CHERY TIGGO 2009 Service Repair Manual

Manufacturer: CHERY, Model Year: 2009, Model line: TIGGO, Model: CHERY TIGGO 2009Pages: 1903, PDF Size: 33.38 MB

Page 1231 of 1903

Downloaded from www.Manualslib.com manuals search engine NOTE :

The following special tools are required to perform the repair procedure:

•MB-998801 - Bearing Remover

• MB-998812 - Installer Cap

• MB-998814 - Installer Connector (200 mm)

• MB-998813 - Installer (100)

• MB-998818 - Installer Connector (38 mm)

• MB-998819 - Installer Connector (40 mm)

• MB-998822 - Installer Connector (46 mm)

• MB-998825 - Installer Connector (52 mm)

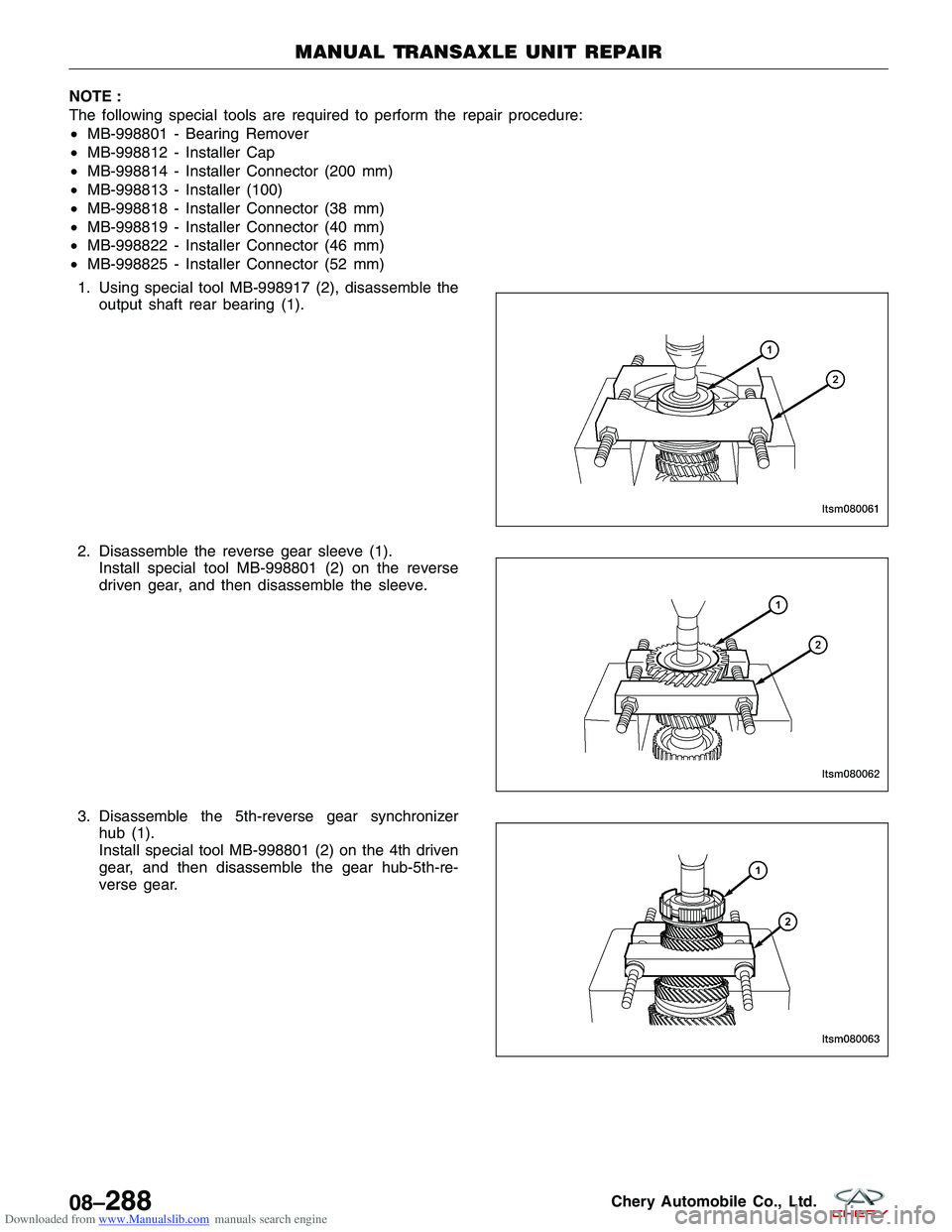

1. Using special tool MB-998917 (2), disassemble the output shaft rear bearing (1).

2. Disassemble the reverse gear sleeve (1). Install special tool MB-998801 (2) on the reverse

driven gear, and then disassemble the sleeve.

3. Disassemble the 5th-reverse gear synchronizer hub (1).

Install special tool MB-998801 (2) on the 4th driven

gear, and then disassemble the gear hub-5th-re-

verse gear.

MANUAL TRANSAXLE UNIT REPAIR

LTSM080061

LTSM080062

LTSM080063

08–288Chery Automobile Co., Ltd.

Page 1232 of 1903

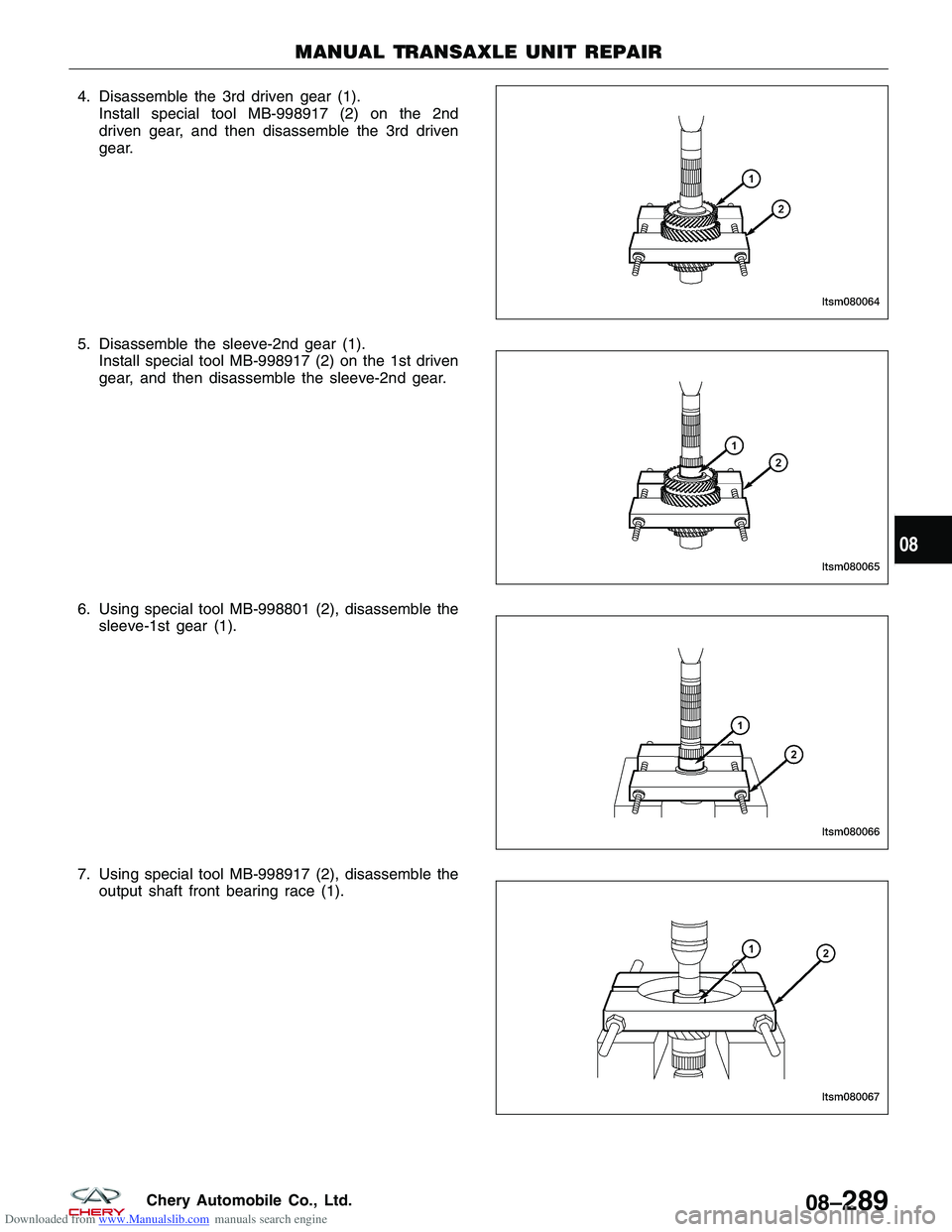

Downloaded from www.Manualslib.com manuals search engine 4. Disassemble the 3rd driven gear (1).Install special tool MB-998917 (2) on the 2nd

driven gear, and then disassemble the 3rd driven

gear.

5. Disassemble the sleeve-2nd gear (1). Install special tool MB-998917 (2) on the 1st driven

gear, and then disassemble the sleeve-2nd gear.

6. Using special tool MB-998801 (2), disassemble the sleeve-1st gear (1).

7. Using special tool MB-998917 (2), disassemble the output shaft front bearing race (1).

MANUAL TRANSAXLE UNIT REPAIR

LTSM080064

LTSM080065

LTSM080066

LTSM080067

08

08–289Chery Automobile Co., Ltd.

Page 1233 of 1903

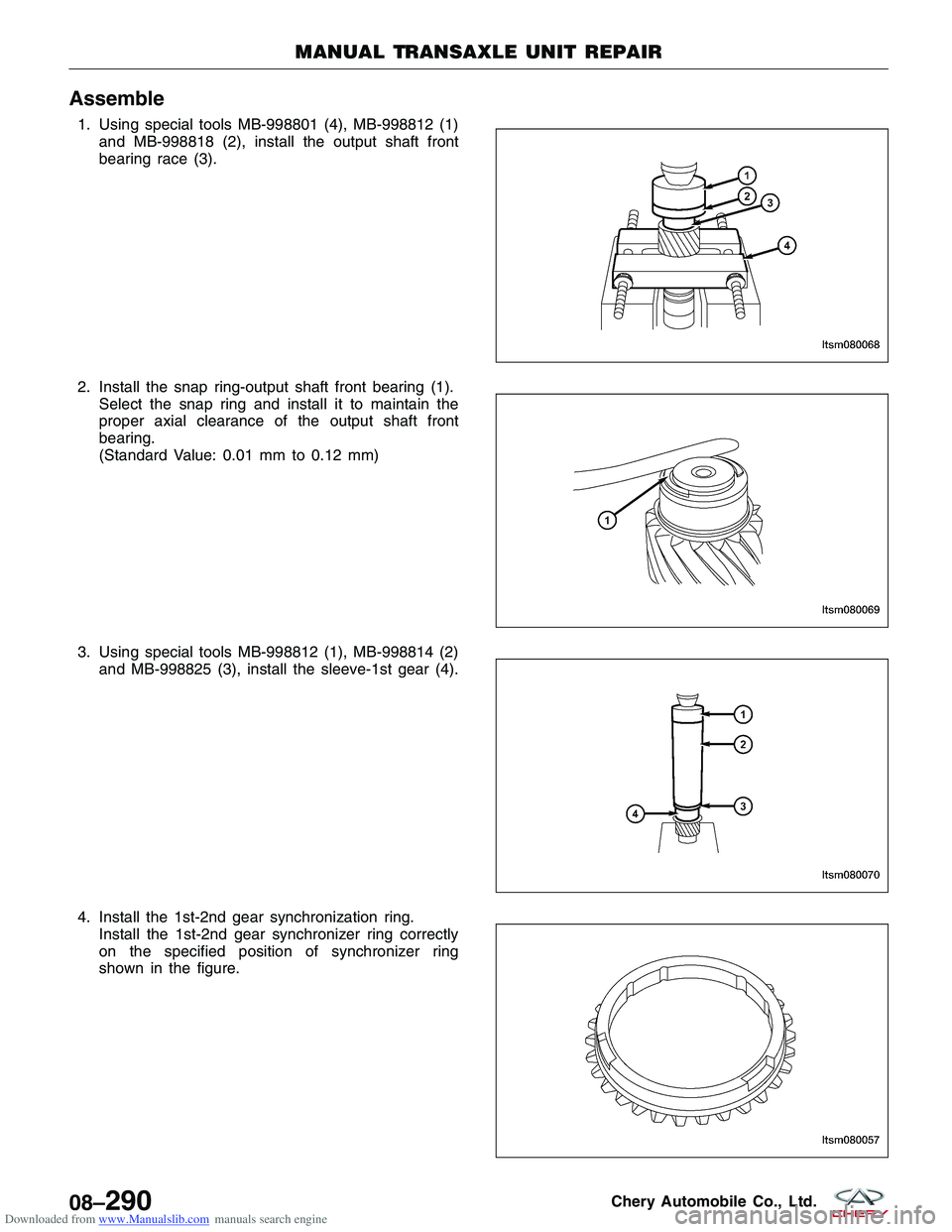

Downloaded from www.Manualslib.com manuals search engine Assemble

1. Using special tools MB-998801 (4), MB-998812 (1)and MB-998818 (2), install the output shaft front

bearing race (3).

2. Install the snap ring-output shaft front bearing (1). Select the snap ring and install it to maintain the

proper axial clearance of the output shaft front

bearing.

(Standard Value: 0.01 mm to 0.12 mm)

3. Using special tools MB-998812 (1), MB-998814 (2) and MB-998825 (3), install the sleeve-1st gear (4).

4. Install the 1st-2nd gear synchronization ring. Install the 1st-2nd gear synchronizer ring correctly

on the specified position of synchronizer ring

shown in the figure.

MANUAL TRANSAXLE UNIT REPAIR

LTSM080068

LTSM080069

LTSM080070

LTSM080057

08–290Chery Automobile Co., Ltd.

Page 1234 of 1903

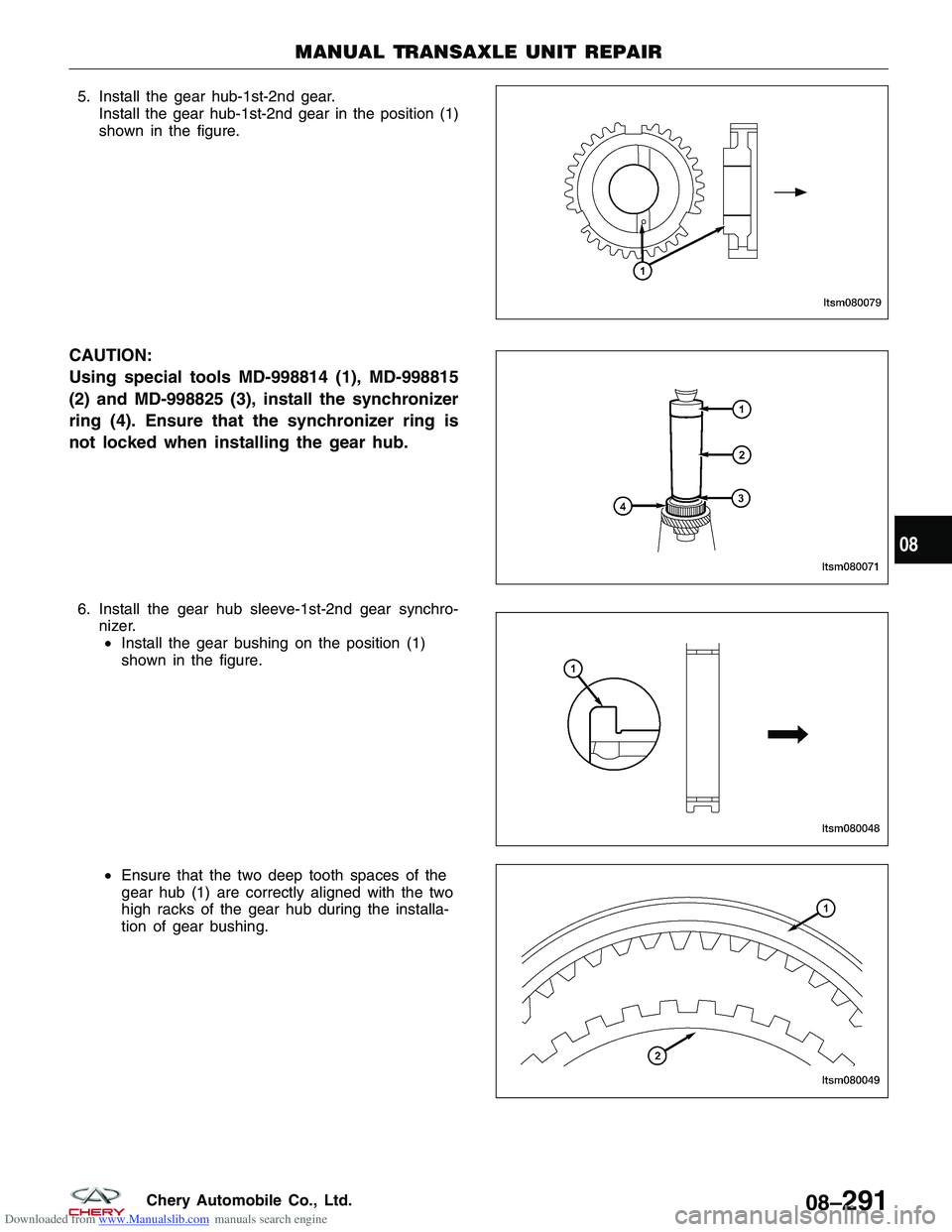

Downloaded from www.Manualslib.com manuals search engine 5. Install the gear hub-1st-2nd gear.Install the gear hub-1st-2nd gear in the position (1)

shown in the figure.

CAUTION:

Using special tools MD-998814 (1), MD-998815

(2) and MD-998825 (3), install the synchronizer

ring (4). Ensure that the synchronizer ring is

not locked when installing the gear hub.

6. Install the gear hub sleeve-1st-2nd gear synchro-nizer.• Install the gear bushing on the position (1)

shown in the figure.

• Ensure that the two deep tooth spaces of the

gear hub (1) are correctly aligned with the two

high racks of the gear hub during the installa-

tion of gear bushing.

MANUAL TRANSAXLE UNIT REPAIR

LTSM080079

LTSM080071

LTSM080048

LTSM080049

08

08–291Chery Automobile Co., Ltd.

Page 1235 of 1903

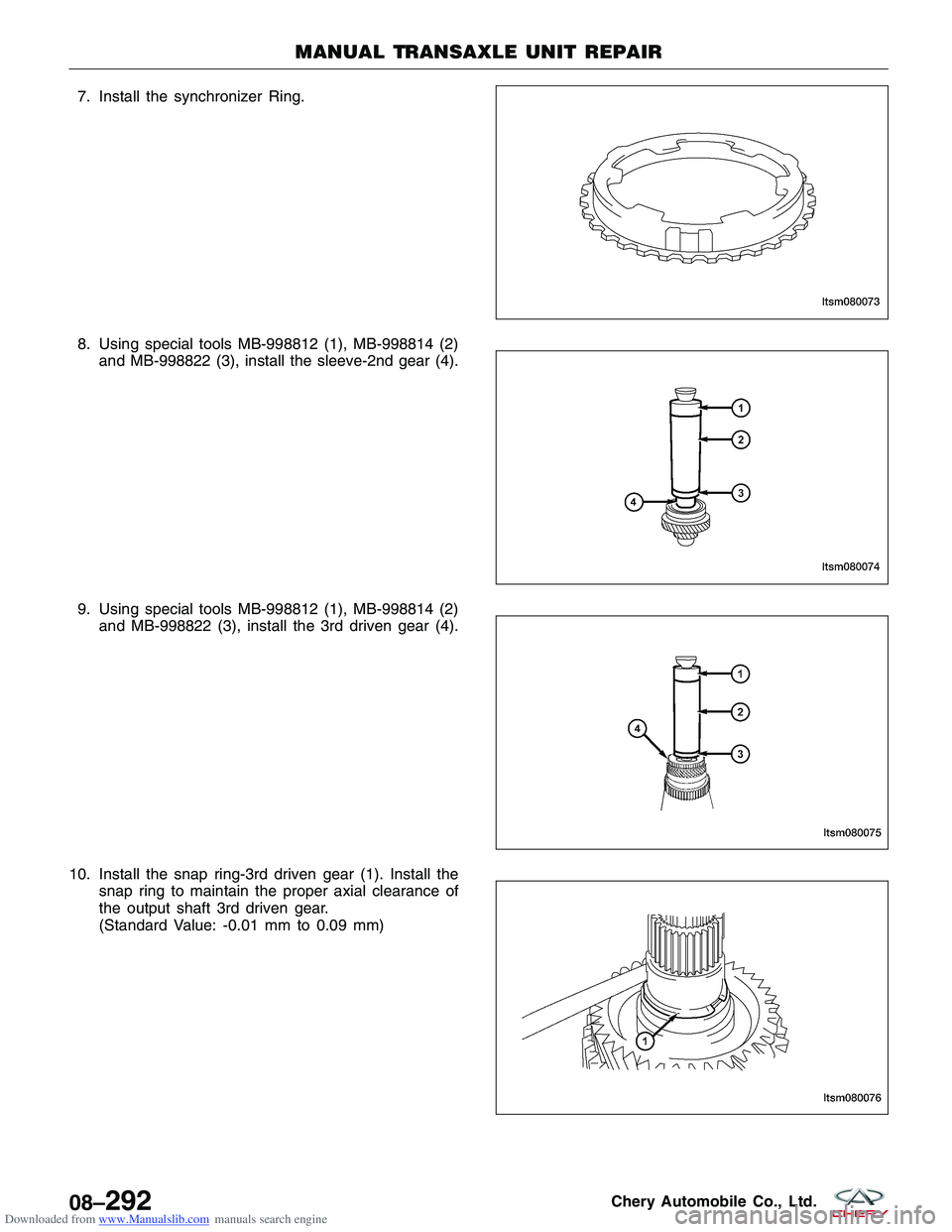

Downloaded from www.Manualslib.com manuals search engine 7. Install the synchronizer Ring.

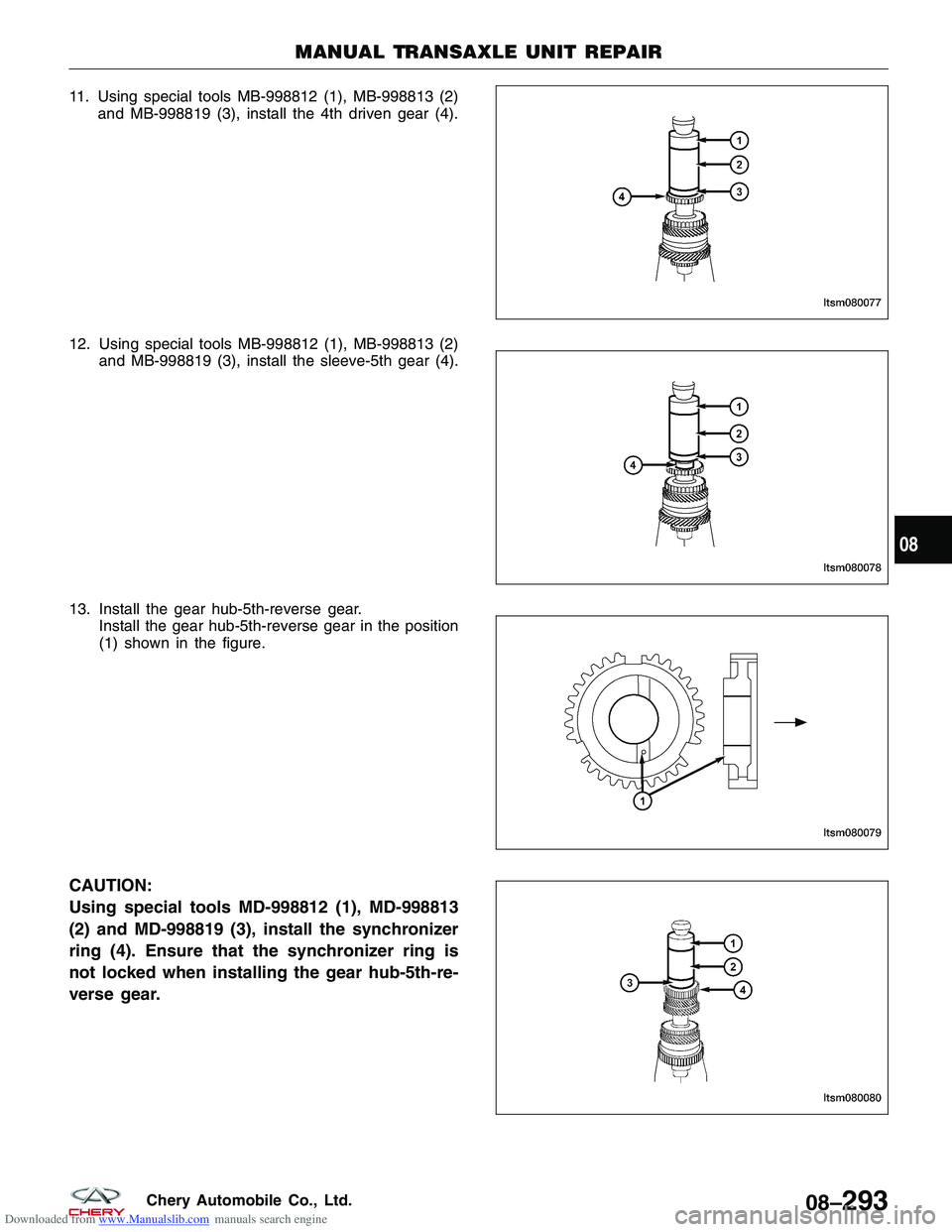

8. Using special tools MB-998812 (1), MB-998814 (2)and MB-998822 (3), install the sleeve-2nd gear (4).

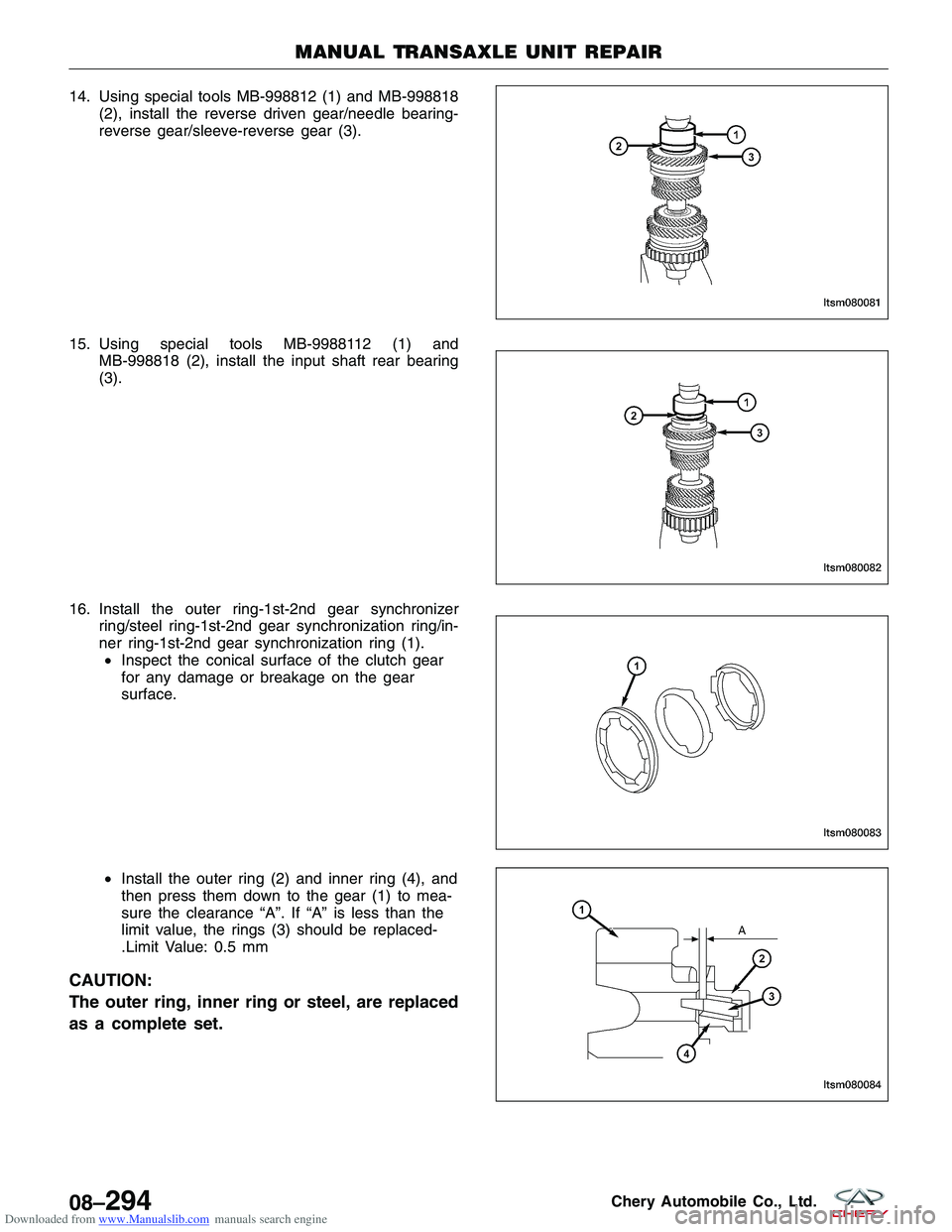

9. Using special tools MB-998812 (1), MB-998814 (2) and MB-998822 (3), install the 3rd driven gear (4).

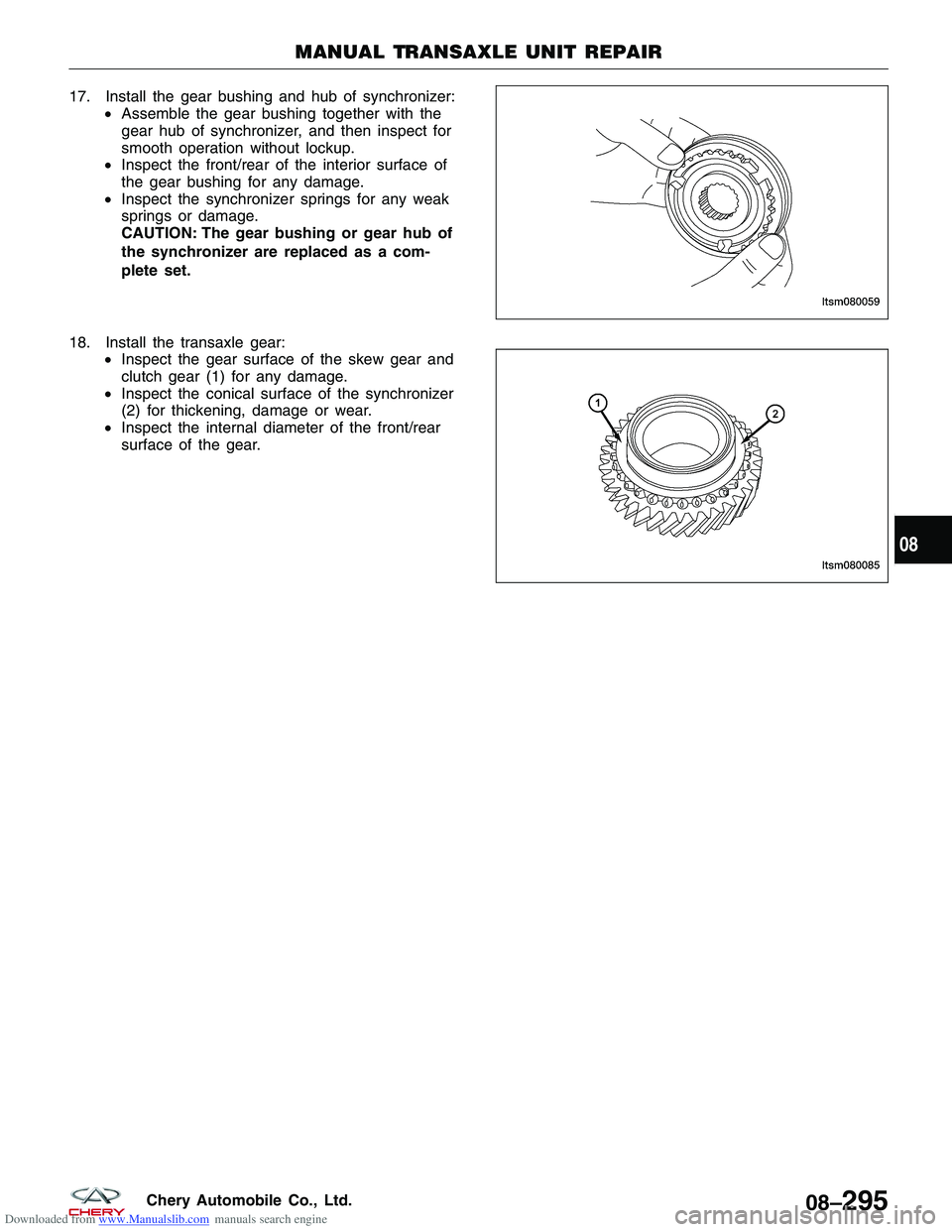

10. Install the snap ring-3rd driven gear (1). Install the snap ring to maintain the proper axial clearance of

the output shaft 3rd driven gear.

(Standard Value: -0.01 mm to 0.09 mm)

MANUAL TRANSAXLE UNIT REPAIR

LTSM080073

LTSM080074

LTSM080075

LTSM080076

08–292Chery Automobile Co., Ltd.

Page 1236 of 1903

Downloaded from www.Manualslib.com manuals search engine 11. Using special tools MB-998812 (1), MB-998813 (2)and MB-998819 (3), install the 4th driven gear (4).

12. Using special tools MB-998812 (1), MB-998813 (2) and MB-998819 (3), install the sleeve-5th gear (4).

13. Install the gear hub-5th-reverse gear. Install the gear hub-5th-reverse gear in the position

(1) shown in the figure.

CAUTION:

Using special tools MD-998812 (1), MD-998813

(2) and MD-998819 (3), install the synchronizer

ring (4). Ensure that the synchronizer ring is

not locked when installing the gear hub-5th-re-

verse gear.

MANUAL TRANSAXLE UNIT REPAIR

LTSM080077

LTSM080078

LTSM080079

LTSM080080

08

08–293Chery Automobile Co., Ltd.

Page 1237 of 1903

Downloaded from www.Manualslib.com manuals search engine 14. Using special tools MB-998812 (1) and MB-998818(2), install the reverse driven gear/needle bearing-

reverse gear/sleeve-reverse gear (3).

15. Using special tools MB-9988112 (1) and MB-998818 (2), install the input shaft rear bearing

(3).

16. Install the outer ring-1st-2nd gear synchronizer ring/steel ring-1st-2nd gear synchronization ring/in-

ner ring-1st-2nd gear synchronization ring (1).• Inspect the conical surface of the clutch gear

for any damage or breakage on the gear

surface.

• Install the outer ring (2) and inner ring (4), and

then press them down to the gear (1) to mea-

sure the clearance “A”. If “A” is less than the

limit value, the rings (3) should be replaced-

.Limit Value: 0.5 mm

CAUTION:

The outer ring, inner ring or steel, are replaced

as a complete set.

MANUAL TRANSAXLE UNIT REPAIR

LTSM080081

LTSM080082

LTSM080083

LTSM080084

08–294Chery Automobile Co., Ltd.

Page 1238 of 1903

Downloaded from www.Manualslib.com manuals search engine 17. Install the gear bushing and hub of synchronizer:•Assemble the gear bushing together with the

gear hub of synchronizer, and then inspect for

smooth operation without lockup.

• Inspect the front/rear of the interior surface of

the gear bushing for any damage.

• Inspect the synchronizer springs for any weak

springs or damage.

CAUTION: The gear bushing or gear hub of

the synchronizer are replaced as a com-

plete set.

18. Install the transaxle gear: •Inspect the gear surface of the skew gear and

clutch gear (1) for any damage.

• Inspect the conical surface of the synchronizer

(2) for thickening, damage or wear.

• Inspect the internal diameter of the front/rear

surface of the gear.

MANUAL TRANSAXLE UNIT REPAIR

LTSM080059

LTSM080085

08

08–295Chery Automobile Co., Ltd.

Page 1239 of 1903

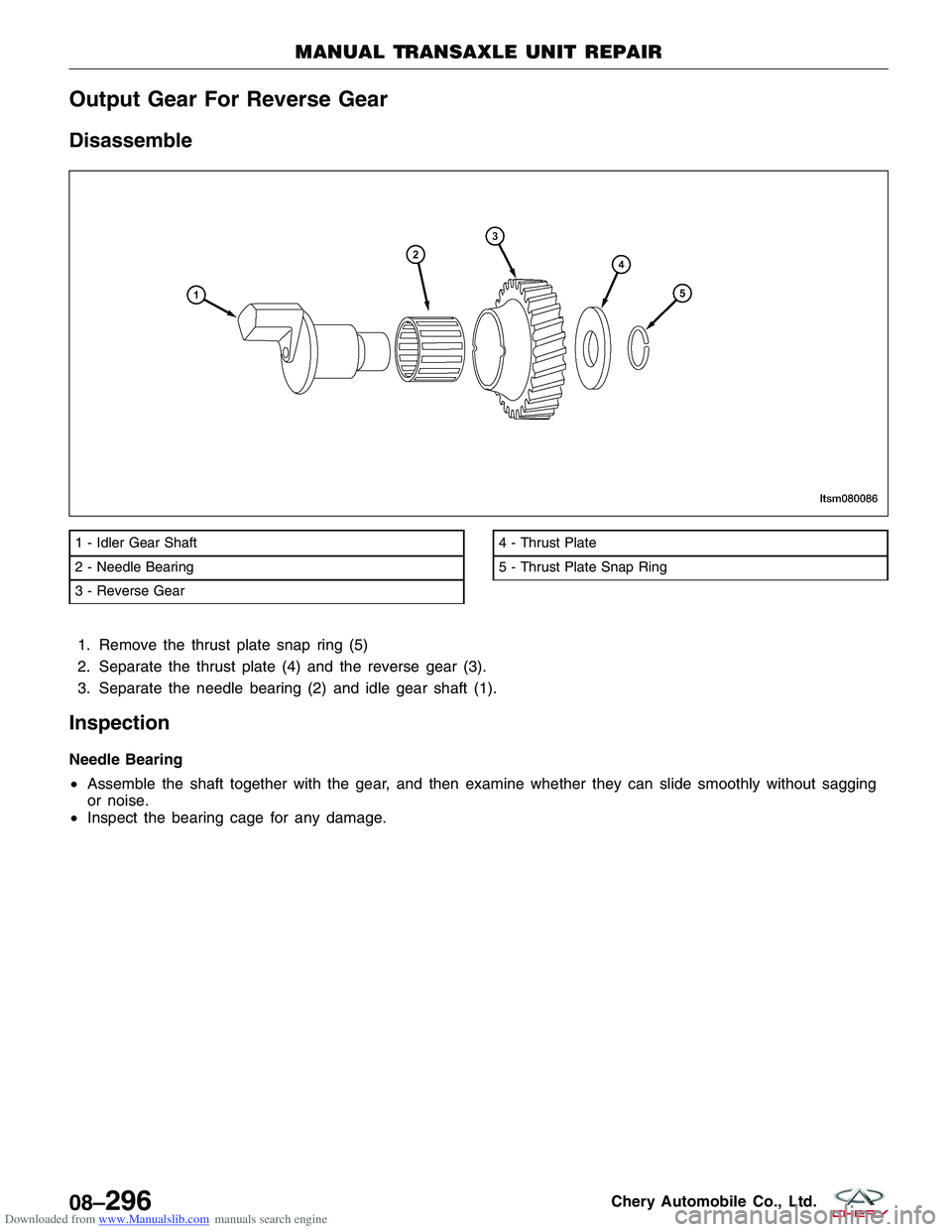

Downloaded from www.Manualslib.com manuals search engine Output Gear For Reverse Gear

Disassemble

1. Remove the thrust plate snap ring (5)

2. Separate the thrust plate (4) and the reverse gear (3).

3. Separate the needle bearing (2) and idle gear shaft (1).

Inspection

Needle Bearing

•Assemble the shaft together with the gear, and then examine whether they can slide smoothly without sagging

or noise.

• Inspect the bearing cage for any damage.

1 - Idler Gear Shaft

2 - Needle Bearing

3 - Reverse Gear4 - Thrust Plate

5 - Thrust Plate Snap Ring

MANUAL TRANSAXLE UNIT REPAIR

LTSM080086

08–296Chery Automobile Co., Ltd.

Page 1240 of 1903

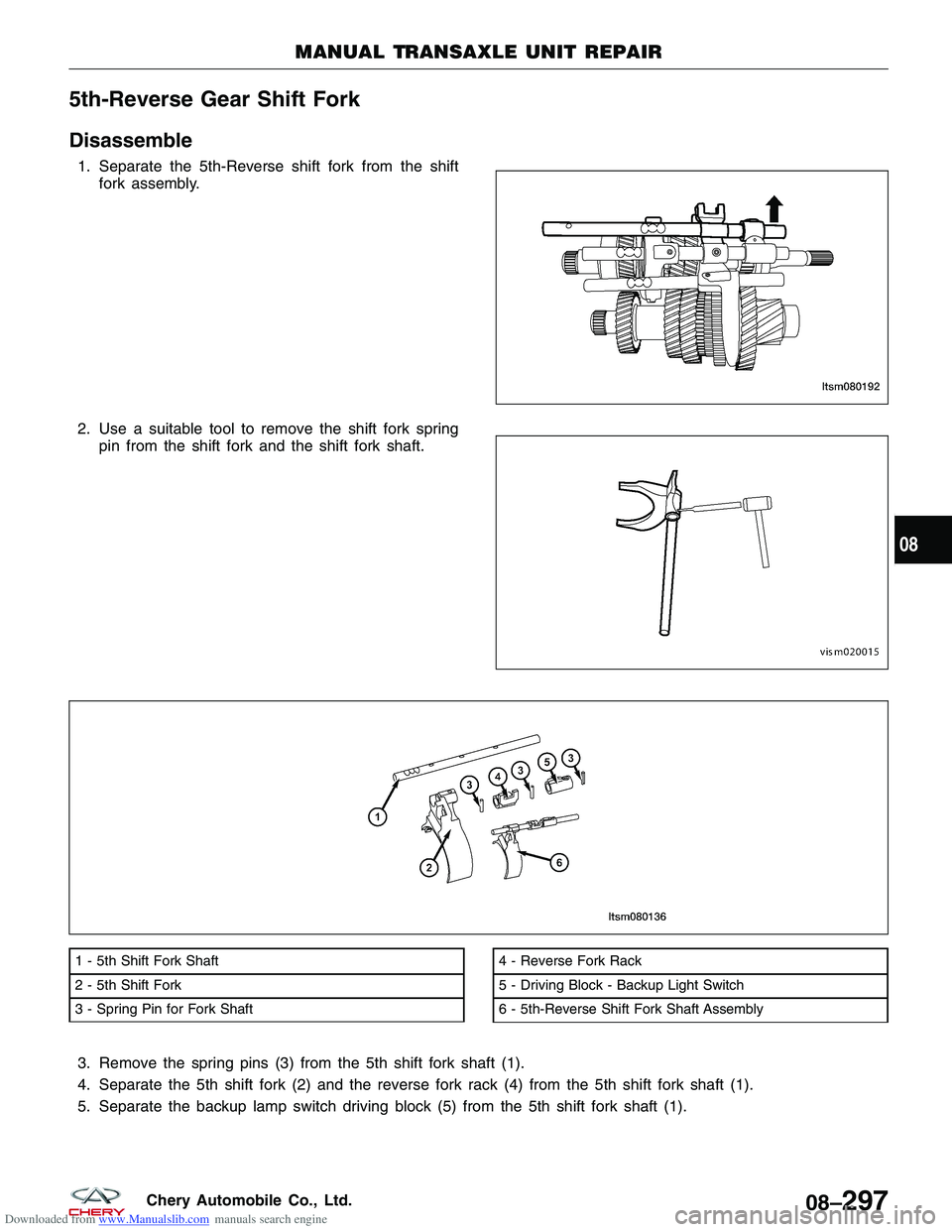

Downloaded from www.Manualslib.com manuals search engine 5th-Reverse Gear Shift Fork

Disassemble

1. Separate the 5th-Reverse shift fork from the shiftfork assembly.

2. Use a suitable tool to remove the shift fork spring pin from the shift fork and the shift fork shaft.

3. Remove the spring pins (3) from the 5th shift fork shaft (1).

4. Separate the 5th shift fork (2) and the reverse fork rack (4) from the 5th shift fork shaft (1).

5. Separate the backup lamp switch driving block (5) from the 5th shift fork shaft (1).

1 - 5th Shift Fork Shaft

2 - 5th Shift Fork

3 - Spring Pin for Fork Shaft4 - Reverse Fork Rack

5 - Driving Block - Backup Light Switch

6 - 5th-Reverse Shift Fork Shaft Assembly

MANUAL TRANSAXLE UNIT REPAIR

LTSM080192 VISM020015

LTSM080136

08

08–297Chery Automobile Co., Ltd.