

with the left or right side acceleration and sends it to the

TCS control unit as a lateral acceleration signal.ProCarManuals.com