ACURA TL 1995 Service Repair Manual

Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 311 of 1771

Lock-up Contro l Solenoi d Valv e A/ B

Tes t

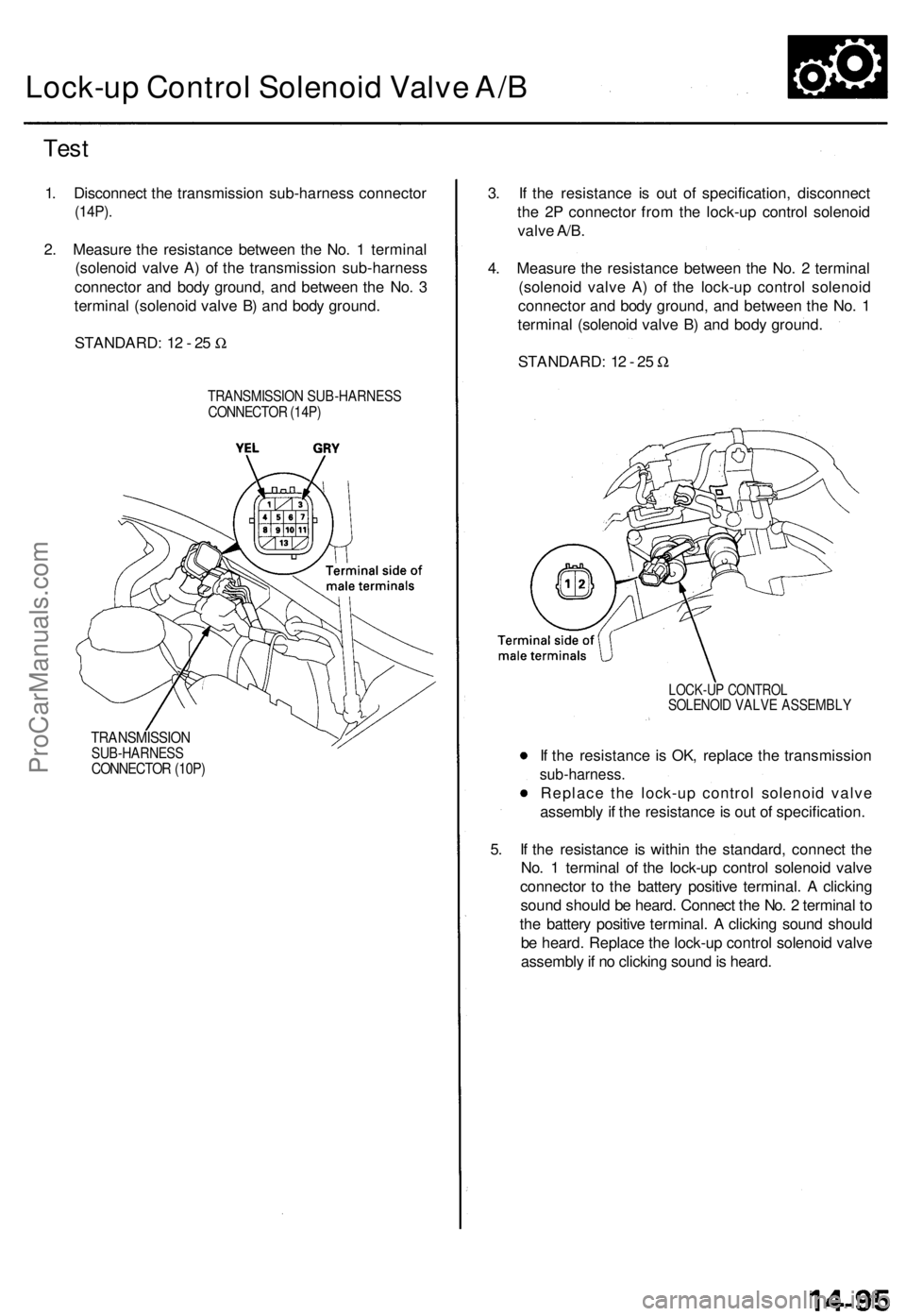

STANDARD : 1 2 - 2 5 W

1

. Disconnec t th e transmissio n sub-harnes s connecto r

(14P).

2. Measur e th e resistanc e betwee n th e No . 1 termina l

(solenoi d valv e A ) o f th e transmissio n sub-harnes s

connecto r an d bod y ground , an d betwee n th e No . 3

termina l (solenoi d valv e B ) an d bod y ground .

TRANSMISSIO N SUB-HARNES SCONNECTOR (14P )

TRANSMISSIO NSUB-HARNESSCONNECTOR (10P )

5. I f th e resistanc e i s withi n th e standard , connec t th e

No . 1 termina l o f th e lock-u p contro l solenoi d valv e

connecto r t o th e batter y positiv e terminal . A clickin g

soun d shoul d b e heard . Connec t th e No . 2 termina l t o

th e batter y positiv e terminal . A clickin g soun d shoul d

b e heard . Replac e th e lock-u p contro l solenoi d valv e

assembl y if n o clickin g soun d is heard .

I

f th e resistanc e i s OK , replac e th e transmissio n

sub-harness .

Replace th e lock-u p contro l solenoi d valv e

assembl y if th e resistanc e is ou t o f specification .

LOCK-UP CONTRO LSOLENOID VALV E ASSEMBL Y

3. I f th e resistanc e i s ou t o f specification , disconnec t

th e 2 P connecto r fro m th e lock-u p contro l solenoi d

valv e A/B .

4 . Measur e th e resistanc e betwee n th e No . 2 termina l

(solenoi d valv e A ) o f th e lock-u p contro l solenoi d

connecto r an d bod y ground , an d betwee n th e No . 1

termina l (solenoi d valv e B ) an d bod y ground .

STANDARD : 1 2 - 2 5 W

ProCarManuals.com

Page 312 of 1771

Lock-up Contro l Solenoi d Valve A/B

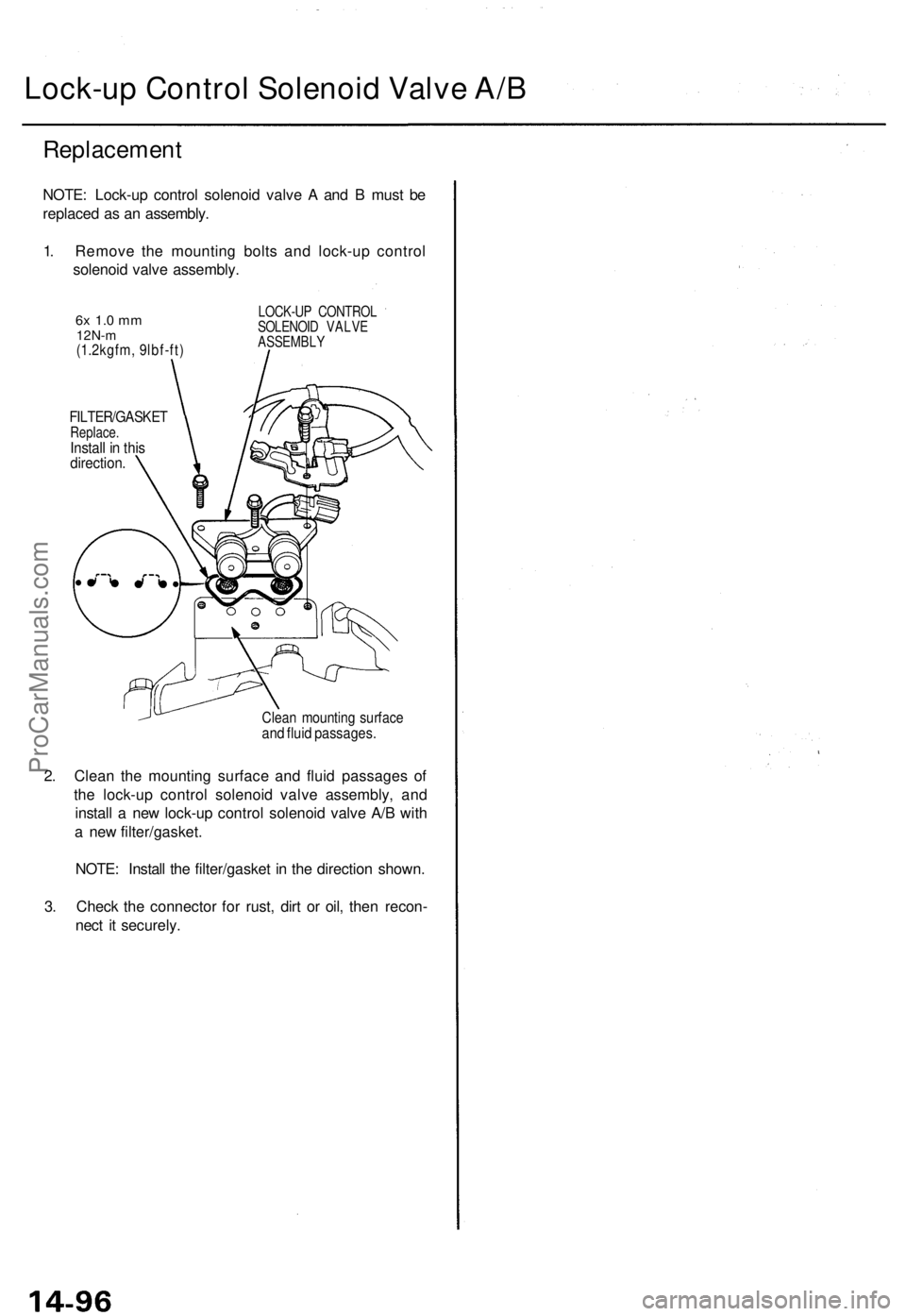

Replacemen t

NOTE: Lock-u p contro l solenoi d valv e A an d B mus t b e

replace d a s a n assembly .

1 . Remov e th e mountin g bolt s an d lock-u p contro l

solenoi d valv e assembly .

2 . Clea n th e mountin g surfac e an d flui d passage s o f

th e lock-u p contro l solenoi d valv e assembly , an d

instal l a ne w lock-u p contro l solenoi d valv e A/ B wit h

a ne w filter/gasket .

NOTE : Instal l th e filter/gaske t i n th e directio n shown .

3 . Chec k th e connecto r fo r rust , dir t o r oil , the n recon -

nec t i t securely .

Clean mountin g surfac eand flui d passages .

FILTER/GASKE TReplace.Install i n thi sdirection .

6x 1. 0 m m12N- m(1.2kgfm , 9lbf-ft )

LOCK-U P CONTRO L

SOLENOI D VALV E

ASSEMBL Y

ProCarManuals.com

Page 313 of 1771

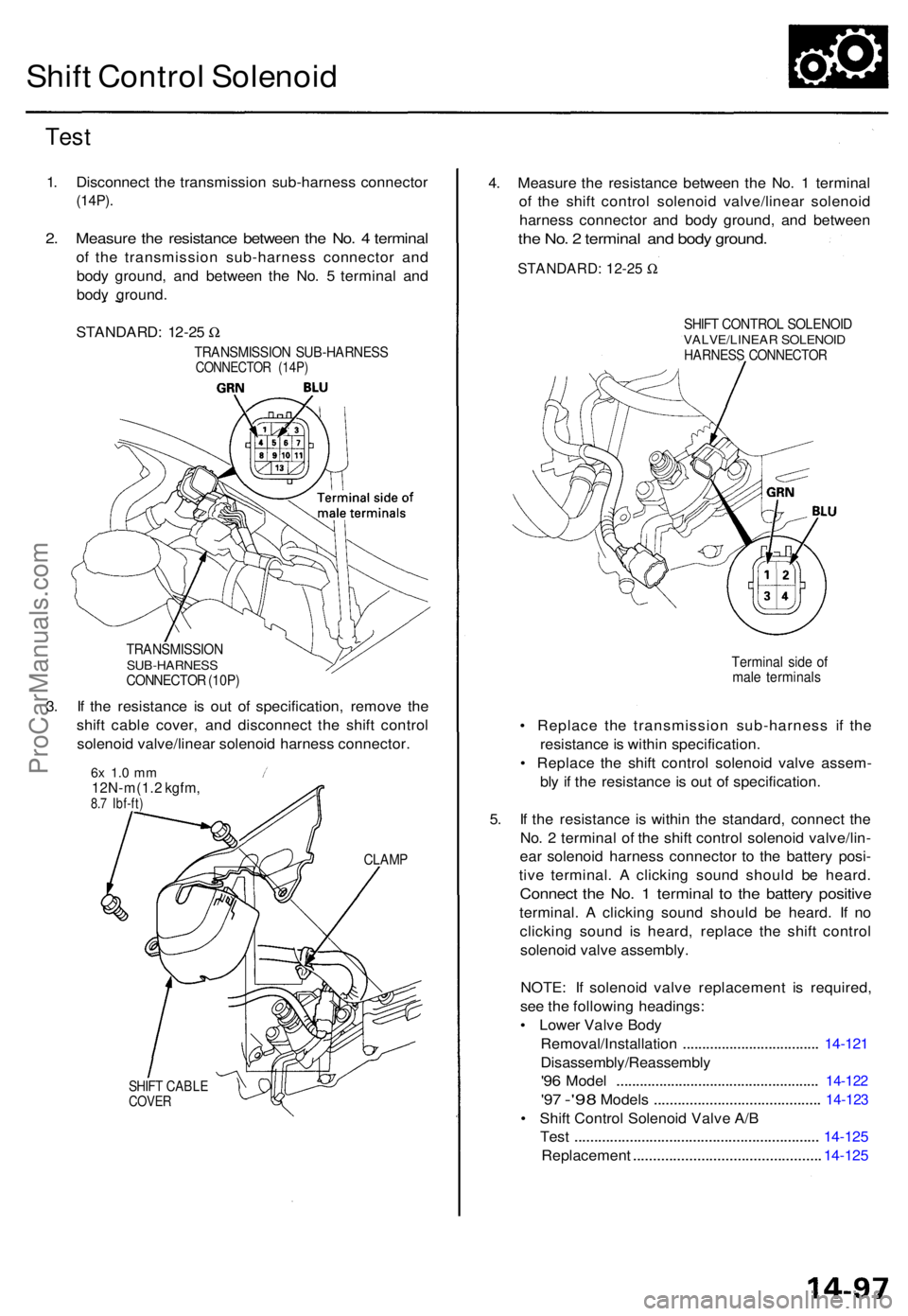

Shift Contro l Solenoi d

Test

1. Disconnec t th e transmissio n sub-harnes s connecto r

(14P).

2. Measur e th e resistanc e betwee n th e No . 4 termina l

of th e transmissio n sub-harnes s connecto r an d

bod y ground , an d betwee n th e No . 5 termina l an d

bod y ground .

TRANSMISSIO NSUB-HARNESSCONNECTOR (10P )

3. I f th e resistanc e i s ou t o f specification , remov e th e

shif t cabl e cover , an d disconnec t th e shif t contro l

solenoi d valve/linea r solenoi d harnes s connector .

6x 1. 0 m m12N-m(1. 2 kgfm ,8.7 Ibf-ft )

CLAM P

SHIFT CABL ECOVER

4. Measur e th e resistanc e betwee n th e No . 1 termina l

o f th e shif t contro l solenoi d valve/linea r solenoi d

harnes s connecto r an d bod y ground , an d betwee n

the No . 2 termina l an d bod y ground .

SHIFT CONTRO L SOLENOI DVALVE/LINEA R SOLENOI DHARNESS CONNECTO R

Terminal sid e o f

mal e terminal s

• Replac e th e transmissio n sub-harnes s i f th e

resistanc e is withi n specification .

• Replac e th e shif t contro l solenoi d valv e assem -

bl y i f th e resistanc e is ou t o f specification .

5 . I f th e resistanc e i s withi n th e standard , connec t th e

No . 2 termina l o f th e shif t contro l solenoi d valve/lin -

ea r solenoi d harnes s connecto r t o th e batter y posi -

tiv e terminal . A clickin g soun d shoul d b e heard .

Connec t th e No . 1 termina l t o th e batter y positiv e

terminal . A clickin g soun d shoul d b e heard . I f n o

clickin g soun d i s heard , replac e th e shif t contro l

solenoi d valv e assembly .

NOTE : I f solenoi d valv e replacemen t i s required ,

se e th e followin g headings :

• Lowe r Valv e Bod y

Removal/Installatio n

................................... 14-12 1

Disassembly/Reassembl y

'96 Mode l ................................................... . 14-12 2

'97 -'9 8 Model s ......................................... . 14-12 3

• Shif t Contro l Solenoi d Valv e A/ B

Tes t

............................................................. . 14-12 5

Replacemen t

.............................................. . 14-12 5

STANDARD

: 1 2-2 5 W

TRANSMISSIO N SUB-HARNES SCONNECTOR (14P )

STANDARD: 12-25 W

ProCarManuals.com

Page 314 of 1771

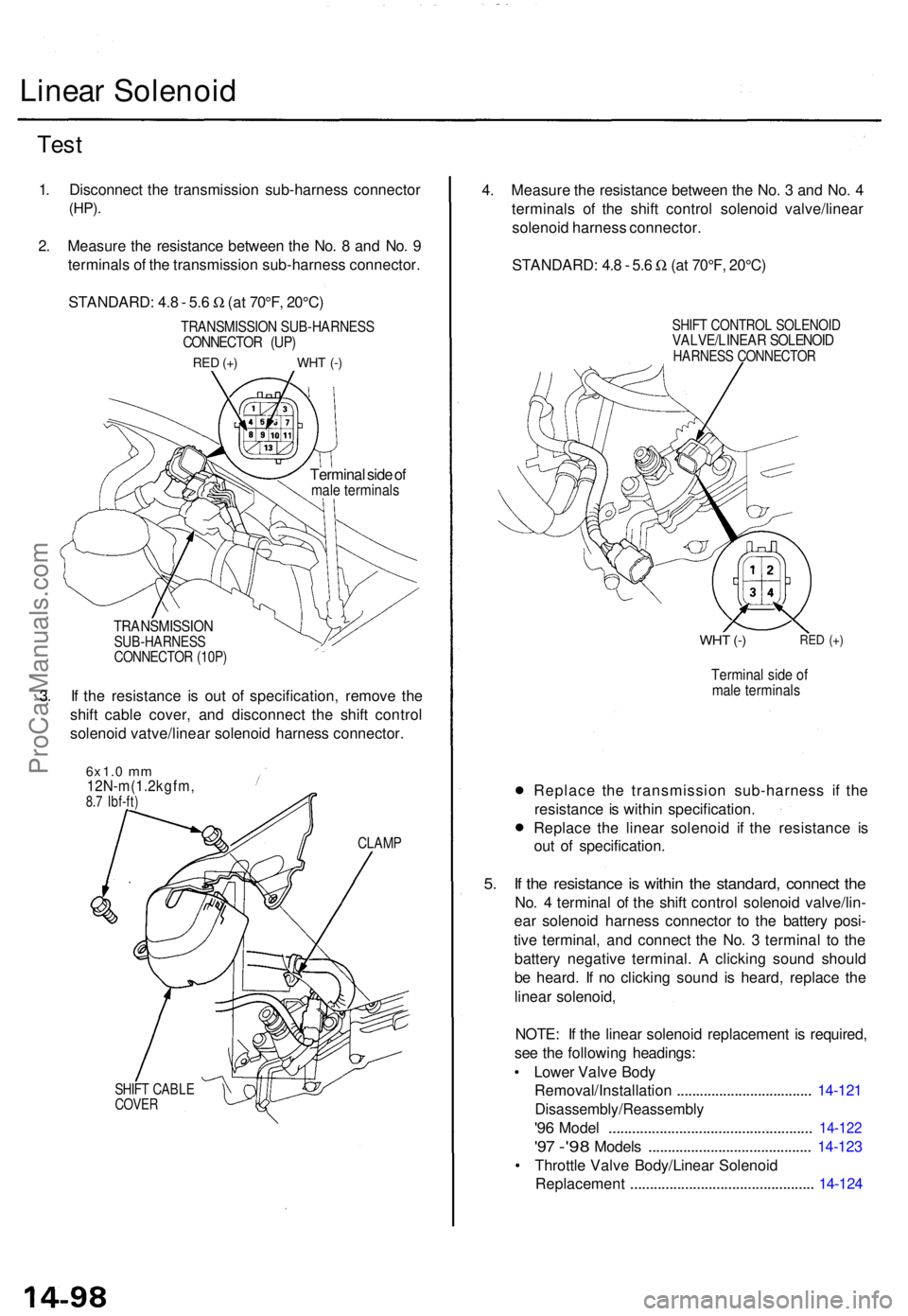

Linear Solenoi d

Test

1. Disconnec t th e transmissio n sub-harnes s connecto r

(HP).

2. Measur e th e resistanc e betwee n th e No . 8 an d No . 9

terminal s o f th e transmissio n sub-harnes s connector .

STANDARD : 4. 8 - 5. 6 W (a t 70°F , 20°C )

TRANSMISSIO N SUB-HARNES SCONNECTOR (UP )

RED (+ ) WH T (- )

Termina l sid e o fmal e terminal s

TRANSMISSIO NSUB-HARNESSCONNECTOR (10P )

3. I f th e resistanc e i s ou t o f specification , remov e th e

shif t cabl e cover , an d disconnec t th e shif t contro l

solenoi d vatve/linea r solenoi d harnes s connector .

6x1.0 mm12N-m(1.2kgfm ,8.7 Ibf-ft )

CLAM P

SHIFT CABL ECOVER

4. Measur e th e resistanc e betwee n th e No . 3 an d No . 4

terminal s o f th e shif t contro l solenoi d valve/linea r

solenoi d harnes s connector .

STANDARD : 4. 8 - 5. 6 W (a t 70°F , 20°C )

SHIFT CONTRO L SOLENOI DVALVE/LINEA R SOLENOI DHARNESS CONNECTO R

WHT (- )RE D (+ )

Termina l sid e o fmal e terminal s

• Replac

e th e transmissio n sub-harnes s i f th e

resistanc e is withi n specification .

• Replac

e th e linea r solenoi d i f th e resistanc e i s

ou t o f specification .

5. I f th e resistanc e is withi n th e standard , connec t th e

No . 4 termina l o f th e shif t contro l solenoi d valve/lin -

ea r solenoi d harnes s connecto r t o th e batter y posi -

tiv e terminal , an d connec t th e No . 3 termina l t o th e

batter y negativ e terminal . A clickin g soun d shoul d

b e heard . I f n o clickin g soun d i s heard , replac e th e

linea r solenoid ,

NOTE : I f th e linea r solenoi d replacemen t i s required ,

se e th e followin g headings :

• Lowe r Valv e Bod y

Removal/Installatio n

................................... 14-12 1

Disassembly/Reassembl y

'96 Mode l ................................................... . 14-12 2

'97 -'9 8 Model s ......................................... . 14-12 3

• Throttl e Valv e Body/Linea r Solenoi d

Replacemen t

.............................................. . 14-12 4

ProCarManuals.com

Page 315 of 1771

Mainshaft/Countershaft Spee d Sensor s

Replacemen t

Make sur e lifts , jack s an d safet y stand s ar e

place d properly , an d hois t bracket s ar e attache d t o th e

correc t positio n o n th e engin e (se e sectio n 1 ).

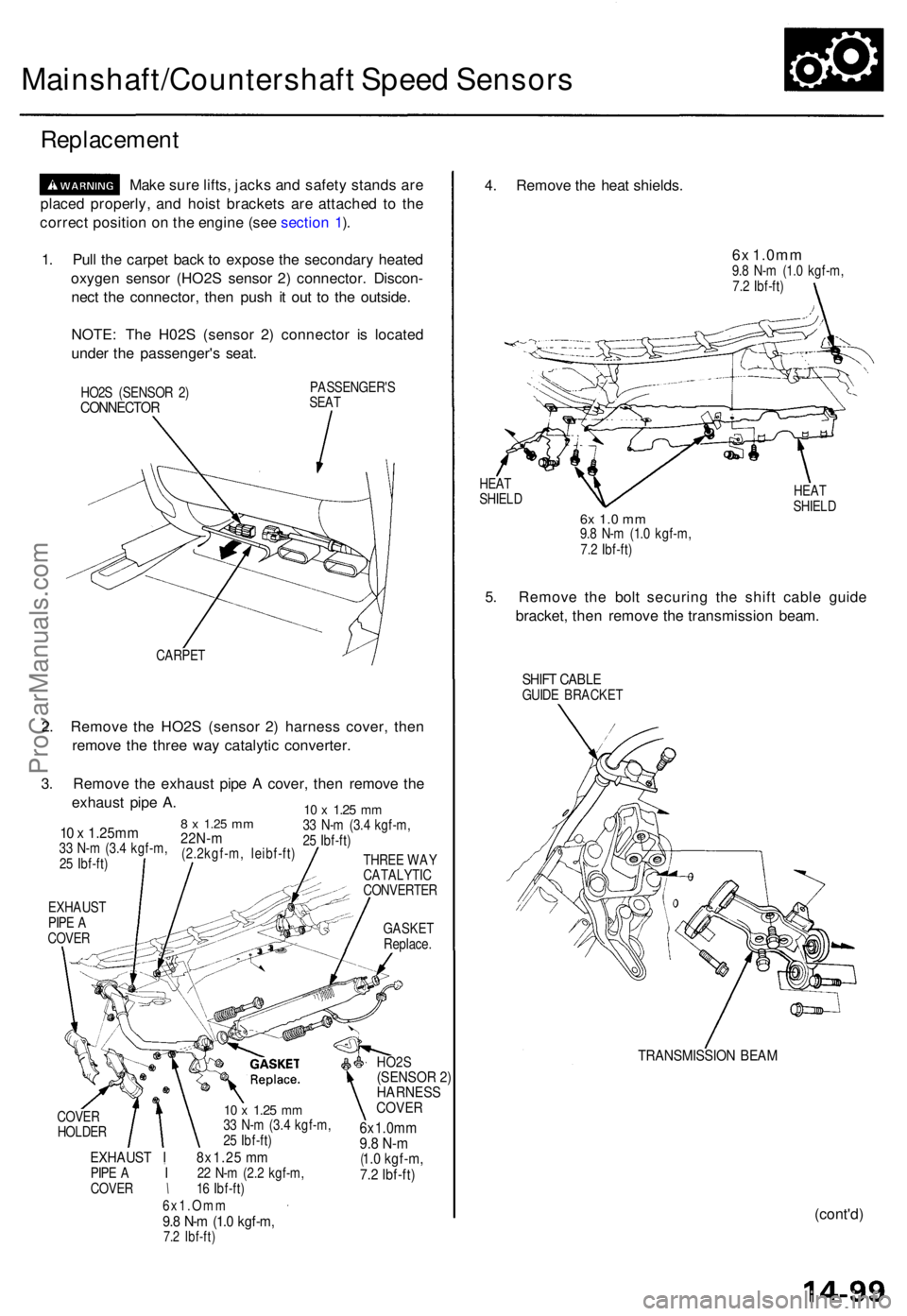

1 . Pul l th e carpe t bac k t o expos e th e secondar y heate d

oxyge n senso r (HO2 S senso r 2 ) connector . Discon -

nec t th e connector , the n pus h i t ou t t o th e outside .

NOTE : Th e H02 S (senso r 2 ) connecto r i s locate d

unde r th e passenger' s seat .

HO2S (SENSO R 2 )CONNECTO R

PASSENGER' S

SEA T

CARPE T

2. Remov e th e HO2 S (senso r 2 ) harnes s cover , the n

remov e th e thre e wa y catalyti c converter .

3 . Remov e th e exhaus t pip e A cover , the n remov e th e

exhaus t pip e A .

8 x 1.2 5 mm22N- m(2.2kgf-m , leibf-ft )

10 x 1.25m m33 N- m (3. 4 kgf-m ,

2 5 Ibf-ft )

10 x 1.2 5 mm33 N- m (3. 4 kgf-m ,

2 5 Ibf-ft )

THRE E WA Y

CATALYTI C

CONVERTE R

EXHAUS T

PIP E A

COVE R GASKE

T

Replace .

COVE R

HOLDE R

10 x 1.2 5 mm33 N- m (3. 4 kgf-m ,

2 5 Ibf-ft )

EXHAUS T I 8x1.2 5 m mPIP E A I 22 N- m (2. 2 kgf-m ,

COVE R \ 16 Ibf-ft )

6x1.Om m

9.8 N- m (1. 0 kgf-m ,7.2 Ibf-ft )

HO2S(SENSOR 2)

HARNESS

COVER

6 x 1. 0 m m9.8 N-m(1.0 kgf-m,

7.2 Ibf-ft)

4 . Remov e th e hea t shields .

6x 1.0m m9.8 N- m (1. 0 kgf-m ,

7. 2 Ibf-ft )

HEA T

SHIEL D HEA

T

SHIEL D

6x 1. 0 m m9.8 N- m (1. 0 kgf-m ,

7. 2 Ibf-ft )

5. Remov e th e bol t securin g th e shif t cabl e guid e

bracket , the n remov e th e transmissio n beam .

SHIFT CABL EGUIDE BRACKE T

TRANSMISSIO N BEA M

(cont'd )

ProCarManuals.com

Page 316 of 1771

Mainshaft/Countershaft Speed Sensors

Replacement (cont'd)

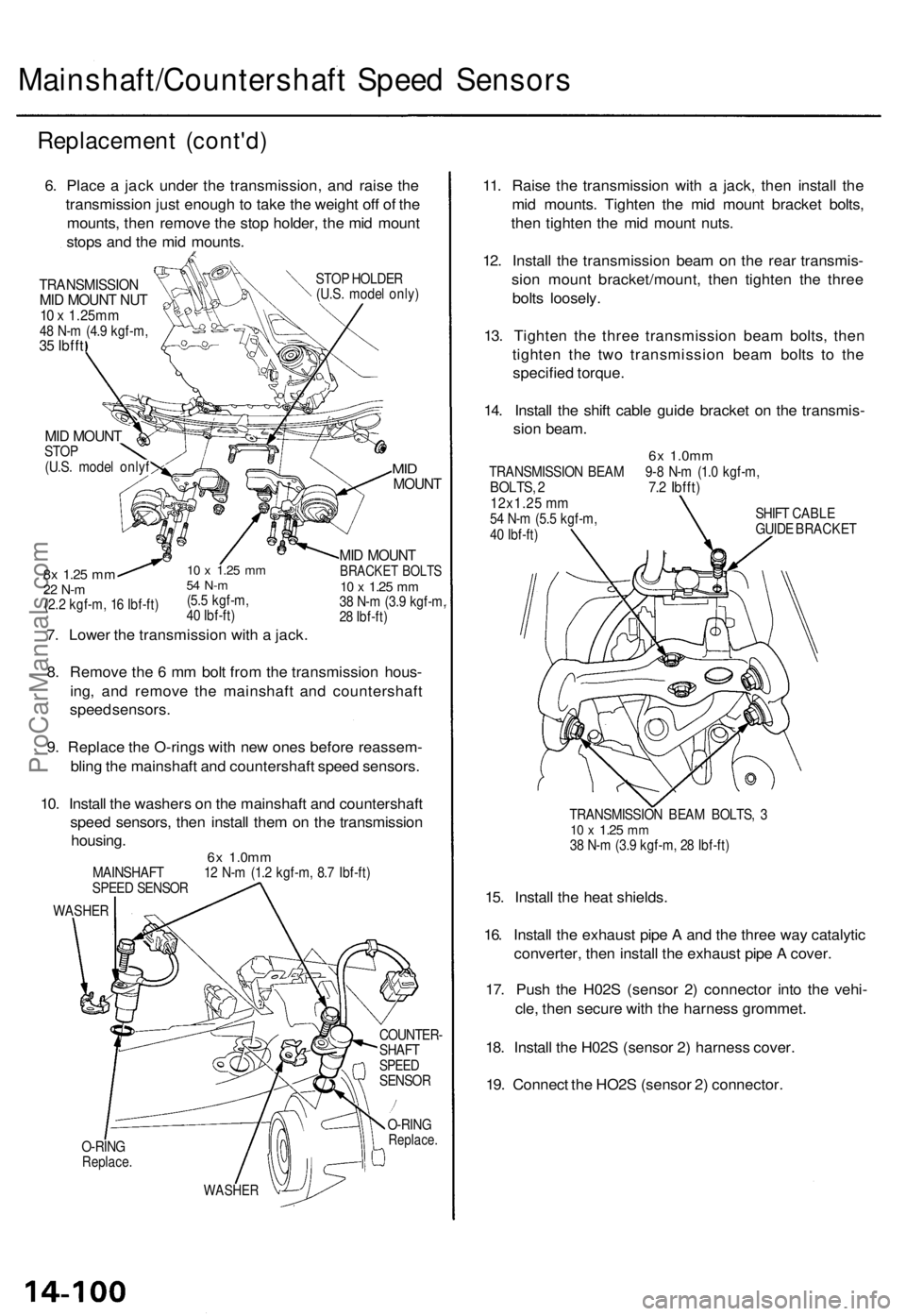

6. Place a jack under the transmission, and raise the

transmission just enough to take the weight off of the

mounts, then remove the stop holder, the mid mount

stops and the mid mounts.

TRANSMISSION

MID MOUNT NUT

10 x 1.25mm

48 N-m (4.9 kgf-m,

35 Ibfft

STOP HOLDER

(U.S. model only)

MID MOUNT

STOP

(U.S. model onlyf

10 x

1.25

mm

54 N-m

(5.5 kgf-m,

40 Ibf-ft)

7. Lower the transmission with a jack.

8x

1.25

mm

22 N-m

(2.2 kgf-m, 16 Ibf-ft)

MID

MOUNT

MID MOUNT

BRACKET BOLTS

10 x

1.25

mm

38 N-m (3.9 kgf-m,

28 Ibf-ft)

8. Remove the 6 mm bolt from the transmission hous-

ing, and remove the mainshaft and countershaft

speed sensors.

9. Replace the O-rings with new ones before reassem-

bling the mainshaft and countershaft speed sensors.

10. Install the washers on the mainshaft and countershaft

speed sensors, then install them on the transmission

housing.

6x

1.0mm

MAINSHAFT 12 N-m (1.2 kgf-m, 8.7 Ibf-ft)

SPEED SENSOR

WASHER

O-RING

Replace.

COUNTER-

SHAFT

SPEED

SENSOR

O-RING

Replace.

WASHER

11. Raise the transmission with a jack, then install the

mid mounts. Tighten the mid mount bracket bolts,

then tighten the mid mount nuts.

12. Install the transmission beam on the rear transmis-

sion mount bracket/mount, then tighten the three

bolts loosely.

13. Tighten the three transmission beam bolts, then

tighten the two transmission beam bolts to the

specified torque.

14. Install the shift cable guide bracket on the transmis-

sion beam.

6x

1.0mm

TRANSMISSION BEAM 9-8 N-m (1.0 kgf-m,

BOLTS, 2 7.2 Ibfft)

12x1.25 mm

54 N-m (5.5 kgf-m,

40 Ibf-ft)

SHIFT CABLE

GUIDE BRACKET

TRANSMISSION BEAM BOLTS, 3

10 x

1.25

mm

38 N-m (3.9 kgf-m, 28 Ibf-ft)

15. Install the heat shields.

16. Install the exhaust pipe A and the three way catalytic

converter, then install the exhaust pipe A cover.

17. Push the H02S (sensor 2) connector into the vehi-

cle, then secure with the harness grommet.

18. Install the H02S (sensor 2) harness cover.

19. Connect the HO2S (sensor 2) connector.ProCarManuals.com

Page 317 of 1771

A/T Gea r Positio n Switc h

Replacemen t

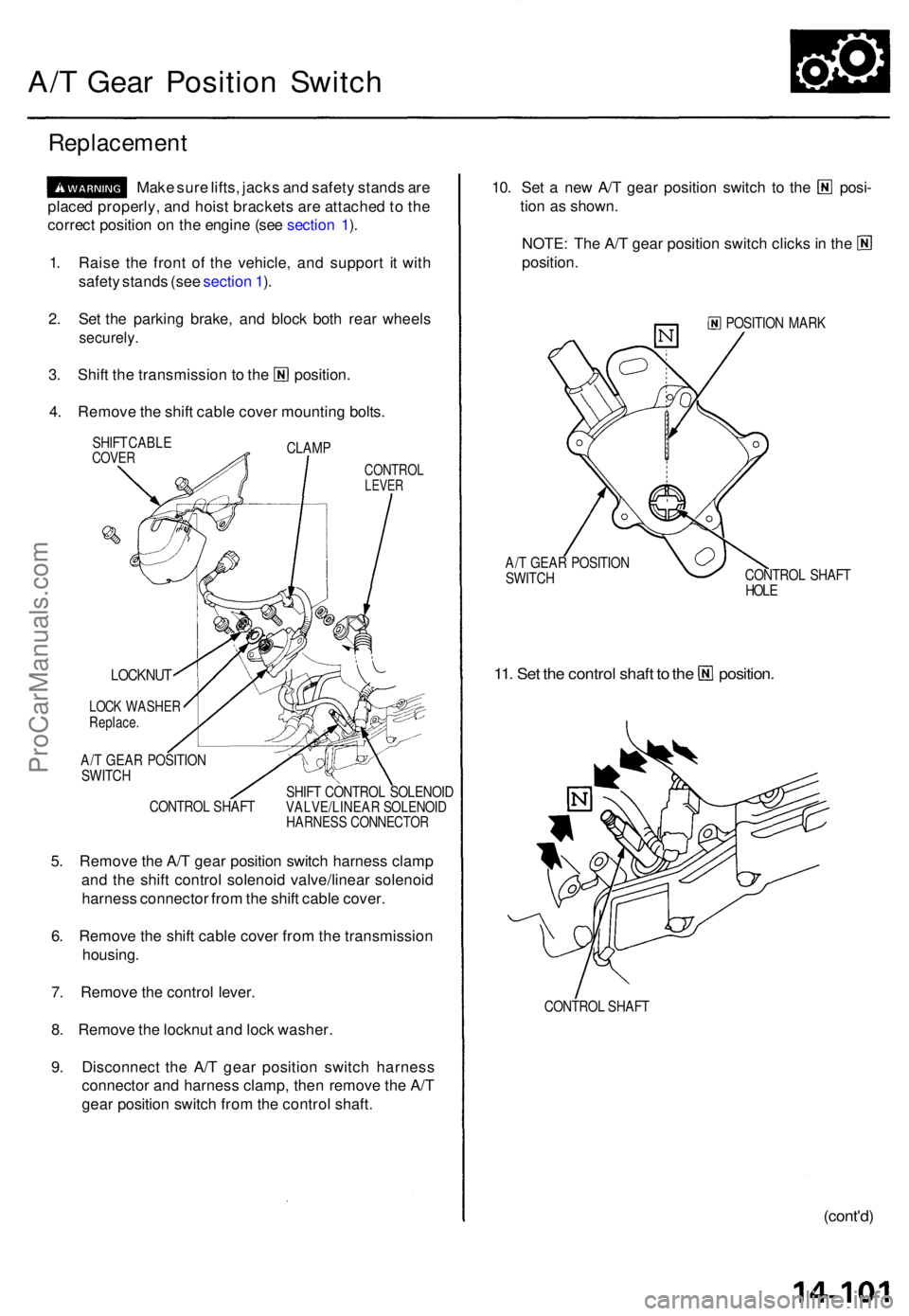

Make sur e lifts , jack s an d safet y stand s ar e

place d properly , an d hois t bracket s ar e attache d to th e

correc t positio n o n th e engin e (se e sectio n 1 ).

1 . Rais e th e fron t o f th e vehicle , an d suppor t i t wit h

safet y stand s (se e sectio n 1 ).

2 . Se t th e parkin g brake , an d bloc k bot h rea r wheel s

securely .

3. Shif t th e transmissio n t o th e position .

4 . Remov e th e shif t cabl e cove r mountin g bolts .

CLAM P

SHIF

T CABL ECOVERCONTRO LLEVER

CONTRO L SHAF T SHIF

T CONTRO L SOLENOI DVALVE/LINEA R SOLENOI DHARNESS CONNECTO R

5. Remov e th e A/ T gea r positio n switc h harnes s clam p

an d th e shif t contro l solenoi d valve/linea r solenoi d

harnes s connecto r fro m th e shif t cabl e cover .

6 . Remov e th e shif t cabl e cove r fro m th e transmissio n

housing .

7 . Remov e th e contro l lever .

8 . Remov e th e locknu t an d loc k washer .

9 . Disconnec t th e A/ T gea r positio n switc h harnes s

connecto r an d harnes s clamp , the n remov e th e A/ T

gea r positio n switc h fro m th e contro l shaft .

10. Se t a ne w A/ T gea r positio n switc h t o th e posi -

tio n a s shown .

NOTE: Th e A/ T gea r positio n switc h click s in th e

position .

POSITIO N MAR K

A/ T GEA R POSITIO N

SWITC H CONTRO

L SHAF T

HOL E

11. Se t th e contro l shaf t t o th e position .

CONTROL SHAF T

(cont'd )

LOCKNU T

LOCK WASHE RReplace.

A/T GEA R POSITIO N

SWITC H

ProCarManuals.com

Page 318 of 1771

A/T Gea r Positio n Switc h

Replacemen t (cont'd )

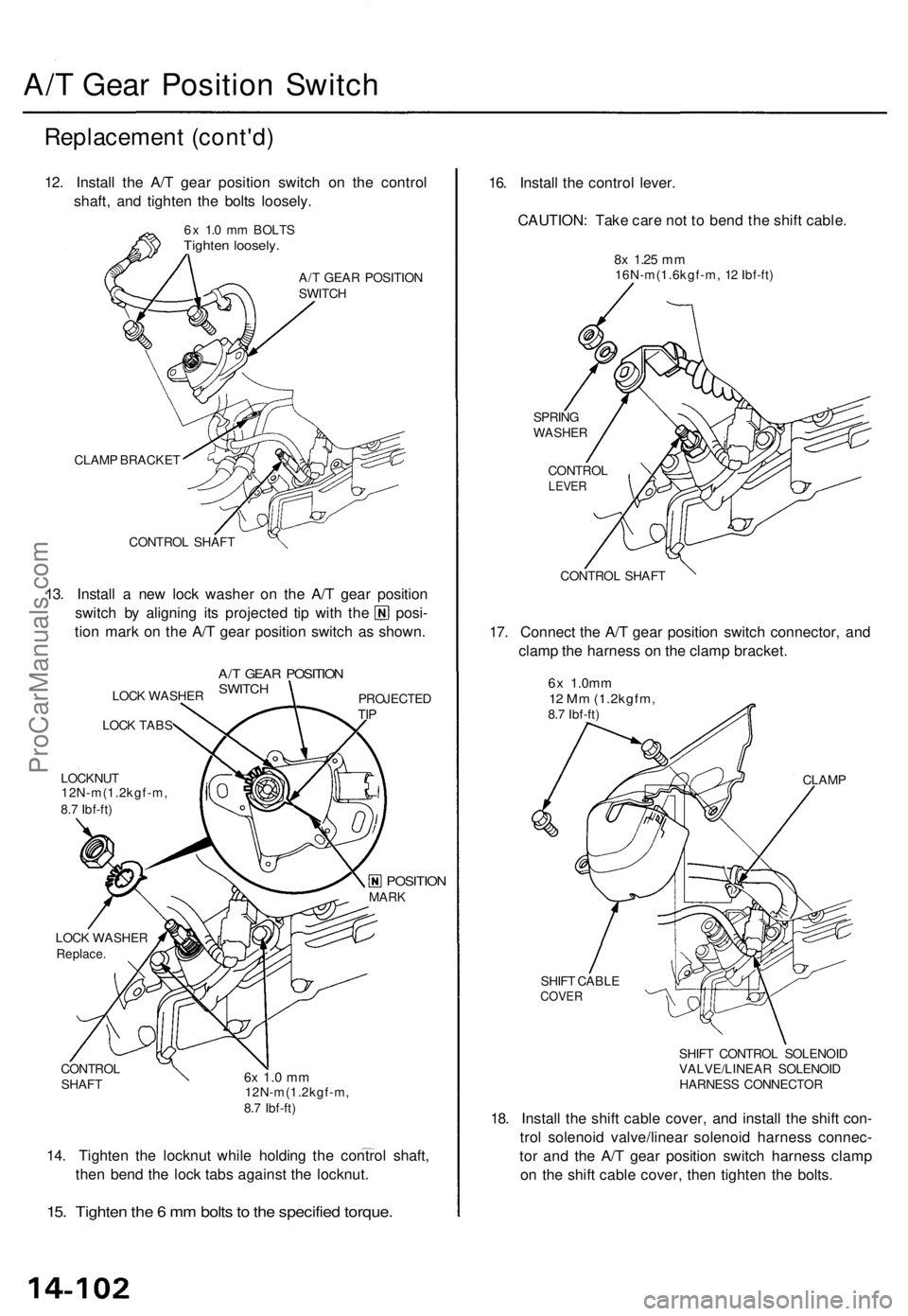

12. Instal l th e A/ T gea r positio n switc h o n th e contro l

shaft , an d tighte n th e bolt s loosely .

6x 1. 0 m m BOLT STighten loosely .

A/T GEA R POSITIO N

SWITC H

CLAM P BRACKE T

CONTRO L SHAF T

13. Instal l a ne w loc k washe r o n th e A/ T gea r positio n

switch b y alignin g it s projecte d ti p wit h th e posi -

tio n mar k o n th e A/ T gea r positio n switc h a s shown .

LOCK WASHE R

LOC K TAB S

LOCKNU T

12N-m(1.2kgf-m ,

8. 7 Ibf-ft )

A/T GEA R POSITIO NSWITCHPROJECTE DTIP

LOC K WASHE RReplace.

CONTRO L

SHAF T6x 1. 0 m m12N-m(1.2kgf-m ,

8. 7 Ibf-ft )

14. Tighte n th e locknu t whil e holdin g th e contro l shaft ,

the n ben d th e loc k tab s agains t th e locknut .

15. Tighte n th e 6 m m bolt s to th e specifie d torque .

16. Instal l th e contro l lever .

CAUTION : Tak e car e no t t o ben d th e shif t cable .

8x 1.2 5 mm16N-m(1.6kgf-m , 1 2 Ibf-ft )

SPRIN G

WASHE R

CONTRO LLEVER

CONTRO L SHAF T

17. Connec t th e A/ T gea r positio n switc h connector , an d

clam p th e harnes s o n th e clam p bracket .

6x 1.0m m12 M m (1.2kgfm ,8.7 Ibf-ft )

CLAMP

SHIF T CABL E

COVER

SHIFT CONTRO L SOLENOI D

VALVE/LINEA R SOLENOI D

HARNES S CONNECTO R

18. Instal l th e shif t cabl e cover , an d instal l th e shif t con -

tro l solenoi d valve/linea r solenoi d harnes s connec -

to r an d th e A/ T gea r positio n switc h harnes s clam p

o n th e shif t cabl e cover , the n tighte n th e bolts .

MARKPOSITIO N

ProCarManuals.com

Page 319 of 1771

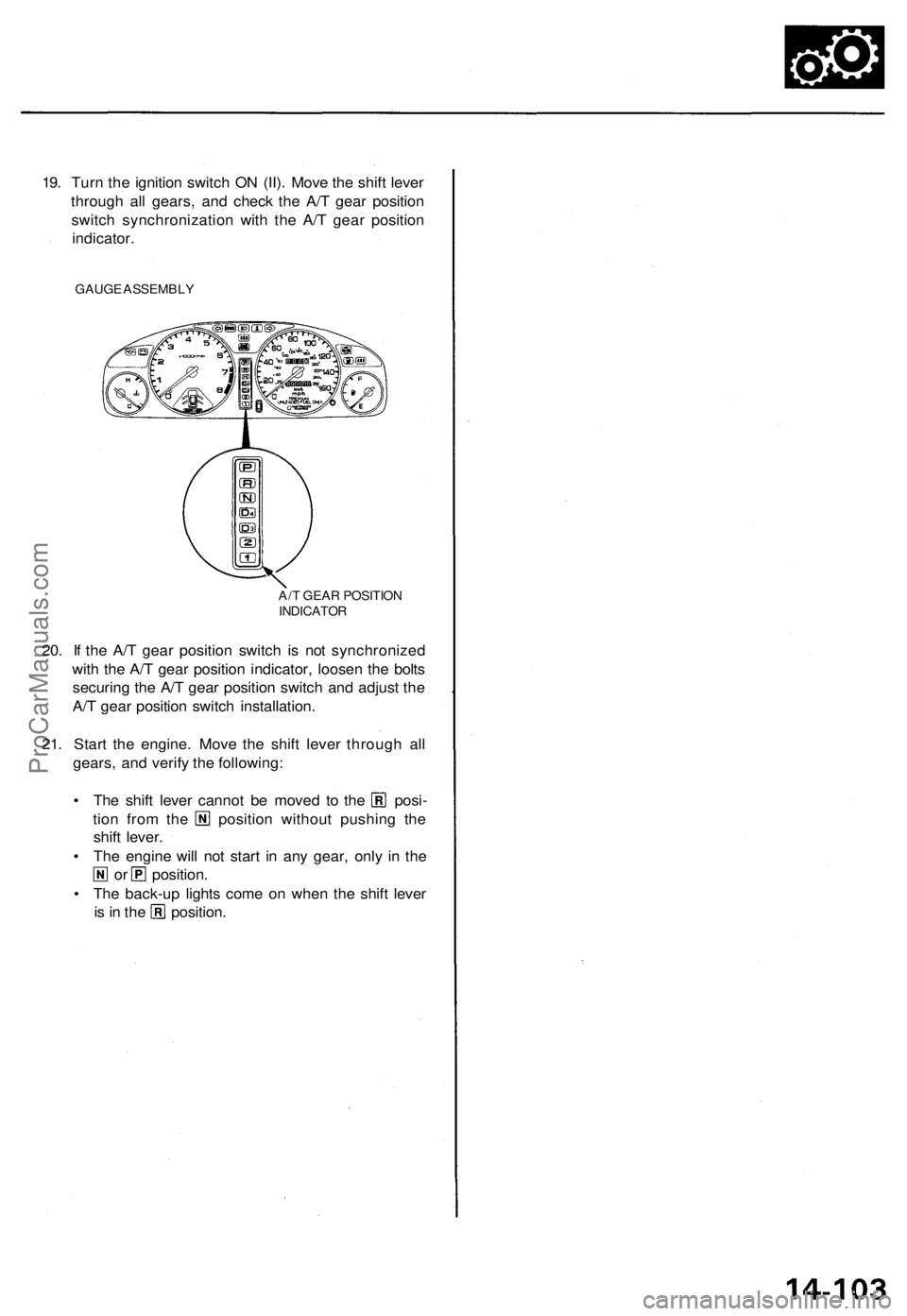

19. Turn the ignition switch ON (II). Move the shift lever

through all gears, and check the A/T gear position

switch synchronization with the A/T gear position

indicator.

GAUGE ASSEMBLY

20. If the A/T gear position switch is not synchronized

with the A/T gear position indicator, loosen the bolts

securing the A/T gear position switch and adjust the

A/T gear position switch installation.

21. Start the engine. Move the shift lever through all

gears, and verify the following:

• The shift lever cannot be moved to the posi-

tion from the position without pushing the

shift lever.

• The engine will not start in any gear, only in the

or position.

• The back-up lights come on when the shift lever

is in the position.

A/T GEAR POSITION

INDICATORProCarManuals.com

Page 320 of 1771

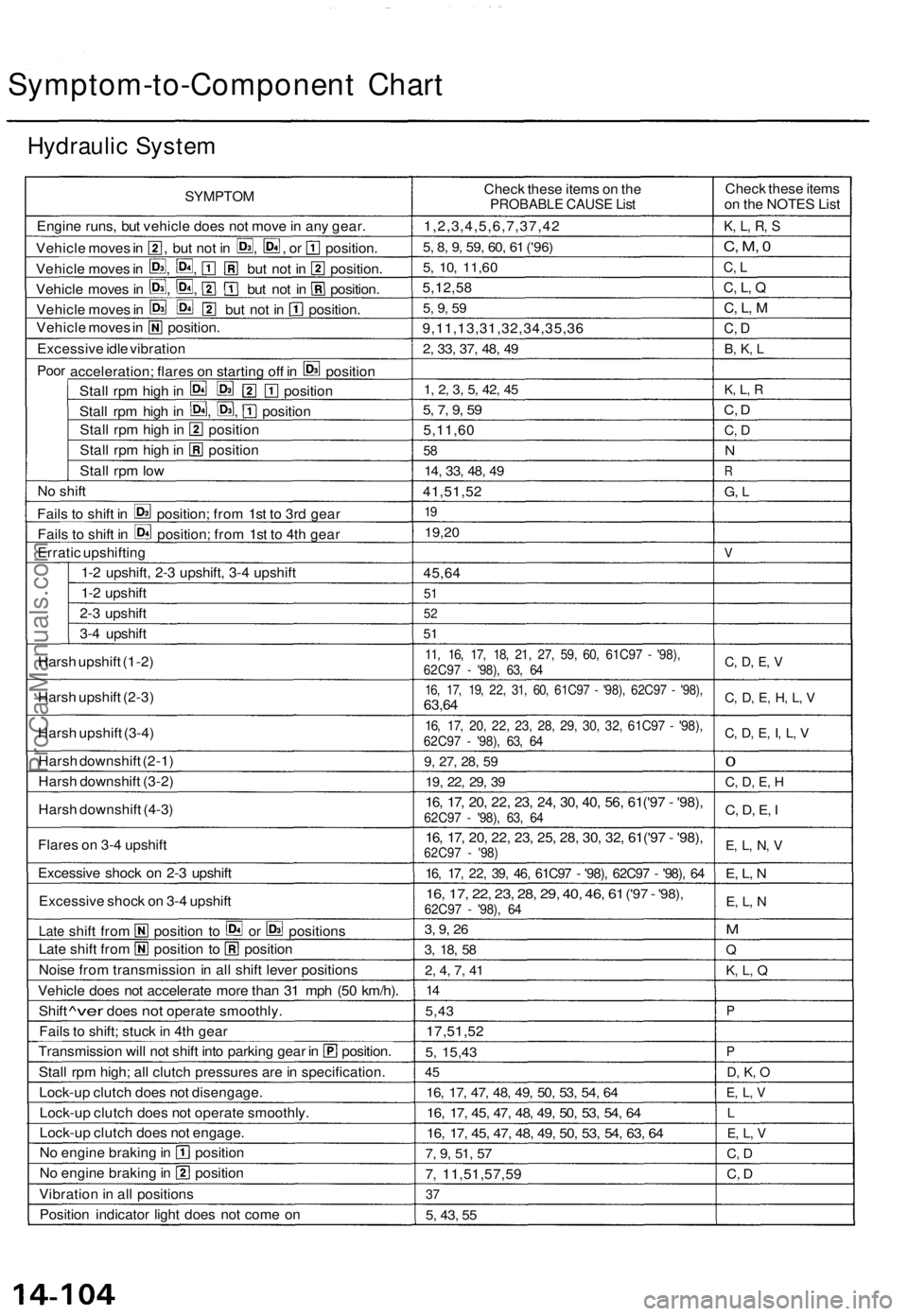

Symptom-to-Component Chart

Hydraulic System

SYMPTOM

Engine runs, but vehicle does not move in any gear.

Vehicle moves in , but not in , , or position.

Vehicle moves in , , but not in position.

Vehicle moves in , , but not in position.

Vehicle moves in but not in position.

Vehicle moves in position.

Excessive idle vibration

Poor

acceleration; flares on starting off in position

Stall rpm high in position

Stall rpm high in , , position

Stall rpm high in position

Stall rpm high in position

Stall rpm low

No shift

Fails to shift in position; from 1st to 3rd gear

Fails to shift in position; from 1st to 4th gear

Erratic upshifting

1-2 upshift, 2-3 upshift, 3-4 upshift

1-2 upshift

2-3 upshift

3-4 upshift

Harsh upshift (1-2)

Harsh upshift (2-3)

Harsh upshift (3-4)

Harsh downshift (2-1)

Harsh downshift (3-2)

Harsh downshift (4-3)

Flares on 3-4 upshift

Excessive shock on 2-3 upshift

Excessive shock on 3-4 upshift

Late

shift from position to or positions

Late shift from position to position

Noise from transmission in all shift lever positions

Vehicle does not accelerate more than 31 mph (50 km/h).

Shift

^ver

does

not

operate smoothly.

Fails to shift; stuck in 4th gear

Transmission will not shift into parking gear in position.

Stall

rpm high; all clutch pressures are in specification.

Lock-up clutch does not disengage.

Lock-up clutch does not operate smoothly.

Lock-up clutch does not engage.

No engine braking in position

No engine braking in position

Vibration in all positions

Position indicator light does not come on

Check these items on the

PROBABLE CAUSE List

1,2,3,4,5,6,7,37,42

5, 8, 9, 59, 60, 61

('96)

5, 10,

11,60

5,12,58

5, 9, 59

9,11,13,31,32,34,35,36

2, 33, 37, 48, 49

1, 2, 3, 5, 42, 45

5, 7, 9, 59

5,11,60

58

14, 33, 48, 49

41,51,52

19

19,20

45,64

51

52

51

11, 16, 17, 18, 21, 27, 59, 60, 61C97 - '98),

62C97 - '98), 63, 64

16, 17, 19, 22, 31, 60, 61C97 - '98), 62C97 - '98),

63,64

16, 17, 20, 22, 23, 28, 29, 30, 32, 61C97 - '98),

62C97 - '98), 63, 64

9, 27, 28, 59

19, 22, 29, 39

16, 17, 20, 22, 23, 24, 30, 40, 56, 61('97 - '98),

62C97 - '98), 63, 64

16, 17, 20, 22, 23, 25, 28, 30, 32, 61('97 - '98),

62C97 - '98)

16, 17, 22, 39, 46, 61C97 - '98), 62C97 - '98), 64

16, 17, 22, 23, 28, 29, 40, 46, 61

('97

-

'98),

62C97 - '98), 64

3, 9, 26

3, 18, 58

2, 4, 7, 41

14

5,43

17,51,52

5,

15,43

45

16, 17, 47, 48, 49, 50, 53, 54, 64

16, 17, 45, 47, 48, 49, 50, 53, 54, 64

16, 17, 45, 47, 48, 49, 50, 53, 54, 63, 64

7, 9, 51, 57

7, 11,51,57,59

37

5, 43, 55

Check these items

on the NOTES List

K, L, R, S

C, M, 0

C, L

C, L, Q

C, L, M

C, D

B, K, L

K, L, R

C, D

C, D

N

R

G, L

V

C, D, E, V

C, D, E, H, L, V

C, D, E, I, L, V

0

C, D, E, H

C, D, E, I

E, L, N, V

E, L, N

E, L, N

M

Q

K, L, Q

P

P

D, K, O

E, L, V

L

E, L, V

C, D

C, DProCarManuals.com