ACURA RL KA9 1996 Service Repair Manual

Manufacturer: ACURA, Model Year: 1996, Model line: RL KA9, Model: ACURA RL KA9 1996Pages: 1954, PDF Size: 61.44 MB

Page 931 of 1954

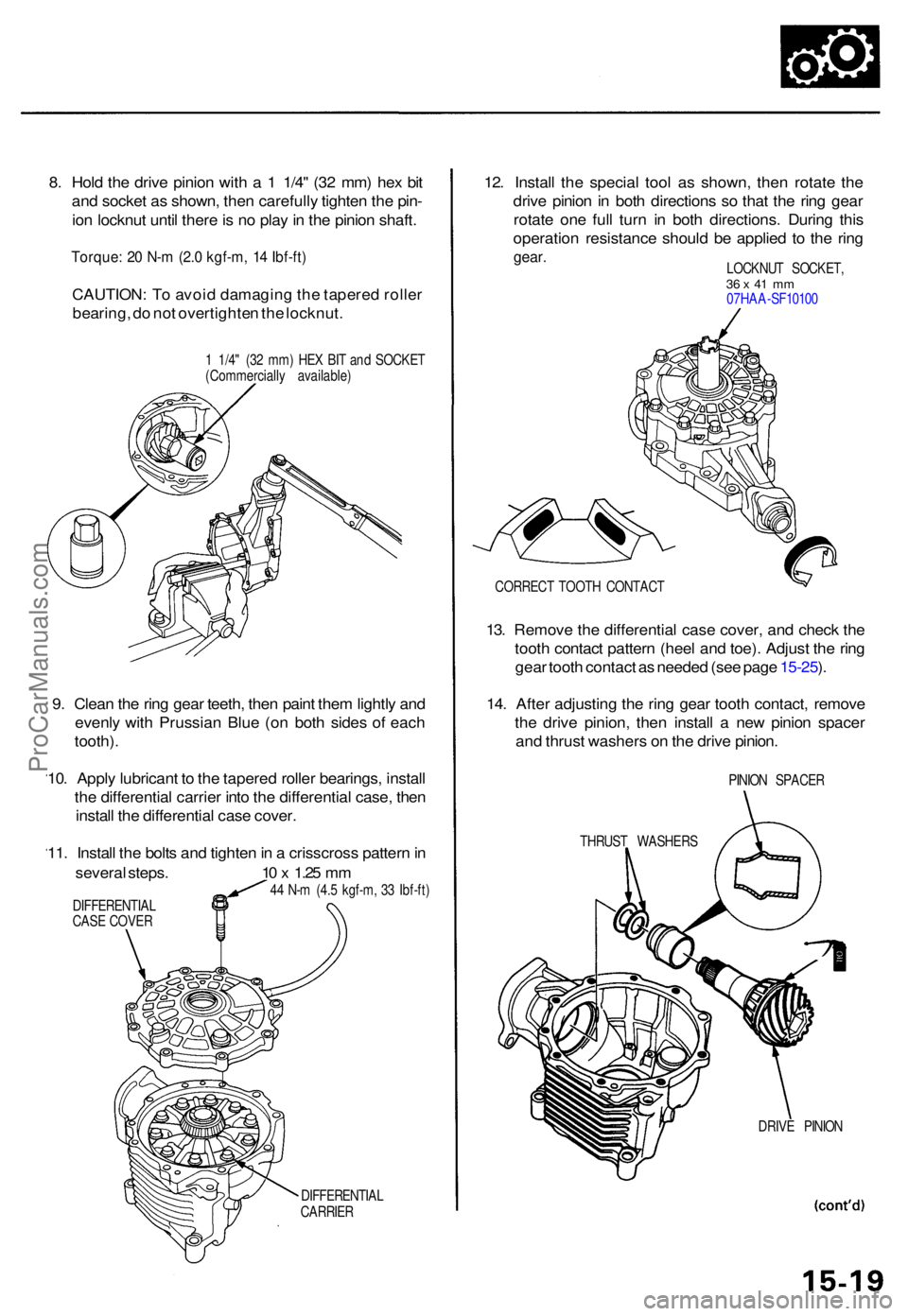

8. Hol d th e driv e pinio n wit h a 1 1/4 " (3 2 mm ) he x bi t

an d socke t a s shown , the n carefull y tighte n th e pin -

io n locknu t unti l ther e is n o pla y in th e pinio n shaft .

Torque : 2 0 N- m (2. 0 kgf-m , 1 4 Ibf-ft )

CAUTION : T o avoi d damagin g th e tapere d rolle r

bearing , d o no t overtighte n th e locknut .

1 1/4 " (3 2 mm ) HE X BI T an d SOCKE T

(Commerciall y available )

DIFFERENTIA L

CARRIE R

12. Instal l th e specia l too l a s shown , the n rotat e th e

driv e pinio n in bot h direction s s o tha t th e rin g gea r

rotat e on e ful l tur n i n bot h directions . Durin g thi s

operatio n resistanc e shoul d b e applie d t o th e rin g

gear .LOCKNU T SOCKET ,36 x 41 m m07HA A-SF1010 0

CORREC T TOOT H CONTAC T

13. Remov e th e differentia l cas e cover , an d chec k th e

toot h contac t patter n (hee l an d toe) . Adjus t th e rin g

gea r toot h contac t a s neede d (se e pag e 15-25 ).

14 . Afte r adjustin g th e rin g gea r toot h contact , remov e

th e driv e pinion , the n instal l a ne w pinio n space r

an d thrus t washer s o n th e driv e pinion .

PINION SPACE R

THRUS T WASHER S

DRIVE PINIO N

9. Clea n th e rin g gea r teeth , the n pain t the m lightl y an d

evenl y wit h Prussia n Blu e (o n bot h side s o f eac h

tooth) .

10 . Appl y lubrican t t o th e tapered roller bearings , instal l

th e differentia l carrie r int o th e differentia l case , the n

instal l th e differentia l cas e cover .

11 . Instal l th e bolt s an d tighte n in a crisscros s patter n in

severa l steps . 10 x 1.2 5 m m

44 N- m (4. 5 kgf-m , 3 3 Ibf-ft )

DIFFERENTIA L

CAS E COVE R

ProCarManuals.com

Page 932 of 1954

Differential Assembl y

Reassembl y (cont'd )

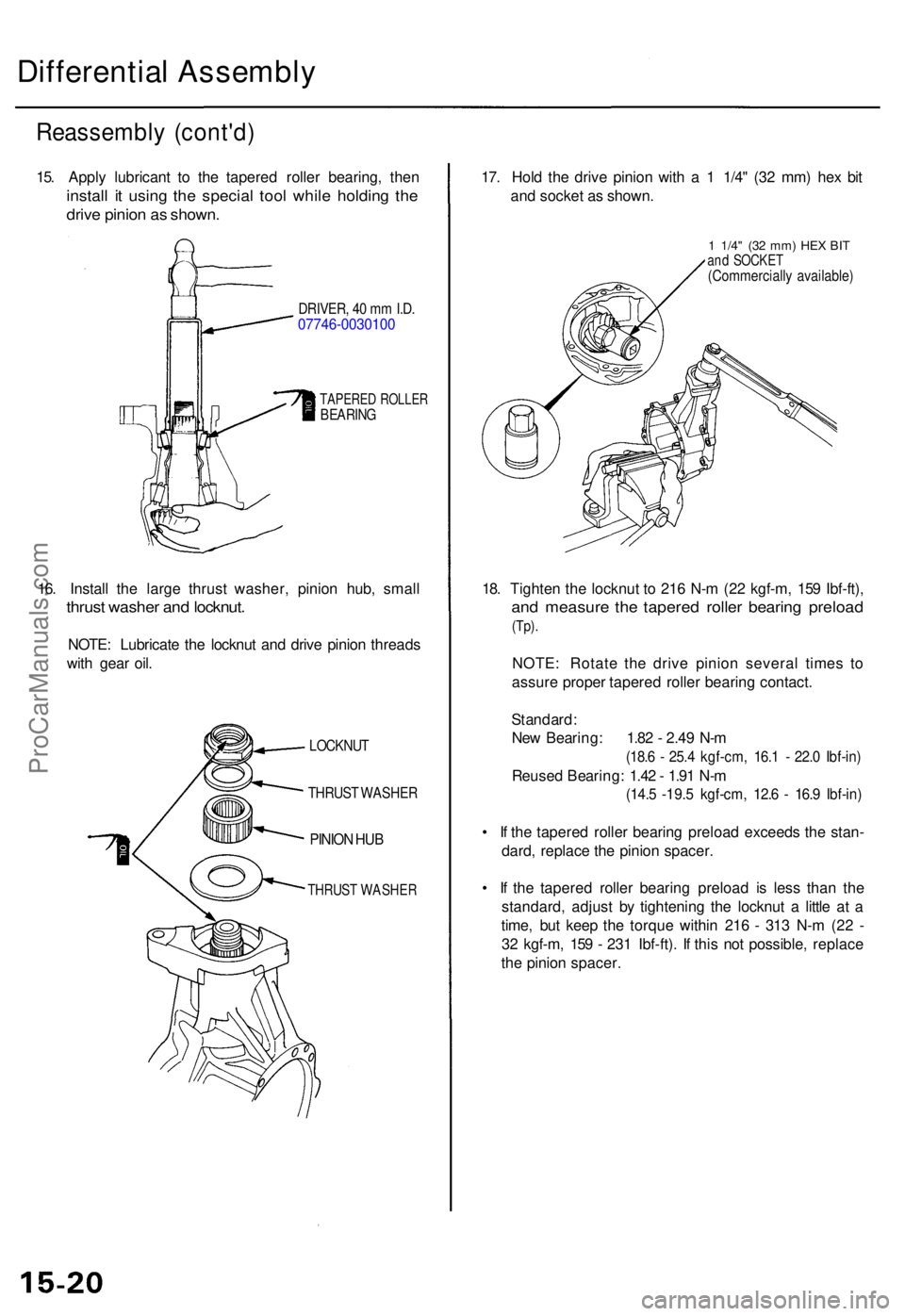

15. Appl y lubrican t t o th e tapere d rolle r bearing , the n

instal l i t usin g th e specia l too l whil e holdin g th e

driv e pinio n a s shown .

DRIVER , 4 0 m m I.D .07746-003010 0

TAPERED ROLLE RBEARIN G

16. Instal l th e larg e thrus t washer , pinio n hub , smal l

thrust washe r an d locknut .

NOTE: Lubricat e th e locknu t an d driv e pinio n thread s

wit h gea r oil .

LOCKNU T

THRUS T WASHE R

PINION HU B

THRUS T WASHE R

17. Hol d th e driv e pinio n wit h a 1 1/4 " (3 2 mm ) he x bi t

an d socke t a s shown .

1 1/4" (32 mm ) HE X BI Tand SOCKE T(Commerciall y available )

18. Tighte n th e locknu t t o 21 6 N- m (2 2 kgf-m , 15 9 Ibf-ft) ,

and measur e th e tapere d rolle r bearin g preloa d

(Tp).

NOTE : Rotat e th e driv e pinio n severa l time s t o

assur e prope r tapere d rolle r bearin g contact .

Standard :

Ne w Bearing : 1.8 2 - 2.4 9 N- m

(18. 6 - 25. 4 kgf-cm , 16. 1 - 22. 0 Ibf-in )

Reuse d Bearing : 1.4 2 - 1.9 1 N- m

(14. 5 -19. 5 kgf-cm , 12. 6 - 16. 9 Ibf-in )

• I f th e tapere d rolle r bearin g preloa d exceed s th e stan -

dard , replac e th e pinio n spacer .

• I f th e tapere d rolle r bearin g preloa d i s les s tha n th e

standard , adjus t b y tightenin g th e locknu t a littl e a t a

time , bu t kee p th e torqu e withi n 21 6 - 31 3 N- m (2 2 -

3 2 kgf-m , 15 9 - 23 1 Ibf-ft) . I f thi s no t possible , replac e

th e pinio n spacer .

ProCarManuals.com

Page 933 of 1954

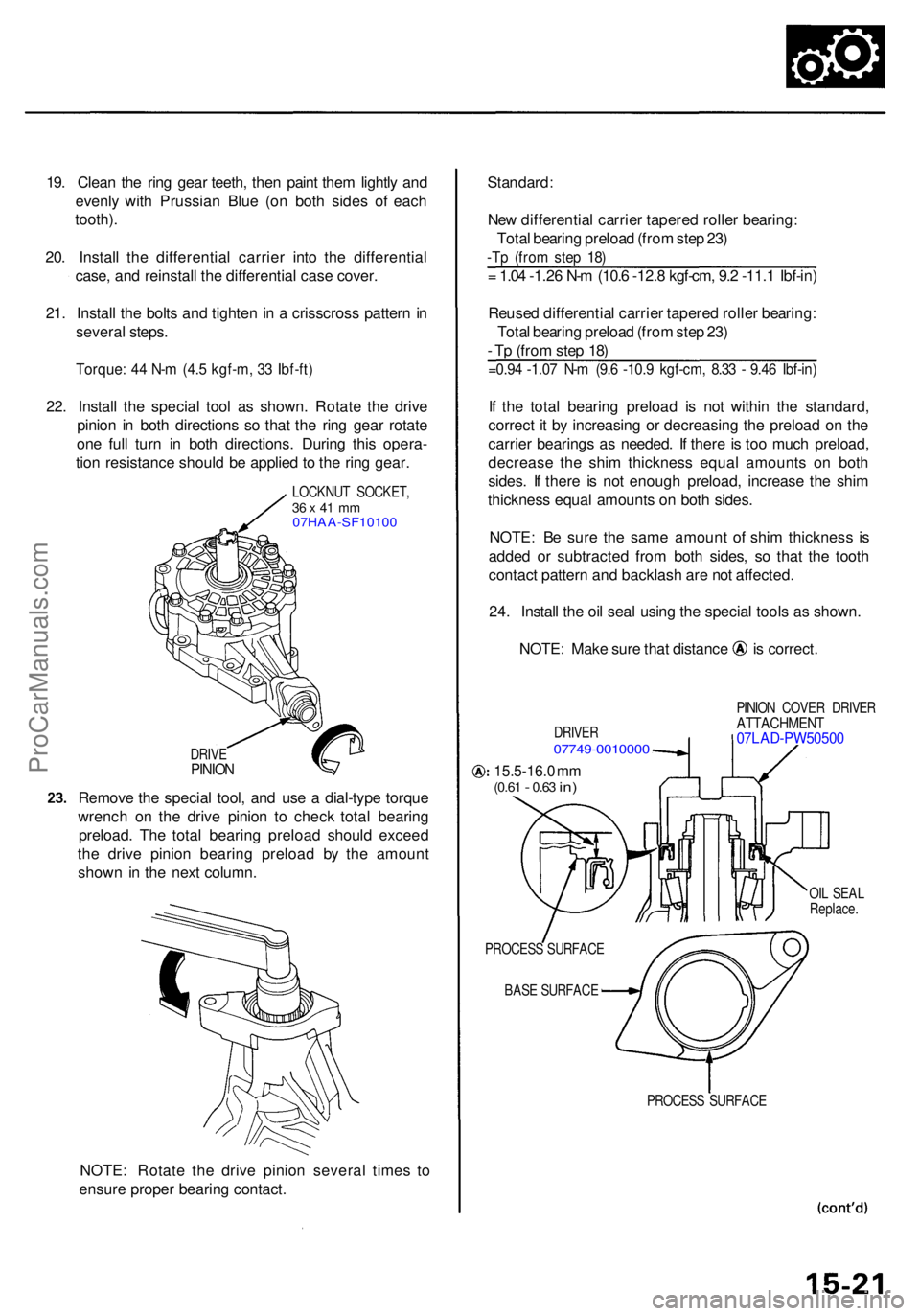

19. Clea n th e rin g gea r teeth , the n pain t the m lightl y an d

evenl y wit h Prussia n Blu e (o n bot h side s of eac h

tooth) .

20 . Instal l th e differentia l carrie r int o th e differentia l

case , an d reinstal l th e differentia l cas e cover .

21 . Instal l th e bolt s an d tighte n in a crisscros s patter n in

severa l steps .

Torque : 4 4 N- m (4. 5 kgf-m , 3 3 Ibf-ft )

22. Instal l th e specia l too l a s shown . Rotat e th e driv e

pinio n i n bot h direction s s o tha t th e rin g gea r rotat e

on e ful l tur n i n bot h directions . Durin g thi s opera -

tio n resistanc e shoul d b e applie d to th e rin g gear .

LOCKNU T SOCKET ,36 x 41 m m07HAA-SF1010 0

DRIVEPINIO N

Remov e th e specia l tool , an d us e a dial-typ e torqu e

wrenc h o n th e driv e pinio n t o chec k tota l bearin g

preload . Th e tota l bearin g preloa d shoul d excee d

th e driv e pinio n bearin g preloa d b y th e amoun t

show n i n th e nex t column .

NOTE : Rotat e th e driv e pinio n severa l time s t o

ensur e prope r bearin g contact .

=0.94 -1.0 7 N- m (9. 6 -10. 9 kgf-cm , 8.3 3 - 9.4 6 Ibf-in )

If th e tota l bearin g preloa d i s no t withi n th e standard ,

correc t i t b y increasin g o r decreasin g th e preloa d o n th e

carrie r bearing s a s needed . I f ther e is to o muc h preload ,

decreas e th e shi m thicknes s equa l amount s o n bot h

sides . I f ther e i s no t enoug h preload , increas e th e shi m

thicknes s equa l amount s o n bot h sides .

NOTE : B e sur e th e sam e amoun t o f shi m thicknes s i s

adde d o r subtracte d fro m bot h sides , s o tha t th e toot h

contac t patter n an d backlas h ar e no t affected .

24 . Instal l th e oi l sea l usin g th e specia l tool s a s shown .

NOTE: Mak e sur e tha t distanc e i s correct .

DRIVER07749-001000 0

PINION COVE R DRIVE RATTACHMEN T07LAD-PW5050 0

15.5-16.0 m m(0.6 1 - 0.63 in)

OIL SEA L

Replace .

PROCES S SURFAC E

BAS E SURFAC E

PROCESS SURFAC E

= 1.0 4 -1.2 6 N- m (10. 6 -12. 8 kgf-cm , 9. 2 -11. 1 Ibf-in )

Reuse d differentia l carrie r tapere d rolle r bearing :

Tota l bearin g preloa d (fro m ste p 23 )

- T p (fro m ste p 18 )

Standard

:

Ne w differentia l carrie r tapere d rolle r bearing :

Tota l bearin g preloa d (fro m ste p 23 )

-Tp (fro m ste p 18 )

ProCarManuals.com

Page 934 of 1954

Differential Assembl y

Reassembl y (cont'd )

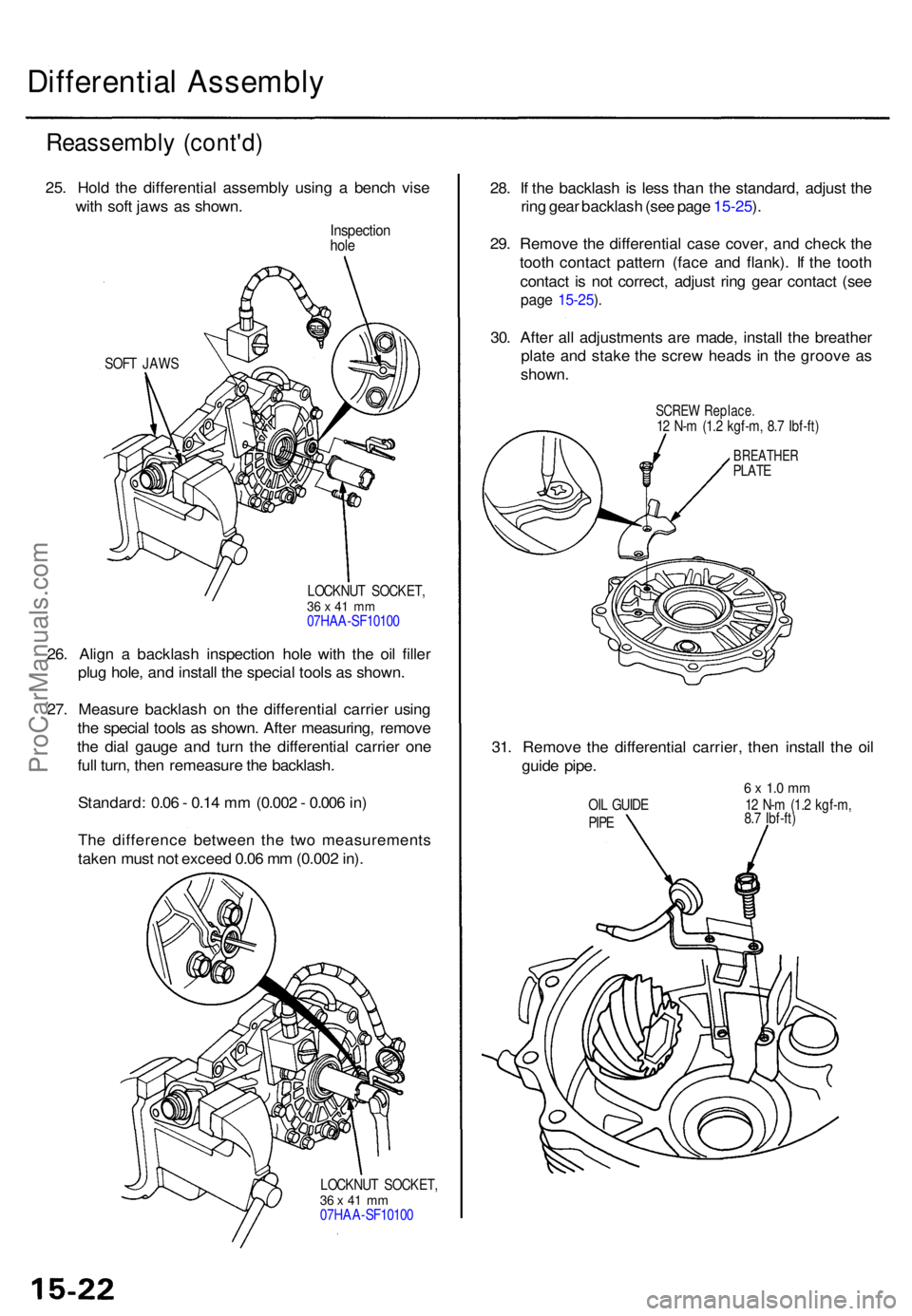

25. Hol d th e differentia l assembl y usin g a benc h vise

wit h sof t jaw s a s shown .

Inspectio nhole

SOF T JAW S

LOCKNUT SOCKET ,

36 x 41 m m07HA A-SF1010 0

26. Alig n a backlas h inspectio n hol e wit h th e oi l fille r

plu g hole , an d instal l th e specia l tool s a s shown .

27 . Measur e backlas h o n th e differentia l carrie r usin g

th e specia l tool s a s shown . Afte r measuring , remov e

th e dia l gaug e an d tur n th e differentia l carrie r on e

ful l turn , the n remeasur e th e backlash .

Standard : 0.0 6 - 0.1 4 m m (0.00 2 - 0.00 6 in )

Th e differenc e betwee n th e tw o measurement s

take n mus t no t excee d 0.0 6 m m (0.00 2 in) .

LOCKNU T SOCKET ,36 x 41 m m07HA A-SF1010 0

28. I f th e backlas h i s les s tha n th e standard , adjus t th e

rin g gea r backlas h (se e pag e 15-25 ).

29 . Remov e th e differentia l cas e cover , an d chec k th e

toot h contac t patter n (fac e an d flank) . I f th e toot h

contac t i s no t correct , adjus t rin g gea r contac t (se e

page 15-25 ).

30 . Afte r al l adjustment s ar e made , instal l th e breathe r

plat e an d stak e th e scre w head s i n th e groov e a s

shown .

SCREW Replace .12 N- m (1. 2 kgf-m , 8. 7 Ibf-ft )

BREATHE RPLATE

31. Remov e th e differentia l carrier , the n instal l th e oi l

guid e pipe .

6 x 1. 0 m m

OIL GUID E 1 2 N- m (1. 2 kgf-m ,

PIP E 8.

7 Ibf-ft )

ProCarManuals.com

Page 935 of 1954

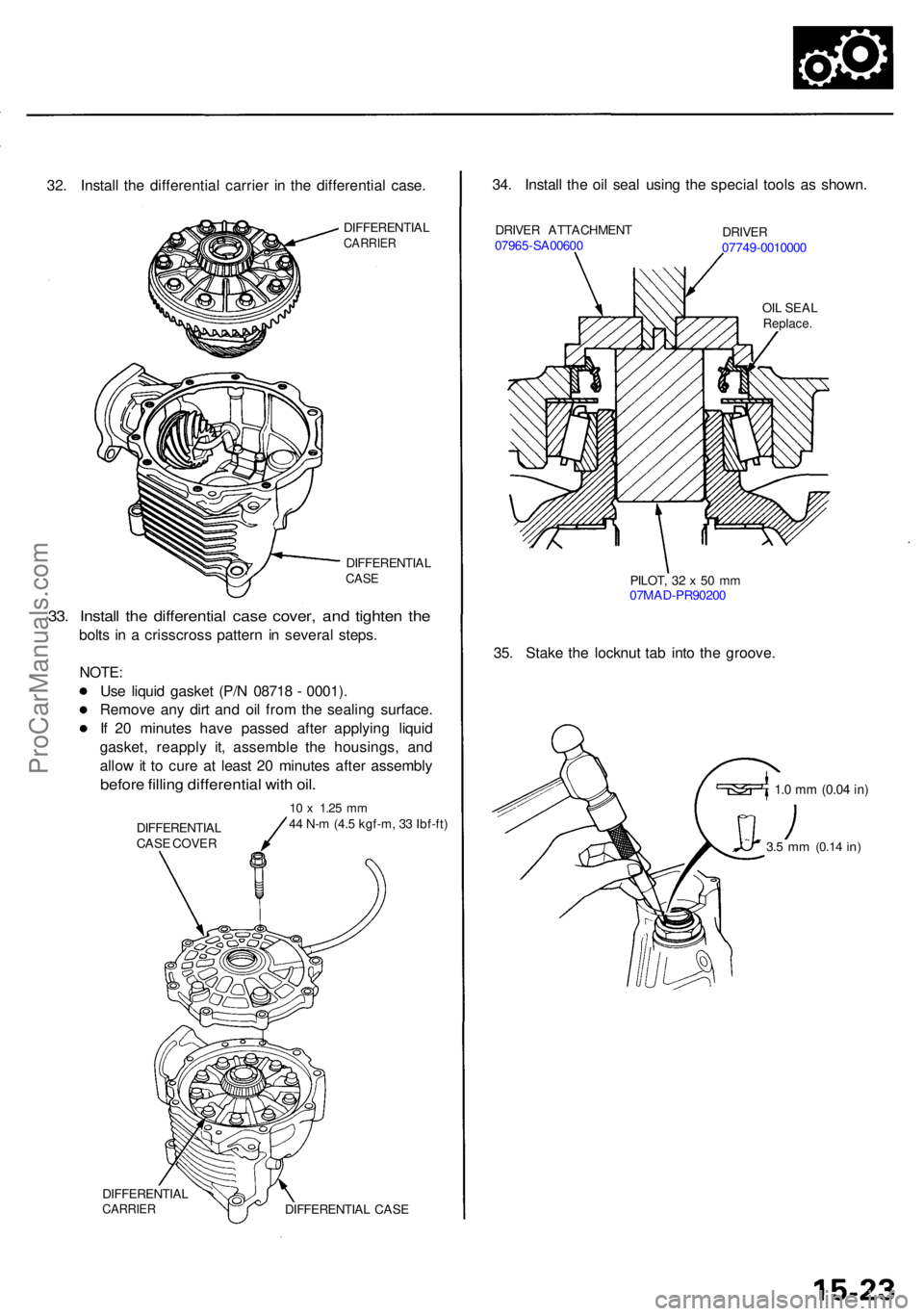

32. Instal l th e differentia l carrie r i n th e differentia l case .

DIFFERENTIA LCARRIER

DIFFERENTIA LCASE

DIFFERENTIA LCARRIERDIFFERENTIA L CAS E

34. Instal l th e oi l sea l usin g th e specia l tool s a s shown .

DRIVER ATTACHMEN T

0796 5-SA0060 0 DRIVE

R

0774 9-001000 0

OI L SEA L

Replace .

PILOT, 3 2 x 50 m m

07MA D-PR9020 0

35. Stak e th e locknu t ta b int o th e groove .

1.0 m m (0.0 4 in)

3.5 m m (0.1 4 in)

33. Instal l th e differentia l cas e cover , an d tighte n th e

bolt s i n a crisscros s patter n i n severa l steps .

NOTE :

Us e liqui d gaske t (P/ N 0871 8 - 0001) .

Remov e an y dir t an d oi l fro m th e sealin g surface .

I f 2 0 minute s hav e passe d afte r applyin g liqui d

gasket , reappl y it , assembl e th e housings , an d

allo w it t o cur e a t leas t 2 0 minute s afte r assembl y

before fillin g differentia l wit h oil .

10 x 1.2 5 mm44 N- m (4. 5 kgf-m , 3 3 Ibf-ft )

DIFFERENTIA L

CAS E COVE R

ProCarManuals.com

Page 936 of 1954

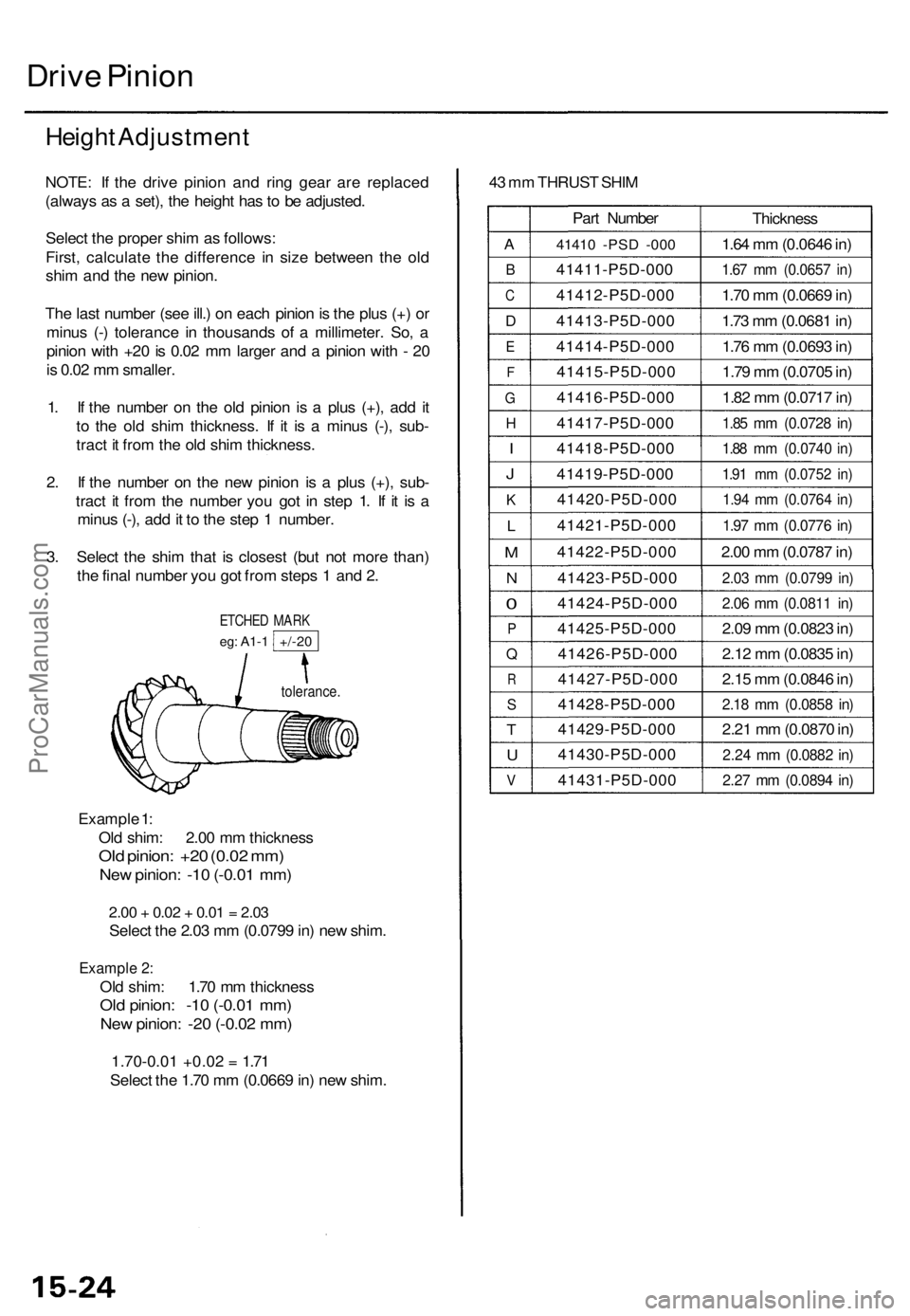

Drive Pinio n

Heigh t Adjustmen t

NOTE: I f th e driv e pinio n an d rin g gea r ar e replace d

(alway s a s a set) , th e heigh t ha s t o b e adjusted .

Selec t th e prope r shi m a s follows :

First , calculat e th e differenc e i n siz e betwee n th e ol d

shi m an d th e ne w pinion .

Th e las t numbe r (se e ill. ) o n eac h pinio n is th e plu s (+ ) o r

minu s (- ) toleranc e i n thousand s o f a millimeter . So , a

pinio n wit h +2 0 is 0.0 2 m m large r an d a pinio n wit h - 2 0

i s 0.0 2 m m smaller .

1 . I f th e numbe r o n th e ol d pinio n i s a plu s (+) , ad d i t

t o th e ol d shi m thickness . I f i t i s a minu s (-) , sub -

trac t i t fro m th e ol d shi m thickness .

2 . I f th e numbe r o n th e ne w pinio n i s a plu s (+) , sub -

trac t i t fro m th e numbe r yo u go t i n ste p 1 . I f i t i s a

minu s (-) , ad d it t o th e ste p 1 number .

3 . Selec t th e shi m tha t i s closes t (bu t no t mor e than )

th e fina l numbe r yo u go t fro m step s 1 an d 2 .

ETCHE D MAR K

eg: A1- 1

Exampl e 1:

Ol d shim : 2.0 0 m m thicknes s

Old pinion : +2 0 (0.0 2 mm )

New pinion : -1 0 (-0.0 1 mm )

2.00 + 0.0 2 + 0.0 1 = 2.03

Selec t th e 2.0 3 m m (0.079 9 in ) ne w shim .

Exampl e 2 :

Ol d shim : 1.7 0 m m thicknes s

Old pinion : -1 0 (-0.0 1 mm )

New pinion : -2 0 (-0.0 2 mm )

1.70-0.0 1 +0.0 2 = 1.7 1

Selec t th e 1.7 0 m m (0.066 9 in ) ne w shim . 4

3 m m THRUS T SHI M

A

B

C

D

E

F

G

H

I

J

K

L

M

N

0

P

Q

R

S

T

U

V

Part Numbe r

41410 -PS D -00 0

41411-P5D-00 0

41412-P5D-00 0

41413-P5D-00 0

41414-P5D-00 0

41415-P5D-00 0

41416-P5D-00 0

41417-P5D-00 0

41418-P5D-00 0

41419-P5D-00 0

41420-P5D-00 0

41421-P5D-00 0

41422-P5D-00 0

41423-P5D-00 0

41424-P5D-00 0

41425-P5D-00 0

41426-P5D-00 0

41427-P5D-00 0

41428-P5D-00 0

41429-P5D-00 0

41430-P5D-00 0

41431-P5D-00 0Thicknes

s

1.6 4 m m (0.064 6 in )1.6 7 m m (0.065 7 in )

1.7 0 m m (0.066 9 in )

1.7 3 m m (0.068 1 in )

1.7 6 m m (0.069 3 in )

1.7 9 m m (0.070 5 in )

1.8 2 m m (0.071 7 in )

1.8 5 m m (0.072 8 in )

1.8 8 m m (0.074 0 in )

1.9 1 m m (0.075 2 in )

1.9 4 m m (0.076 4 in )

1.9 7 m m (0.077 6 in )

2.0 0 m m (0.078 7 in )

2.0 3 m m (0.079 9 in )

2.0 6 m m (0.081 1 in )

2.0 9 m m (0.082 3 in )

2.1 2 m m (0.083 5 in )

2.1 5 m m (0.084 6 in )

2.1 8 m m (0.085 8 in )

2.2 1 m m (0.087 0 in )

2.2 4 m m (0.088 2 in )

2.2 7 m m (0.089 4 in )

tolerance .

+/-20

ProCarManuals.com

Page 937 of 1954

Ring Gea r Toot h Contac tRing Gea r Backlas h

Adjustmen t

1) Correc t Toot h Contac t

2 ) To e Contac t

Us e a thinne r driv e pinio n shi m (4 3 m m thrus t

shim ) t o mov e th e driv e pinio n awa y fro m th e rin g

gear .

3) Hee l Contac t

Us e a thicke r driv e pinio n shi m (4 3 m m thrus t

shim ) t o mov e th e driv e pinio n towar d th e rin g

gear .

4) Flan k Contac t

T o mov e th e rin g gea r awa y fro m th e driv e pin -

ion , us e a thicke r sid e bearin g shi m (79. 5 m m

thrus t shim ) o n th e driv e pinio n sid e an d a thinne r

on e o n th e rin g gea r side .

NOTE : Rechec k backlas h afte r replacin g th e sid e

bearin g shims . I f ou t o f specification , adjus t a s

describe d unde r To e Contact .

5) Fac e Contac t

To mov e th e rin g gea r towar d th e driv e pinion ,

us e a thinne r sid e bearin g shi m (79. 5 m m thrus t

shim ) o n th e driv e pinio n sid e an d a thicke r on e

o n th e rin g gea r side .

NOTE : Rechec k backlas h afte r replacin g th e sid e

bearin g shims . I f ou t o f specification , adjus t a s

describe d unde r Hee l Contact .

Adjustmen t

1. I f th e backlas h exceed s th e standard , correc t b y

decreasin g th e shi m thicknes s o n on e sid e an d

increasin g th e thicknes s o f th e othe r shi m th e sam e

amount .

NOTE:

• Th e tota l thicknes s o f bot h shim s mus t stil l equa l

th e tota l thicknes s o f th e origina l shims .

• I f ther e is to o muc h backlash , mov e th e rin g gea r

towar d th e driv e pinion . I f ther e i s no t enoug h

backlash , mov e th e rin g gea r awa y fro m th e

driv e pinion .

2 . Afte r adjustment , rechec k backlas h (se e page , 15-10 ).

Standard : 0.0 6 - 0.1 4 m m (0.00 2 - 0.00 6 in )

79. 5 m m THRUS T SHI M

AA

A B

AC

AD

AE

A F

AG

A H

A l

AJ

A K

AL

AM

A N

AO

A P

A Q

AR

AS

AT

A U

A V

AW

A X

Par t Numbe r

41460-P5D-00 0

41461-P5D-00 0

41462-P5D-00 0

41 46 3 -PS D -00 0

41464-P5D-00 0

41 46 5 -PS D -00 0

41466-P5D-00 0

4 1467 -PS D -00 0

41468-P5D-00 0

41 46 9 -PS D -00 0

41 47 0 -PS D -00 0

4147 1 -PS D -00 0

41 47 2 -PS D -00 0

41 47 3 -PS D -00 0

41 47 4 -PS D -00 0

41 47 5 -PS D -00 0

41 47 6 -PS D -00 0

41 47 7 -PS D -00 0

41 47 8 -PS D -00 0

41479-P5D-00 0

41 48 0 -PS D -00 0

41481-P5D-00 0

41 48 2 -PS D -00 0

41 48 3 -PS D -00 0

Thicknes s

0.66 m m (0.026 0 in )

1.1 7 m m (0.046 1 in )

1.2 0 m m (0.047 2 in )

1.2 3 m m (0.048 4 in )

1.2 6 m m (0.049 6 in )

1.2 9 m m (0.050 8 in )

1.3 2 m m (0.052 0 in )

1.3 5 m m (0.053 1 in )

1.38 m m (0.054 3 in )

1.4 1 m m (0.055 5 in )

1.4 4 m m (0.056 7 in )

1.4 7 m m (0.057 9 in )

1.5 0 m m (0.059 1 in )

1.5 3 m m (0.060 2 in )

1.5 6 m m (0.061 4 in )

1.5 9 m m (0.062 6 in )

1.6 2 m m (0.063 8 in )

1.6 5 m m (0.065 0 in )

1.6 8 m m (0.066 1 in )

1.7 1 m m (0.067 3 in )

1.7 4 m m (0.068 5 in )

1.7 7 m m (0.069 7 in )

1.8 0 m m (0.070 9 in )

1.8 3 m m (0.072 0 in )

ProCarManuals.com

Page 938 of 1954

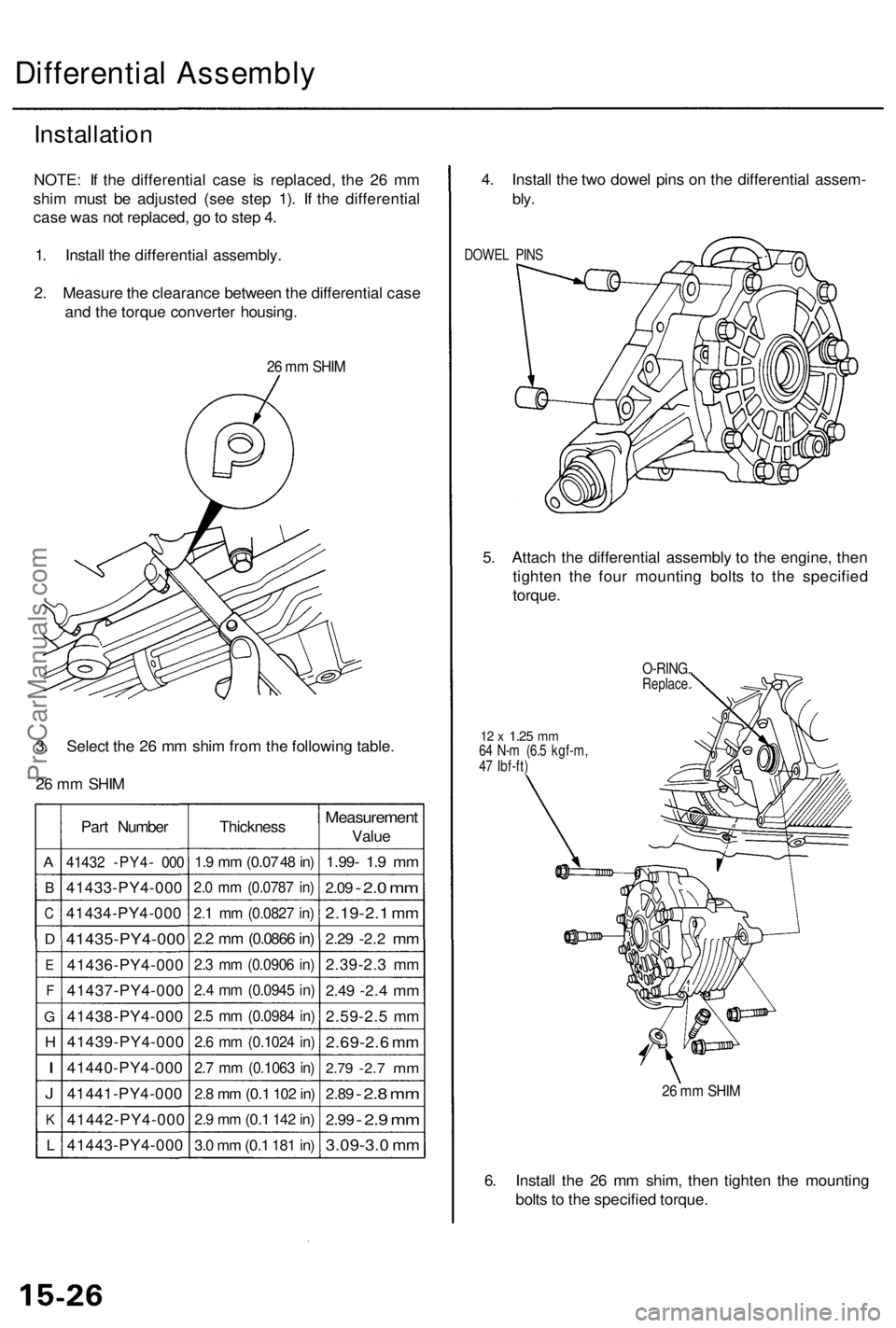

Differential Assembl y

Installation

NOTE: I f th e differentia l cas e i s replaced , th e 2 6 m m

shi m mus t b e adjuste d (se e ste p 1) . I f th e differentia l

cas e wa s no t replaced , g o to ste p 4 .

1 . Instal l th e differentia l assembly .

2 . Measur e th e clearanc e betwee n th e differentia l cas e

an d th e torqu e converte r housing .

26 m m SHI M

3. Selec t th e 2 6 m m shi m fro m th e followin g table .

2 6 m m SHI M

A

B

C

D

E

F

G

H

I

J

K

L

Part Numbe r

41432 -PY4 - 00 0

41433-PY4-00 0

41434-PY4-00 0

41435-PY4-000

41436-PY4-00 0

41437-PY4-00 0

41438-PY4-00 0

41439-PY4-00 0

41440-PY4-00 0

41441-PY4-00 0

41442-PY4-00 0

41443-PY4-00 0Thicknes

s

1.9 m m (0.0 7 48 in )

2.0 m m (0.078 7 in )

2.1 m m (0.082 7 in )

2.2 m m (0.086 6 in )

2.3 m m (0.090 6 in )

2.4 m m (0.094 5 in )

2.5 m m (0.098 4 in )

2.6 m m (0.102 4 in )

2.7 m m (0.106 3 in )

2.8 m m (0. 1 102 in )

2.9 m m (0. 1 142 in )

3.0 m m (0. 1 181 in )

Measuremen t

Value

1.99- 1.9 m m

2.0 9 - 2.0 m m

2.19-2. 1 m m

2.2 9 -2. 2 mm

2.39-2. 3 m m

2.4 9 -2. 4 mm

2.59-2. 5 m m

2.69-2. 6 m m

2.7 9 -2. 7 mm

2.89 - 2.8 m m

2.9 9 - 2.9 m m

3.09-3. 0 m m

4. Instal l th e tw o dowe l pin s o n th e differentia l assem -

bly.

DOWE L PIN S

5. Attac h th e differentia l assembl y t o th e engine , the n

tighte n th e fou r mountin g bolt s t o th e specifie d

torque .

O-RING .Replace .

12 x 1.2 5 mm64 N- m (6. 5 kgf-m ,

4 7 Ibf-ft )

26 m m SHI M

6. Instal l th e 2 6 m m shim , the n tighte n th e mountin g

bolt s t o th e specifie d torque .

ProCarManuals.com

Page 939 of 1954

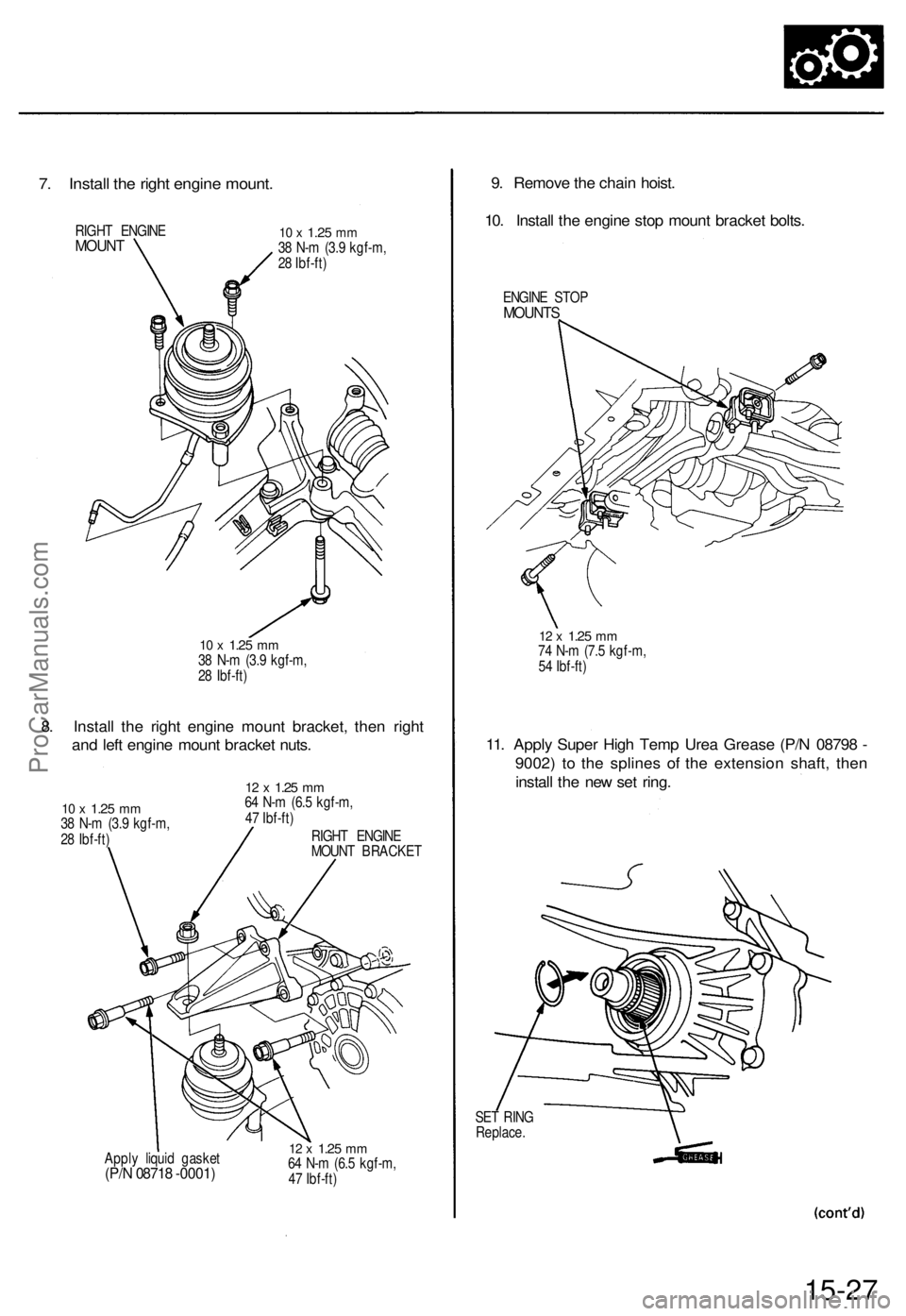

7. Instal l th e righ t engin e mount .

RIGHT ENGIN EMOUNT10 x 1.2 5 mm38 N- m (3. 9 kgf-m ,

2 8 Ibf-ft )

10 x 1.2 5 mm38 N- m (3. 9 kgf-m ,

2 8 Ibf-ft )

8. Instal l th e righ t engin e moun t bracket , the n righ t

an d lef t engin e moun t bracke t nuts .

10 x 1.2 5 mm38 N- m (3. 9 kgf-m ,

2 8 Ibf-ft )

12 x 1.2 5 mm64 N- m (6. 5 kgf-m ,

4 7 Ibf-ft )

RIGH T ENGIN E

MOUN T BRACKE T

Appl y liqui d gaske t

(P/N 0871 8 -0001 )

12 x 1.2 5 mm64 N- m (6. 5 kgf-m ,

4 7 Ibf-ft )

9. Remov e th e chai n hoist .

10 . Instal l th e engin e sto p moun t bracke t bolts .

ENGIN E STO PMOUNT S

12 x 1.2 5 mm74 N- m (7. 5 kgf-m ,

5 4 Ibf-ft )

11. Appl y Supe r Hig h Tem p Ure a Greas e (P/ N 0879 8 -

9002 ) t o th e spline s o f th e extensio n shaft , the n

instal l th e ne w se t ring .

SET RIN GReplace .

15-27ProCarManuals.com

Page 940 of 1954

Differential Assembl y

Installation (cont'd )

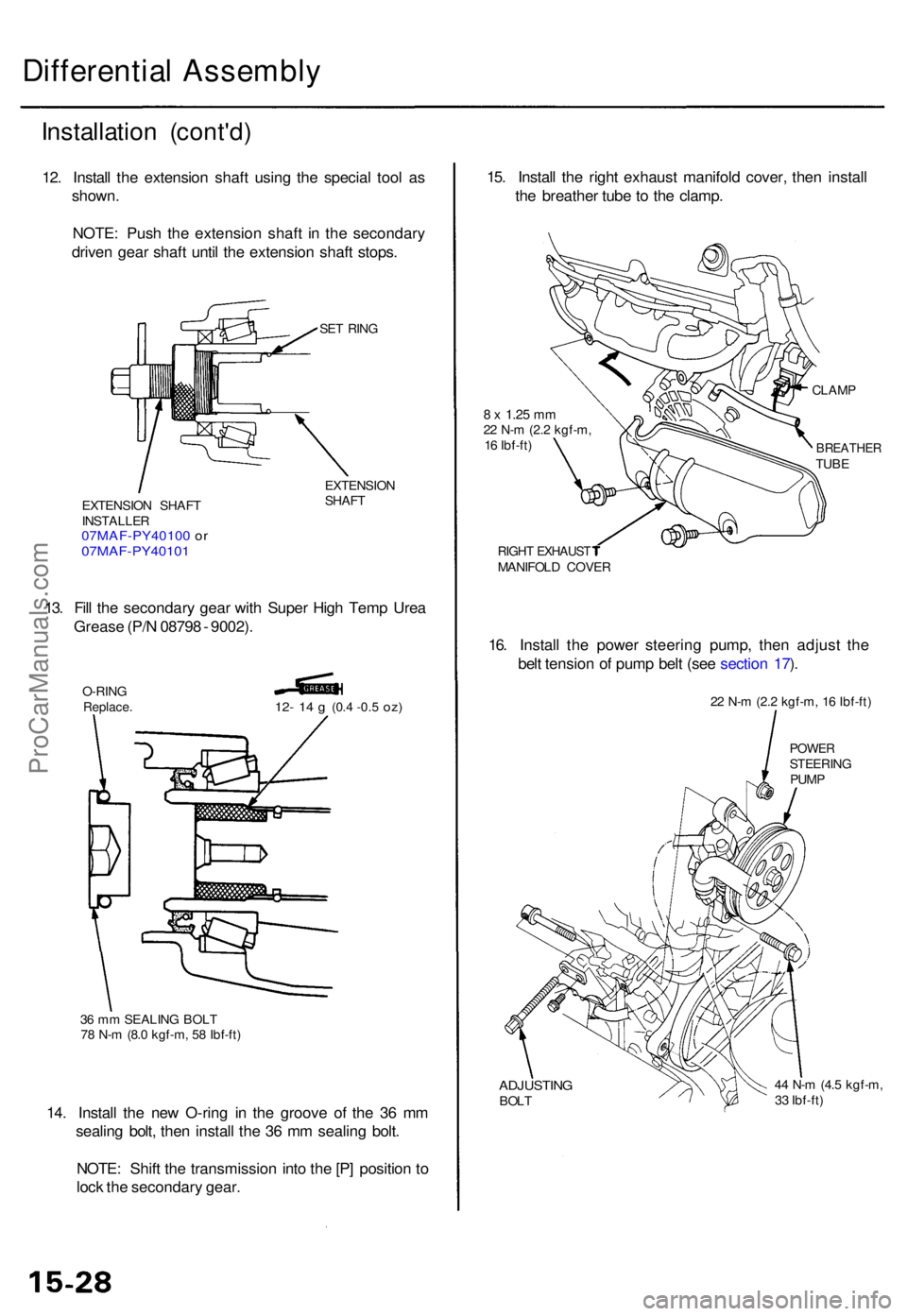

12. Instal l th e extensio n shaf t usin g th e specia l too l a s

shown .

NOTE : Pus h th e extensio n shaf t i n th e secondar y

drive n gea r shaf t unti l th e extensio n shaf t stops .

EXTENSIO N

SHAF T

EXTENSIO N SHAF T

INSTALLE R

07MAF-PY40100 or07MAF-PY4010 1

13. Fil l th e secondar y gea r wit h Supe r Hig h Tem p Ure a

Greas e (P/ N 0879 8 - 9002) .

O-RIN GReplace .12- 1 4 g (0. 4 -0. 5 oz)

36 m m SEALIN G BOL T

7 8 N- m (8. 0 kgf-m , 5 8 Ibf-ft )

14. Instal l th e ne w O-rin g i n th e groov e o f th e 3 6 m m

sealin g bolt , the n instal l th e 3 6 m m sealin g bolt .

NOTE : Shif t th e transmissio n int o th e [P ] positio n t o

loc k th e secondar y gear . 15

. Instal l th e righ t exhaus t manifol d cover , the n instal l

th e breathe r tub e to th e clamp .

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft ) CLAM

P

BREATHE RTUBE

RIGH T EXHAUS TMANIFOL D COVE R

16. Instal l th e powe r steerin g pump , the n adjus t th e

bel t tensio n o f pum p bel t (se e sectio n 17 ).

2 2 N- m (2. 2 kgf-m , 1 6 Ibf-ft )

POWE RSTEERIN G

PUM P

ADJUSTIN GBOLT44 N- m (4. 5 kgf-m ,

3 3 Ibf-ft )

SE

T RIN G

ProCarManuals.com