CHEVROLET CAMARO 1967 1.G Chassis Workshop Manual

Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 251 of 659

BRAKES

5-18

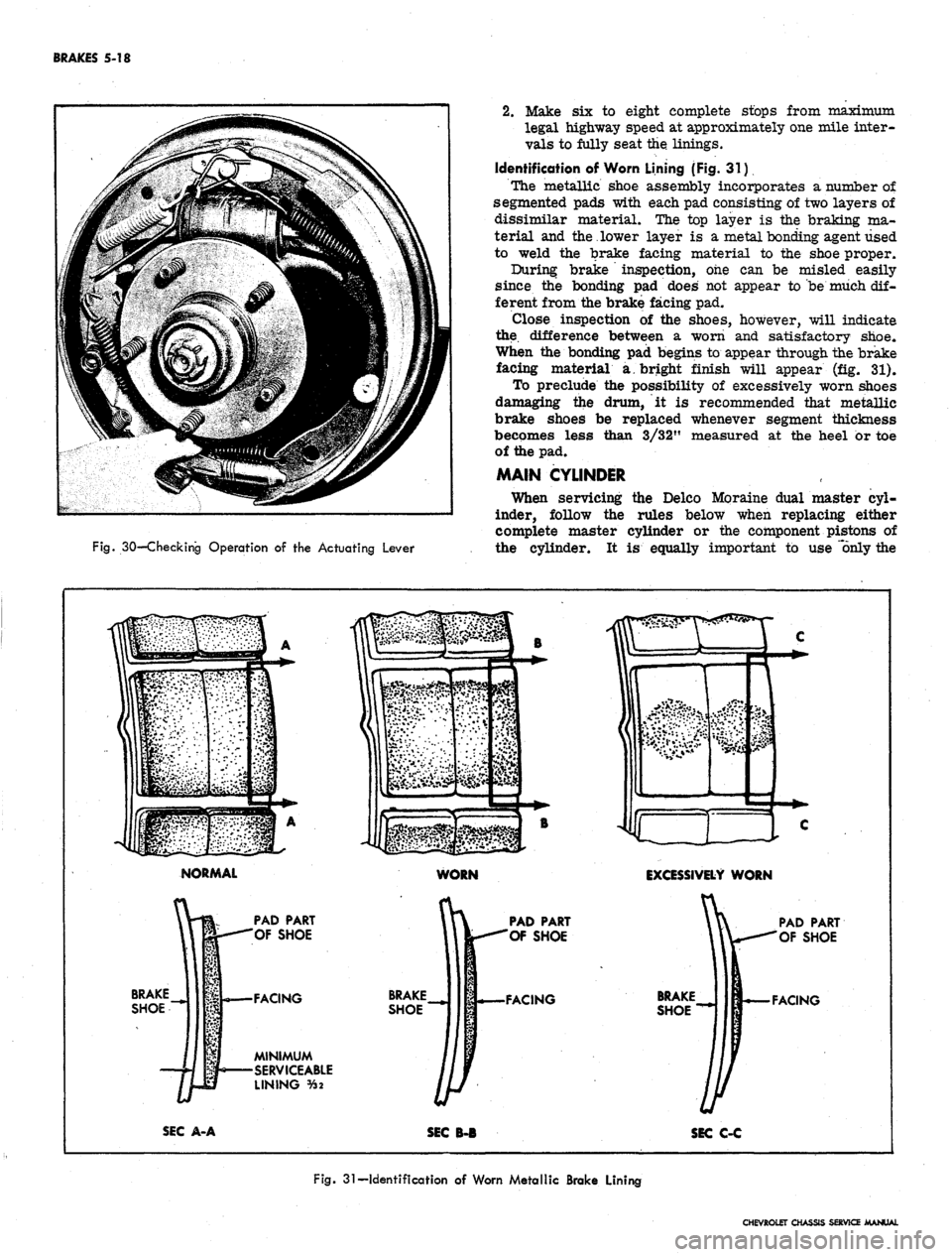

Fig.

30—Checking

Operation

of the

Actuating

Lever

2.

Make six to eight complete stops from maximum

legal highway speed at approximately one mile inter-

vals to fully seat the linings.

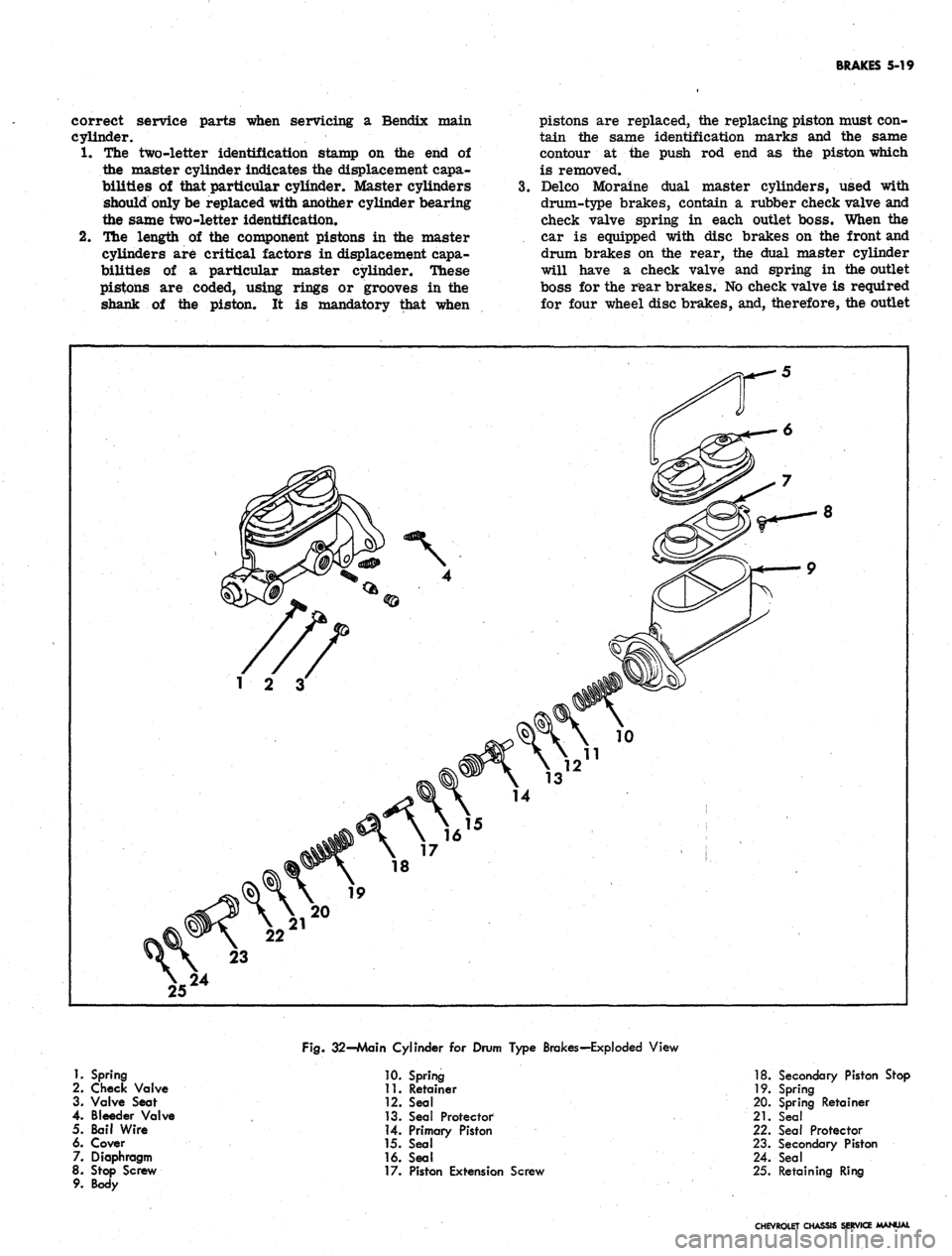

Identification of Worn Lining (Fig. 31)

The metallic shoe assembly incorporates a number of

segmented pads with each pad consisting of two layers of

dissimilar material. The top layer is the braking ma-

terial and the lower layer is a metal bonding agent used

to weld the brake facing material to the shoe proper.

During brake inspection, one can be misled easily

since the bonding pad does not appear to be much dif-

ferent from the brake facing pad.

Close inspection of the shoes, however, will indicate

the difference between a worn and satisfactory shoe.

When the bonding pad begins to appear through the brake

facing material a bright finish will appear (fig. 31).

To preclude the possibility of excessively worn shoes

damaging the drum, it is recommended that metallic

brake shoes be replaced whenever segment thickness

becomes less than 3/32" measured at the heel or toe

of the pad.

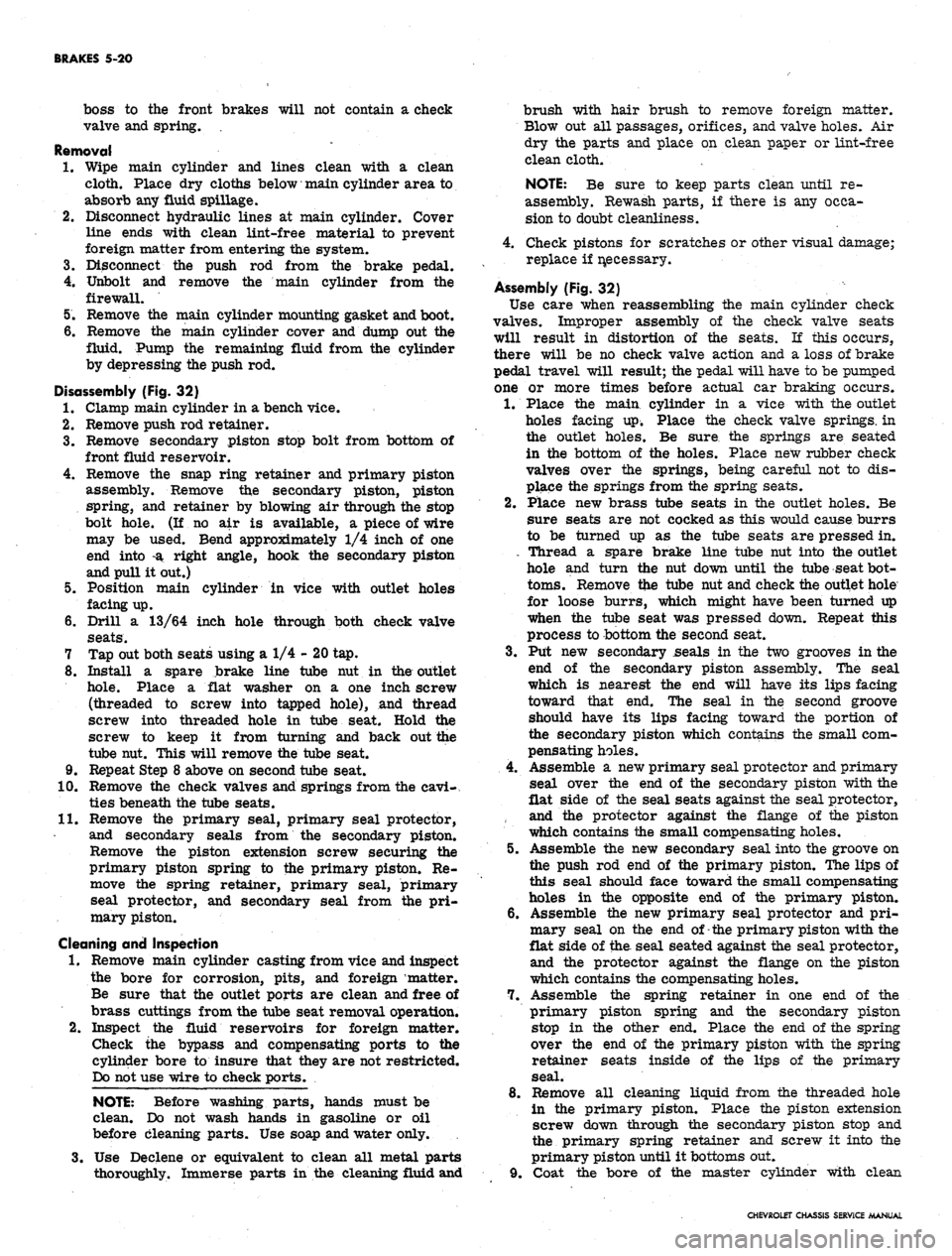

MAIN CYLINDER

When servicing the Delco Moraine dual master cyl-

inder, follow the rules below when replacing either

complete master cylinder or the component pistons of

the cylinder. It is equally important to use 'only the

NORMAL

WORN

EXCESSIVELY

WORN

BRAKE

SHOE

PAD PART

'OF SHOE

•FACING

MINIMUM

•SERVICEABLE

LINING

%2

BRAKE

SHOE

PAD PART

OF SHOE

FACING

BRAKE

SHOE

PAD PART

OF SHOE

FACING

SEC

A-A

SEC

B-B

SEC

C-C

Fig. 31—Identification of Worn Metallic Brake Lining

CHEVROLET CHASSIS SERVICE MANUAL

Page 252 of 659

BRAKES 5-19

correct service parts when servicing a Bendix main

cylinder.

1.

The two-letter identification stamp on the end of

the master cylinder indicates the displacement capa-

bilities of that particular cylinder. Master cylinders

should only be replaced with another cylinder bearing

the same two-letter identification.

2.

The length of the component pistons in the master

cylinders are critical factors in displacement capa-

bilities of a particular master cylinder. These

pistons are coded, using rings or grooves in the

shank of the piston. It is mandatory that when

pistons are replaced, the replacing piston must con-

tain the same identification marks and the same

contour at the push rod end as the piston which

is removed.

Delco Moraine dual master cylinders, used with

drum-type brakes, contain a rubber check valve and

check valve spring in each outlet boss. When the

car is equipped with disc brakes on the front and

drum brakes on the rear, the dual master cylinder

will have a check valve and spring in the outlet

boss for the rear brakes. No check valve is required

for four wheel disc brakes, and, therefore, the outlet

1.

Spring

2.

Check Valve

3. Valve Seat

4.

Bleeder Valve

5. Bail Wire

6. Cover

7. Diaphragm

8. Stop Screw

9. Body

Fig.

32-Main Cylinder for Drum Type Brakes-Exploded View

10.

Spring

11.

Retainer

12.

Seal

13.

Seal Protector

14.

Primary Piston

15.

Seal

16.

Seal

17.

Piston Extension Screw

18.

Secondary Piston Stop

19.

Spring

20.

Spring Retainer

21.

Seal

22.

Seal Protector

23.

Secondary Piston

24.

Seal

25.

Retaining Ring

CHEVROLET CHASSIS SERVICE MANUAL

Page 253 of 659

BRAKES 5-20

boss to the front brakes will not contain a check

valve and spring. .

Removal

1.

Wipe main cylinder and lines clean with a clean

cloth. Place dry cloths below main cylinder area to

absorb any fluid spillage.

2.

Disconnect hydraulic lines at main cylinder. Cover

line ends with clean lint-free material to prevent

foreign matter from entering the system.

3.

Disconnect the push rod from the brake pedal.

4.

Unbolt and remove the main cylinder from the

firewall.

5.

Remove the main cylinder mounting gasket and boot.

6. Remove the main cylinder cover and dump out the

fluid. Pump the remaining fluid from the cylinder

by depressing the push rod.

Disassembly (Fig. 32)

1.

Clamp main cylinder in a bench vice.

2.

Remove push rod retainer.

3.

Remove secondary piston stop bolt from bottom of

front fluid reservoir.

4.

Remove the snap ring retainer and primary piston

assembly. Remove the secondary piston, piston

spring, and retainer by blowing air through the stop

bolt hole. (If no air is available, a piece of wire

may be used. Bend approximately 1/4 inch of one

end into -a right angle, hook the secondary piston

and pull it out.)

5.

Position main cylinder in vice with outlet holes

facing up.

6. Drill a 13/64 inch hole through both check valve

seats.

7 Tap out both seats using a 1/4 - 20 tap.

8. Install a spare brake line tube nut in the outlet

hole.

Place a flat washer on a one inch screw

(threaded to screw into tapped hole), and thread

screw into threaded hole in tube seat. Hold the

screw to keep it from turning and back out the

tube nut. This will remove the tube seat.

9. Repeat Step 8 above on second tube seat.

10.

Remove the check valves and springs from the cavi-

ties beneath the tube seats.

11.

Remove the primary seal, primary seal protector,

and secondary seals from the secondary piston.

Remove the piston extension screw securing the

primary piston spring to the primary piston. Re-

move the spring retainer, primary seal, primary

seal protector, and secondary seal from the pri-

mary piston.

Cleaning and Inspection

1.

Remove main cylinder casting from vice and inspect

the bore for corrosion, pits, and foreign matter.

Be sure that the outlet ports are clean and free of

brass cuttings from the tube seat removal operation.

2.

Inspect the fluid reservoirs for foreign matter.

Check the bypass and compensating ports to the

cylinder bore to insure that they are not restricted.

Do not use wire to check ports.

NOTE: Before washing parts, hands must be

clean. Do not wash hands in gasoline or oil

before cleaning parts. Use soap and water only.

3.

Use Declene or equivalent to clean all metal parts

thoroughly. Immerse parts in the cleaning fluid and

brush with hair brush to remove foreign matter.

Blow out all passages, orifices, and valve holes. Air

dry the parts and place on clean paper or lint-free

clean cloth.

NOTE: Be sure to keep parts clean until re-

assembly. Rewash parts, if there is any occa-

sion to doubt cleanliness.

4.

Check pistons for scratches or other visual damage;

replace if necessary.

Assembly (Fig. 32)

Use care when reassembling the main cylinder check

valves. Improper assembly of the check valve seats

will result in distortion of the seats. If this occurs,

there will be no check valve action and a loss of brake

pedal travel will result; the pedal will have to be pumped

one or more times before actual car braking occurs.

1.

Place the main cylinder in a vice with the outlet

holes facing up. Place the check valve springs, in

the outlet holes. Be sure the springs are seated

in the bottom of the holes. Place new rubber check

valves over the springs, being careful not to dis-

place the springs from the spring seats.

2.

Place new brass tube seats in the outlet holes. Be

sure seats are not cocked as this would cause burrs

to be turned up as the tube seats are pressed in.

. Thread a spare brake line tube nut into the outlet

hole and turn the nut down until the tube seat bot-

toms.

Remove the tube nut and check the outlet hole

for loose burrs, which might have been turned up

when the tube seat was pressed down. Repeat this

process to bottom the second seat.

3.

Put new secondary seals in the two grooves in the

end of the secondary piston assembly. The seal

which is nearest the end will have its lips facing

toward that end. The seal in the second groove

should have its lips facing toward the portion of

the secondary piston which contains the small com-

pensating holes.

4.

Assemble a new primary seal protector and primary

seal over the end of the secondary piston with the

flat side of the seal seats against the seal protector,

and the protector against the flange of the piston

which contains the small compensating holes.

5.

Assemble the new secondary seal into the groove on

the push rod end of the primary piston. The lips of

this seal should face toward the small compensating

holes in the opposite end of the primary piston.

6. Assemble the new primary seal protector and pri-

mary seal on the end of-the primary piston with the

flat side of the. seal seated against the seal protector,

and the protector against the flange on the piston

which contains the compensating holes.

7.

Assemble the spring retainer in one end of the

primary piston spring and the secondary piston

stop in the other end. Place the end of the spring

over the end of the primary piston with the spring

retainer seats inside of the lips of the primary

seal.

8. Remove all cleaning liquid from the threaded hole

in the primary piston. Place the piston extension

screw down through the secondary piston stop and

the primary spring retainer and screw it into the

primary piston until it bottoms out.

9. Coat the bore of the master cylinder with clean

CHEVROLET CHASSIS SERVICE MANUAL

Page 254 of 659

BRAKES 5-21

brake fluid. Coat the primary and secondary seals

on the secondary piston with clean brake fluid. Insert

the secondary piston spring retainer into the sec-

ondary piston spring. Place the retainer and spring

down over the end of the secondary piston until the

retainer locates inside of the lips of the primary

cup.

10.

Hold the master cylinder with the open end of the

bore down. Push the secondary piston into the bore

until the spring seats against the closed end of the

bore.

11.

Position the master cylinder in a vise with the

open end of the bore up. Coat the primary and

secondary seal on the primary piston with clean

brake fluid. Push the primary piston assembly,

spring end first, into the bore of the master cylinder*

Hold the piston down and snap the lock ring into

position in the small groove in the I.D. of the bore.

12.

Push the primary piston down to move the secondary

piston forward far enough to clear the stop screw

hole in the bottom of the front fluid reservoir. Install

the stop screw.

13.

Install reservoir diaphragm in the reservoir cover

and install the cover on the main cylinder. Push

bail wire into position to secure the reservoir cover.

Installation

1.

Assemble the push rod through the push rod retainer,

if it has been disassembled.

2.

Push the retainer over the end of the main cylinder.

Assemble new boot over push rod and press it down

over the push rod retainer. Slide new mounting

gasket into position.

3.

Secure .the main cylinder to the firewall with mount-

ing bolts.

4.

Connect the push rod clevis to the brake pedal with

pin and retainer.

5. Connect the brake lines to the main cylinder.

6. Fill the main cylinder reservoirs to the levels

shown in Figure 8. Bleed the brake system as out-

lined in this section.

7. K necessary, adjust the brake pedal free play as

outlined in this section.

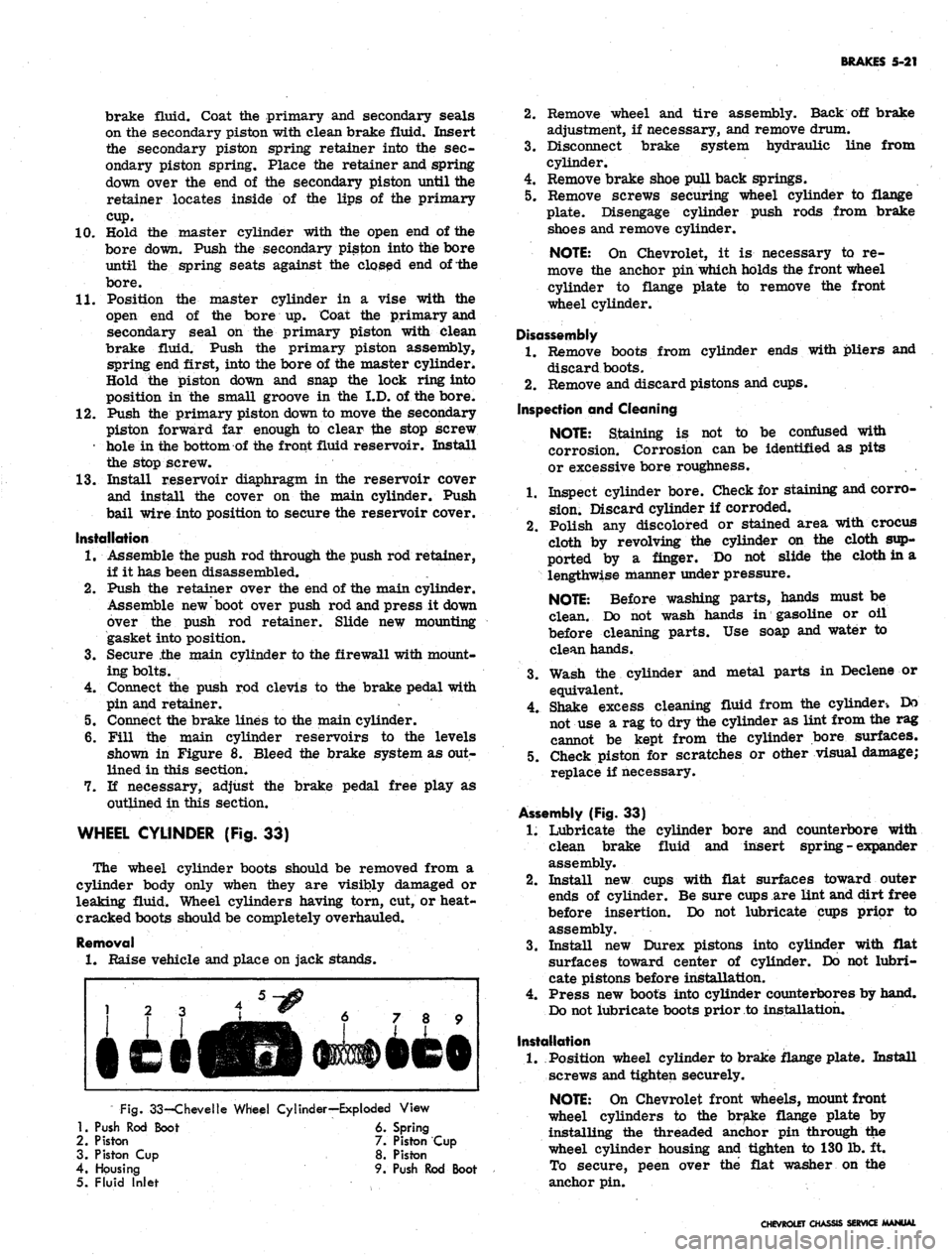

WHEEL CYLINDER (Fig. 33)

The wheel cylinder boots should be removed from a

cylinder body only when they are visibly damaged or

leaking fluid. Wheel cylinders having torn, cut, or heat-

cracked boots should be completely overhauled.

Removal

1.

Raise vehicle and place on jack stands.

Fig.

33-Chevelle Wheel Cylinder—Exploded View

1.

Push Rod Boot 6. Spring

2.

Piston 7. Piston Cup

3. Piston Cup 8. Piston

4.

Housing 9. Push Rod Boot

5. Fluid Inlet

2.

Remove wheel and tire assembly. Back off brake

adjustment, if necessary, and remove drum.

3.

Disconnect brake system hydraulic line from

cylinder.

4.

Remove brake shoe pull back springs.

5. Remove screws securing wheel cylinder to flange

plate. Disengage cylinder push rods from brake

shoes and remove cylinder.

NOTE:

On Chevrolet, it is necessary to re-

move the anchor pin which holds the front wheel

cylinder to flange plate to remove the front

wheel cylinder.

Disassembly

1.

Remove boots from cylinder ends with pliers and

discard boots.

2.

Remove and discard pistons and cups.

Inspection and Cleaning

NOTE:

Staining is not to be confused with

corrosion. Corrosion can be identified as pits

or excessive bore roughness.

1.

Inspect cylinder bore. Check for staining and corro-

sion.

Discard cylinder if corroded.

2.

Polish any discolored or stained area with crocus

cloth by revolving the cylinder on the cloth sup-

ported by a finger. Do not slide tfce cloth in a

lengthwise manner under pressure.

NOTE:

Before washing parts, hands must be

clean. Do not wash hands in gasoline or oil

before cleaning parts. Use soap and water to

clean hands.

3.

Wash the cylinder and metal parts in Declene or

equivalent.

4.

Shake excess cleaning fluid from the cylinder-. Do

not use a rag to dry the cylinder as lint from the rag

cannot be kept from the cylinder bore surfaces.

5. Check piston for scratches or other visual damage;

replace if necessary.

Assembly (Fig. 33)

1.

Lubricate the cylinder bore and counterbore with

clean brake fluid and insert spring - expander

assembly.

2.

Install new cups with flat surfaces toward outer

ends of cylinder. Be sure cups are lint and dirt free

before insertion. Do not lubricate cups prior to

assembly.

3.

Install new Durex pistons into cylinder with flat

surfaces toward center of cylinder. Do not lubri-

cate pistons before installation.

4.

Press new boots into cylinder counterbores by hand.

Do not lubricate boots prior to installation.

Installation

1.

Position wheel cylinder to brake flange plate. Install

screws and tighten securely.

NOTE:

On Chevrolet front wheels, mount front

wheel cylinders to the brake flange plate by

installing the threaded anchor pin through the

wheel cylinder housing and tighten to 130 lb. ft.

To secure, peen over the flat washer on the

anchor pin.

CHEVROLET CHASSIS SERVICE MANUAL

Page 255 of 659

BRAKES 5-22

2.

Replace ail push rods and pull back springs.

3.

Connect hose or line to wheel cylinder.

NOTE:

If replacing front wheel cylinder, con-

nect hose and inspect installation as outlined in

"Hydraulic Brake Hose Replacement".

4.

Install drum and wheel.

5. Bleed brakes as outlined in this section.

ANCHOR PIN

Front Wheel

1.

Raise front of vehicle and place on jack stands.

2.

Remove wheel and drum as outlined in this section.

3.

Remove brake shoe pull back springs, link and guide

plate.

4.

Disengage anchor pin lock and remove anchor pin by

turning counterclockwise.

5. Place new lock plate on anchor pin and pass pin

through the hole in flange plate and screw into tapped

hole in spindle support.

6. Torque pin to 130 lb. ft. and lock by peening over

washer tabs.

7. Install brake shoe guide plate, link and pull back

springs.

8. Adjust brakes, install drum and wheel as outlined

in this section. Test brake operation.

Rear Wheel

Two type anchor pins are used in production for the

rear wheels. The riveted type is not serviced and if

failure or damage should occur to either the anchor

pin or flange plate, both parts will have to be replaced

and the threaded type anchor pin used.

Threaded Type

1.

Raise rear of vehicle and place on jack stands,

2.

Remove wheel and drum as outlined in this section.

3.

Remove brake shoe pull back springs, link and guide

plate.

4.

Remove anchor pin retaining nut and washer and

remove pin from flange plate.

5. Position anchor pin to flange plate, install lock

washer and nut, and torque pin to 80 lb. ft.

6. Install brake shoe guide plate, link and pull back

springs.

7. Adjust brakes and install drum and wheel as outlined

in this section.

8. Test brake operation.

BRAKE DRUMS

Front brake drums are the demountable type; that is,

they can be removed without removing the hub. Rear

brake drums are demountable and may be removed

wihtout removing the axle shaft.

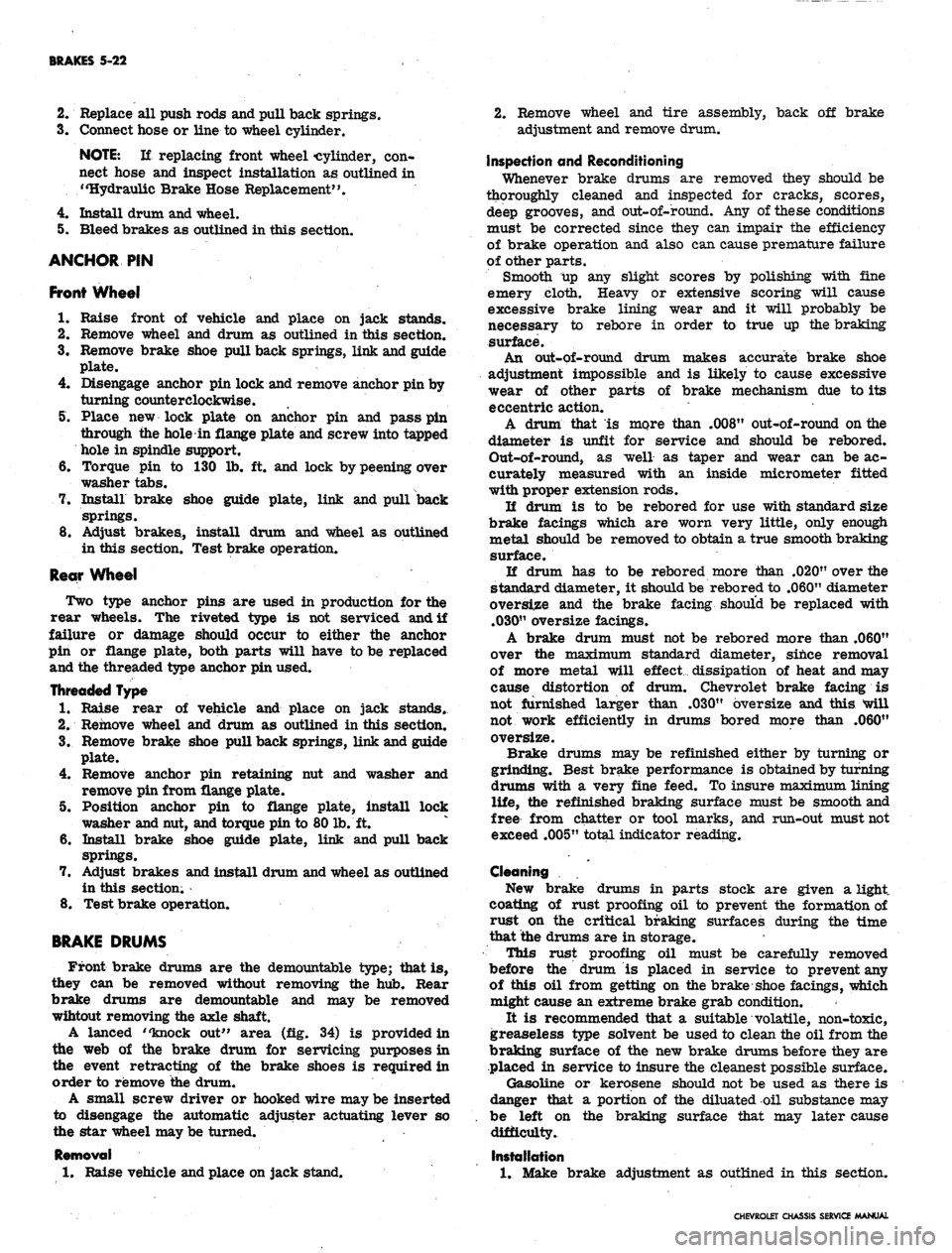

A lanced "knock out" area (fig. 34) is provided in

the web of the brake drum for servicing purposes in

the event retracting of the brake shoes is required in

order to remove the drum.

A small screw driver or hooked wire may be inserted

to disengage the automatic adjuster actuating lever so

the star wheel may be turned.

Removal

1.

Raise vehicle and place on jack stand.

2.

Remove wheel and tire assembly, back off brake

adjustment and remove drum.

Inspection and Reconditioning

Whenever brake drums are removed they should be

thoroughly cleaned and inspected for cracks, scores,

deep grooves, and out-of-round. Any of these conditions

must be corrected since they can impair the efficiency

of brake operation and also can cause premature failure

of other parts.

Smooth up any slight scores by polishing with fine

emery cloth. Heavy or extensive scoring will cause

excessive brake lining wear and it will probably be

necessary to rebore in order to true up the braking

surface.

An out-of-round drum makes accurate brake shoe

adjustment impossible and is likely to cause excessive

wear of other parts of brake mechanism due to its

eccentric action.

A drum that is more than .008" out-of-round on the

diameter is unfit for service and should be rebored.

Out-of^round, as well as taper and wear can be ac-

curately measured with an inside micrometer fitted

with proper extension rods.

If drum is to be rebored for use with standard size

brake facings which are worn very little, only enough

metal should be removed to obtain a true smooth braking

surface.

If drum has to be rebored more than .020" over the

standard diameter, it should be rebored to .060" diameter

oversize and the brake facing should be replaced with

.030"

oversize facings.

A brake drum must not be rebored more than .060"

over the maximum standard diameter, since removal

of more metal will effect, dissipation of heat and may

cause distortion of drum. Chevrolet brake facing is

not furnished larger than .030" oversize and this will

not work efficiently in drums bored more than .060"

oversize.

Brake drums may be refinished either by turning or

grinding. Best brake performance is obtained by turning

drums with a very fine feed. To insure maximum lining

life,

the refinished braking surface must be smooth and

free from chatter or tool marks, and run-out must not

exceed .005" total indicator reading.

Cleaning

New brake drums in parts stock are given a light.

coating of rust proofing oil to prevent the formation of

rust on the critical braking surfaces during the time

that the drums are in storage.

This rust proofing oil must be carefully removed

before the drum is placed in service to prevent any

of this oil from getting on the brake shoe facings, which

might cause an extreme brake grab condition.

It is recommended that a suitable volatile, non-toxic,

greaseless type solvent be used to clean the oil from the

braking surface of the new brake drums before they are

•placed in service to insure the cleanest possible surface.

Gasoline or kerosene should not be used as there is

danger that a portion of the diluated oil substance may

be left on the braking surface that may later cause

difficulty.

Installation

1.

Make brake adjustment as outlined in this section.

CHEVROLET CHASSIS SERVICE MANUAL

Page 256 of 659

BRAKES 5-23

Fig.

34—Brake Drum Access Hole

2.

Install brake drum, aligning tang with wheel hub

(fig. 18).

3.

Install wheel and tire assembly.

. 4. Make final brake adjustment as outlined in this

section and check brake operation.

BRAKE PIPE DISTRIBUTION AND SWITCH

ASSEMBLY (Fig. 2)

Removal

1.

Disconnect battery cable.

2.

Disconnect electrical lead from switch assembly.

3.

Place dry rags below the switch to absorb any fluid

spilled during removal of switch.

4.

Disconnect four hydraulic lines from connections

at switch. If necessary, loosen line connections at

main cylinder to loosen lines. Cover open line ends

with clean, lint-free material to prevent foreign

matter from entering the system.

5.

Remove mounting screw and remove switch from

vehicle.

Installation

1.

Make sure new switch is clean and free of dust and

lint. If any doubt exists, wash switch in Declene,

or equivalent, and dry with air.

2.

Place switch in position and secure to bracket with

mounting screw.

3.

Remove protective material from open hydraulic

brake lines and connect lines to switch. If necessary,

tighten brake line connections at main cylinder.

4.

Connect switch electrical lead.

5.

Connect battery cable.

6. Bleed the brake systems as outlined in this section.

CAMARO PRESSURE REGULATOR VALVE

(AIR CONDITIONED MODELS ONLY)

Removal (Fig. 3)

1.

Place dry rags below valve to absorb any fluid

spilled during removal of valve.

2.

Disconnect hydraulic brake lines from both sides

of switch. Cover open line ends with clean, lint-free

material to prevent foreign matter from entering

the system.

3.

Remove mounting screw and remove switch from

vehicle.

Installation

1.

Make sure new valve is clean and free of dust and

lint. If any doubt exists, wash valve in Declene, or

equivalent, and dry with air.

2.

Place valve in position and secure to frame side

rail with mounting screw.

3.

Remove protective material from open hydraulic

brake lines and connect lines to each side of valve.

4.

Bleed brake system as outlined in this section.

CHEVROLET CHASSIS SERVICE

Page 257 of 659

BRAKES

5-24

DISC BRAKES

INDEX

Page

General Description

. 5-24

Maintenance

and

Adjustments

5-24

Bleeding Hydraulic System

5-24

Parking Brake Adjustment

-

Corvette

5-24

Component Replacement

and

Repairs

5-25

Page

Brake Shoes

. . . . . 5-25

Brake Caliper

5-26

Brake Disc

5-29

Main Cylinder.

5-30

Parking Brake Shoes

-

Corvette

5-30

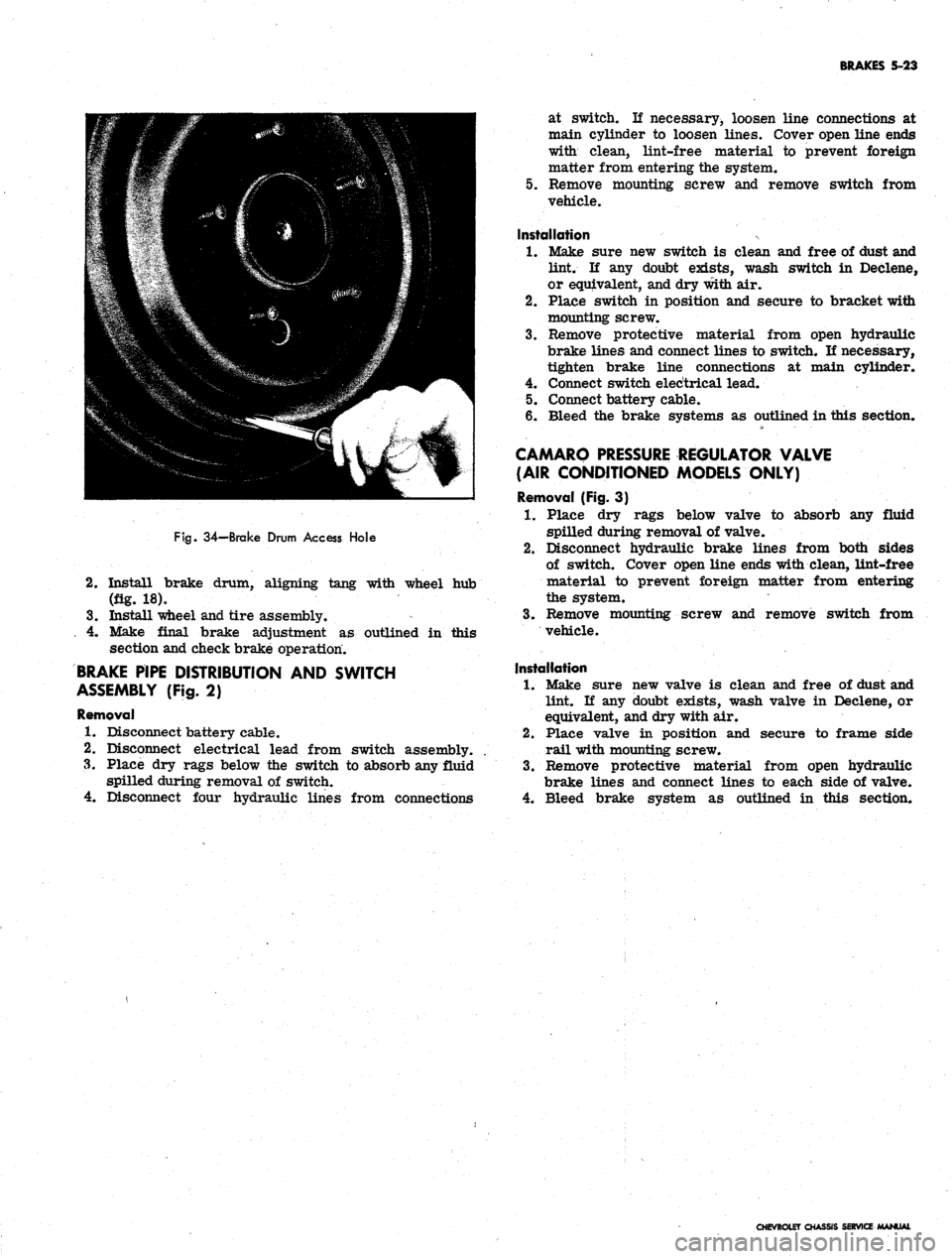

GENERAL DESCRIPTION

Four wheel disc brakes

are

standard equipment

on

the

1967

Corvette,

as in 1966. The

Corvette

may

also

be equipped with heavy duty disc brakes which include

new front calipers, shoes, linings,

and

rear pressure

regulator valve. This heavy duty option

is

used

in

conjunction with

a

vacuum power unit. Front wheel disc

brakes

are

installed

as

optional equipment

on

Chevrolet,

Chevelle, Camaro,

and

Chevy

II

models.

The disc brake,

(fig. 35),

consists

of a

fixed caliper,

rotating disc, splash shield,

and

mounting bracket.

The

caliper assembly contains four pistons and two shoe

and

lining assemblies with

the

lining riveted

to the

steel

shoes.

A

seal

and

dust boot

are

installed

on

each piston,

with

a

piston spring

in the

caliper cylinder bore beneath

each piston.

A

retaining pin extends through each caliper

half

and

both shoes

to

hold

the

shoes and linings

in

posi-

tion

in the

caliper.

On

Corvette heavy duty disc brakes,

two retaining cotter pins

are

used

at

each end

of the

caliper

to

secure

the

shoes

and

linings. Machined

sur-

faces within

the

caliper prevent

the

shoe

and

lining

assembly from rotating with

the

brake disc when pres-

sure

is

applied.

The disc, which

has a

series

of air

vent louvers

to

provide cooling,

is

mounted

on the

front wheel-hub.

The caliper straddles

the

disc and mounts

on a

mounting

bracket attached

to the

steering knuckle with

two

bolts.

The Corvette heavy duty option includes

a

pressure

regulator valve mounted

in the

rear brake line just

below

the

main cylinder. Chevrolet, Chevelle, Camaro,

and Chevy

n

models with disc brakes have

a

pressure

regulator valve mounted

in the

front brake line just

below

the

main cylinder. The valve controls

the

hydraulic

pressure

to the

front

or

rear brakes,

as

applicable,

resulting,

in the

correct pressure balance between

the

front

and

rear hydraulic systems. This valve guards

against premature .lock-up

of

front

or

rear wheels when

brakes

are

applied.

Maintenance, adjustment,

and

service operations which

are

not

included

in

this section

are the

same

as for

the Duo-Servo type brakes.

MAINTENANCE

AND

ADJUSTMENTS

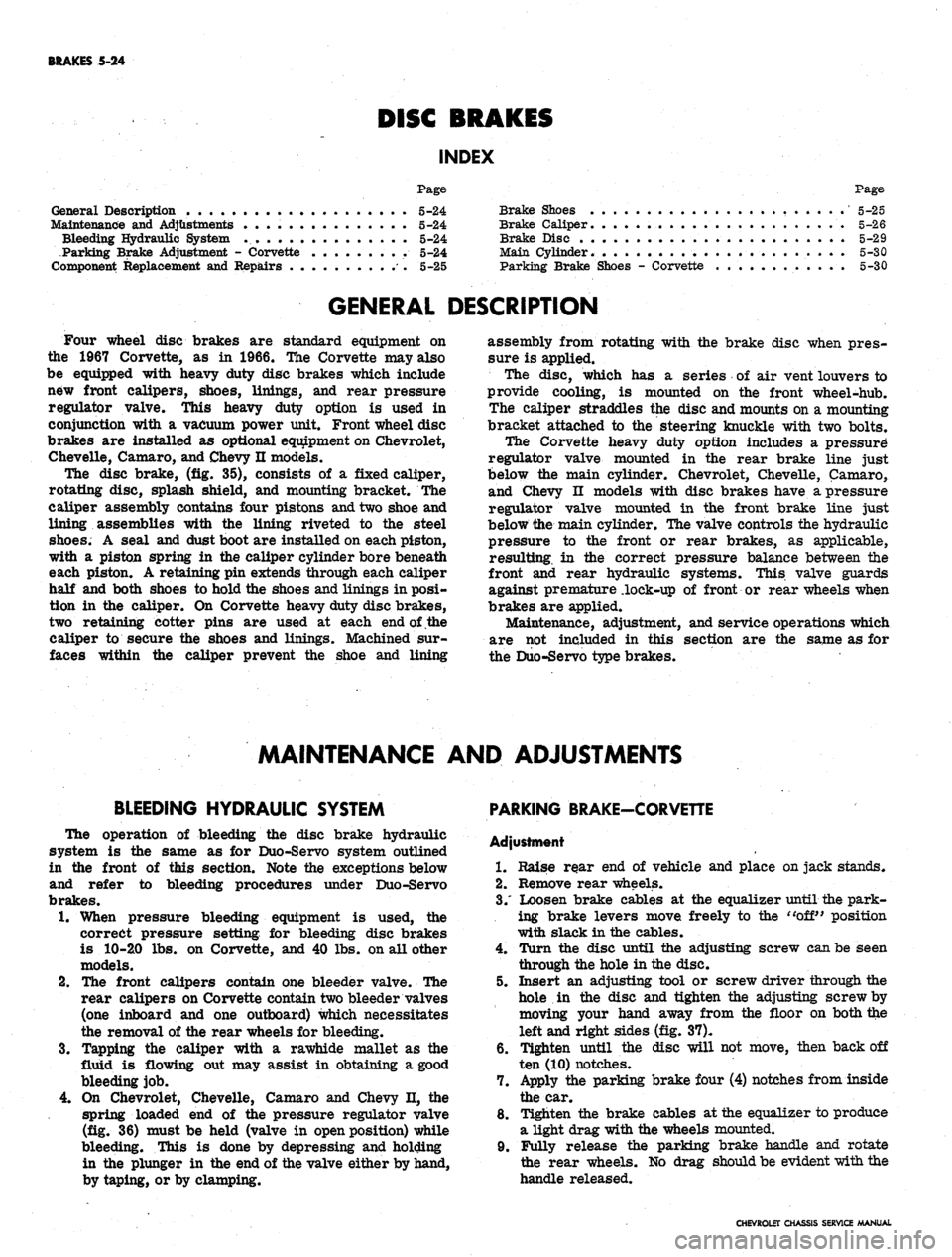

BLEEDING HYDRAULIC SYSTEM

The operation

of

bleeding

the

disc brake hydraulic

system

is the

same

as for

Duo-Servo system outlined

in

the

front

of

this section. Note

the

exceptions below

and refer

to

bleeding procedures under Duo-Servo

brakes.

1.

When pressure bleeding equipment

is

used,

the

correct pressure setting

for

bleeding disc brakes

is 10-2.0

lbs. on

Corvette,

and 40 lbs. on all

other

models.

2.

The

front calipers contain

one

bleeder valve.

The

rear calipers

on

Corvette contain two bleeder valves

(one inboard

and one

outboard) which necessitates

the removal

of the

rear wheels

for

bleeding.

3.

Tapping

the

caliper with

a

rawhide mallet

as the

fluid

is

flowing

out may

assist

in

obtaining

a

good

bleeding

job.

4.

On

Chevrolet, Chevelle, Camaro

and

Chevy

II, the

spring loaded

end of the

pressure regulator valve

(fig.

36)

must

be

held (valve

in

open position) while

bleeding. This

is

done

by

depressing

and

holding

in

the

plunger

in the

end

of

the valve either

by

hand,

by taping,

or by

clamping.

PARKING BRAKE-CORVETTE

Adjustment

1.

Raise rear

end of

vehicle

and

place

on

jack stands.

2.

Remove rear wheels.

3/

Loosen brake cables

at the

equalizer until

the

park-

ing brake levers move freely

to the "off"

position

with slack

in the

cables.

4.

Turn

the

disc until

the

adjusting screw can

be

seen

through

the

hole

in the

disc.

5. Insert

an

adjusting tool

or

screw driver through

the

hole

in the

disc

and

tighten

the

adjusting screw

by

moving your hand away from

the

floor

on

both

the

left and right sides

(fig. 37).

6. Tighten until

the

disc will

not

move, then back

off

ten

(10)

notches.

7. Apply

the

parking brake four

(4)

notches from inside

the

car.

8. Tighten

the

brake cables

at the

equalizer

to

produce

a light drag with

the

wheels mounted.

9. Fully release

the

parking brake handle

and

rotate

the rear wheels.

No

drag should be evident with

the

handle released.

CHEVROLET CHASSIS SERVICE MANUAL

Page 258 of 659

BRAKES 5-25

CORVETTE

CHEVELLE-CAMARO-CHEVY II

Fig.

35-Disc Brake-Cutaway View

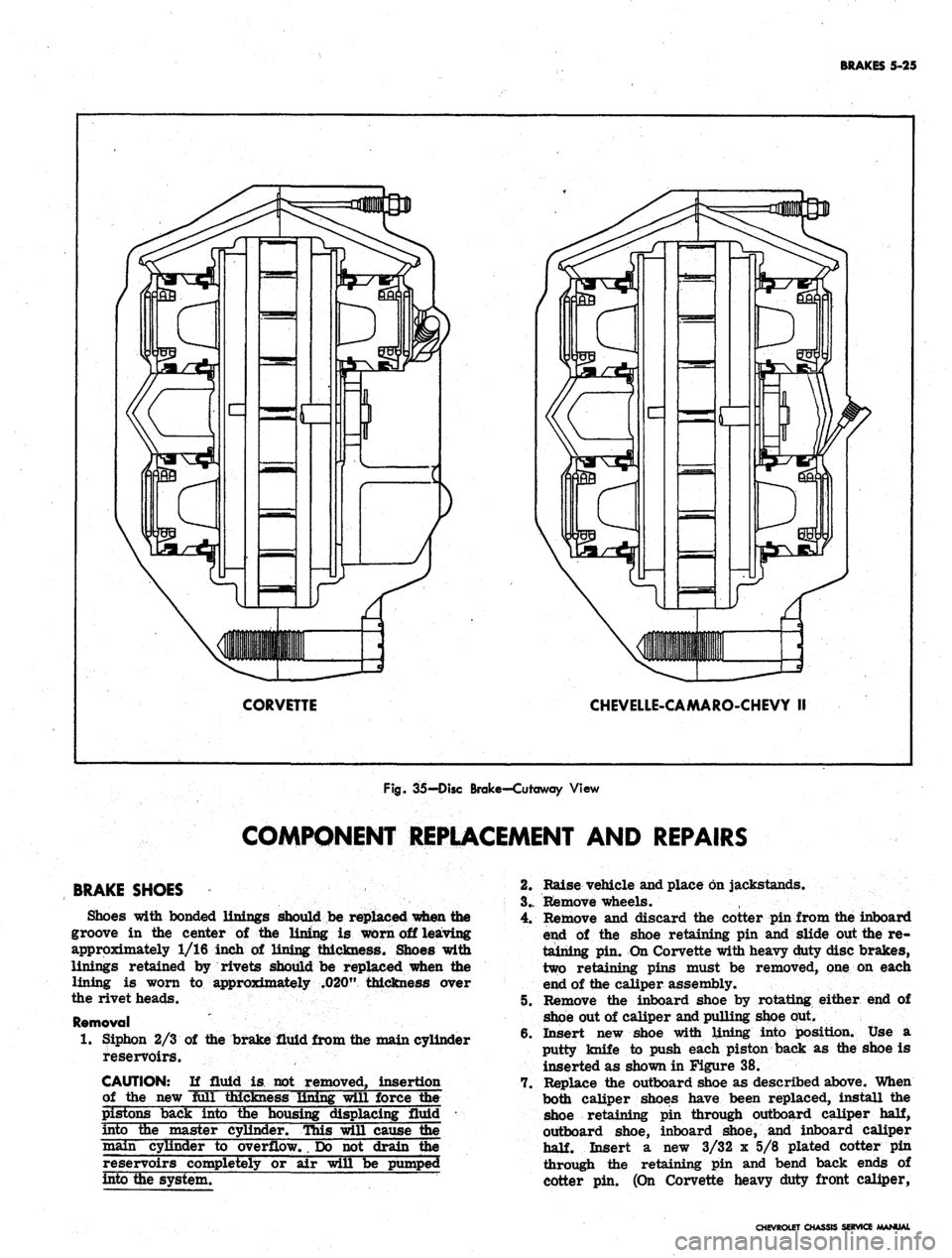

COMPONENT REPLACEMENT AND REPAIRS

BRAKE SHOES

Shoes 'with bonded linings should be replaced when the

groove in the center of the lining is worn off leaving

approximately 1/16 inch of lining thickness. Shoes with

linings retained by rivets should be replaced when the

lining is worn to approximately .020" thickness over

the rivet heads.

Removal

1.

Siphon 2/3 of the brake fluid from the main cylinder

reservoirs.

CAUTION: If fluid is not removed, insertion

of the new full thickness lining will force the

pistons back into the housing displacing fluid •••

into the master cylinder. This will cause fee

main cylinder to overflow,, Do not drain the

reservoirs completely or air will be pumped

into the system. ~

2.

Raise vehicle and place on jackstands.

3..

Remove wheels.

4.

Remove and discard the cotter pin from the inboard

end of the shoe retaining pin and slide out the re-

taining pin. On Corvette with heavy duty disc brakes,

two retaining pins must be removed, one on each

end of the caliper assembly.

5. Remove the inboard shoe by rotating either end of

shoe out of caliper and pulling shoe out.

6. Insert new shoe with lining into position. Use a

putty knife to push each piston back as the shoe is

inserted as shown in Figure 38.

7. Replace the outboard shoe as described above. When

both caliper shoes have been replaced, install the

shoe retaining pin through outboard caliper

half,

outboard shoe, inboard shoe, and inboard caliper

half.

Insert a new 3/32 x 5/8 plated cotter pin

through the retaining pin and bend back ends of

cotter pin. (On Corvette heavy duty front caliper,

CHEVROLET CHASSIS SERVICE

Page 259 of 659

BRAKES 5-26

PRESSURE

REGULATOR

VALVE

CHEVROLET

PRESSURE

REGULATOR

VALVE

CAMARO

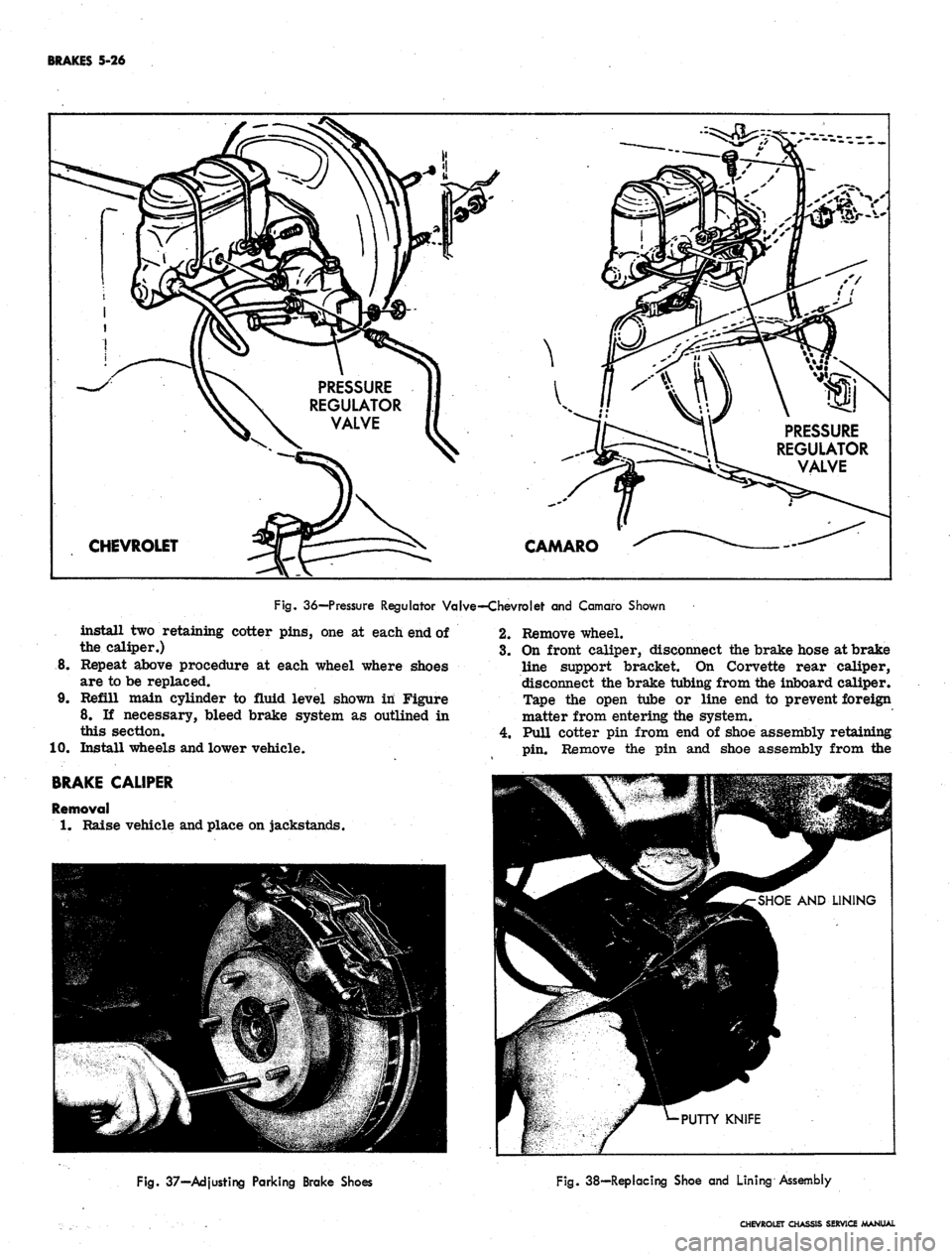

Fig.

36—Pressure Regulator Valve—Chevrolet and Camaro Shown

install two retaining cotter pins, one at each end of

the caliper.)

8. Repeat above procedure at each wheel where shoes

are to be replaced.

9. Refill main cylinder to fluid level shown in Figure

8. If necessary, bleed brake system as outlined in

this section.

10.

Install wheels and lower vehicle.

BRAKE

CALIPER

Removal

1.

Raise vehicle and place on jackstands.

2.

Remove wheel.

3.

On front caliper, disconnect the brake hose at brake

line support bracket. On Corvette rear caliper,

disconnect the brake tubing from the inboard caliper.

Tape the open tube or line end to prevent foreign

matter from entering the system.

4.

Pull cotter pin from end of shoe assembly retaining

pin.

Remove the pin and shoe assembly from the

Fig.

37—Adjusting Parking Brake Shoes

Fig.

38—Replacing Shoe and Lining Assembly

CHEVROLET CHASSIS SERVICE MANUAL

Page 260 of 659

BRAKES 5-27

CHEVELLE

, CHEVY II AND CAMARO SHOWN

1.

Caliper Belts

2.

Bleeder Valve

3. Caliper Half

4.

Piston Spring

Fig.

39-Caliper Assembly-Exploded View

5. Seal

6. Piston

7. Piston Boot

8. Brake Shoes

9. "O" Ri

10.

Caliper

11.

Retaining Pin

12.

Cotter Pin

caliper. Two retaining pins must be removed on

heavy duty Corvette front calipers. Identify the

inboard and outboard shoe if they are to be reused.

5. Remove the end of brake hose at bracket by re-

moving U-shaped retainer from the hose fitting and

withdrawing the hose from bracket.

6. Remove the caliper assembly from the mounting

bracket by removing two hex head bolts.

Disassembly (Fig. 39)

1.

Clean exterior of caliper with Declene, or equivalent.

On Chevrolet and Corvette front caliper, remove

brake hose.

2.

Separate the caliper halves by removing the two

large hex head bolts. Remove the two small "O"

rings from the cavities around the fluid transfer

holes in the two ends of the caliper halves.

3.

To free the piston boots so that the pistons may be

removed, push the piston down into the caliper

as far as it will go. Insert a screwdriver blade

under the inner edge of the steel ring in the boot,

and using the piston as a fulcrum, pry the boot from

its seat in the caliper

half.

CAUTION: Use care not to puncture seal when

removing pistons from caliper. ' ~

4.

Remove the pistons and piston springs from the

caliper

half.

Remove the boot and seal from their

grooves in the piston.

Cleaning and Inspection

1.

Clean all metal parts using Declene, or equivalent.

Remove all traces of dirt and grease. Do not use

mineral base solvents to clean brake parts.

2.

Using an air hose, blow out all fluid passages in the

caliper halves, making sure that there is no dirt

or foreign material blocking any of these passages.

3.

Discard all rubber parts. Boots, seals, and "O"

rings should be replaced with new service kit parts.

4.

Carefully inspect the piston bores in the caliper

halves. They must be free of scores and pits. A

scored or otherwise damaged bore will cause leaks

and unsatisfactory brake operation. Replace the

caliper half if either bore is damaged to the extent

that polishing with very fine crocus cloth will not

restore it.

CHEVROLET CHASSIS SERVICE MANUAL