CHEVROLET CAMARO 1982 Repair Guide

Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 661 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 661

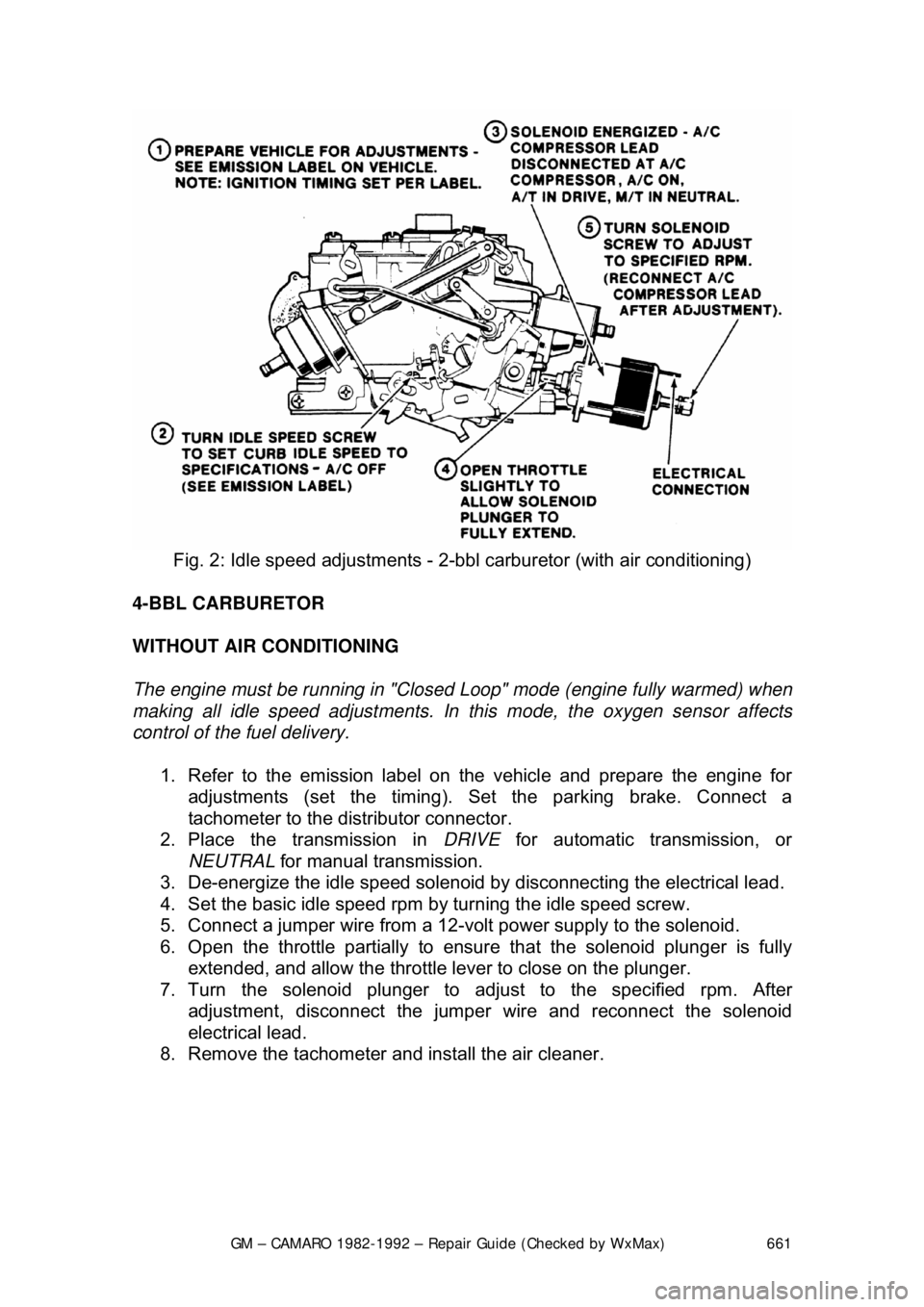

Fig. 2: Idle speed adjustm ents - 2-bbl carburetor (with air conditioning)

4-BBL CARBURETOR

WITHOUT AIR CONDITIONING

The engine must be running in "Closed Loop" mode (engine fully warmed) when

making all idle speed adjustments. In this mode, the oxygen sensor affects

control of the fuel delivery.

1. Refer to the emission label on the vehicle and prepare the engine for

adjustments (set the timing). Se t the parking brake. Connect a

tachometer to the dist ributor connector.

2. Place the transmission in DRIVE for automatic transmission, or

NEUTRAL for manual transmission.

3. De-energize the idle speed solenoid by disconnecting the electrical lead.

4. Set the basic idle speed rpm by turning the idle speed screw.

5. Connect a jumper wire from a 12-vo lt power supply to the solenoid.

6. Open the throttle partially to ensure that the solenoid plunger is fully

extended, and allow the throttle lever to close on the plunger.

7. Turn the solenoid plunger to adj ust to the specified rpm. After

adjustment, disconnect the jumper wire and reconnect the solenoid

electrical lead.

8. Remove the tachometer and install the air cleaner.

Page 662 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 662

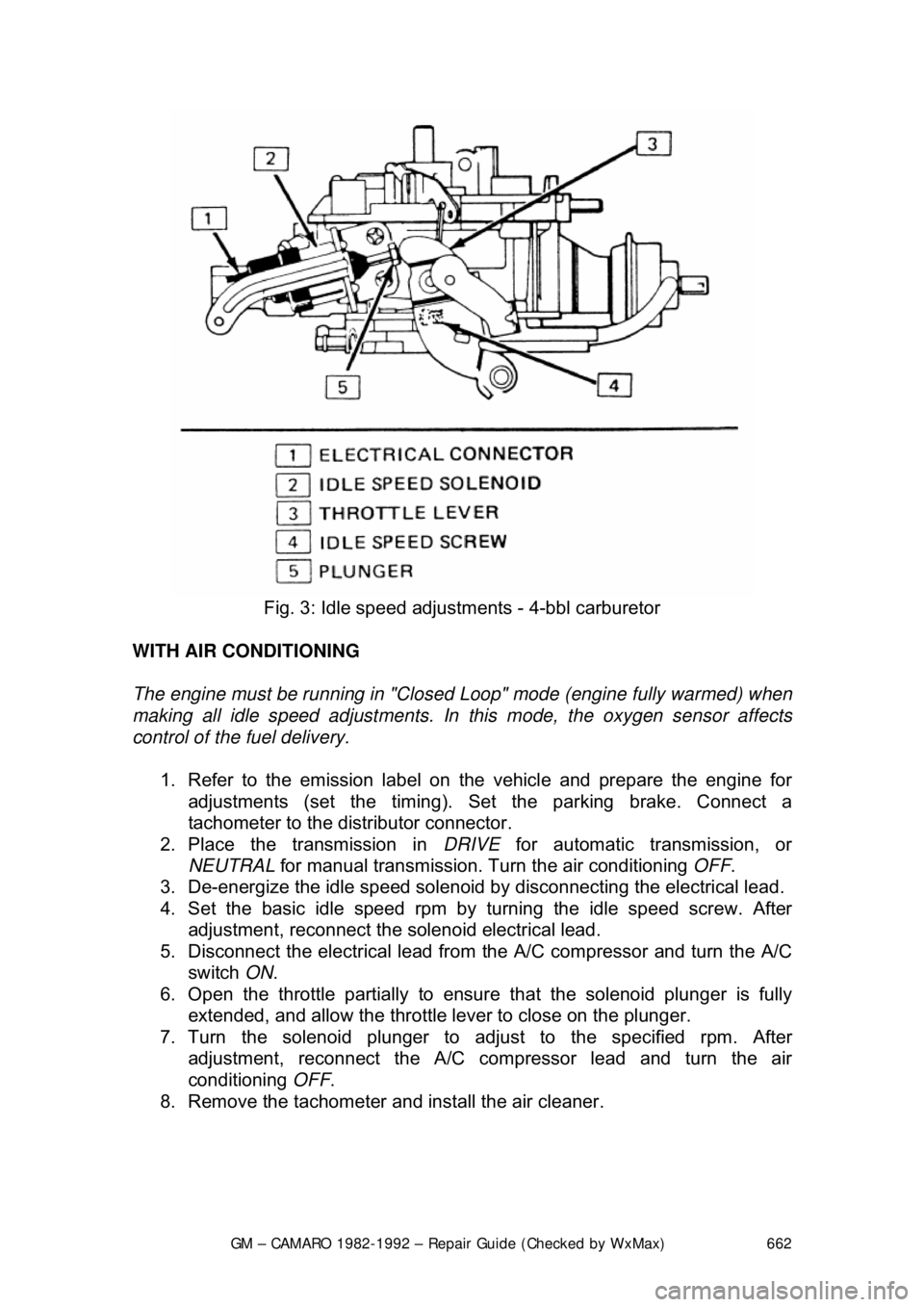

Fig. 3: Idle speed adjustm ents - 4-bbl carburetor

WITH AIR CONDITIONING

The engine must be running in "Closed Loop" mode (engine fully warmed) when

making all idle speed adjustments. In this mode, the oxygen sensor affects

control of the fuel delivery.

1. Refer to the emission label on the vehicle and prepare the engine for

adjustments (set the timing). Se t the parking brake. Connect a

tachometer to the dist ributor connector.

2. Place the transmission in DRIVE for automatic transmission, or

NEUTRAL for manual transmission. Tu rn the air conditioning OFF.

3. De-energize the idle speed solenoid by disconnecting the electrical lead.

4. Set the basic idle speed rpm by turning the idle speed screw. After

adjustment, reconnect the solenoid electrical lead.

5. Disconnect the electrical lead from the A/C compressor and turn the A/C

switch ON.

6. Open the throttle partially to ensure that the solenoid plunger is fully

extended, and allow the throttle lever to close on the plunger.

7. Turn the solenoid plunger to adj ust to the specified rpm. After

adjustment, reconnect the A/C co mpressor lead and turn the air

conditioning OFF.

8. Remove the tachometer and install the air cleaner.

Page 663 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 663

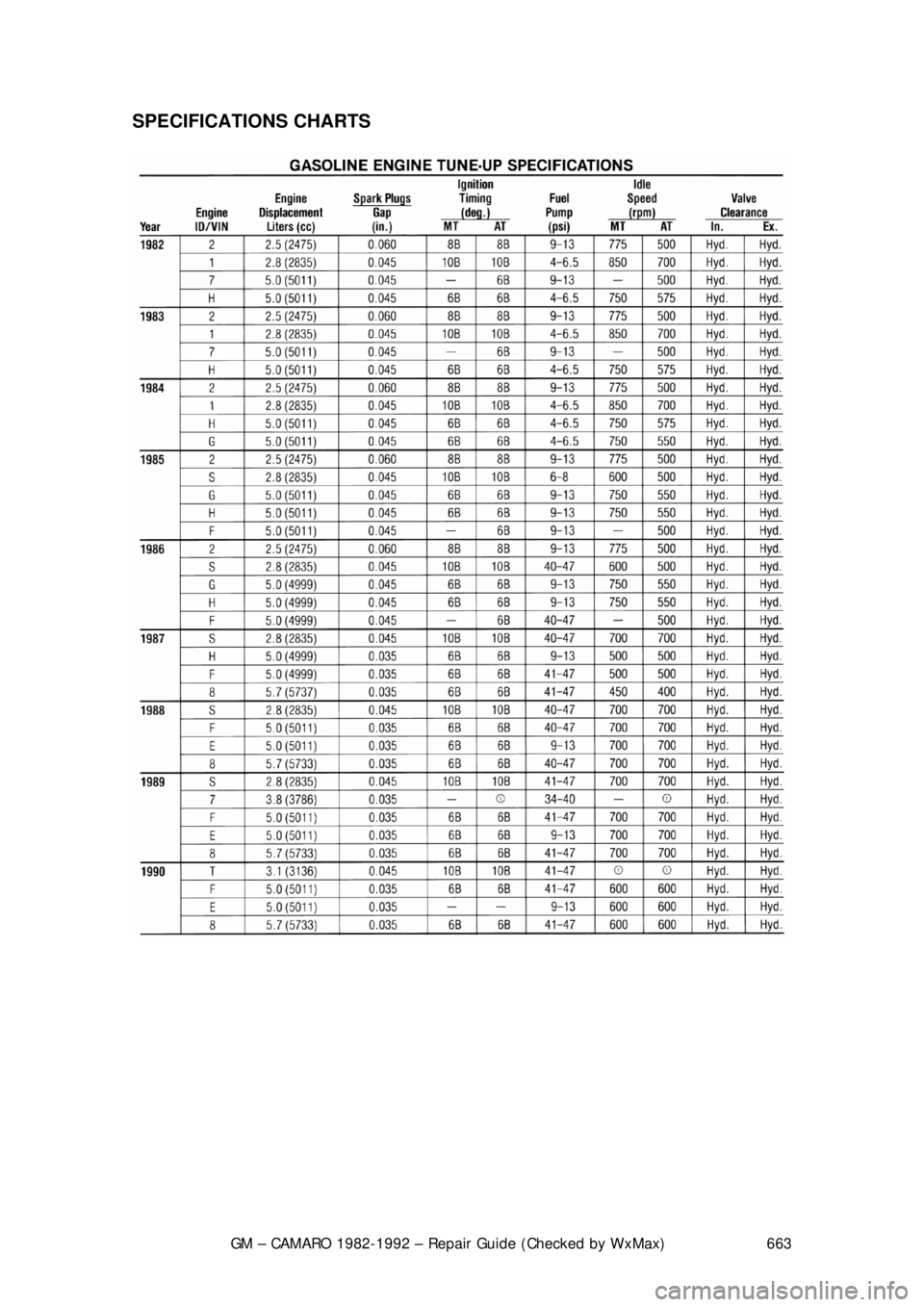

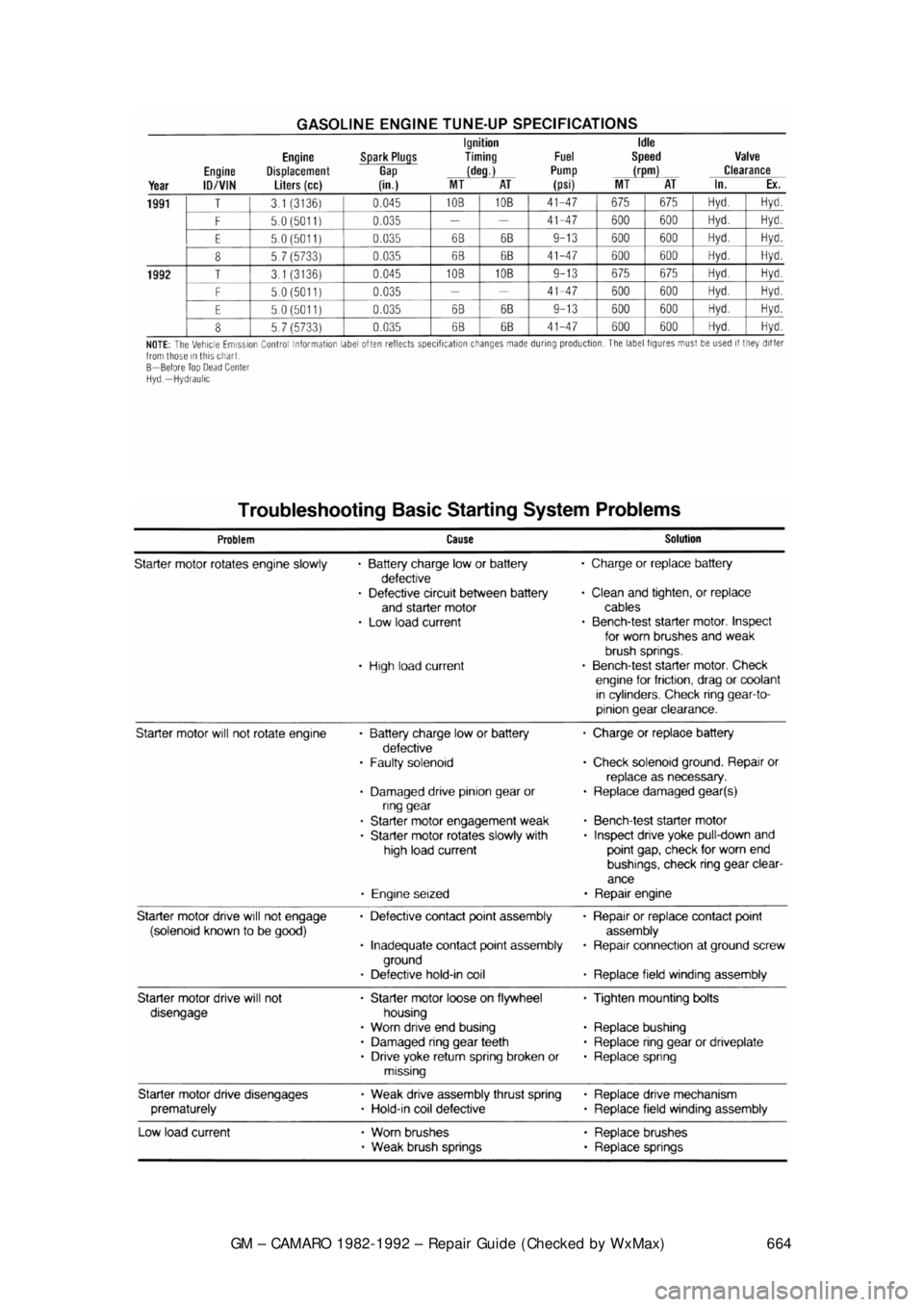

SPECIFICATIONS CHARTS

Page 664 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 664

Page 665 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 665

Page 666 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 666

FUEL SYSTEM

BASIC FUEL SYSTEM DIAGNOSIS

When there is a problem star ting or driving a vehicle, two of the most important

checks involve the ignition and the fuel systems. The questions most mechanics

attempt to answer first, "is there spark?" an d "is there fuel?" will often lead to

solving most basic problems. For igni tion system diagnosis and testing, please

refer to the information on engine electr ical components and ignition systems

found earlier in this repair guide. If the ignition system checks out (there is

spark), then you must determine if the f uel system is operating properly (is there

fuel?).

CARBURETED FUEL SYSTEM

MECHANICAL FUEL PUMP

All fuel pumps used on carbureted V6 and V8 engines are of the diaphragm

type and are serviced by replacement onl y. No adjustments or repairs are

possible. The fuel pump is mounted on th e left front (V6) and right front (V8) of

the engine.

The fuel pumps are also equipped with vapor return lines for purposes of

emission control and to reduce vapor lock. All pumps are operated by an

eccentric on the camshaft. On V6 an d V8 engines, a pushrod between the

camshaft eccentric and the fuel pump operates the pump.

REMOVAL & INSTALLATION

When disconnecting the fuel pump outlet fitting, always use two wrenches to

avoid twisting the line.

1. Disconnect the fuel in take and outlet lines at the pump, then plug the

pump intake line.

2. Remove the two pump mounting bol ts and lockwashers; remove the

pump and its gasket.

3. If the pump pushrod is to be remo ved from the V8, remove the two

adapter bolts and lockwashers, then re move the adapter and its gasket.

4. Install the fuel pump with a new gasket reversing the removal procedure.

Coat the mating surfaces with sealer.

5. Connect the fuel lines and check for leaks.

Page 667 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 667

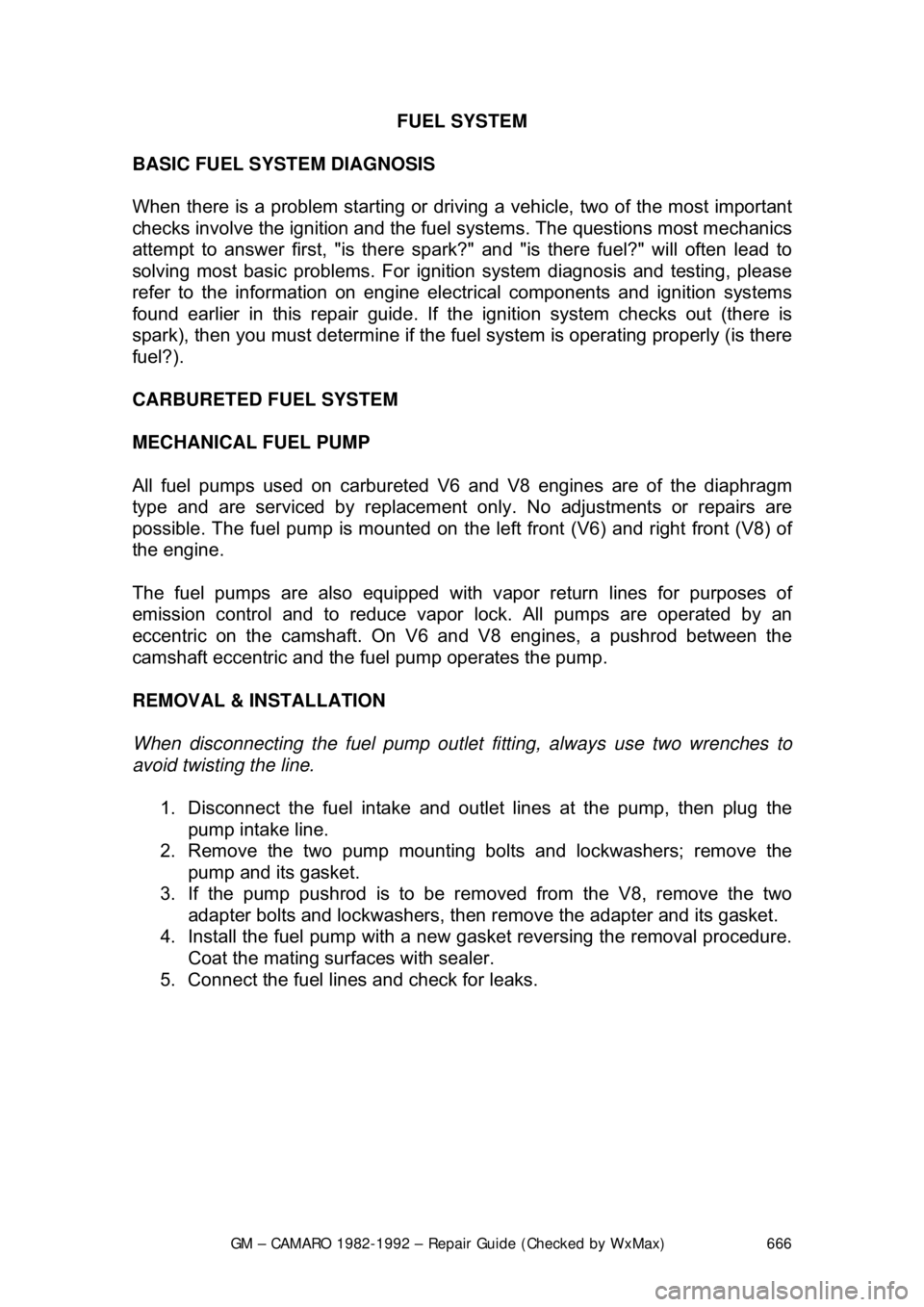

Fig. 1: Most fuel pumps are more easily accessed from underneath the car

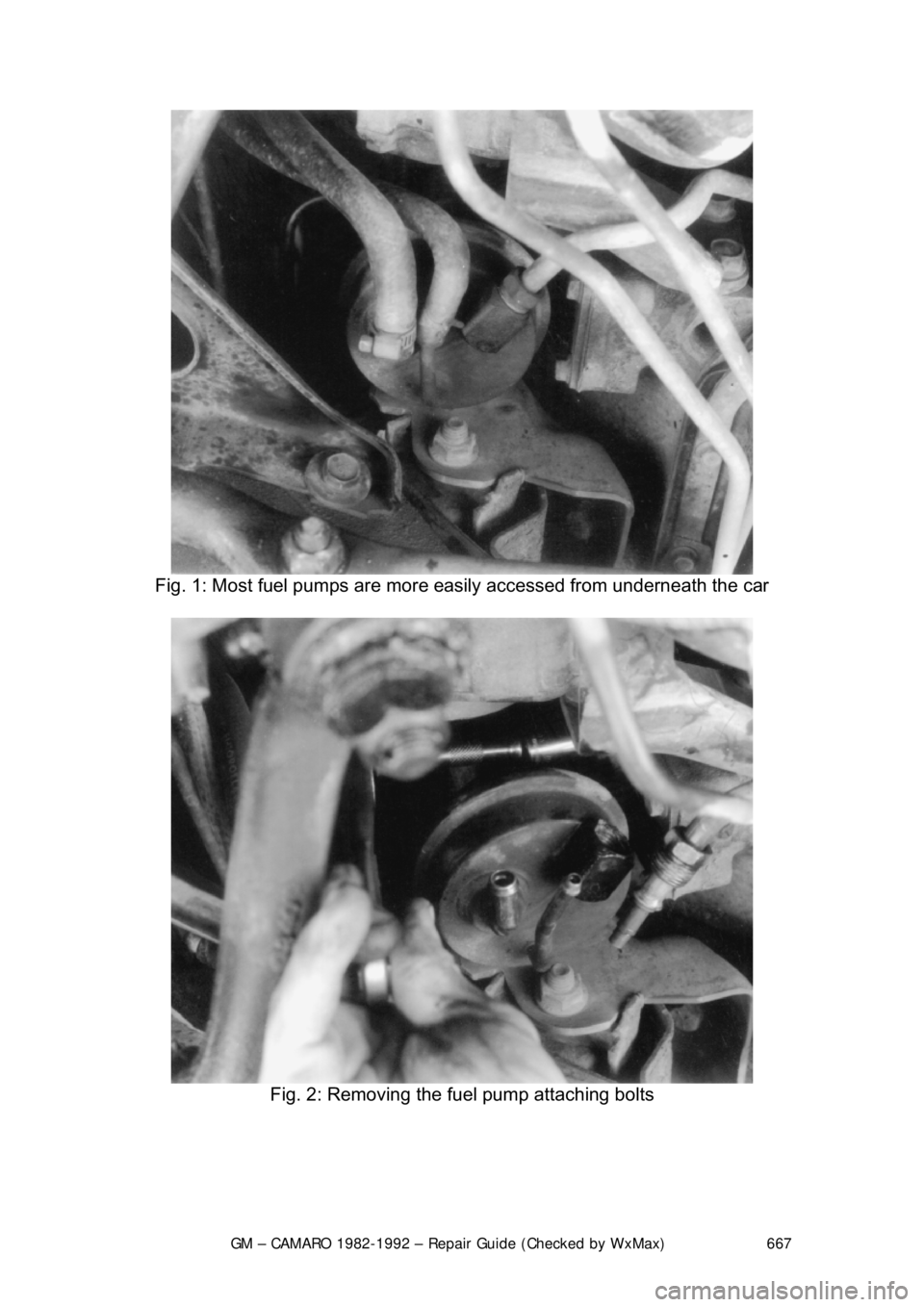

Fig. 2: Removing the fuel pump attaching bolts

Page 668 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 668

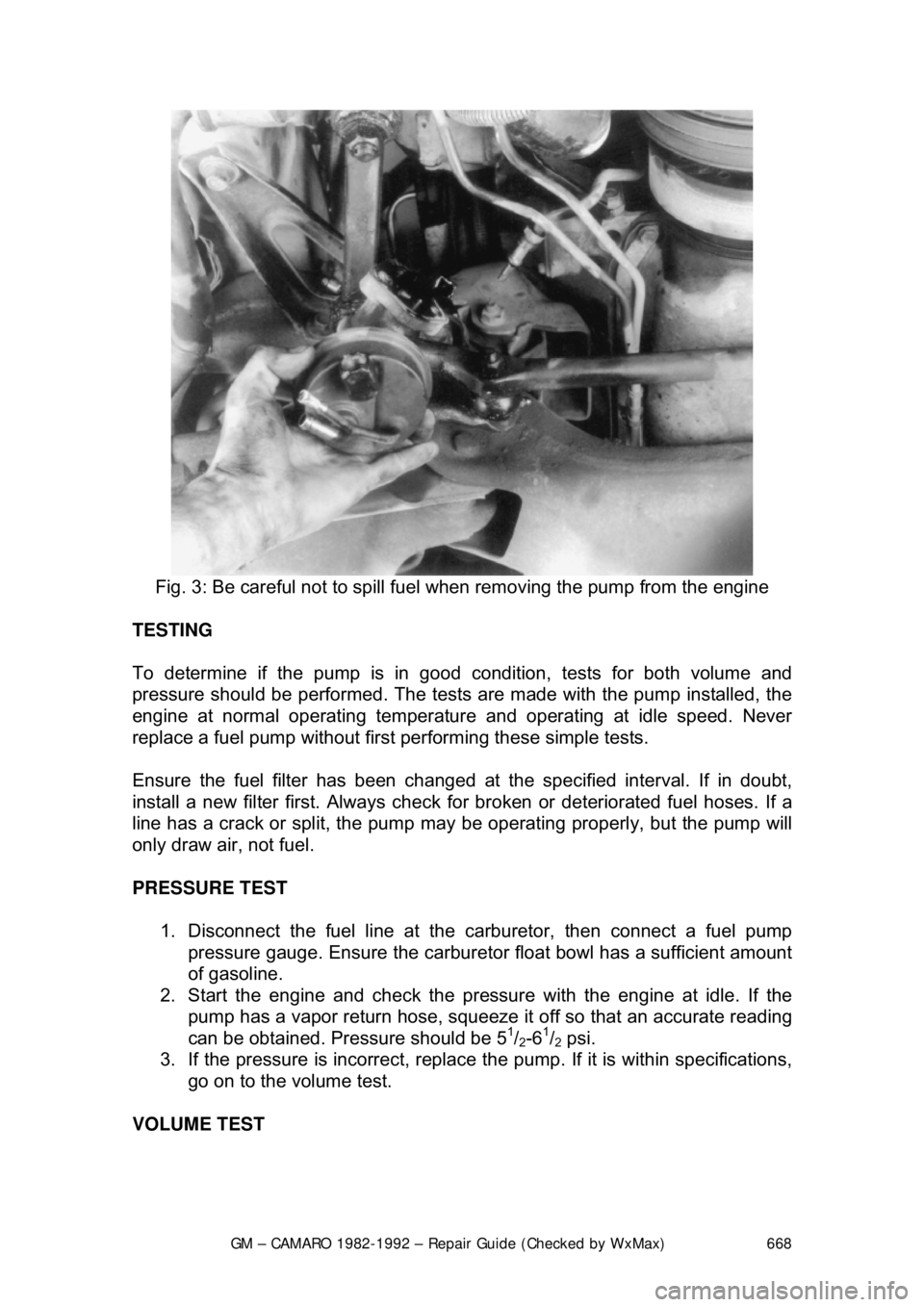

Fig. 3: Be careful not to spill fuel when removing the pump from the engine

TESTING

To determine if the pump is in good condition, tests for both volume and

pressure should be performed. The test s are made with the pump installed, the

engine at normal operating temperatur e and operating at idle speed. Never

replace a fuel pump without first performing these simple tests.

Ensure the fuel filter has been changed at the specified interval. If in doubt,

install a new filter first. Always check fo r broken or deteriorated fuel hoses. If a

line has a crack or split, the pump may be operating properly, but the pump will

only draw air, not fuel.

PRESSURE TEST

1. Disconnect the fuel line at the carburetor, then connect a fuel pump

pressure gauge. Ensure the carburet or float bowl has a sufficient amount

of gasoline.

2. Start the engine and c heck the pressure with the engine at idle. If the

pump has a vapor return hose, squeeze it off so that an accurate reading

can be obtained. Pressure should be 5

1/2-61/2 psi.

3. If the pressure is incorrect, replace t he pump. If it is within specifications,

go on to the volume test.

VOLUME TEST

Page 669 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 669

1. Disconnect the pressure gauge. R

un the fuel line into a graduated

container.

2. Run the engine at idle until one pint of gasoline has been pumped. One

pint should be delivered in 30 seconds or less. There is normally enough

fuel in the carburetor float bowl to perform this test, but refill it if

necessary.

3. If the delivery rate is below the mini mum, check the lines for restrictions

or leaks, then r eplace the pump.

CARBURETORS

The V6 engine is equipped with the Ro chester E2SE carburetor, V8 engines

use the E4ME and E4MC. These carburet ors are of the downdraft design and

are used in conjunction with the CCC system for fuel cont rol. They have special

design features for optimum air/fuel mixt ure control during all ranges of engine

operation.

An electric solenoid in the carburetor controls the air/fu el ratio. The solenoid is

connected to an Electronic Control Module (ECM) which is an on-board

computer. The ECM provides a controllin g signal to the solenoid. The solenoid

controls the metering rod(s) and an id le air bleed valve, thereby closely

controlling the air/fuel ratio throughout the operating range of the engine.

MODEL IDENTIFICATION

General Motors Rochester carburetors ar e identified by their model code. The

first number indicates the number of ba rrels, while one of the last letters

indicates the type of choke used. These are V for the manifold mounted choke

coil, C for the choke coil mounted in the carburetor body, and E for electric

choke, also mounted on the carburetor. Model codes ending in A indicate an

altitude-compensatin g carburetor.

Because of their intricate nature and co mputer controls, the E2SE, E4ME and

E4MC carburetors should only be se rviced by a qualified technician.

PRELIMINARY CHECKS

The following should be observed befor e attempting any adjustments.

1. Thoroughly warm the engine. If the engine is cold, be sure that it reaches

operating temperature.

2. Check the torque of all carburet or mounting nuts and assembly screws.

Also check the intake manifold-to-cyli nder head bolts. If air is leaking at

any of these points, any attempts at adjustment will inevitably lead to

frustration.

3. Check the manifold heat control valve (if used) to be sure that it is free.

4. Check and adjust the choke as necessary.

5. Adjust the idle speed and mixture. If the mixture screws are capped,

don't adjust them unless all other c auses of rough idle have been

eliminated. If any adjustments are per formed that might possibly change

Page 670 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 670

the idle speed or mixture,

adjust the idle and mixture again when you are

finished.

Before you make any carburetor adjustment s make sure that the engine is in

tune. Many problems which are thought to be carburetor related can be traced

to an engine which is simply out-of-tune. Any trouble in these areas will have

symptoms like those of carburetor problems.

ADJUSTMENTS

FAST IDLE

ROCHESTER E2SE 1. Refer to the emission label and pr epare the vehicle for adjustment.

2. Place the fast idle screw on the highest step of the fast idle cam.

3. Turn the fast idle screw to obtain the fast idle speed.

ROCHESTER E4ME AND E4MC

The fast idle adjustment must be perform ed according to the directions of the

emissions label.

FLOAT AND FUEL LEVEL

ROCHESTER E2SE

1. Remove the air horn and gasket.

2. While holding the retainer in place, push the float down lightly against the

needle.

3. Place a measuring gauge on the float at the farthest point from the float

hinge.

4. To adjust, remove the float and bend the arm up or down. Also check the

float alignment.

5. Install the air horn and gasket.