ACURA TL 1995 Service Repair Manual

Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 1131 of 1771

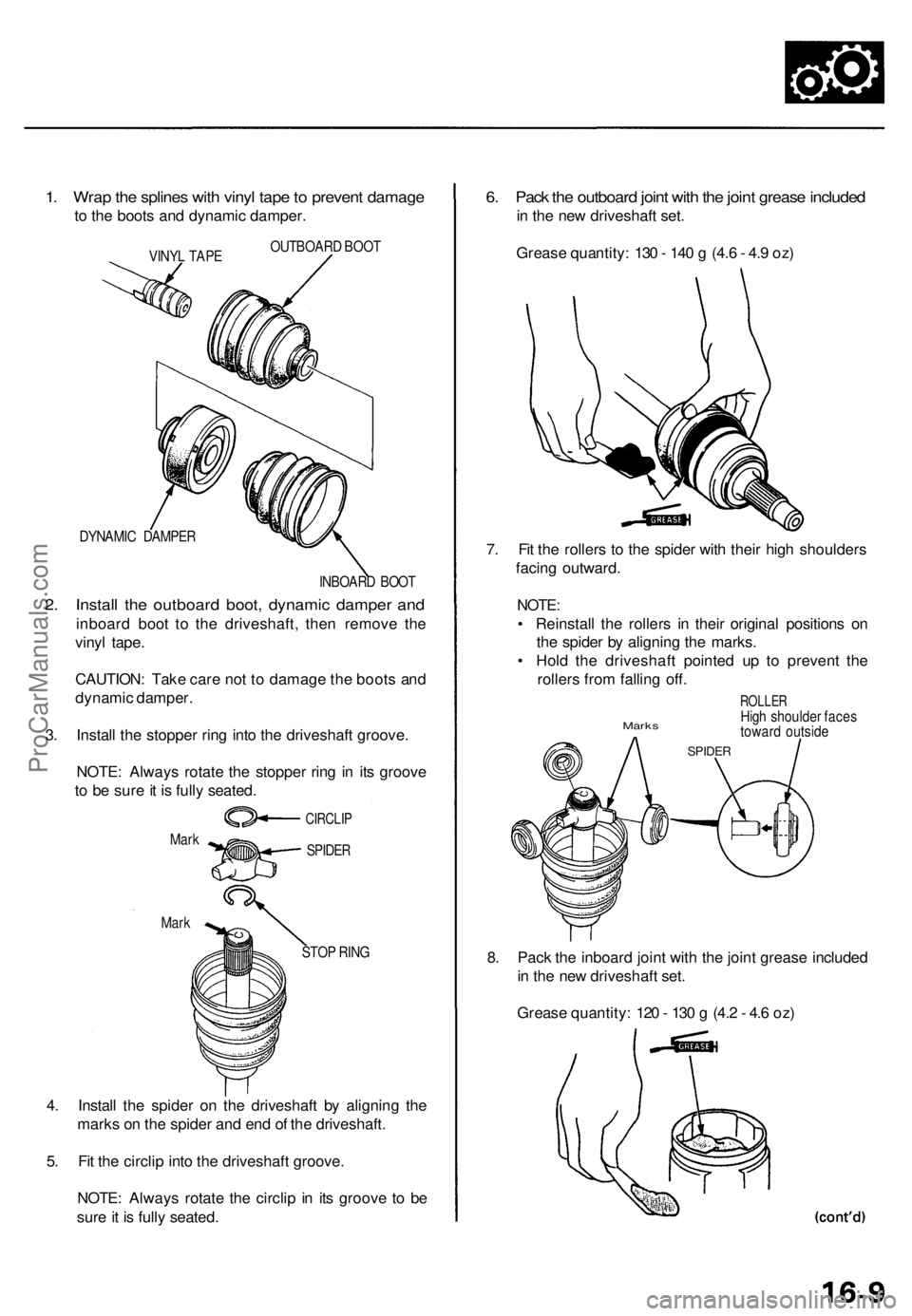

1. Wra p th e spline s wit h viny l tap e to preven t damag e

to th e boot s an d dynami c damper .

VINYL TAP E OUTBOAR

D BOO T

DYNAMI C DAMPE R

INBOARD BOO T

2. Instal l th e outboar d boot , dynami c dampe r an d

inboar d boo t t o th e driveshaft , the n remov e th e

viny l tape .

CAUTION : Tak e car e no t t o damag e th e boot s an d

dynami c damper .

3 . Instal l th e stoppe r rin g int o th e driveshaf t groove .

NOTE : Alway s rotat e th e stoppe r rin g i n it s groov e

t o b e sur e it i s full y seated .

Mark

Mar k

STOP RIN G

4. Instal l th e spide r o n th e driveshaf t b y alignin g th e

mark s o n th e spide r an d en d o f th e driveshaft .

5 . Fi t th e circli p int o th e driveshaf t groove .

NOTE : Alway s rotat e th e circli p in it s groov e t o b e

sur e it i s full y seated .

6. Pac k th e outboar d join t wit h th e join t greas e include d

in th e ne w driveshaf t set .

Greas e quantity : 13 0 - 14 0 g (4. 6 - 4. 9 oz )

7 . Fi t th e roller s t o th e spide r wit h thei r hig h shoulder s

facin g outward .

NOTE:

• Reinstal l th e roller s i n thei r origina l position s o n

th e spide r b y alignin g th e marks .

• Hol d th e driveshaf t pointe d u p t o preven t th e

roller s fro m fallin g off .

ROLLE RHigh shoulde r face sMark s towar d outsid e

SPIDER

8. Pac k th e inboar d join t wit h th e join t greas e include d

i n th e ne w driveshaf t set .

Greas e quantity : 12 0 - 13 0 g (4. 2 - 4. 6 oz )

CIRCLI P

SPIDER

ProCarManuals.com

Page 1132 of 1771

Driveshaft

Reassembl y (cont'd )

9. Fi t th e inboar d join t ont o th e driveshaft .

NOTE:

• Reinstal l th e inboar d join t ont o th e driveshaf t b y

alignin g th e mark s o n th e inboar d join t an d th e

rollers .

• Hol d th e driveshaf t s o th e inboar d join t point s u p

t o preven t i t fro m fallin g off .

INBOAR DJOINT

10. Adjus t th e lengt h of the driveshaft s t o th e figur e

below , the n adjus t th e boot s t o halfwa y betwee n

full compressio n an d ful l extension .

NOTE: Th e end s o f boot s sea t i n th e groov e o f th e

driveshaf t an d joint .

Left: 49 6 - 50 1 m m (19. 5 - 19. 7 in )

Right : 50 3 - 50 8 m m (19. 8 - 20. 0 in )

11. Positio n th e dynami c dampe r a s show n below .

45 2 mm (1. 8 0. 1 in )

DYNAMI C DAMPE R

(Fo r righ t driveshaft )

DYNAMI C DAMPE R BAN D

12. Se t th e doubl e loo p ban d ont o th e boo t an d dynami c

damper wit h th e ban d en d towar d t o fron t o f th e

vehicle .

Front DOUBL

E LOO P BAN D

BOO T

NOTE : Refe r t o page 16-3a of the '96-9 8 Acura 3.2TL Servic e Manual supplement forfor the differences on this page for the 3.2TL.

ProCarManuals.com

Page 1133 of 1771

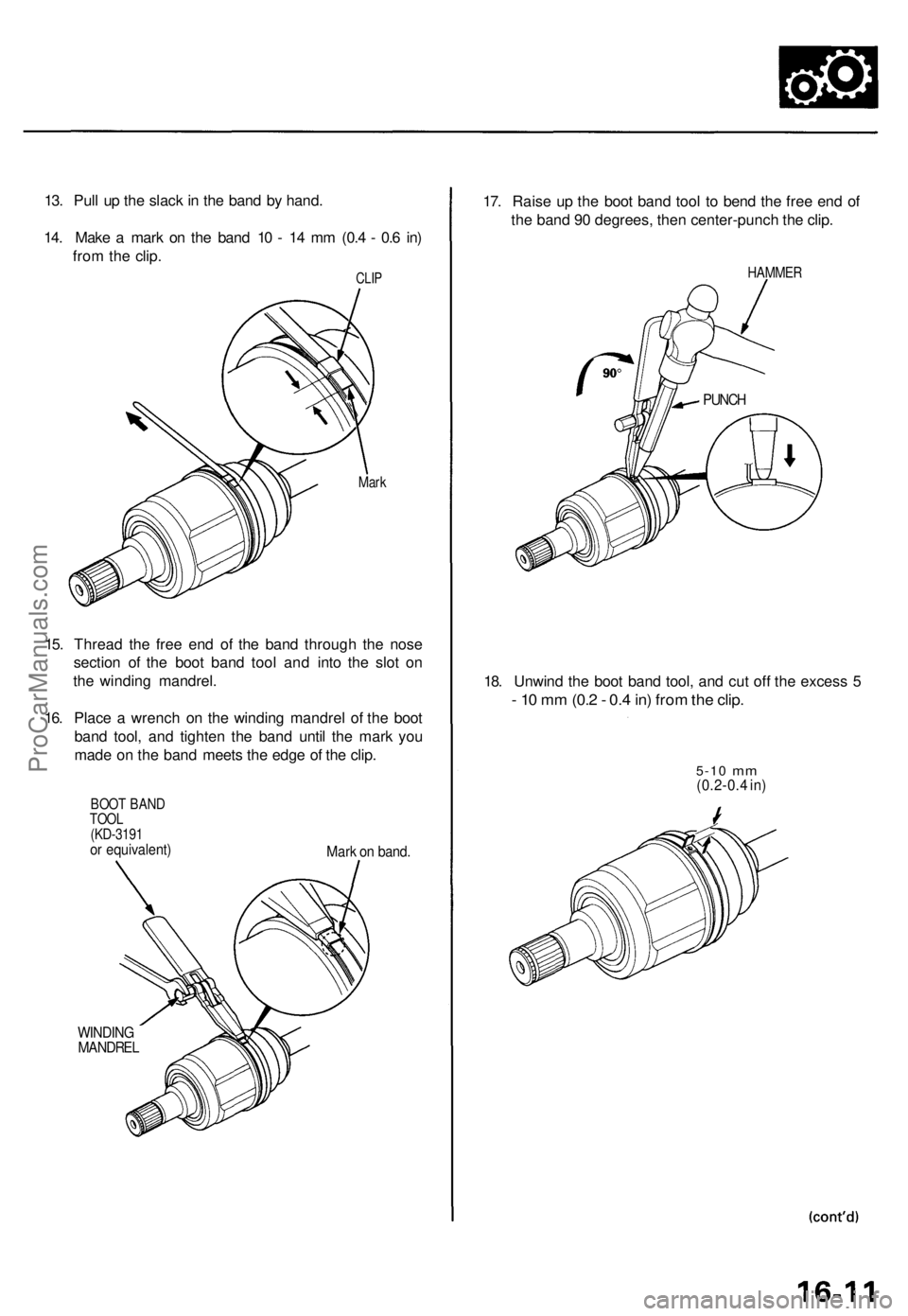

13. Pul l u p th e slac k in th e ban d b y hand .

14 . Mak e a mar k o n th e ban d 1 0 - 1 4 m m (0. 4 - 0. 6 in )

fro m th e clip .

CLIP

Mar k

15. Threa d th e fre e en d o f th e ban d throug h th e nos e

sectio n o f th e boo t ban d too l an d int o th e slo t o n

th e windin g mandrel .

16 . Plac e a wrenc h o n th e windin g mandre l o f th e boo t

ban d tool , an d tighte n th e ban d unti l th e mar k yo u

mad e o n th e ban d meet s th e edg e o f th e clip .

BOO T BAN D

TOO L

(KD-319 1

or equivalent )

Mark o n band .

WINDIN G

MANDRE L

17. Rais e u p th e boo t ban d too l t o ben d th e fre e en d o f

th e ban d 9 0 degrees , the n center-punc h th e clip .

HAMME R

18. Unwin d th e boo t ban d tool , an d cu t of f th e exces s 5

- 1 0 m m (0. 2 - 0. 4 in ) fro m th e clip .

5-1 0 mm(0.2-0. 4 in )

PUNC H

ProCarManuals.com

Page 1134 of 1771

Driveshaft

Reassembl y (cont'd )

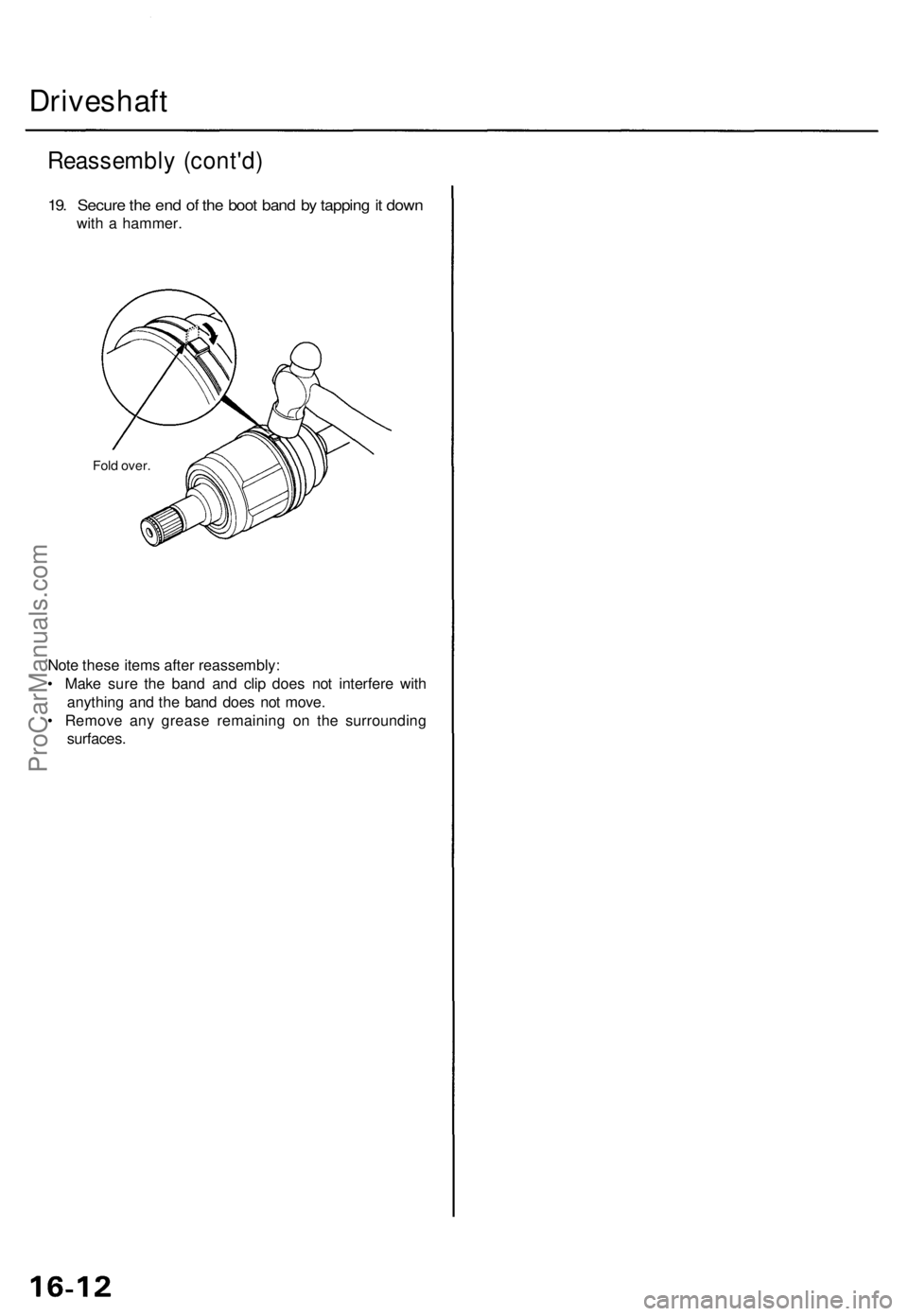

19. Secur e th e en d o f th e boo t ban d b y tappin g it dow n

with a hammer .

Fold over .

Note thes e item s afte r reassembly :

• Mak e sur e th e ban d an d cli p doe s no t interfer e wit h

anythin g an d th e ban d doe s no t move .

• Remov e an y greas e remainin g o n th e surroundin g

surfaces .

ProCarManuals.com

Page 1135 of 1771

Driveshaft

Installation

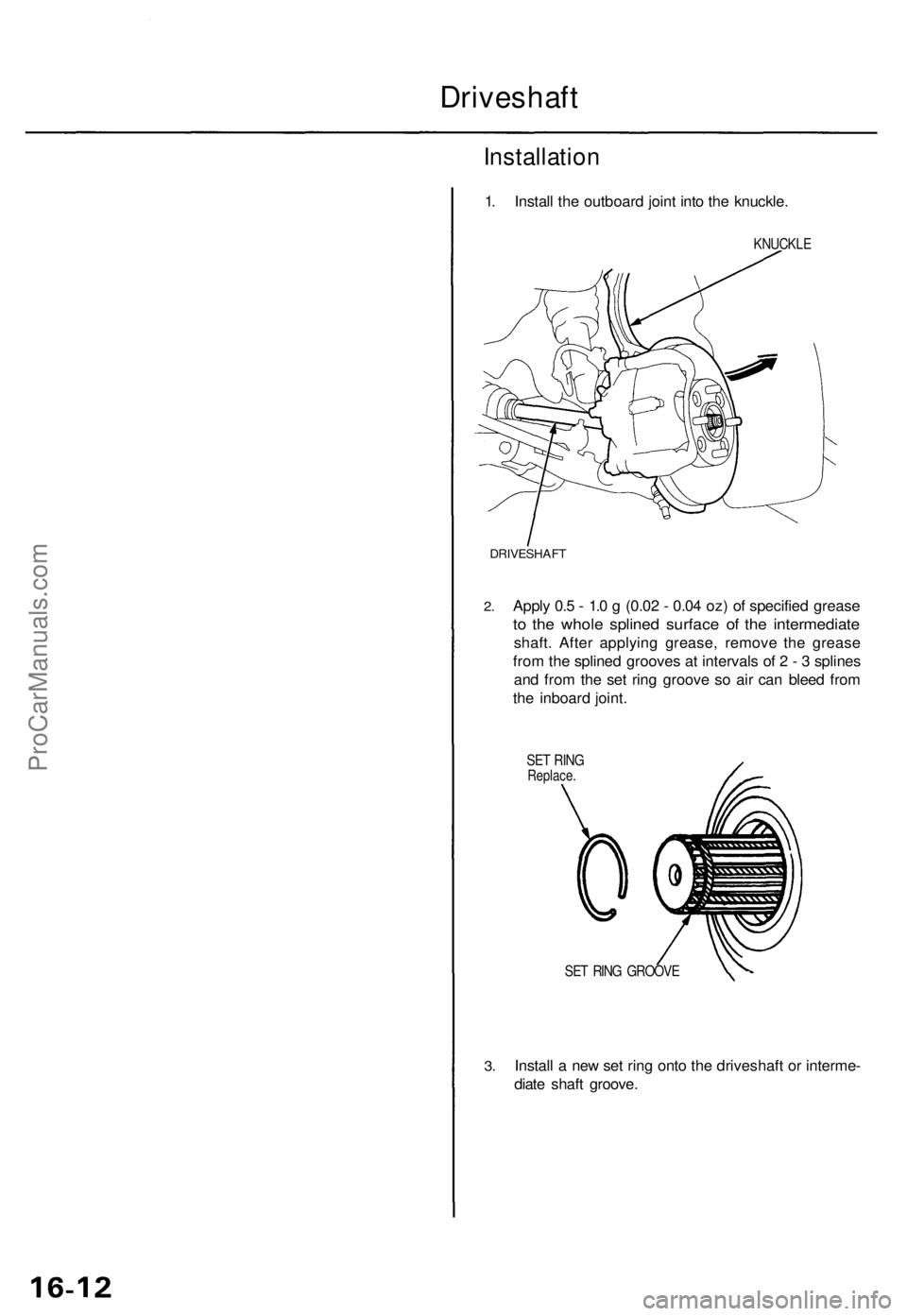

1. Instal l th e outboar d join t int o th e knuckle .

KNUCKL E

DRIVESHAF T

2.Appl y 0. 5 - 1. 0 g (0.0 2 - 0.0 4 oz ) o f specifie d greas e

to th e whol e spline d surfac e o f th e intermediat e

shaft. Afte r applyin g grease , remov e th e greas e

fro m th e spline d groove s a t interval s o f 2 - 3 spline s

an d fro m th e se t rin g groov e s o ai r ca n blee d fro m

th e inboar d joint .

SET RIN GReplace .

3.

SE T RIN G GROOV E

Install a ne w se t rin g ont o th e driveshaf t o r interme -

diat e shaf t groove .

ProCarManuals.com

Page 1136 of 1771

4. Instal l th e inboar d en d o f th e driveshaf t int o th e dif -

ferentia l o r th e intermediat e shaft .

SET RIN GReplace .Make sur e th e lef t driveshaf t lock s in th e differen -

tia l sid e gea r groove , an d th e inboar d join t sub-axl e

bottom s i n th e differential .

Lef t Driveshaf t

SE T RIN G GROOV E SE

T RIN G

Replace .

Right Driveshaf t

Inser t th e righ t driveshaf t inboar d join t sub-axl e int o

the intermediat e shaf t unti l th e intermediat e shaf tset rin g lock s in th e groov e in th e righ t driveshaft .

5. Instal l th e knuckl e o n th e lowe r arm , the n tighte n

the castl e nu t an d instal l a ne w cotte r pin .

FLANG E BOL T10 x 1.2 5 mm43 N- m (4. 4 kgf-m , 3 2 Ibf-ft )

SELF-LOCKIN G NU T

12 x 1.2 5 mm64 N- m (6. 5 kgf-m , 4 7 Ibf-ft )Replace .

CASTL E NU T

14 x 2. 0 m m49-5 9 N- m (5. 0 - 6. 0 kgf-m ,

36-4 3 Ibf-ft )

6. Instal l th e dampe r for k ove r th e driveshaf t an d ont o

th e lowe r arm . Instal l th e dampe r i n th e dampe r

fork s o th e alignin g ta b i s aligne d wit h th e slo t i n

th e dampe r for k (se e sectio n 18 ).

Loosel y instal l th e flang e bolt s an d th e ne w self -

lockin g nut .

NOTE : Th e bolt s an d nu t shoul d b e tightene d wit h

the vehicle' s weigh t o n th e damper .

Install a ne w spindl e nut , the n tighte n th e nut .

7.

8.

FRON T WHEE L

WHEE L NU T

SPINDL E NU T24 x 1. 5 m mReplace .

9. Instal l th e fron t whee l wit h th e whee l nuts .

NOTE : Befor e installin g th e wheel , clea n th e matin g

surface s o f th e brak e dis c an d th e wheel .

10 . Tighte n th e flang e bolt s an d th e ne w self-lockin g

nu t wit h th e vehicle' s weigh t o n th e damper .

11. Refil l th e transmissio n wit h recommende d flui d (se e

sectio n 14 ).

12 . Chec k th e fron t whee l alignmen t an d adjus t i f nec -

essar y (se e sectio n 18 ).

COTTE R PI N'Replace .On reassembly , ben d th ecotte r pi n a s shown .

SET RIN G GROOV ESIDE GEA R

ProCarManuals.com

Page 1137 of 1771

Intermediate Shaf t

Removal/Installatio n

1. Drai n th e automati c transmissio n flui d (se e

section 14 ).

2 . Remov e th e righ t driveshaf t assembl y (se e pag e 16-3 ).

3 . Remov e th e thre e flang e bolts .

FLANG E BOL T8 x 1.2 5 mm

4. Remov e th e intermediat e shaf t assembl y fro m th e

oil pan .

INTERMEDIAT E SHAF T

5. Instal l th e intermediat e shaf t i n th e revers e orde r o f

removal .

CAUTION : Whe n installing , mak e sur e th e O-rin g i s

i n plac e an d no t pinched .

NOTE : Appl y sealan t t o th e bol t threads , an d tighte n

th e bolt s t o th e specifie d torque .

22 N- m (2. 2 kgf-m , 1 6 Ibf-ft )

ProCarManuals.com

Page 1138 of 1771

Intermediate Shaf t

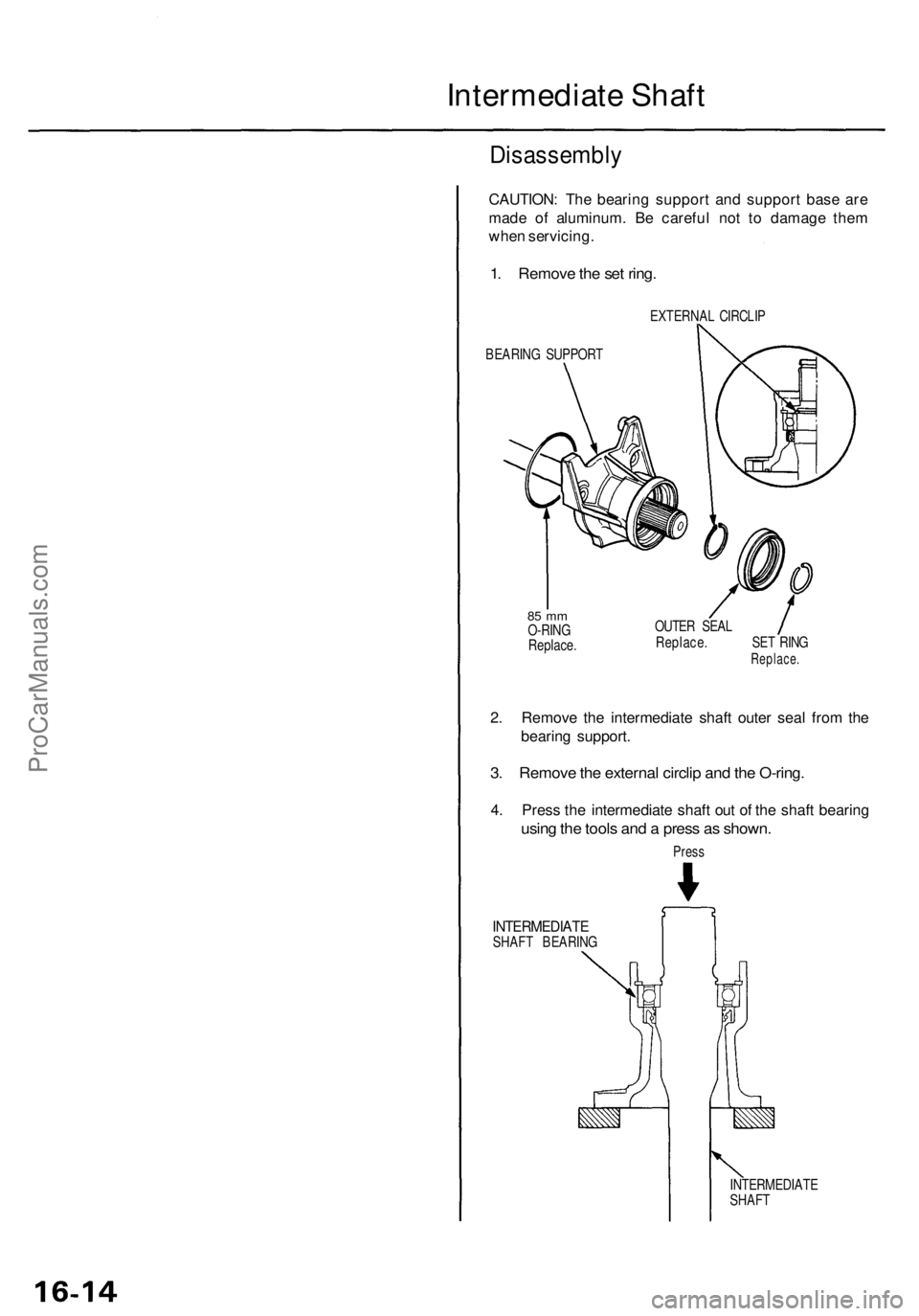

Disassembl y

CAUTION: Th e bearin g suppor t an d suppor t bas e ar e

mad e o f aluminum . B e carefu l no t t o damag e the m

whe n servicing .

1. Remov e th e se t ring .

EXTERNA L CIRCLI P

BEARIN G SUPPOR T

85 m mO-RIN G

Replace . OUTE

R SEA L

Replace . SE T RIN G

Replace .

2. Remov e th e intermediat e shaf t oute r sea l fro m th e

bearin g support .

3. Remov e th e externa l circli p an d th e O-ring .

4. Pres s th e intermediat e shaf t ou t o f th e shaf t bearin g

using th e tool s an d a pres s a s shown .

Press

INTERMEDIAT ESHAFT BEARIN G

INTERMEDIATE

SHAF T

ProCarManuals.com

Page 1139 of 1771

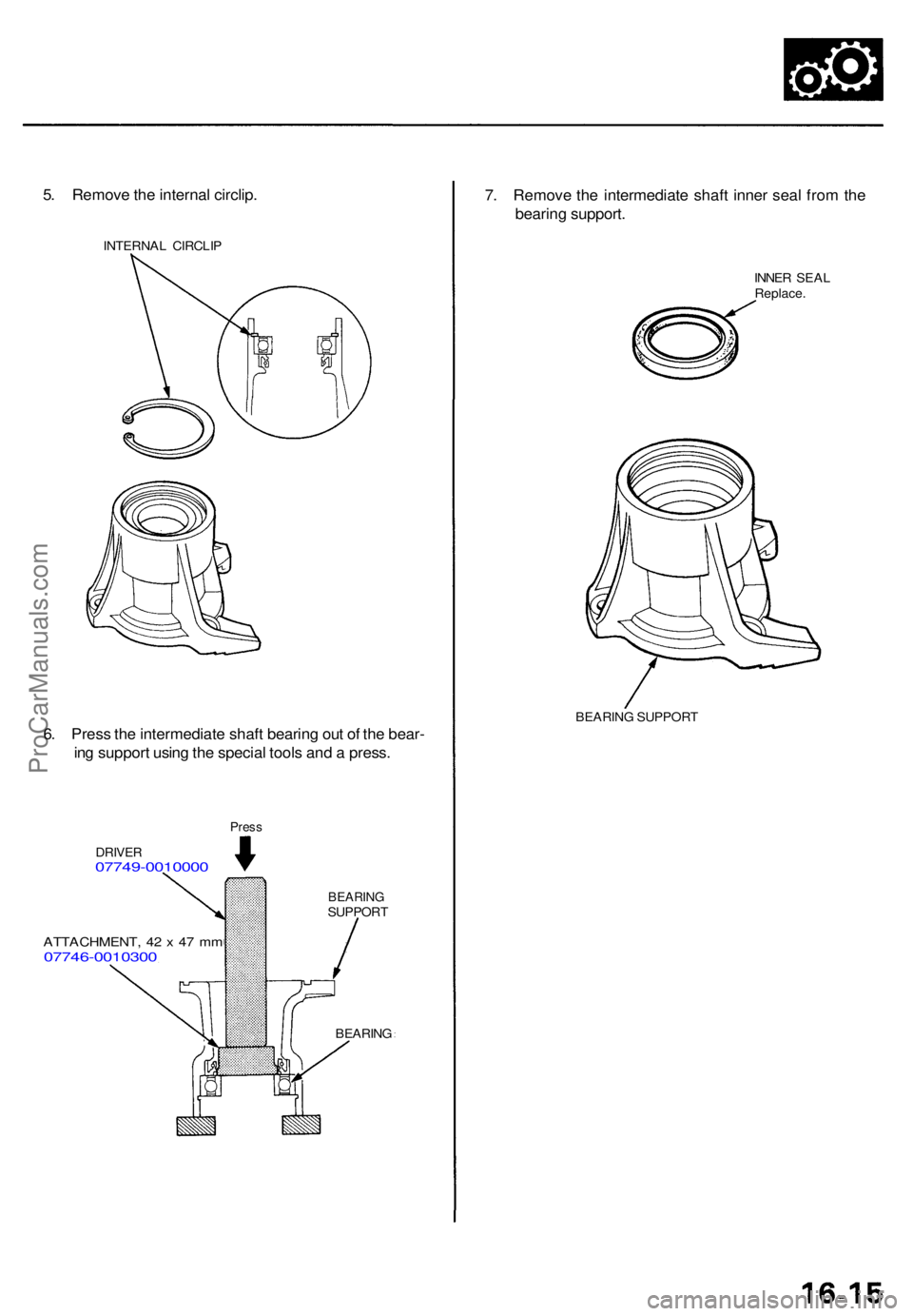

5. Remov e th e interna l circlip .

INTERNA L CIRCLI P

6. Pres s th e intermediat e shaf t bearin g ou t o f th e bear -

in g suppor t usin g th e specia l tool s an d a press .

Press

DRIVE R07749-001000 0

ATTACHMENT , 4 2 x 47 m m07746-001030 0

BEARINGSUPPOR T

BEARING

7. Remov e th e intermediat e shaf t inne r sea l fro m th e

bearin g support .

INNER SEA L

Replace .

BEARIN G SUPPOR T

ProCarManuals.com

Page 1140 of 1771

Intermediate Shaf t

Reassembl y

CAUTION:

• Th e bearin g suppor t i s mad e o f aluminum . B e carefu l no t t o damag e it whe n servicing .

• D o no t damag e th e li p o n inne r an d oute r seal s durin g installation .

INTERMEDIAT E SHAF T

Chec k fo r damage .

BEARING SUPPOR T

Chec k fo r damage .

INNER SEA LReplace .

85 m mO-RIN GReplac e

INTERMEDIAT E SHAF TBEARIN GReplace.

INTERNA LCIRCLIPOUTER SEA LReplace .

Pack th e interio r an d li p o f th e

oute r seal .

EXTERNA LCIRCLIP

ProCarManuals.com