ACURA TL 1995 Service Repair Manual

Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 811 of 1771

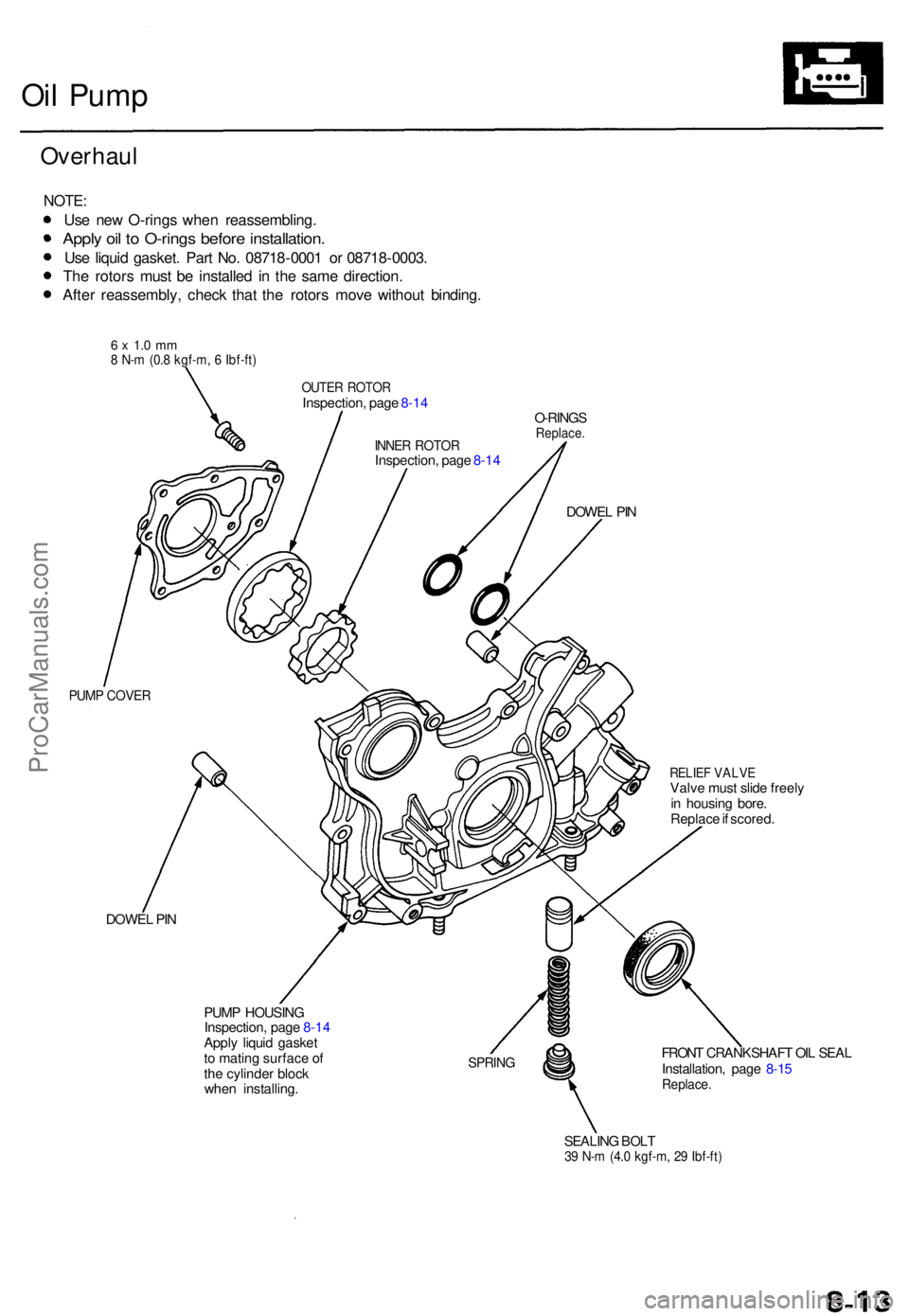

Oil Pum p

Overhau l

NOTE:

Use ne w O-ring s whe n reassembling .

Apply oi l t o O-ring s befor e installation .

Use liqui d gasket . Par t No . 0871 8-000 1 o r 0871 8-0003 .

Th e rotor s mus t b e installe d i n th e sam e direction .

Afte r reassembly , chec k tha t th e rotor s mov e withou t binding .

6 x 1. 0 m m8 N- m (0. 8 kgf-m , 6 Ibf-ft )

OUTE R ROTO RInspection , pag e 8-1 4

O-RINGS

Replace .

DOWEL PI N

PUM P COVE R

RELIEF VALV EValve mus t slid e freel y

i n housin g bore .

Replac e if scored .

DOWE L PI N

PUMP HOUSIN G

Inspection , pag e 8-1 4

Appl y liqui d gaske t

t o matin g surfac e o f

th e cylinde r bloc k

whe n installing .

SPRING FRON T CRANKSHAF T OI L SEA L

Installation , pag e 8-1 5

Replace .

SEALING BOL T39 N- m (4. 0 kgf-m , 2 9 Ibf-ft )

INNER ROTO RInspection , pag e 8-1 4

ProCarManuals.com

Page 812 of 1771

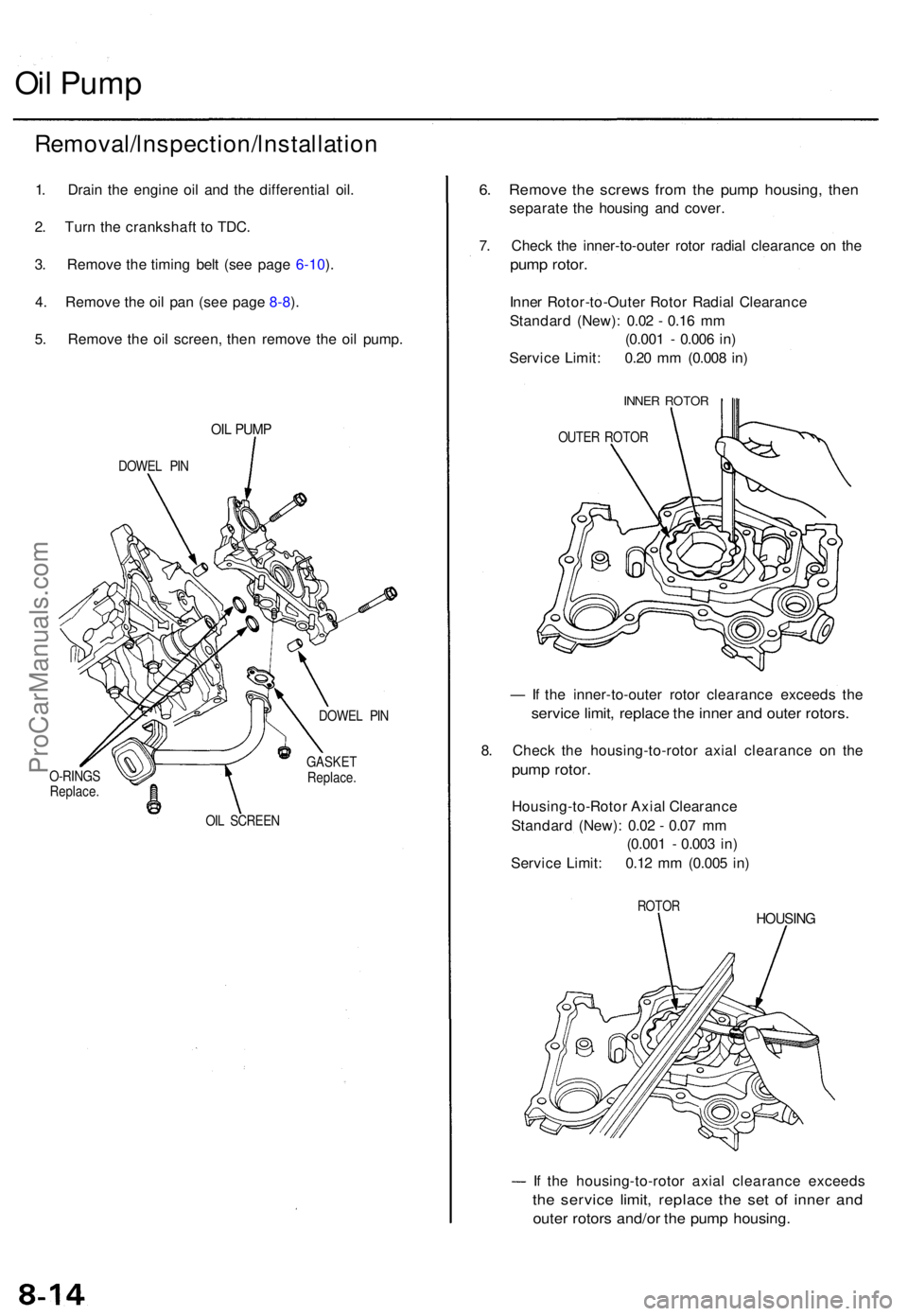

Oil Pum p

Removal/lnspection/lnstallatio n

1. Drai n th e engin e oi l an d th e differentia l oil .

2 . Tur n th e crankshaf t t o TDC .

3 . Remov e th e timin g bel t (se e pag e 6-10 ).

4 . Remov e th e oi l pa n (se e pag e 8-8 ).

5 . Remov e th e oi l screen , the n remov e th e oi l pump .

OIL PUM P

DOWE L PI N

O-RING S

Replace . DOWE

L PI N

GASKE T

Replace .

OI L SCREE N

6. Remov e th e screw s fro m th e pum p housing , the n

separat e th e housin g an d cover .

7 . Chec k th e inner-to-oute r roto r radia l clearanc e o n th e

pum p rotor .

Inner Rotor-to-Oute r Roto r Radia l Clearanc e

Standar d (New) : 0.0 2 - 0.1 6 m m

(0.00 1 - 0.00 6 in )

Servic e Limit : 0.2 0 m m (0.00 8 in )

INNE R ROTO R

OUTER ROTO R

— If th e inner-to-oute r roto r clearanc e exceed s th e

servic e limit , replac e th e inne r an d oute r rotors .

8. Chec k th e housing-to-roto r axia l clearanc e o n th e

pum p rotor .

Housing-to-Roto r Axia l Clearanc e

Standar d (New) : 0.0 2 - 0.0 7 m m

(0.00 1 - 0.00 3 in )

Servic e Limit : 0.1 2 m m (0.00 5 in )

ROTO RHOUSIN G

If th e housing-to-roto r axia l clearanc e exceed s

the servic e limit , replac e th e se t of inne r an d

oute r rotor s and/o r th e pum p housing .

ProCarManuals.com

Page 813 of 1771

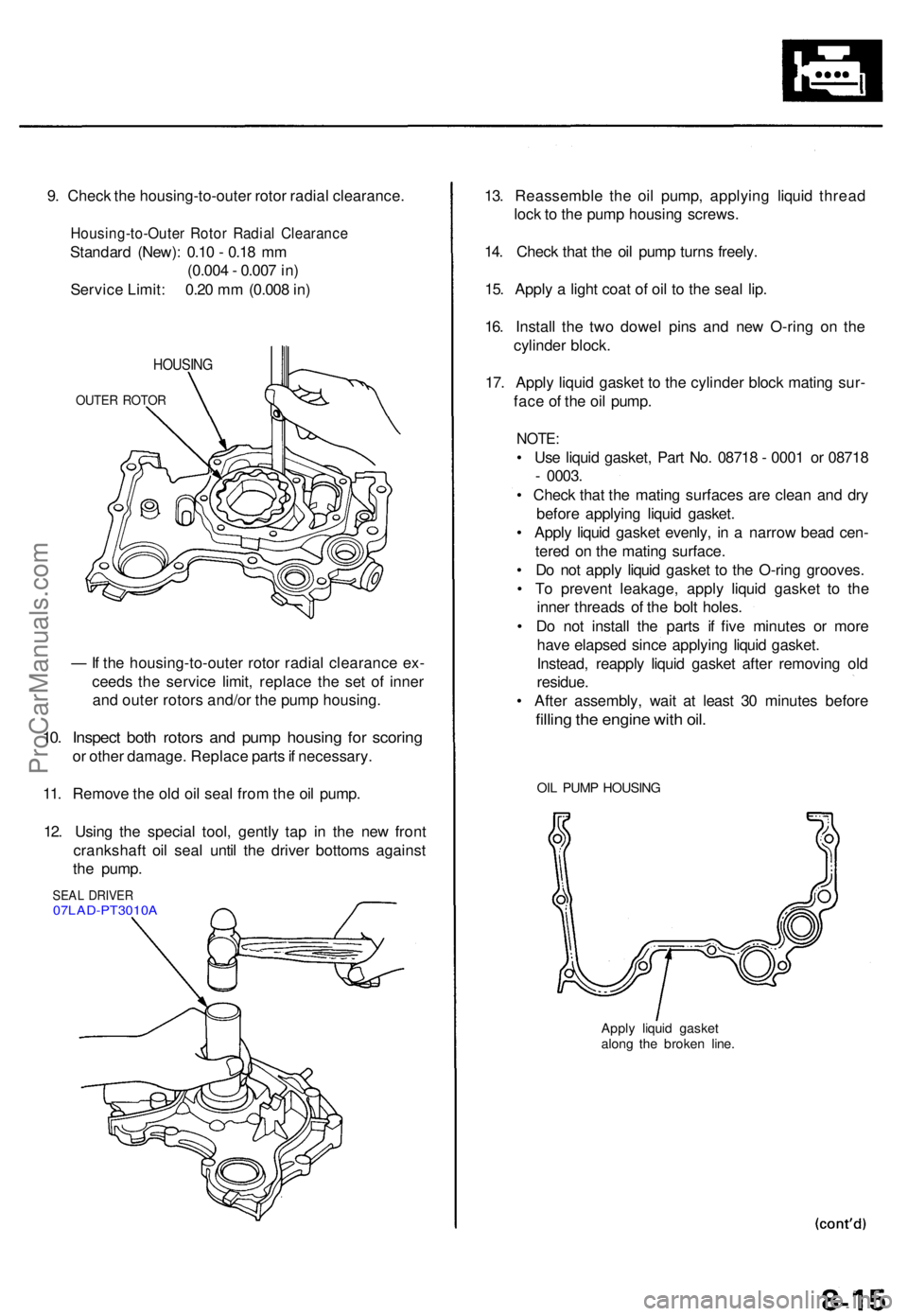

9. Chec k th e housing-to-oute r roto r radia l clearance .

Housing-to-Oute r Roto r Radia l Clearanc e

Standard (New) : 0.1 0 - 0.1 8 m m

(0.00 4 - 0.00 7 in )

Servic e Limit : 0.2 0 m m (0.00 8 in )

HOUSIN G

OUTER ROTO R

— If th e housing-to-oute r roto r radia l clearanc e ex -

ceed s th e servic e limit , replac e th e se t o f inne r

an d oute r rotor s and/o r th e pum p housing .

10. Inspec t bot h rotor s an d pum p housin g fo r scorin g

or othe r damage . Replac e part s if necessary .

11 . Remov e th e ol d oi l sea l fro m th e oi l pump .

12 . Usin g th e specia l tool , gentl y ta p i n th e ne w fron t

crankshaf t oi l sea l unti l th e drive r bottom s agains t

th e pump .

SEAL DRIVE R07LAD-PT3010 A

13. Reassembl e th e oi l pump , applyin g liqui d threa d

loc k t o th e pum p housin g screws .

14 . Chec k tha t th e oi l pum p turn s freely .

15 . Appl y a ligh t coa t o f oi l t o th e sea l lip .

16 . Instal l th e tw o dowe l pin s an d ne w O-rin g o n th e

cylinde r block .

17 . Appl y liqui d gaske t t o th e cylinde r bloc k matin g sur -

fac e o f th e oi l pump .

NOTE:

• Us e liqui d gasket , Par t No . 0871 8 - 000 1 o r 0871 8

- 0003 .

• Chec k tha t th e matin g surfaces are clea n an d dr y

befor e applyin g liqui d gasket .

• Appl y liqui d gaske t evenly , i n a narro w bea d cen -

tere d o n th e matin g surface .

• D o no t appl y liqui d gaske t t o th e O-rin g grooves .

• T o preven t leakage , appl y liqui d gaske t t o th e

inne r thread s o f th e bol t holes .

• D o no t instal l th e part s i f fiv e minute s o r mor e

hav e elapse d sinc e applyin g liqui d gasket .

Instead , reappl y liqui d gaske t afte r removin g ol d

residue .

• Afte r assembly , wai t a t leas t 3 0 minute s befor e

filling th e engin e wit h oil .

OIL PUM P HOUSIN G

Apply liqui d gaske t

alon g th e broke n line .

ProCarManuals.com

Page 814 of 1771

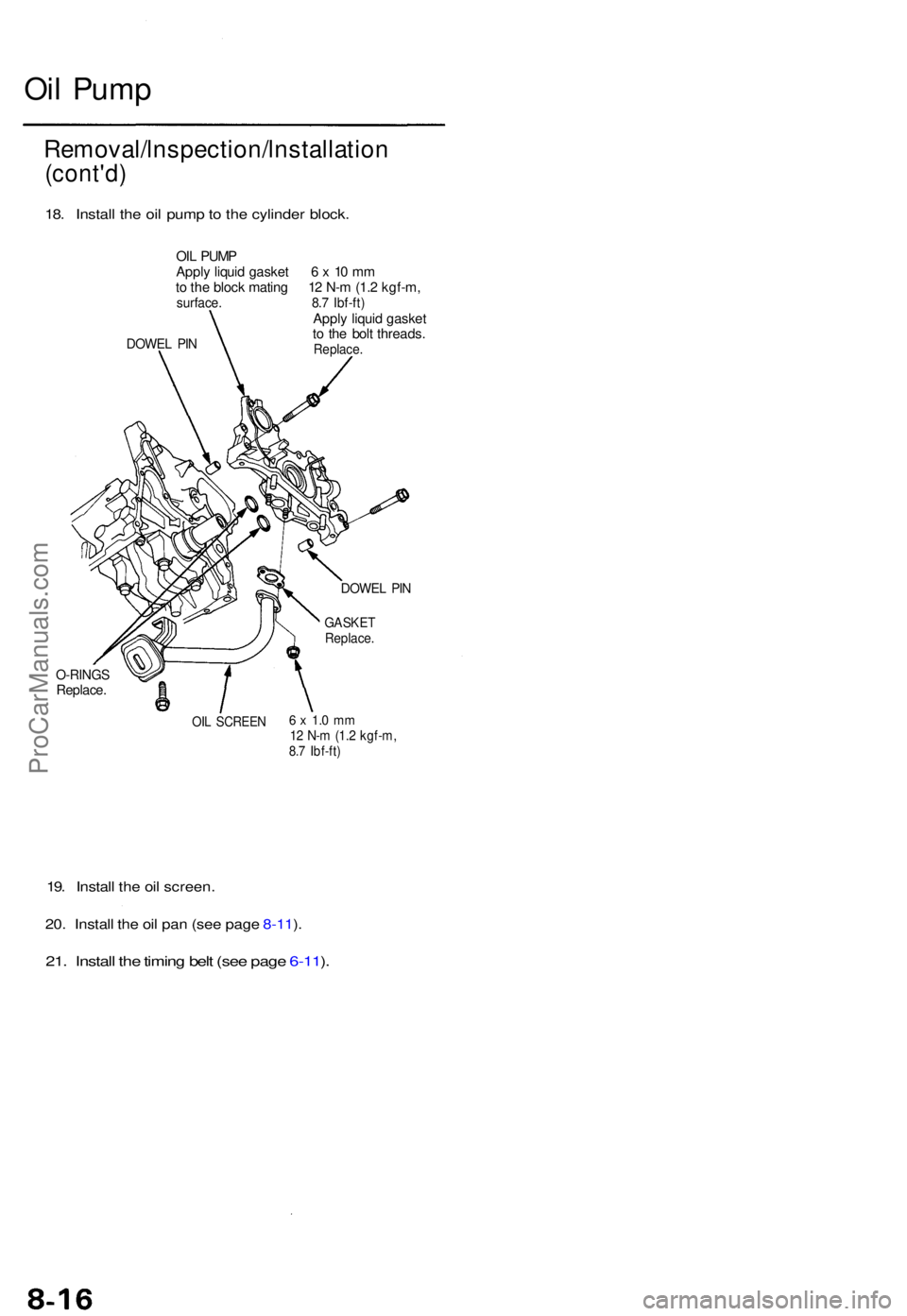

Removal/lnspection/lnstallation

(cont'd)

18. Instal l th e oi l pum p to th e cylinde r block .

OIL PUM P

Appl y liqui d gaske t 6 x 10 m m

t o th e bloc k matin g 1 2 N- m (1. 2 kgf-m ,

surface . 8. 7 Ibf-ft )Apply liqui d gaske t

t o th e bol t threads .

Replace .DOWEL PI N

O-RING SReplace .

OIL SCREE N6 x 1. 0 m m12 N- m (1. 2 kgf-m ,8.7 Ibf-ft )

19. Instal l th e oi l screen .

20 . Instal l th e oi l pa n (se e pag e 8-11 ).

21 . Instal l th e timin g bel t (se e pag e 6-11 ).

DOWE L PI N

GASKE TReplace .

Oil Pum p

ProCarManuals.com

Page 815 of 1771

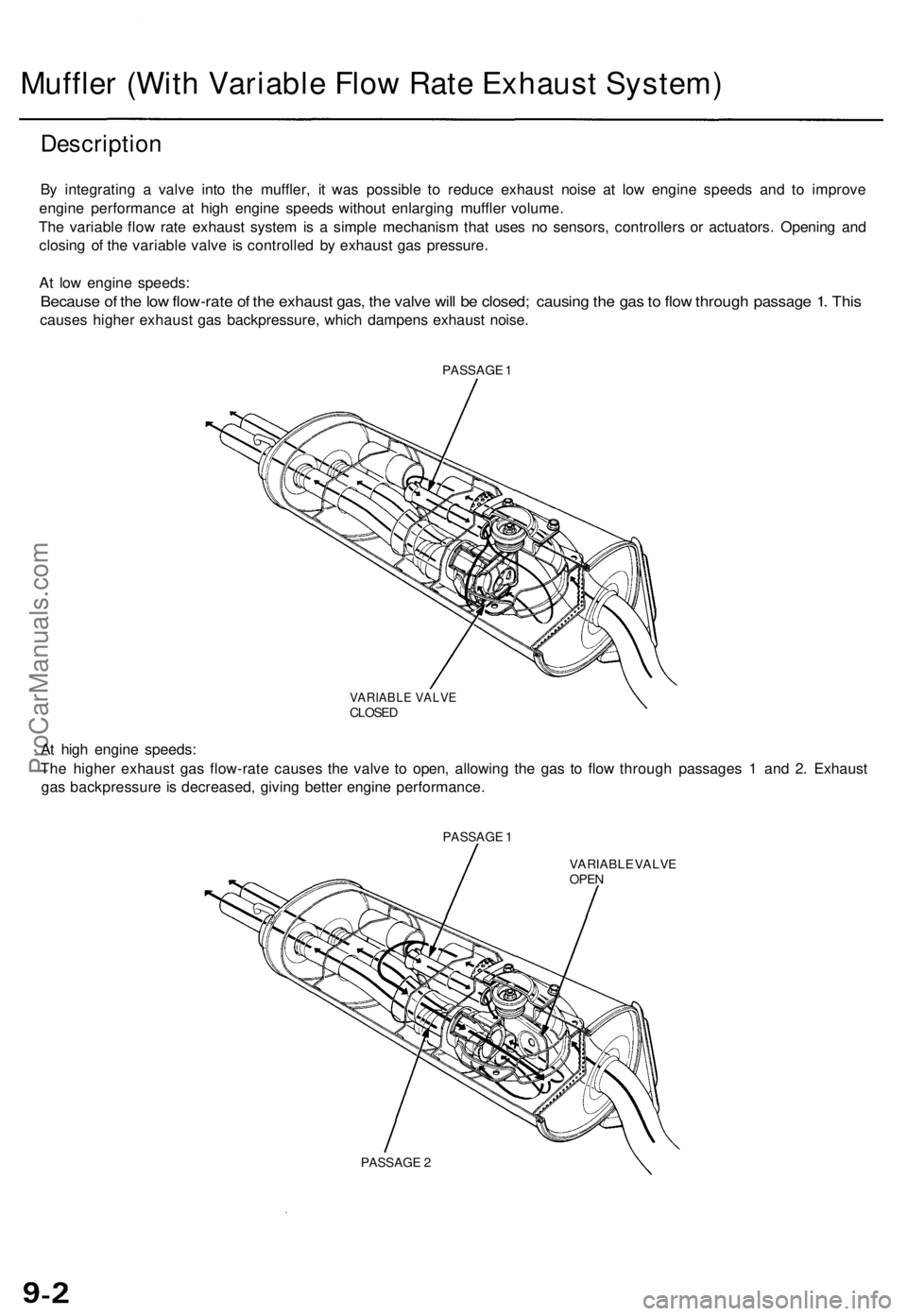

Description

By integratin g a valv e int o th e muffler , i t wa s possibl e t o reduc e exhaus t nois e a t lo w engin e speed s an d t o improv e

engin e performanc e a t hig h engine speeds withou t enlargin g muffle r volume .

Th e variabl e flo w rat e exhaus t syste m is a simpl e mechanis m tha t use s n o sensors , controller s o r actuators . Openin g an d

closin g o f th e variabl e valv e i s controlle d b y exhaus t ga s pressure .

A t lo w engin e speeds :

Because o f th e lo w flow-rat e o f th e exhaus t gas , th e valv e wil l b e closed ; causin g th e ga s to flo w throug h passag e 1 . Thi s

cause s highe r exhaus t ga s backpressure , whic h dampen s exhaus t noise .

PASSAG E 1

VARIABL E VALV ECLOSE D

At hig h engine speeds :

Th e highe r exhaus t ga s flow-rat e cause s th e valv e t o open , allowin g th e ga s t o flo w throug h passage s 1 an d 2 . Exhaust

ga s backpressur e is decreased , givin g bette r engin e performance .

PASSAGE 1

VARIABLE VALV E

OPE N

PASSAG E 2

Muffle r (Wit h Variabl e Flo w Rat e Exhaus t System )

ProCarManuals.com

Page 816 of 1771

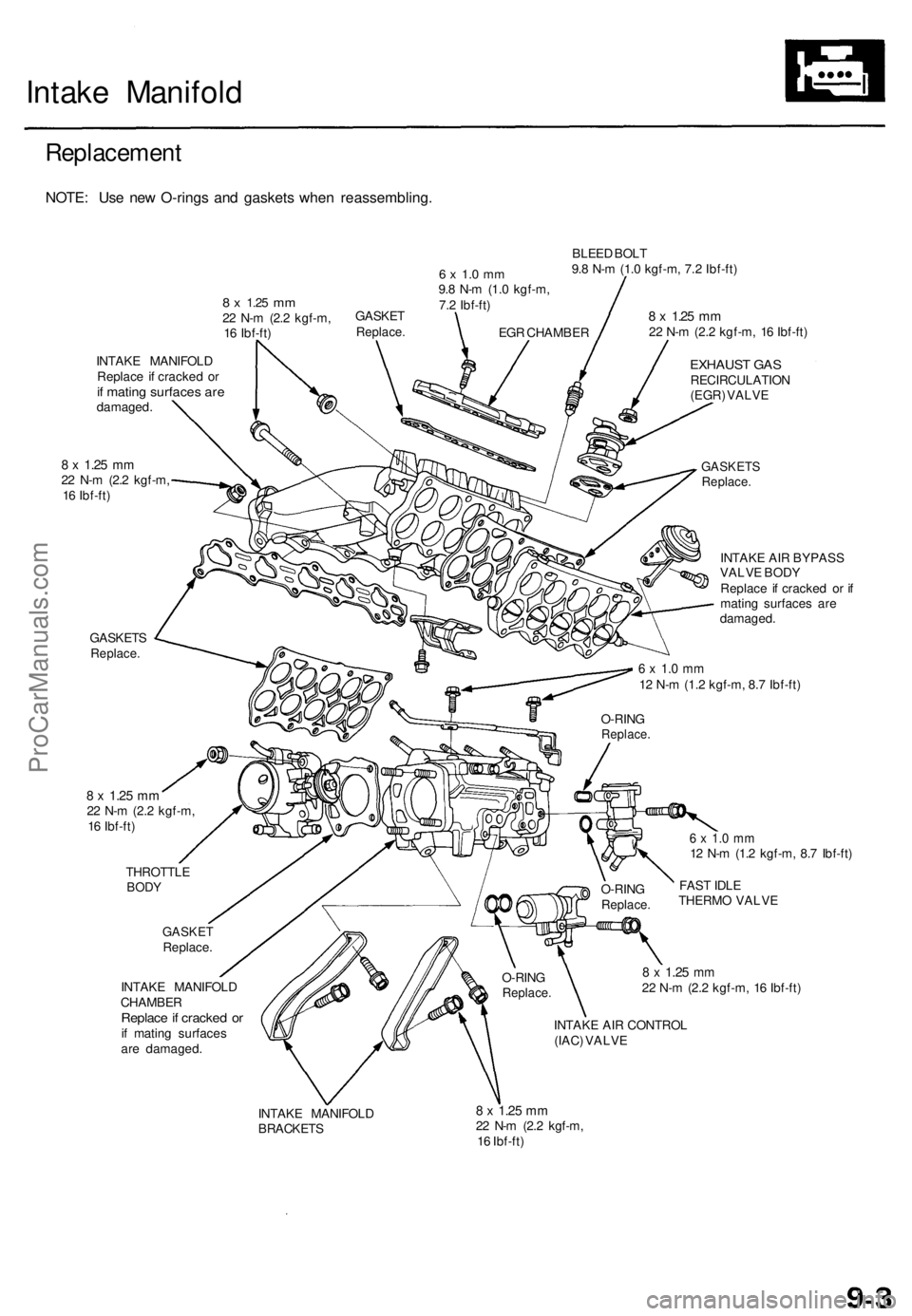

Intake Manifol d

Replacemen t

NOTE: Us e ne w O-ring s an d gasket s whe n reassembling .

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

6 x 1. 0 m m9.8 N- m (1. 0 kgf-m ,

7. 2 Ibf-ft ) BLEE

D BOL T

9. 8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )

INTAK E MANIFOL D

Replac e i f cracke d o r

if matin g surface s ar edamaged .

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

GASKET S

Replace.

8 x 1.2 5 m m22 N- m (2. 2 kgf-m , 1 6 Ibf-ft )

EXHAUS T GA SRECIRCULATIO N

(EGR ) VALV E

GASKET SReplace.

INTAKE AI R BYPAS S

VALV E BOD Y

Replac e i f cracke d o r i f

matin g surface s ar e

damaged .

6 x 1. 0 m m12 N- m (1. 2 kgf-m , 8. 7 Ibf-ft )

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

THROTTL E

BODY

GASKE TReplace .

INTAK E MANIFOL D

CHAMBE R

Replace if cracke d o rif matin g surface s

ar e damaged .

6 x 1. 0 m m12 N- m (1. 2 kgf-m , 8. 7 Ibf-ft )

FAS T IDL E

THERM O VALV E

8 x 1.2 5 mm22 N- m (2. 2 kgf-m , 1 6 Ibf-ft )

INTAK E AI R CONTRO L

(IAC ) VALV E

INTAK E MANIFOL D

BRACKET S

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

O-RIN

G

Replace .

O-RINGReplace .

O-RINGReplace .

EGR CHAMBE R

GASKE

TReplace .

ProCarManuals.com

Page 817 of 1771

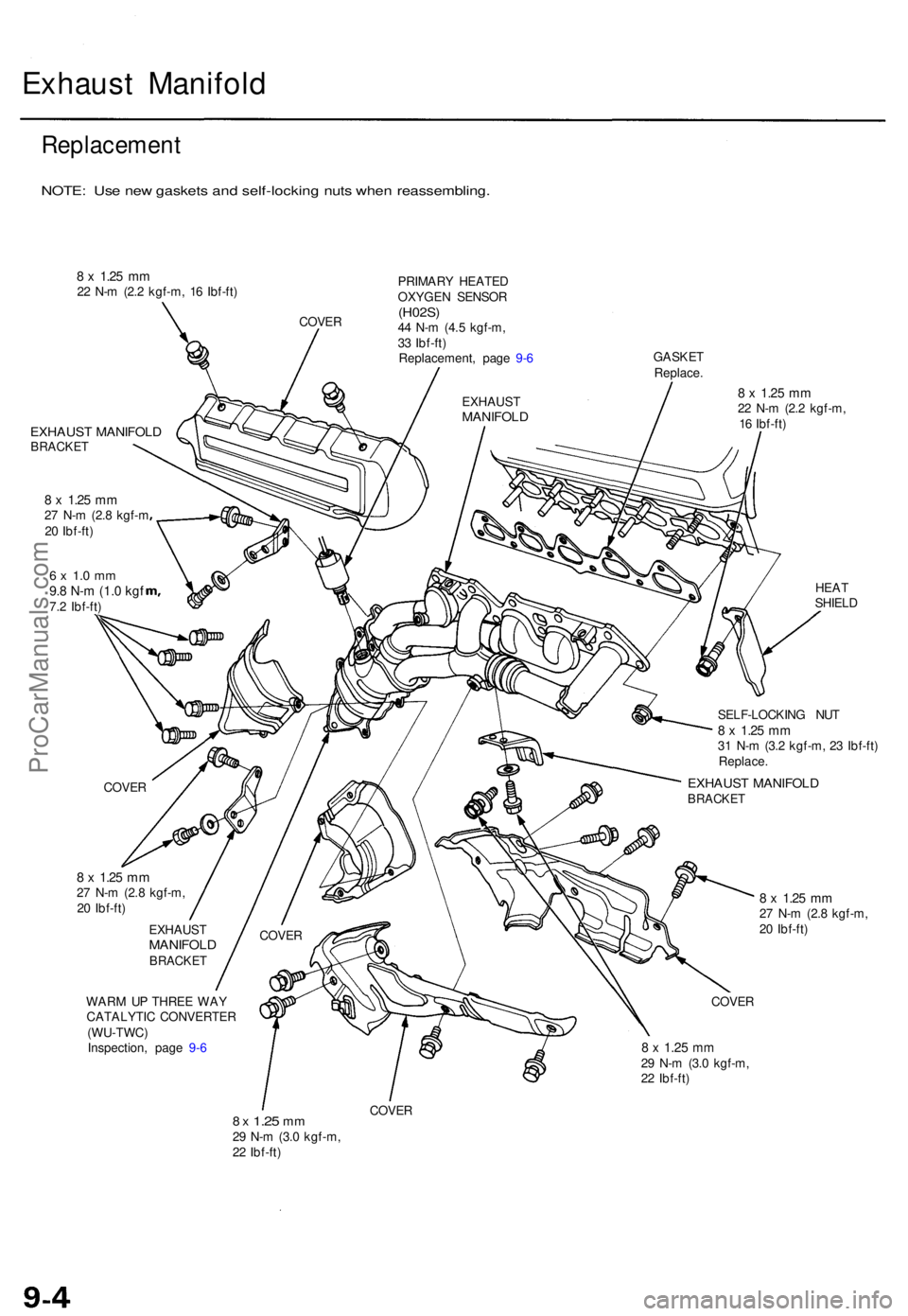

Exhaust Manifol d

Replacemen t

NOTE: Us e ne w gasket s an d self-lockin g nut s whe n reassembling .

8 x 1.2 5 mm22 N- m (2. 2 kgf-m , 1 6 Ibf-ft )

COVER PRIMAR

Y HEATE D

OXYGE N SENSO R

(H02S)44 N- m (4. 5 kgf-m ,

3 3 Ibf-ft )

Replacement , pag e 9- 6 GASKE

T

Replace .

EXHAUS T MANIFOL DBRACKET

8 x 1.2 5 mm27 N- m (2. 8 kgf- m

2 0 Ibf-ft )

6 x 1. 0 m m9.8 N- m (1. 0 kg f7.2 Ibf-ft )

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

HEAT

SHIEL D

SELF-LOCKIN G NU T

8 x 1.2 5 m m31 N- m (3. 2 kgf-m , 2 3 Ibf-ft )Replace .

8 x 1.2 5 mm27 N- m (2. 8 kgf-m ,

2 0 Ibf-ft )

EXHAUS T

MANIFOL DBRACKET

WARM U P THRE E WA Y

CATALYTI C CONVERTE R

(WU-TWC )

Inspection , pag e 9- 6

8 x 1.2 5 mm27 N- m (2. 8 kgf-m ,

2 0 Ibf-ft )

COVE R

8 x 1.2 5 mm29 N- m (3. 0 kgf-m ,

2 2 Ibf-ft )

8 x 1.2 5 mm29 N- m (3. 0 kgf-m ,

2 2 Ibf-ft )

COVE R

EXHAUS TMANIFOL D

EXHAUST MANIFOL DBRACKETCOVER

COVER

ProCarManuals.com

Page 818 of 1771

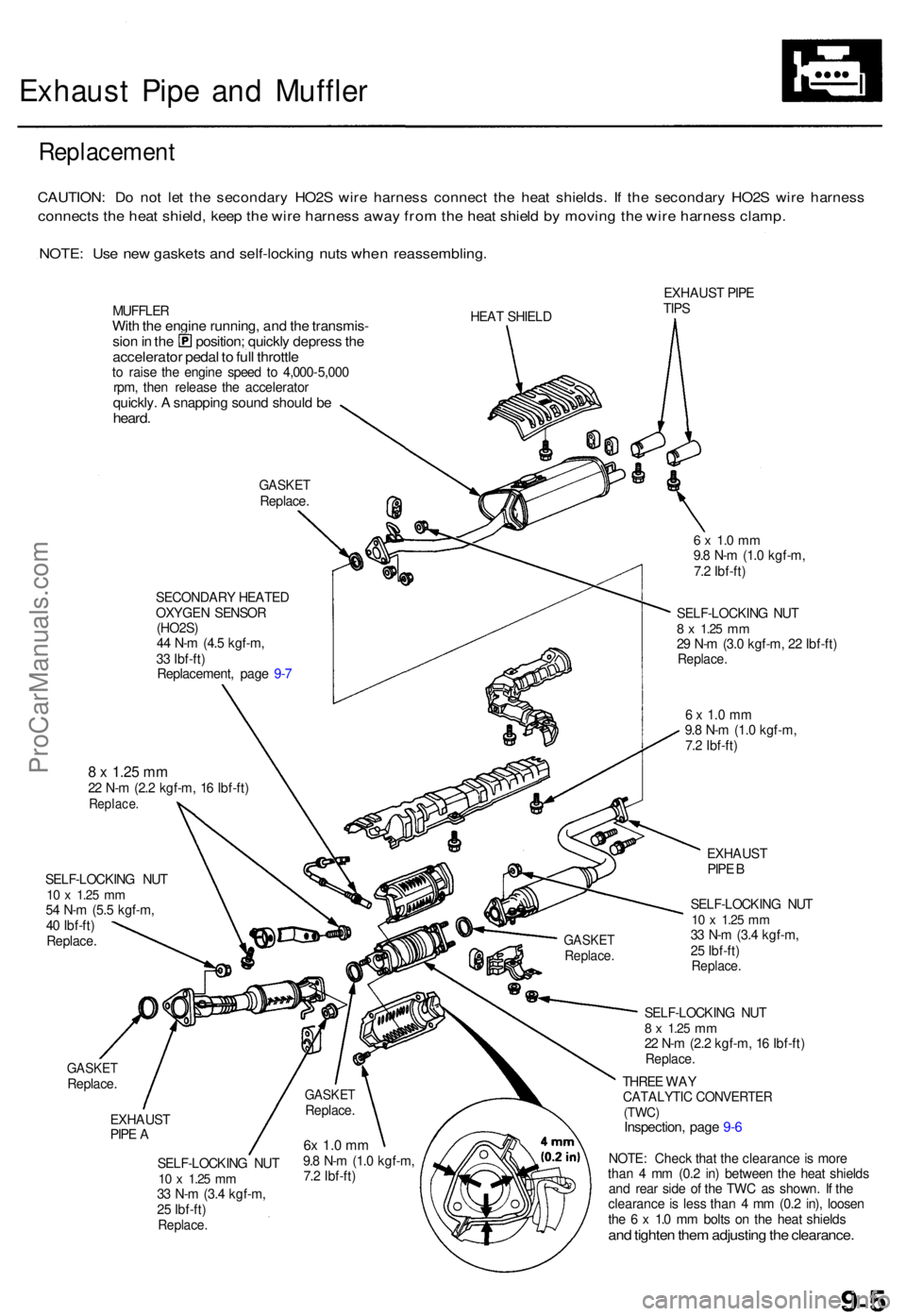

Exhaust Pip e an d Muffle r

Replacemen t

CAUTION: D o no t le t th e secondar y HO2 S wir e harnes s connec t th e hea t shields . I f th e secondar y HO2 S wir e harnes s

connect s th e hea t shield , kee p th e wir e harnes s awa y fro m th e hea t shiel d b y movin g th e wir e harnes s clamp .

NOTE: Us e ne w gasket s an d self-lockin g nut s whe n reassembling .

MUFFLERWith th e engin e running , an d th e transmis -sion in th e position ; quickl y depres s th eaccelerato r peda l t o ful l throttl eto rais e th e engin e spee d t o 4,00 0-5,00 0

rpm , the n releas e th e accelerato r

quickly. A snappin g soun d shoul d b eheard .

GASKE TReplace .

SECONDAR Y HEATE D

OXYGE N SENSO R

(HO2S )

4 4 N- m (4. 5 kgf-m ,

3 3 Ibf-ft )

Replacement , pag e 9- 7 HEA

T SHIEL D EXHAUS

T PIP E

TIP S

GASKE TReplace .

8 x 1.2 5 mm22 N- m (2. 2 kgf-m , 1 6 Ibf-ft )Replace .

SELF-LOCKIN G NU T10 x 1.2 5 mm54 N- m (5. 5 kgf-m ,

4 0 Ibf-ft )

Replace .

6 x 1. 0 m m9.8 N- m (1. 0 kgf-m ,

7. 2 Ibf-ft )

SELF-LOCKIN G NU T

8 x 1.2 5 mm29 N- m (3. 0 kgf-m , 2 2 Ibf-ft )Replace .

6 x 1. 0 m m9.8 N- m (1. 0 kgf-m ,

7. 2 Ibf-ft )

EXHAUS T

PIP E A

SELF-LOCKIN G NU T

10 x 1.2 5 mm33 N- m (3. 4 kgf-m ,

2 5 Ibf-ft )

Replace .

EXHAUS T

PIP E B

SELF-LOCKIN G NU T

10 x 1.2 5 mm33 N- m (3. 4 kgf-m ,

2 5 Ibf-ft )

Replace .

SELF-LOCKIN G NU T8 x 1.2 5 mm22 N- m (2. 2 kgf-m , 1 6 Ibf-ft )Replace .

THREE WA YCATALYTI C CONVERTE R(TWC)Inspection , pag e 9- 6

NOTE : Chec k tha t th e clearanc e is mor e

tha n 4 m m (0. 2 in ) betwee n th e hea t shield s

an d rea r sid e o f th e TW C a s shown . I f th e

clearanc e is les s tha n 4 m m (0. 2 in) , loose n

th e 6 x 1. 0 m m bolt s o n th e hea t shield s

and tighte n the m adjustin g th e clearance .

6x 1. 0 m m9.8 N- m (1. 0 kgf-m ,

7. 2 Ibf-ft )

GASKE TReplace .

GASKETReplace .

ProCarManuals.com

Page 819 of 1771

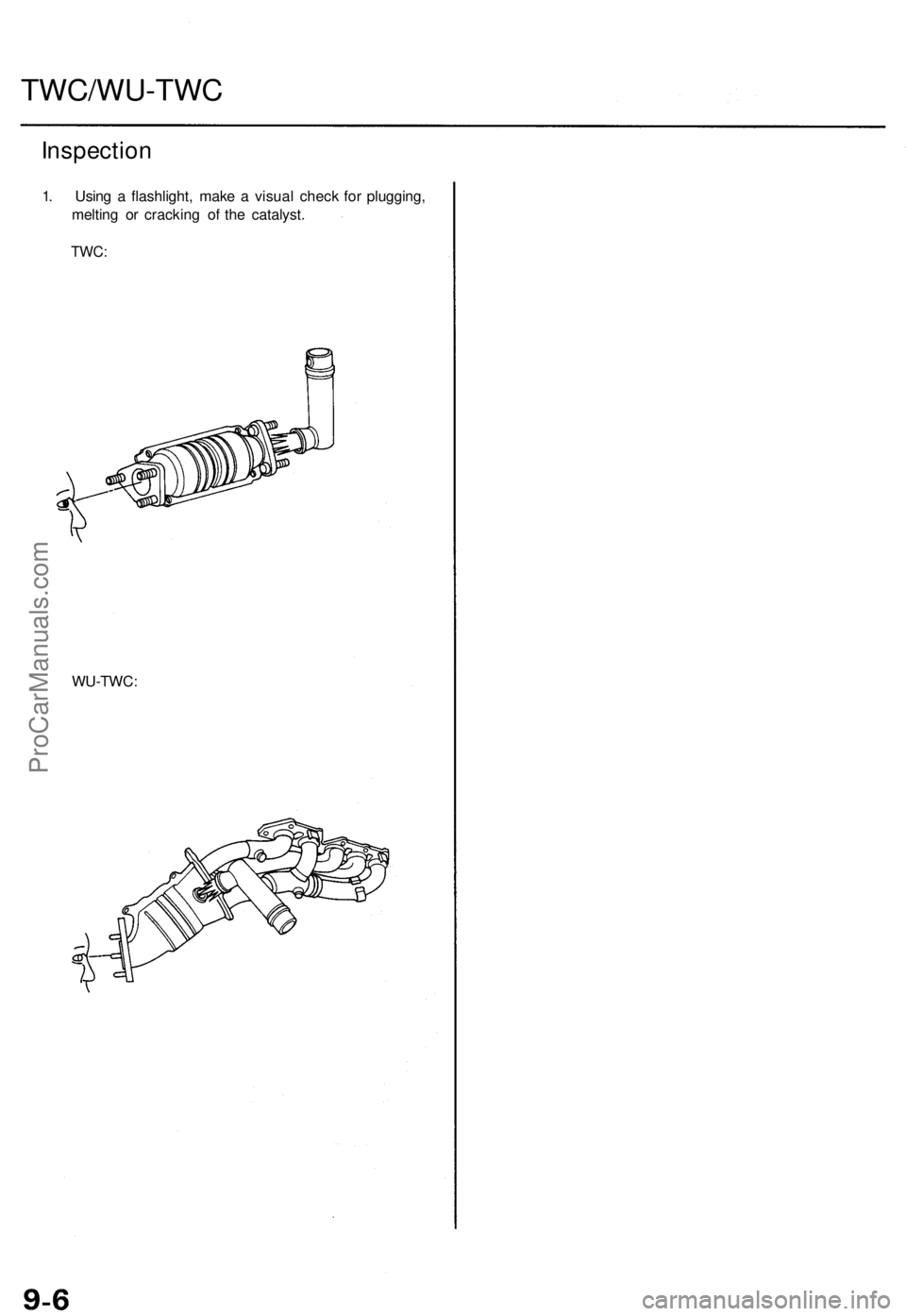

TWC/WU-TWC

Inspection

1. Usin g a flashlight , mak e a visua l chec k fo r plugging ,

meltin g o r crackin g o f th e catalyst .

TWC:

WU-TWC :

ProCarManuals.com

Page 820 of 1771

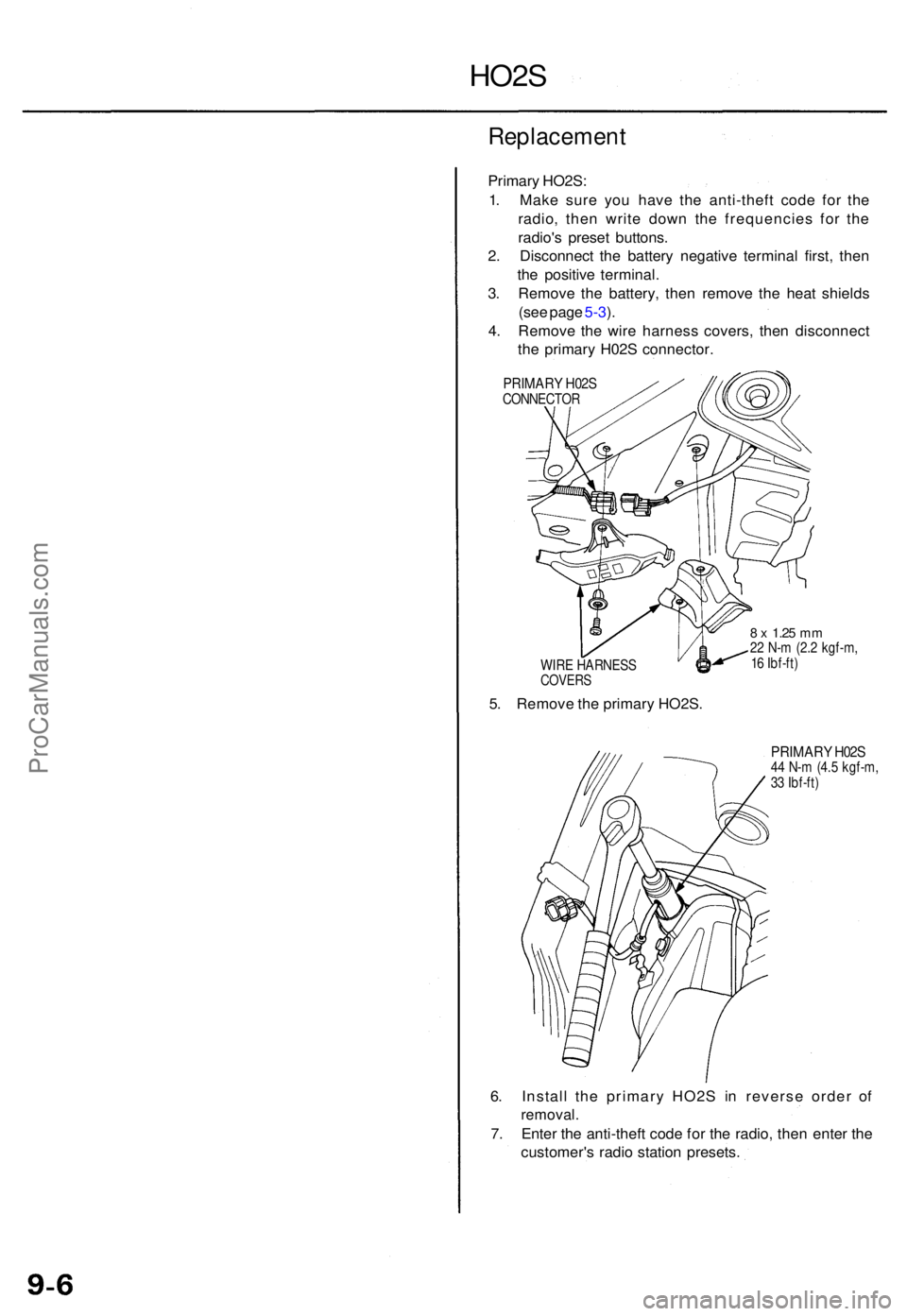

HO2S

Replacemen t

Primary HO2S :

1 . Mak e sur e yo u hav e th e anti-thef t cod e fo r th e

radio , the n writ e dow n th e frequencie s fo r th e

radio' s prese t buttons .

2 . Disconnec t th e batter y negativ e termina l first , the n

th e positiv e terminal .

3 . Remov e th e battery , the n remov e th e hea t shield s

(se e pag e 5-3 ).

4 . Remov e th e wir e harnes s covers , the n disconnec t

th e primar y H02 S connector .

PRIMARY H02 SCONNECTO R

WIR E HARNES S

COVERS

5. Remov e th e primar y HO2S .

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

PRIMAR Y H02 S44 N- m (4. 5 kgf-m ,

3 3 Ibf-ft )

6. Instal l th e primar y HO2 S i n revers e orde r o f

removal .

7. Ente r th e anti-thef t cod e fo r th e radio , the n ente r th e

customer' s radi o statio n presets .

ProCarManuals.com