ACURA RL KA9 1996 Service Repair Manual

Manufacturer: ACURA, Model Year: 1996, Model line: RL KA9, Model: ACURA RL KA9 1996Pages: 1954, PDF Size: 61.44 MB

Page 981 of 1954

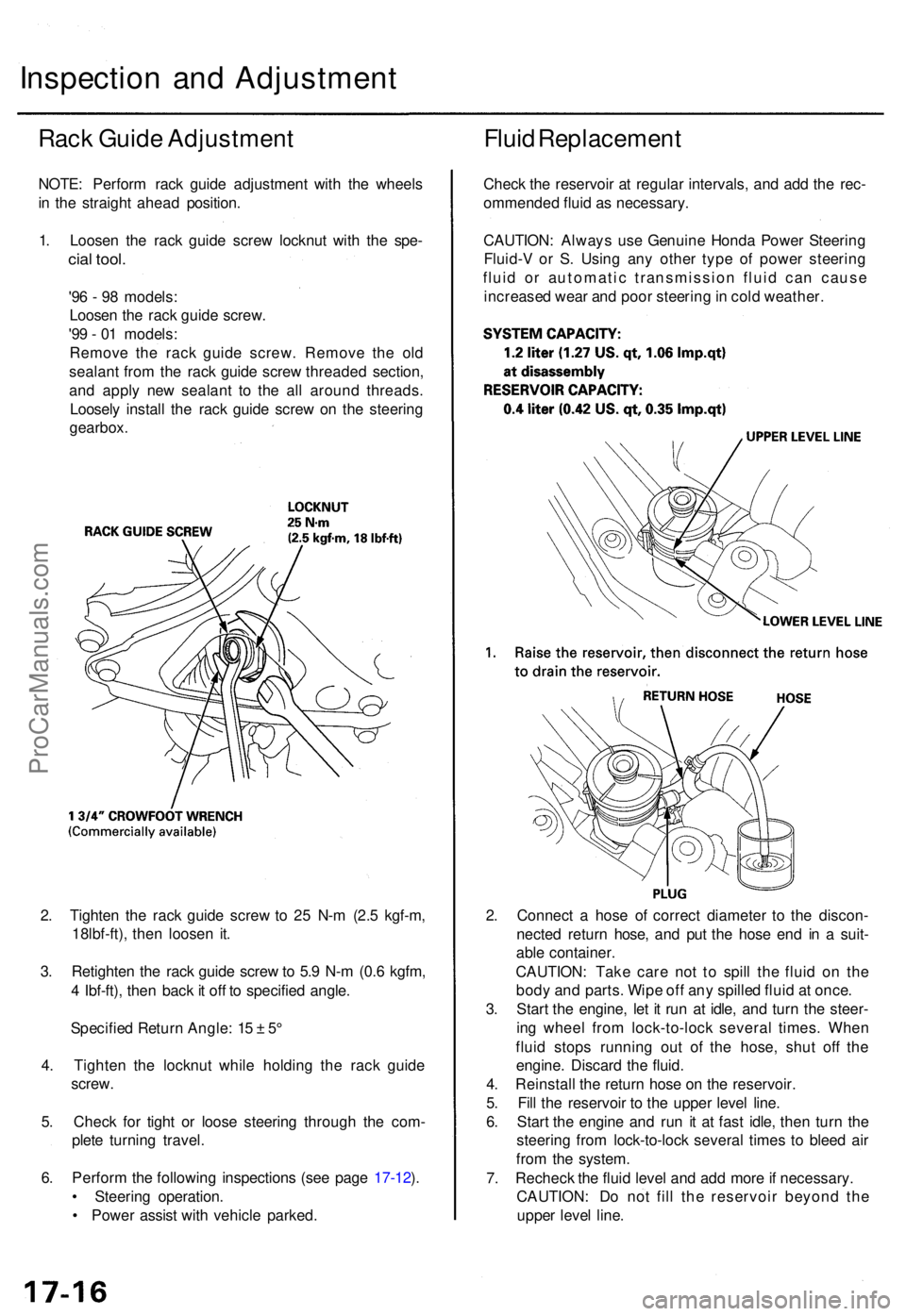

2. Tighte n th e rac k guid e scre w to 2 5 N- m (2. 5 kgf-m ,

18lbf-ft) , the n loose n it .

3 . Retighte n th e rac k guid e scre w to 5. 9 N- m (0. 6 kgfm ,

4 Ibf-ft) , the n bac k it of f t o specifie d angle .

Specifie d Retur n Angle : 1 5 ± 5°

4 . Tighte n th e locknu t whil e holdin g th e rac k guid e

screw .

5 . Chec k fo r tigh t o r loos e steerin g throug h th e com -

plet e turnin g travel .

6 . Perfor m th e followin g inspection s (se e pag e 17-12 ).

• Steerin g operation .

• Powe r assis t wit h vehicl e parked . 2

. Connec t a hos e o f correc t diamete r t o th e discon -

necte d retur n hose , an d pu t th e hos e en d i n a suit -

abl e container .

CAUTION : Tak e car e no t t o spil l th e flui d o n th e

bod y an d parts . Wip e of f an y spille d flui d a t once .

3 . Star t th e engine , le t i t ru n a t idle , an d tur n th e steer -

in g whee l fro m lock-to-loc k severa l times . Whe n

flui d stop s runnin g ou t of the hose , shu t of f th e

engine . Discar d th e fluid .

4 . Reinstal l th e retur n hos e o n th e reservoir .

5 . Fil l th e reservoi r t o th e uppe r leve l line .

6 . Star t th e engin e an d ru n i t a t fas t idle , the n tur n th e

steerin g fro m lock-to-loc k severa l time s t o blee d ai r

fro m th e system .

7 . Rechec k th e flui d leve l an d ad d mor e if necessary .

CAUTION : D o no t fil l th e reservoi r beyon d th e

uppe r leve l line .

Inspectio n an d Adjustmen t

Rack Guid e Adjustmen t

NOTE: Perfor m rac k guid e adjustmen t wit h th e wheel s

i n th e straigh t ahea d position .

1 . Loose n th e rac k guid e scre w locknu t wit h th e spe -

cial tool .

'96 - 9 8 models :

Loose n th e rac k guid e screw .

'9 9 - 0 1 models :

Remov e th e rac k guid e screw . Remov e th e ol d

sealan t fro m th e rac k guid e scre w threade d section ,

an d appl y ne w sealan t t o th e al l aroun d threads .

Loosel y instal l th e rac k guid e scre w o n th e steerin g

gearbox .

Fluid Replacemen t

Check th e reservoi r a t regula r intervals , an d ad d th e rec -

ommende d flui d a s necessary .

CAUTION : Alway s us e Genuin e Hond a Powe r Steerin g

Fluid- V o r S . Usin g an y othe r typ e o f powe r steerin g

flui d o r automati c transmissio n flui d ca n caus e

increase d wea r an d poo r steerin g in col d weather .

ProCarManuals.com

Page 982 of 1954

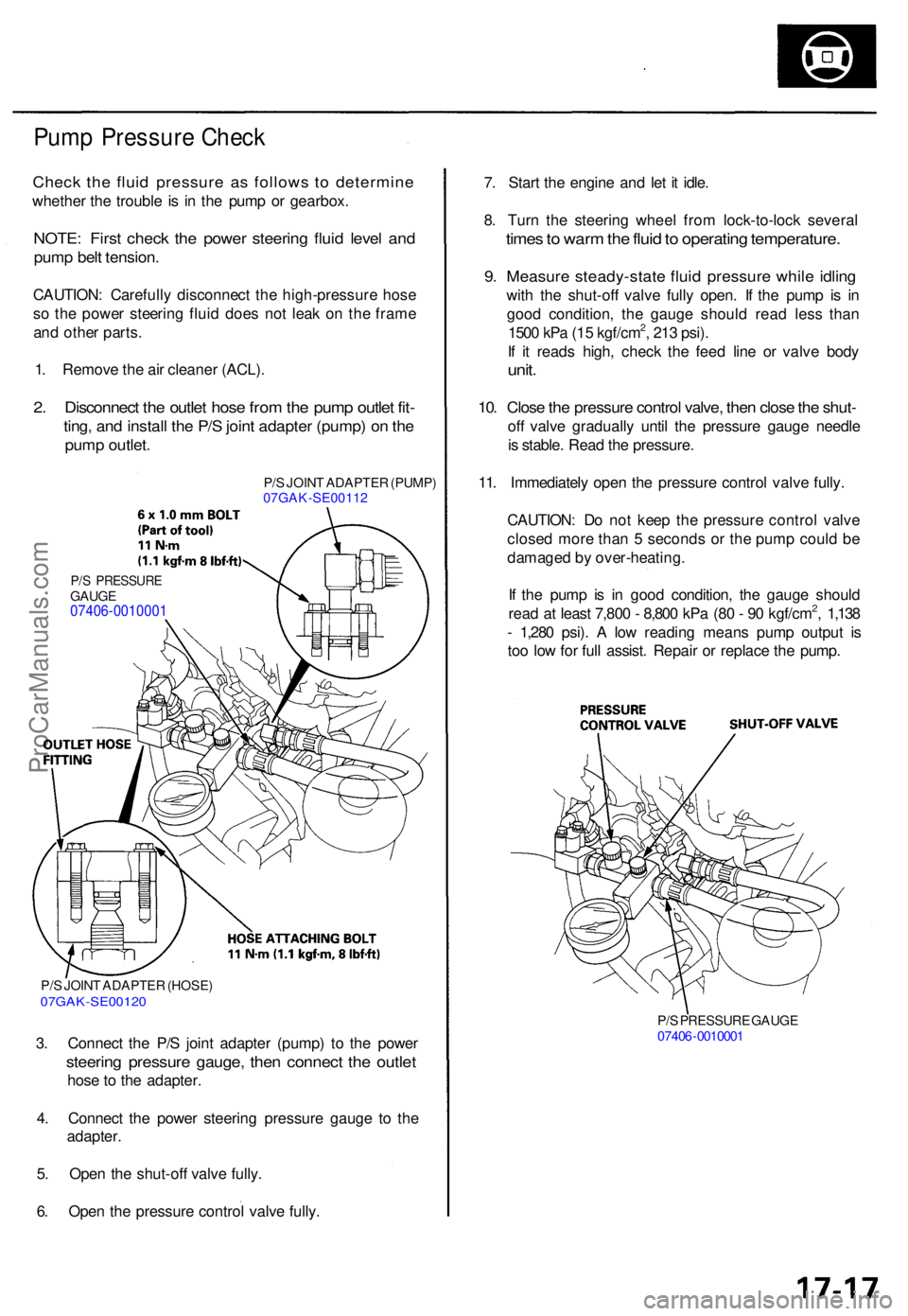

Pump Pressur e Chec k

Check th e flui d pressur e a s follow s t o determin e

whether th e troubl e i s i n th e pum p o r gearbox .

NOTE: Firs t chec k th e powe r steerin g flui d leve l an d

pum p bel t tension .

CAUTION : Carefull y disconnec t th e high-pressur e hos e

s o th e powe r steerin g flui d doe s no t lea k o n th e fram e

an d othe r parts .

1 . Remov e th e ai r cleane r (ACL) .

2. Disconnec t th e outle t hos e fro m th e pum p outle t fit -

ting , an d instal l th e P/ S join t adapte r (pump ) o n th e

pum p outlet .

P/S JOIN T ADAPTE R (PUMP )

07GAK-SE0011 2

P/S PRESSUR EGAUGE07406-0010001

P/S JOIN T ADAPTE R (HOSE )07GAK-SE0012 0

3. Connec t th e P/ S join t adapte r (pump ) t o th e powe r

steerin g pressur e gauge , the n connec t th e outle t

hose t o th e adapter .

4 . Connec t th e powe r steerin g pressur e gaug e t o th e

adapter .

5 . Ope n th e shut-of f valv e fully .

6 . Ope n th e pressur e contro l valv e fully .

P/S PRESSUR E GAUG E

0740 6-001000 1

7. Star t th e engin e an d le t i t idle .

8 . Tur n th e steerin g whee l fro m lock-to-loc k severa l

times to war m th e flui d to operatin g temperature .

9. Measur e steady-stat e flui d pressur e whil e idlin g

with th e shut-of f valv e full y open . I f th e pum p i s i n

goo d condition , th e gaug e shoul d rea d les s tha n

150 0 kP a (1 5 kgf/cm

2, 21 3 psi) .

I f i t read s high , chec k th e fee d lin e o r valv e bod y

unit.

10. Clos e th e pressur e contro l valve , the n clos e th e shut -

off valv e graduall y unti l th e pressur e gaug e needl e

i s stable . Rea d th e pressure .

11 . Immediatel y ope n th e pressur e contro l valv e fully .

CAUTION : D o no t kee p th e pressur e contro l valv e

close d mor e tha n 5 second s o r th e pum p coul d b e

damage d b y over-heating .

I f th e pum p i s i n goo d condition , th e gaug e shoul d

rea d a t leas t 7,80 0 - 8,80 0 kP a (8 0 - 9 0 kgf/cm

2, 1,13 8

- 1,28 0 psi) . A lo w readin g mean s pum p outpu t i s

to o lo w fo r ful l assist . Repai r o r replac e th e pump .

ProCarManuals.com

Page 983 of 1954

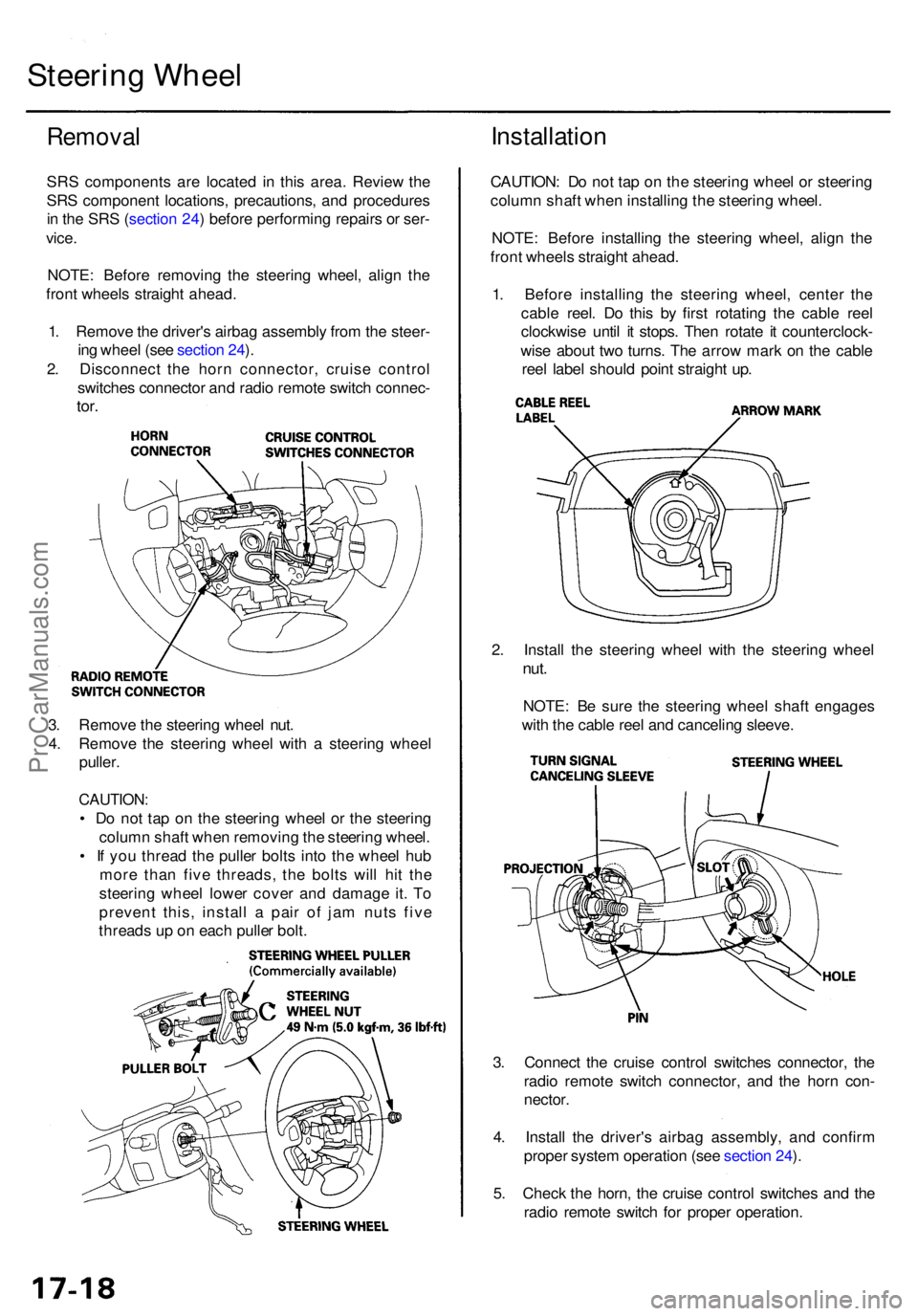

3. Connec t th e cruis e contro l switche s connector , th e

radi o remot e switc h connector , an d th e hor n con -

nector .

4 . Instal l th e driver' s airba g assembly , an d confir m

prope r syste m operatio n (se e sectio n 24 ).

5 . Chec k th e horn , th e cruis e contro l switche s an d th e

radi o remot e switc h fo r prope r operation .

3

. Remov e th e steerin g whee l nut .

4 . Remov e th e steerin g whee l wit h a steerin g whee l

puller .

CAUTION :

• D o no t ta p o n th e steerin g whee l o r th e steerin g

colum n shaf t whe n removin g th e steerin g wheel .

• I f yo u threa d th e pulle r bolt s int o th e whee l hu b

mor e tha n fiv e threads , th e bolt s wil l hi t th e

steerin g whee l lowe r cove r an d damag e it . T o

preven t this , instal l a pai r o f ja m nut s fiv e

thread s u p o n eac h pulle r bolt . 2

. Instal l th e steerin g whee l wit h th e steerin g whee l

nut.

NOTE : B e sur e th e steerin g whee l shaf t engage s

wit h th e cabl e ree l an d cancelin g sleeve .

Remova l

SRS component s ar e locate d i n thi s area . Revie w th e

SR S componen t locations , precautions , an d procedure s

i n th e SR S (sectio n 24 ) befor e performin g repair s o r ser -

vice .

NOTE : Befor e removin g th e steerin g wheel , alig n th e

fron t wheel s straigh t ahead .

1 . Remov e th e driver' s airba g assembl y fro m th e steer -

in g whee l (se e sectio n 24 ).

2 . Disconnec t th e hor n connector , cruis e contro l

switche s connecto r an d radi o remot e switc h connec -

tor.

Installatio n

CAUTION : D o no t ta p o n th e steerin g whee l o r steerin g

colum n shaf t whe n installin g th e steerin g wheel .

NOTE : Befor e installin g th e steerin g wheel , alig n th e

fron t wheel s straigh t ahead .

1 . Befor e installin g th e steerin g wheel , cente r th e

cabl e reel . D o thi s b y firs t rotatin g th e cabl e ree l

clockwis e unti l i t stops . The n rotat e i t counterclock -

wis e abou t tw o turns . Th e arro w mar k o n th e cabl e

ree l labe l shoul d poin t straigh t up .

Steerin g Whee l

ProCarManuals.com

Page 984 of 1954

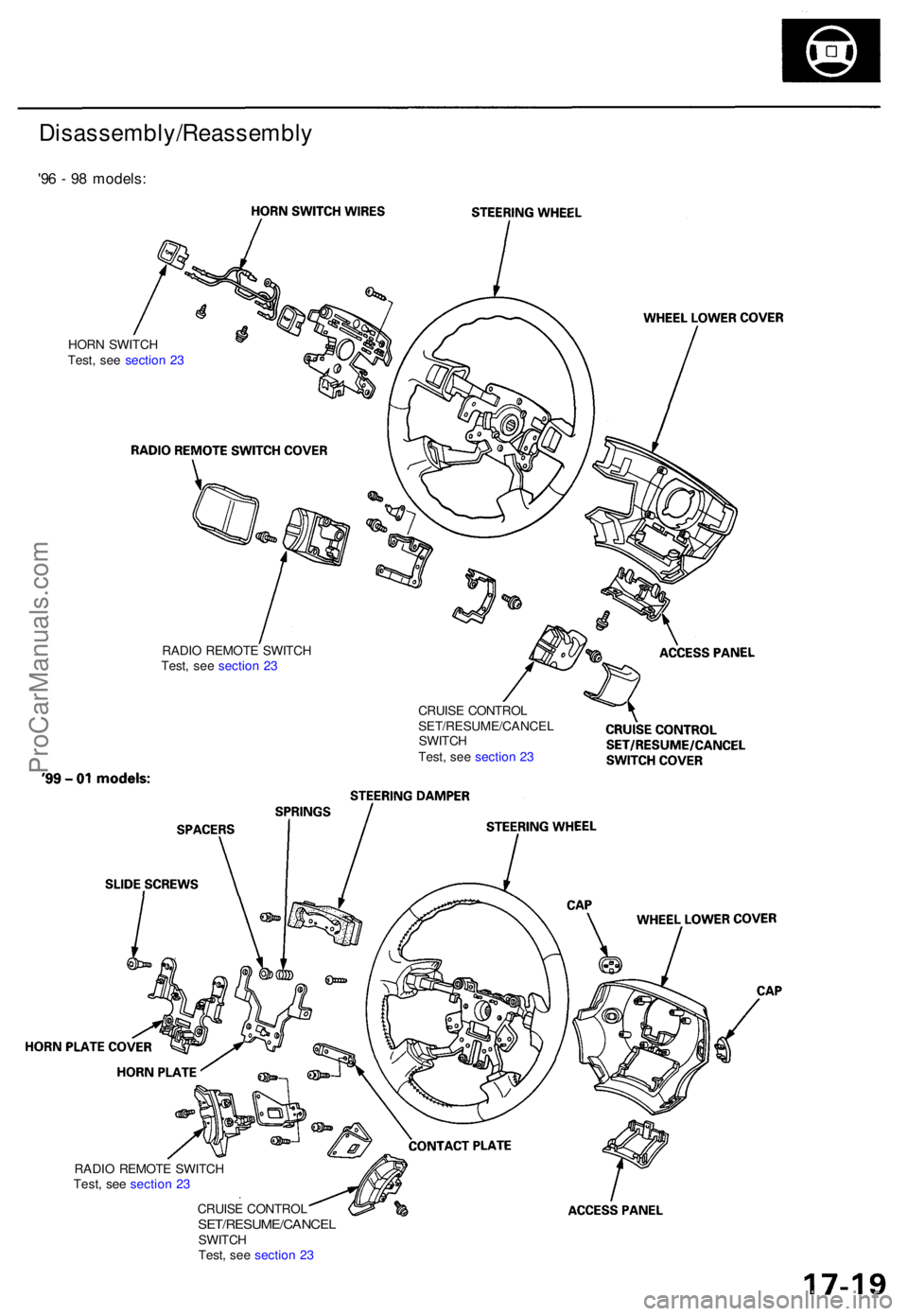

Disassembly/Reassembly

'96 - 9 8 models :

HORN SWITC H

Test , se e sectio n 2 3

CRUISE CONTRO L

SET/RESUME/CANCE L

SWITC H

Test , se e sectio n 2 3

RADI

O REMOT E SWITC H

Test , se e sectio n 2 3

RADI O REMOT E SWITC H

Test , se e sectio n 2 3

CRUIS E CONTRO L

SET/RESUME/CANCE LSWITCH

Test , se e sectio n 2 3

ProCarManuals.com

Page 985 of 1954

Steering Colum n

Removal/Installatio n

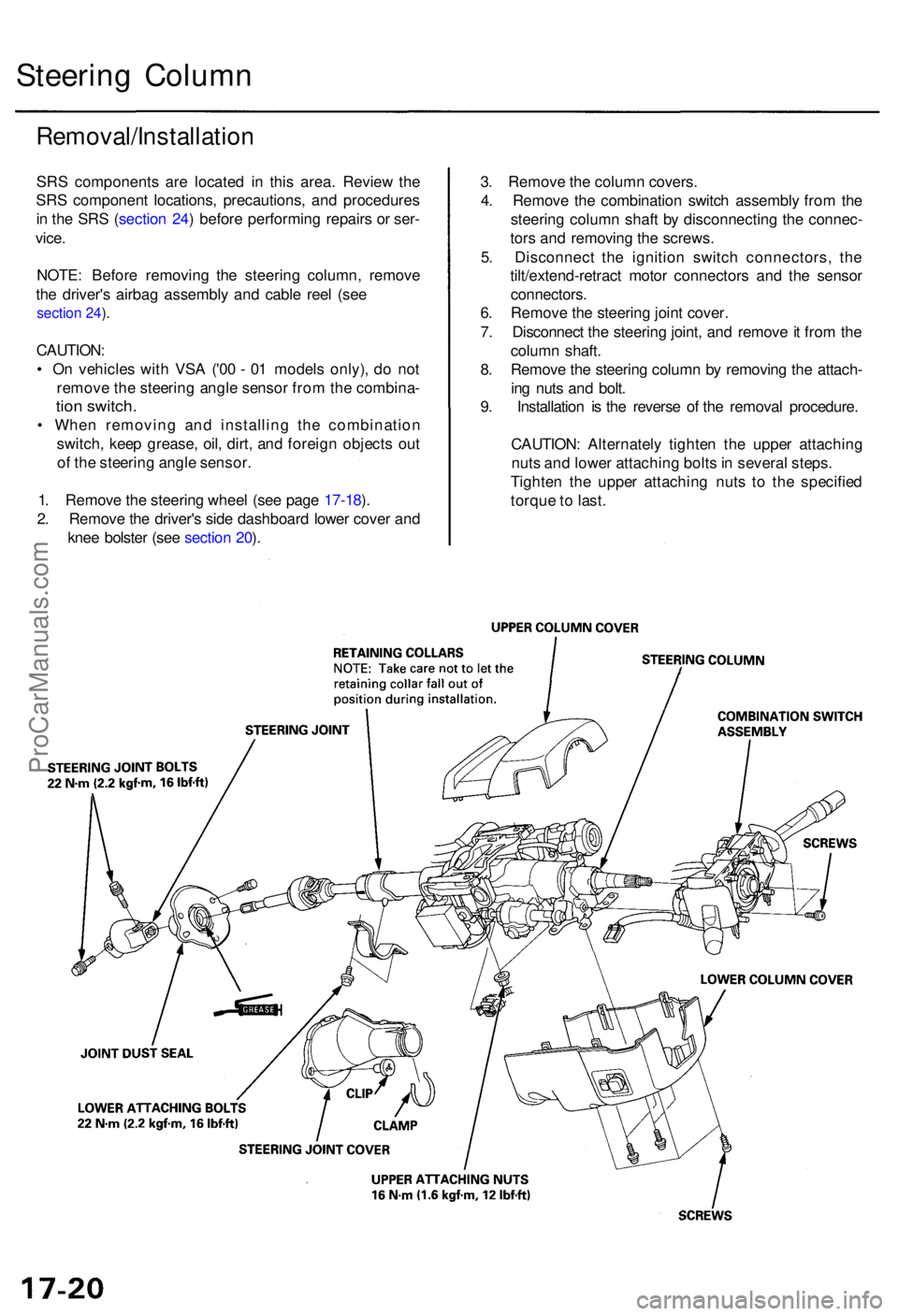

SRS component s ar e locate d i n thi s area . Revie w th e

SR S componen t locations , precautions , an d procedure s

i n th e SR S (sectio n 24 ) befor e performin g repair s o r ser -

vice .

NOTE : Befor e removin g th e steerin g column , remov e

th e driver' s airba g assembl y an d cabl e ree l (se e

section 24 ).

CAUTION :

• O n vehicle s wit h VS A ('0 0 - 0 1 model s only) , d o no t

remov e th e steerin g angl e senso r fro m th e combina -

tion switch .

• Whe n removin g an d installin g th e combinatio n

switch , kee p grease , oil , dirt , an d foreig n object s ou t

o f th e steerin g angl e sensor .

1 . Remov e th e steerin g whee l (se e pag e 17-18 ).

2 . Remov e th e driver' s sid e dashboar d lowe r cove r an d

kne e bolste r (se e sectio n 20 ). 3

. Remov e th e colum n covers .

4 . Remov e th e combinatio n switc h assembl y fro m th e

steerin g colum n shaf t b y disconnectin g th e connec -

tor s an d removin g th e screws .

5 . Disconnec t th e ignitio n switc h connectors , th e

tilt/extend-retrac t moto r connector s an d th e senso r

connectors .

6 . Remov e th e steerin g join t cover .

7 . Disconnec t th e steerin g joint , an d remov e it fro m th e

colum n shaft .

8 . Remov e th e steerin g colum n b y removin g th e attach -

in g nut s an d bolt .

9 . Installatio n i s th e revers e o f th e remova l procedure .

CAUTION : Alternatel y tighte n th e uppe r attachin g

nut s an d lowe r attachin g bolt s in severa l steps .

Tighte n th e uppe r attachin g nut s t o th e specifie d

torqu e to last .

ProCarManuals.com

Page 986 of 1954

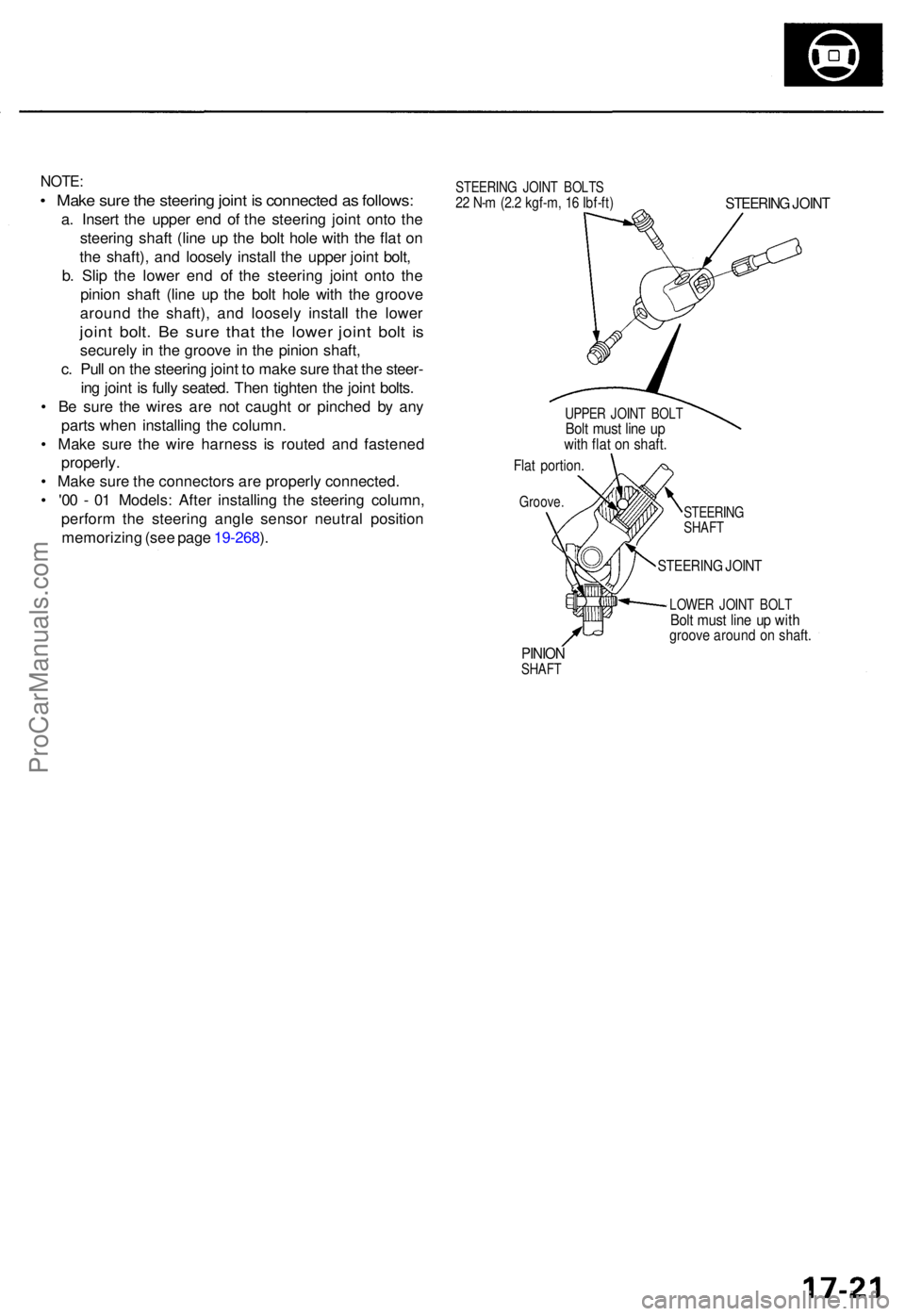

NOTE:

• Mak e sur e th e steerin g join t i s connecte d a s follows :

a. Inser t th e uppe r en d o f th e steerin g join t ont o th e

steerin g shaf t (lin e u p th e bol t hol e wit h th e fla t o n

th e shaft) , an d loosel y instal l th e uppe r join t bolt ,

b . Sli p th e lowe r en d o f th e steerin g join t ont o th e

pinio n shaf t (lin e u p th e bol t hol e wit h th e groov e

aroun d th e shaft) , an d loosel y instal l th e lowe r

joint bolt . B e sur e tha t th e lowe r join t bol t i s

securel y i n th e groov e in th e pinio n shaft ,

c . Pul l o n th e steerin g join t t o mak e sur e tha t th e steer -

in g join t i s full y seated . The n tighte n th e join t bolts .

• B e sur e th e wire s ar e no t caugh t o r pinche d b y an y

part s whe n installin g th e column .

• Mak e sur e th e wir e harnes s i s route d an d fastene d

properly .

• Mak e sur e th e connector s ar e properl y connected .

• '0 0 - 0 1 Models : Afte r installin g th e steerin g column ,

perfor m th e steerin g angl e senso r neutra l positio n

memorizin g (se e pag e 19-268 ).

STEERIN G JOIN T BOLT S22 N- m (2. 2 kgf-m , 1 6 Ibf-ft )STEERIN G JOIN T

UPPE R JOIN T BOL TBolt mus t lin e u pwit h fla t o n shaft .

Flat portion .

Groove.

STEERING

SHAF T

STEERIN G JOIN T

LOWE R JOIN T BOL TBolt mus t lin e u p wit hgroov e aroun d o n shaft .

PINIONSHAF T

ProCarManuals.com

Page 987 of 1954

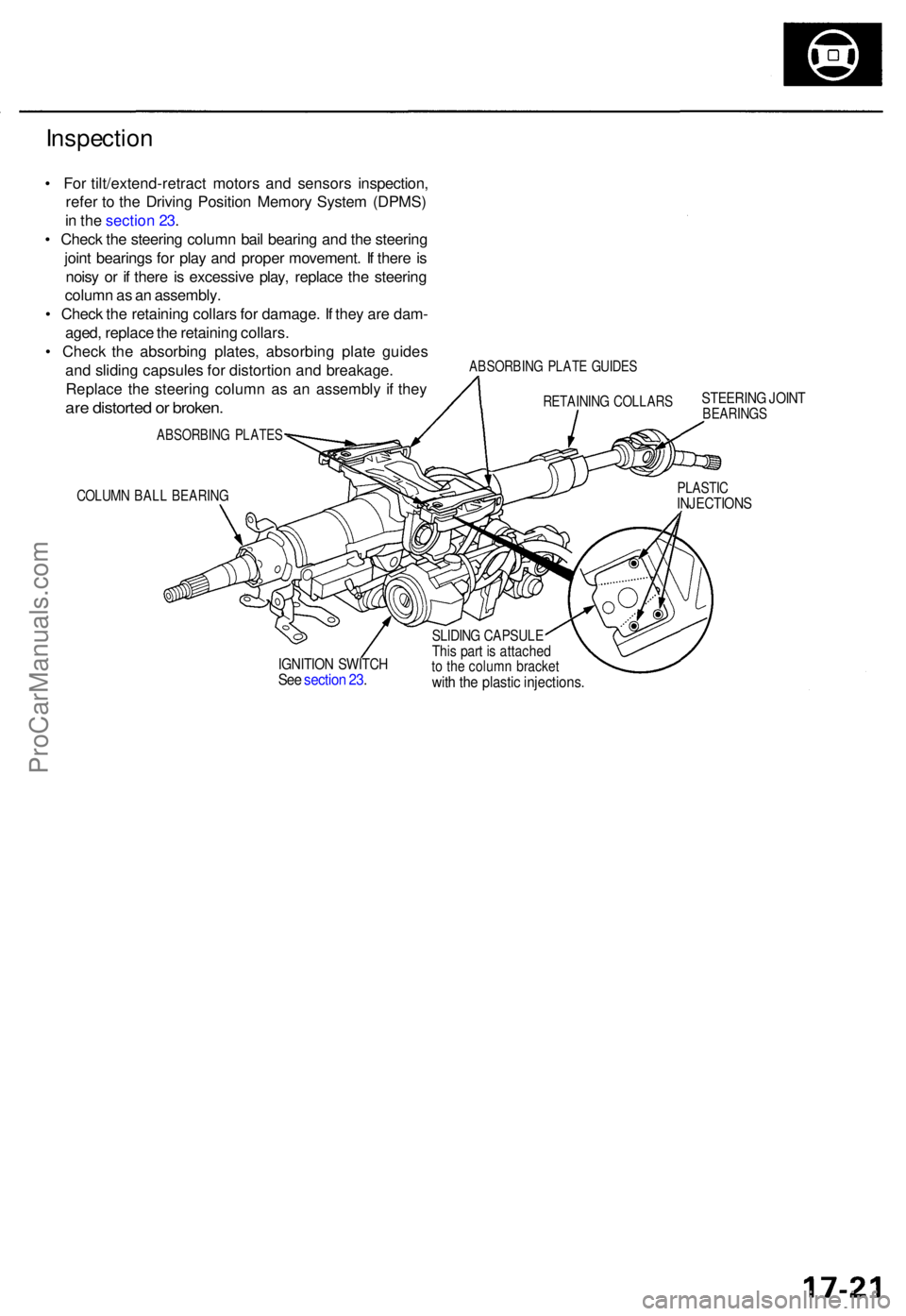

Inspection

• Fo r tilt/extend-retrac t motor s an d sensor s inspection ,

refe r t o th e Drivin g Positio n Memor y Syste m (DPMS )

i n th e sectio n 23 .

• Chec k th e steerin g colum n bai l bearin g an d th e steerin g

join t bearing s fo r pla y an d prope r movement . I f ther e is

nois y o r i f ther e is excessiv e play , replac e th e steerin g

colum n a s a n assembly .

• Chec k th e retainin g collar s fo r damage . I f the y ar e dam -

aged , replac e th e retainin g collars .

• Chec k th e absorbin g plates , absorbin g plat e guide s

an d slidin g capsule s fo r distortio n an d breakage .

Replac e th e steerin g colum n a s a n assembl y i f the y

are distorte d o r broken .

ABSORBIN G PLATE S

COLUMN BAL L BEARIN G

ABSORBIN G PLAT E GUIDE S

STEERIN G JOIN TBEARING S

PLASTICINJECTION S

IGNITION SWITC HSee sectio n 23 .

SLIDIN G CAPSUL EThis par t i s attache dto th e colum n bracke twith th e plasti c injections .

RETAININ G COLLAR S

ProCarManuals.com

Page 988 of 1954

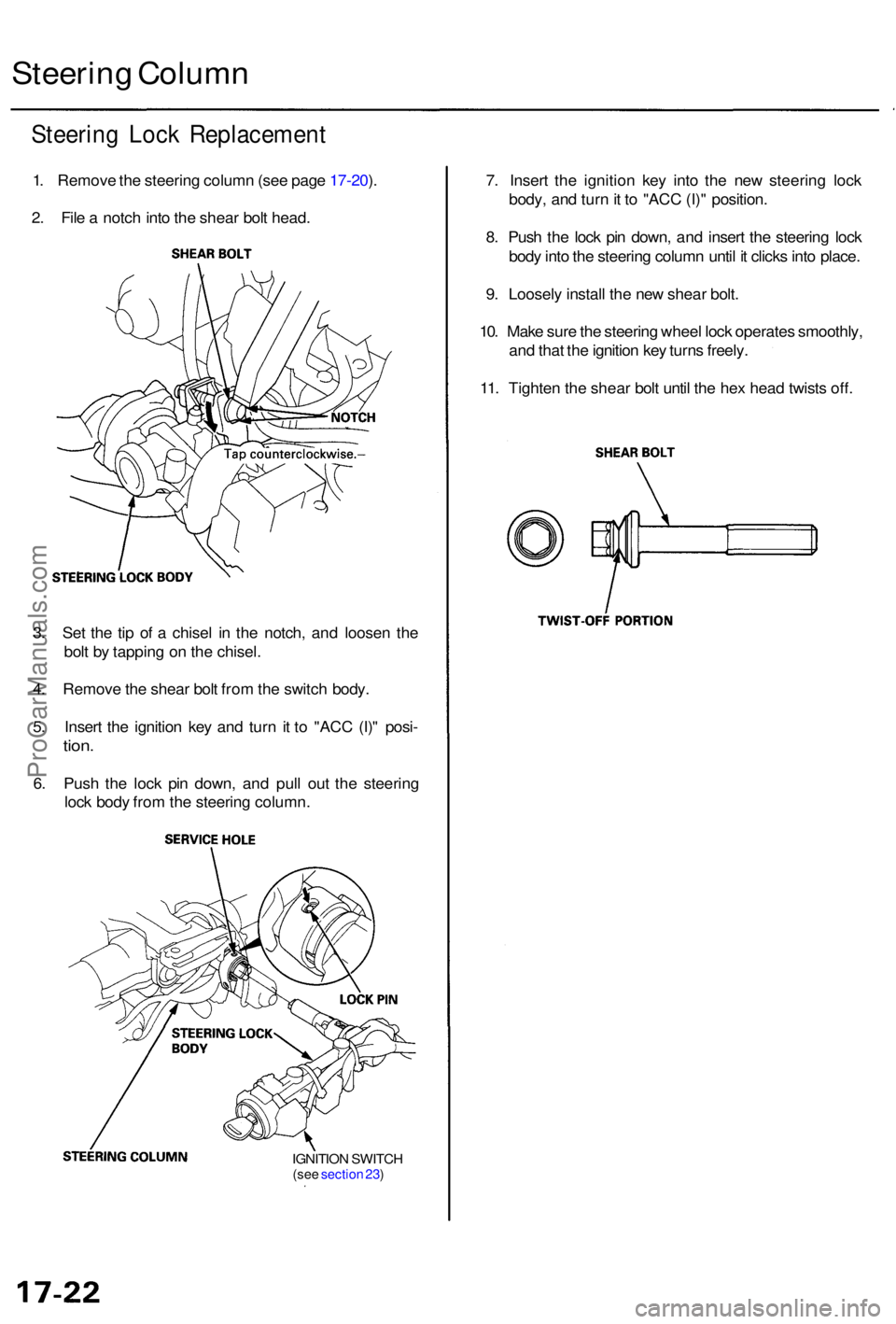

Steering Loc k Replacemen t

1. Remov e th e steerin g colum n (se e pag e 17-20 ).

2 . Fil e a notc h int o th e shea r bol t head .

Steerin g Colum n

7. Inser t th e ignitio n ke y int o th e ne w steerin g loc k

body , an d tur n it t o "AC C (I) " position .

8 . Pus h th e loc k pi n down , an d inser t th e steerin g loc k

bod y int o th e steerin g colum n unti l i t click s int o place .

9 . Loosel y instal l th e ne w shea r bolt .

10 . Mak e sur e th e steerin g whee l loc k operate s smoothly ,

an d tha t th e ignitio n ke y turn s freely .

11 . Tighte n th e shea r bol t unti l th e he x hea d twist s off .

3 . Se t th e ti p o f a chise l i n th e notch , an d loose n th e

bol t b y tappin g o n th e chisel .

4 . Remov e th e shea r bol t fro m th e switc h body .

5 . Inser t th e ignitio n ke y an d tur n i t t o "AC C (I) " posi -

tion.

6. Pus h th e loc k pi n down , an d pul l ou t th e steerin g

loc k bod y fro m th e steerin g column .

IGNITION SWITC H(see sectio n 23 )

ProCarManuals.com

Page 989 of 1954

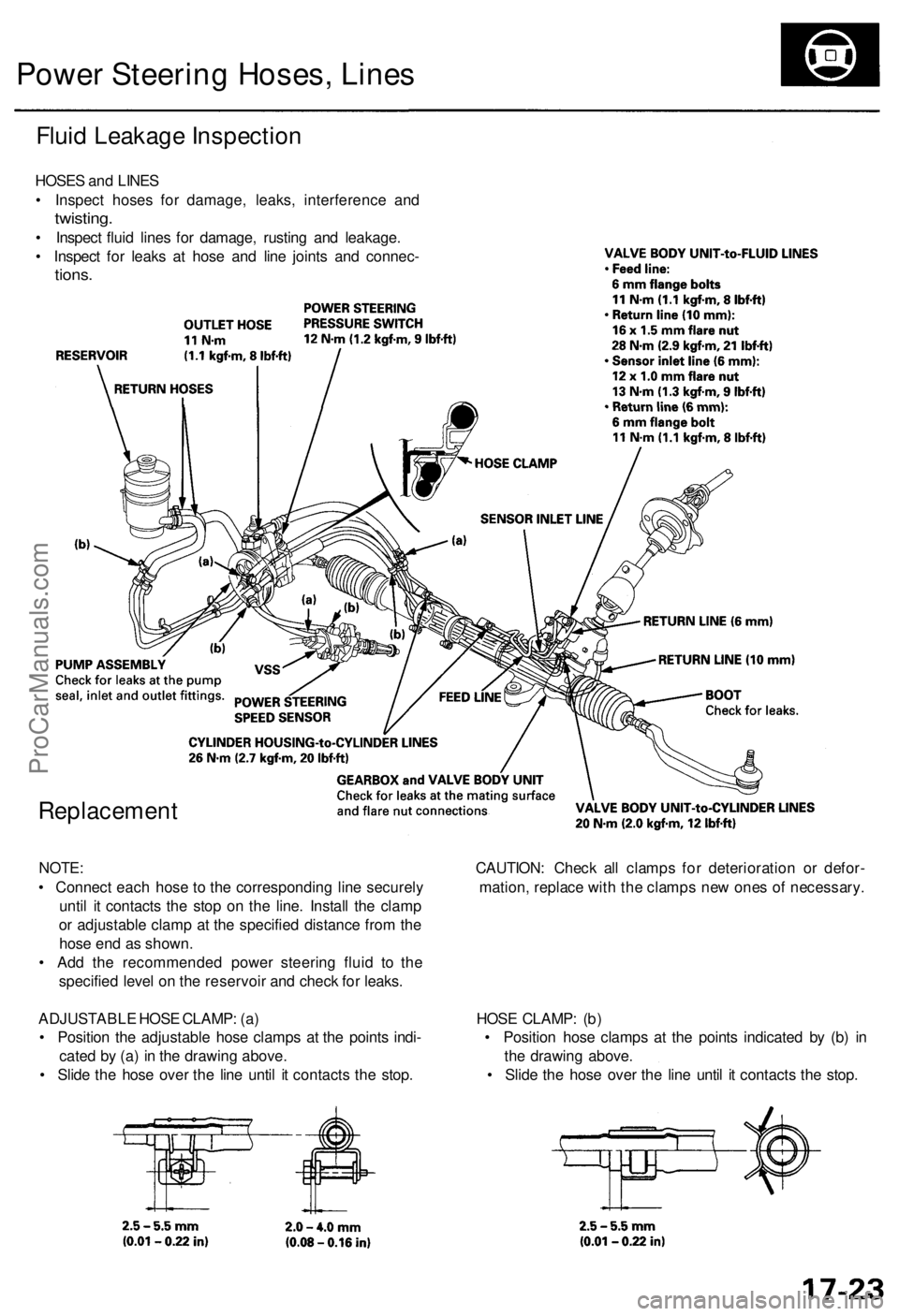

Power Steering Hoses, Lines

Fluid Leakage Inspection

HOSES and LINES

• Inspect hoses for damage, leaks, interference and

twisting.

• Inspect fluid lines for damage, rusting and leakage.

• Inspect for leaks at hose and line joints and connec-

tions.

Replacement

NOTE: CAUTION: Check all clamps for deterioration or defor-

• Connect each hose to the corresponding line securely mation, replace with the clamps new ones of necessary.

until it contacts the stop on the line. Install the clamp

or adjustable clamp at the specified distance from the

hose end as shown.

• Add the recommended power steering fluid to the

specified level on the reservoir and check for leaks.

ADJUSTABLE HOSE CLAMP: (a) HOSE CLAMP: (b)

• Position the adjustable hose clamps at the points indi- • Position hose clamps at the points indicated by (b) in

cated by (a) in the drawing above. the drawing above.

• Slide the hose over the line until it contacts the stop. • Slide the hose over the line until it contacts the stop.ProCarManuals.com

Page 990 of 1954

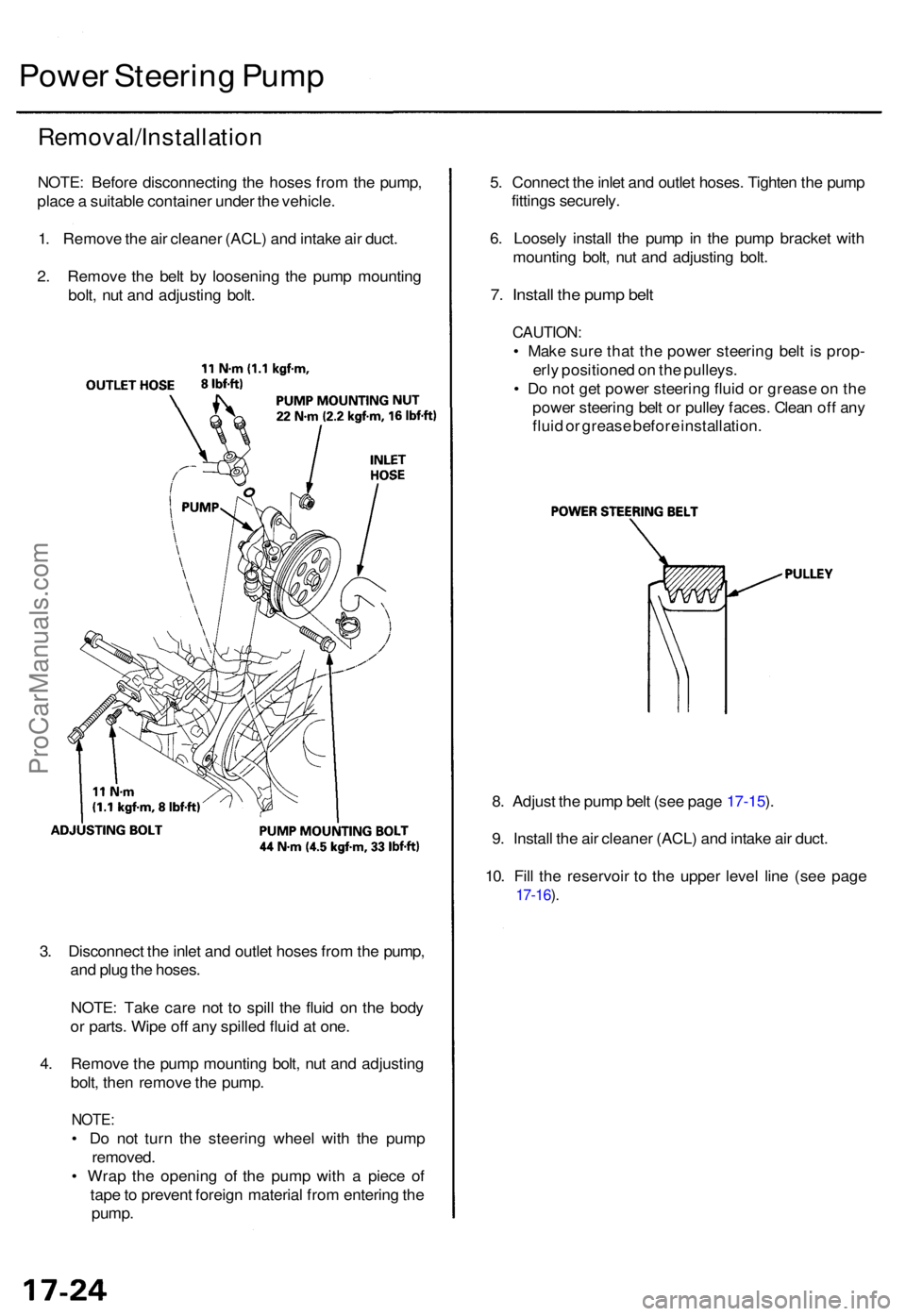

Power Steerin g Pum p

Removal/Installatio n

NOTE: Befor e disconnectin g th e hose s fro m th e pump ,

plac e a suitabl e containe r unde r th e vehicle .

1 . Remov e th e ai r cleane r (ACL ) an d intak e ai r duct .

2 . Remov e th e bel t b y loosenin g th e pum p mountin g

bolt , nu t an d adjustin g bolt . 5

. Connec t th e inle t an d outle t hoses . Tighte n th e pum p

fitting s securely .

6 . Loosel y instal l th e pum p i n th e pum p bracke t wit h

mountin g bolt , nu t an d adjustin g bolt .

7. Instal l th e pum p bel t

CAUTION :

• Mak e sur e tha t th e powe r steerin g bel t i s prop -

erl y positione d o n th e pulleys .

• D o no t ge t powe r steerin g flui d o r greas e o n th e

powe r steerin g bel t o r pulle y faces . Clea n of f an y

flui d o r greas e befor e installation .

8 . Adjus t th e pum p bel t (se e pag e 17-15 ).

9 . Instal l th e ai r cleane r (ACL ) an d intak e ai r duct .

10 . Fil l th e reservoi r t o th e uppe r leve l lin e (se e pag e

17-16 ).

3 . Disconnec t th e inle t an d outle t hose s fro m th e pump ,

an d plu g th e hoses .

NOTE : Tak e car e no t t o spil l th e flui d o n th e bod y

o r parts . Wip e of f an y spille d flui d a t one .

4 . Remov e th e pum p mountin g bolt , nu t an d adjustin g

bolt , the n remov e th e pump .

NOTE:

• D o no t tur n th e steerin g whee l wit h th e pum p

removed .

• Wra p th e openin g o f th e pum p wit h a piec e o f

tap e to preven t foreig n materia l fro m enterin g th e

pump .

ProCarManuals.com