ASTON MARTIN V8 VANTAGE 2010 Workshop Manual

Manufacturer: ASTON MARTIN, Model Year: 2010, Model line: V8 VANTAGE, Model: ASTON MARTIN V8 VANTAGE 2010Pages: 947, PDF Size: 43.21 MB

Page 501 of 947

Power Brake System (06.07)

Brake System (06.00)

May 2007 Workshop Manual 6-7-1

Brake System (06.00)

Power Brake System (06.07)

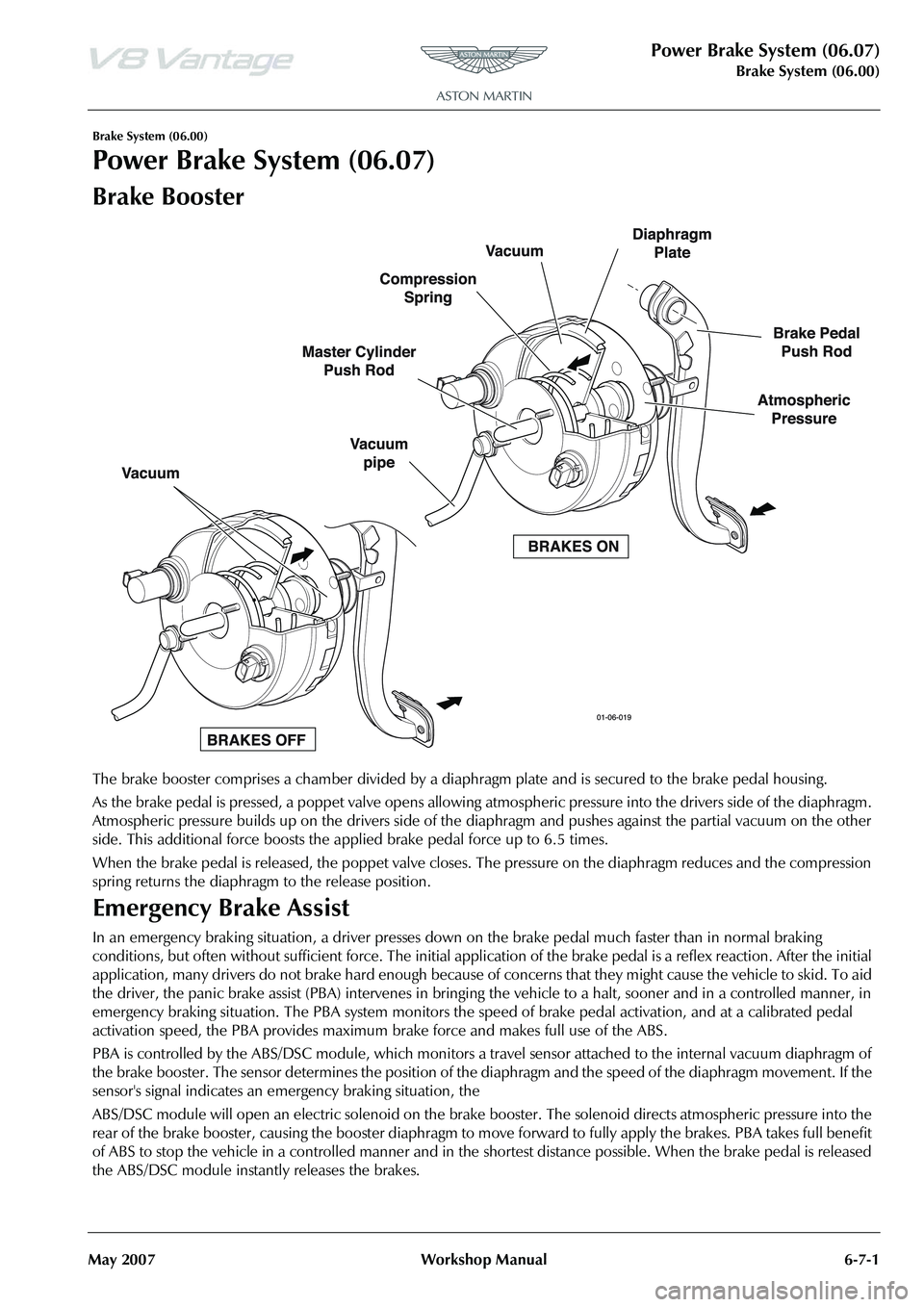

Brake Booster

The brake booster comprises a chamber divided by a diap hragm plate and is secured to the brake pedal housing.

As the brake pedal is pressed, a poppet valve opens allowing at mospheric pressure into the drivers side of the diaphragm.

Atmospheric pressure builds up on the drivers side of the diaphragm and pushes against the partial vacuum on the other

side. This additional force boosts the a pplied brake pedal force up to 6.5 times.

When the brake pedal is released, the poppet valve closes. The pressure on the diaphragm reduces and the compression

spring returns the diaphragm to the release position.

Emergency Brake Assist

In an emergency braking situation, a driver presses down on the brake pedal much faster than in normal braking

conditions, but often without sufficient force. The initial appli cation of the brake pedal is a reflex reaction. After the initial

application, many drivers do not brake ha rd enough because of concerns that they might cause the vehicle to skid. To aid

the driver, the panic brake assist (PBA) intervenes in bringing the vehicle to a halt, sooner and in a controlled manner, in

emergency braking situation. The PBA system monitors the speed of brake pedal activation, and at a calibrated pedal

activation speed, the PBA provides maximum brake force and makes full use of the ABS.

PBA is controlled by the ABS/DSC module, which monitors a travel sensor attached to the internal vacuum diaphragm of

the brake booster. The sensor determines the position of th e diaphragm and the speed of the diaphragm movement. If the

sensor's signal indicates an emergency braking situation, the

ABS/DSC module will open an electric solenoid on the brake booster. The solenoid directs atmospheric pressure into the

rear of the brake booster, causing the booster diaphragm to mo ve forward to fully apply the brakes. PBA takes full benefit

of ABS to stop the vehicle in a controlled manner and in the shortest distance possible. When the brake pedal is released

the ABS/DSC module instantly releases the brakes.

Page 502 of 947

Power Brake System (06.07)

Brake System (06.00)6-7-2 Workshop Manual May 2007

Specifications

Maintenance

Brake Booster-RHD-Renew

Removal

1. Remove brake master cylind er (see Workshop Manual

procedure 06.06.EB Brake Master Cylinder Assembly

Renew).

2. Remove oil dipstick.

3. Remove vacuum hose.

4. Disconnect multiplugs (x2).

5. Remove pedal cover.

6. Remove clevis pin and clip.

7. Remove servo securing nuts (x4).

8. Remove servo assembly.

9. Remove brake light switch.

Installation

1. Install brake light switch.

2. Install servo assembly.

3. Install servo retaining nuts (x4) (torque).

4. Install clevis pin and clip.

5. Install pedal cover.

6. Connect multiplugs (x2).

7. Install vacuum hose.

8. Install dipstick. 9. Install brake master cylinder (see Workshop Manual

procedure 06.06.EB Brake Master Cylinder Assembly

Renew).

Brake Booster-LHD-Renew

Removal

1. Move drivers seat fully rearward.

2. Remove clevis pin and clip.

3. Remove booster securing nuts (x4).

4. Remove corner cross brace.

5. Move expansion tank aside for access (bolt x1, nut x1,

hose clips x2, multiplug x1).

6. Remove vacuum hose move aside.

7. Remove bolts (x2) from clutch pipe bracket and move aside.

8. Disconnect clutch reservoir feed pipe.

9. Disconnect multiplugs (x4).

10. Disconnect brake pipes from master cylinder (move aside).

11. Remove booster assembly.

12. Split components.

13. Remove reservoir securing screw (for access to securing nut).

14. Remove master cylinder from booster (nuts x2).

15. Re-fit components.

16. Install master cylinder to booster (nuts x2).

17. Install reservoir securing screw.

Torque Figures

DescriptionNm.lb. / ft.

Brake Booster Mount 21-24 15.5-18

Repair Operation Time (ROT)

Repair Operation Time (ROT)

ItemCode

Brake Booster-Renew 06.07.AC

WAR NI NG

AVOID SKIN / EYE CONTACT OR INGESTION OF

BRAKE FLUID. IF SKIN OR EYES ARE SPLASHED WITH BRAKE FLUID, RINSE THE AFFECTED AREA

IMMEDIATELY WITH PLENTY OF WATER AND OBTAIN MEDICAL ATTENTION. IF BR AKE FLUID IS INGESTED,

OBTAIN IMMEDIATE MEDICAL ATTENTION.

WAR NI NG

BRAKE FLUID IS HYGROSCOPIC. IF KEPT IN OPENED CONTAINERS IT WILL ABSORB WATER VAPOUR. USE

ONLY BRAKE FLUID FROM FRESHLY OPENED

CONTAINERS WHEN TOPPING-UP THE BRAKE FLUID RESERVOIR.

Caution

Brake fluid must not be allowed to contact the vehicle

paint work. Remove spilt brake fluid from the paint work

by rinsing away with running water.

Caution

Always plug pipe ends to prevent ingress of dirt or

moisture into the system.

Caution

Always plug pipe ends to prevent ingress of dirt or

moisture into the system.

Page 503 of 947

Power Brake System (06.07)

Brake System (06.00)

May 2007 Workshop Manual 6-7-3

Installation

1. Install booster assembly.

2. Connect brake pipes to master cylinder.

3. Install bolts (x2) clutch pipe bracket.

4. Connect clutch reservoir feed pipe.

5. Connect multiplugs (x4).

6. Install vacuum hose.

7. Install expansion tank asid e (bolt x1, nut x1, hose clips

x2, multiplug x1).

8. Install corner cross brace (torque) (only fully tighten

when vehicle on level floor).

9. Install servo retaining nuts (x4) (torque).

10. Install clevis pin and clip.

11. Bleed Brakes (see Workshop Manual procedure 06.06.AD Pad Kit - Manual Brake and Clutch Pedal -

Renew).

12. Top-up coolant.

Brake Fluid Reservoir-Renew

Removal

1. Remove corner cross brace.

2. Move expansion tank aside for access (bolt x1, nut x1, hose clips x2, multiplug x1).

3. Disconnect clutch reservoir feed pipe.

4. Disconnect multiplugs (x2). 5. Disconnect brake pipes from master cylinder (move

aside).

6. Remove reservoir holding screw for access to master cylinder retaining nut.

7. Remove master cylinder from booster (nuts x2).

8. Remove reservoir from master cylinder.

Installation

1. Fit new seals and install reservoir to master cylinder.

2. Install master cylinder to booster (nuts x2).

3. Install reservoir holding screw for access to master cylinder retaining nut

4. Connect brake pipes to master cylinder.

5. Connect clutch reservoir feed pipe.

6. Connect multiplugs (x2).

7. Install expansion tank aside (bolt x1, nut x1, hose clips x2, multiplug x1).

8. Install corner cross brace (torque) (only fully tighten

when vehicle on level floor).

9. Bleed Brakes (see Workshop Manual procedure 06.07.DD Brake Hydraulic System - Flush/Refill/Bleed).

10. Top-up coolant.

Brake Bleeding - AMDS

Use the AMDS to bleed the brakes if you are bleeding the

brake system after you replaced a major component, for

example: a modulator or a mast er cylinder or when filling

from empty.

If you are bleeding a caliper, you can use a manual brake-

bleed procedure.

1. Connect the AMDS.

Repair Operation Time (ROT)

Repair Operation Time (ROT)

Page 504 of 947

Power Brake System (06.07)

Brake System (06.00)6-7-4 Workshop Manual May 2007

2. Clean each caliper around the bleed screws. Remove the dust caps.

3. Prepare a bleed tube and a bottle that contains a small quantity of clean brake fluid.

4. If necessary, top up the brake fluid reservoir with brake fluid from a new container.

5. Switch on the AMDS and load the ‘Anti-lock braking diagnostics’ software.

6. Select ‘Brake Bleed’ and follow the AMDS instructions.

Brake Master Cylinder and Vacuum

Booster-Renew

Removal

1. Move drivers seat fully rearward.

2. Remove clevis pin and clip.

3. Remove booster securing nuts (x4).

4. Remove corner cross brace.

5. Move expansion tank aside for access (bolt x1, nut x1,

hose clips x2, multiplug x1).

6. Remove vacuum hose move aside.

7. Remove bolts (x2) from clutch pipe bracket and move aside.

8. Disconnect clutch reservoir feed pipe.

9. Disconnect multiplugs (x4).

10. Disconnect brake pipes from master cylinder (move aside).

11. Remove booster assembly.

Installation

1. Install booster assembly.

2. Connect brake pipes to master cylinder.

3. Install bolts (x2) clutch pipe bracket.

4. Connect clutch reservoir feed pipe.

5. Connect multiplugs (x4).

6. Install vacuum hose.

7. Install expansion tank aside (bolt x1, nut x1, hose clips x2, multiplug x1).

8. Install corner cross brace (torque) (only fully tighten when vehicle on level floor).

9. Install servo retaining nuts (x4) (torque).

10. Install clevis pin and clip.

11. Bleed Brakes (see Workshop Manual procedure 06.07.DD Brake Hydraulic System - Flush/Refill/Bleed).

WA R N I N G

BRAKE FLUID THAT CONTAINS WATER CAN AFFECT THE PERFORMANCE OF THE BRAKES AND CAUSE CORROSION IN THE BRAKE SYSTEM.

IF YOU KEEP BRAKE FLUID IN OPEN CONTAINERS, IT WILL ABSORB WATER VAPOUR.

USE ONLY BRAKE FLUID FROM NEW CONTAINERS

WHEN YOU TOP-UP THE BRAKE FLUID RESERVOIR..

When you bleed a brake caliper, always bleed the inner bleed screw first, followed by the outer bleed screw, then bleed the inne r bleed screw again.

Repair Operation Time (ROT)

WAR NI NG

AVOID SKIN / EYE CONTACT OR INGESTION OF

BRAKE FLUID. IF SKIN OR EYES ARE SPLASHED WITH BRAKE FLUID, RINSE THE AFFECTED AREA

IMMEDIATELY WITH PLENTY OF WATER AND OBTAIN

MEDICAL ATTENTION. IF BR AKE FLUID IS INGESTED,

OBTAIN IMMEDIATE MEDICAL ATTENTION.

WAR NI NG

BRAKE FLUID IS HYGROSCOPIC. IF KEPT IN OPENED CONTAINERS IT WILL ABSORB WATER VAPOUR. USE ONLY BRAKE FLUID FROM FRESHLY OPENED

CONTAINERS WHEN TOPPING-UP THE BRAKE FLUID RESERVOIR.

Caution

Brake fluid must not be allowed to contact the vehicle

paint work. Remove spilt brake fluid from the paint work

by rinsing away with running water.

Caution

Always plug pipe ends to prevent ingress of dirt or

moisture into the system.

Caution

Always plug pipe ends to prevent ingress of dirt or

moisture into the system.

Page 505 of 947

Power Brake System (06.07)

Brake System (06.00)

May 2007 Workshop Manual 6-7-5

12. Top-up coolant.

Brake Master Cylinder-Renew

Removal

1. Remove corner cross brace.

2. Move expansion tank aside for access (bolt x1, nut x1, hose clips x2, multiplug x1).

3. Disconnect clutch reservoir feed pipe.

4. Disconnect multiplugs (x2).

5. Disconnect brake pipes from master cylinder (move aside).

6. Remove reservoir holding screw for access to master cylinder retaining nut.

7. Remove master cylinder from booster (nuts x2).

Installation

1. On new master cylinder - Remove reservoir holding screw for access to master cylinder retaining nut

2. Install master cylinder to booster (nuts x2).

3. Install reservoir holding screw for access to master cylinder retaining nut

4. Connect brake pipes to master cylinder.

5. Connect clutch reservoir feed pipe.

6. Connect multiplugs (x2).

7. Install expansion tank asid e (bolt x1, nut x1, hose clips

x2, multiplug x1). 8. Install corner cross brace

(torque) (only fully tighten

when vehicle on level floor).

9. Bleed Brakes (see Workshop Manual procedure 006.07.DD Brake Hydraulic System - Flush/Refill/

Bleed).

10. Top-up coolant.

Repair Operation Time (ROT)

Page 506 of 947

Power Brake System (06.07)

Brake System (06.00)6-7-6 Workshop Manual May 2007

Page 507 of 947

Anti-lock Braking System (ABS) (06.09)

Brake system (06.00)

Issue 4, November 2008 Workshop Manual 6-9-1

Brake system (06.00)

Anti-lock Braking System (ABS) (06.09)

The anti-lock braking system (ABS) is a four-channel system

having independent inputs from all four-wheel speed

sensors.

The ABS module, monitors signals from the sensors to

calculate, brake slip and the acceleration / deceleration of

individual wheels. When the brake pedal is depressed, and

the ABS module detects incipient wheel lock-up from the

incoming signals, it triggers the re-circulation pump inside

the module’s hydraulic modulator, and the solenoid valves

for the wheel(s) concerned. Brake pressure, is then

modulated to increase / decrease or remain constant at the

wheel(s) concerned until whee l lock-up is eliminated. The

ABS provides self-diagnosis and any malfunction within the

system will be indicated to the dr iver by the illumination of

the brake warning light and ‘ABS FAULT’ displayed in the

message centre right. Should a fault develop within the ABS,

the brake system will operate conventionally and with the

same standard of performanc e as a vehicle not equipped

with ABS.

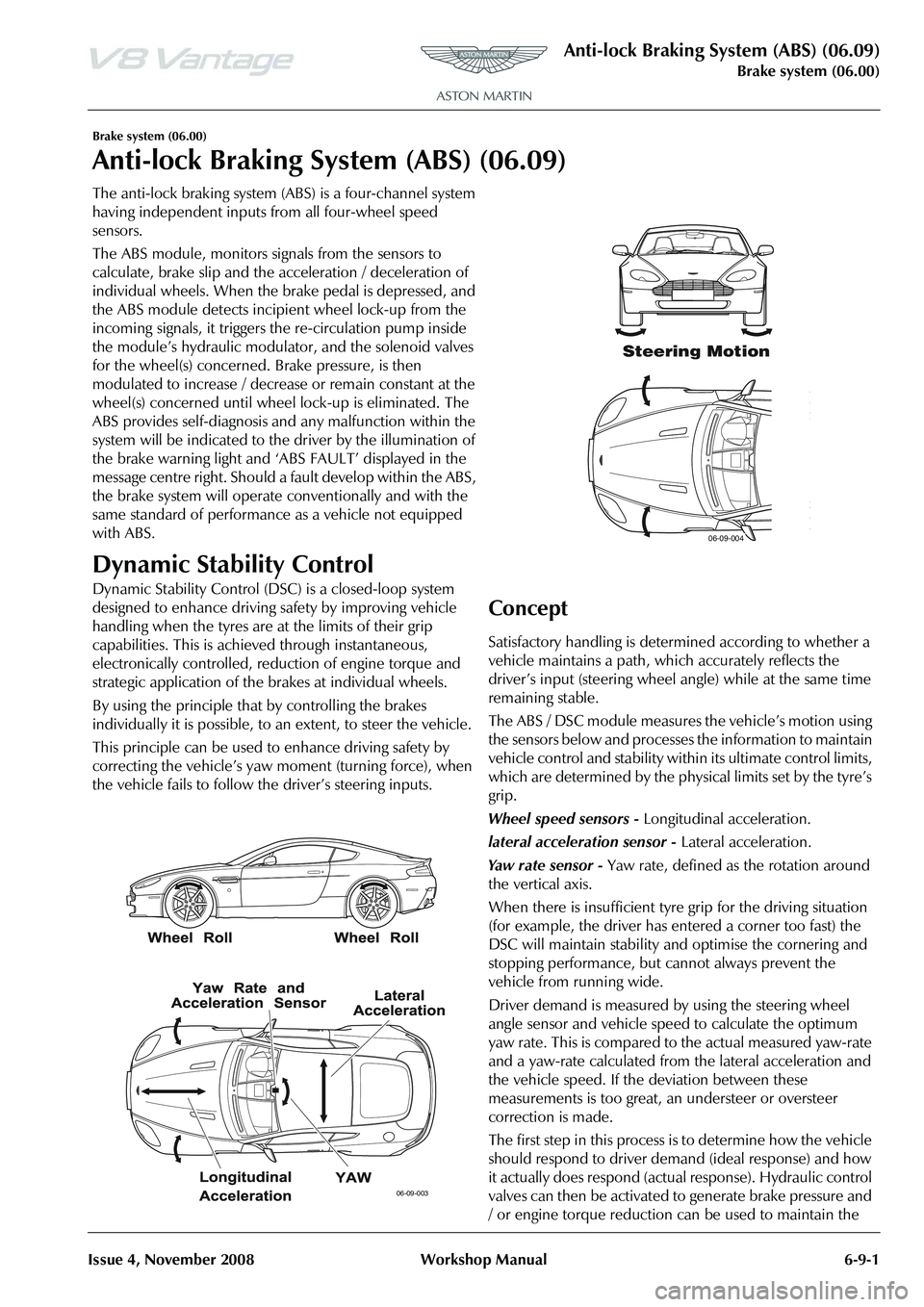

Dynamic Stability Control

Dynamic Stability Control (DSC ) is a closed-loop system

designed to enhance driving safety by improving vehicle

handling when the tyres are at the limits of their grip

capabilities. This is achieved through instantaneous,

electronically controlled, reduction of engine torque and

strategic application of the brakes at individual wheels.

By using the principle that by controlling the brakes

individually it is possible, to an extent, to steer the vehicle.

This principle can be used to enhance driving safety by

correcting the vehicle’s yaw moment (turning force), when

the vehicle fails to follow th e driver’s steering inputs.

Concept

Satisfactory handling is determined according to whether a

vehicle maintains a path, wh ich accurately reflects the

driver

Page 508 of 947

Anti-lock Braking System (ABS) (06.09)

Brake system (06.00)

6-9-2 Workshop Manual Issue 4, November 2008

difference between the ideal and actual response within a

tolerance band. This directly influences the forces on the

tires to generate a corrective yaw moment to reduce the side

forces of the tires where appropriate

System Overview

The DSC system embraces capabilities far beyond that of

ABS, or ABS and traction control combined, while relying on

the components of these systems. It also incorporates these

additional sensors for measur ing the vehicle’s motion and

brake system pressure:

Ya w r a t e s e n s o r - located centrally on the transmission

tunnel.

Lateral acceleration sensor - integrated with the yaw rate

sensor.

Steering angle sensor - located on the upper steering

column.

Pressure transducer - located on master cylinder.

The ABS / DSC module supports data exchange with other

vehicle electronic systems via the CAN network; the module

also enables diagnostic interrogation using WDS.

The following components register driver demand and the

ABS / DSC module processes their signals as a basis for

defining an ideal response:

PCM - position of accelerator pedal.

Brake master cylinder pressure transducer - driver’s

braking effort.

Steering angle sensor - position of steering wheel.

There are many supplementary parameters also included in

the processing calculations these include the coefficient of

friction and vehicle speed. The ABS / DSC module monitors

these factors based on signals transmitted by the sensors for:

• Wheel speed

• Lateral acceleration

• Brake pressure

• Yaw rate

Using these parameters, the function of the ABS / DSC

module is to determine the current vehicle status based on

the yaw-rate signal and the slip as estimated by the ABS /

DSC module. It then maintains the vehicle response within

a tolerance of the ‘normal’ behaviour, which is easily

controlled by the driver.

In order to generate the desired yaw behaviour the ABS /

DSC module controls the selected wheels using the ABS

hydraulic system and engine control system. In the event of

engine intervention, the ABS / DSC module calculates the

torque which should be supplied by the engine to the

wheels, and relays this request signal to the PCM which

implements the torque request.

The PCM receives signals from the DSC system via the CAN

bus and reduces engine torque as follows:

• The throttle is positioned to provide the requested engine target torque. • During the transient phase of torque reduction caused by

mechanical and combustion delays, other alternative

torque reduction methods are used to provide a quicker

response.

• The ignition is retarded and / or the fuel is cut-off at the injectors at selected cylinders.

• Ignition and fuelling are reinstated when the engine torque reaches the requested value

Operation Summary

• DSC is switched ‘ON’ when the engine is started

• When the system is operating , the DSC light in the instrument cluster will flash, at the rate of twice a second

• DSC can be switched ‘OFF / ON’ by pressing the DSC switch

• The DSC light in the instru ment cluster will illuminate

continuously when the system is switched ‘Off’.

• ‘DSC OFF’ will be displayed in the message centre right to indicate the system has been switched ‘OFF’

• A malfunction in the traction control system will be indicated to the driver by the following:

• The DSC light in the instru ment cluster will illuminate

continuously

• The message ‘DSC NOT AVAILABLE’ will be displayed in the message centre right

• If vehicle speed control is engaged it will automatically disengage when traction control is operating .

Traction Control

Traction control is a function of DSC, and is operated in

association with DSC. Traction control prevents excessive

wheel-spin at standing starts, or during acceleration. Wheel-

spin is usually caused by ex cessive use of the accelerator

pedal, or slippery, loose or bumpy road surfaces. To prevent

excessive wheel-spin and mainta in vehicle stability such

situations are overcome by the intervention of the traction

control system by:

• Braking the driven-wheel when it starts to slip

• And / or adapting the engine torque to a level corresponding to the traction available on the road

surface.

Functional Description

Traction control uses the ABS electronic and mechanical /

hydraulic hardware with additional valves to control the

braking pressure at the calipe rs. An engine interface also

enables the engine to respond to torque reduction requests

from the traction control. As with ABS, the signals from the

wheel-speed sensors are supplied to the ABS module, where

they are used to calculate the wheel-slip of the individual

wheels. Traction control intervention is initiated if the slip at

one of the wheels is excessive.

Page 509 of 947

Anti-lock Braking System (ABS) (06.09)

Brake system (06.00)

Issue 4, November 2008 Workshop Manual 6-9-3

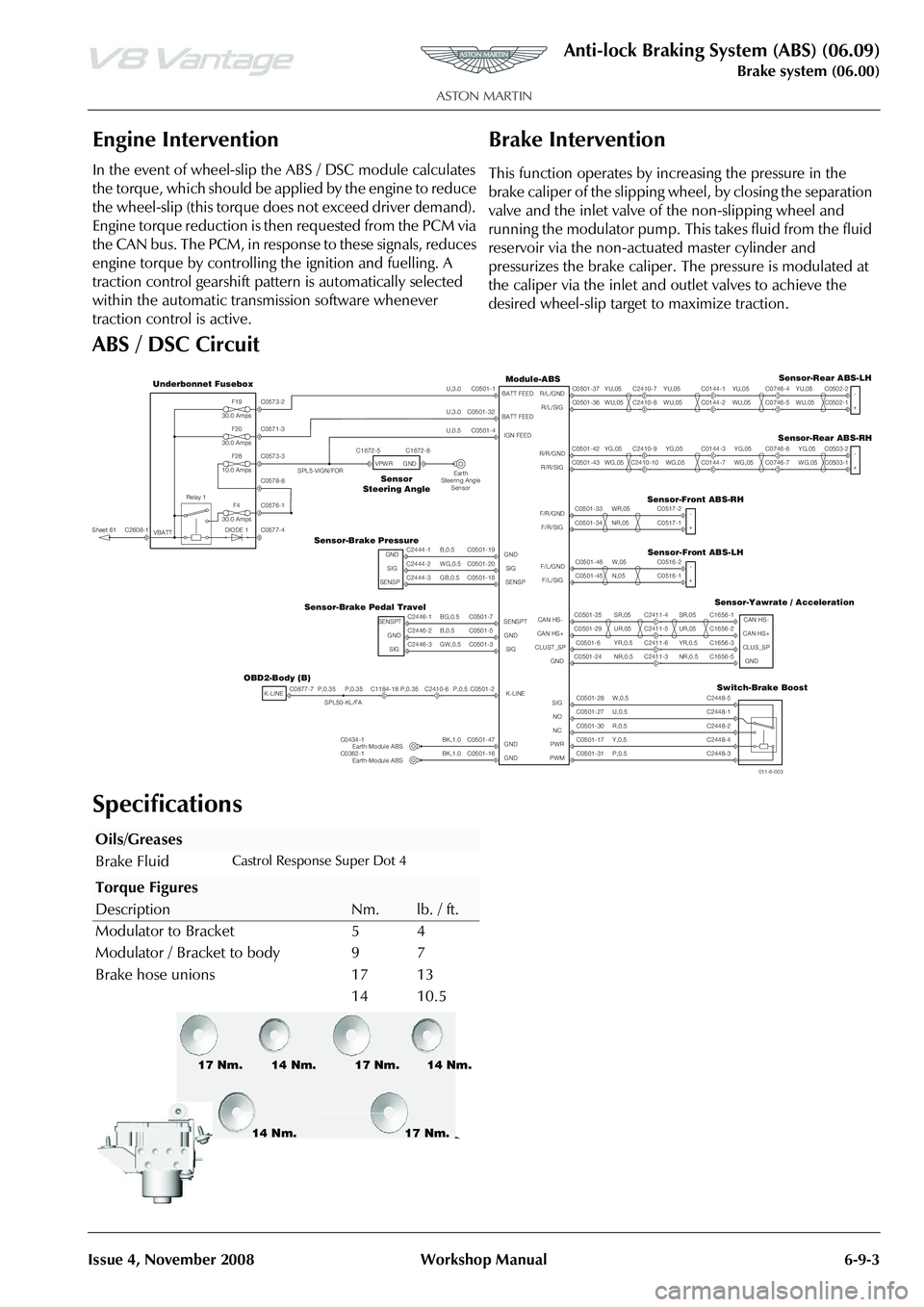

Engine Intervention

In the event of wheel-slip the ABS / DSC module calculates

the torque, which should be applied by the engine to reduce

the wheel-slip (this torque does not exceed driver demand).

Engine torque reduction is then requested from the PCM via

the CAN bus. The PCM, in response to these signals, reduces

engine torque by controlling the ignition and fuelling. A

traction control gearshift pattern is automatically selected

within the automatic transmission software whenever

traction control is active.

Brake Intervention

This function operates by increasing the pressure in the

brake caliper of the slipping wheel, by closing the separation

valve and the inlet valve of the non-slipping wheel and

running the modulator pump. This takes fluid from the fluid

reservoir via the non-actuated master cylinder and

pressurizes the brake caliper. The pressure is modulated at

the caliper via the inlet and outlet valves to achieve the

desired wheel-slip target to maximize traction.

ABS / DSC Circuit

Specifications

SR,05UR,05YR,0.5NR,0.5

WR,05NR,05

YG,05WG,05

YU,05WU,05

W,05N,05

W,0.5U,0.5R,0.5

P,0.5Y,0.5

B,0.5WG,0.5GB,0.5

B,0.5BG,0.5

GW,0.5

P,0.5

U,0.5

U,3.0

BK,1.0BK,1.0

P,0.35P,0.35P,0.35 U,3.0

WG,05YG,05

WU,05

SR,05UR,05YR,0.5NR,0.5

WG,05YG,05

WU,05

WG,05YG,05

WU,05YU,05YU,05YU,05Module-ABS

OBD2-Body (B)

Earth-Module ABSEarth-Module ABS

C1184-18C2410-6

Sensor-Brake Pressure

Sensor-Brake Pedal Travel

Sensor-Rear ABS-LH

C0746-7C0746-6

C0746-5

Switch-Brake Boost

Sensor-Yawrate / Acceleration

C2411-6C2411-5C2411-4

C2411-3

C0144-7C0144-3

C0144-2

Sensor-Front ABS-LH

Sensor-Front ABS-RH

C2410-10C2410-9

C2410-8

Sensor-Rear ABS-RH

C0746-4C0144-1C2410-7

C0877-7

K-LINESPL50-KL/FA

C0362-1C0434-1

C2444-2

SIGC2444-1

GND

C2444-3

SENSP

C2446-2

GNDC2446-1

SENSPT

C2446-3

SIG

C0501-47

GNDC0501-16

GND

C0501-2K-LINE

C0501-24

GND

C0501-31

PWM

C0501-30

NC

C0501-25

CAN HS-

C0501-28

SIGC0501-27

NO

C0501-29

CAN HS+C0501-6

CLUST_SP

C0501-17

PWR

C0501-5

GND

C0501-32BATT FEED

C0501-7

SENSPT

C0501-3 SIG

C0501-20 SIGC0501-19

GND

C0501-18 SENSP

C0501-4IGN FEED

C0501-46

F/L/GNDC0501-45

F/L/SIG

C0501-42

R/R/GNDC0501-43

R/R/SIG

C0501-36

R/L/SIG

C0501-34

F/R/SIGC0501-33

F/R/GND

C0501-1

BATT FEEDC0501-37

R/L/GND

C2448-5

C2448-3

C2448-2C2448-1

C2448-4

C1656-3 CLUS_SPC1656-2

CAN HS+C1656-1 CAN HS-

C1656-5

GND

C0516-2-C0516-1+

C0517-2

-C0517-1+

C0502-1

+

C0503-2 -C0503-1+

C0502-2 -

Sensor

Steering Angle

Sheet 61

F4

30.0 AmpsRelay 1

Underbonnet Fusebox

DIODE 1

F28

10.0 Amps

F20

30.0 Amps

F19

30.0 Amps

Earth

Steering Angle

Sensor

C0576-1

C0577-4C2608-1 VBATT

C0573-2

C0571-3

C0573-3

C0578-8SPL5-VIGN/FOR

C1672-5

VPWRC1672-8

GND

011-6-003

Oils/Greases

Brake FluidCastrol Response Super Dot 4

Torque Figures

DescriptionNm.lb. / ft.

Modulator to Bracket 5 4

Modulator / Bracket to body 9 7

Brake hose unions 17 1413

10.5

17 Nm. 17 Nm.

17 Nm.

14 Nm.

14 Nm. 14 Nm.

Page 510 of 947

Anti-lock Braking System (ABS) (06.09)

Brake system (06.00)

6-9-4 Workshop ManualIssue 4, November 2008

Maintenance

ABS Modulator - Remove and Install

Remove

1. Disconnect the vehicle battery.

2. Raise the vehicle and make it safe.

3. Remove the four road wheels.

4. Remove the dust caps from the four brake caliper bleed

nipples .

5. Put a container in position under the rear left-side caliper to collect brake fluid.

6. Connect a bleed hose to rear left-side caliper.

7. Open the bleed nipple.

8. Put a container in position under the front left-side caliper to collect brake fluid.

9. Connect a bleed hose to front left-side caliper

10. Open the bleed nipple.

11. Operate the brake pedal more than 60 mm and install a pedal clamp to hold it.

12. Tighten the two bleed nipples.

13. Disconnect the two bleed hoses.

14. Remove the two fluid containers.

15. Install the two dust caps.

16. Remove the five or six screws that attach the rear half of the front left wheelarch liner.

17. Remove the self-tapping screw that attaches the rear of the wheelarch liner into the wheelarch.

18. Move the wheel arch liner to get access. 19. Disconnect the electrical connector from the modulator.

20. Put a label on each brake pipe union for the assembly

procedure.

21. Loosen and disconnect the six brake pipe unions from

the modulator. Install plugs into the modulator and the

pipe connections.

22. Remove the three M8 Torx-head screws (1) that attach the modulator mounting bracket to the body.

23. Remove the modulator.

24. Remove the three M6 Torx-head bolts that attach the modulator to the mounting bracket. Remove the

mounting bracket from the modulator.

Installation

1. Install the modulator onto the mounting bracket.

2. Install and torque the three M6 Torx-head bolts.

3. Install the modulator to the body.

4. Install and torque the three M8 Torx-head screws.

5. Remove the sealing plugs.

6. Install and torque the six brake unions to the modulator.

7. Connect the electrical connector to the modulator.

8. Put the wheel arch liner back in the correct position.

9. Install the self-tapping screw that attaches the rear of the wheelarch liner into the wheelarch.

10. Install the five or six scre ws to attach the wheel arch

liner.

11. Bleed the braking system (Refer to ’Brake Bleeding - AMDS