CHEVROLET CAMARO 1982 Repair Guide

Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 341 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 341

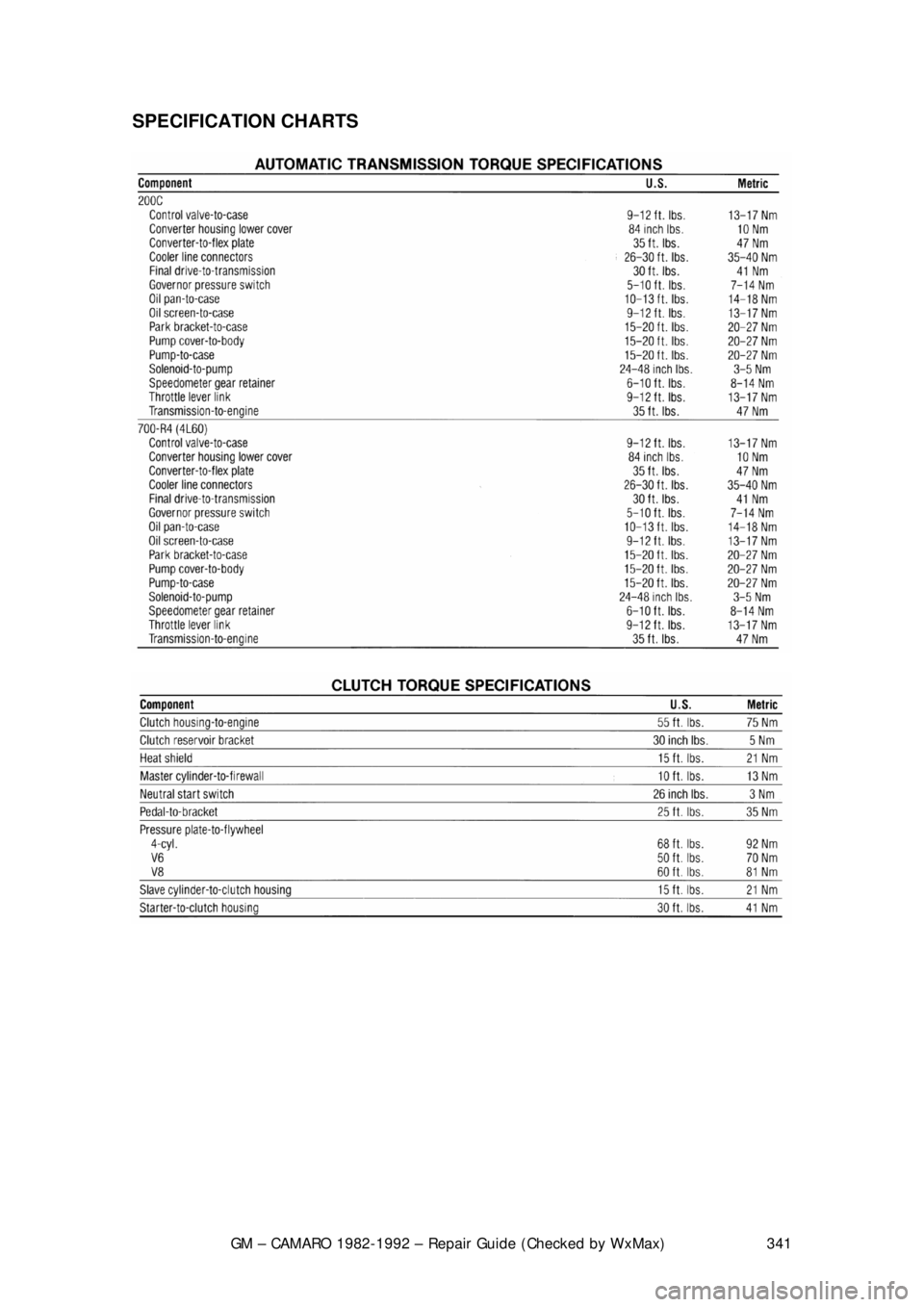

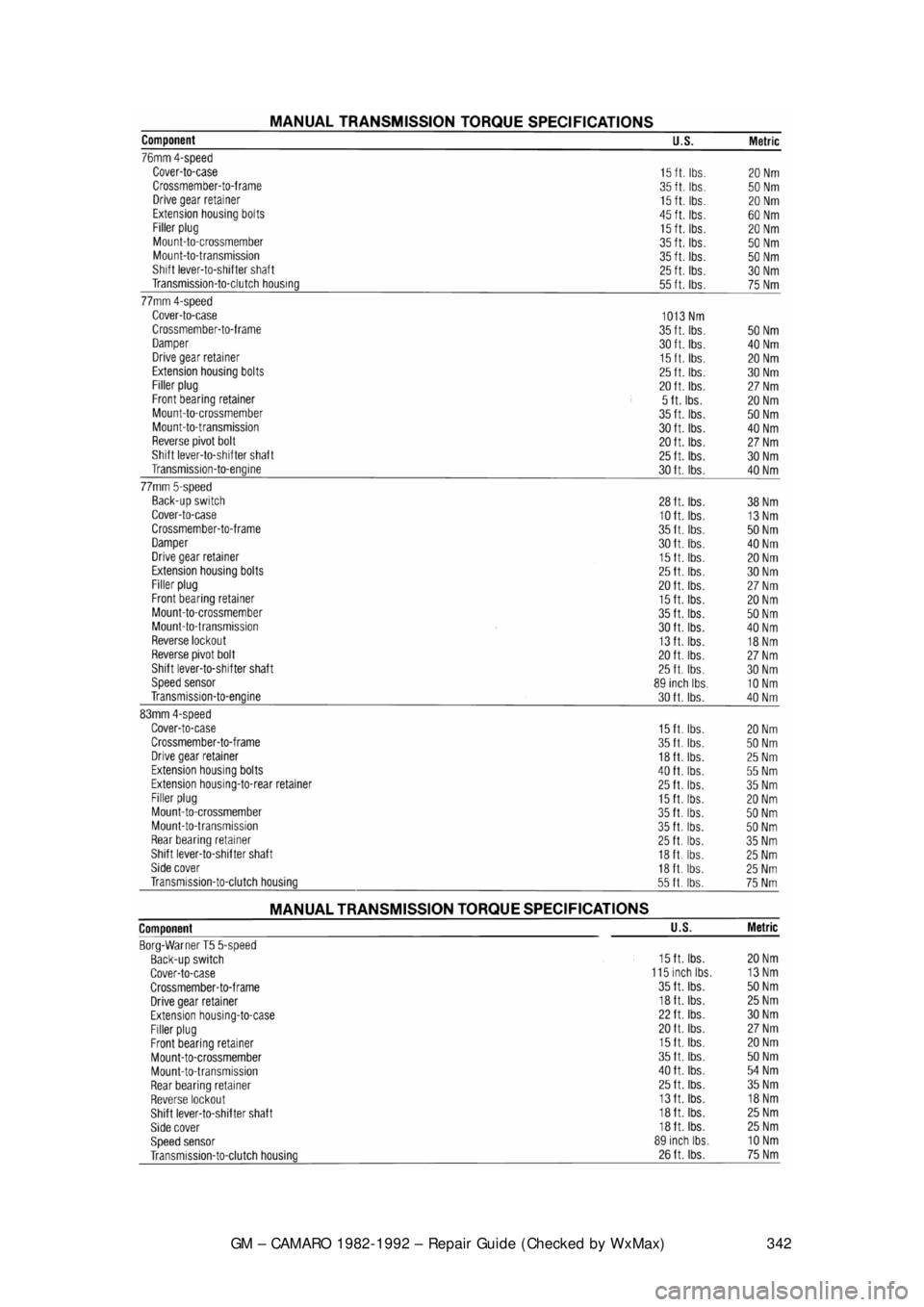

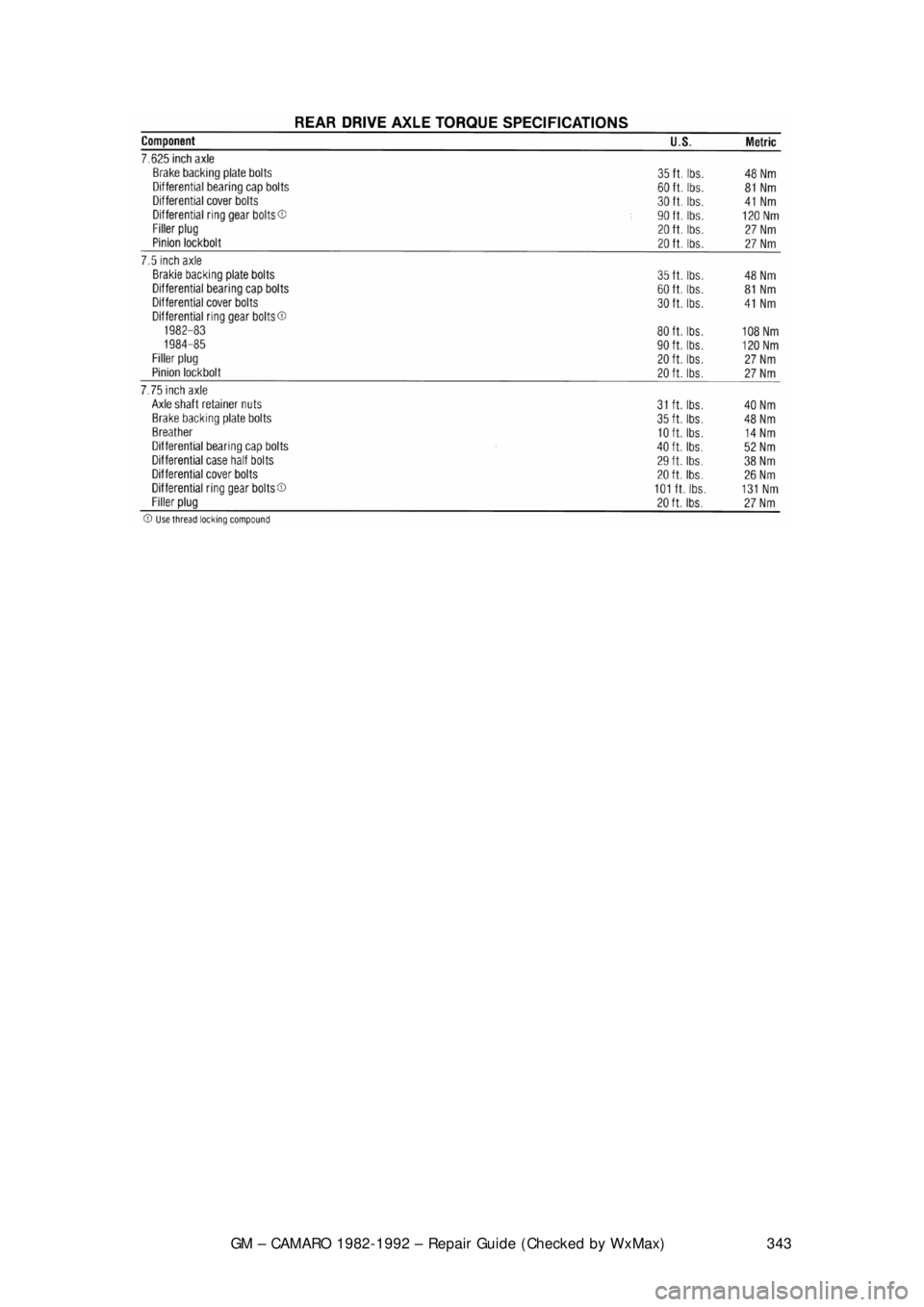

SPECIFICATION CHARTS

Page 342 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 342

Page 343 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 343

Page 344 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 344

ENGINE & ENGINE OVERHAUL

ENGINE ELECTRICAL

ENGINE ELECTRICAL

The engine electrical system can be brok en down into three inter-related, but

distinct systems:

1. The starting system.

2. The charging system.

3. The ignition system.

BATTERY AND STARTING SYSTEM

The battery is the first link in the chai n of mechanisms which work together to

provide cranking of the autom obile engine. In most modern cars, the battery is a

lead-acid electrochemical device consis ting of six two-volt (2V) subsections

connected in series so the unit is c apable of producing approximately 12V of

electrical pressure. Each subsection, or ce ll, consists of a series of positive and

negative plates held a short distance apart in a solution of sulfuric acid and

water. The two types of plates are of di ssimilar metals. This causes a chemical

reaction to be set up, and it is this reacti on which produces current flow from the

battery when its positive and negative te rminals are connected to an electrical

appliance such as a lamp or motor.

The continued transfer of electrons would ev entually convert the sulfuric acid in

the electrolyte to water and make t he two plates identical in chemical

composition. As electrical energy is removed from the battery, its voltage output

tends to drop. Thus, measuring batte ry voltage and battery electrolyte

composition are two ways of checking the ability of the unit to supply power.

During the starting of the eng ine, electrical energy is removed from the battery.

However, if the charging circuit is in good condition and the operating conditions

are normal, the power removed from the battery will be replaced by the

generator (or alternator) which will forc e electrons back through the battery,

reversing the normal flow, and restoring the ba ttery to its original chemical state.

The battery and starting motor are linked by very heavy electrical cable\

s

designed to minimize resistance to the flow of current. Generally, the major

power supply cable that leaves the batte ry goes directly to the starter, while

other electrical system needs are supplied by a smaller cable. During the starter

operation, power flows from the battery to the starter and is grounded through

the car's frame and the batte ry's negative ground strap.

The starting motor is a specially designed, direct current electric motor capable

of producing a very great am ount of power for its size. One thing that allows the

motor to produce a great deal of power is its tremendous rotating speed. It

drives the engine through a ti ny pinion gear (attached to the starter's armature),

which drives the very large flywheel ring gear at a greatly reduced speed.

Another factor allowing it to produce so much power is that only intermittent

Page 345 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 345

operation is required of it. Thus, little a

llowance for air circulation is required,

and the windings can be built into a very small space.

The starter solenoid is a magnetic dev ice which employs the small current

supplied by the starting switch circuit of the ignition switch. This magnetic action

moves a plunger which mechanically engages the starter and electrically closes

the heavy switch which connects it to t he battery. The starting switch circuit

consists of the starting switch cont ained within the ignition switch, a

transmission neutral safety switch or clutch pedal switch, and the wiring

necessary to connect these with the starter solenoid or relay.

A pinion, which is a small gear, is m ounted to a one-way drive clutch. This

clutch is splined to the starter armature shaft. When the ignition switch is moved

to the start position, the solenoid plunger slides the pinion toward the flywheel

ring gear via a collar and spring. If t he teeth on the pinion and flywheel match

properly, the pinion will engage the flywheel immediately. If the gear teeth butt

one another, the spring will be compressed and will force the gears to mesh as

soon as the starter turns far enough to a llow them to do so. As the solenoid

plunger reaches the end of it s travel, it closes the contacts that connect the

battery and starter and then the engine is cranked.

As soon as the engine star ts, the flywheel ring gear begins turning fast enough

to drive the pinion at an ex tremely high rate of speed. At this point, the one-way

clutch begins allowing the pi nion to spin faster than the starter shaft so that the

starter will not operate at excessive speed. When the i gnition switch is released

from the starter position, the solenoid is de-energized, and a spring contained

within the solenoid assembly pulls the gear out of mesh and interrupts the

current flow to the starter.

Some starters employ a separate relay, mounted away from the starter, to

switch the motor and solenoid current on and off. The relay thus replaces the

solenoid electrical switch, but does not eliminate the need for a solenoid

mounted on the starter used to mechanica lly engage the starter drive gears.

The relay is used to reduce the amount of current the starting switch must carry.

THE CHARGING SYSTEM

The automobile charging system provides electrical power for operation of the

vehicle's ignition and star ting systems and all the electrical accessories. The

battery serves as an electrical surge or storage tank, storing (in chemical form)

the energy originally pr oduced by the engine driven gen erator. The system also

provides a means of regulating alternat or output to protect the battery from

being overcharged and to avoid excess ive voltage to the accessories.

The storage battery is a chemical device in corporating parallel lead plates in a

tank containing a sulfuric acid-water solution. Adjacent plates are slightly

dissimilar, and the chemical reaction of the two dissimilar plates produces

electrical energy when the battery is connected to a load such as the starter

motor. The chemical reaction is reversible, so that when the generator i\

s

producing a voltage (electrical pressure ) greater than that produced by the

Page 346 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 346

battery, electricity is forced into the battery

, and the battery is returned to its fully

charged state.

Alternators are used on the modern autom obiles for they are lighter, more

efficient, can rotate at higher speeds and have fewer brush problems. In an

alternator, the field rotates while al l the current produced passes only through

the stators windings. The brushes bear agains t continuous slip rings rather than

a commutator. This causes the current produced to periodically reverse the

direction of its flow. Diodes (electrica l one-way switches) block the flow of

current from traveling in t he wrong direction. A series of diodes is wired together

to permit the alternating flow of the st ator to be converted to a pulsating, but

unidirectional flow at the alternator out put. The alternator's field is wired in

series with the voltage regulator.

Please refer to Engine Performance & Tune-up for ignition system testing

procedures.

IGNITION COIL

REMOVAL & INSTALLATION

INTERNALLY MOUNTED COIL 1. Disconnect and label the wires from cap.

2. Remove the distributor cap from the distributor.

3. On the distributor cap, remove t he coil cover attaching screws and the

cover.

4. Remove the ignition coil attaching screws and lift the coil from the cap.

To install: 5. Position the coil and secure it with the attaching screws. Be sure to install

the carbon button and rubber disc first.

6. Install the coil cover and attaching screws.

7. Install the distributor cap.

8. Connect the wires to the cap.

EXTERNALLY MOUNTED COIL 1. Label and disconnect the wires from the coil.

2. Remove the ignition coil mounting bolts and the coil.

To install: 3. To install, position the coil into place and se cure it with the mounting

bolts.

4. Connect the wires to the coil.

IGNITION MODULE

Page 347 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 347

REMOVAL & INSTALLATION

1. Disconnect the wires from the cap.

2. Remove the distributor cap.

3. Remove the two module attaching screws and capacitor attaching screw.

Lift module, capacitor and harnes s assembly from base.

4. Disconnect wiring harness.

To install: 5. Apply silicone grease underneath the module. This grease is necessary

for ignition module cooling.

6. Connect the wiring harness.

7. Install the module and attaching screws.

8. Install the distributor cap and wires.

DISTRIBUTOR

REMOVAL & INSTALLATION

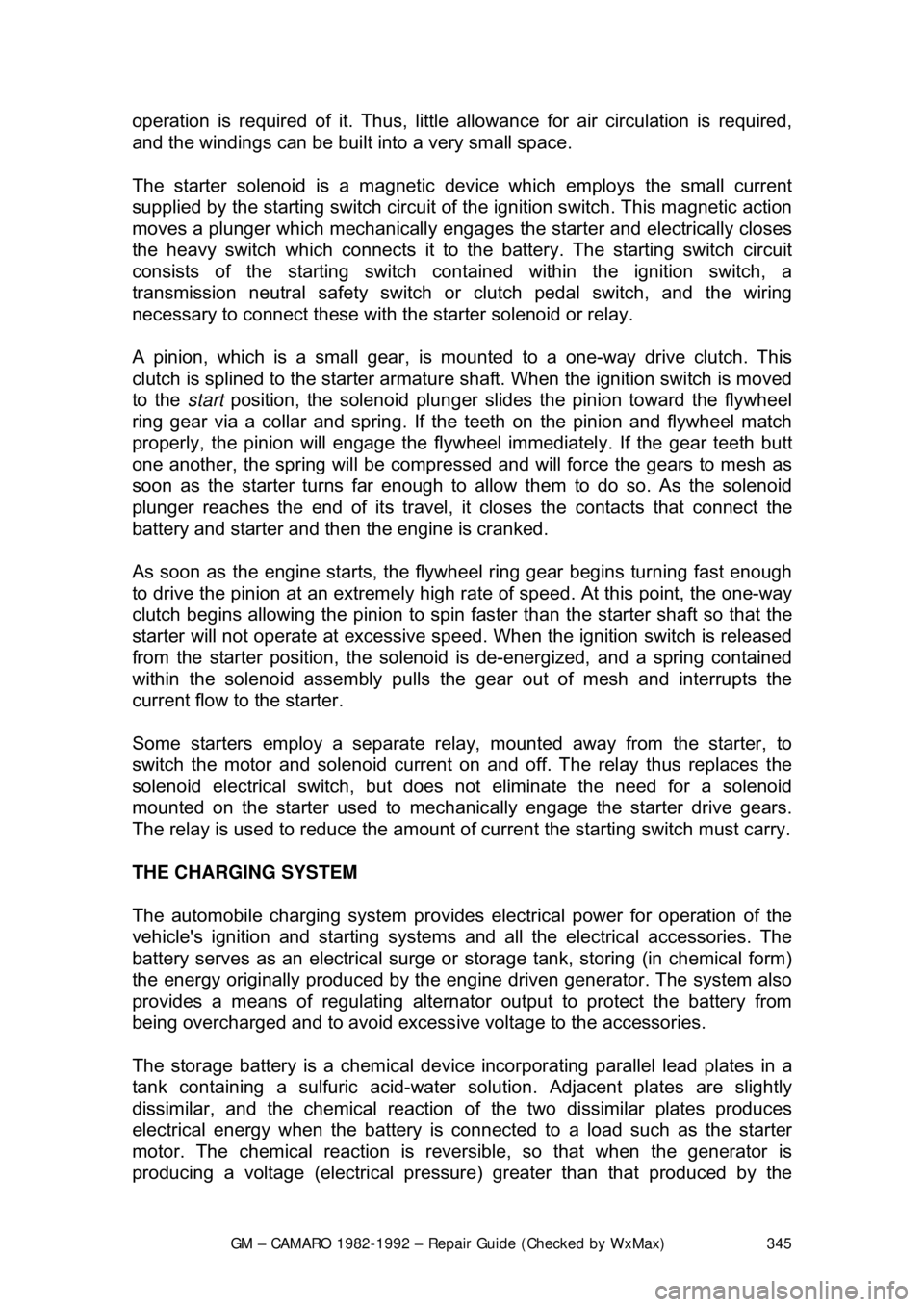

Fig. 1: Matchmarking the rotor

Page 348 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 348

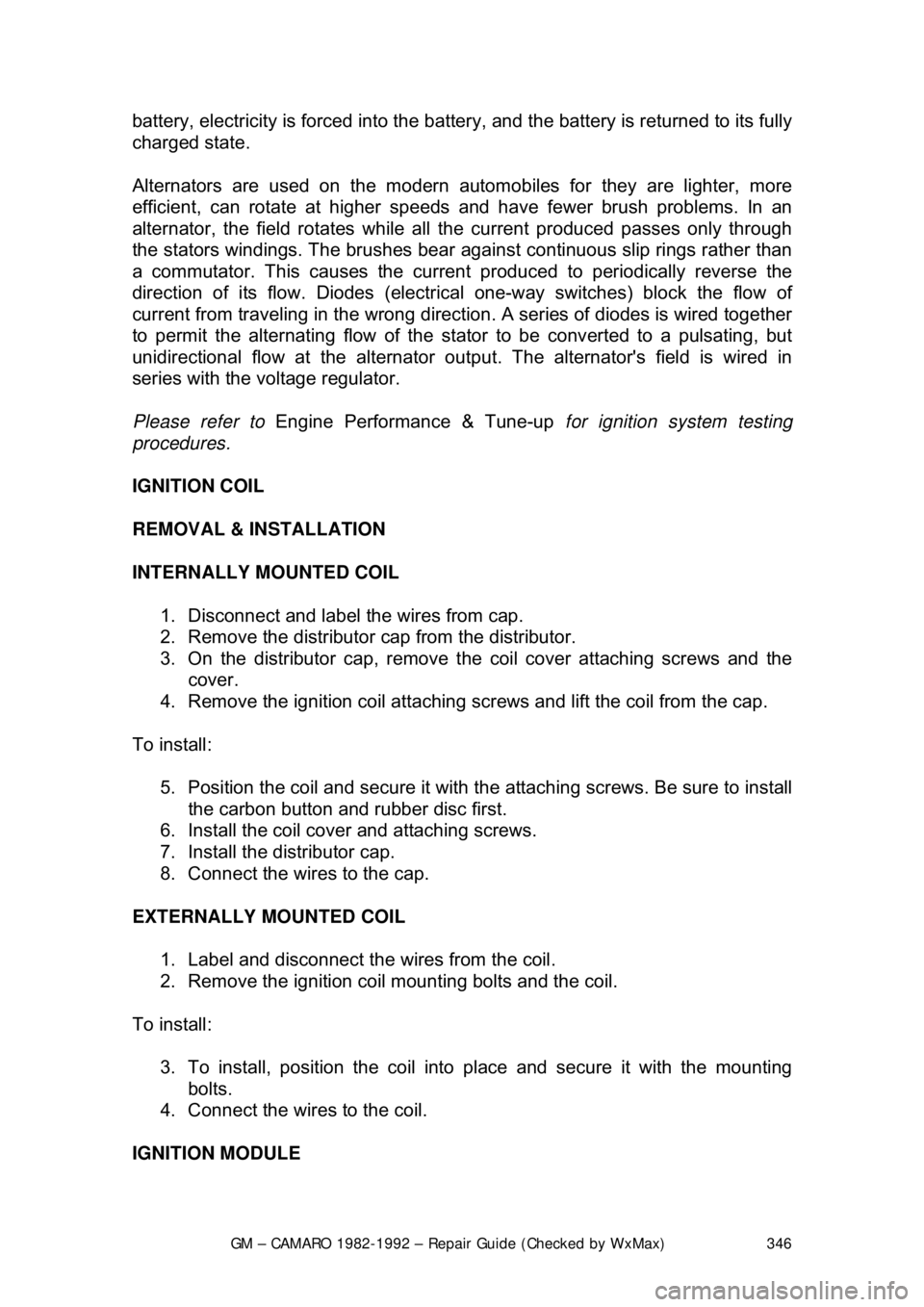

Fig. 2: Unplugging the connector

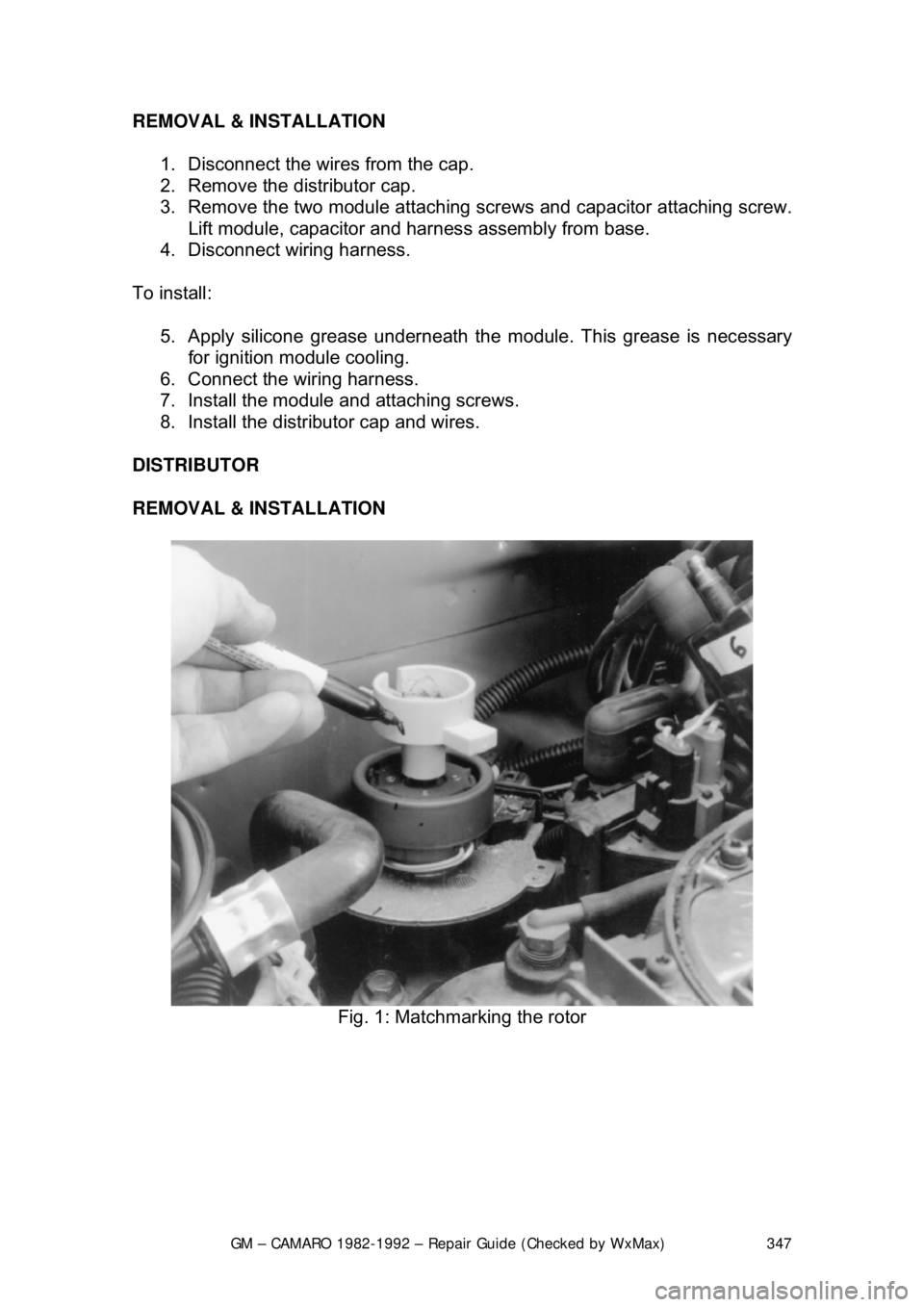

Fig. 3: Loosening the hold-down bolt

Page 349 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 349

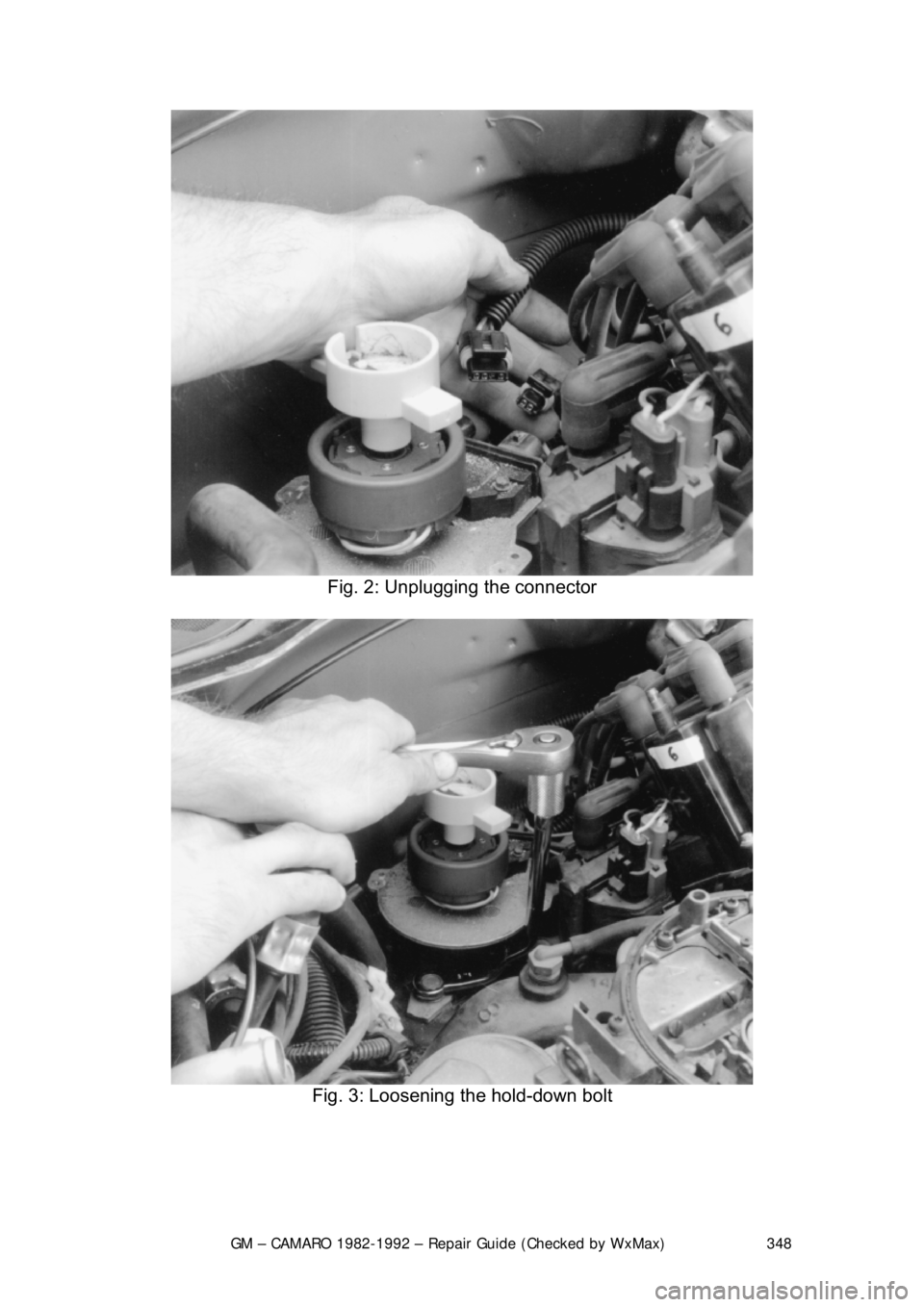

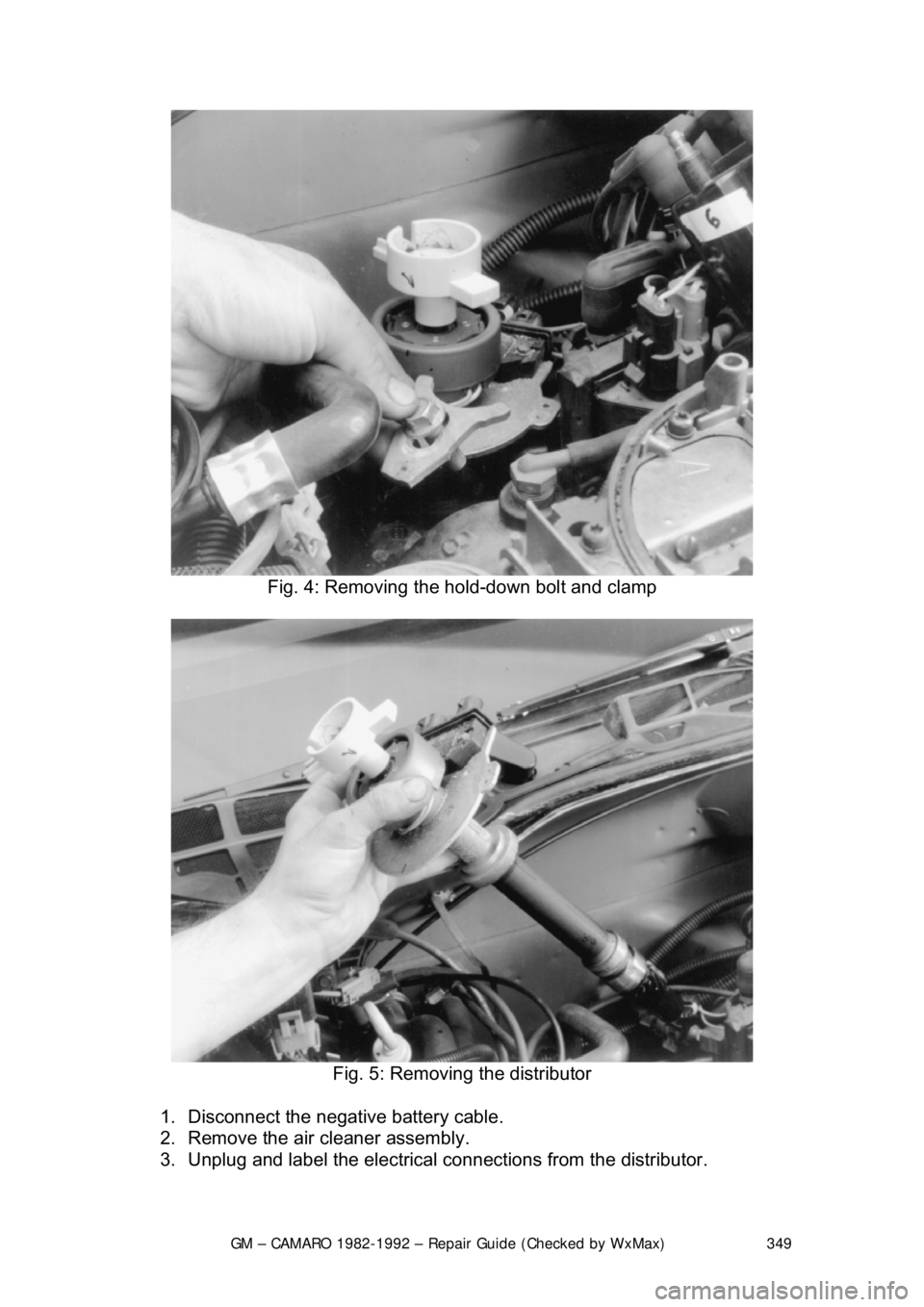

Fig. 4: Removing the hold-down bolt and clamp

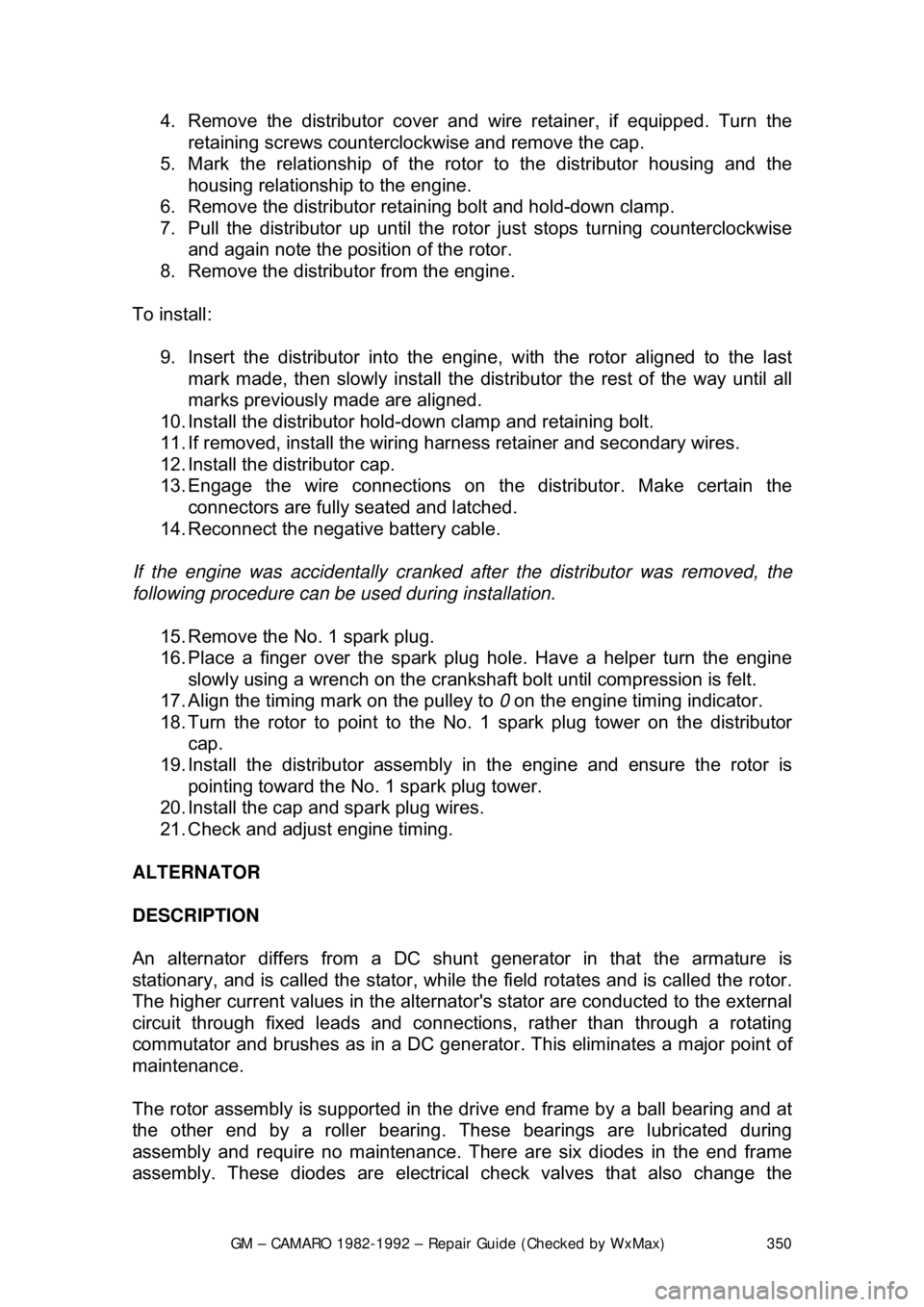

Fig. 5: Removing the distributor

1. Disconnect the negative battery cable.

2. Remove the air cleaner assembly.

3. Unplug and label the electrical connections from the distributor.

Page 350 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 350

4. Remove the distributor cover and wi

re retainer, if equipped. Turn the

retaining screws counterclockwise and remove the cap.

5. Mark the relationship of the roto r to the distributor housing and the

housing relationship to the engine.

6. Remove the distributor reta ining bolt and hold-down clamp.

7. Pull the distri butor up until the rotor just stops turning counterclockwise

and again note the position of the rotor.

8. Remove the distribut or from the engine.

To install: 9. Insert the distributor into the engine, with the rotor aligned to the last

mark made, then slowly install the dist ributor the rest of the way until all

marks previously made are aligned.

10. Install the distributor hold- down clamp and retaining bolt.

11. If removed, install the wiring harness retainer and secondary wires.

12. Install the distributor cap.

13. Engage the wire connections on t he distributor. Make certain the

connectors are fully seated and latched.

14. Reconnect the negative battery cable.

If the engine was accidentally cranked afte r the distributor was removed, the

following procedure can be used during installation.

15. Remove the No. 1 spark plug.

16. Place a finger over the spark pl ug hole. Have a helper turn the engine

slowly using a wrench on the crankshaft bolt until compression is felt. \

17. Align the timing mark on the pulley to 0 on the engine timing indicator.

18. Turn the rotor to point to the No . 1 spark plug tower on the distributor

cap.

19. Install the distributor assembly in the engine and ensure the rotor is

pointing toward the No. 1 spark plug tower.

20. Install the cap and spark plug wires.

21. Check and adjust engine timing.

ALTERNATOR

DESCRIPTION

An alternator differs from a DC shunt generator in that the armature is

stationary, and is called the stator, while the field rotates and is called the rotor.

The higher current values in the alternator's stator are conducted to the external

circuit through fixed leads and connecti ons, rather than through a rotating

commutator and brushes as in a DC generator. This eliminates a major point of

maintenance.

The rotor assembly is supported in the drive end frame by a ball bearing and at

the other end by a roller bearing. These bearings are lubricated during

assembly and require no main tenance. There are six diodes in the end frame

assembly. These diodes are electrical check valves that also change the