ACURA RL KA9 1996 Service Repair Manual

Manufacturer: ACURA, Model Year: 1996, Model line: RL KA9, Model: ACURA RL KA9 1996Pages: 1954, PDF Size: 61.44 MB

Page 721 of 1954

Description

Power Flo w (cont'd )

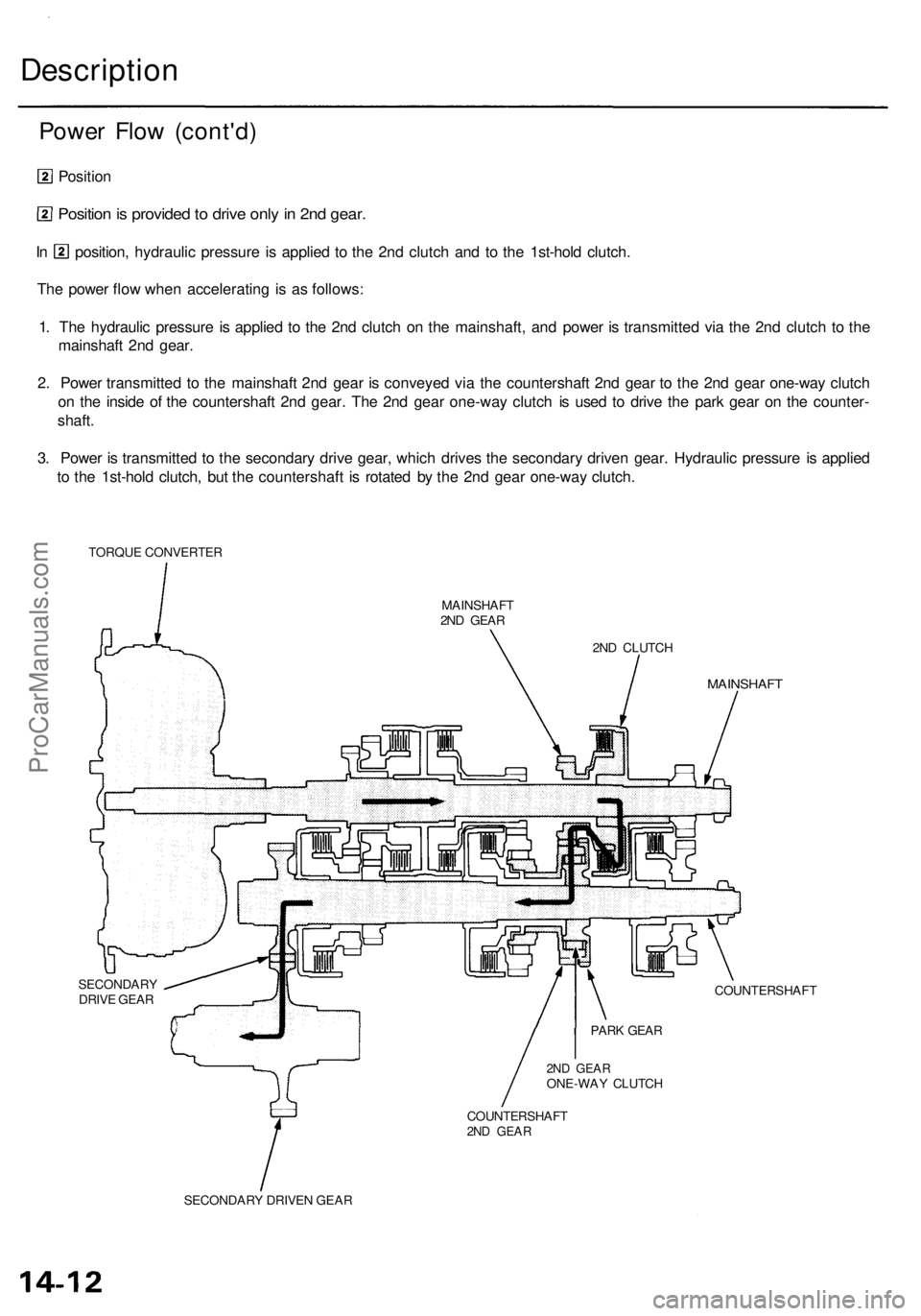

Position

Position is provide d to driv e onl y in 2n d gear .

In position , hydrauli c pressur e i s applie d t o th e 2n d clutc h an d t o th e 1st-hol d clutch .

Th e powe r flo w whe n acceleratin g i s a s follows :

1 . Th e hydrauli c pressur e is applie d t o th e 2n d clutc h o n th e mainshaft , an d powe r i s transmitte d vi a th e 2n d clutc h t o th e

mainshaf t 2n d gear .

2 . Powe r transmitte d t o th e mainshaf t 2n d gea r i s conveye d vi a th e countershaf t 2n d gea r t o th e 2n d gea r one-wa y clutc h

o n th e insid e o f th e countershaf t 2n d gear . Th e 2n d gea r one-wa y clutc h i s use d t o driv e th e par k gea r o n th e counter -

shaft .

3 . Powe r i s transmitte d t o th e secondar y driv e gear , whic h drive s th e secondar y drive n gear . Hydrauli c pressur e i s applie d

t o th e 1st-hol d clutch , bu t th e countershaf t i s rotate d b y th e 2n d gea r one-wa y clutch .

TORQU E CONVERTE R

MAINSHAFT

2N D GEA R

2ND CLUTC H

MAINSHAF T

SECONDAR YDRIVE GEA R COUNTERSHAF

T

2ND GEA RONE-WA Y CLUTC H

COUNTERSHAF T

2ND GEA R

SECONDAR Y DRIVE N GEA R PAR

K GEA R

ProCarManuals.com

Page 722 of 1954

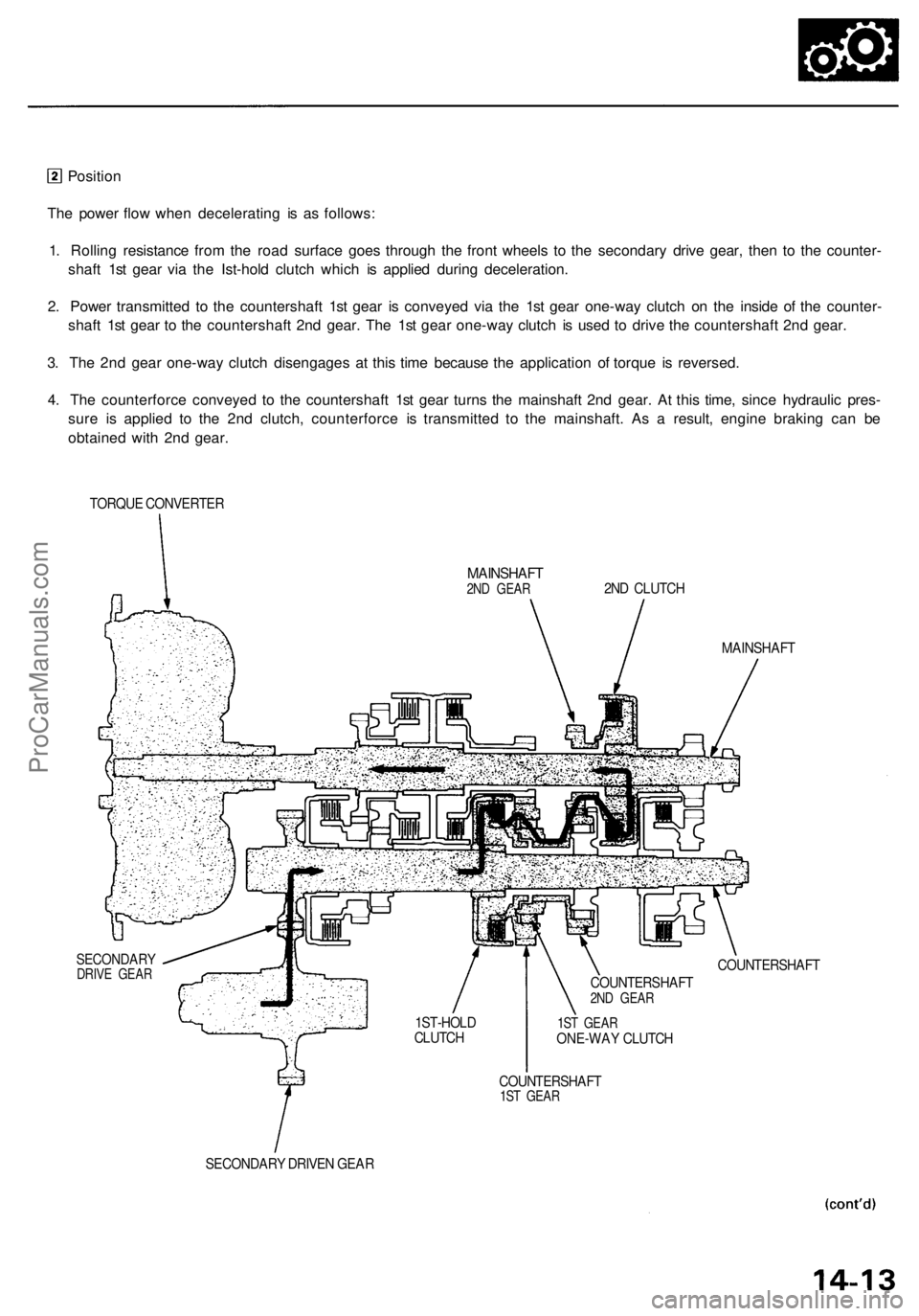

Position

The power flow when decelerating is as follows:

1. Rolling resistance from the road surface goes through the front wheels to the secondary drive gear, then to the counter-

shaft 1st gear via the Ist-hold clutch which is applied during deceleration.

2. Power transmitted to the countershaft 1st gear is conveyed via the 1st gear one-way clutch on the inside of the counter-

shaft 1st gear to the countershaft 2nd gear. The 1st gear one-way clutch is used to drive the countershaft 2nd gear.

3. The 2nd gear one-way clutch disengages at this time because the application of torque is reversed.

4. The counterforce conveyed to the countershaft 1st gear turns the mainshaft 2nd gear. At this time, since hydraulic pres-

sure is applied to the 2nd clutch, counterforce is transmitted to the mainshaft. As a result, engine braking can be

obtained with 2nd gear.

TORQUE CONVERTER

MAINSHAFT

2ND GEAR

2ND CLUTCH

MAINSHAFT

SECONDARY

DRIVE GEAR

COUNTERSHAFT

1ST GEAR

ONE-WAY CLUTCH

COUNTERSHAFT

1ST GEAR

SECONDARY DRIVEN GEAR

1ST-HOLD

CLUTCH

COUNTERSHAFT

2ND GEARProCarManuals.com

Page 723 of 1954

Description

Power Flo w (cont'd )

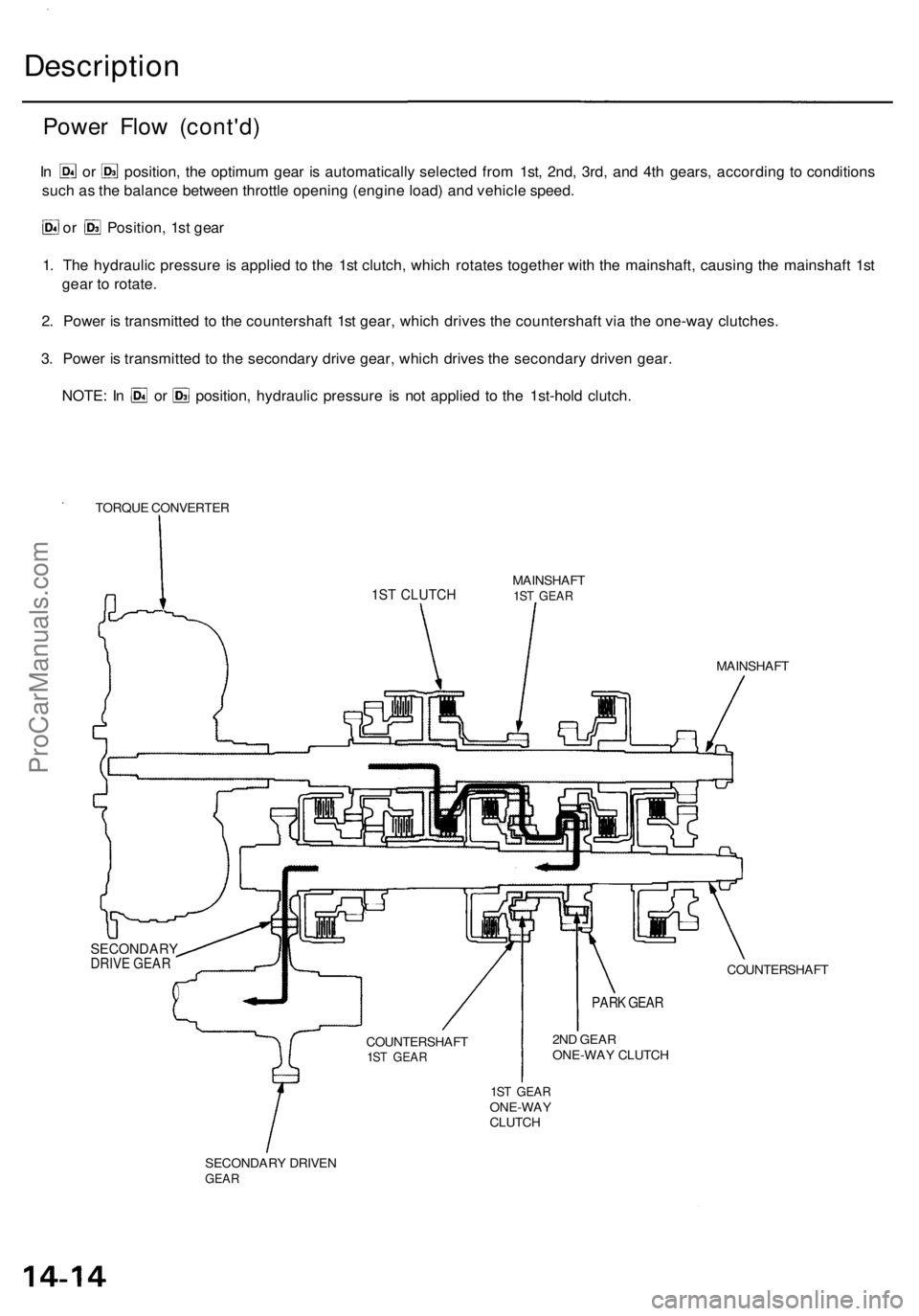

In o r position , th e optimu m gea r i s automaticall y selecte d fro m 1st , 2nd , 3rd , an d 4t h gears , accordin g t o condition s

suc h a s th e balanc e betwee n throttl e openin g (engin e load ) an d vehicl e speed .

or Position , 1s t gea r

1 . Th e hydrauli c pressur e i s applie d t o th e 1s t clutch , whic h rotate s togethe r wit h th e mainshaft , causin g th e mainshaf t 1s t

gea r t o rotate .

2 . Powe r i s transmitte d t o th e countershaf t 1s t gear , whic h drive s th e countershaf t vi a th e one-wa y clutches .

3 . Powe r i s transmitte d t o th e secondar y driv e gear , whic h drive s th e secondar y drive n gear .

NOTE : I n o r position , hydrauli c pressur e i s no t applie d t o th e 1st-hol d clutch .

TORQU E CONVERTE R

MAINSHAFT

1ST GEA R

2ND GEA R

ONE-WA Y CLUTC H

1ST GEA RONE-WA Y

CLUTC H MAINSHAF

T

COUNTERSHAF T

SECONDAR Y DRIVE N

GEAR

COUNTERSHAF T1ST GEA R

PARK GEAR

SECONDARYDRIVE GEAR

1ST CLUTCH

ProCarManuals.com

Page 724 of 1954

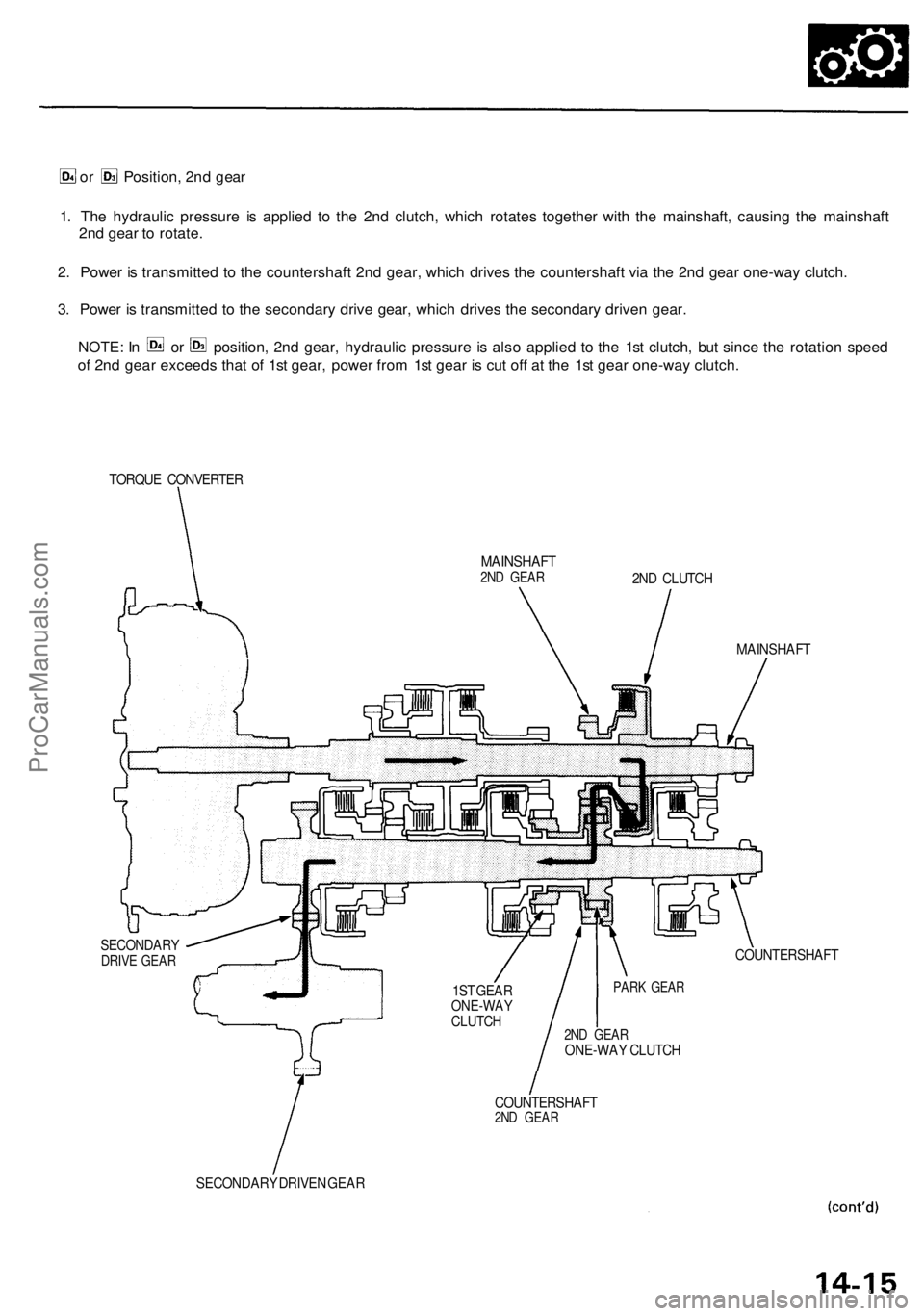

or Position, 2nd gear

1. The hydraulic pressure is applied to the 2nd clutch, which rotates together with the mainshaft, causing the mainshaft

2nd gear to rotate.

2. Power is transmitted to the countershaft 2nd gear, which drives the countershaft via the 2nd gear one-way clutch.

3. Power is transmitted to the secondary drive gear, which drives the secondary driven gear.

NOTE: In or position, 2nd gear, hydraulic pressure is also applied to the 1st clutch, but since the rotation speed

of 2nd gear exceeds that of 1st gear, power from 1st gear is cut off at the 1st gear one-way clutch.

TORQUE CONVERTER

SECONDARY

DRIVE GEAR

MAINSHAFT

2ND GEAR

2ND CLUTCH

MAINSHAFT

COUNTERSHAFT

2ND GEAR

ONE-WAY CLUTCH

COUNTERSHAFT

2ND GEAR

SECONDARY DRIVEN GEAR

1ST GEAR

ONE-WAY

CLUTCH

PARK GEARProCarManuals.com

Page 725 of 1954

Power Flo w (cont'd )

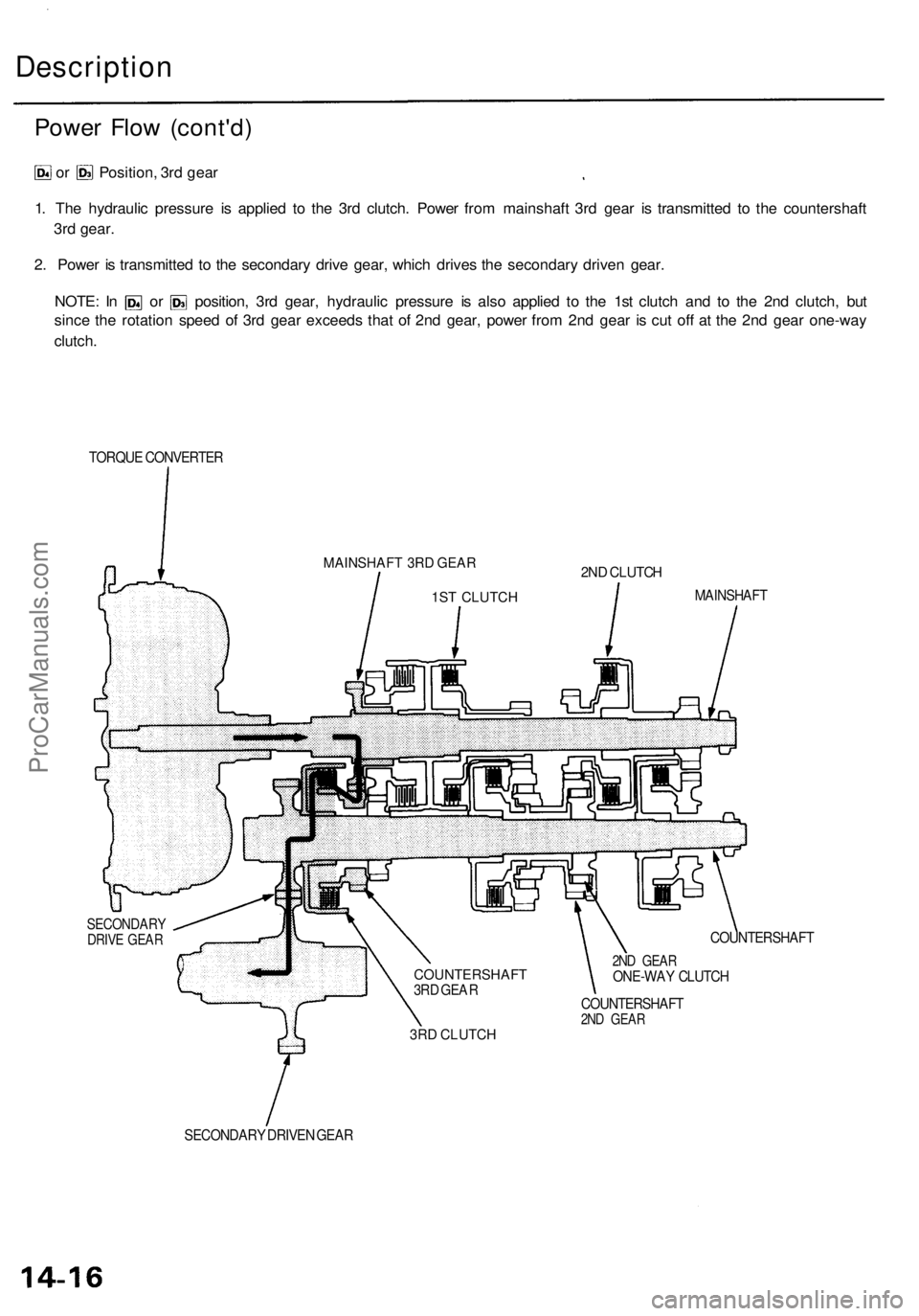

or Position , 3r d gea r

1 . Th e hydrauli c pressur e i s applie d t o th e 3r d clutch . Powe r fro m mainshaf t 3r d gea r i s transmitte d t o th e countershaf t

3r d gear .

2 . Powe r i s transmitte d t o th e secondar y driv e gear , whic h drive s th e secondar y drive n gear .

NOTE : I n o r position , 3r d gear , hydrauli c pressur e i s als o applie d t o th e 1s t clutc h an d t o th e 2n d clutch , bu t

sinc e th e rotatio n spee d o f 3r d gea r exceed s tha t o f 2n d gear , powe r fro m 2n d gea r i s cu t of f a t th e 2n d gea r one-wa y

clutch .

TORQU E CONVERTE R

SECONDAR YDRIVE GEA RCOUNTERSHAF T

2ND GEA RONE-WA Y CLUTC H

COUNTERSHAF T

2ND GEA R

SECONDAR Y DRIVE N GEA R

3RD CLUTCH

COUNTERSHAFT3RD GEA R MAINSHAFT

2ND CLUTCH

1ST

CLUTCH

MAINSHAFT 3RD GEAR

Description

ProCarManuals.com

Page 726 of 1954

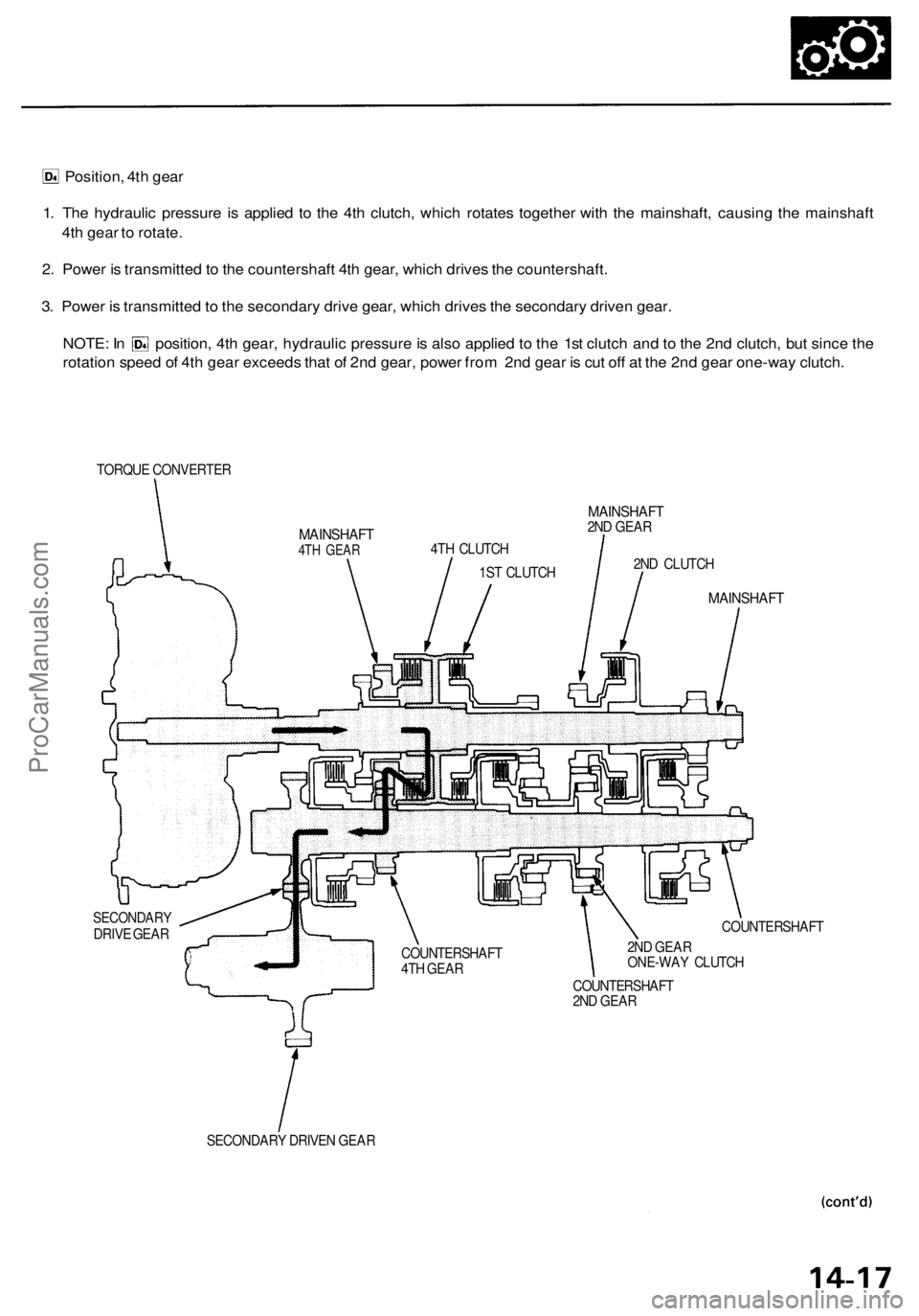

Position, 4th gear

1. The hydraulic pressure is applied to the 4th clutch, which rotates together with the mainshaft, causing the mainshaft

4th gear to rotate.

2. Power is transmitted to the countershaft 4th gear, which drives the countershaft.

3. Power is transmitted to the secondary drive gear, which drives the secondary driven gear.

NOTE: In position, 4th gear, hydraulic pressure is also applied to the 1st clutch and to the 2nd clutch, but since the

rotation speed of 4th gear exceeds that of 2nd gear, power from 2nd gear is cut off at the 2nd gear one-way clutch.

TORQUE CONVERTER

MAINSHAFT

4TH GEAR

MAINSHAFT

2ND GEAR

SECONDARY

DRIVE GEAR

COUNTERSHAFT

2ND GEAR

SECONDARY DRIVEN GEAR

COUNTERSHAFT

4TH GEAR

2ND GEAR

ONE-WAY CLUTCH

COUNTERSHAFT

MAINSHAFT

2ND CLUTCH

4TH CLUTCH

1ST CLUTCHProCarManuals.com

Page 727 of 1954

Description

Power Flo w (cont'd )

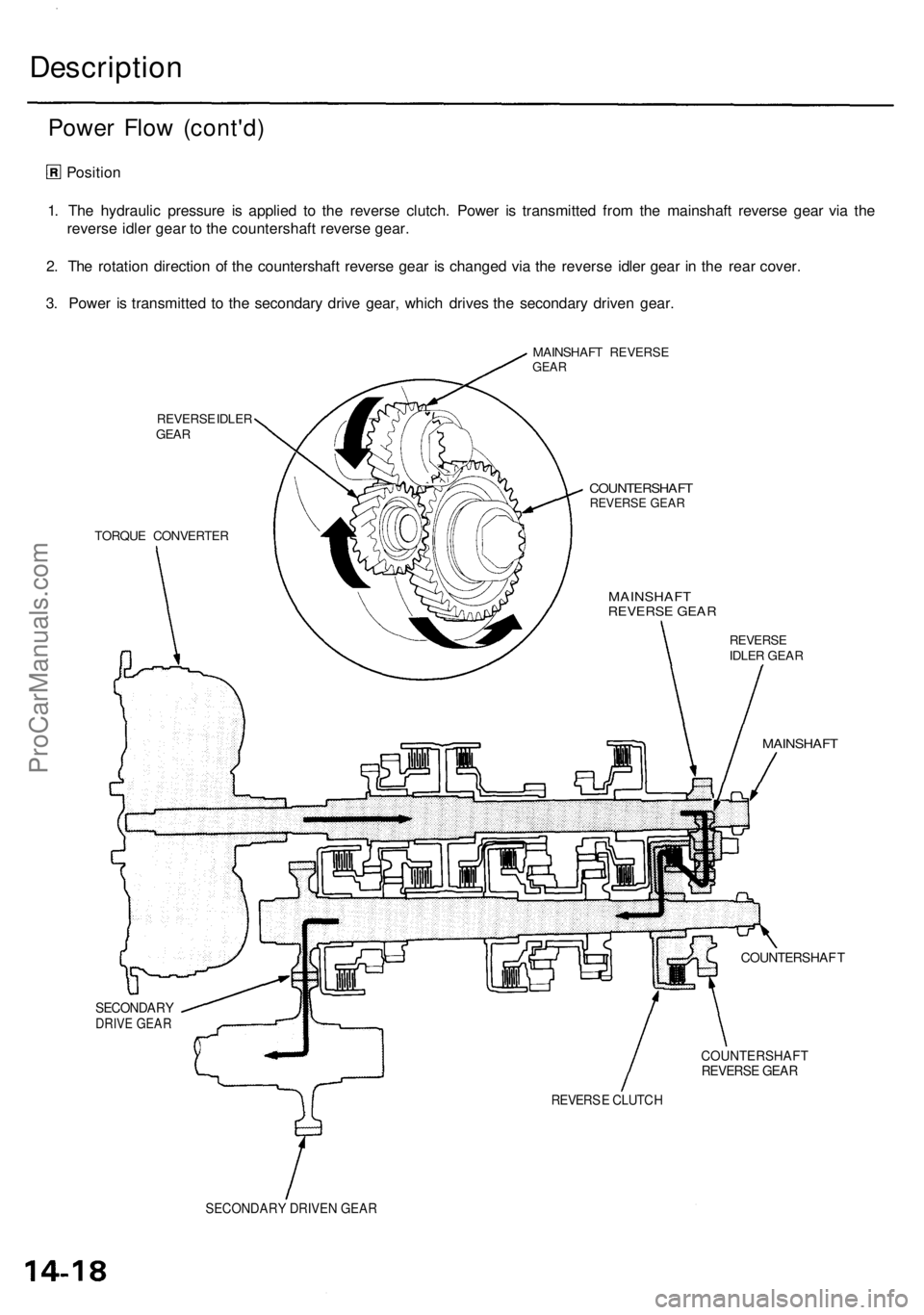

Position

1 . Th e hydrauli c pressur e i s applie d t o th e revers e clutch . Powe r i s transmitte d fro m th e mainshaf t revers e gea r vi a th e

revers e idle r gea r t o th e countershaf t revers e gear .

2 . Th e rotatio n directio n o f th e countershaf t revers e gea r i s change d vi a th e revers e idle r gea r i n th e rea r cover .

3 . Powe r i s transmitte d t o th e secondar y driv e gear , whic h drive s th e secondar y drive n gear .

REVERS E IDLE R

GEA R MAINSHAF

T REVERS E

GEAR

COUNTERSHAF TREVERSE GEA R

TORQU E CONVERTE R

REVERSEIDLER GEA R

MAINSHAF T

COUNTERSHAF T

SECONDARYDRIVE GEAR

COUNTERSHAFTREVERSE GEAR

REVERS E CLUTC H

SECONDARY DRIVEN GEAR

MAINSHAF T

REVERSE GEAR

ProCarManuals.com

Page 728 of 1954

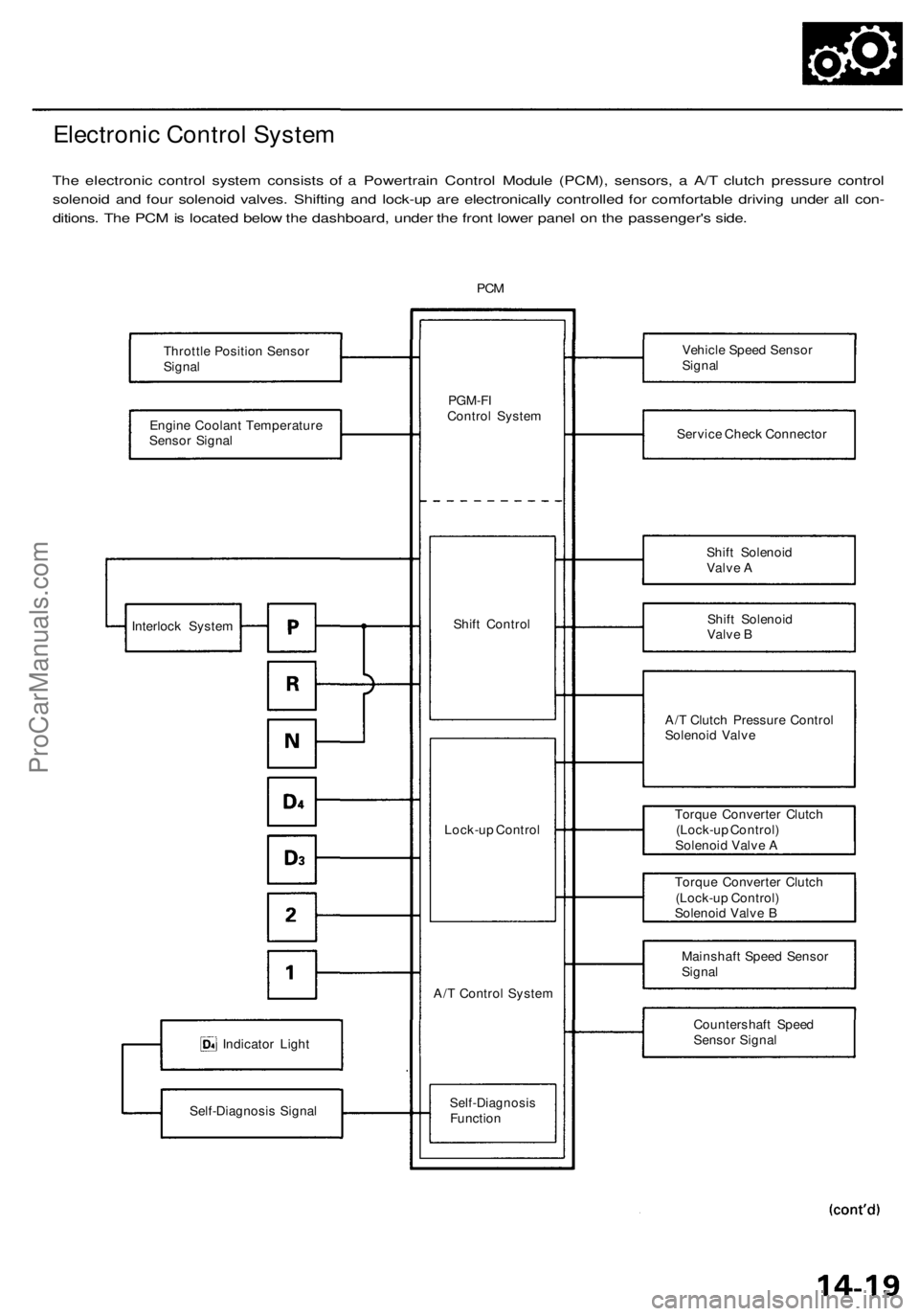

Electronic Control System

The electronic control system consists of a Powertrain Control Module (PCM), sensors, a A/T clutch pressure control

solenoid and four solenoid valves. Shifting and lock-up are electronically controlled for comfortable driving under all con-

ditions. The PCM is located below the dashboard, under the front lower panel on the passenger's side.

PCM

Throttle Position Sensor

Signal

Engine Coolant Temperature

Sensor Signal

Indicator Light

Self-Diagnosis Signal

PGM-FI

Control System

Shift Control

Lock-up Control

A/T Control System

Self-Diagnosis

Function

Vehicle Speed Sensor

Signal

Service Check Connector

Shift Solenoid

Valve A

Shift Solenoid

Valve B

A/T Clutch Pressure Control

Solenoid Valve

Torque Converter Clutch

(Lock-up Control)

Solenoid Valve A

Torque Converter Clutch

(Lock-up Control)

Solenoid Valve B

Mainshaft Speed Sensor

Signal

Countershaft Speed

Sensor Signal

Interlock SystemProCarManuals.com

Page 729 of 1954

Description

Electronic Contro l Syste m (cont'd )

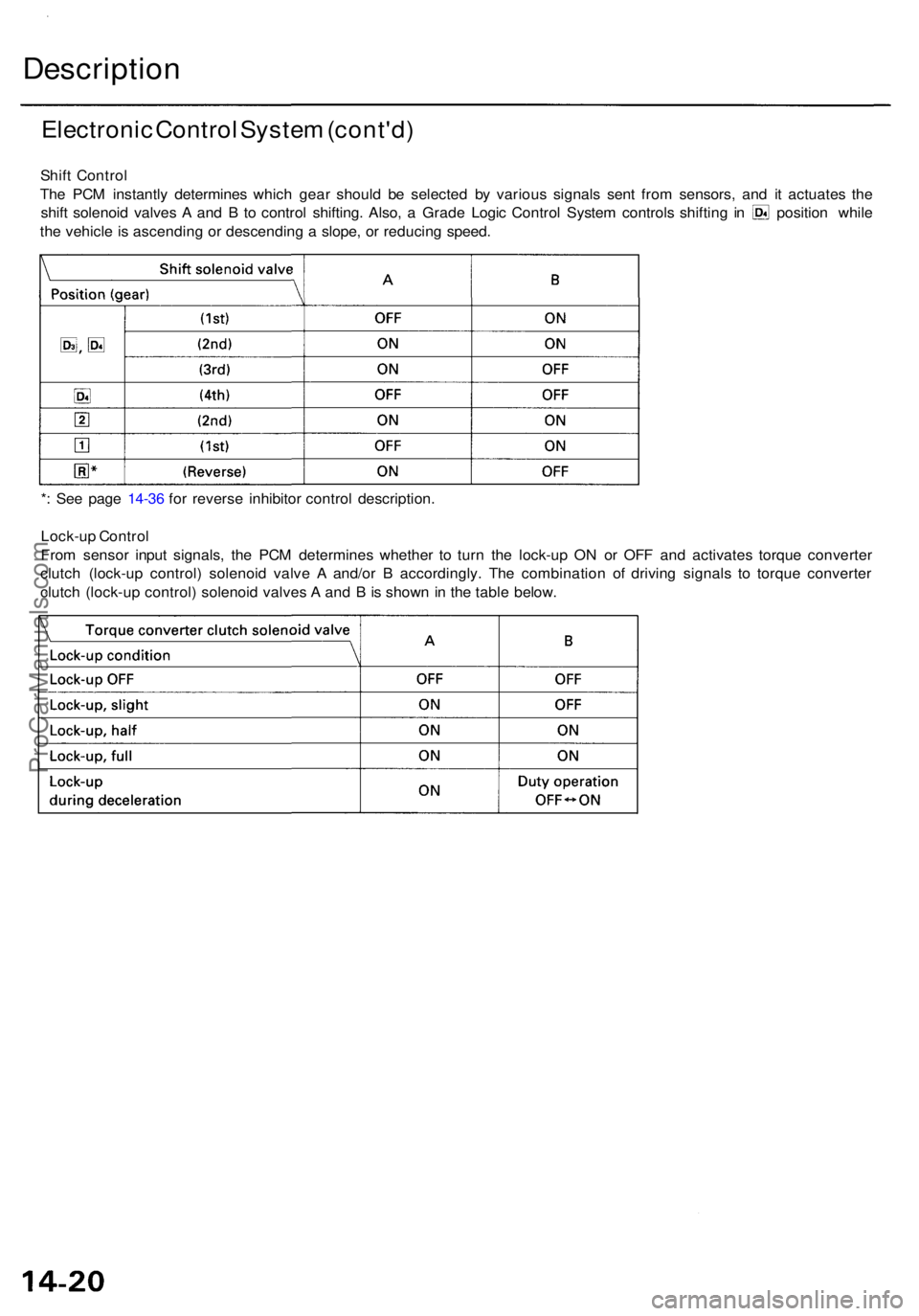

Shift Contro l

Th e PC M instantl y determine s whic h gea r shoul d b e selecte d b y variou s signal s sen t fro m sensors , an d i t actuate s th e

shif t solenoi d valve s A an d B to contro l shifting . Also , a Grad e Logi c Contro l Syste m control s shiftin g i n positio n whil e

th e vehicl e is ascendin g o r descendin g a slope , o r reducin g speed .

* : Se e pag e 14-3 6 fo r revers e inhibito r contro l description .

Lock-u p Contro l

Fro m senso r inpu t signals , th e PC M determine s whethe r t o tur n th e lock-u p O N o r OF F an d activate s torqu e converte r

clutc h (lock-u p control ) solenoi d valv e A and/o r B accordingly . Th e combinatio n o f drivin g signal s t o torqu e converte r

clutc h (lock-u p control ) solenoi d valve s A an d B is show n in th e tabl e below .

ProCarManuals.com

Page 730 of 1954

Grade Logic Control System

How it works:

The PCM compares actual driving conditions with driving conditions memorized in the PCM, based on the input from the

vehicle speed sensor, throttle position sensor, engine coolant temperature sensor, barometric pressure sensor, brake

pedal position switch signal and shift lever position signal, to control shifting while a vehicle is ascending or descending a

slope.ProCarManuals.com