tow CHEVROLET CAMARO 1967 1.G Chassis User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 79 of 659

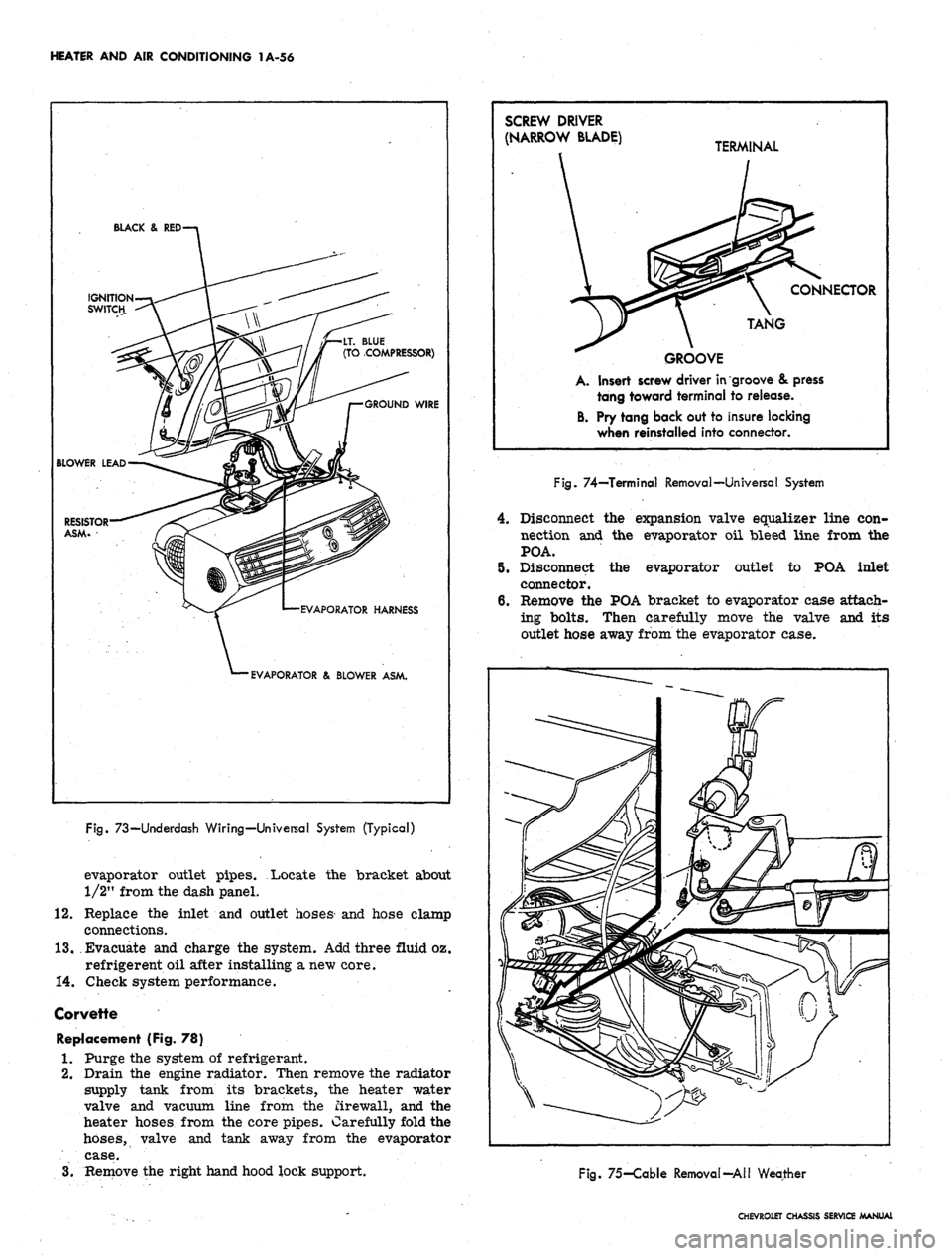

HEATER AND AIR CONDITIONING 1A-56

BLACK & RED

IGNITION—-y^****

SWITCH -"A

/

BLOWER LEAD—^^^

RESISTOR—-" \^<

ASM.

f'

i

'fu^^^^A^^^^^r"G^OUH£>

WIRE

^^

k4

^EVAPORATOR HARNESS

' EVAPORATOR & BLOWER ASM.

Fig.

73—Underdash Wiring—Universal System (Typical)

evaporator outlet pipes. Locate the bracket about

1/2" from the dash panel.

12.

Replace the inlet and outlet hoses and hose clamp

connections.

13.

Evacuate and charge the system. Add three fluid oz.

refrigerent oil after installing a new core.

14.

Check system performance.

Corvette

Replacement (Fig. 78)

1.

Purge the system of refrigerant.

2.

Drain the engine radiator. Then remove the radiator

supply tank from its brackets, the heater water

valve and vacuum line from the firewall, and the

heater hoses from the core pipes. Carefully fold the

hoses,

valve and tank away from the evaporator

case.

3.

Remove the right hand hood lock support.

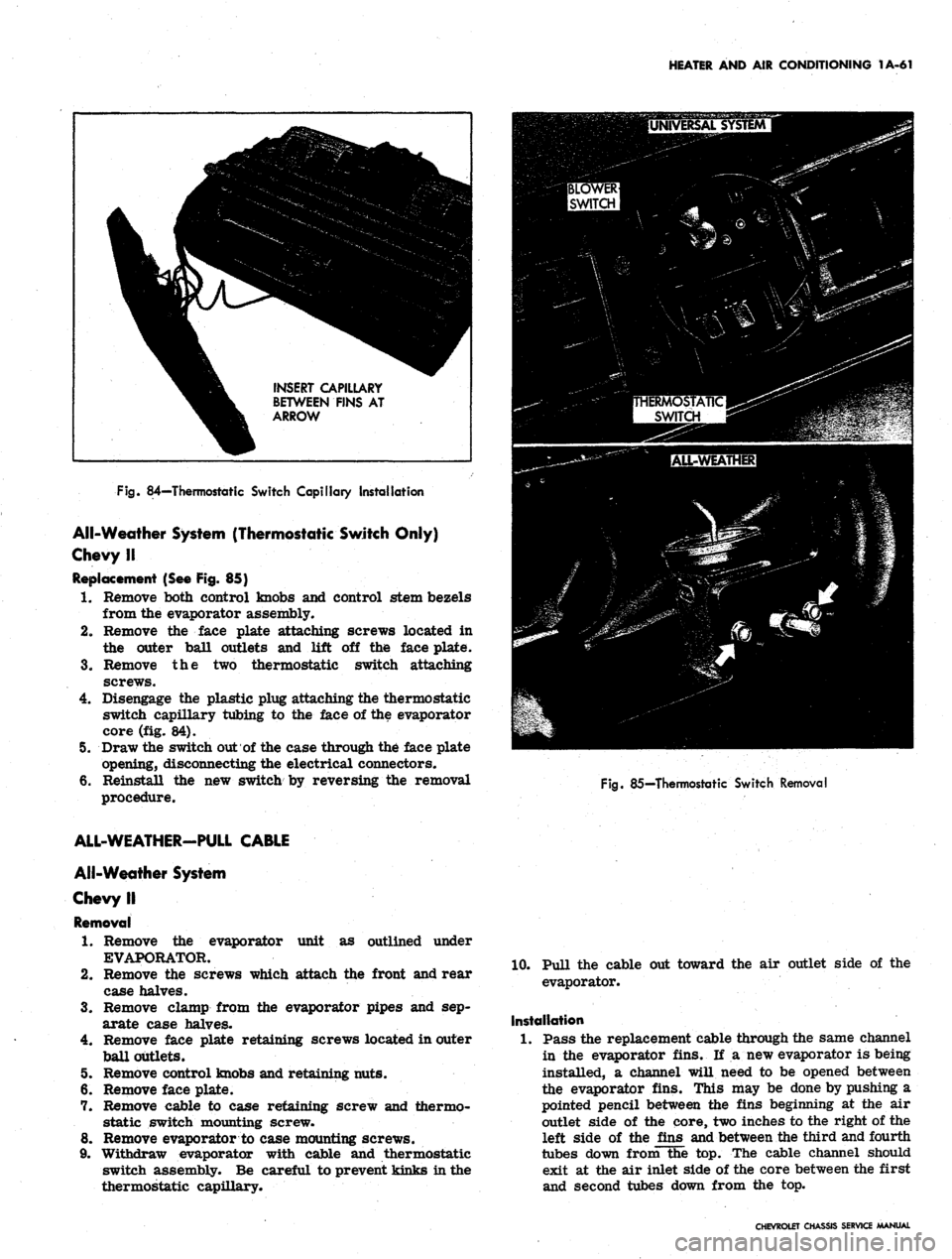

SCREW DRIVER

(NARROW BLADE) T£

GROOVE

A. Insert screw driver in

tang toward terminal

B. Pry tang back out to

when reinstalled into

RMINAL

\ CONNECTOR

TANG

groove & press

to release.

insure locking

connector.

Fig.

74—Terminal Removal—Universal System

4.

Disconnect the expansion valve equalizer line con-

nection and the evaporator oil bleed line from the

POA.

5.

Disconnect the evaporator outlet to POA inlet

connector.

6. Remove the POA bracket to evaporator case attach-

ing bolts. Then carefully move the valve and its

outlet hose away from the evaporator case.

Fig.

75-Cable Removal-All Weather

CHEVROLET CHASSIS SERVICE MANUAL

Page 84 of 659

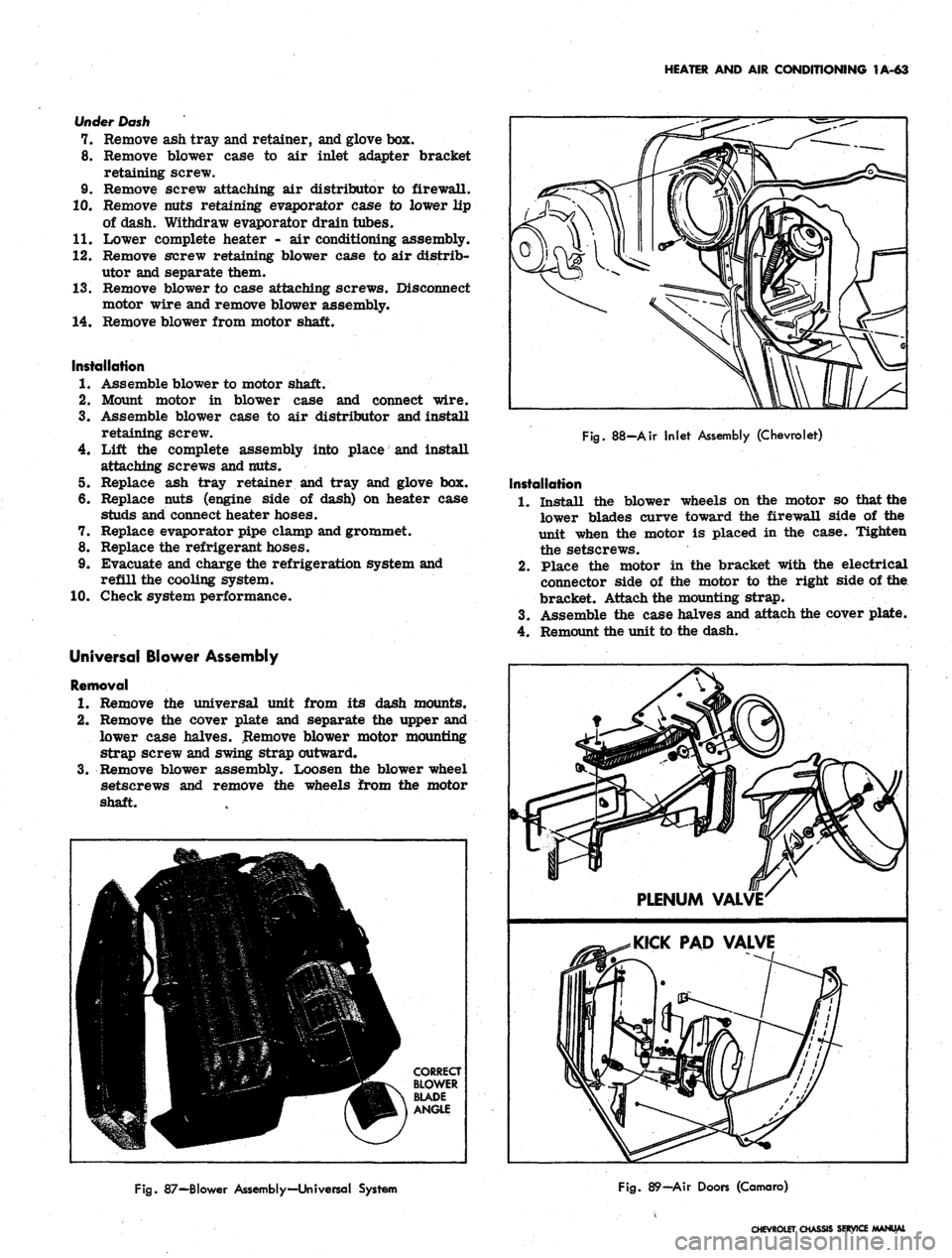

HEATER AND AIR CONDITIONING 1A-61

INSERT CAPILLARY

BETWEEN FINS AT

ARROW

Fig.

84—Thermostatic Switch Capillary Installation

All-Weather System (Thermostatic Switch Only)

Chevy II

Replacement (See Fig. 85)

1.

Remove both control knobs and control stem bezels

from the evaporator assembly.

2.

Remove the face plate attaching screws located in

the outer ball outlets and lift off the face plate.

3.

Remove the two thermostatic switch attaching

screws.

4.

Disengage the plastic plug attaching the thermostatic

switch capillary tubing to the face of the evaporator

core (fig. 84).

5. Draw the switch out of the case through the face plate

opening, disconnecting the electrical connectors.

6. Reinstall the new switch by reversing the removal

procedure.

Fig.

85—Thermostatic Switch Removal

unit as outlined under

ALL-WEATHER-PULL CABLE

All-Weather System

Chevy II

Removal

1.

Remove the evaporator

EVAPORATOR.

2.

Remove the screws which attach the front and rear

case halves.

3.

Remove clamp from the evaporator pipes and sep-

arate case halves.

4.

Remove face plate retaining screws located in outer

ball outlets.

5. Remove control knobs and retaining nuts.

6. Remove face plate.

7. Remove cable to case retaining screw and thermo-

static switch mounting screw.

8. Remove evaporator to case mounting screws.

9. Withdraw evaporator with cable and thermostatic

switch assembly. Be careful to prevent kinks in the

thermostatic capillary.

10.

Pull the cable out toward the air outlet side of the

evaporator.

Installation

1.

Pass the replacement cable through the same channel

in the evaporator fins. If a new evaporator is being

installed, a channel will need to be opened between

the evaporator fins. This may be done by pushing a

pointed pencil between the fins beginning at the air

outlet side of the core, two inches to the right of the

left side of the fins and between the third and fourth

tubes down from the top. The cable channel should

exit at the air inlet side of the core between the first

and second tubes down from the top.

CHEVROLET CHASSIS SERVICE MANUAL

Page 86 of 659

HEATER AND AIR CONDITIONING 1A-63

Under Dash

7. Remove ash tray and retainer, and glove box.

8. Remove blower case to air inlet adapter bracket

retaining screw.

9. Remove screw attaching air distributor to firewall.

10.

Remove nuts retaining evaporator case to lower lip

of dash. Withdraw evaporator drain tubes.

11.

Lower complete heater - air conditioning assembly.

12.

Remove screw retaining blower case to air distrib-

utor and separate them.

13.

Remove blower to case attaching screws. Disconnect

motor wire and remove blower assembly.

14.

Remove blower from motor shaft.

Installation

1.

Assemble blower to motor shaft.

2.

Mount motor in blower case and connect wire.

3.

Assemble blower case to air distributor and install

retaining screw.

4.

Lift the complete assembly into place and install

attaching screws and nuts.

5. Replace ash tray retainer and tray and glove box.

6. Replace nuts (engine side of dash) on heater case

studs and connect heater hoses.

7. Replace evaporator pipe clamp and grommet.

8. Replace the refrigerant hoses.

9. Evacuate and charge the refrigeration system and

refill the cooling system.

10.

Check system performance.

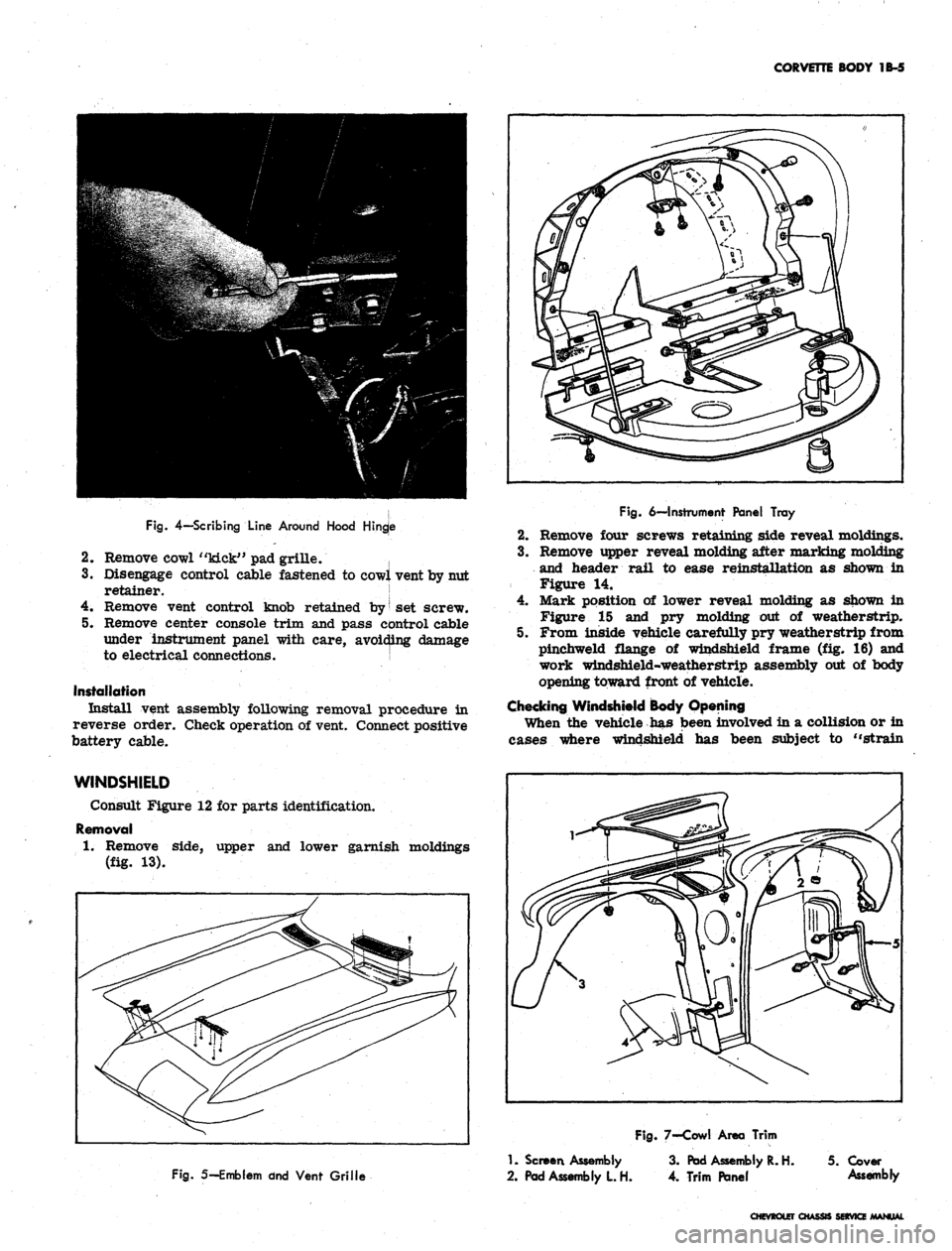

Universal Blower Assembly

Removal

1.

Remove the universal unit from its dash mounts.

2.

Remove the cover plate and separate the upper and

lower case halves. Remove blower motor mounting

strap screw and swing strap outward.

3.

Remove blower assembly. Loosen the blower wheel

setscrews and remove the wheels from the motor

shaft. . ' .

Fig.

88-Air Inlet Assembly (Chevrolet)

Installation

1.

Install the blower wheels on the motor so that the

lower blades curve toward the firewall side of the

unit when the motor is placed in the case. Tighten

the setscrews.

2.

Place the motor in the bracket with the electrical

connector side of the motor to the right side of the

bracket. Attach the mounting strap.

3.

Assemble the case halves and attach the cover plate.

4.

Remount the unit to the dash.

Fig.

87—Blower Assembly—Universal System

Fig.

89—Air Doors (Camaro)

CHEVROLET CHASSIS SERVICE

Page 112 of 659

CORVETTE BODY 1B-5

Fig.

4—Scribing

Line

Around

Hood

Hingje

2.

Remove cowl "kick" pad grille. |

3.

Disengage control cable fastened to cowl vent by nut

retainer. !

4.

Remove vent control knob retained by

|

set screw.

5. Remove center console trim and pass control cable

under instrument panel with care, avoiding damage

to electrical connections. j

Installation

Install vent assembly following removal procedure in

reverse order. Check operation of vent. Connect positive

battery cable.

Fig.

6—Instrument

Panel Tray

2.

Remove four screws retaining side reveal moldings.

3.

Remove upper reveal molding after marking molding

and header rail to ease reinstallation as shown in

Figure 14.

4.

Mark position of lower reveal molding as shown in

Figure 15 and pry molding out of weatherstrip.

5. From inside vehicle carefully pry weatherstrip from

pinchweld flange of windshield frame (fig. 16) and

work windshield-weatherstrip assembly out of body

opening toward front of vehicle.

Checking Windshield Body Opening

When the vehicle has been involved in a collision or in

cases where windshield has been subject to "strain

WINDSHIELD

Consult Figure 12 for parts identification.

Removal

1.

Remove side, upper and lower garnish moldings

(fig. 13).

Fig.

5—Emblem dnd

Vent Grille

1.

Screen

Assembly

2.

Pad

Assembly

L H.

Fig.

7-Cowl

Area Trim

3.

Pad

Assembly

R. H. 5.

Cover

4.

Trim Panel

Assembly

CHEVROLET CHASSIS SERVICE MANUAL

Page 113 of 659

CORVETTE BODY

1B-6

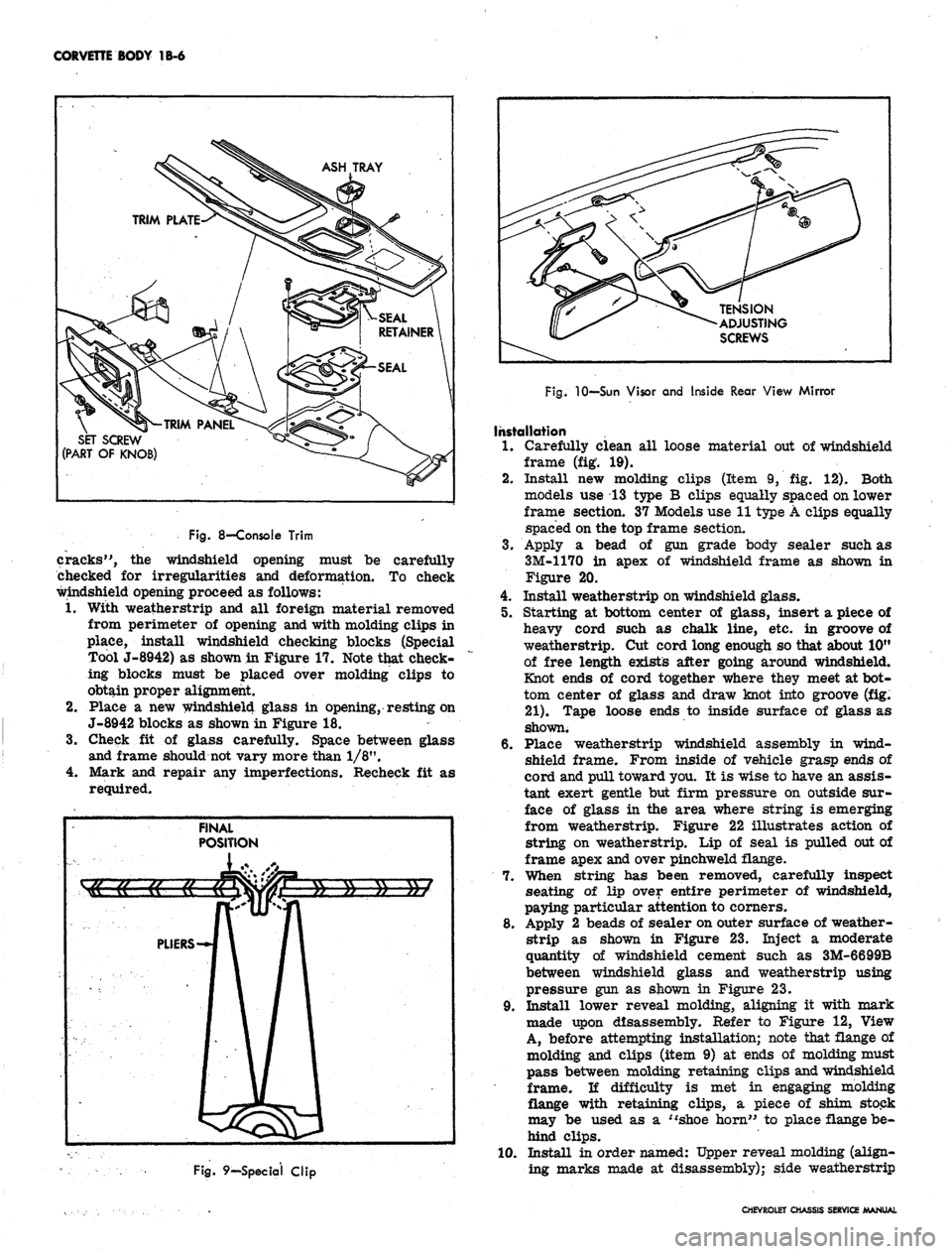

ASH TRAY

SET SCREW

(PART

OF

KNOB)

TENSION

ADJUSTING

SCREWS

Fig.

8—Console Trim

cracks",

the

windshield opening must

be

carefully

checked

for

irregularities

and

deformation.

To

check

windshield opening proceed

as

follows:

1.

With weatherstrip

and all

foreign material removed

from perimeter

of

opening and with molding clips

in

place, install windshield checking blocks (Special

Tool J-8942)

as

shown in Figure 17. Note that check-

ing blocks must

be

placed over molding clips

to

obtain proper alignment.

2.

Place

a new

windshield glass

in

opening, resting on

J-8942 blocks

as

shown in Figure

18.

3.

Check

fit of

glass carefully. Space between glass

and frame should not vary more than 1/8".

4.

Mark

and

repair

any

imperfections. Recheck

fit as

required.

Fig.

9—Special Clip

Fig.

10—Sun Visor and Inside Rear View Mirror

Installation

1.

Carefully clean

all

loose material

out of

windshield

frame

(fig. 19).

2.

Install

new

molding clips (Item

9, fig. 12).

Both

models

use 13

type

B

clips equally spaced on lower

frame section.

37

Models use 11 type A clips equally

spaced on the top frame section.

3.

Apply

a

bead

of gun

grade body sealer such

as

3M-1170

in

apex

of

windshield frame

as

shown

in

Figure

20.

4.

Install weatherstrip on windshield glass.

5. Starting

at

bottom center

of

glass, insert

a

piece

of

heavy cord such

as

chalk line,

etc. in

groove

of

weatherstrip.

Cut

cord long enough so that about 10"

of free length exists after going around windshield.

Knot ends

of

cord together where they meet at bot-

tom center

of

glass

and

draw knot into groove

(fig.

21).

Tape loose ends

to

inside surface

of

glass

as

shown.

6. Place weatherstrip windshield assembly

in

wind-

shield frame. From inside

of

vehicle grasp ends

of

cord and pull toward you.

It is

wise to have an assis-

tant exert gentle

but

firm pressure

on

outside sur-

face

of

glass

in the

area where string

is

emerging

from weatherstrip. Figure

22

illustrates action

of

string

on

weatherstrip.

Lip of

seal

is

pulled out of

frame apex and over pinchweld flange.

7. When string

has

been removed, carefully inspect

seating

of lip

over entire perimeter

of

windshield,

paying particular attention to corners.

8. Apply

2

beads

of

sealer on outer surface

of

weather-

strip

as

shown

in

Figure

23.

Inject

a

moderate

quantity

of

windshield cement such

as

3M-6699B

between windshield glass

and

weatherstrip using

pressure gun

as

shown

in

Figure

23.

9. Install lower reveal molding, aligning

it

with mark

made upon disassembly. Refer

to

Figure

12,

View

A, before attempting installation; note that flange

of

molding

and

clips (item

9) at

ends

of

molding must

pass between molding retaining clips and windshield

frame.

li

difficulty

is met in

engaging molding

flange with retaining clips,

a

piece

of

shim stock

may

be

used

as a

"shoe horn"

to

place flange be-

hind clips.

10.

Install

in

order named: Upper reveal molding (align-

ing marks made

at

disassembly); side weatherstrip

CHEVROLET CHASSIS SERVICE MANUAL

Page 117 of 659

CORVETTE BODY IB-10

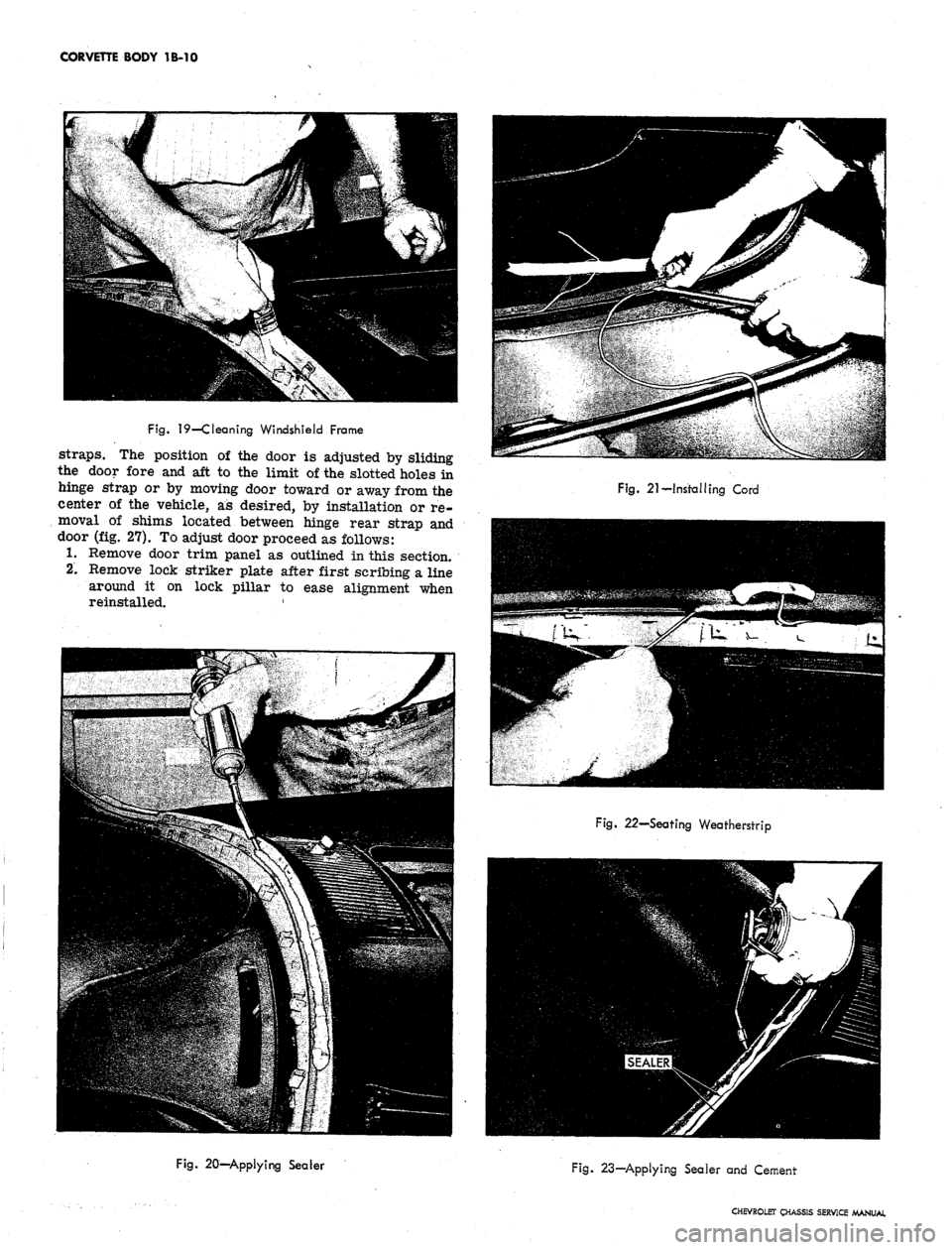

Fig.

19—Cleaning Windshield Frame

straps.

The position of the door is adjusted by sliding

the door fore and aft to the limit of the slotted holes in

hinge strap or by moving door toward or away from the

center of the vehicle, as desired, by installation or re-

moval of shims located between hinge rear strap and

door (fig. 27). To adjust door proceed as follows:

1.

Remove door trim panel as outlined in this section.

2.

Remove lock striker plate after first scribing a line

around it on lock pillar to ease alignment when

reinstalled. '

Fig. 21-Installing Cord

Fig. 22—Seating Weatherstrip

Fig. 20—Applying Sealer

Fig. 23—Applying Sealer and Cement

CHEVROLET CHASSIS SERVICE MANUAL

Page 124 of 659

CORVETTE BODY 1B-17

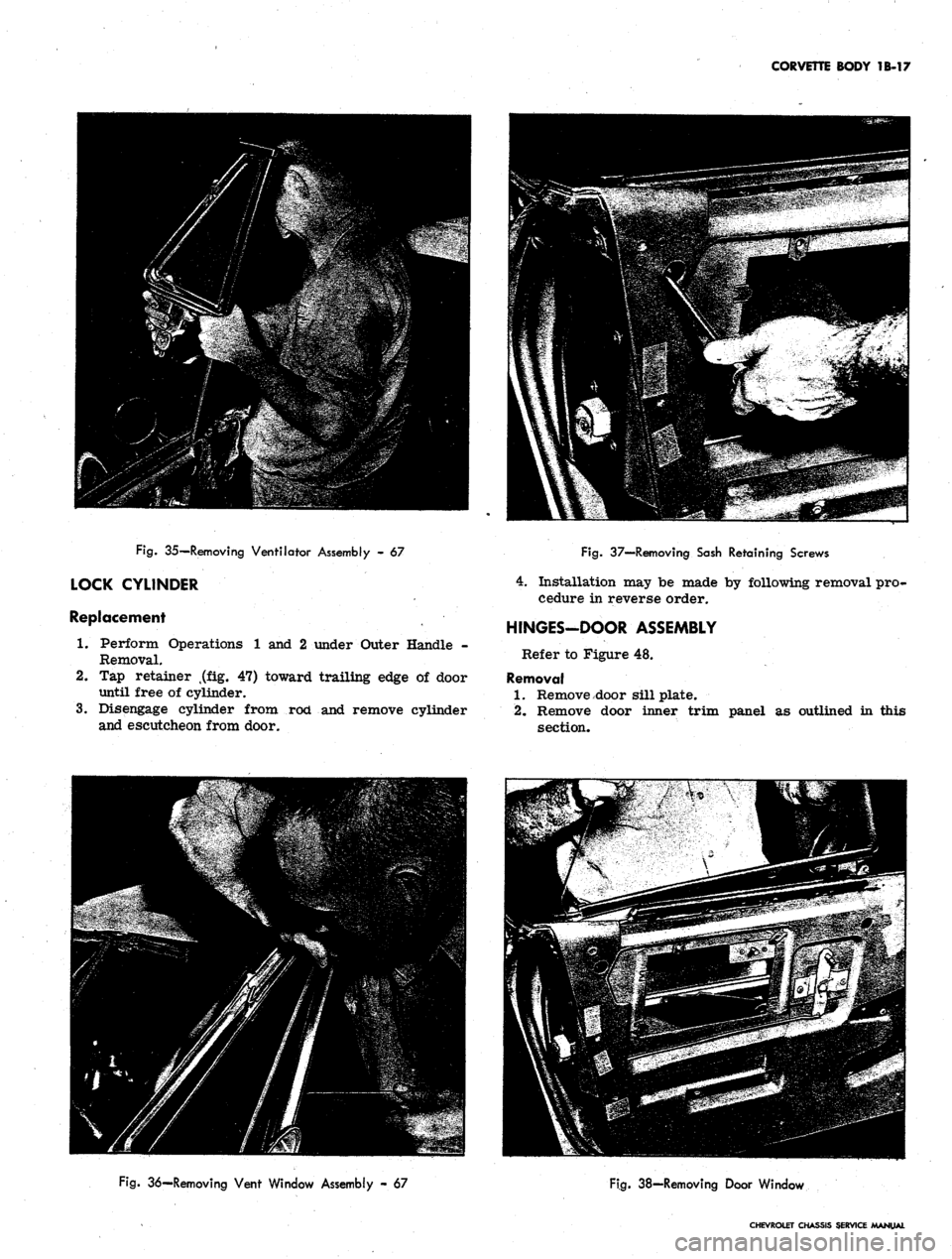

Fig.

35—Removing Ventilator Assembly - 67

LOCK CYLINDER

Replacement

1.

Perform Operations 1 and 2 under Outer Handle -

Removal.

2.

Tap retainer t(flLg. 47) toward trailing edge of door

until free of cylinder.

3.

Disengage cylinder from rod and remove cylinder

and escutcheon from door.

Fig.

37—Removing Sash Retaining Screws

4.

Installation may be made by following removal pro-

cedure in reverse order.

HINGES-DOOR ASSEMBLY

Refer to Figure 48.

Removal

1.

Remove door sill plate.

2.

Remove door inner trim panel as outlined in this

section.

Fig.

36—Removing Vent Window Assembly - 67

Fig.

38-Removing Door Window

CHEVROLET CHASSIS SERVICE /MANUAL

Page 136 of 659

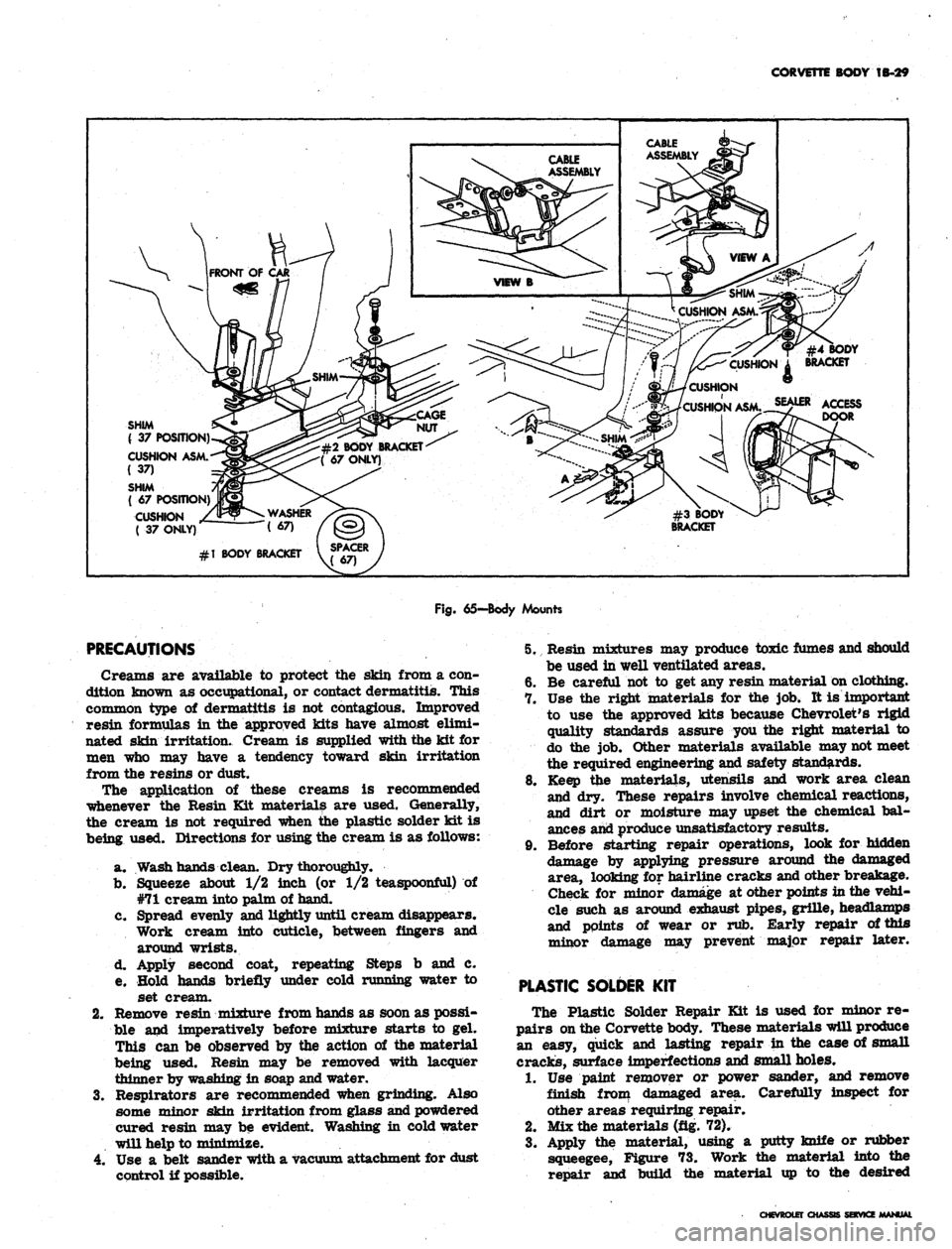

CORVETTE BODY 1B-29

CUSHION

CUSHION ASNi.^ty** ACCESS

#2 BODY BRACKET

( 67 ONLY)

SHIM

( 37 POSITION).

CUSHION ASM.

( 37)

SHIM

( 67 POSITION)

CUSHION

( 37 ONLY)

#1 BODY BRACKET

Fig.

65—Body Mounts

PRECAUTIONS

Creams are available to protect the skin from a con-

dition known as occupational, or contact dermatitis. This

common type of dermatitis is not contagious. Improved

resin formulas in the approved kits have almost elimi-

nated skin irritation. Cream is supplied with the kit for

men who may have a tendency toward skin irritation

from the resins or dust.

The application of these creams is recommended

whenever the Resin Kit materials are used. Generally,

the cream is not required when the plastic solder kit is

being used. Directions for using the cream is as follows:

a. Wash hands clean. Dry thoroughly.

b.

Squeeze about 1/2 inch (or 1/2 teaspoonful) of

#71 cream into palm of hand.

c. Spread evenly and lightly until cream disappears.

Work cream into cuticle, between fingers and

around wrists.

d. Apply second coat, repeating Steps b and c.

e. Hold hands briefly under cold running water to

set cream.

2.

Remove resin mixture from hands as soon as possi-

ble and imperatively before mixture starts to gel.

This can be observed by the action of the material

being used. Resin may be removed with lacquer

thinner by washing in soap and water.

3.

Respirators are recommended when grinding. Also

some minor skin irritation from glass and powdered

cured resin may be evident. Washing in cold water

will help to minimize.

4.

Use a belt sander with a vacuum attachment for dust

control if possible.

5. Resin mixtures may produce toxic fumes and should

be used in well ventilated areas.

6. Be careful not to get any resin material on clothing.

7. Use the right materials for the job. It is important

to use the approved kits because Chevrolet's rigid

quality standards assure you the right material to

do the job. Other materials available may not meet

the required engineering and safety standards.

8. Keep the materials, utensils and work area clean

and dry. These repairs involve chemical reactions,

and dirt or moisture may upset the chemical bal-

ances and produce unsatisfactory results.

9. Before starting repair operations, look for hidden

damage by applying pressure around the damaged

area, looking for hairline cracks and other breakage.

Check for minor damage at other points in the vehi-

cle such as around exhaust pipes, grille, headlamps

and points of wear or rub. Early repair of this

minor damage may prevent major repair later.

PLASTIC SOLDER

KIT

The Plastic Solder Repair Kit is used for minor re-

pairs on the Corvette body. These materials will produce

an easy, quick and lasting repair in the case of small

cracks, surface imperfections and small holes.

1.

Use paint remover or power sander, and remove

finish from damaged area. Carefully inspect for

other areas requiring repair.

2.

Mix the materials (fig. 72).

3.

Apply the material, using a putty knife or rubber

squeegee, Figure 73. Work the material into the

repair and build the material up to the desired

CHEVROLET CHASSIS SERVICE

Page 148 of 659

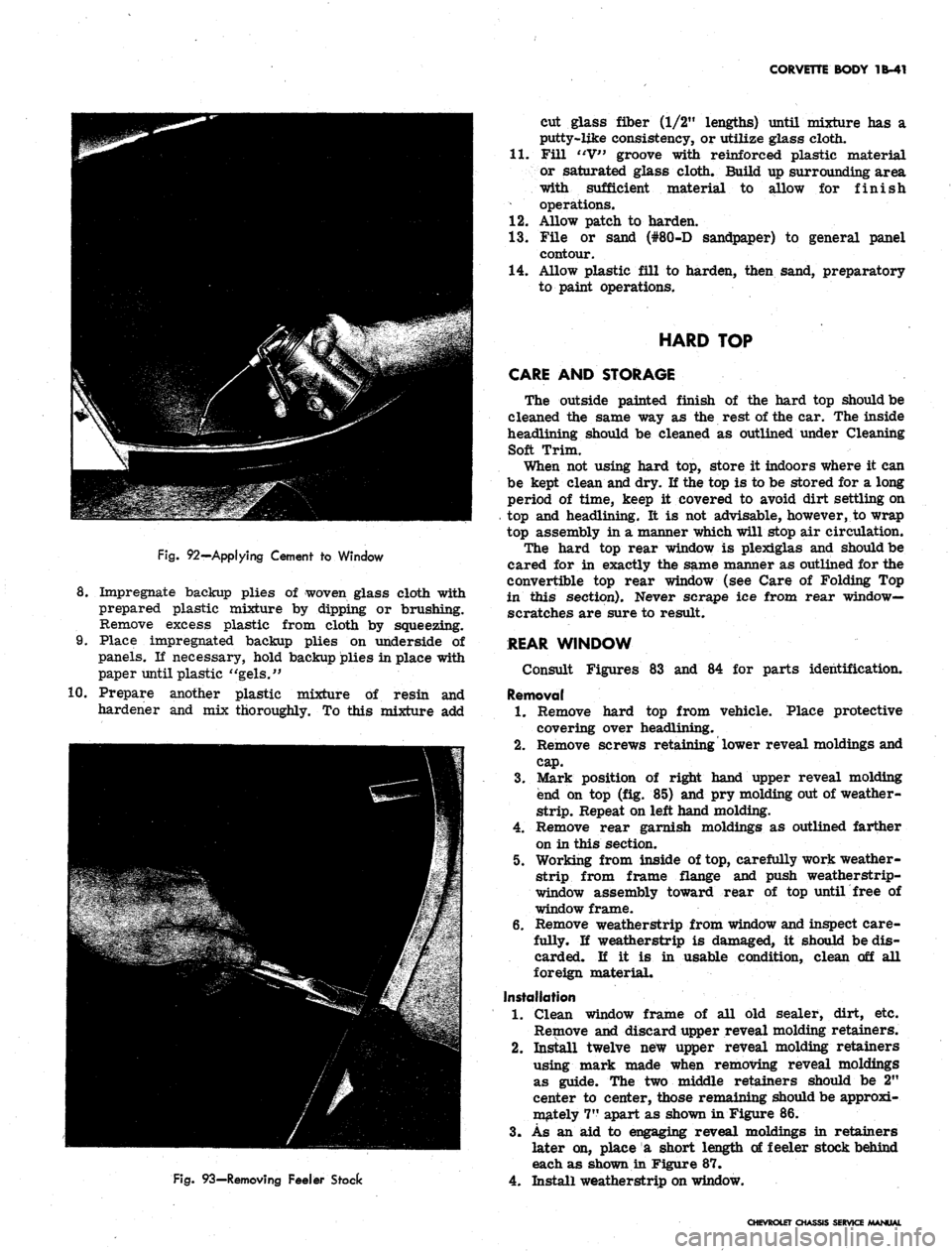

CORVETTE BODY 1B-41

Fig.

92—Applying Cement to Window

8. Impregnate backup plies of woven glass cloth with

prepared plastic mixture by dipping or brushing.

Remove excess plastic from cloth by squeezing.

9. Place impregnated backup plies on underside of

panels. If necessary, hold backup plies in place with

paper until plastic "gels."

10.

Prepare another plastic mixture of resin and

hardener and mix thoroughly. To this mixture add

Fig.

93—Removing Feeler Stock

cut glass fiber (1/2" lengths) until mixture has a

putty-like consistency, or utilize glass cloth.

11.

Fill "V" groove with reinforced plastic material

or saturated glass cloth. Build up surrounding area

with sufficient material to allow for finish

operations.

12.

Allow patch to harden.

1.3. File or sand (#80-D sandpaper) to general panel

contour.

14.

Allow plastic fill to harden, then sand, preparatory

to paint operations.

HARD TOP

CARE AND STORAGE

The outside painted finish of the hard top should be

cleaned the same way as the rest of the car. The inside

headlining should be cleaned as outlined under Cleaning

Soft Trim.

When not using hard top, store it indoors where it can

be kept clean and dry. If the top is to be stored for a long

period of time, keep it covered to avoid dirt settling on

top and headlining. It is not advisable, however, to wrap

top assembly in a manner which will stop air circulation.

The hard top rear window is plexiglas and should be

cared for in exactly the same manner as outlined for the

convertible top rear window (see Care of Folding Top

in this section). Never scrape ice from rear window-

scratches are sure to result.

REAR WINDOW

Consult Figures 83 and 84 for parts identification.

Removal

1.

Remove hard top from vehicle. Place protective

covering over headlining.

2.

Remove screws retaining lower reveal moldings and

cap.

3.

Mark position of right hand upper reveal molding

end on top (fig. 85) and pry molding out of weather-

strip.

Repeat on left hand molding.

4.

Remove rear garnish moldings as outlined farther

on in this section.

5. Working from inside of top, carefully work weather-

strip from frame flange and push weatherstrip-

window assembly toward rear of top until free of

window frame.

6. Remove weatherstrip from window and inspect care-

fully. If weatherstrip is damaged, it should be dis-

carded. If it is in usable condition, clean off all

foreign material.

Installation

1.

Clean window frame of all old sealer, dirt, etc.

Remove and discard upper reveal molding retainers.

2.

Install twelve new upper reveal molding retainers

using mark made when removing reveal moldings

as guide. The two middle retainers should be 2"

center to center, those remaining should be approxi-

mately 7" apart as shown in Figure 86.

3.

As an aid to engaging reveal moldings in retainers

later on, place a short length of feeler stock behind

each as shown in Figure 87.

4.

Install weatherstrip on window.

CHEVROLET CHASSIS SERVICE MANUAL

Page 149 of 659

CORVETTE BODY 1B-42

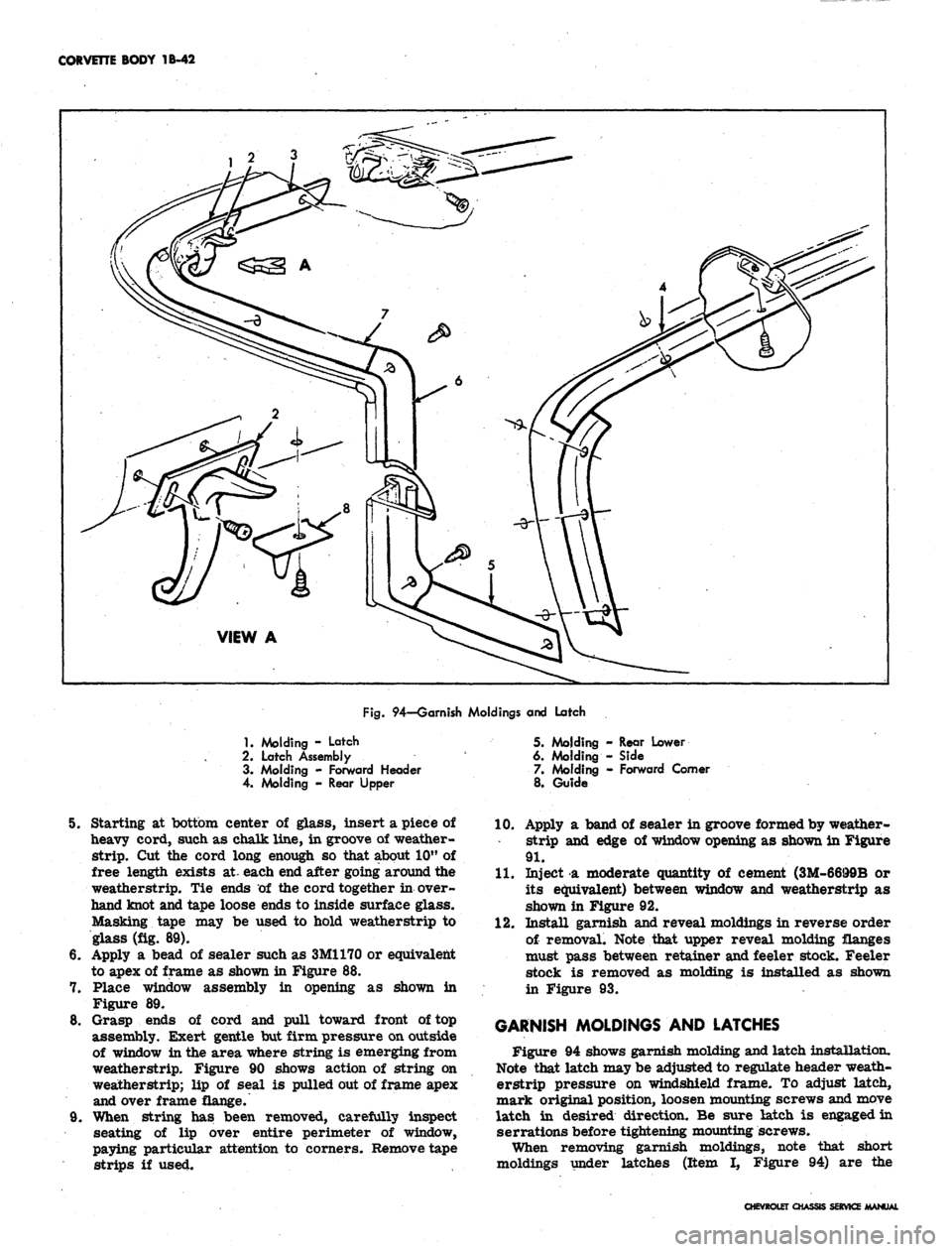

Fig.

94—Garnish Moldings and Latch

1.

Molding - Latch

2.

Latch Assembly

3. Molding - Forward Header

4. Molding - Rear Upper

5. Molding - Rear Lower

6. Molding - Side

7. Molding - Forward Comer

8. Guide

8.

9,

Starting at bottom center of glass, insert a piece of

heavy cord, such as chalk line, in groove of weather-

strip.

Cut the cord long enough so that about 10" of

free length exists at- each end after going around the

weatherstrip. Tie ends of the cord together in over-

hand knot and tape loose ends to inside surface glass.

Masking tape may be used to hold weatherstrip to

glass (fig. 89).

Apply a bead of sealer such as 3M1170 or equivalent

to apex of frame as shown in Figure 88.

Place window assembly in opening as shown in

Figure 89.

Grasp ends of cord and pull toward front of top

assembly. Exert gentle but firm pressure on outside

of window in the area where string is emerging from

weatherstrip. Figure 90 shows action of string on

weatherstrip; lip of seal is pulled out of frame apex

and over frame flange.

When string has been removed, carefully inspect

seating of lip over entire perimeter of window,

paying particular attention to corners. Remove tape

strips if used.

10.

Apply a band of sealer in groove formed by weather-

strip and edge of window opening as shown in Figure

91.

11.

Inject a moderate quantity of cement (3M-6699B or

its equivalent) between window and weatherstrip as

shown in Figure 92.

12.

Install garnish and reveal moldings in reverse order

of removal. Note that upper reveal molding flanges

must pass between retainer and feeler stock. Feeler

stock is removed as molding is installed as shown

in Figure 93.

GARNISH MOLDINGS AND LATCHES

Figure 94 shows garnish molding and latch installation.

Note that latch may be adjusted to regulate header weath-

erstrip pressure on windshield frame. To adjust latch,

mark original position, loosen mounting screws and move

latch in desired direction. Be sure latch is engaged in

serrations before tightening mounting screws.

When removing garnish moldings, note that short

moldings under latches (Item I, Figure 94) are the

CHEVROLET CHASSIS SERVICE MANUAL