ACURA RL KA9 1996 Service Repair Manual

Manufacturer: ACURA, Model Year: 1996, Model line: RL KA9, Model: ACURA RL KA9 1996Pages: 1954, PDF Size: 61.44 MB

Page 891 of 1954

Transmission

Reassembly

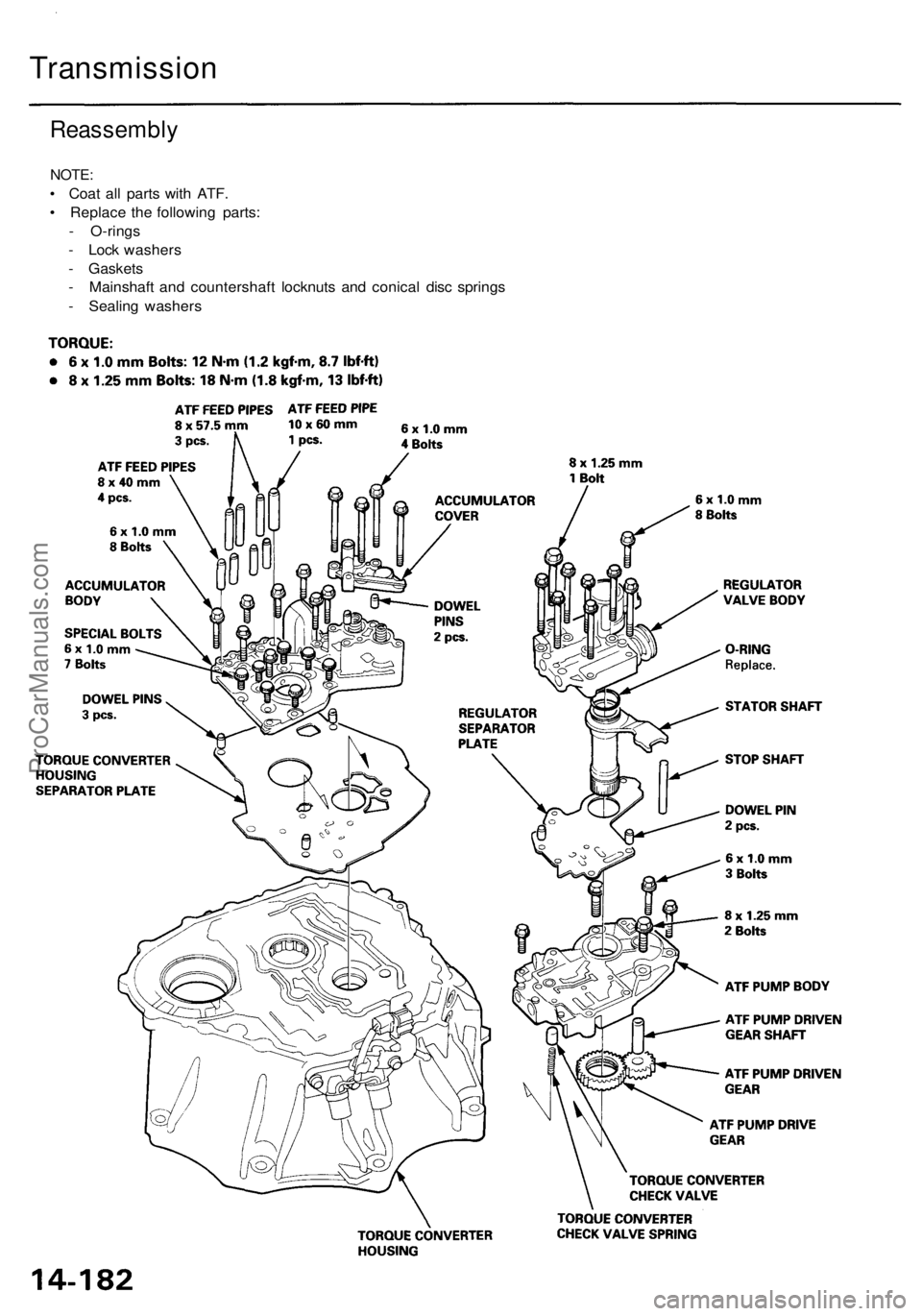

NOTE:

• Coat all parts with ATF.

• Replace the following parts:

- O-rings

- Lock washers

- Gaskets

- Mainshaft and countershaft locknuts and conical disc springs

- Sealing washersProCarManuals.com

Page 892 of 1954

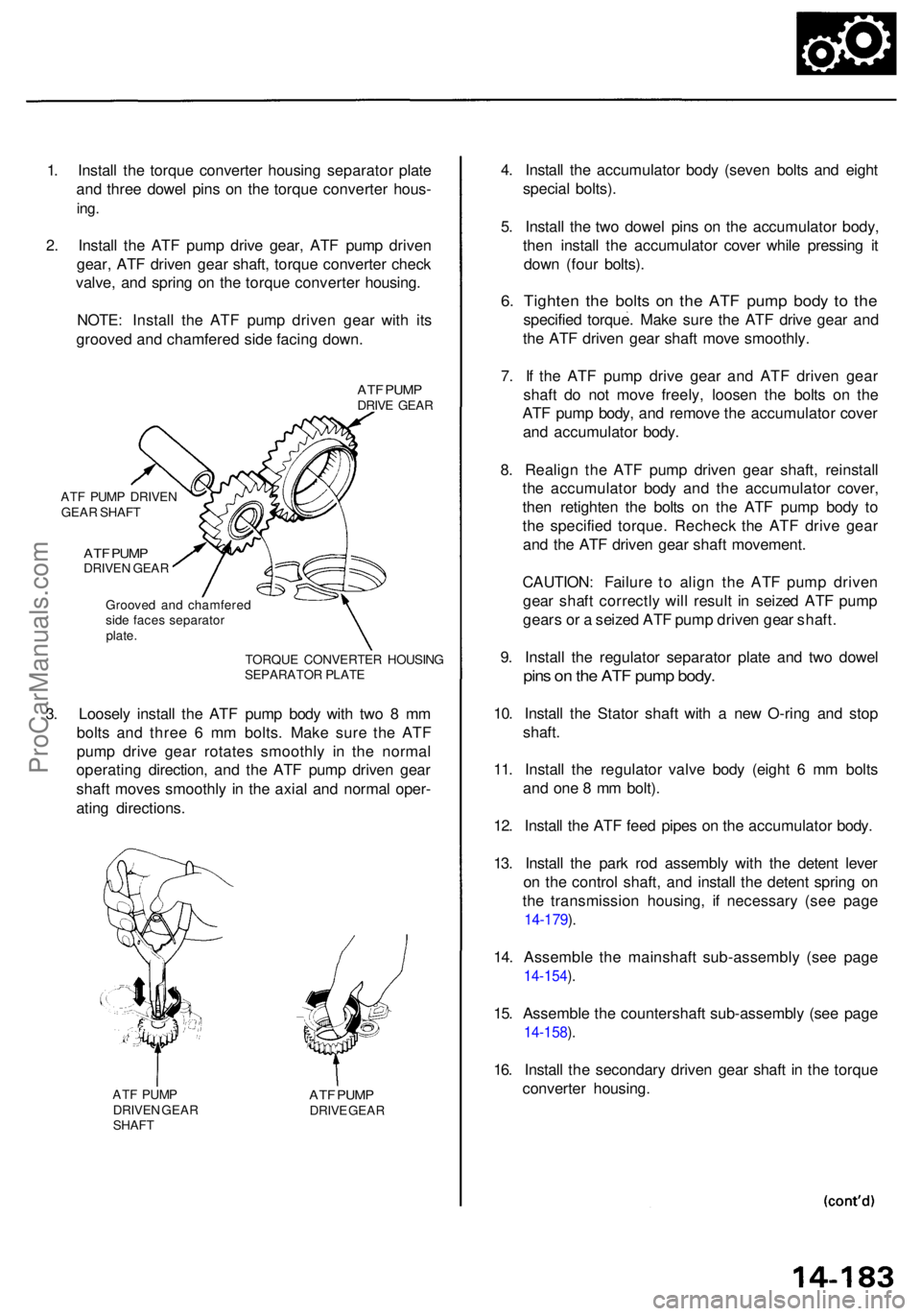

1. Instal l th e torqu e converte r housin g separato r plat e

an d thre e dowe l pin s o n th e torqu e converte r hous -

ing.

2. Instal l th e AT F pum p driv e gear , AT F pum p drive n

gear , AT F drive n gea r shaft , torqu e converte r chec k

valve , an d sprin g o n th e torqu e converte r housing .

NOTE : Instal l th e AT F pum p drive n gea r wit h it s

groove d an d chamfere d sid e facin g down .

ATF PUM PDRIVE GEA R

AT F PUM P

DRIVE N GEAR

SHAF T

ATF PUM PDRIV E GEA R

4. Instal l th e accumulato r bod y (seve n bolt s an d eigh t

specia l bolts) .

5 . Instal l th e tw o dowe l pin s o n th e accumulato r body ,

the n instal l th e accumulato r cove r whil e pressin g i t

dow n (fou r bolts) .

6. Tighte n th e bolt s o n th e AT F pum p bod y t o th e

specifie d torque . Mak e sur e th e AT F driv e gea r an d

th e AT F drive n gea r shaf t mov e smoothly .

7 . I f th e AT F pum p driv e gea r an d AT F drive n gea r

shaf t d o no t mov e freely , loose n th e bolt s o n th e

AT F pum p body , an d remov e th e accumulato r cove r

an d accumulato r body .

8 . Realig n th e AT F pum p drive n gea r shaft , reinstal l

th e accumulato r bod y an d th e accumulato r cover ,

the n retighte n th e bolt s o n th e AT F pum p bod y t o

th e specifie d torque . Rechec k th e AT F driv e gea r

an d th e AT F drive n gea r shaf t movement .

CAUTION : Failur e t o alig n th e AT F pum p drive n

gea r shaf t correctl y wil l resul t i n seize d AT F pum p

gear s o r a seize d AT F pum p drive n gea r shaft .

9 . Instal l th e regulato r separato r plat e an d tw o dowe l

pins o n th e AT F pum p body .

10. Instal l th e Stato r shaf t wit h a ne w O-rin g an d sto p

shaft .

11 . Instal l th e regulato r valv e bod y (eigh t 6 m m bolt s

an d on e 8 m m bolt) .

12 . Instal l th e AT F fee d pipe s o n th e accumulato r body .

13 . Instal l th e par k ro d assembl y wit h th e deten t leve r

o n th e contro l shaft , an d instal l th e deten t sprin g o n

th e transmissio n housing , i f necessar y (se e pag e

14-179 ).

14 . Assembl e th e mainshaf t sub-assembl y (se e pag e

14-154 ).

15 . Assembl e th e countershaf t sub-assembl y (se e pag e

14-158 ).

16 . Instal l th e secondar y drive n gea r shaf t i n th e torqu e

converte r housing .

3

. Loosel y instal l th e AT F pum p bod y wit h tw o 8 m m

bolt s an d thre e 6 m m bolts . Mak e sur e th e AT F

pum p driv e gea r rotate s smoothl y i n th e norma l

operatin g direction , an d th e AT F pum p drive n gea r

shaf t move s smoothly in th e axia l an d norma l oper -

atin g directions .

TORQUE CONVERTE R HOUSIN G

SEPARATO R PLAT E

Groove

d an d chamfere d

sid e face s separato r

plate .

AT

F PUM P DRIVE N

GEA R SHAF T

ATF PUM PDRIVE N GEA R

ProCarManuals.com

Page 893 of 1954

Transmission

Reassembly (cont'd )

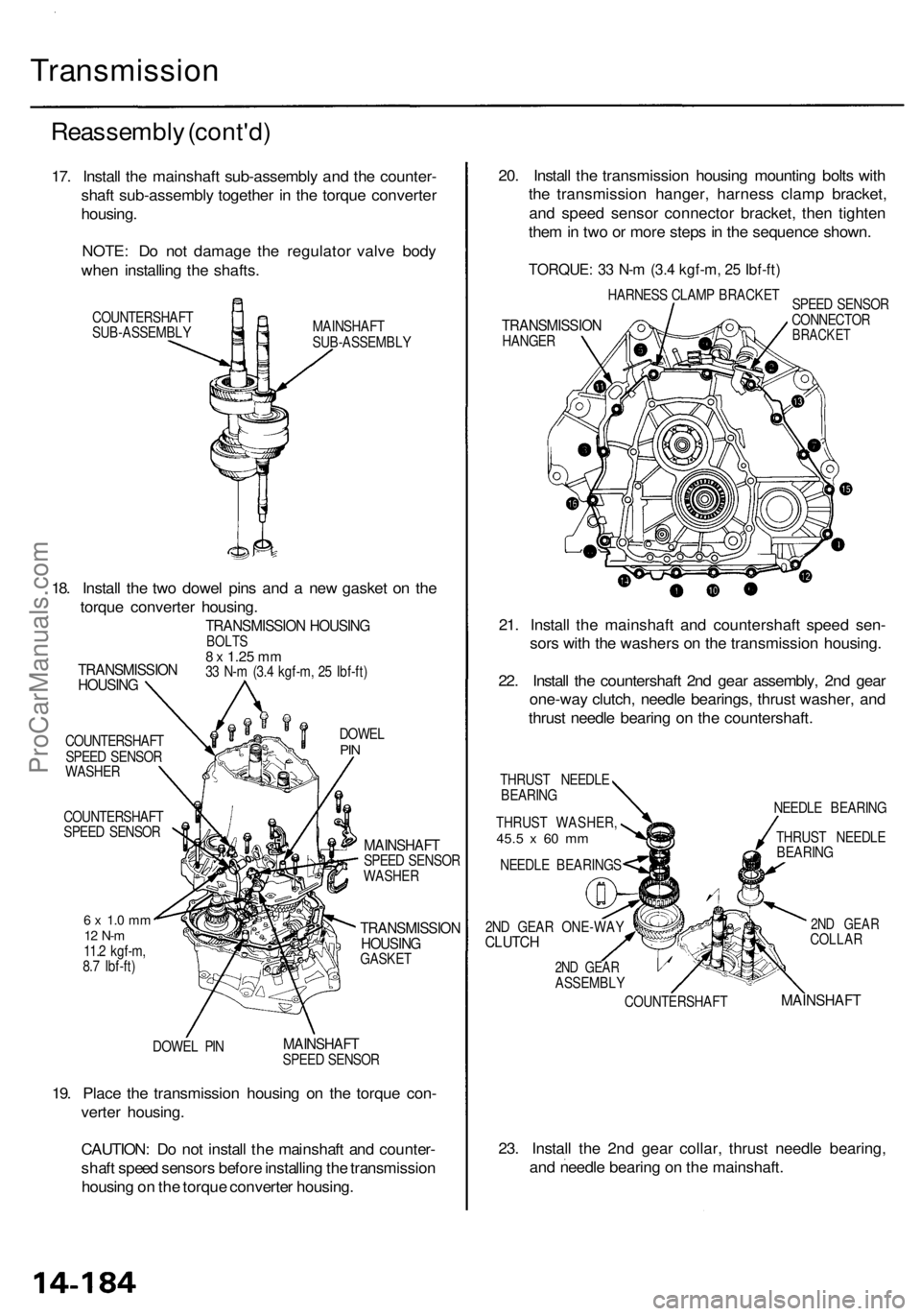

17. Instal l th e mainshaf t sub-assembl y an d th e counter -

shaf t sub-assembl y togethe r i n th e torqu e converte r

housing .

NOTE : D o no t damag e th e regulato r valv e bod y

whe n installin g th e shafts .

COUNTERSHAF T

SUB-ASSEMBL Y MAINSHAF

T

SUB-ASSEMBL Y

COUNTERSHAF T

SPEE D SENSO R

WASHE R

COUNTERSHAF T

SPEE D SENSO R

6 x 1. 0 m m12 N- m11.2 kgf-m ,

8. 7 Ibf-ft )

DOWE L PI N DOWE

L

PIN

MAINSHAF TSPEED SENSO R

WASHE R

TRANSMISSIO NHOUSINGGASKET

MAINSHAF TSPEED SENSO R

19. Plac e th e transmissio n housin g o n th e torqu e con -

verte r housing .

CAUTION : D o no t instal l th e mainshaf t an d counter -

shaf t spee d sensor s befor e installin g th e transmissio n

housin g o n th e torqu e converte r housing . 20

. Instal l th e transmissio n housin g mountin g bolt s wit h

th e transmissio n hanger , harnes s clam p bracket ,

an d spee d senso r connecto r bracket , the n tighte n

the m in tw o o r mor e step s in th e sequenc e shown .

TORQUE : 3 3 N- m (3. 4 kgf-m , 2 5 Ibf-ft )

HARNES S CLAM P BRACKE T

TRANSMISSIO NHANGER SPEE

D SENSO R

CONNECTO RBRACKET

21. Instal l th e mainshaf t an d countershaf t spee d sen -

sor s wit h th e washer s o n th e transmissio n housing .

22 . Instal l th e countershaf t 2n d gea r assembly , 2n d gea r

one-wa y clutch , needl e bearings , thrus t washer , an d

thrus t needl e bearin g o n th e countershaft .

THRUST NEEDL E

BEARIN G

THRUS T WASHER ,

45.5 x 60 m m

NEEDL E BEARING S NEEDL

E BEARIN G

COUNTERSHAF TTHRUS

T NEEDL E

BEARIN G

2ND GEA RCOLLA R

MAINSHAF T

23. Instal l th e 2n d gea r collar , thrus t needl e bearing ,

an d needl e bearin g o n th e mainshaft .

TRANSMISSIO NHOUSING

TRANSMISSIO N HOUSIN GBOLTS8 x 1.2 5 mm33 N- m (3. 4 kgf-m , 2 5 Ibf-ft )

18. Instal l th e tw o dowe l pin s an d a ne w gaske t o n th e

torqu e converte r housing .

2ND GEA R ONE-WA YCLUTCH

2ND GEA RASSEMBL Y

ProCarManuals.com

Page 894 of 1954

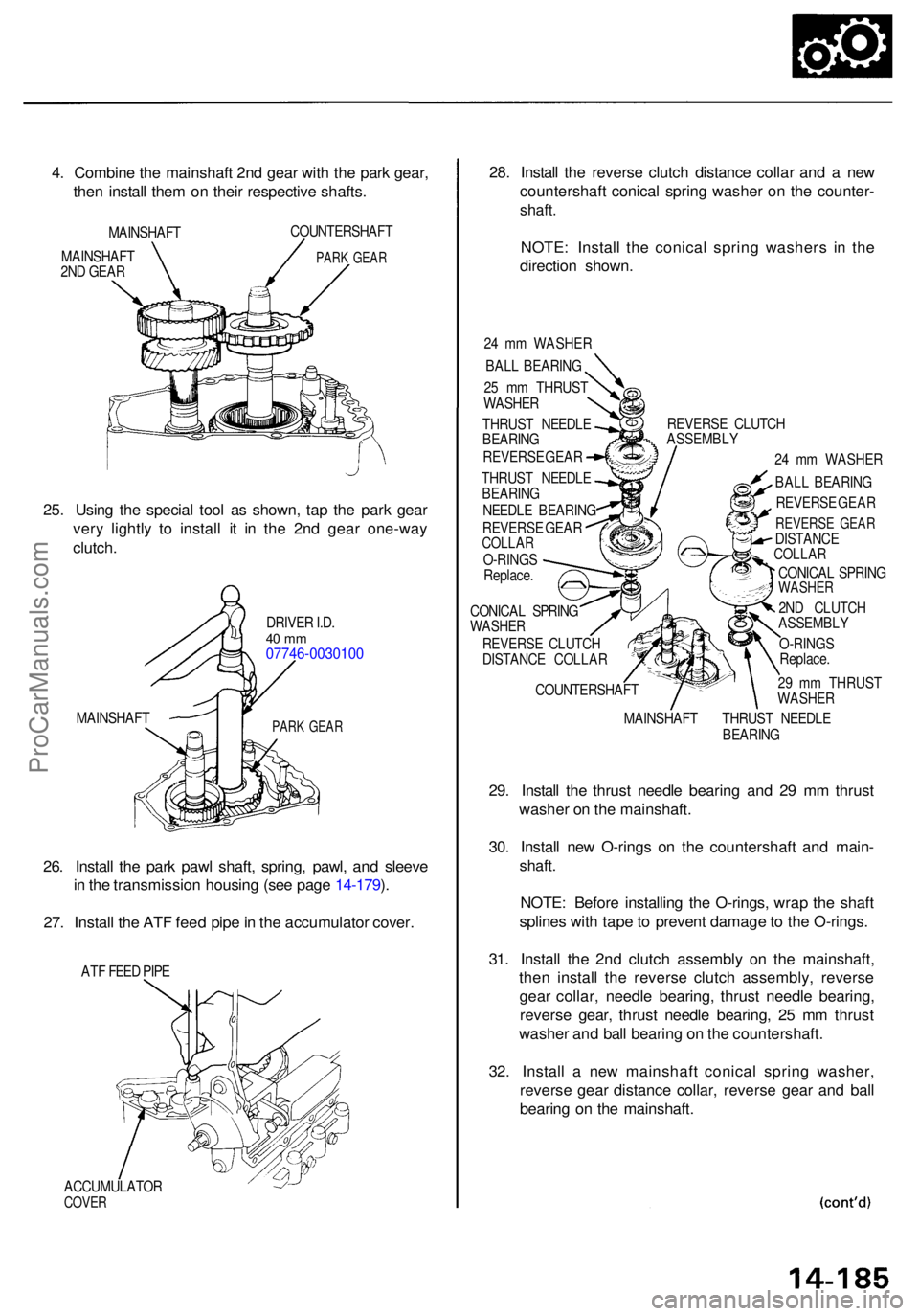

4. Combin e th e mainshaf t 2n d gea r wit h th e par k gear ,

the n instal l the m o n thei r respectiv e shafts .

MAINSHAF T

MAINSHAF T

2N D GEA R COUNTERSHAF

T

PARK GEA R

25. Usin g th e specia l too l a s shown , ta p th e par k gea r

ver y lightl y t o instal l i t i n th e 2n d gea r one-wa y

clutch .

DRIVE R I.D .40 m m07746-003010 0

MAINSHAFTPARK GEA R

26. Instal l th e par k paw l shaft , spring , pawl , an d sleev e

i n th e transmissio n housin g (se e pag e 14-179 ).

27 . Instal l th e AT F fee d pip e in th e accumulato r cover .

ATF FEE D PIP E

ACCUMULATO R

COVER

28. Instal l th e revers e clutc h distanc e colla r an d a ne w

countershaf t conica l sprin g washe r o n th e counter -

shaft.

NOTE : Instal l th e conica l sprin g washer s i n th e

directio n shown .

24 m m WASHE R

BAL L BEARIN G

2 5 m m THRUS T

WASHE R

THRUS T NEEDL E

BEARIN G

REVERS E GEA R

THRUS T NEEDL E

BEARIN G

NEEDL E BEARIN G

REVERS E GEA R

COLLA RO-RING S

Replace . REVERS

E CLUTC H

ASSEMBL Y

24 m m WASHE R

BAL L BEARIN G

REVERS E GEA R

REVERS E GEA RDISTANC ECOLLAR

CONICA L SPRIN GWASHE R

2ND CLUTC H

ASSEMBL Y

O-RING S

Replace .

2 9 m m THRUS T

WASHE R

MAINSHAF T THRUS T NEEDL E

BEARIN G

CONICA

L SPRIN G

WASHE R

REVERS E CLUTC H

DISTANC E COLLA R

COUNTERSHAF T

29. Instal l th e thrus t needl e bearin g an d 2 9 m m thrus t

washe r o n th e mainshaft .

30 . Instal l ne w O-ring s o n th e countershaf t an d main -

shaft.

NOTE : Befor e installin g th e O-rings , wra p th e shaf t

spline s wit h tap e to preven t damag e to th e O-rings .

31 . Instal l th e 2n d clutc h assembl y o n th e mainshaft ,

the n instal l th e revers e clutc h assembly , revers e

gea r collar , needl e bearing , thrus t needl e bearing ,

revers e gear , thrus t needl e bearing , 2 5 m m thrus t

washe r an d bal l bearin g o n th e countershaft .

32 . Instal l a ne w mainshaf t conica l sprin g washer ,

revers e gea r distanc e collar , revers e gea r an d bal l

bearin g o n th e mainshaft .

ProCarManuals.com

Page 895 of 1954

Transmission

Reassembly (cont'd )

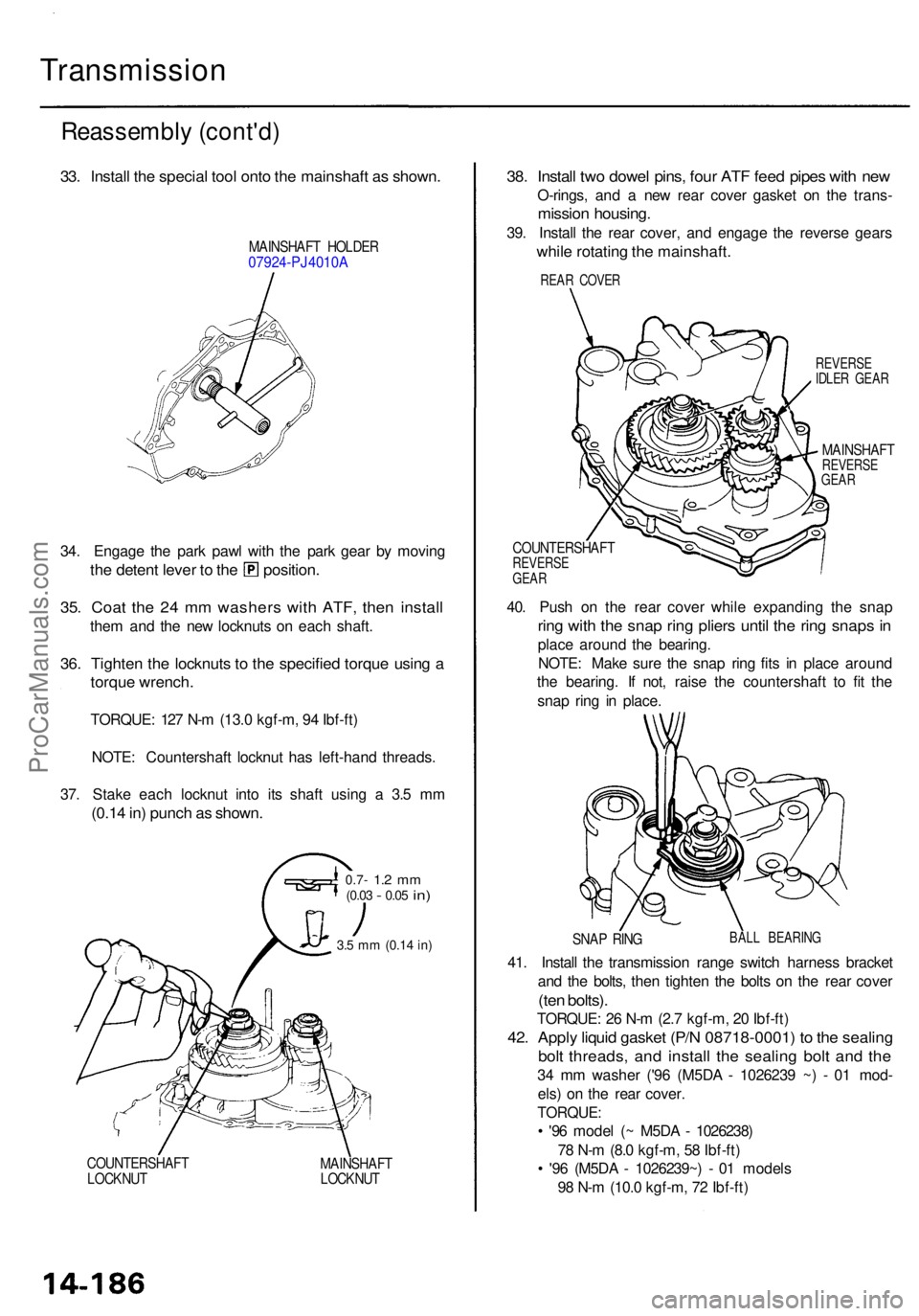

33. Instal l th e specia l too l ont o th e mainshaf t a s shown .

MAINSHAF T HOLDE R07924-PJ4010 A

34. Engag e th e par k paw l wit h th e par k gea r b y movin g

the deten t leve r t o th e position .

35. Coa t th e 2 4 m m washer s wit h ATF , the n instal l

them an d th e ne w locknut s o n eac h shaft .

36. Tighte n th e locknut s t o th e specifie d torqu e usin g a

torqu e wrench .

TORQUE : 12 7 N- m (13. 0 kgf-m , 9 4 Ibf-ft )

NOTE : Countershaf t locknu t ha s left-han d threads .

37 . Stak e eac h locknu t int o it s shaf t usin g a 3. 5 m m

(0.1 4 in ) punc h a s shown .

0.7- 1.2 m m(0.0 3 - 0.05 in)

3.5 m m (0.1 4 in )

COUNTERSHAF T

LOCKNU T MAINSHAF

T

LOCKNU T

38. Instal l tw o dowe l pins , fou r AT F fee d pipe s wit h ne w

O-rings , an d a ne w rea r cove r gaske t o n th e trans -

mission housing .

39. Instal l th e rea r cover , an d engag e th e revers e gear s

while rotatin g th e mainshaft .

REVERSE

IDLE R GEA R

MAINSHAF TREVERSE

GEA R

COUNTERSHAF TREVERSEGEAR

40. Pus h o n th e rea r cove r whil e expandin g th e sna p

ring wit h th e sna p rin g plier s unti l th e rin g snap s i n

plac e aroun d th e bearing .

NOTE : Mak e sur e th e sna p rin g fit s i n plac e aroun d

th e bearing . I f not , rais e th e countershaf t t o fi t th e

sna p rin g i n place .

SNAP RIN GBAL L BEARIN G

41. Instal l th e transmissio n rang e switc h harnes s bracke t

an d th e bolts , the n tighte n th e bolt s o n th e rea r cove r

(ten bolts) .

TORQUE : 2 6 N- m (2. 7 kgf-m , 2 0 Ibf-ft )

42. Appl y liqui d gaske t (P/ N 08718-0001 ) t o th e sealin g

bolt threads , an d instal l th e sealin g bol t an d th e

34 m m washe r ('9 6 (M5D A - 102623 9 ~ ) - 0 1 mod -

els ) o n th e rea r cover .

TORQUE :

• '9 6 mode l ( ~ M5D A - 1026238 )

7 8 N- m (8. 0 kgf-m , 5 8 Ibf-ft )

• '9 6 (M5D A - 1026239~ ) - 0 1 model s

9 8 N- m (10. 0 kgf-m , 7 2 Ibf-ft )

REAR COVE R

ProCarManuals.com

Page 896 of 1954

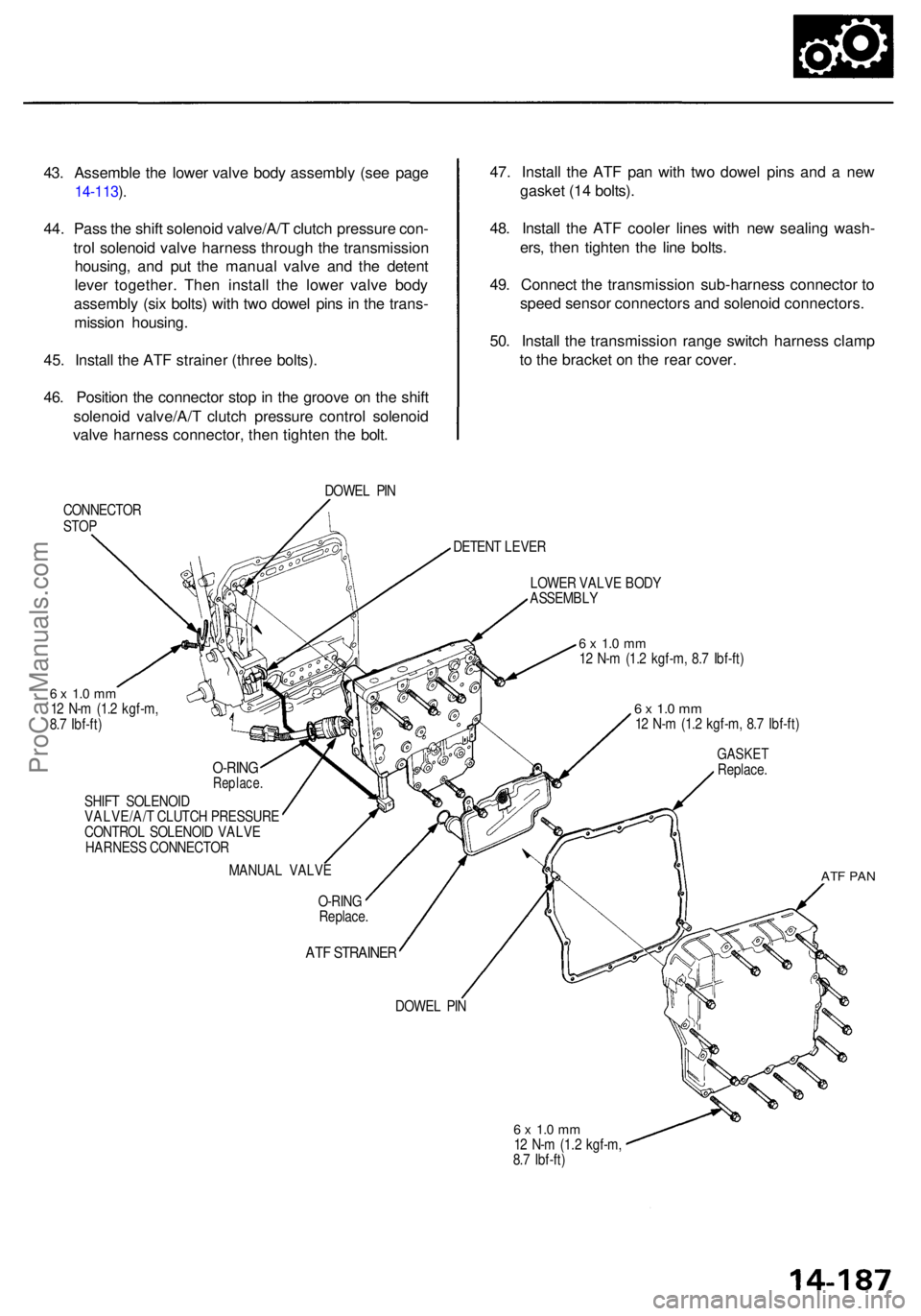

43. Assembl e th e lowe r valv e bod y assembl y (se e pag e

14-113 ).

44 . Pas s th e shif t solenoi d valve/A/ T clutc h pressur e con -

tro l solenoi d valv e harnes s throug h th e transmissio n

housing , an d pu t th e manua l valv e an d th e deten t

leve r together . The n instal l th e lowe r valv e bod y

assembl y (si x bolts ) wit h tw o dowe l pin s i n th e trans -

missio n housing .

45 . Instal l th e AT F straine r (thre e bolts) .

46 . Positio n th e connecto r sto p in th e groov e o n th e shif t

solenoi d valve/A/ T clutc h pressur e contro l solenoi d

valv e harnes s connector , the n tighte n th e bolt . 47

. Instal l th e AT F pa n wit h tw o dowe l pin s an d a ne w

gaske t (1 4 bolts) .

48 . Instal l th e AT F coole r line s wit h ne w sealin g wash -

ers , the n tighte n th e lin e bolts .

49 . Connec t th e transmissio n sub-harnes s connecto r t o

spee d senso r connector s an d solenoi d connectors .

50 . Instal l th e transmissio n rang e switc h harnes s clam p

t o th e bracke t o n th e rea r cover .

DOWE L PI N

CONNECTO R

STO P

DETENT LEVE R

LOWE R VALV E BOD Y

ASSEMBL Y

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

O-RIN GReplace .

SHIFT SOLENOI D

VALVE/A/ T CLUTC H PRESSUR E

CONTRO L SOLENOI D VALV E

HARNES S CONNECTO R

6 x 1. 0 m m12 N- m (1. 2 kgf-m , 8. 7 Ibf-ft )

6 x 1. 0 m m12 N- m (1. 2 kgf-m , 8. 7 Ibf-ft )

GASKE TReplace .

MANUA L VALV E

ATF PA N

O-RIN G

Replace .

ATF STRAINE R

DOWEL PI N

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

ProCarManuals.com

Page 897 of 1954

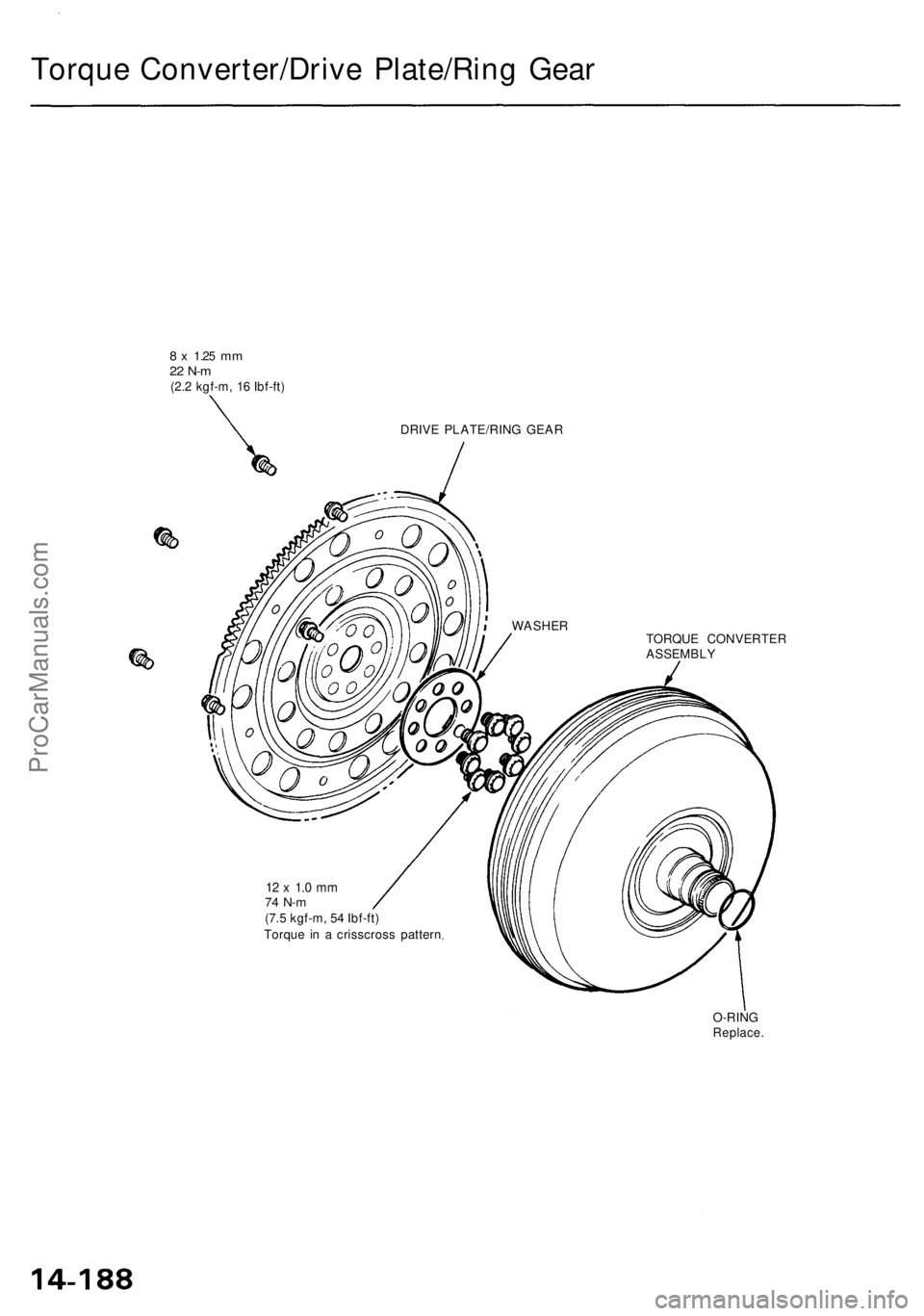

Torque Converter/Drive Plate/Ring Gear

8 x

1.25

mm

22 N-m

(2.2 kgf-m, 16 Ibf-ft)

DRIVE PLATE/RING GEAR

TORQUE CONVERTER

ASSEMBLY

12 x 1.0 mm

74 N-m

(7.5 kgf-m, 54 Ibf-ft)

Torque in a crisscross pattern

O-RING

Replace.

WASHERProCarManuals.com

Page 898 of 1954

Transmission

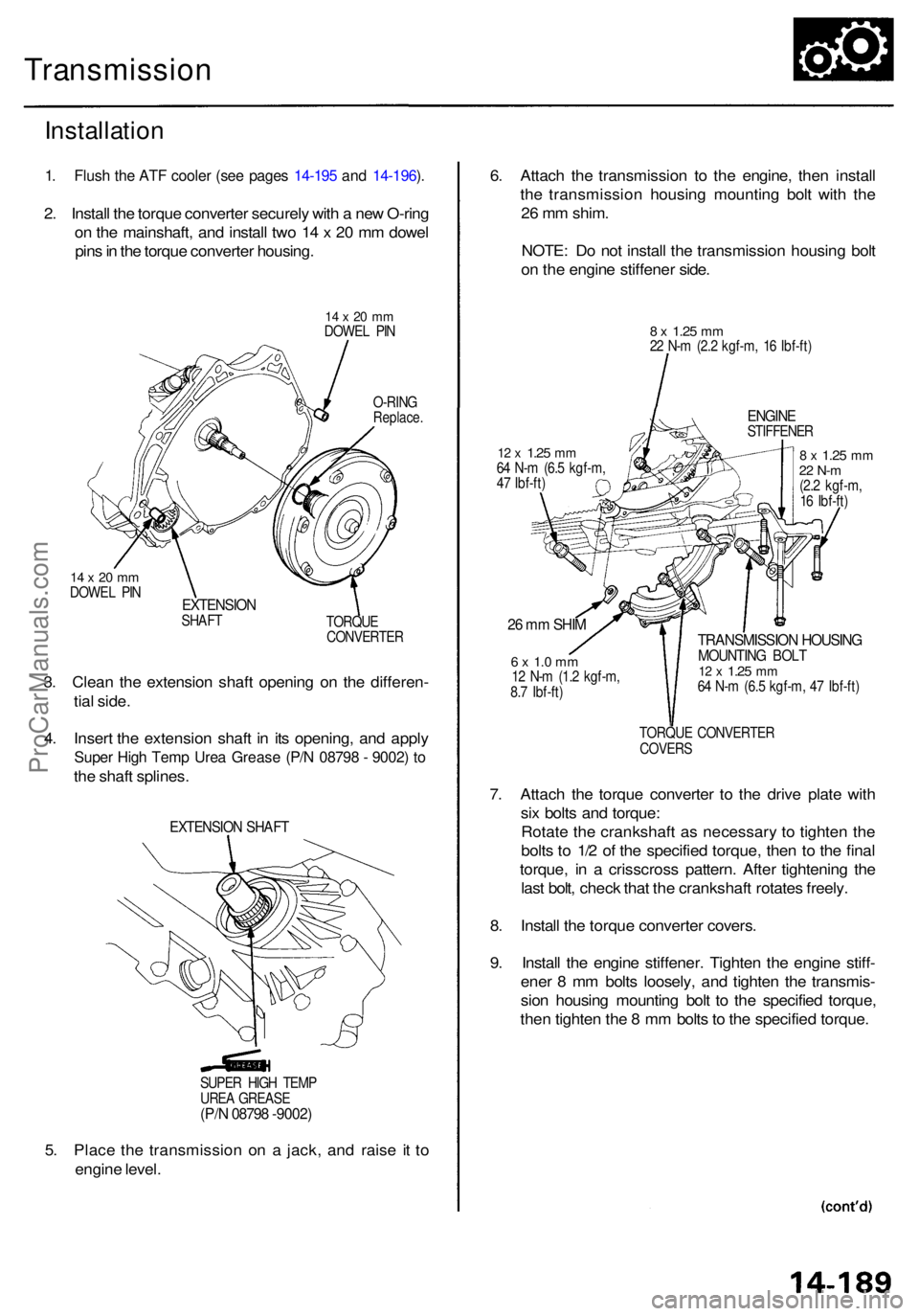

Installation

1. Flus h th e AT F coole r (se e page s 14-19 5 an d 14-196 ).

2 . Instal l th e torqu e converte r securel y wit h a ne w O-rin g

o n th e mainshaft , an d instal l tw o 1 4 x 2 0 m m dowe l

pin s in th e torqu e converte r housing .

14 x 20 m mDOWE L PI N

O-RIN G

Replace .

14 x 20 m mDOWE L PI NEXTENSIO NSHAFT

TORQUE

CONVERTE R

3. Clea n th e extensio n shaf t openin g o n th e differen -

tia l side .

4 . Inser t th e extensio n shaf t i n it s opening , an d appl y

Supe r Hig h Tem p Ure a Greas e (P/ N 0879 8 - 9002 ) t o

th e shaf t splines .

EXTENSIO N SHAF T

5. Plac e th e transmissio n o n a jack , an d rais e i t t o

engin e level . 6

. Attac h th e transmissio n t o th e engine , the n instal l

th e transmissio n housin g mountin g bol t wit h th e

2 6 m m shim .

NOTE : D o no t instal l th e transmissio n housin g bol t

o n th e engin e stiffene r side .

8 x 1.2 5 mm22 N- m (2. 2 kgf-m , 1 6 Ibf-ft )

ENGIN ESTIFFENE R

12 x 1.2 5 mm64 N- m (6. 5 kgf-m ,

4 7 Ibf-ft )8 x 1.2 5 mm22 N- m(2.2 kgf-m ,

1 6 Ibf-ft )

26 m m SHI M

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

TRANSMISSIO N HOUSIN GMOUNTIN G BOL T12 x 1.2 5 mm64 N- m (6. 5 kgf-m , 4 7 Ibf-ft )

TORQU E CONVERTE R

COVER S

7. Attac h th e torqu e converte r t o th e driv e plat e wit h

si x bolt s an d torque :

Rotat e th e crankshaf t a s necessar y t o tighte n th e

bolt s t o 1/ 2 o f th e specifie d torque , the n t o th e fina l

torque , i n a crisscros s pattern . Afte r tightenin g th e

las t bolt , chec k tha t th e crankshaf t rotate s freely .

8 . Instal l th e torqu e converte r covers .

9 . Instal l th e engin e stiffener . Tighte n th e engin e stiff -

ene r 8 m m bolt s loosely , an d tighte n th e transmis -

sio n housin g mountin g bol t t o th e specifie d torque ,

the n tighte n th e 8 m m bolt s t o th e specifie d torque .

SUPER HIG H TEM P

URE A GREAS E

(P/N 0879 8 -9002 )

ProCarManuals.com

Page 899 of 1954

Transmission

Installation (cont'd )

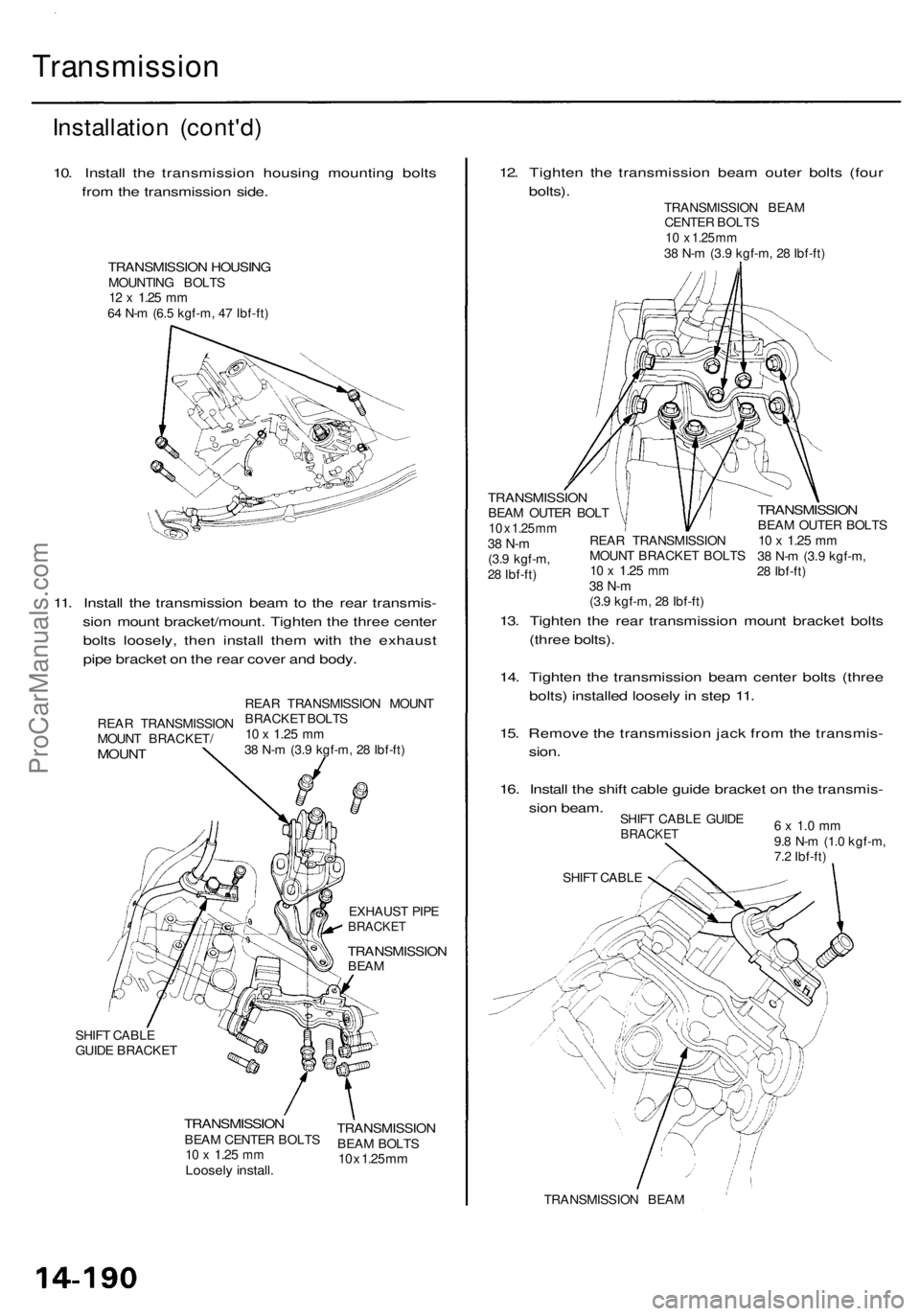

10. Instal l th e transmissio n housin g mountin g bolt s

fro m th e transmissio n side .

TRANSMISSIO N HOUSIN GMOUNTIN G BOLT S12 x 1.2 5 mm64 N- m (6. 5 kgf-m , 4 7 Ibf-ft )

11. Instal l th e transmissio n bea m to th e rea r transmis -

sio n moun t bracket/mount . Tighte n th e thre e cente r

bolt s loosely , the n instal l the m with the exhaus t

pip e bracke t o n th e rea r cove r an d body .

EXHAUS T PIP EBRACKE T

TRANSMISSIO NBEAM

SHIF T CABL E

GUID E BRACKE T

TRANSMISSIO NBEAM CENTE R BOLT S10 x 1.2 5 mmLoosel y install .

12. Tighte n th e transmissio n bea m oute r bolt s (fou r

bolts) .

13 . Tighte n th e rea r transmissio n moun t bracke t bolt s

(thre e bolts) .

14 . Tighte n th e transmissio n bea m cente r bolt s (thre e

bolts ) installe d loosel y in ste p 11 .

15 . Remov e th e transmissio n jac k fro m th e transmis -

sion .

16 . Instal l th e shif t cabl e guid e bracke t o n th e transmis -

sio n beam .

SHIFT CABL E GUID EBRACKE T

TRANSMISSIO N BEA M

6 x 1. 0 m m9.8 N- m (1. 0 kgf-m ,

7. 2 Ibf-ft )

SHIF T CABL E

TRANSMISSIO NBEAM BOLT S10 x 1.2 5 m m

REA R TRANSMISSIO N

MOUN T BRACKET /

MOUNT

REAR TRANSMISSIO N MOUN T

BRACKE T BOLT S

10 x 1.2 5 mm38 N- m (3. 9 kgf-m , 2 8 Ibf-ft ) TRANSMISSIO

N BEA M

CENTE R BOLT S

10 x 1.2 5 m m38 N- m (3. 9 kgf-m , 2 8 Ibf-ft )

TRANSMISSIO NBEAM OUTE R BOL T10 x 1.2 5 m m38 N- m(3.9 kgf-m ,

2 8 Ibf-ft )

TRANSMISSIO NBEAM OUTE R BOLT S10 x 1.2 5 mm38 N- m (3. 9 kgf-m ,

2 8 Ibf-ft )

REA

R TRANSMISSIO N

MOUN T BRACKE T BOLT S10 x 1.2 5 mm38 N- m(3.9 kgf-m , 2 8 Ibf-ft )

ProCarManuals.com

Page 900 of 1954

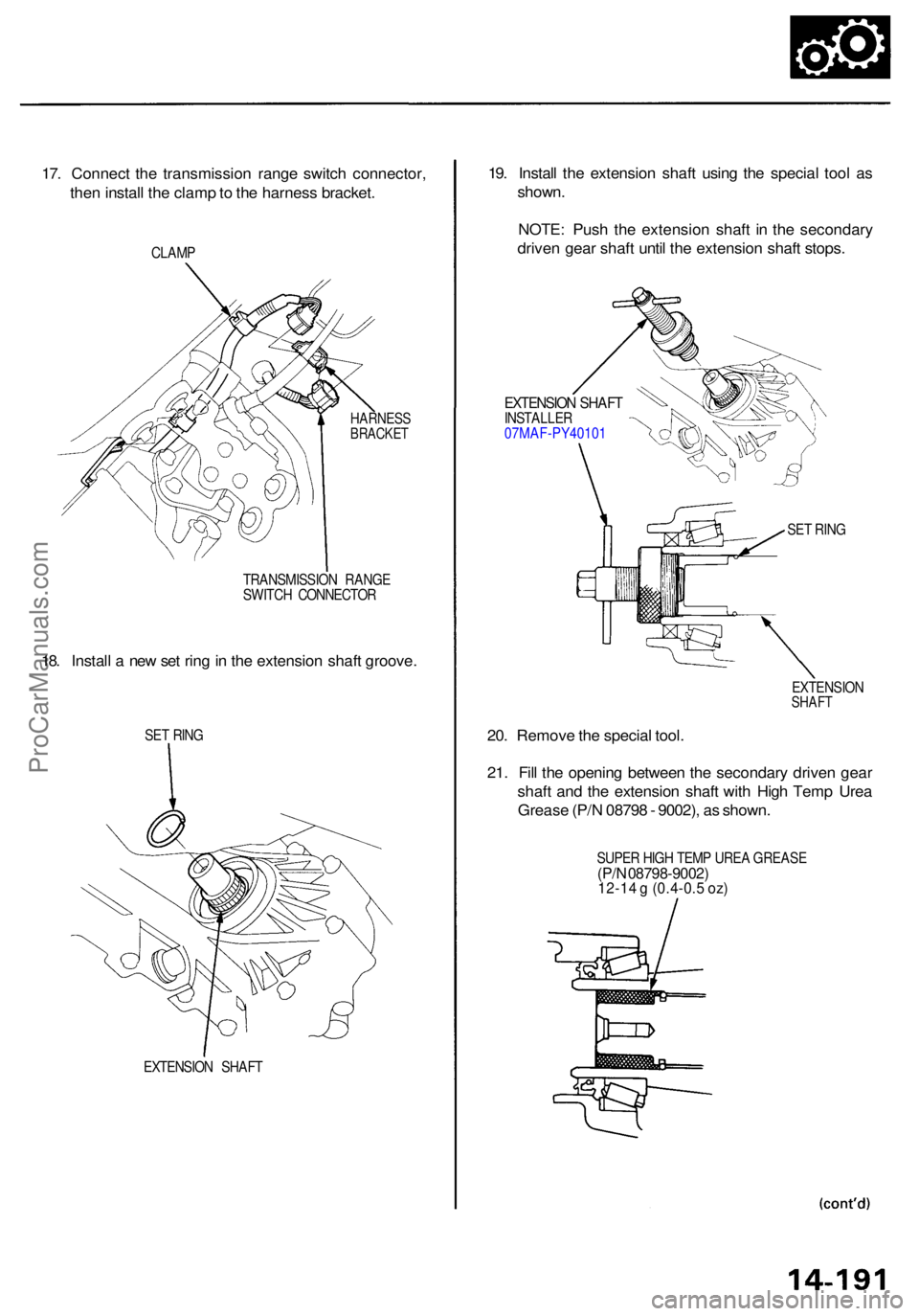

17. Connec t th e transmissio n rang e switc h connector ,

the n instal l th e clam p to th e harnes s bracket .

CLAMP

HARNES SBRACKET

TRANSMISSIO N RANG E

SWITC H CONNECTO R

18. Instal l a ne w se t rin g in th e extensio n shaf t groove .

SET RIN G

EXTENSIO N SHAF T

19. Instal l th e extensio n shaf t usin g th e specia l too l a s

shown .

NOTE : Pus h th e extensio n shaf t i n th e secondar y

drive n gea r shaf t unti l th e extensio n shaf t stops .

EXTENSIO N SHAF TINSTALLE R

07MAF-PY4010 1

SET RIN G

EXTENSIO N

SHAFT

20. Remov e th e specia l tool .

21 . Fil l th e openin g betwee n th e secondar y drive n gea r

shaf t an d th e extensio n shaf t wit h Hig h Tem p Ure a

Greas e (P/ N 0879 8 - 9002) , a s shown .

SUPER HIG H TEM P URE A GREAS E(P/N 08798-9002 )12-14 g (0.4-0. 5 oz )

ProCarManuals.com