CHERY TIGGO 2009 Service Repair Manual

Manufacturer: CHERY, Model Year: 2009, Model line: TIGGO, Model: CHERY TIGGO 2009Pages: 1903, PDF Size: 33.38 MB

Page 271 of 1903

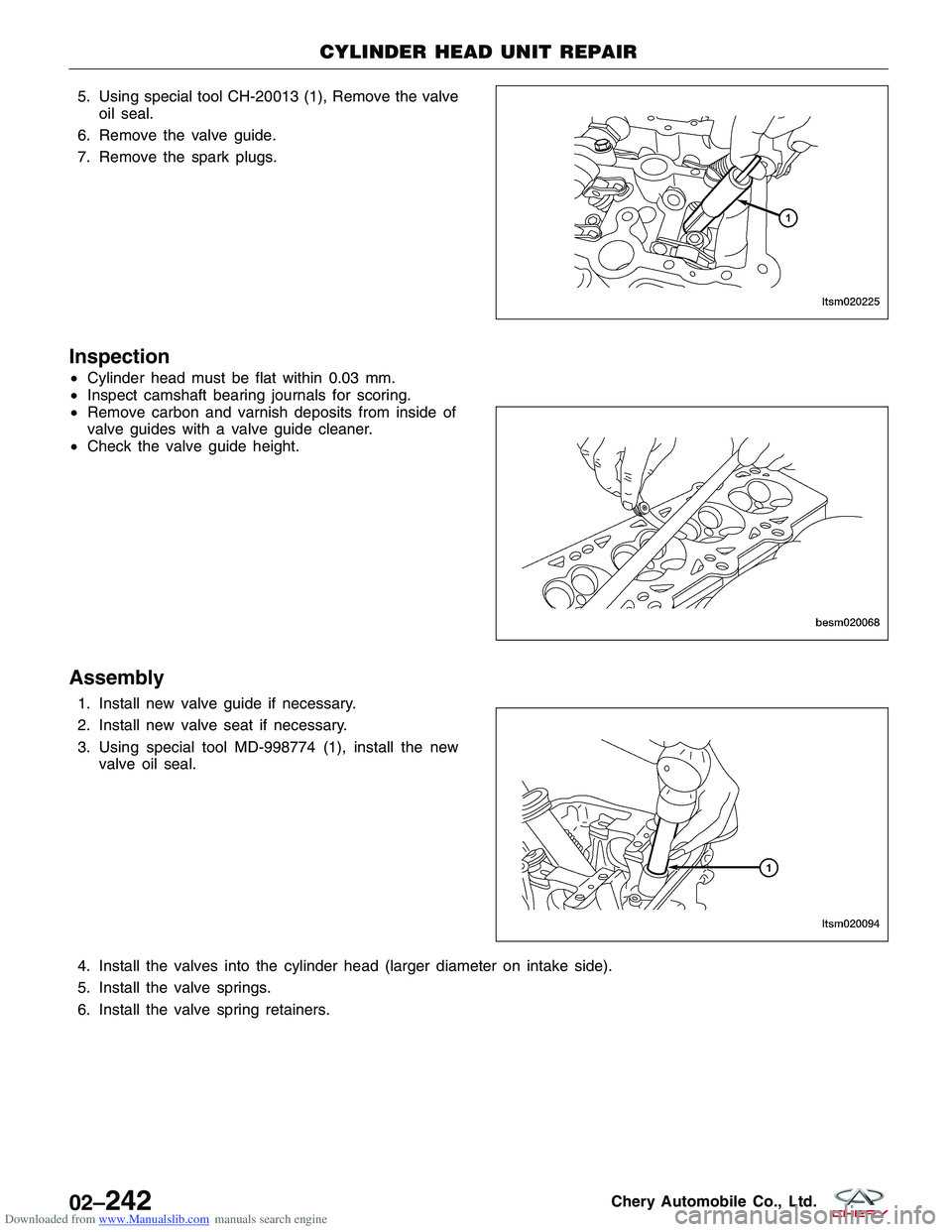

Downloaded from www.Manualslib.com manuals search engine 5. Using special tool CH-20013 (1), Remove the valveoil seal.

6. Remove the valve guide.

7. Remove the spark plugs.

Inspection

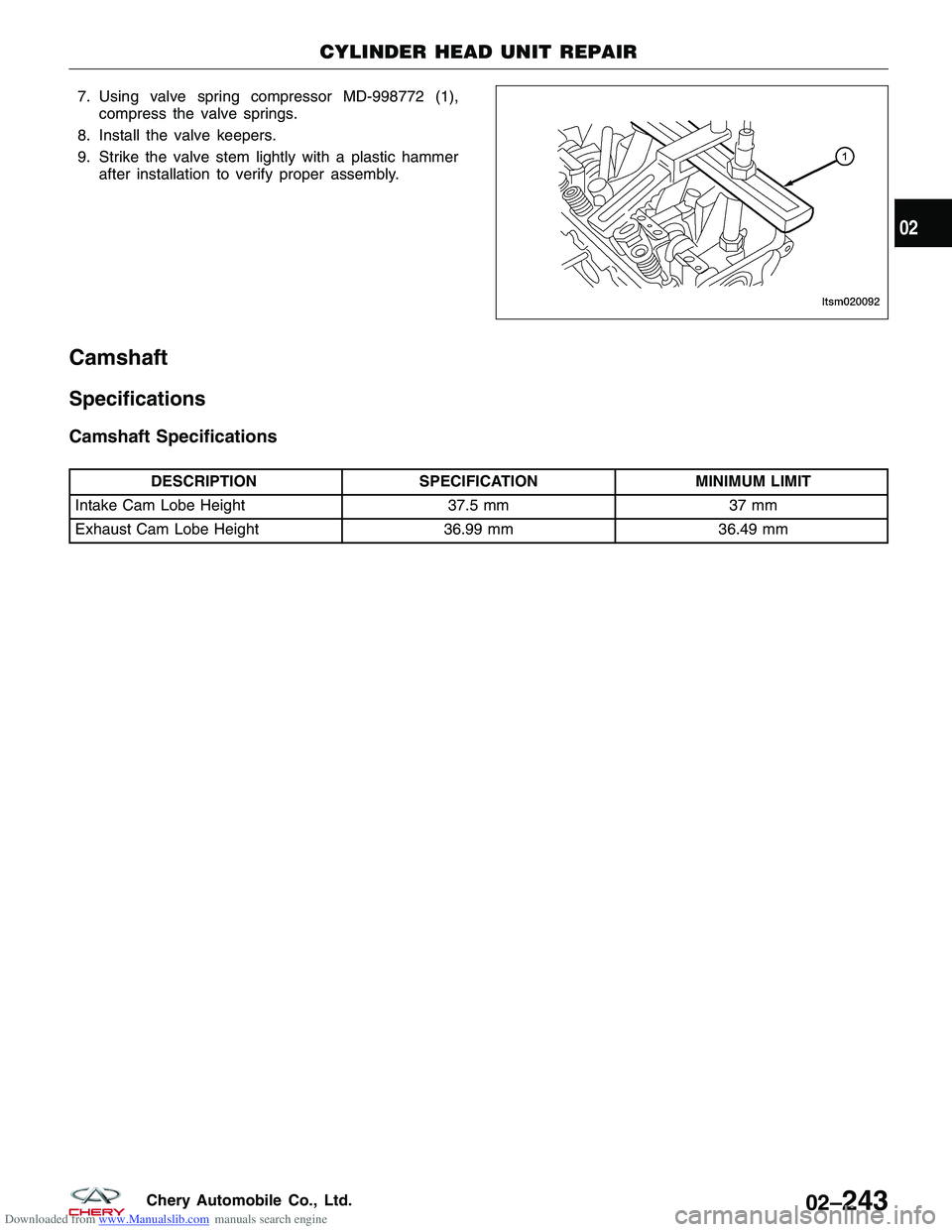

• Cylinder head must be flat within 0.03 mm.

• Inspect camshaft bearing journals for scoring.

• Remove carbon and varnish deposits from inside of

valve guides with a valve guide cleaner.

• Check the valve guide height.

Assembly

1. Install new valve guide if necessary.

2. Install new valve seat if necessary.

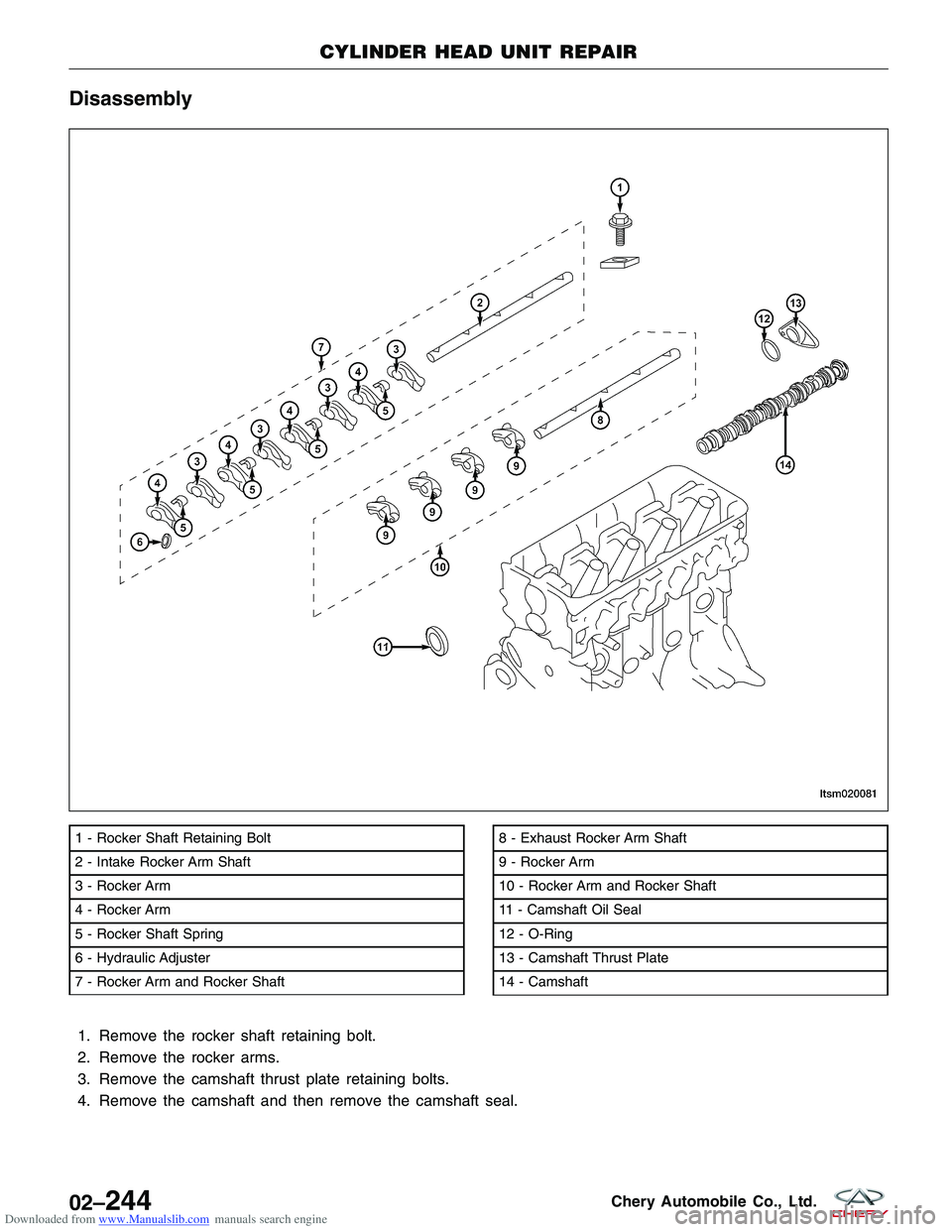

3. Using special tool MD-998774 (1), install the new

valve oil seal.

4. Install the valves into the cylinder head (larger diameter on intake side).

5. Install the valve springs.

6. Install the valve spring retainers.

CYLINDER HEAD UNIT REPAIR

LTSM020225

BESM020068 LTSM020094

02–242Chery Automobile Co., Ltd.

Page 272 of 1903

Downloaded from www.Manualslib.com manuals search engine 7. Using valve spring compressor MD-998772 (1),compress the valve springs.

8. Install the valve keepers.

9. Strike the valve stem lightly with a plastic hammer after installation to verify proper assembly.

Camshaft

Specifications

Camshaft Specifications

DESCRIPTION SPECIFICATION MINIMUM LIMIT

Intake Cam Lobe Height 37.5 mm37 mm

Exhaust Cam Lobe Height 36.99 mm36.49 mm

CYLINDER HEAD UNIT REPAIR

LTSM020092

02

02–243Chery Automobile Co., Ltd.

Page 273 of 1903

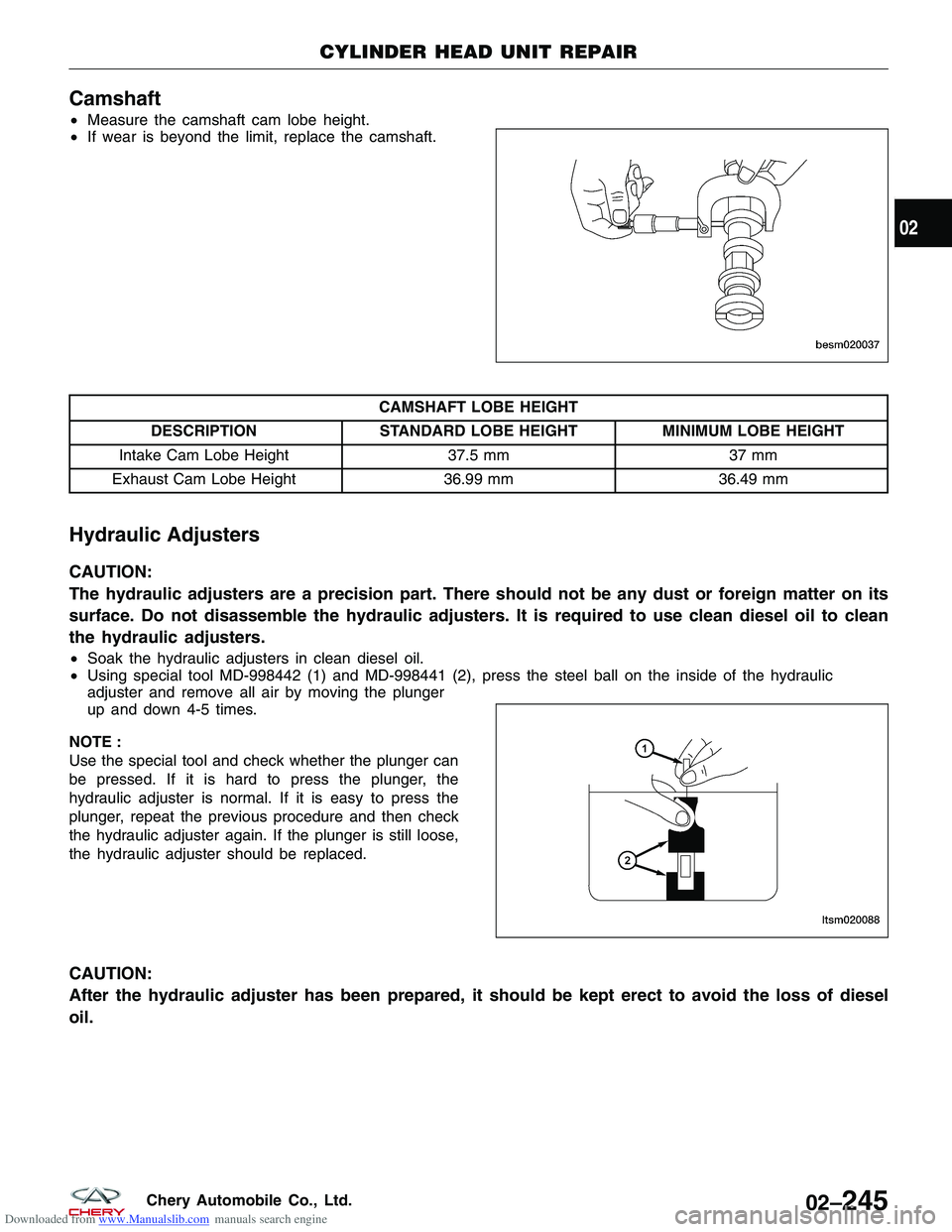

Downloaded from www.Manualslib.com manuals search engine Disassembly

1. Remove the rocker shaft retaining bolt.

2. Remove the rocker arms.

3. Remove the camshaft thrust plate retaining bolts.

4. Remove the camshaft and then remove the camshaft seal.

1 - Rocker Shaft Retaining Bolt

2 - Intake Rocker Arm Shaft

3 - Rocker Arm

4 - Rocker Arm

5 - Rocker Shaft Spring

6 - Hydraulic Adjuster

7 - Rocker Arm and Rocker Shaft8 - Exhaust Rocker Arm Shaft

9 - Rocker Arm

10 - Rocker Arm and Rocker Shaft

11 - Camshaft Oil Seal

12 - O-Ring

13 - Camshaft Thrust Plate

14 - Camshaft

CYLINDER HEAD UNIT REPAIR

LTSM020081

02–244Chery Automobile Co., Ltd.

Page 274 of 1903

Downloaded from www.Manualslib.com manuals search engine Camshaft

•Measure the camshaft cam lobe height.

• If wear is beyond the limit, replace the camshaft.

CAMSHAFT LOBE HEIGHT

DESCRIPTION STANDARD LOBE HEIGHT MINIMUM LOBE HEIGHT

Intake Cam Lobe Height 37.5 mm37 mm

Exhaust Cam Lobe Height 36.99 mm36.49 mm

Hydraulic Adjusters

CAUTION:

The hydraulic adjusters are a precision part. There should not be any dust or foreign matter on its

surface. Do not disassemble the hydraulic adjusters. It is required to use clean diesel oil to clean

the hydraulic adjusters.

•Soak the hydraulic adjusters in clean diesel oil.

• Using special tool MD-998442 (1) and MD-998441 (2), press the steel ball on the inside of the hydraulic

adjuster and remove all air by moving the plunger

up and down 4-5 times.

NOTE :

Use the special tool and check whether the plunger can

be pressed. If it is hard to press the plunger, the

hydraulic adjuster is normal. If it is easy to press the

plunger, repeat the previous procedure and then check

the hydraulic adjuster again. If the plunger is still loose,

the hydraulic adjuster should be replaced.

CAUTION:

After the hydraulic adjuster has been prepared, it should be kept erect to avoid the loss of diesel

oil.

CYLINDER HEAD UNIT REPAIR

BESM020037

LTSM020088

02

02–245Chery Automobile Co., Ltd.

Page 275 of 1903

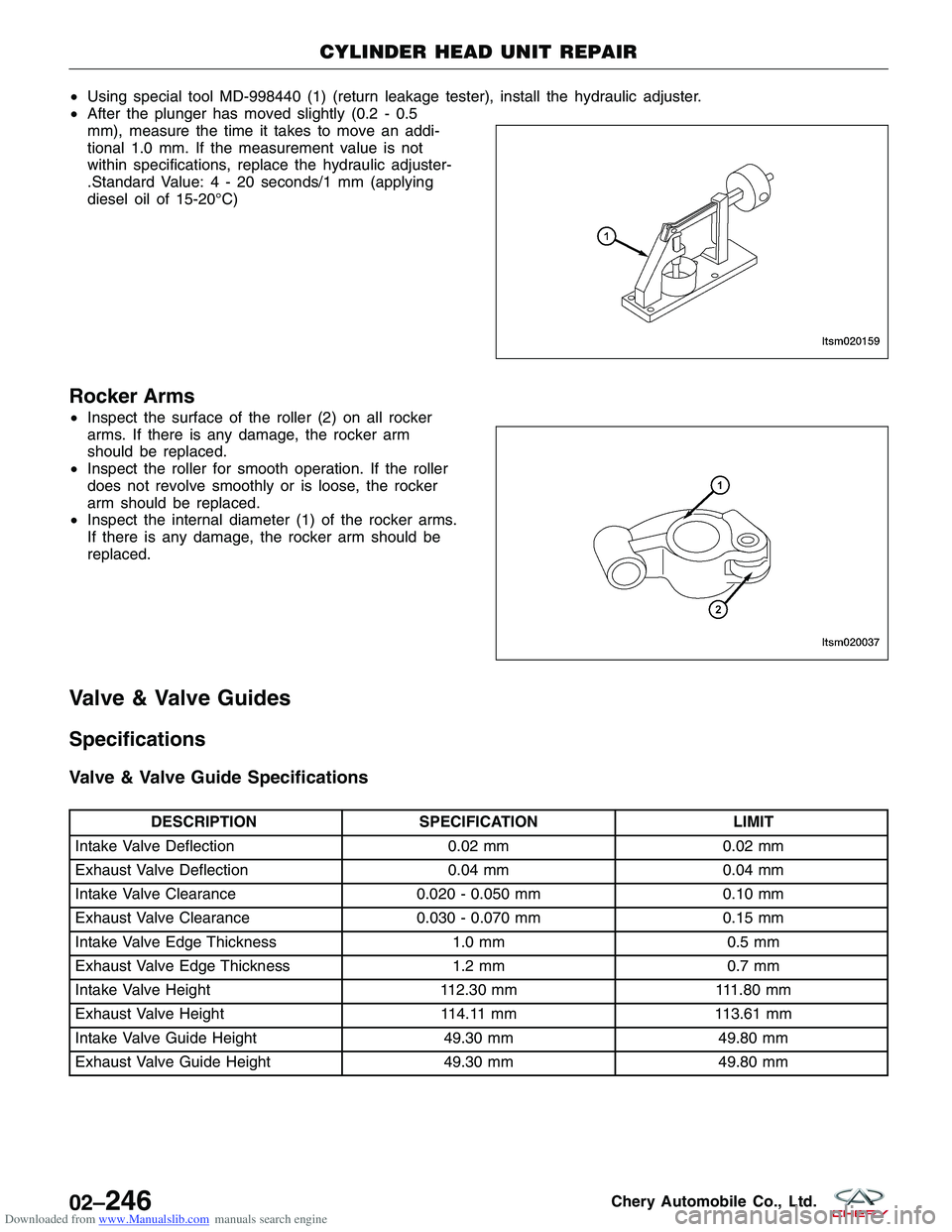

Downloaded from www.Manualslib.com manuals search engine •Using special tool MD-998440 (1) (return leakage tester), install the hydraulic adjuster.

• After the plunger has moved slightly (0.2 - 0.5

mm), measure the time it takes to move an addi-

tional 1.0 mm. If the measurement value is not

within specifications, replace the hydraulic adjuster-

.Standard Value:4-20seconds/1 mm (applying

diesel oil of 15-20°C)

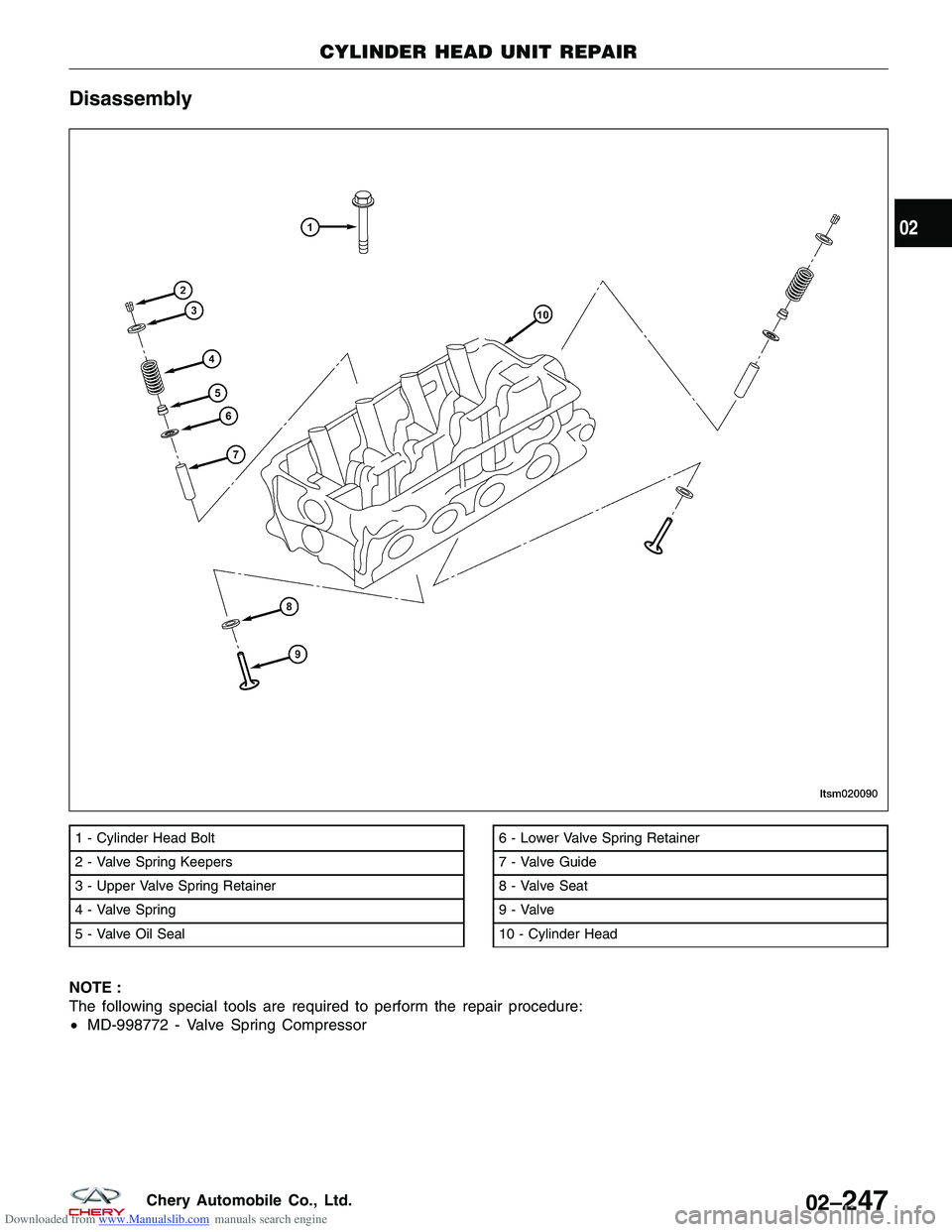

Rocker Arms

•Inspect the surface of the roller (2) on all rocker

arms. If there is any damage, the rocker arm

should be replaced.

• Inspect the roller for smooth operation. If the roller

does not revolve smoothly or is loose, the rocker

arm should be replaced.

• Inspect the internal diameter (1) of the rocker arms.

If there is any damage, the rocker arm should be

replaced.

Valve & Valve Guides

Specifications

Valve & Valve Guide Specifications

DESCRIPTION SPECIFICATION LIMIT

Intake Valve Deflection 0.02 mm0.02 mm

Exhaust Valve Deflection 0.04 mm0.04 mm

Intake Valve Clearance 0.020 - 0.050 mm0.10 mm

Exhaust Valve Clearance 0.030 - 0.070 mm0.15 mm

Intake Valve Edge Thickness 1.0 mm0.5 mm

Exhaust Valve Edge Thickness 1.2 mm0.7 mm

Intake Valve Height 112.30 mm111.80 mm

Exhaust Valve Height 114.11 mm113.61 mm

Intake Valve Guide Height 49.30 mm49.80 mm

Exhaust Valve Guide Height 49.30 mm49.80 mm

CYLINDER HEAD UNIT REPAIR

LTSM020159

LTSM020037

02–246Chery Automobile Co., Ltd.

Page 276 of 1903

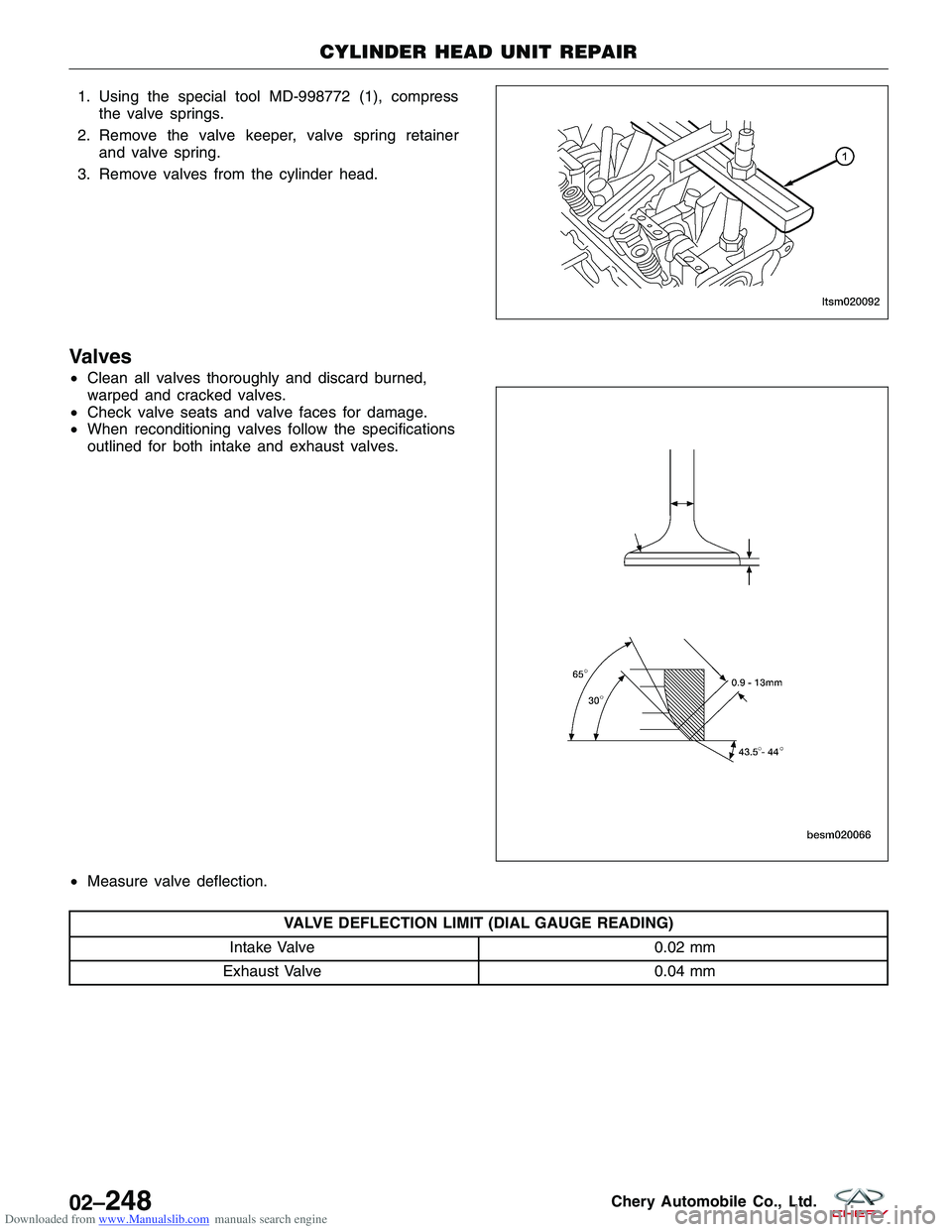

Downloaded from www.Manualslib.com manuals search engine Disassembly

NOTE :

The following special tools are required to perform the repair procedure:

•MD-998772 - Valve Spring Compressor

1 - Cylinder Head Bolt

2 - Valve Spring Keepers

3 - Upper Valve Spring Retainer

4 - Valve Spring

5 - Valve Oil Seal6 - Lower Valve Spring Retainer

7 - Valve Guide

8 - Valve Seat

9 - Valve

10 - Cylinder Head

CYLINDER HEAD UNIT REPAIR

LTSM020090

02

02–247Chery Automobile Co., Ltd.

Page 277 of 1903

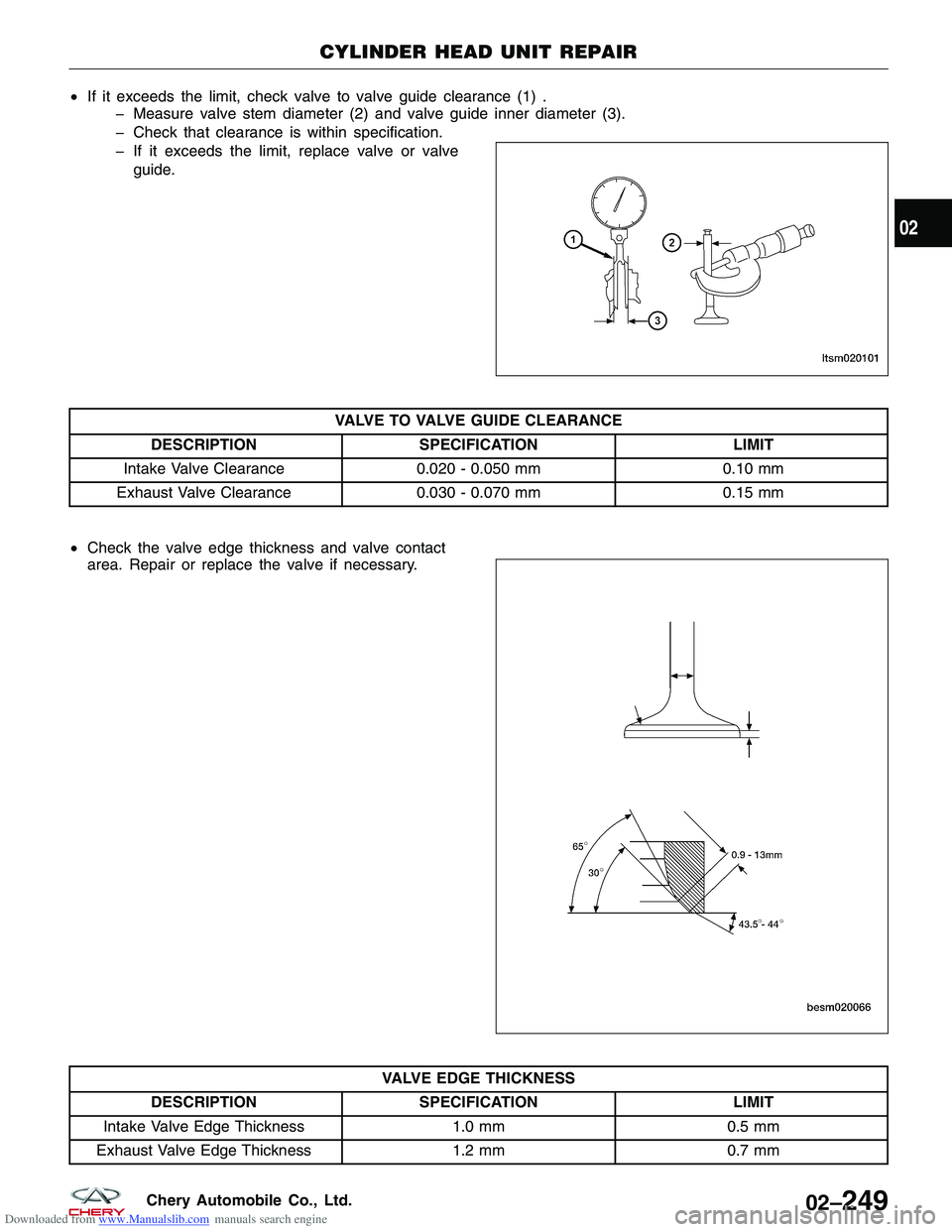

Downloaded from www.Manualslib.com manuals search engine 1. Using the special tool MD-998772 (1), compressthe valve springs.

2. Remove the valve keeper, valve spring retainer and valve spring.

3. Remove valves from the cylinder head.

Valves

• Clean all valves thoroughly and discard burned,

warped and cracked valves.

• Check valve seats and valve faces for damage.

• When reconditioning valves follow the specifications

outlined for both intake and exhaust valves.

• Measure valve deflection.

VALVE DEFLECTION LIMIT (DIAL GAUGE READING)

Intake Valve 0.02 mm

Exhaust Valve 0.04 mm

CYLINDER HEAD UNIT REPAIR

LTSM020092

BESM020066

02–248Chery Automobile Co., Ltd.

Page 278 of 1903

Downloaded from www.Manualslib.com manuals search engine •If it exceeds the limit, check valve to valve guide clearance (1) .

� Measure valve stem diameter (2) and valve guide inner diameter (3).

� Check that clearance is within specification.

� If it exceeds the limit, replace valve or valve

guide.

VALVE TO VALVE GUIDE CLEARANCE

DESCRIPTION SPECIFICATION LIMIT

Intake Valve Clearance 0.020 - 0.050 mm 0.10 mm

Exhaust Valve Clearance 0.030 - 0.070 mm 0.15 mm

• Check the valve edge thickness and valve contact

area. Repair or replace the valve if necessary.

VALVE EDGE THICKNESS

DESCRIPTION SPECIFICATION LIMIT

Intake Valve Edge Thickness 1.0 mm0.5 mm

Exhaust Valve Edge Thickness 1.2 mm0.7 mm

CYLINDER HEAD UNIT REPAIR

LTSM020101

BESM020066

02

02–249Chery Automobile Co., Ltd.

Page 279 of 1903

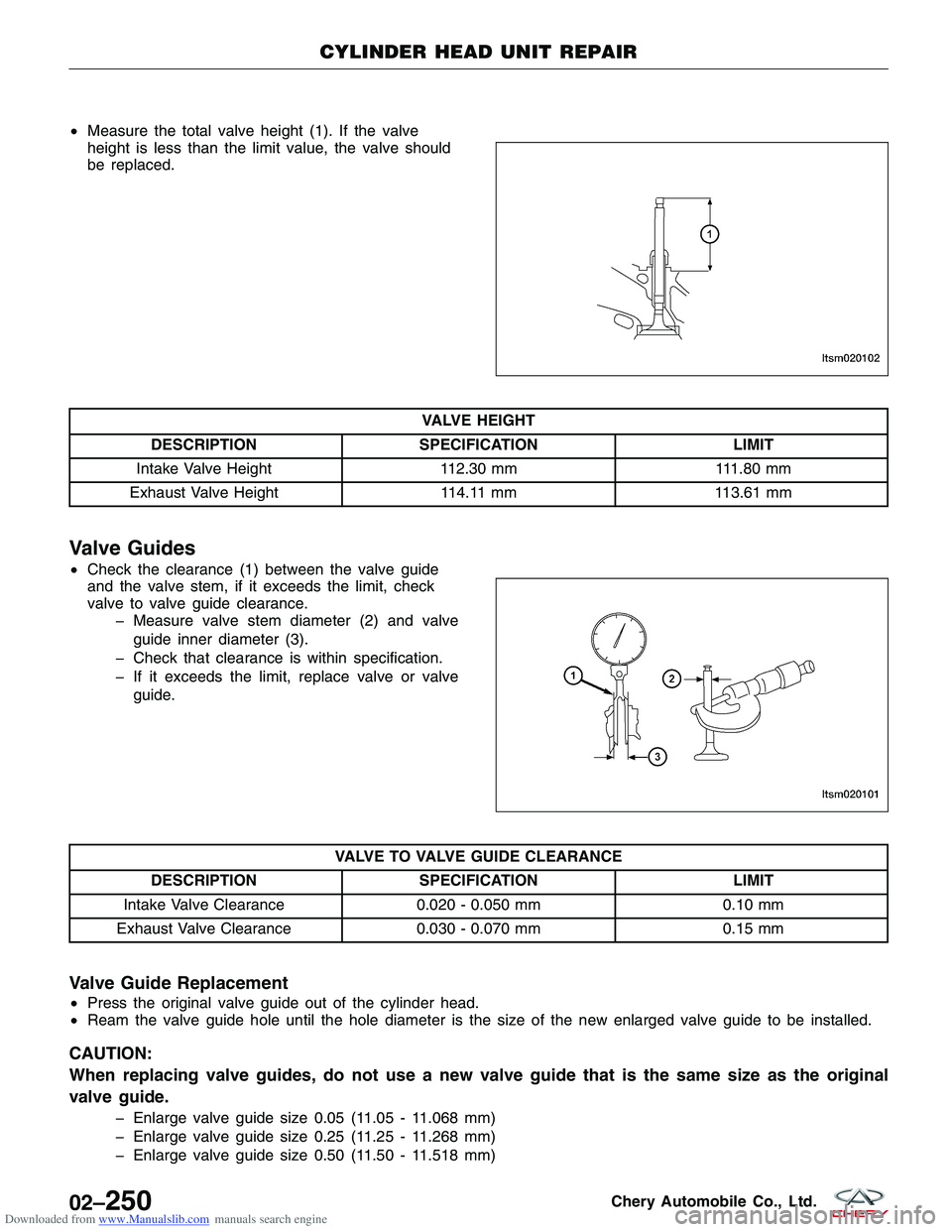

Downloaded from www.Manualslib.com manuals search engine •Measure the total valve height (1). If the valve

height is less than the limit value, the valve should

be replaced.

VALVE HEIGHT

DESCRIPTION SPECIFICATION LIMIT

Intake Valve Height 112.30 mm111.80 mm

Exhaust Valve Height 114.11 mm113.61 mm

Valve Guides

•Check the clearance (1) between the valve guide

and the valve stem, if it exceeds the limit, check

valve to valve guide clearance.

� Measure valve stem diameter (2) and valve

guide inner diameter (3).

� Check that clearance is within specification.

� If it exceeds the limit, replace valve or valve guide.

VALVE TO VALVE GUIDE CLEARANCE

DESCRIPTION SPECIFICATION LIMIT

Intake Valve Clearance 0.020 - 0.050 mm 0.10 mm

Exhaust Valve Clearance 0.030 - 0.070 mm 0.15 mm

Valve Guide Replacement

•Press the original valve guide out of the cylinder head.

• Ream the valve guide hole until the hole diameter is the size of the new enlarged valve guide to be installed.

CAUTION:

When replacing valve guides, do not use a new valve guide that is the same size as the original

valve guide.

� Enlarge valve guide size 0.05 (11.05 - 11.068 mm)

� Enlarge valve guide size 0.25 (11.25 - 11.268 mm)

� Enlarge valve guide size 0.50 (11.50 - 11.518 mm)

CYLINDER HEAD UNIT REPAIR

LTSM020102

LTSM020101

02–250Chery Automobile Co., Ltd.

Page 280 of 1903

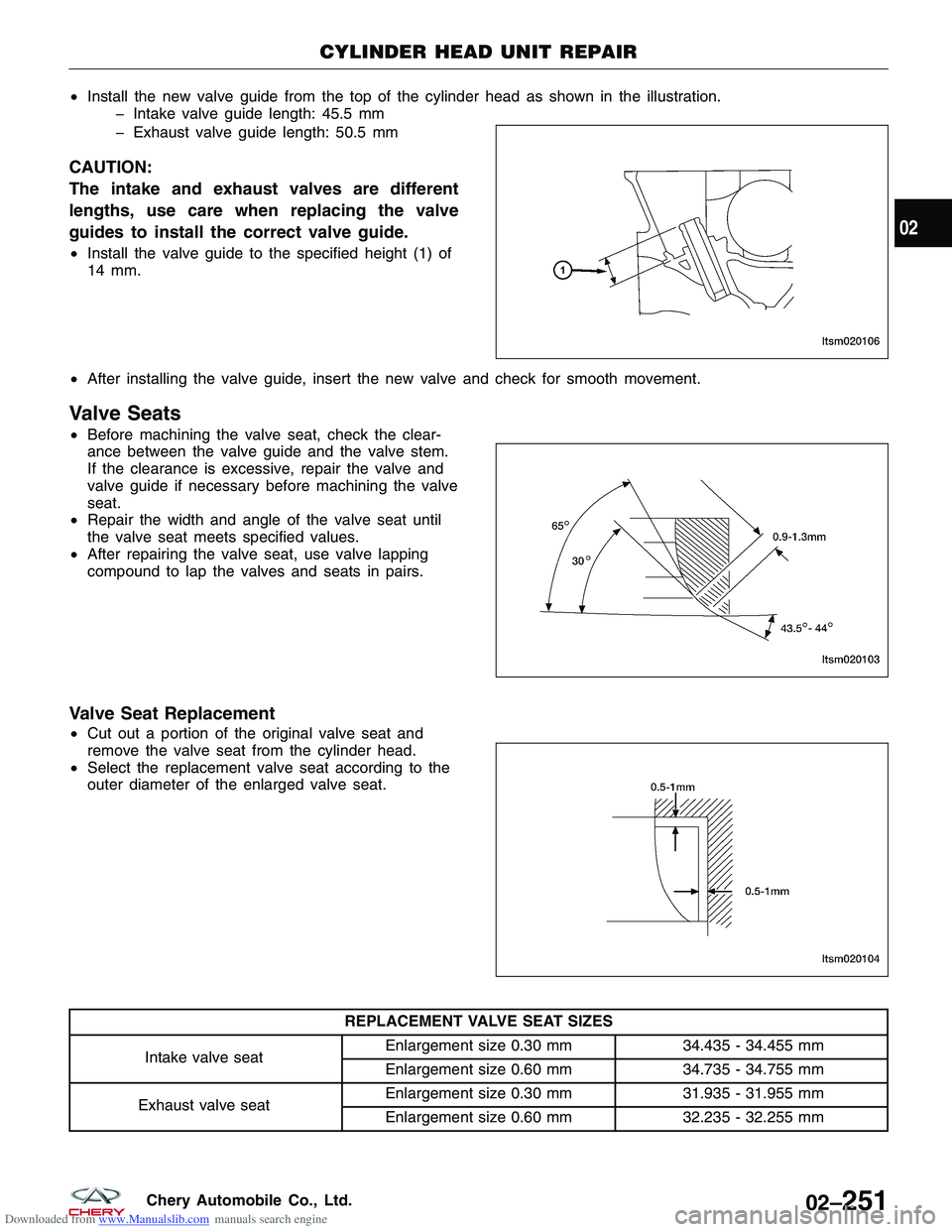

Downloaded from www.Manualslib.com manuals search engine •Install the new valve guide from the top of the cylinder head as shown in the illustration.

� Intake valve guide length: 45.5 mm

� Exhaust valve guide length: 50.5 mm

CAUTION:

The intake and exhaust valves are different

lengths, use care when replacing the valve

guides to install the correct valve guide.

•Install the valve guide to the specified height (1) of

14 mm.

• After installing the valve guide, insert the new valve and check for smooth movement.

Valve Seats

•Before machining the valve seat, check the clear-

ance between the valve guide and the valve stem.

If the clearance is excessive, repair the valve and

valve guide if necessary before machining the valve

seat.

• Repair the width and angle of the valve seat until

the valve seat meets specified values.

• After repairing the valve seat, use valve lapping

compound to lap the valves and seats in pairs.

Valve Seat Replacement

•Cut out a portion of the original valve seat and

remove the valve seat from the cylinder head.

• Select the replacement valve seat according to the

outer diameter of the enlarged valve seat.

REPLACEMENT VALVE SEAT SIZES

Intake valve seat Enlargement size 0.30 mm

34.435 - 34.455 mm

Enlargement size 0.60 mm 34.735 - 34.755 mm

Exhaust valve seat Enlargement size 0.30 mm

31.935 - 31.955 mm

Enlargement size 0.60 mm 32.235 - 32.255 mm

CYLINDER HEAD UNIT REPAIR

LTSM020106

LTSM020103

LTSM020104

02

02–251Chery Automobile Co., Ltd.