CADILLAC SEVILLE 1993 4.G Owners Manual

Manufacturer: CADILLAC, Model Year: 1993, Model line: SEVILLE, Model: CADILLAC SEVILLE 1993 4.GPages: 407, PDF Size: 22.28 MB

Page 351 of 407

Downloaded from www.Manualslib.com manuals search engine I

The Northstar engine is designed to require less maintenance than many

other

DOHC V-8 engines. Engine systems are designed to remind the

driver when service is required.

An oil life index indicator monitors

ongoing operating conditions and reminds the driver when an oil change

is needed.

A low coolant warning message keeps track of the level of this

vital fluid. Direct acting hydraulic tappets provide maintenance free zero

lash operation

of the 32 valves from idle to the 6500 rpm redline. The

camshafts are driven by a two stage roller chain assembly which is

designed to provide quiet maintenance free operation. Platinum tipped

spark plugs increase the replacement interval

to 100,OO miles.

The four valve per cylinder design provides more efficient engine

breathing which results in higher power than comparable

two valve

engines. The central location

of each spark plug ensures a fast and

complete burning

of the fuel/air mixture. The induction system uses

smooth thermoplastic tubes

to channel air into the cylinders. The

smoothness

of the tubes is equivalent to the elaborate port polishing

methods used for race car engines. Careful design using the shape and

length

of the tubes boosts horsepower by using sonic pressure waves

created by the motion

of the inlet valves to increase the amount of air

entering each cylinder.

The Northstar engine

is also designed to be very durable. The aluminum

block has cast-in-place iron cylinder liners for greater wear resistance.

High strength forged steel connecting rods support the free floating

piston pins

in bronze bushings for superior high speed performance. The

fillits

of the nodular iron crankshaft undergo a high pressure compression

rolling operation

to improve their resistance to fatigue.

Quiet operation

is enhanced by the use of special materials and designs.

The front cover of the engine is stamped from laminated steel which

damps out noise. Special cam cover gasket seals isolate valve train

operation.

The fuel injectors are placed inside the induction system

housing

to eliminate the clicking noise which is common to other fuel

injected engines.

The Northstar engine

is designed to provide years of efficient, reliable,

satisfying operation. We

think it is also just plain fun to drive.

33 7

Page 352 of 407

Downloaded from www.Manualslib.com manuals search engine 4.9 LITER ENGINE

The 4.9 Liter transverse engine is an overhead valve, 90 degree V-8

design. The cylinder bore diameter and the piston stroke provide a piston

This engine utilizes an aluminum crankcase with a separate aluminum

lifter carrier and removable cast iron cylinder liners. The

cylinder heads

are made of cast iron and feature integral valve seats and guides. The cast

nodular iron crankshaft is supported at

five main bearing journals by cast

iron main bearing caps and shell type steel-backed aluminum inserts.

The

center main bearing is the thrust bearing.

- displacement of 4.9 liters (300 cubic inches).

338

n

3

3

Page 353 of 407

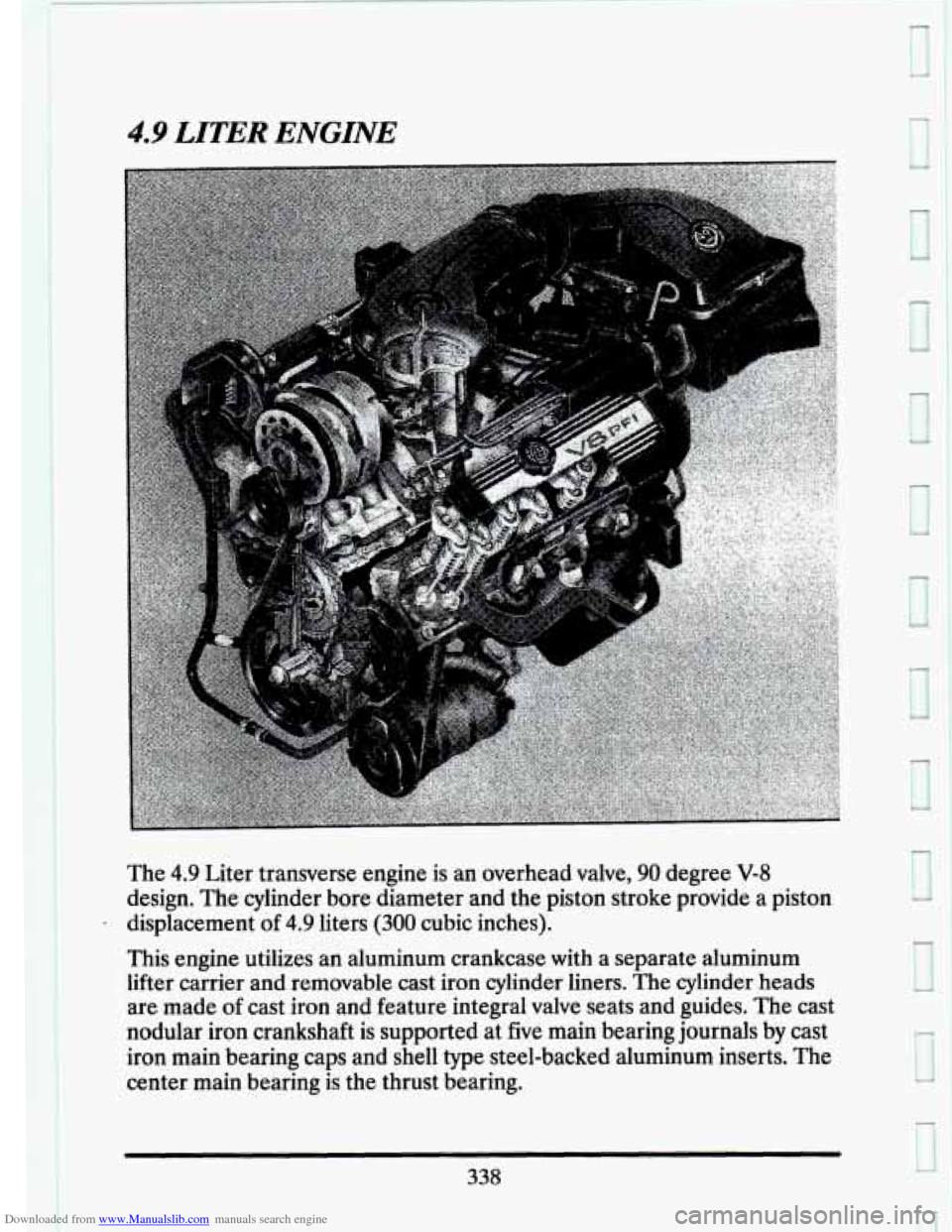

Downloaded from www.Manualslib.com manuals search engine The cast aluminum pistons use two compression rings and one oil control

ring. The pistons are tin plated to provide a non-scuffing surface when

the engine is new.

A steel camshaft is supported by five steel backed babbit bearings. It is

driven

by the crankshaft through a chain at the front of the engine. The

drive gear

is keyed to the crankshaft and the driven sprocket is bolted to

the camshaft. Both the crankshaft gear and camshaft sprocket have

locating marks

to provide the correct valve timing and timing chain

installation. The valve lifters are roller hydraulic type and are positioned

in the aluminum lifter carrier.

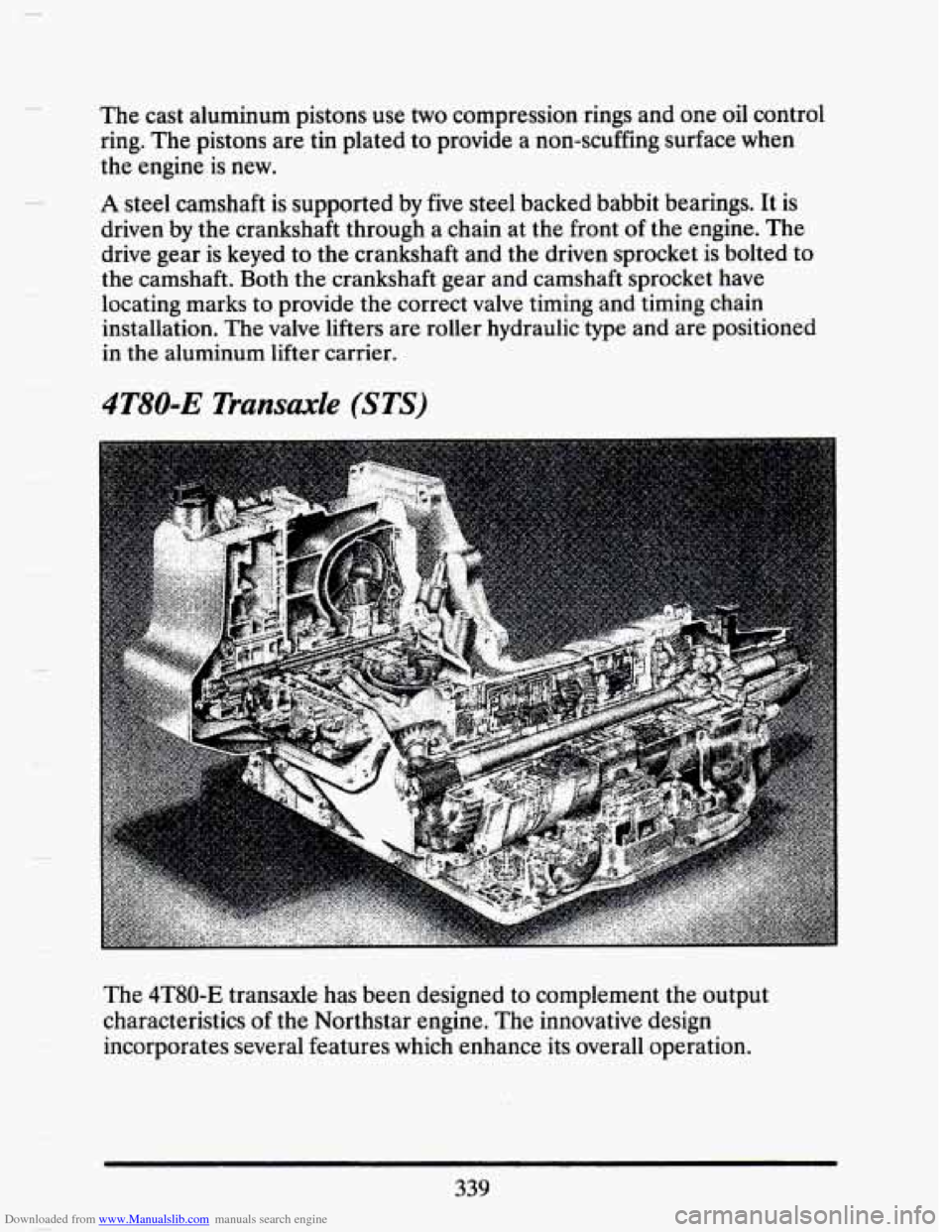

4T80-E Transaxle (STS)

The 4T80-E transaxle has been designed to complement the output

characteristics of the Northstar engine. The innovative design

incorporates several features which enhance its overall operation.

339

Page 354 of 407

Downloaded from www.Manualslib.com manuals search engine This transaxle is the first of a new generation of “SMART” transmissions.

The computer which controls the electronic shift solenoids adapts to

changing environments while you drive. This provides consistent high

quality shifts under all conditions. Communication between the engine

and transaxle through this computer controls engine output during

activation

of torque management or traction control. Smooth shifting is

ensured by design. Hydraulic accumulators control shift pressures and all

shifts are made to free wheeling elements.

The 4T80E uses a

dry sump lubrication system with a scavenger pump.

This unique feature enables the transaxlc to maintain itdcqlriltt!

pressurized oil supply during all mancl~vcr\.

340

Page 355 of 407

Downloaded from www.Manualslib.com manuals search engine The Hydra-matic 4T60-E 4-speed overdrive, electronic transaxle consists

primarily of a five element torque converter;

two planetary gear sets,

various clutches, final drive assembly, differential assembly, an\

d a control

valve body.

The torque converter houses a pump, turbine, pressure plate which is

splined to the turbine, and a stator assembly, serving as a fluid coupling, it

smoothly transmits power

from the engine to the transaxle. It also

hydraulically provides additional torque

when required. When applied,

the pressure plate provides a mechanical direct drive coupling of the

engine to the transaxle.

The

two planetary gear sets provide the four forward gear ratios and

reverse. Changing of the gear ratios is

fully automatic and is

accomplished through the use

of various electronic and mechanical

requirements. Four multiple disc clutches,

two roller clutches, a sprag

clutch, and three bands provide the friction elements required to obtain

the various ratios with the planetary gear sets.

A hydraulic system (the control valve body), pressurized by a vane type

pump provides the working pressure needed to operate the friction

elements and automatic controls.

341

Page 356 of 407

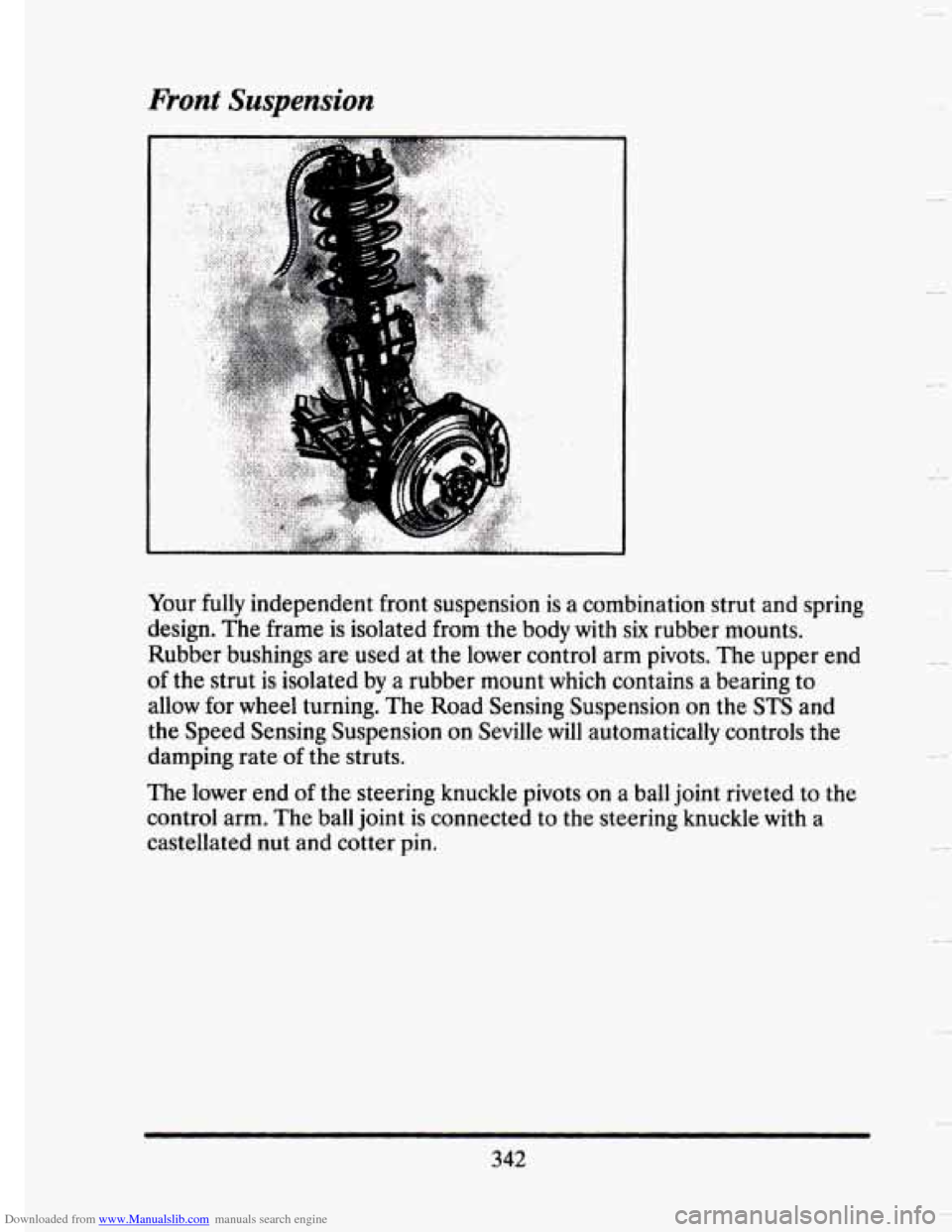

Downloaded from www.Manualslib.com manuals search engine Front Suspension

Your fully independent front suspension is a combination strut and sp~

design. The frame is isolated from the body with six rubber mounts. -ing

Rubber bushings are used at the lower control arm pivots. The upper

end

of the strut is isolated by a rubber mount which contains a bearing to

allow for wheel turning. The Road Sensing Suspension

on the STS and

the Speed Sensing Suspension on Seville

will automatically controls the

damping rate

of the struts.

The lower end

of the steering knuckle pivots on a ball joint riveted to the

control arm. The ball joint is connected to the steering knuckle with a

castellated nut and cotter pin.

342

Page 357 of 407

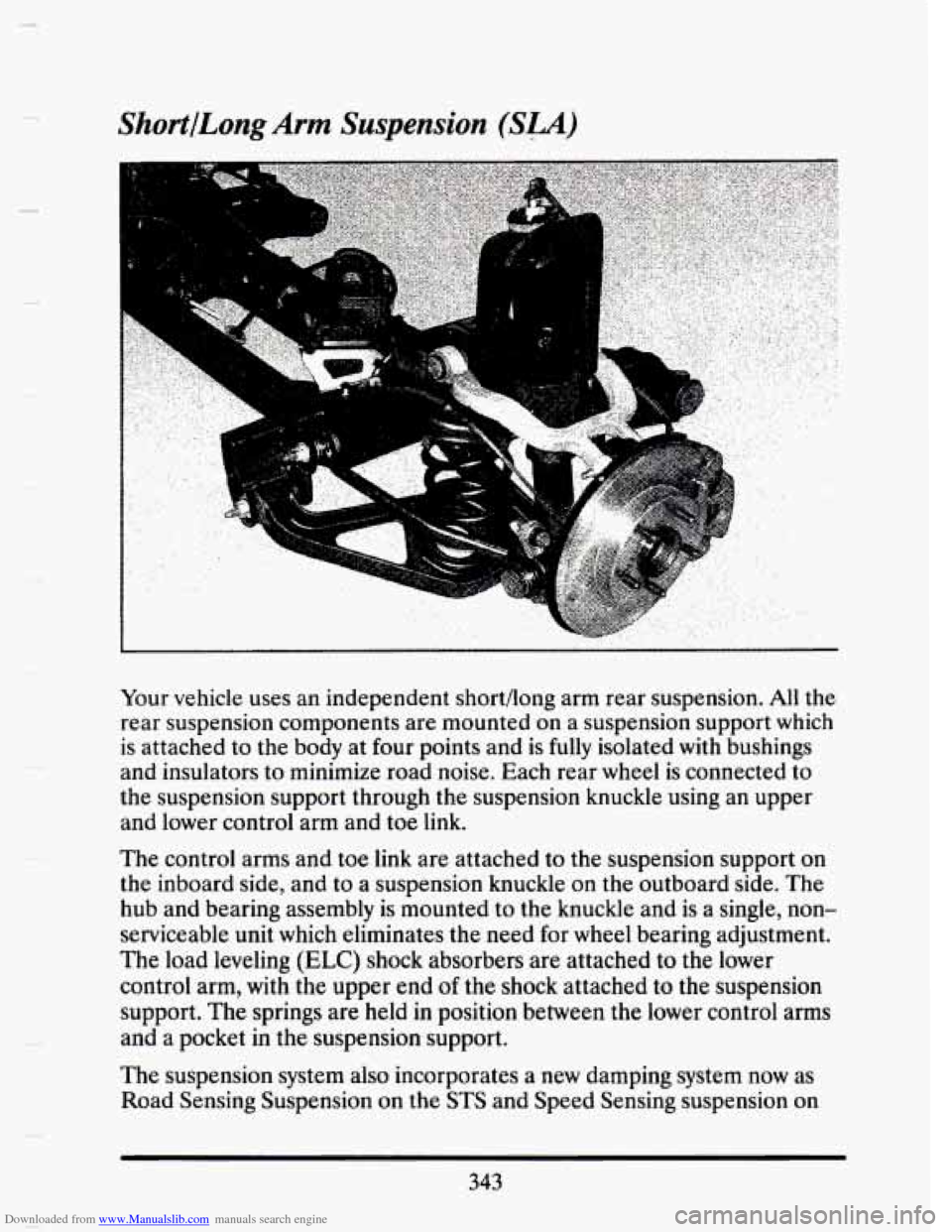

Downloaded from www.Manualslib.com manuals search engine ShortlLong Arm Suspension (SLA)

r

Your vehicle uses an independent shortfiong arm rear suspension. All the

rear suspension components are mounted

on a suspension support which

is attached to the

body at four points and is fully isolated with bushings

and insulators to minimize road noise. Each rear wheel is connected to

the suspension support through the suspension knuckle using an upper

and lower control arm and toe link.

The control arms and toe link are attached to the suspension support on

the inboard side, and to a suspension knuckle on the outboard side. The

hub and bearing assembly is mounted to the knuckle and is a single, non-

serviceable unit which eliminates the need for wheel bearing adjustment.

The load leveling

(ELC) shock absorbers are attached to the lower

control arm, with the upper end

of the shock attached to the suspension

support.

The springs are held in position between the lower control arms

and a pocket in the suspension support.

The suspension system also incorporates

a new damping system now as

Road Sensing Suspension on the

STS and Speed Sensing suspension on

343

Page 358 of 407

Downloaded from www.Manualslib.com manuals search engine the Seville. These systems control the damping forces in the shock

absorbers and struts,

in response to various road and driving conditions.

The systems are capable of

making these damping changes extremely fast.

A computer receives inputs from vertical acceleration sensors, whee\

l to

body position sensors, vehicle speed sensor,

lift and dive signals. This

computer evaluates the inputs from these sensors, to control the damping

of each of the struts and shocks independently to provide varied levels of

suspension control.

The system also has the capability of providing Speed Sensitive Ste\

ering

control. This system changes your steering effort based on your\

vehicle

speed.

Speed Sensitive Steering

This system varies the amount of steering effort proportionate to your

vehicle speed. Steering is easier at

a lower speed for increased

maneuverability and parking ease.

As your vehicle speed increases, the

steering effort is also increased to provide a manual like steering feel for

maximum control and enhanced vehicle stability.

344

.-

A

Page 359 of 407

Downloaded from www.Manualslib.com manuals search engine The power rack and pinion steering system has a rotary spool valve which

directs hydraulic fluid coming from the power steering pump to one side

or the other side

of the rack piston. The integral rack piston is attached to

the rack. The rack piston converts hydraulic pressure to a linear force

which moves the rack left or right. The force is then transmitted through

the inner and outer tie rods to the steering knuckles, which turn the

wheels

If hydraulic assist

is not available, manual control is maintained. However

under these conditions more steering effort is required.

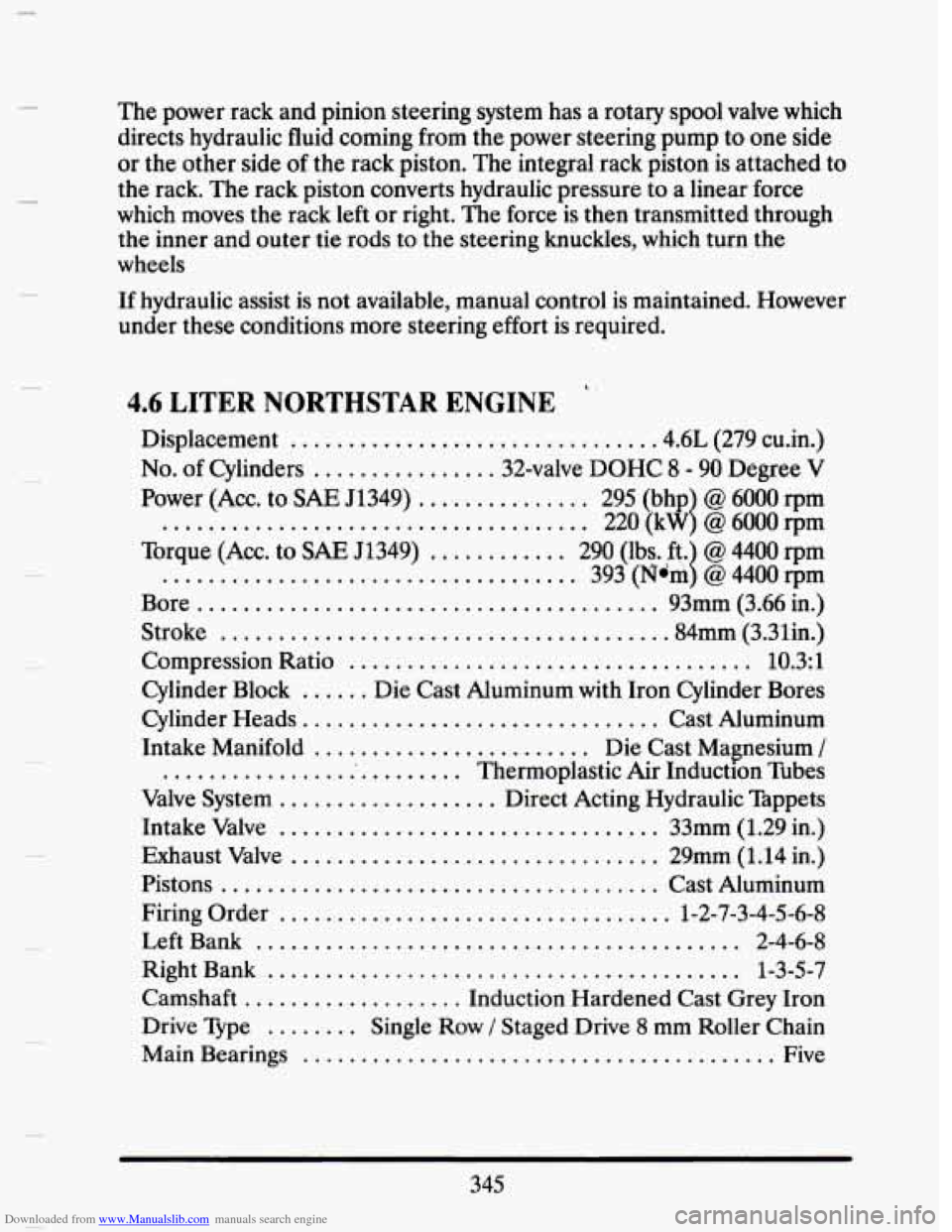

4.6 LITER NORTHSTAR ENGINE

Displacement ............................... .4.6L (279 cu.in.)

No. of Cylinders ................ 32-valve DOHC 8 - 90 Degree V

Power (Acc.

to SAE 51349) ............... 295 (bhp @ 6000 rpm

..................................... 220 (kW @ 6000rpm

Torque (ACC. to

SAE 51349) ............ 290 (lbs. ft. @ 4400 rpm

Bore ........................................ 93mm (3.66 in.)

Stroke

...................................... .84mm (3.31in.)

Compression Ratio

................................... 10.3:l

Cylinder Heads ............................... Cast Aluminum

Intake Manifold

........................ Die Cast Magnesium /

........................... Thermoplastic Air Induction nbes

Valve System

................... Direct Acting Hydraulic Tappets

Intake Valve

................................. 33mm (1.29 in.)

Exhaust Valve

................................ 29mm (1.14 in.)

Pistons

...................................... Cast Aluminum

Firing Order

.................................. 1-2-7-3-4-5-6-8

Left Bank

.......................................... 2-4-6-8

Right Bank

......................................... 1-3-5-7

Camshaft

................... Induction Hardened Cast Grey Iron

Drive Type

........ Single Row / Staged Drive 8 mm Roller Chain

Main Bearings

......................................... Five

1

1 .................................... 393 (Ndm @ 4400 rpm

Cylinder Block

...... Die Cast Aluminum with Iron Cylinder Bores

345

Page 360 of 407

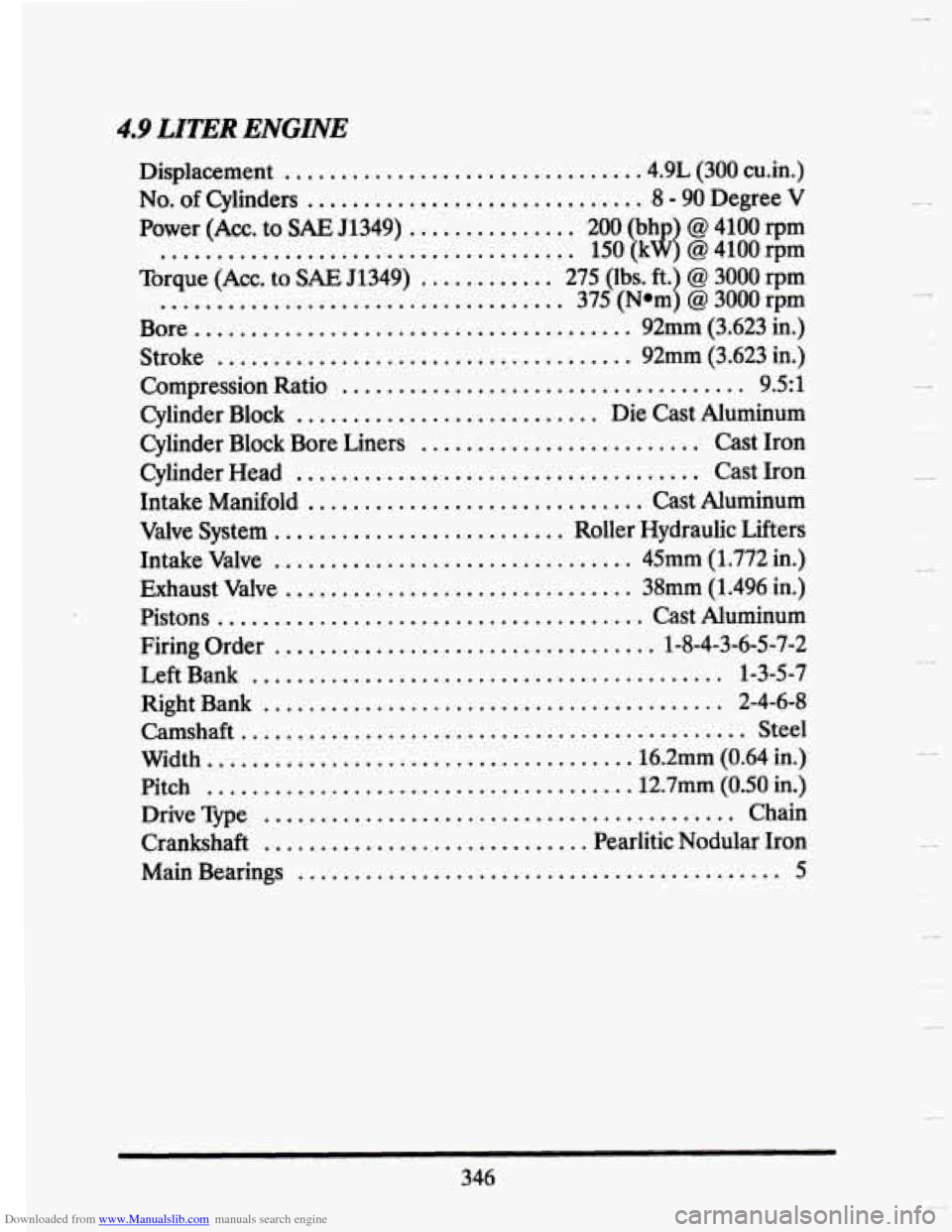

Downloaded from www.Manualslib.com manuals search engine 4.9 LITER ENGINE

Displacement ............................... .4.9L (300 cuin.)

No.

of Cylinders .............................. 8 - 90 Degree V

Power (Acc. to SAE 51349) ............... 200 (bhp @ 4100 rpm

Torque (ACC.

to SAE 51349) ............ 275 (lbs. ft. @ 3000 rpm

Bore

....................................... 92mm (3.623 in.)

Stroke

..................................... 92mm (3.623 in.)

Compression Ratio

.................................... 9.5: 1

Cyiinder Block ........................... Die Cast Aluminum

Cylinder Block Bore Liners

......................... Cast Iron

Cylinder Head

.................................... Cast Iron

Intake Manifold

.............................. Cast Aluminum

Valve System

.......................... Roller Hydraulic Lifters

Intake Valve

................................ 45mm (1.772 in.)

Exhaust Valve

............................... 38mm (1.496 in.)

Pistons

...................................... Cast Aluminum

Firing Order

.................................. 1-8-4-3-6-5-7-2

Left Bank

.......................................... 1-3-5-7

Right Bank

......................................... 2-4-6-8

Camsha

............................................... Steel

Width.

..................................... 16.2mm (0.64 in.)

Pitch

..................................... .12.7mm (0.50 in.)

Drive Vpe

.......................................... Chain

Crankshaft

............................. Pearlitic Nodular Iron

..................................... 150 (kW @ 4100 rpm

.................................... 375 (Nom @ 3000 rpm

1

1

I

Main Bearings ........................................... 5

346