sensor ACURA NSX 1997 Service Owners Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 1202 of 1503

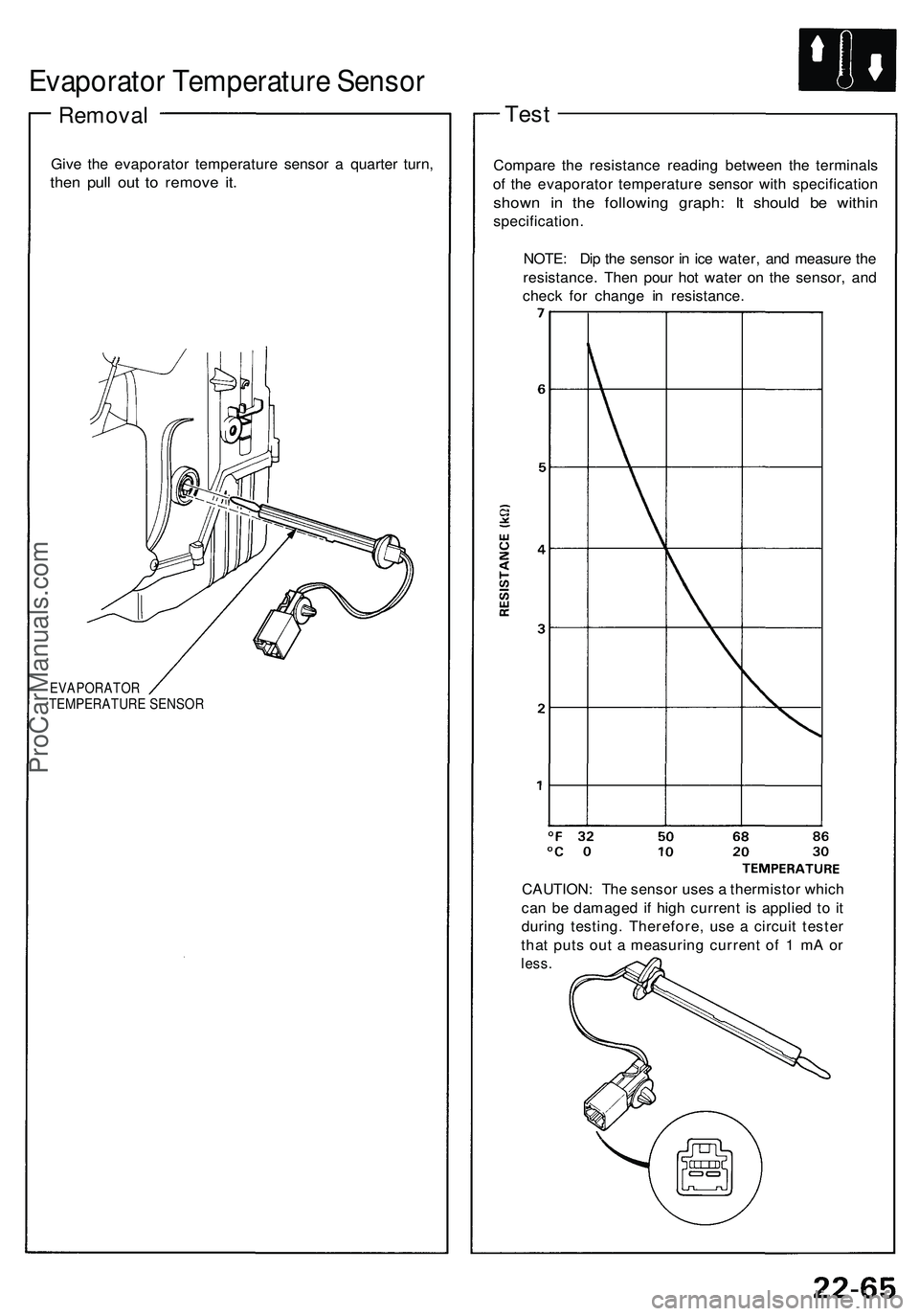

Evaporator Temperature Sensor

Removal

Give th e evaporato r temperatur e senso r a quarte r turn ,

then pul l ou t t o remov e it .

EVAPORATO RTEMPERATUR E SENSO R

Test

Compar e th e resistanc e readin g betwee n th e terminal s

of th e evaporato r temperatur e senso r wit h specificatio n

shown i n th e followin g graph : I t shoul d b e withi n

specification .

NOTE : Di p th e senso r i n ic e water , an d measur e th e

resistance . The n pou r ho t wate r o n th e sensor , an d

chec k fo r chang e i n resistance .

CAUTION : Th e senso r use s a thermisto r whic h

ca n b e damage d if hig h curren t i s applie d t o it

durin g testing . Therefore , us e a circui t teste r

tha t put s ou t a measurin g curren t o f 1 m A o r

less .

ProCarManuals.com

Page 1212 of 1503

11. Disconnec t th e connector s fro m al l th e contro l

motors an d sensor s attache d t o th e heater -

evaporato r unit .

1 2 . Remov e th e tw o mountin g bolt s an d tw o nuts , the n

remov e th e heater-evaporato r uni t throug h th e

passenge r door .

CORROSIO N RESISTAN TBOLTHEATER-EVAPORATO R UNIT

NUT S29 N- m (3. 0 kgf-m ,

2 2 Ibf-ft )

6 x 1. 0 m m9.8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )

13. Instal l th e heater-evaporato r uni t i n th e revers e

orde r of removal , and :

• I f you'r e installin g a ne w evaporator , ad d

refrigeran t oi l (ND-OI L 8 ) se e pag e 22-69 ).

• Replac e O-ring s wit h ne w one s a t eac h fitting ,

and appl y refrigeran t oi l t o them .

NOTE : B e sur e t o us e th e righ t O-ring s fo r

R-134 a t o avoi d leakage .

14. Fil l th e radiato r an d reservoi r tan k wit h th e prope r

engine coolan t mixture . Blee d th e ai r fro m th e cool -

in g syste m (se e sectio n 10 ).

CAUTION : Follo w th e sequenc e describe d in th e ai r

blee d procedure . I f you don't , yo u ma y leav e ai r i n

th e syste m whic h coul d damag e th e engine .

15. I f necessary , adjus t th e heate r valv e cable :

• Se t th e ai r mi x contro l moto r a t COO L positio n

(se e pag e 22-57 ).

• Connec t th e en d o f th e heate r valv e cabl e t o th e

heate r valv e arm .

• Gentl y slid e th e cabl e oute r housin g bac k fro m

the en d enoug h to tak e u p an y slac k in th e cable ,

but no t enoug h t o mak e th e othe r en d mov e th e

ar m o n th e ai r mi x contro l motor . The n sna p th e

clam p dow n ove r th e cabl e housing .

CLAMP

HEATE R VALV EARM

HEATE R VALV ECABLE

16. Tur n th e blowe r on , an d mak e sur e tha t ther e is n o

air leakage .

1 7 . Charg e th e syste m (se e pag e 22-91 ), an d tes t per -

formanc e (se e pag e 22-70 ).

SR S UNI T

ProCarManuals.com

Page 1261 of 1503

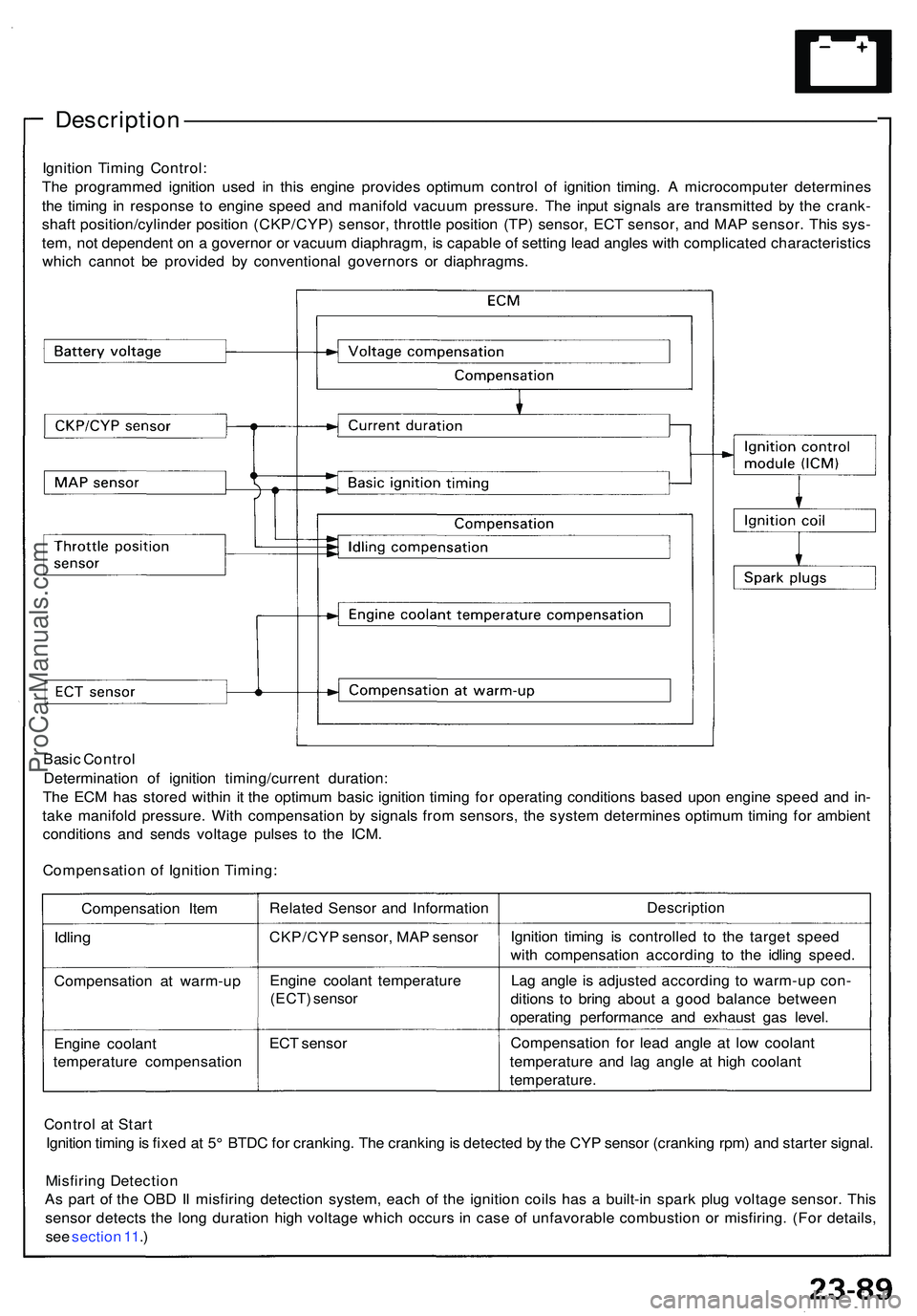

Description ——————————————————\

——————————————————\

———

Ignition Timin g Control :

Th e programme d ignitio n use d i n thi s engin e provide s optimu m contro l o f ignitio n timing . A microcompute r determine s

th e timin g i n respons e t o engin e spee d an d manifol d vacuu m pressure . Th e inpu t signal s ar e transmitte d b y th e crank -

shaf t position/cylinde r positio n (CKP/CYP ) sensor , throttl e positio n (TP ) sensor , EC T sensor , an d MA P sensor . Thi s sys -

tem , no t dependen t o n a governo r o r vacuu m diaphragm , i s capabl e o f settin g lea d angle s wit h complicate d characteristic s

whic h canno t b e provide d b y conventiona l governor s o r diaphragms .

Basi c Contro l

Determinatio n of ignitio n timing/curren t duration :

Th e EC M ha s store d withi n i t th e optimu m basi c ignitio n timin g fo r operatin g condition s base d upo n engin e spee d an d in -

tak e manifol d pressure . Wit h compensatio n b y signal s fro m sensors , th e syste m determine s optimu m timin g fo r ambien t

condition s an d send s voltag e pulse s t o th e ICM .

Compensatio n o f Ignitio n Timing :

Compensatio n Ite m

Idlin g

Compensatio n a t warm-u p

Engin e coolan t

temperatur e compensatio nRelate

d Senso r an d Informatio n

CKP/CY P sensor , MA P senso r

Engin e coolan t temperatur e

(ECT) senso r

ECT senso r Descriptio

n

Ignitio n timin g i s controlle d t o th e targe t spee d

wit h compensatio n accordin g t o th e idlin g speed .

La g angl e i s adjuste d accordin g t o warm-u p con -

dition s t o brin g abou t a goo d balanc e betwee n

operatin g performanc e an d exhaus t ga s level .

Compensatio n fo r lea d angl e a t low coolan t

temperatur e an d la g angl e a t hig h coolan t

temperature .

Contro l a t Star t

Ignitio n timin g is fixe d a t 5 ° BTD C fo r cranking . Th e crankin g is detecte d b y th e CY P senso r (crankin g rpm ) an d starte r signal .

Misfirin g Detectio n

A s par t o f th e OB D II misfirin g detectio n system , eac h o f th e ignitio n coil s ha s a built-i n spar k plu g voltag e sensor . Thi s

senso r detect s th e lon g duratio n hig h voltag e whic h occur s i n cas e o f unfavorabl e combustio n o r misfiring . (Fo r details ,

se e sectio n 11 .)

ProCarManuals.com

Page 1282 of 1503

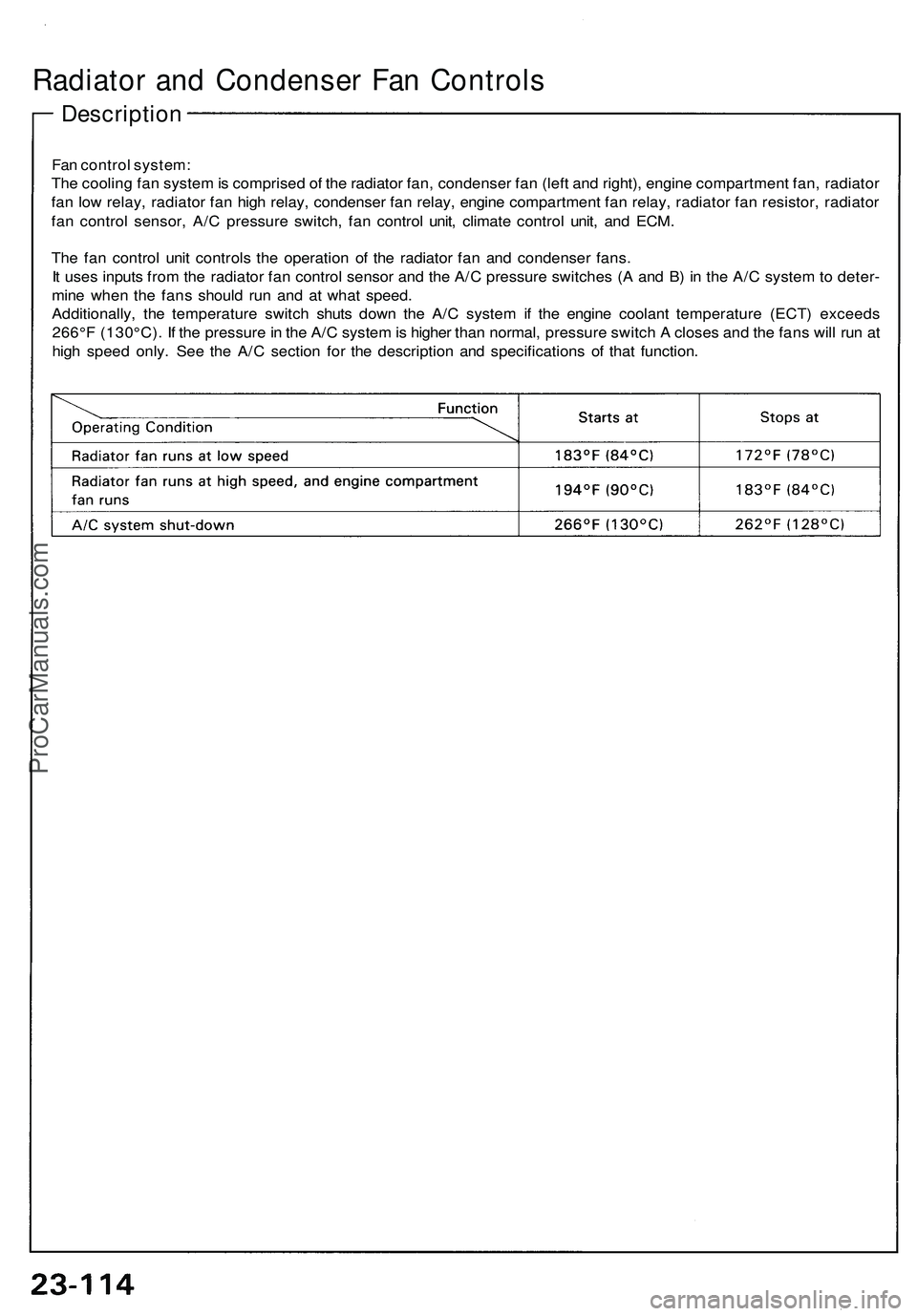

Radiator and Condenser Fan Controls

Description

Fan control system:

The cooling fan system is comprised of the radiator fan, condenser fan (left and right), engine compartment fan, radiator

fan low relay, radiator fan high relay, condenser fan relay, engine compartment fan relay, radiator fan resistor, radiator

fan control sensor, A/C pressure switch, fan control unit, climate control unit, and ECM.

The fan control unit controls the operation of the radiator fan and condenser fans.

It uses inputs from the radiator fan control sensor and the A/C pressure switches (A and B) in the A/C system to deter-

mine when the fans should run and at what speed.

Additionally, the temperature switch shuts down the A/C system if the engine coolant temperature (ECT) exceeds

266°F (130°C). If the pressure in the A/C system is higher than normal, pressure switch A closes and the fans will run at

high speed only. See the A/C section for the description and specifications of that function.ProCarManuals.com

Page 1284 of 1503

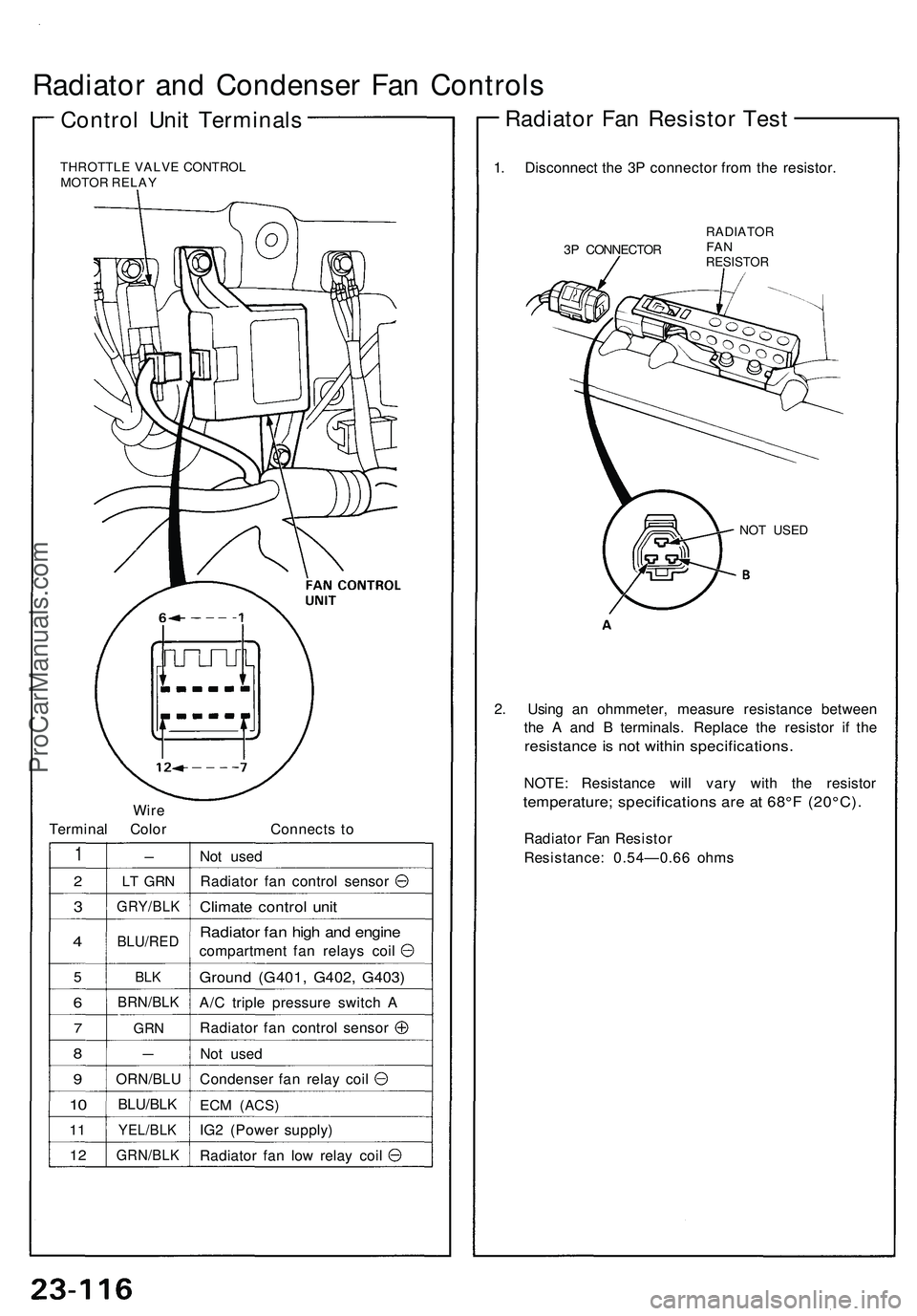

Radiator and Condenser Fan Controls

Control Unit Terminals

THROTTLE VALVE CONTROL

MOTOR RELAY

Wire

Terminal Color

Connects to

1

2

3

4

5

6

7

8

9

10

11

12

-

LT GRN

GRY/BLK

BLU/RED

BLK

BRN/BLK

GRN

—

ORN/BLU

BLU/BLK

YEL/BLK

GRN/BLK

Not used

Radiator fan control sensor

Climate control unit

Radiator fan high and engine

compartment fan relays coil

Ground (G401, G402, G403)

A/C triple pressure switch A

Radiator fan control sensor

Not used

Condenser fan relay coil

ECM

(ACS)

IG2 (Power supply)

Radiator fan low relay coil

1. Disconnect the 3P connector from the resistor.

3P CONNECTOR

RADIATOR

FAN

RESISTOR

NOT USED

2. Using an ohmmeter, measure resistance between

the A and B terminals. Replace the resistor if the

resistance is not within specifications.

NOTE: Resistance will vary with the resistor

temperature; specifications are at 68°F (20°C).

Radiator Fan Resistor

Resistance: 0.54—0.66 ohms

Radiator Fan Resistor TestProCarManuals.com

Page 1288 of 1503

Radiator an d Condense r Fa n Control s

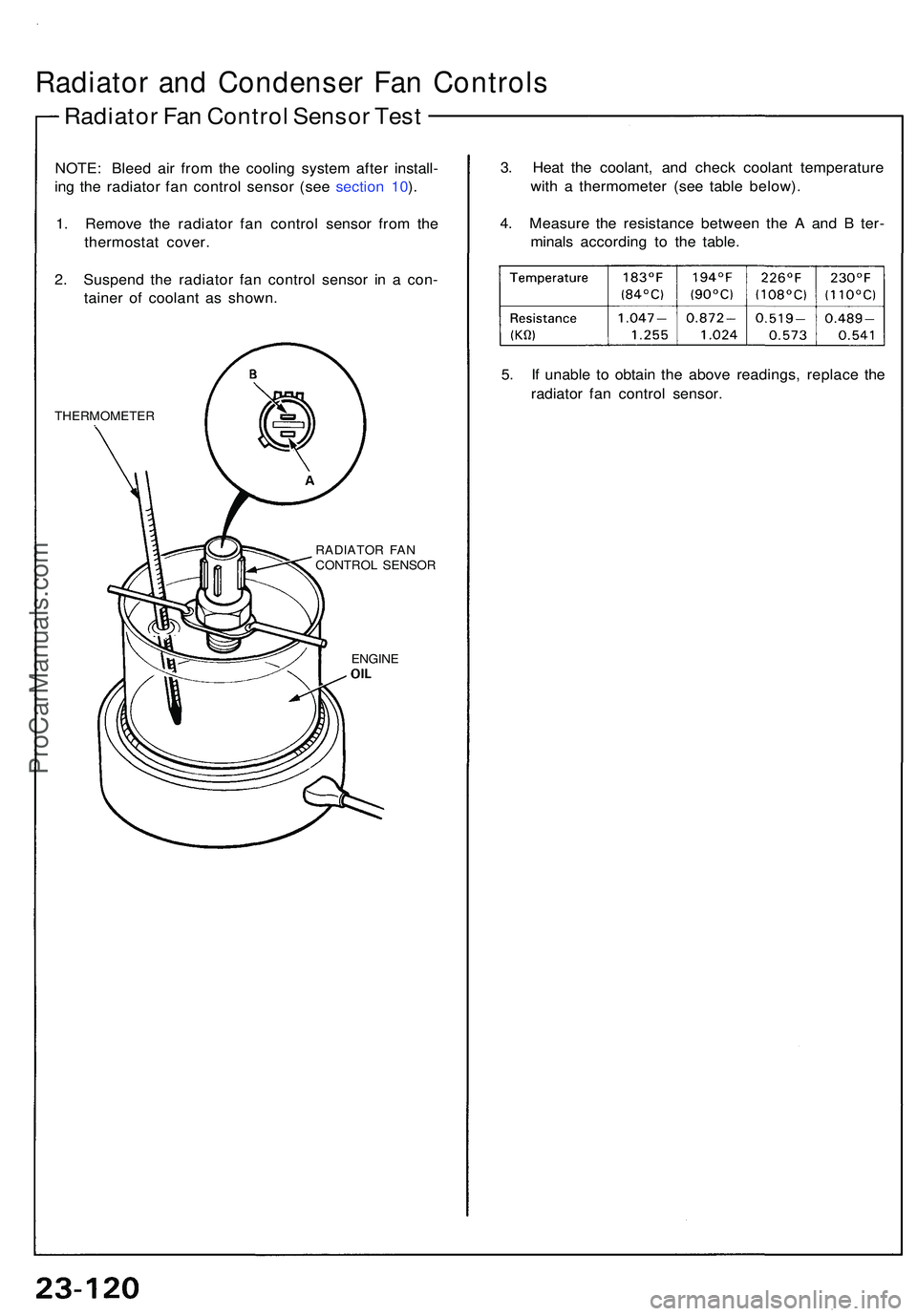

Radiator Fa n Contro l Senso r Tes t

NOTE : Blee d ai r fro m th e coolin g syste m afte r install -

in g th e radiato r fa n contro l senso r (se e sectio n 10 ).

1 . Remov e th e radiato r fa n contro l senso r fro m th e

thermosta t cover .

2 . Suspen d th e radiato r fa n contro l senso r i n a con -

taine r o f coolan t a s shown .

THERMOMETE R

RADIATOR FA N

CONTRO L SENSO R

ENGIN E

3. Hea t th e coolant , an d chec k coolan t temperatur e

wit h a thermomete r (se e tabl e below) .

4 . Measur e th e resistanc e betwee n th e A an d B ter -

minal s accordin g t o th e table .

5 . I f unabl e t o obtai n th e abov e readings , replac e th e

radiato r fa n contro l sensor .

ProCarManuals.com

Page 1295 of 1503

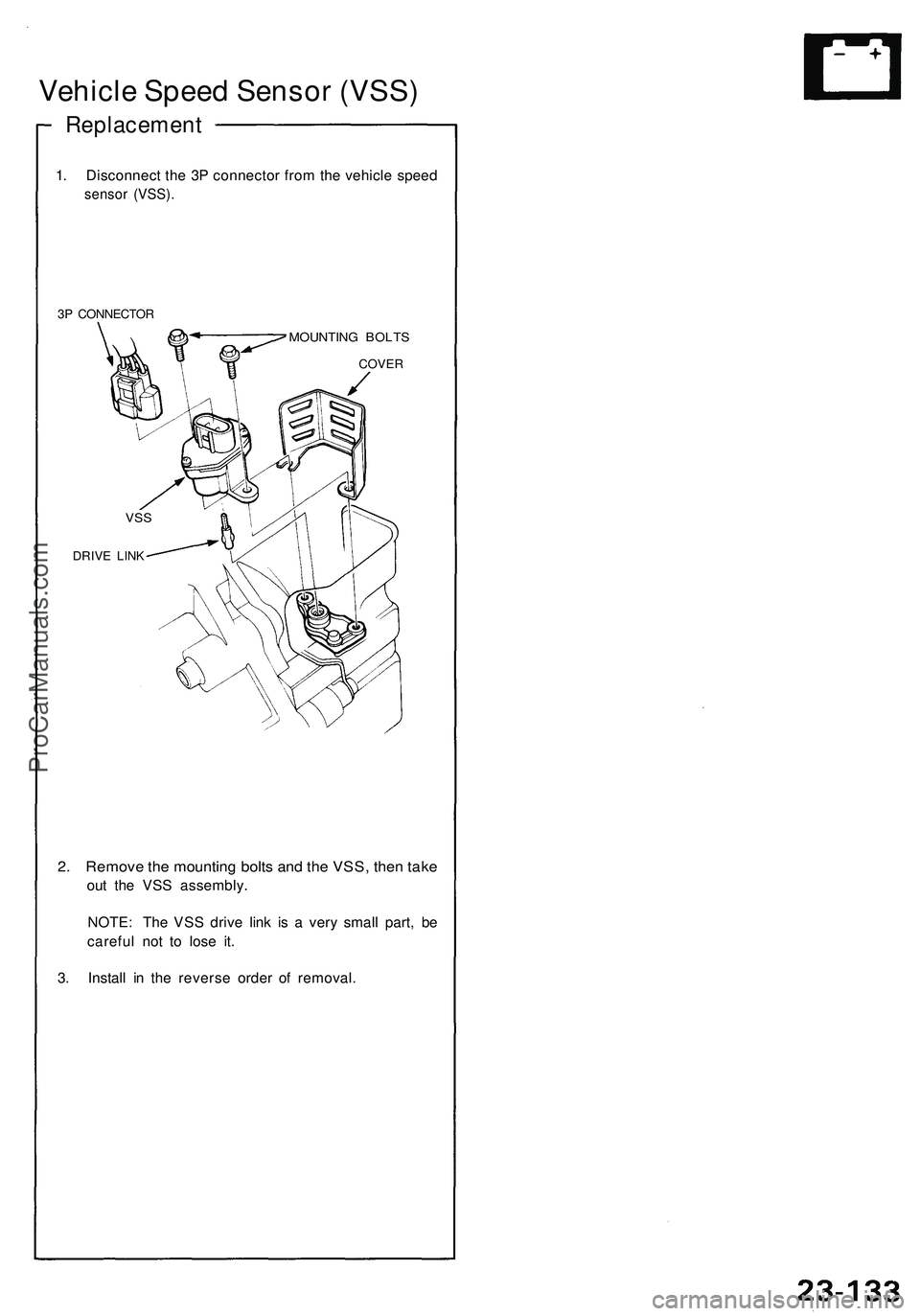

Vehicle Speed Sensor (VSS)

Replacement

1. Disconnect the 3P connector from the vehicle speed

sensor (VSS).

3P CONNECTOR

MOUNTING BOLTS

2. Remove the mounting bolts and the VSS, then take

out the VSS assembly.

NOTE: The VSS drive link is a very small part, be

careful not to lose it.

3. Install in the reverse order of removal.

VSS

DRIVE LINK

COVERProCarManuals.com

Page 1308 of 1503

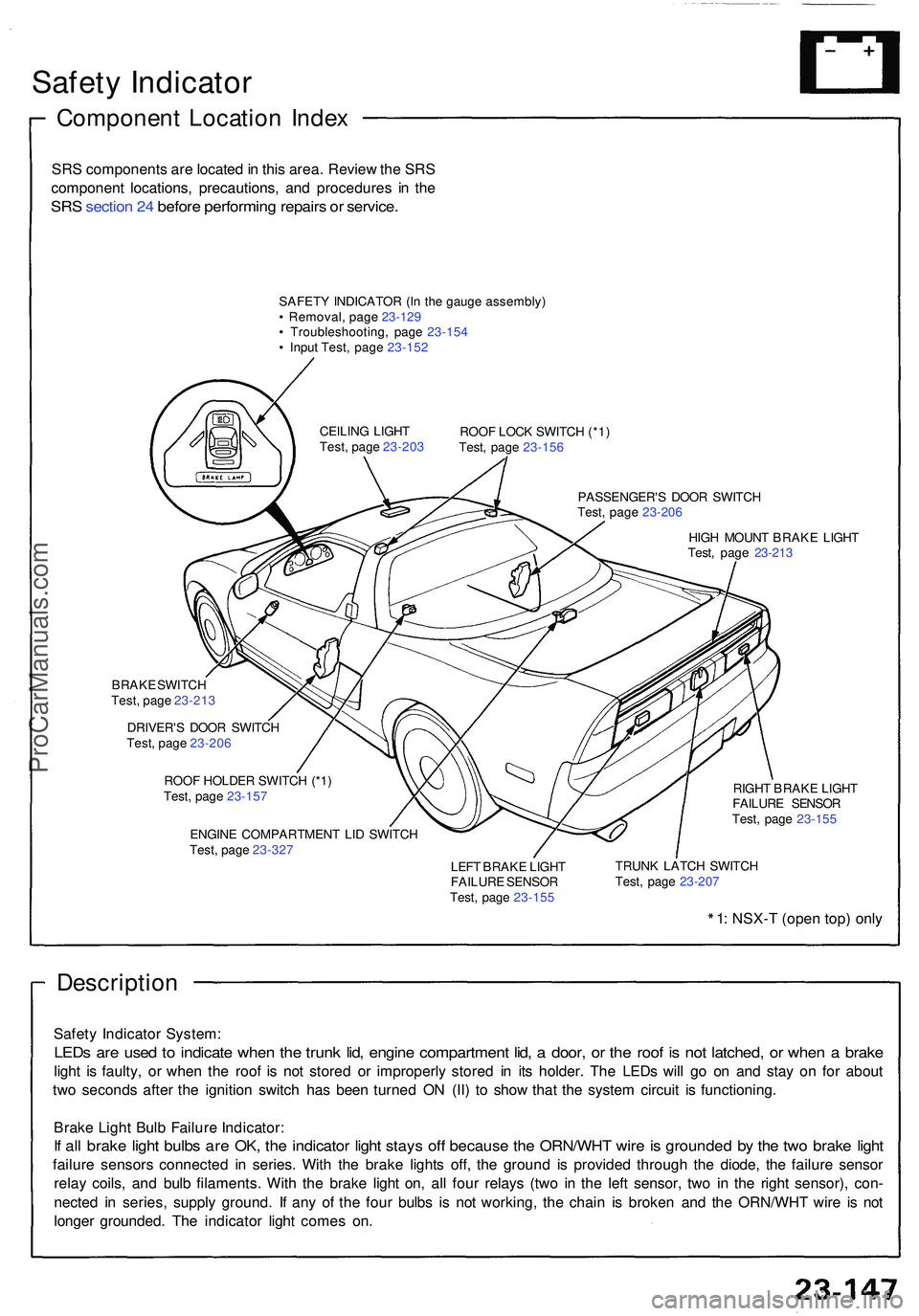

Safety Indicato r

Componen t Locatio n Inde x

SRS component s ar e locate d in thi s area . Revie w th e SR S

componen t locations , precautions , an d procedure s i n th e

SR S sectio n 24 befor e performin g repair s o r service .

SAFET Y INDICATO R (I n th e gaug e assembly )

• Removal , pag e 23-12 9

• Troubleshooting , pag e 23-15 4

• Inpu t Test , pag e 23-15 2

ROOF LOC K SWITC H (*1 )

Test , pag e 23-15 6

PASSENGER' S DOO R SWITC H

Test , pag e 23-20 6

HIG H MOUN T BRAK E LIGH T

Test , pag e 23-21 3

CEILIN

G LIGH T

Test , pag e 23-20 3

BRAK E SWITC H

Test , pag e 23-21 3

DRIVER' S DOO R SWITC H

Test , pag e 23-20 6

ROO F HOLDE R SWITC H (*1 )

Test , pag e 23-15 7

ENGIN E COMPARTMEN T LI D SWITC H

Test , pag e 23-32 7 RIGH

T BRAK E LIGH T

FAILUR E SENSO R

Test , pag e 23-15 5

LEF T BRAK E LIGH T

FAILUR E SENSO R

Test , pag e 23-15 5 TRUN

K LATC H SWITC H

Test , pag e 23-20 7

1: NSX- T (ope n top ) onl y

Descriptio n

Safety Indicato r System :

LEDs ar e use d t o indicat e whe n th e trun k lid , engin e compartmen t lid , a door , o r th e roo f i s no t latched , o r whe n a brak e

light i s faulty , o r whe n th e roo f i s no t store d o r improperl y store d i n it s holder . Th e LED s wil l g o o n an d sta y o n fo r abou t

tw o second s afte r th e ignitio n switc h ha s bee n turne d O N (II ) t o sho w tha t th e syste m circui t i s functioning .

Brak e Ligh t Bul b Failur e Indicator :

If al l brak e ligh t bulb s ar e OK , th e indicato r ligh t stay s of f becaus e th e ORN/WH T wir e is grounde d b y th e tw o brak e ligh t

failur e sensor s connecte d i n series . Wit h th e brak e light s off , th e groun d i s provide d throug h th e diode , th e failur e senso r

rela y coils , an d bul b filaments . Wit h th e brak e ligh t on , al l fou r relay s (tw o i n th e lef t sensor , tw o i n th e righ t sensor) , con -

necte d i n series , suppl y ground . I f an y o f th e fou r bulb s i s no t working , th e chai n i s broke n an d th e ORN/WH T wir e i s no t

longe r grounded . Th e indicato r ligh t come s on .

ProCarManuals.com

Page 1310 of 1503

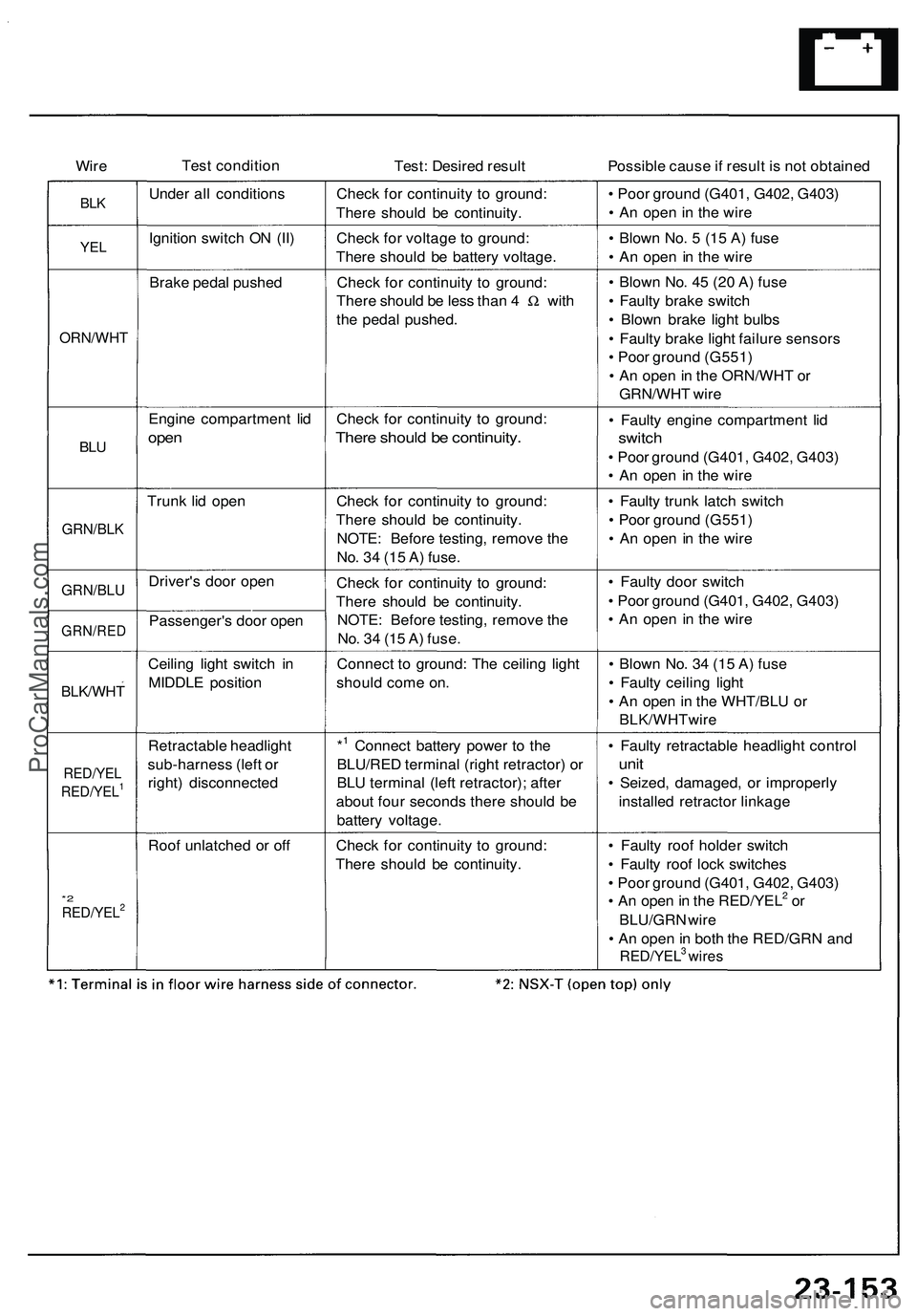

Wire Tes

t conditio n

Test: Desire d resul t Possible caus e if resul t i s no t obtaine d

BLKUnde r al l condition sCheck fo r continuit y t o ground :

Ther e shoul d b e continuity . •

Poo r groun d (G401 , G402 , G403 )

• A n ope n in th e wir e

YELIgnitio n switc h O N (II ) Check fo r voltag e t o ground :

Ther e shoul d b e batter y voltage . •

Blow n No . 5 (1 5 A ) fus e

• A n ope n i n th e wir e

Brak e peda l pushe d Check fo r continuit y t o ground :

Ther e shoul d b e les s tha n 4 W wit h

th e peda l pushed .

ORN/WH T

• Blow n No . 4 5 (2 0 A ) fus e

• Fault y brak e switc h

• Blow n brak e ligh t bulb s

• Fault y brak e ligh t failur e sensor s

• Poo r groun d (G551 )

• A n ope n in th e ORN/WH T o r

GRN/WH T wir e

BLU

Engin e compartmen t li d

ope n

Chec k fo r continuit y t o ground :

There shoul d b e continuity .

• Fault y engin e compartmen t li d

switc h

• Poo r groun d (G401 , G402 , G403 )

• A n ope n i n th e wir e

Trun k li d ope n

GRN/BL K

Check fo r continuit y t o ground :

Ther e shoul d b e continuity .

NOTE : Befor e testing , remov e th e

No . 3 4 (1 5 A ) fuse . •

Fault y trun k latc h switc h

• Poo r groun d (G551 )

• A n ope n in th e wir e

GRN/BL UDriver's doo r ope n

GRN/RE DPassenger' s doo r ope n Chec

k fo r continuit y t o ground :

Ther e shoul d b e continuity .

NOTE : Befor e testing , remov e th e

No . 3 4 (1 5 A ) fuse . •

Fault y doo r switc h

• Poo r groun d (G401 , G402 , G403 )

• A n ope n i n th e wir e

BLK/WH T

Ceiling ligh t switc h i n

MIDDL E positio n Connec

t t o ground : Th e ceilin g ligh t

shoul d com e on . •

Blow n No . 3 4 (1 5 A ) fus e

• Fault y ceilin g ligh t

• A n ope n in th e WHT/BL U o r

BLK/WHTwir e

RED/YEL

RED/YEL1

Retractabl e headligh t

sub-harnes s (lef t o r

right ) disconnecte d*1 Connec

t batter y powe r t o th e

BLU/RE D termina l (righ t retractor ) o r

BL U termina l (lef t retractor) ; afte r

abou t fou r second s ther e shoul d b e

batter y voltage . •

Fault y retractabl e headligh t contro l

unit

• Seized , damaged , o r improperl y

installe d retracto r linkag e

Roo f unlatche d o r of f Check fo r continuit y t o ground :

Ther e shoul d b e continuity .

*2RED/YEL2

• Fault y roo f holde r switc h

• Fault y roo f loc k switche s

• Poo r groun d (G401 , G402 , G403 )

• A n ope n in th e RED/YEL

2 o r

BLU/GR N wir e

• A n ope n in bot h th e RED/GR N an d

RED/YEL3 wire s

ProCarManuals.com

Page 1312 of 1503

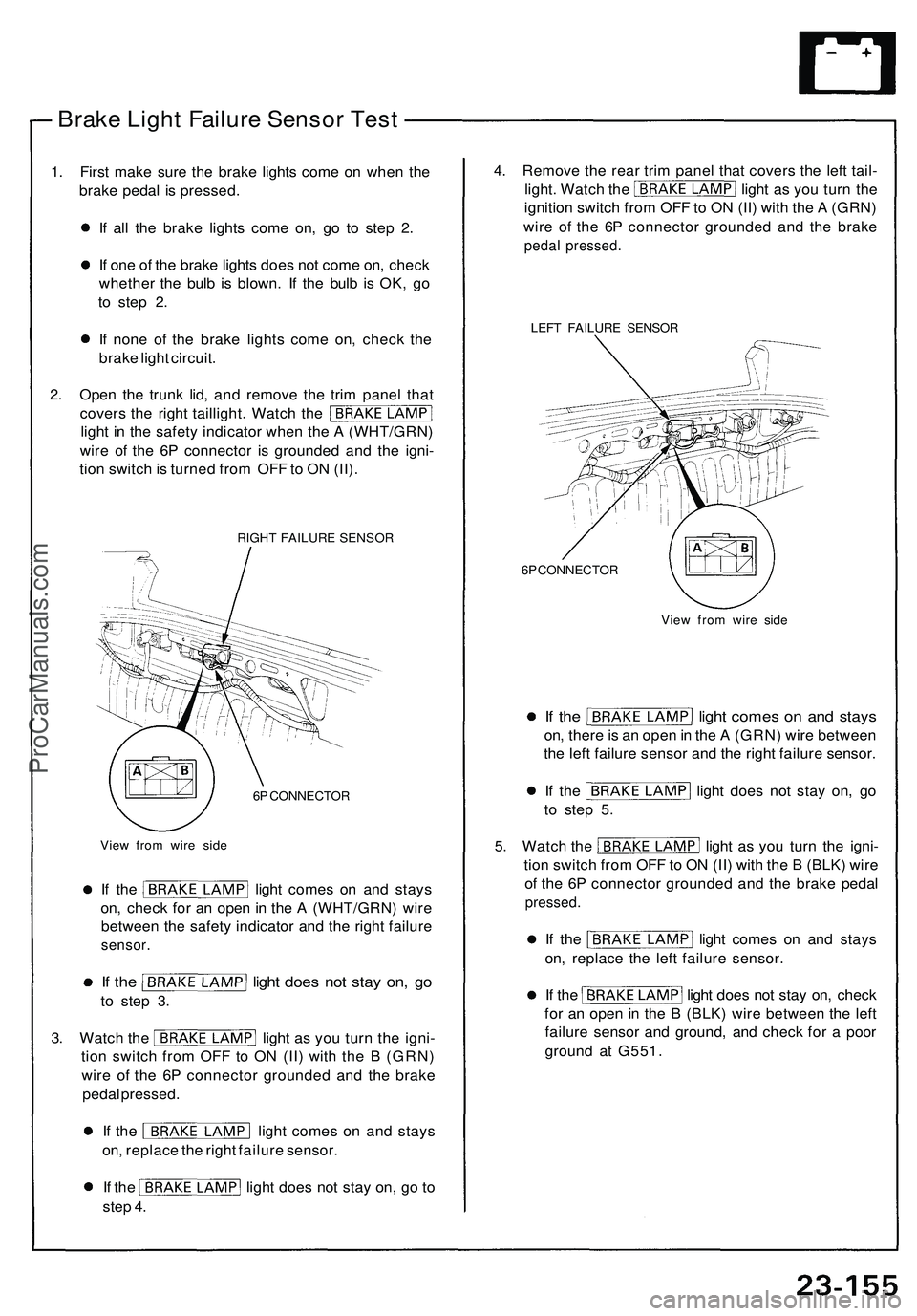

Brake Ligh t Failur e Senso r Tes t

1. Firs t mak e sur e th e brak e light s com e o n whe n th e

brak e peda l i s pressed .

I f al l th e brak e light s com e on , g o t o ste p 2 .

I f on e o f th e brak e light s doe s no t com e on , chec k

whethe r th e bul b i s blown . I f th e bul b i s OK , g o

t o ste p 2 .

I f non e o f th e brak e light s com e on , chec k th e

brak e ligh t circui t.

2 . Ope n th e trun k lid , an d remov e th e tri m pane l tha t

cover s th e righ t taillight . Watc h th e

ligh t i n th e safet y indicato r whe n th e A (WHT/GRN )

wir e o f th e 6 P connecto r i s grounde d an d th e igni -

tio n switc h is turne d fro m OF F to O N (II) .

RIGH T FAILUR E SENSO R

6 P CONNECTO R

Vie w fro m wir e sid e LEF

T FAILUR E SENSO R

6 P CONNECTO R

View fro m wir e sid e

If th e ligh t come s o n an d stay s

on, ther e is a n ope n in th e A (GRN ) wir e betwee n

th e lef t failur e senso r an d th e righ t failur e sensor .

If th e ligh t doe s no t sta y on , g o

t o ste p 5 .

5. Watc h th e ligh t a s yo u tur n th e igni -

tio n switc h fro m OF F to O N (II ) wit h th e B (BLK ) wir e

o f th e 6 P connecto r grounde d an d th e brak e peda l

pressed .

If th e ligh t come s o n an d stay s

on , replac e th e lef t failur e sensor .

If th e ligh t doe s no t sta y on , chec k

fo r a n ope n in th e B (BLK ) wir e betwee n th e lef t

failur e senso r an d ground , an d chec k fo r a poo r

groun d a t G551 .

If th e ligh t come s o n an d stay s

on , chec k fo r a n ope n in th e A (WHT/GRN ) wir e

betwee n th e safet y indicato r an d th e righ t failur e

sensor .

If th e ligh t doe s no t sta y on , g o

to ste p 3 .

3. Watc h th e ligh t a s yo u tur n th e igni -

tio n switc h fro m OF F t o O N (II ) wit h th e B (GRN )

wir e o f th e 6 P connecto r grounde d an d th e brak e

peda l pressed .

If th e ligh t come s o n an d stay s

on , replac e th e righ t failur e sensor .

If th e ligh t doe s no t sta y on , g o t o

ste p 4 . 4

. Remov e th e rea r tri m pane l tha t cover s th e lef t tail -

light . Watc h th e ligh t a s yo u tur n th e

ignitio n switc h fro m OF F to O N (II ) wit h th e A (GRN )

wir e o f th e 6 P connecto r grounde d an d th e brak e

pedal pressed .

ProCarManuals.com