CHEVROLET CAMARO 1982 Repair Guide

Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 321 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 321

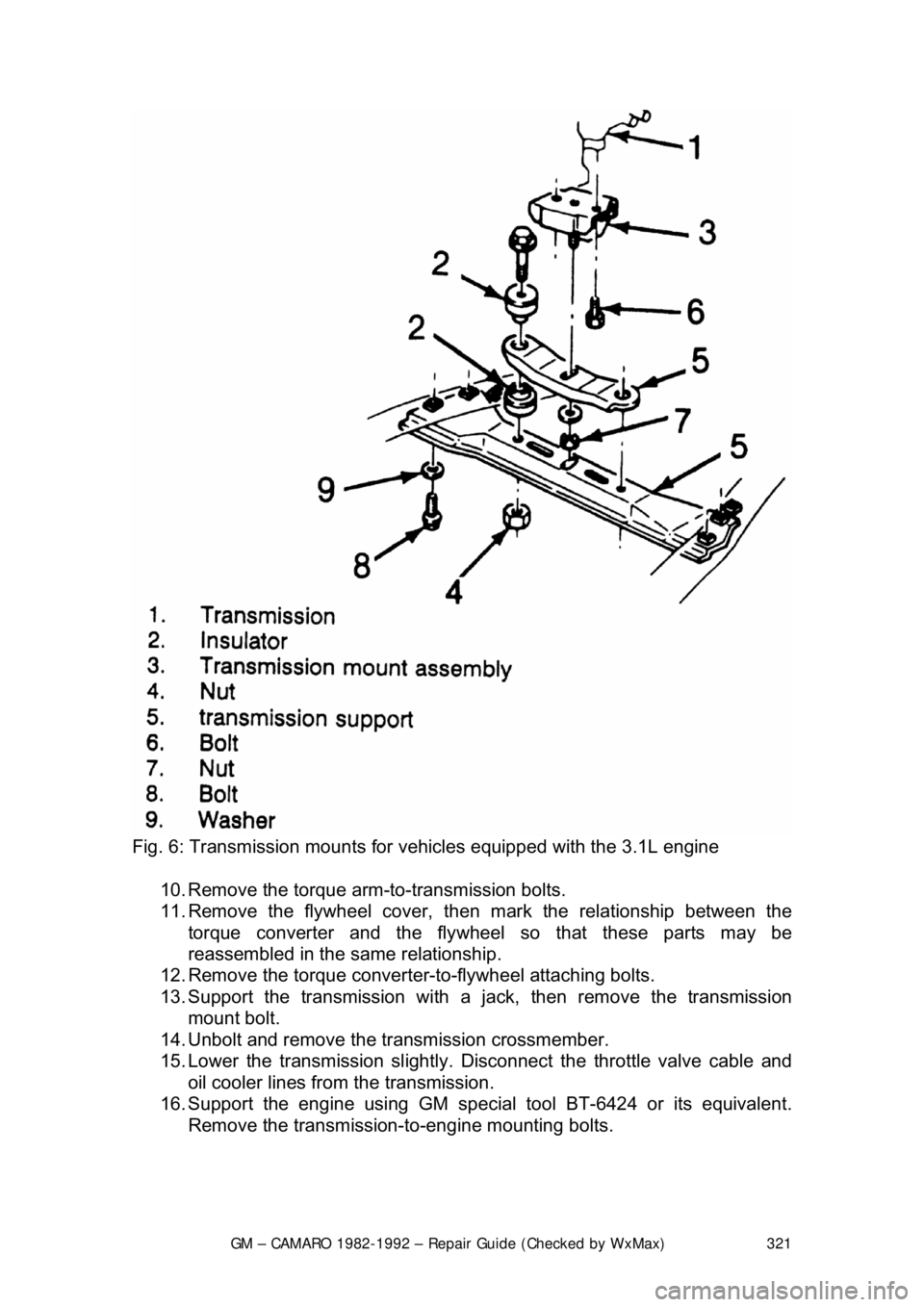

Fig. 6: Transmission mounts for vehi cles equipped with the 3.1L engine

10. Remove the torque arm-to-transmission bolts.

11. Remove the flywheel cover, t hen mark the relationship between the

torque converter and the flywheel so that these parts may be

reassembled in the same relationship.

12. Remove the torque converter-t o-flywheel attaching bolts.

13. Support the transmission with a ja ck, then remove the transmission

mount bolt.

14. Unbolt and remove the transmission crossmember.

15. Lower the transmission slightly. Disco nnect the throttle valve cable and

oil cooler lines from the transmission.

16. Support the engine using GM specia l tool BT-6424 or its equivalent.

Remove the transmission- to-engine mounting bolts.

Page 322 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 322

CAUTION - The transmission must be secu red to the transmission jack

17. Remove the transmission from the vehicle. Be careful not to damage the oil cooler lines, throttle valve cable, or the shift control cable. Also, keep

the rear of the transmissi on lower than the front to avoid the possibility of

the torque converter disengagi ng from the transmission.

To install: 18. Position the transmission and converter into place.

19. Install the transmission -to-engine mounting bolts.

20. Connect the throttle valve cable and oil cooler lines to the transmissio\

n.

21. Install the transmission cro ssmember and secure with bolts.

22. Install the transmission mount bolt.

23. Matchmark the torque converter-to-f lywheel. Install the torque converter-

to-flywheel attaching bolts.

Before installing the converter-to-flywheel bolts, be sure that the weld nuts on

the converter are flush with the flywheel, and that the converter rotates freely by

hand in this position.

24. Install the flywheel cover.

25. Install the torque arm-to-transmission bolts.

26. Connect the speedometer cable, el ectrical connectors and the shift

control cable from the transmission.

27. Connect the catalytic converter s upport bracket at the transmission.

28. Align the matchmark m ade earlier, then install the driveshaft to the axle

pinion. Bolt the universal joint straps to the pinion flange.

29. Lower the vehicle.

30. Install the dipstick tube using a ne w dipstick tube O-ring and secure with

the bolt. Install the tran smission oil dipstick.

31. Connect the throttle valve (TV) c ontrol cable at the carburetor.

32. Install the air cleaner assembly.

33. Connect the negative battery cable at the battery.

DRIVELINE

DRIVESHAFT AND U-JOINTS

The U-joint is secured to the yoke in one of two ways. Dana and Cleveland

shafts use a conventional snapring to ho ld each bearing cup in the yoke. The

snapring fits into a groove located in eac h yoke end just on top of each bearing

cup. The Saginaw design shaft secures its U-joints in another way. Nylon

material is injected through a small hole in the yoke and flows along a circular

groove between the U-joint and the yoke , creating a synthetic snapring.

Disassembly of the Saginaw U-joint requi res the joint to be pressed from the

yoke. This results in damage to the be aring cups and destruction of the nylon

rings.

Page 323 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 323

Replacement kits include new bearing

cups and conventional snaprings to

replace the original nylon rings. These replacement rings must go inboard of the

yoke in contrast to outboard mounting of the Dana and Cleveland designs.

Previous service to the Saginaw U-joints can be recognized by the presence of

snaprings inboard of the yoke.

Bad U-joints, requiring replacement, will produce a clunking sound when the car

is put into gear. This is due to worn needle bearings or a scored trunnion end

possibly caused by improper lubricati on during assembly. Camaro U-joints

require no periodic maintenance and theref ore have no lubrication fittings.

DRIVESHAFT

REMOVAL & INSTALLATION 1. Raise the vehicle and safely su pport it on jackstands. Paint a reference

line from the rear end of the drives haft to the companion flange so that

they can be reassembled in the same position.

2. Disconnect the rear universal join t by removing the U-bolts, retaining

straps, or the flange bolts.

3. To prevent loss of the needle bear ings, tape the bearing caps to the

trunnion.

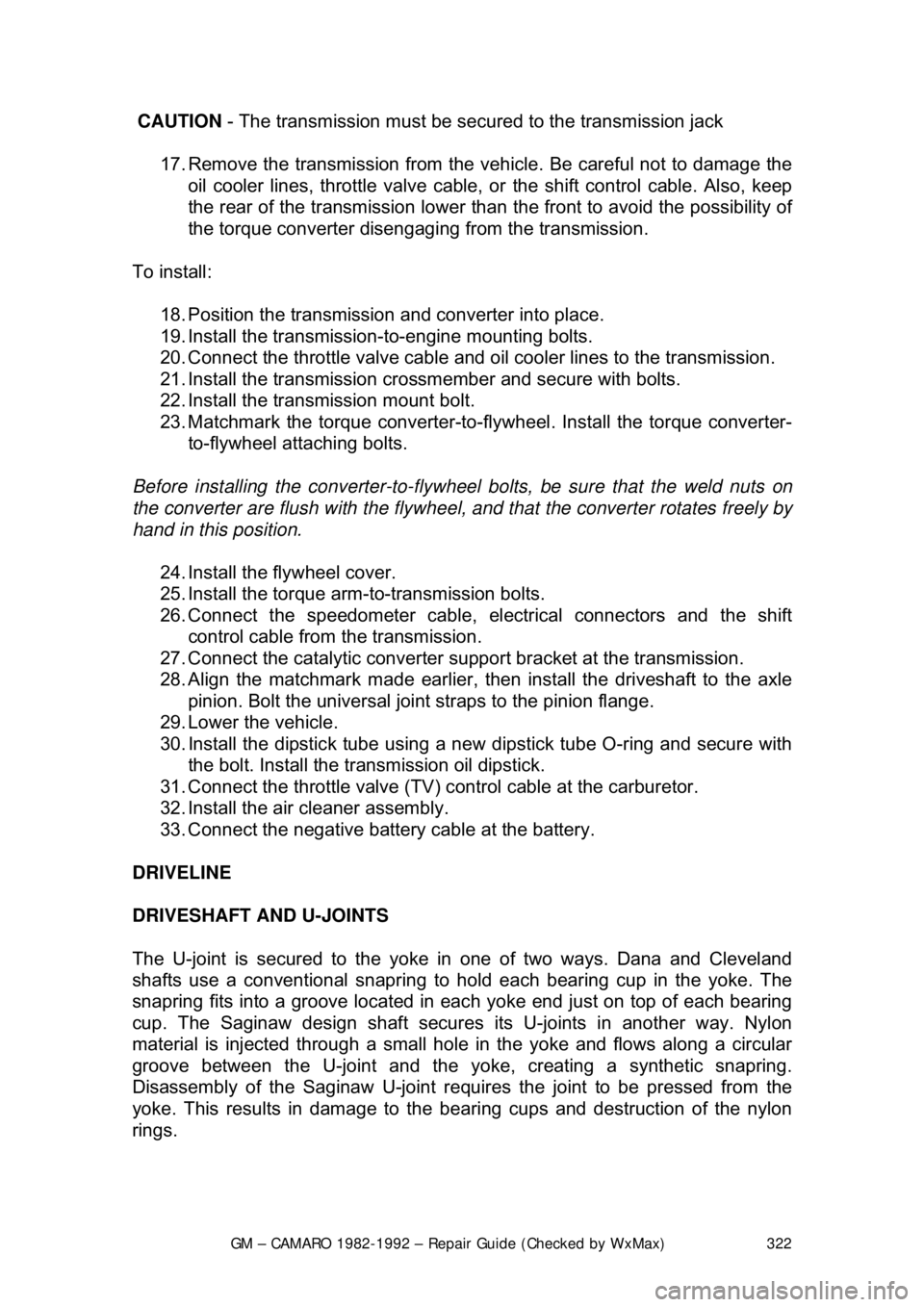

Fig. 1: Driveshaft

4. Remove the driveshaft from the tr ansmission by sliding it rearward.

Do not be alarmed by oil l eakage at the transmission output shaft. This oil is

there to lubricate the sp lines of the front yoke.

To install: 5. Check the yoke seal in the transmi ssion case extension and replace it if

necessary. See the transmission sect ion for replacement procedures.

6. Position the driveshaft and insert t he front yoke into the transmission so

the splines mesh with the transmission shaft splines.

7. Using reference marks made during re moval, align the driveshaft with the

companion flange and secure it with U-bolts or, retaining straps.

U-JOINT REPLACEMENT 1. Support the driveshaft horizontally in line with the base plate of a press.

Page 324 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 324

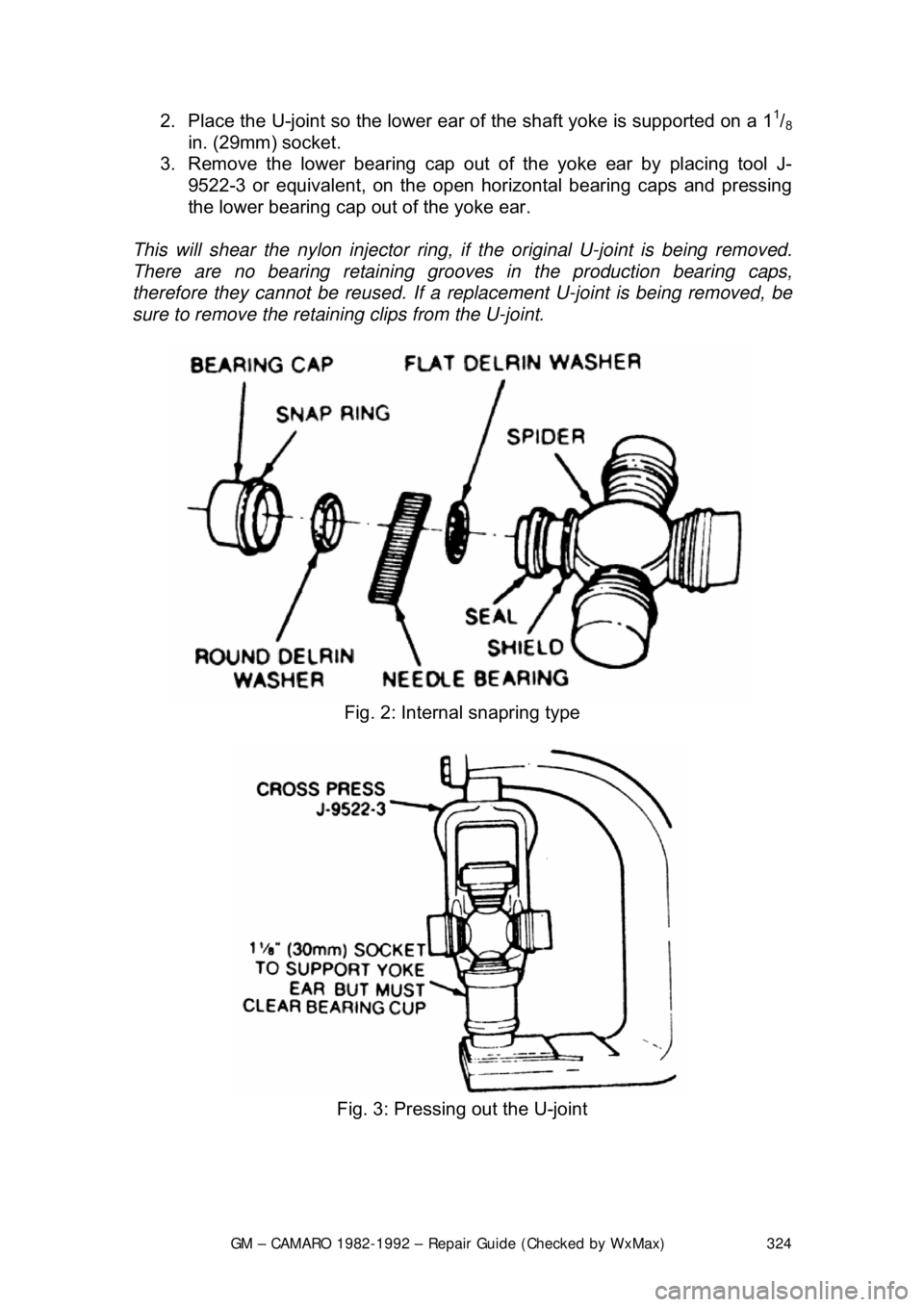

2. Place the U-joint so the lower ear

of the shaft yoke is supported on a 11/8

in. (29mm) socket.

3. Remove the lower bear ing cap out of the yoke ear by placing tool J-

9522-3 or equivalent, on the open horiz ontal bearing caps and pressing

the lower bearing cap out of the yoke ear.

This will shear the nylon injector ring, if the original U-joint is being removed.

There are no bearing re taining grooves in the production bearing caps,

therefore they cannot be reus ed. If a replacement U-joint is being removed, be

sure to remove the retaining clips from the U-joint.

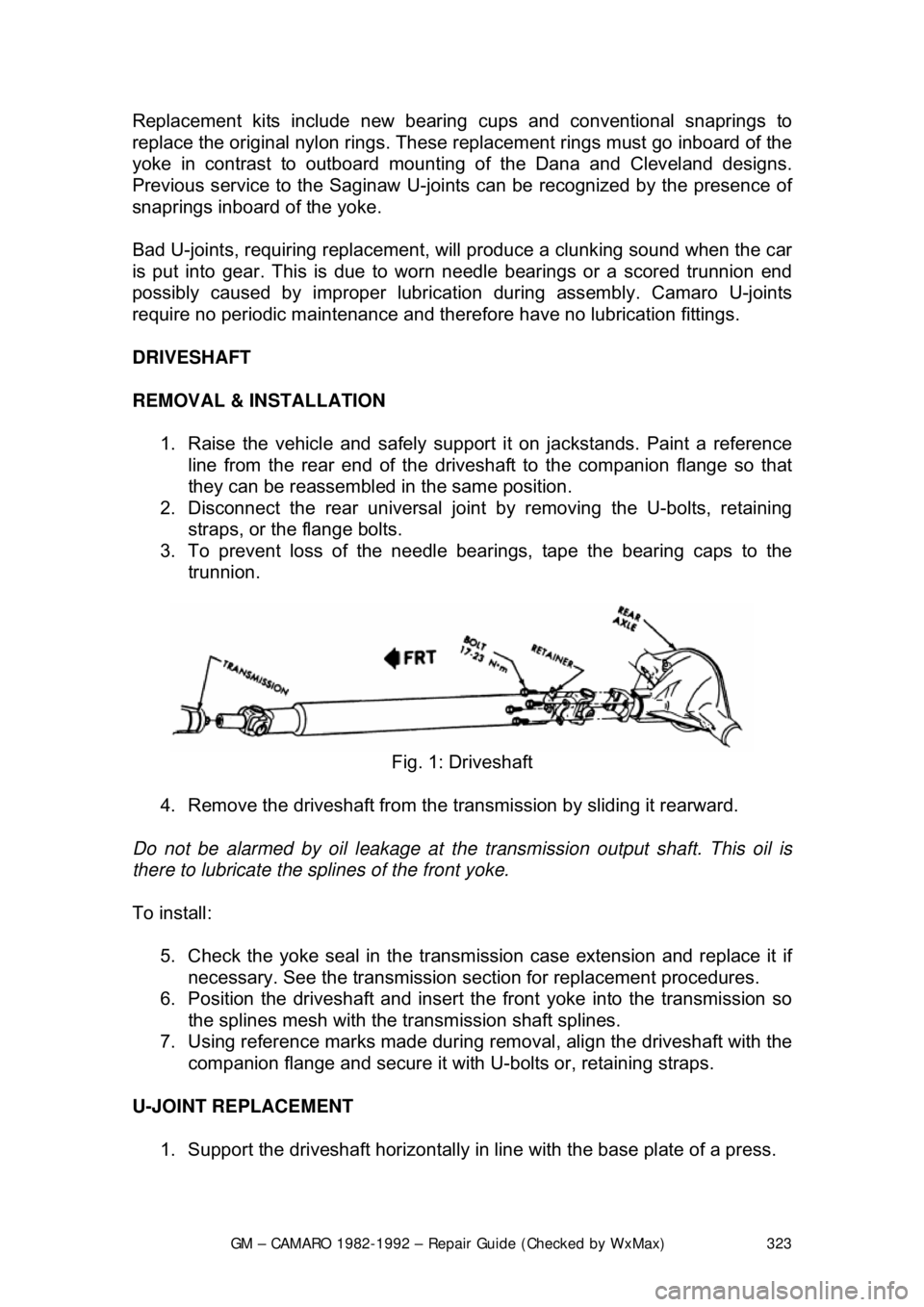

Fig. 2: Internal snapring type

Fig. 3: Pressing out the U-joint

Page 325 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 325

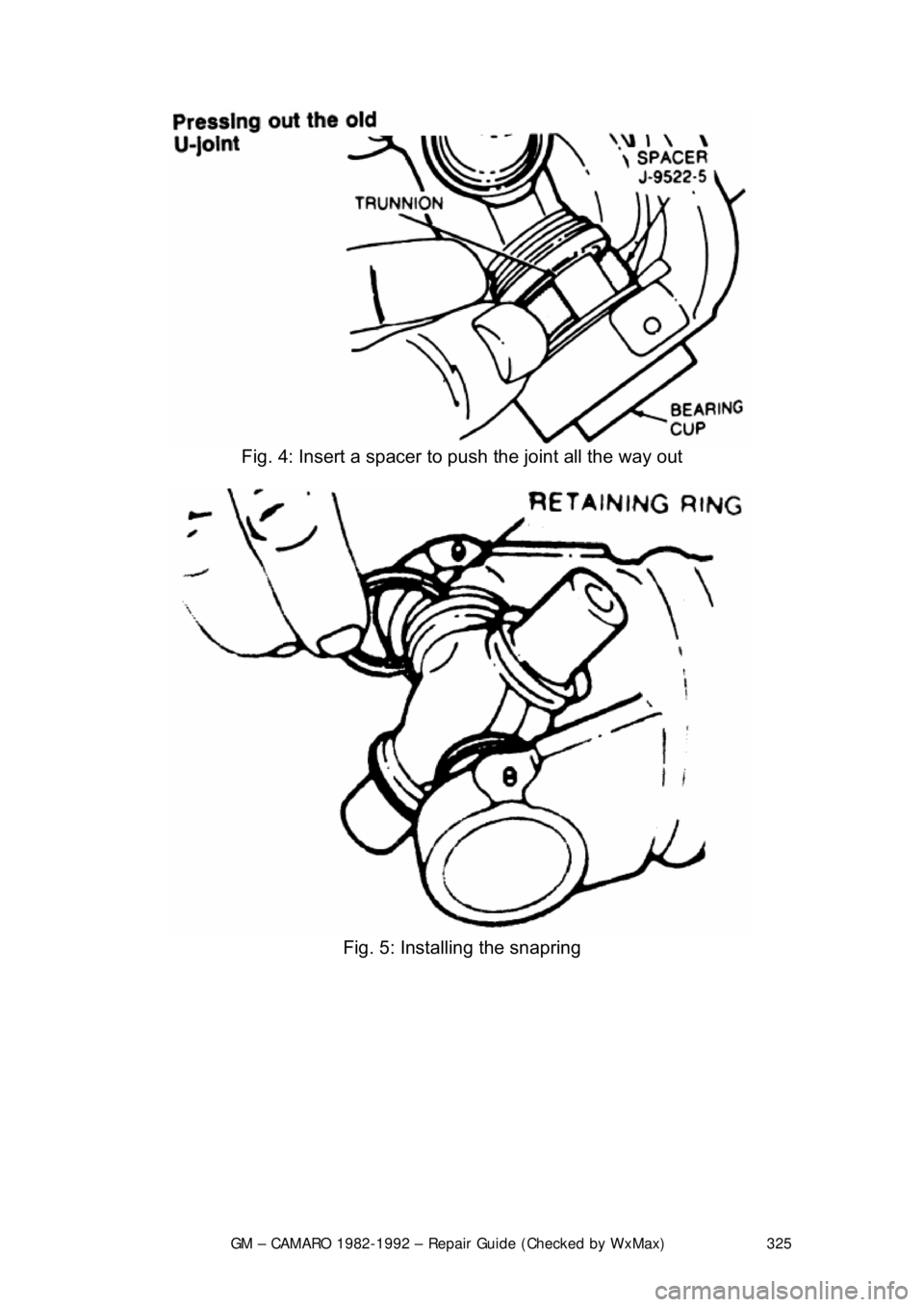

Fig. 4: Insert a spacer to push the joint all the way out

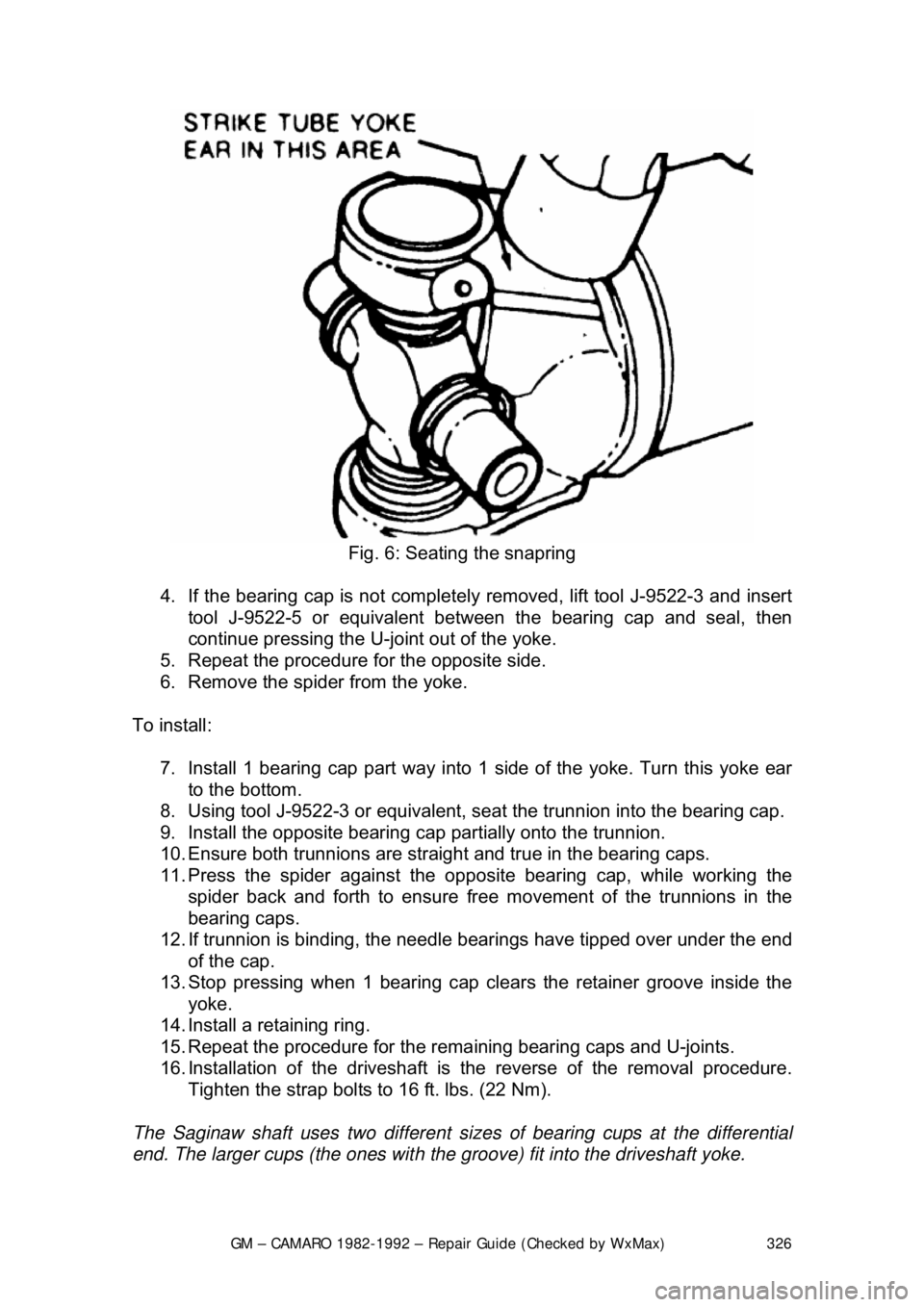

Fig. 5: Installing the snapring

Page 326 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 326

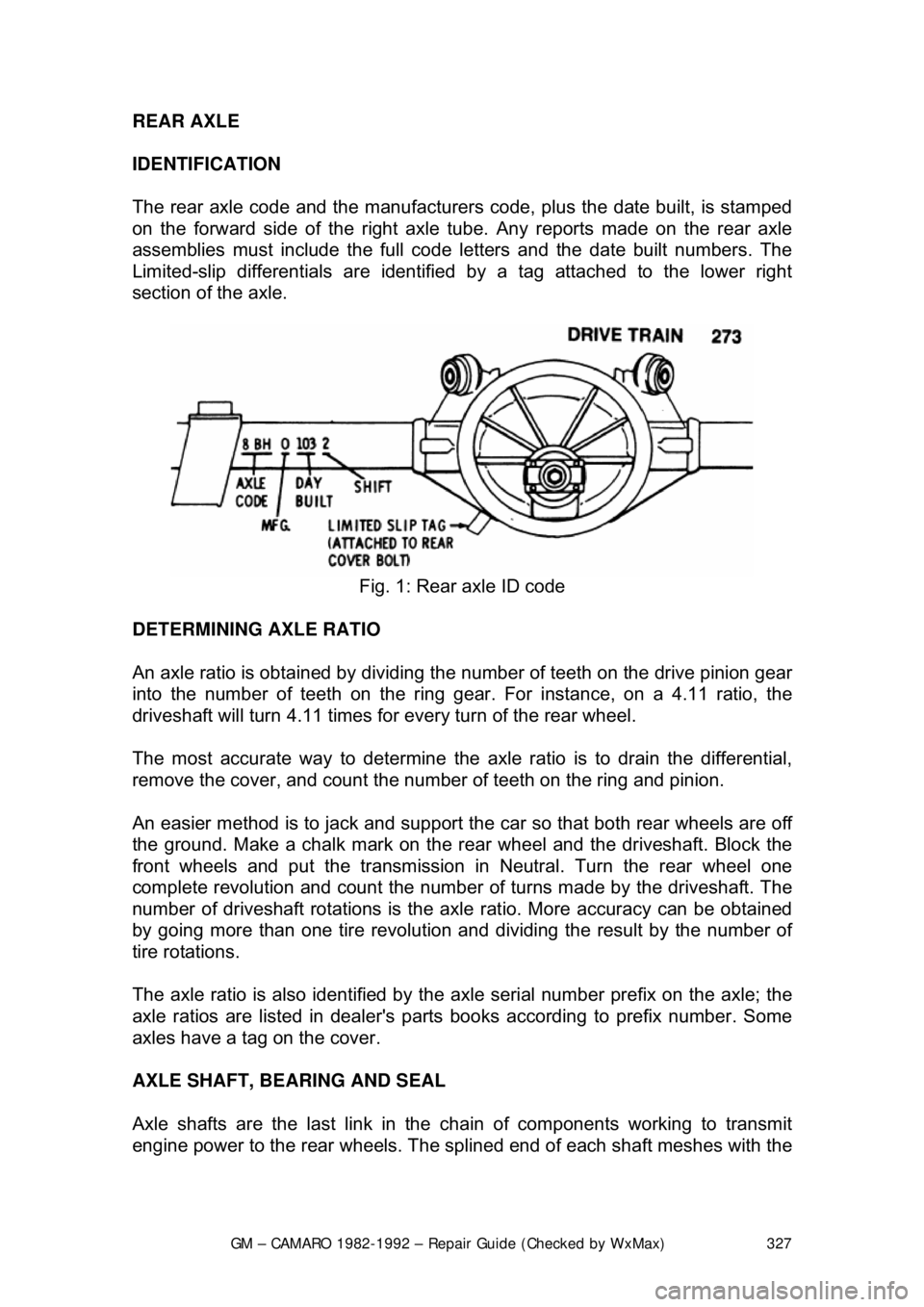

Fig. 6: Seating the snapring

4. If the bearing cap is not completely removed, lift tool J-9522-3 and insert

tool J-9522-5 or equivalent between the bearing cap and seal, then

continue pressing the U-jo int out of the yoke.

5. Repeat the procedure fo r the opposite side.

6. Remove the spider from the yoke.

To install: 7. Install 1 bearing cap part way into 1 side of the yoke. Turn this yoke ear

to the bottom.

8. Using tool J-9522-3 or equivalent, seat the trunnion into the bearing cap.

9. Install the opposite bearing c ap partially onto the trunnion.

10. Ensure both trunnions are straight and true in the bearing caps.

11. Press the spider agai nst the opposite bearing cap, while working the

spider back and forth to ensure free mo vement of the trunnions in the

bearing caps.

12. If trunnion is binding, the needle bearings have tipped over under the end

of the cap.

13. Stop pressing when 1 bearing cap clears the retainer groove inside the yoke.

14. Install a retaining ring.

15. Repeat the procedure for the rema ining bearing caps and U-joints.

16. Installation of the driveshaft is the reverse of the removal procedure.

Tighten the strap bolts to 16 ft. lbs. (22 Nm).

The Saginaw shaft uses two different si zes of bearing cups at the differential

end. The larger cups (the ones with the groove) fit into the driveshaft yoke.

Page 327 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 327

REAR AXLE

IDENTIFICATION

The rear axle code and the

manufacturers code, plus the date built, is stamped

on the forward side of the right axle tube. Any reports made on the rear axle

assemblies must include the full code le tters and the date built numbers. The

Limited-slip differentials are identified by a tag attached to the lower right

section of the axle.

Fig. 1: Rear axle ID code

DETERMINING AXLE RATIO

An axle ratio is obtained by dividing the number of teeth on the drive pinion gear

into the number of teeth on the ring gear. For instance, on a 4.11 ratio, the

driveshaft will turn 4.11 times for every turn of the rear wheel.

The most accurate way to determine the ax le ratio is to drain the differential,

remove the cover, and count the num ber of teeth on the ring and pinion.

An easier method is to jack and support th e car so that both rear wheels are off

the ground. Make a chalk mark on the r ear wheel and the driveshaft. Block the

front wheels and put the transmission in Neutral. Turn the rear wheel one

complete revolution and count the number of turns made by the driveshaft. The

number of driveshaft rotations is the ax le ratio. More accuracy can be obtained

by going more than one tire revolution and dividing the result by the number of

tire rotations.

The axle ratio is also identified by the ax le serial number prefix on the axle; the

axle ratios are listed in dealer's parts books according to prefix number. Some

axles have a tag on the cover.

AXLE SHAFT, BEARING AND SEAL

Axle shafts are the last link in the chain of components working to transmit

engine power to the rear wheels. The sp lined end of each shaft meshes with the

Page 328 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 328

internal splines of each differential side

gear. As the side gears turn, so do the

axle shafts, and, since they are also connected, so do the wheels.

Each shaft passes through the side gear and is locked into place by either a C-

lock or flange plate bolted to the end of the axle housing with pressed on

bearings. As the name implies, the C-lock is a flat, C-shaped piece of metal that

fits into a groove at t he end of the shaft. A round pinion shaft is wedged in

between the end of the shafts. This pinion shaft prevents the shafts from sliding

inward and makes the C-locks functional by pushing them tightly against each

side gear. Removing this pini on shaft allows the shafts to slide inward making

the C-locks accessible for removal. Once the C-locks are removed, the axle

shafts can be pulled from the car.

The wheel end of each shaft is flanged and pressed into it are five wheel lug

bolts serving to hold on t he wheel. Each axle shaft is supported by an axle

bearing (wheel bearing) and oil seal located within the axle shaft housing just to

the outside of the br ake backing plate.

REMOVAL & INSTALLATION

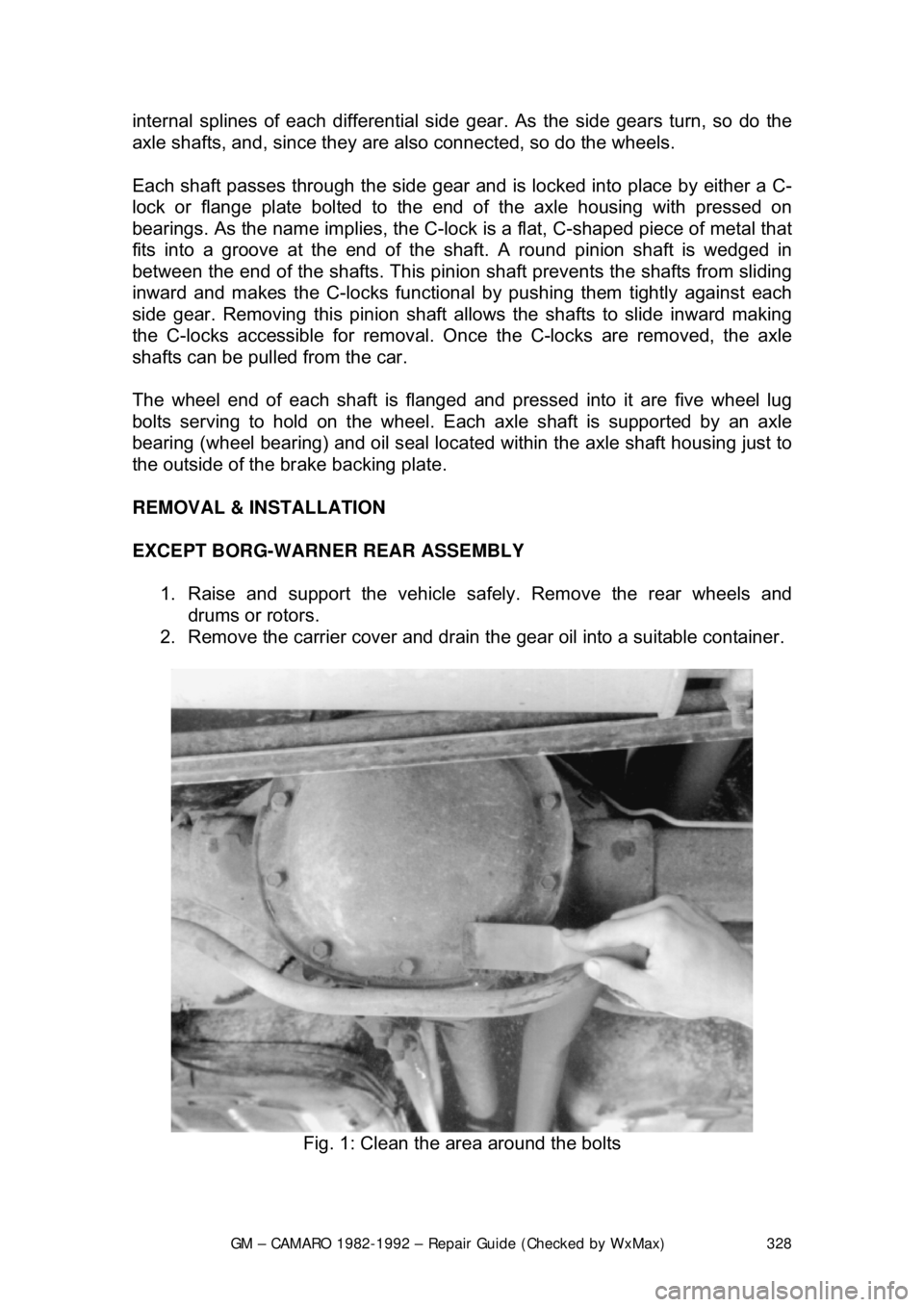

EXCEPT BORG-WARNER REAR ASSEMBLY 1. Raise and support the vehicle safe ly. Remove the rear wheels and

drums or rotors.

2. Remove the carrier cover and drain t he gear oil into a suitable container.

Fig. 1: Clean the area around the bolts

Page 329 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 329

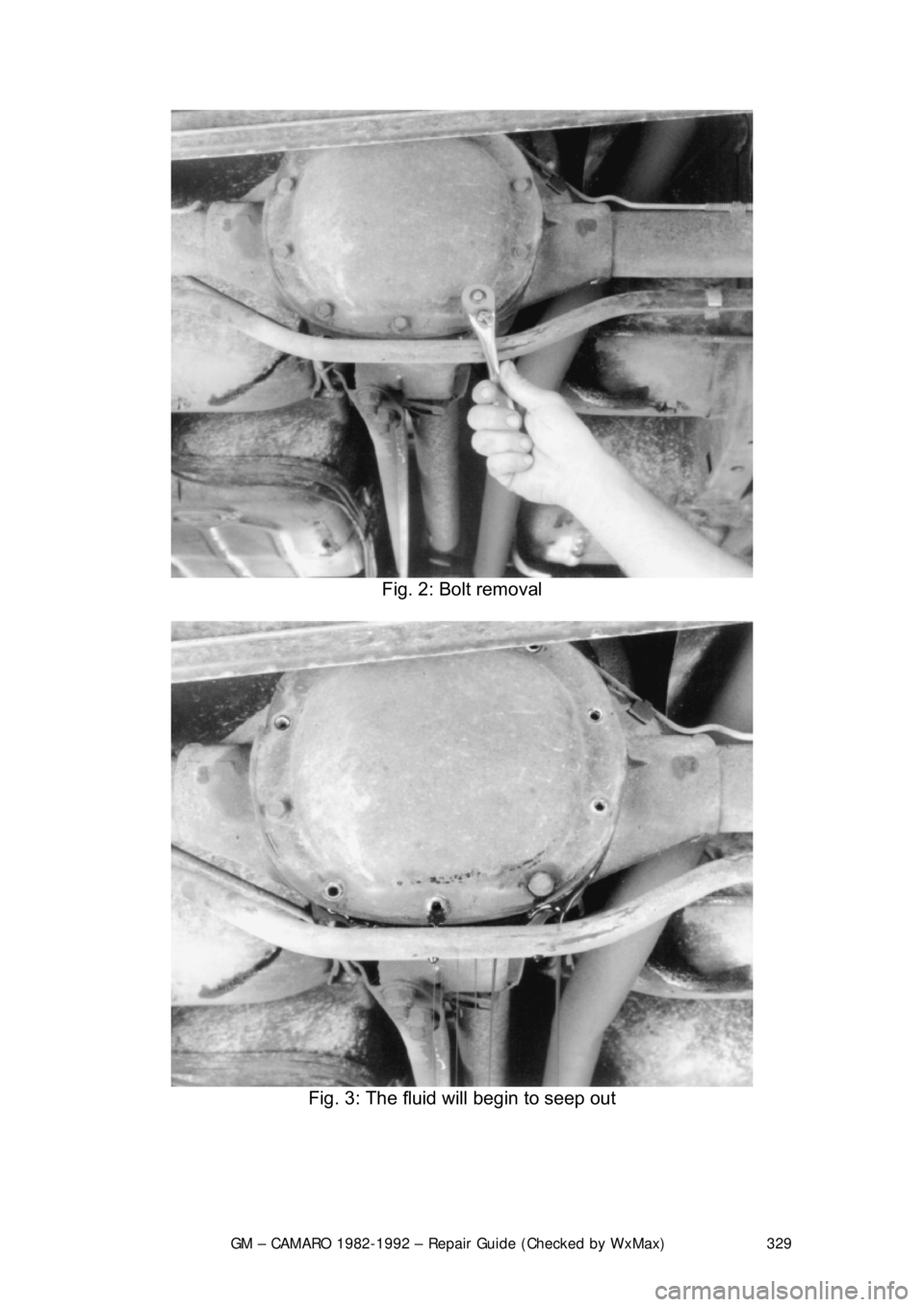

Fig. 2: Bolt removal

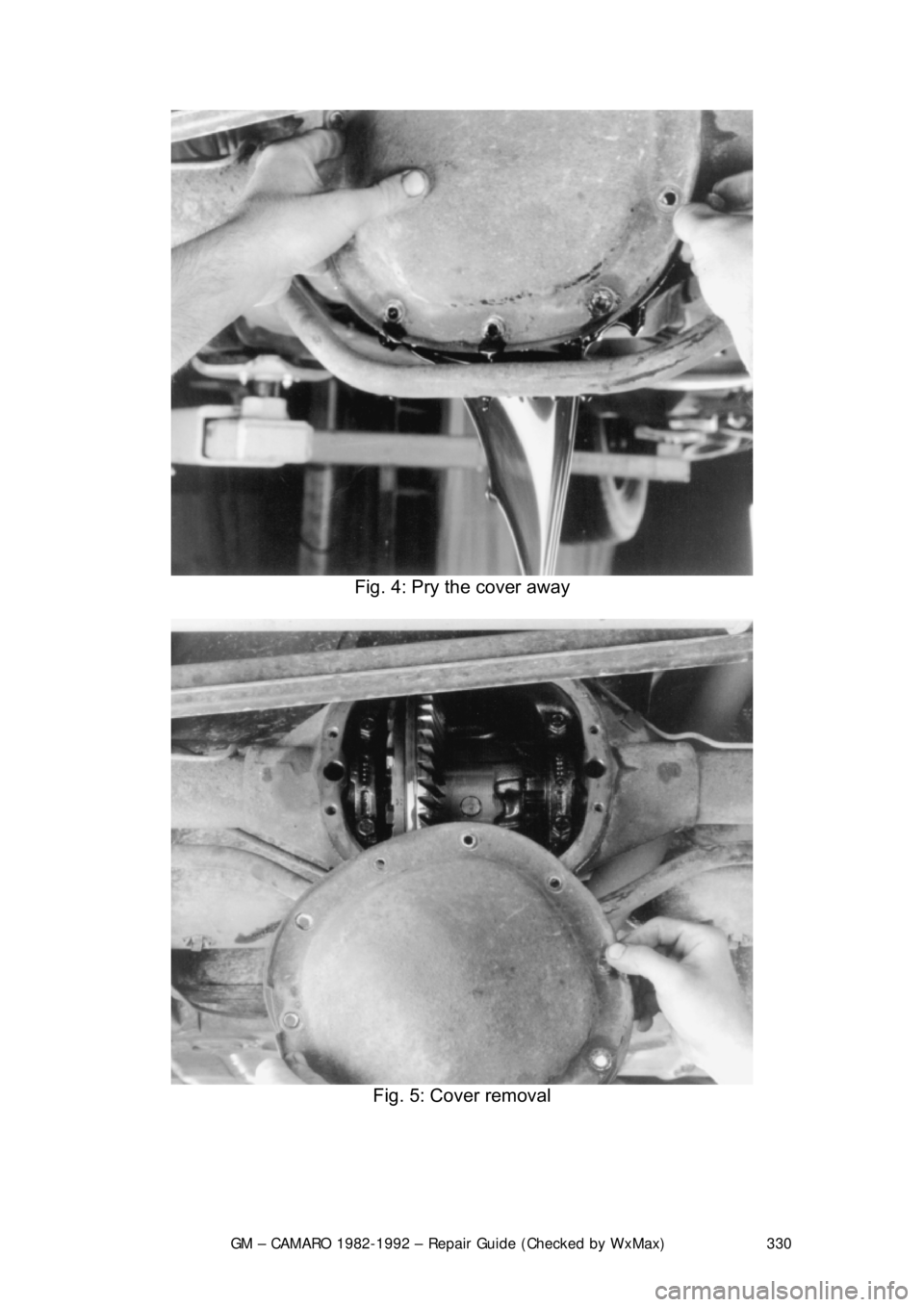

Fig. 3: The fluid will begin to seep out

Page 330 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 330

Fig. 4: Pry the cover away

Fig. 5: Cover removal