CHEVROLET CAMARO 1982 Repair Guide

Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 651 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 651

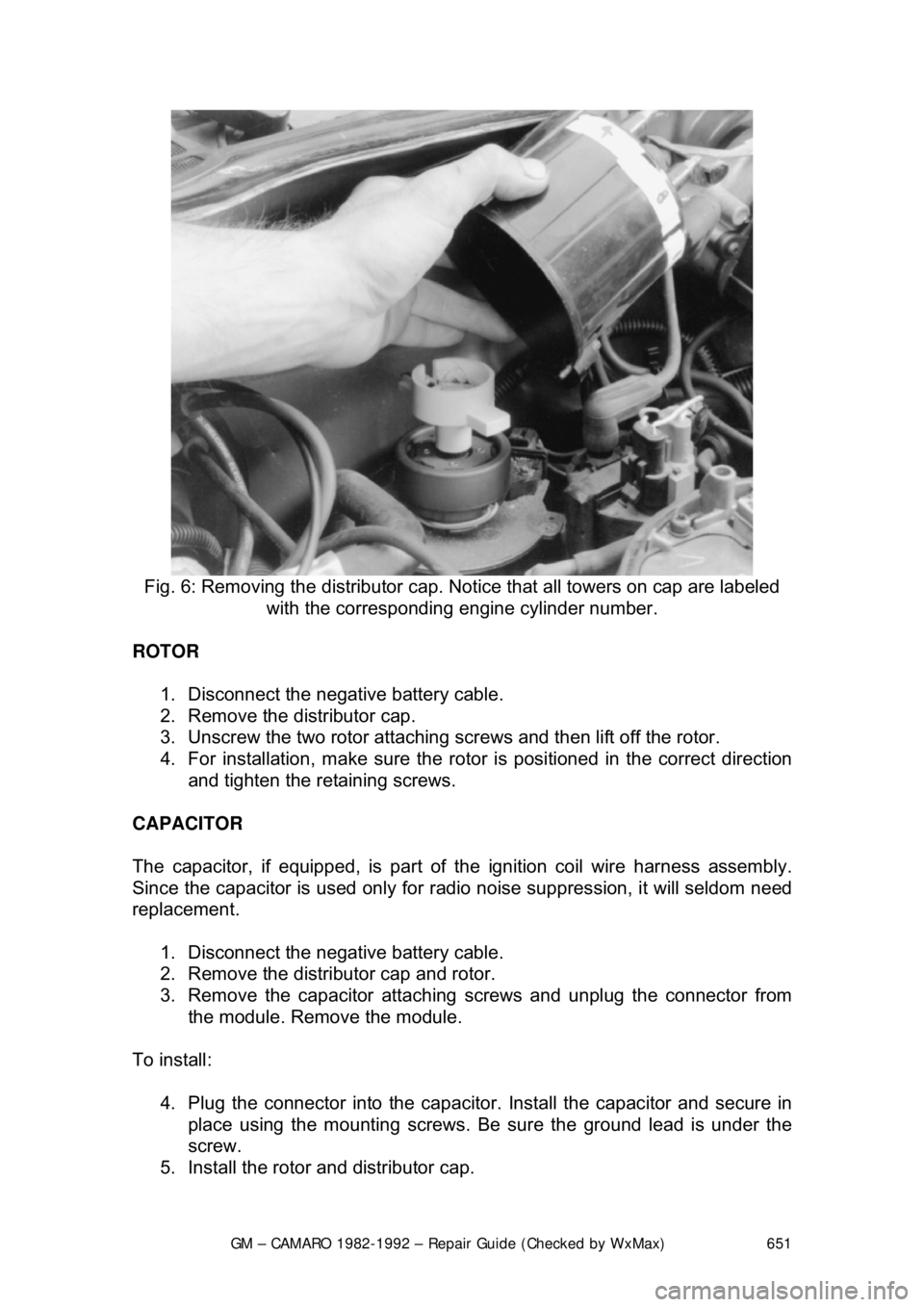

Fig. 6: Removing the distri butor cap. Notice that all towers on cap are labeled

with the corresponding engine cylinder number.

ROTOR 1. Disconnect the negative battery cable.

2. Remove the distributor cap.

3. Unscrew the two rotor attaching screws and then lift off the rotor.

4. For installation, make sure the roto r is positioned in the correct direction

and tighten the retaining screws.

CAPACITOR

The capacitor, if equipped, is part of the ignition coil wire harness assembly.

Since the capacitor is used only for radio noise suppres sion, it will seldom need

replacement.

1. Disconnect the negative battery cable.

2. Remove the distributor cap and rotor.

3. Remove the capacitor attaching screws and unplug the connector from

the module. Remove the module.

To install: 4. Plug the connector into the capacitor. Install the capacitor and secure in

place using the mounting screws. Be sure the ground lead is under the

screw.

5. Install the rotor and distributor cap.

Page 652 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 652

6. Connect the negative battery cable.

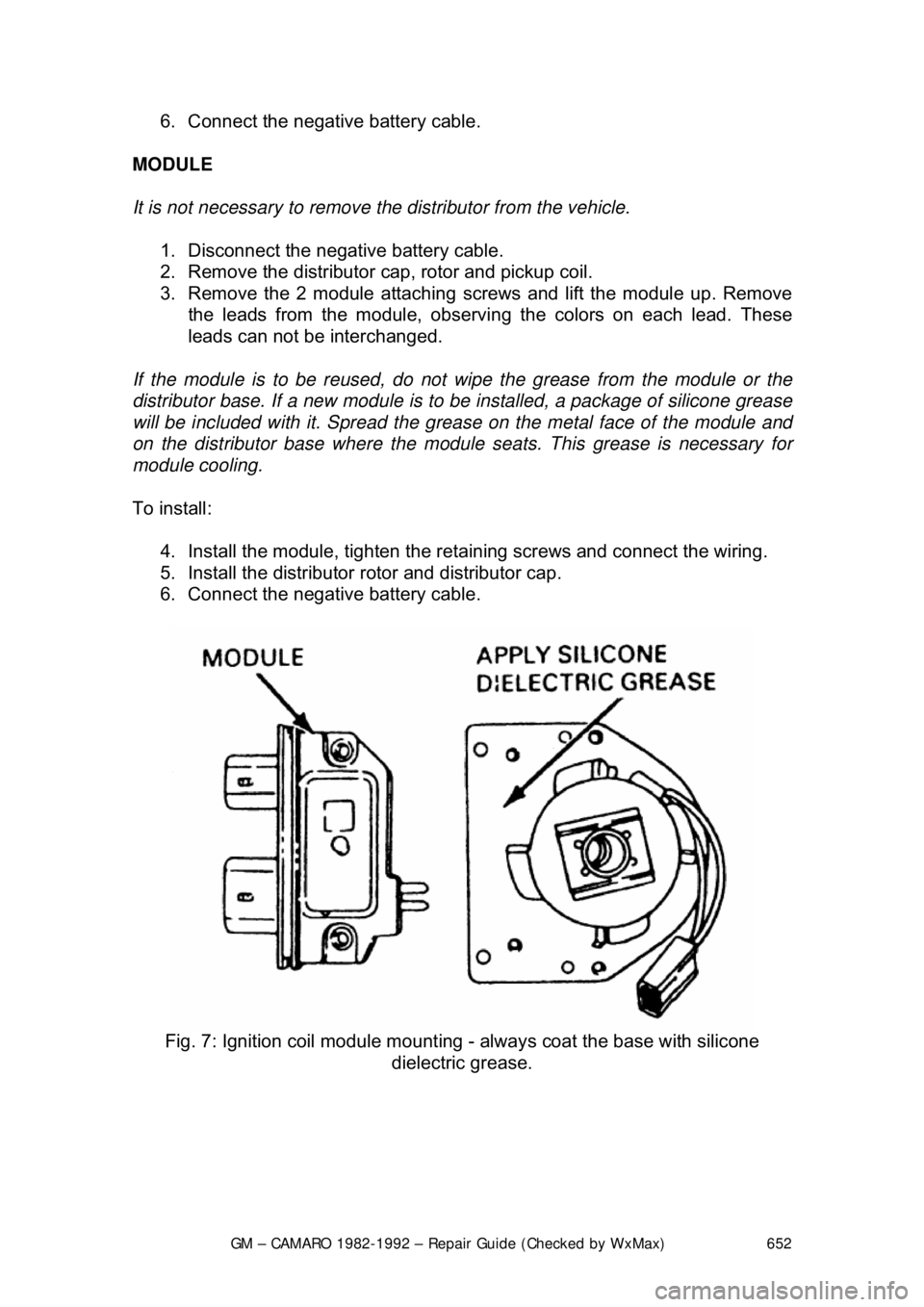

MODULE

It is not necessary to remove t he distributor from the vehicle.

1. Disconnect the negative battery cable.

2. Remove the distributor cap, rotor and pickup coil.

3. Remove the 2 module attaching screws and lift the module up. Remove

the leads from the module, observi ng the colors on each lead. These

leads can not be interchanged.

If the module is to be reused, do not wi pe the grease from the module or the

distributor base. If a new module is to be installed, a package of silicone grease

will be included with it. Spr ead the grease on the metal face of the module and

on the distributor base wher e the module seats. This grease is necessary for

module cooling.

To install: 4. Install the module, tighten the reta ining screws and connect the wiring.

5. Install the distributor rotor and distributor cap.

6. Connect the negative battery cable.

Fig. 7: Ignition coil module mounting - always coat the base with silicone

dielectric grease.

Page 653 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 653

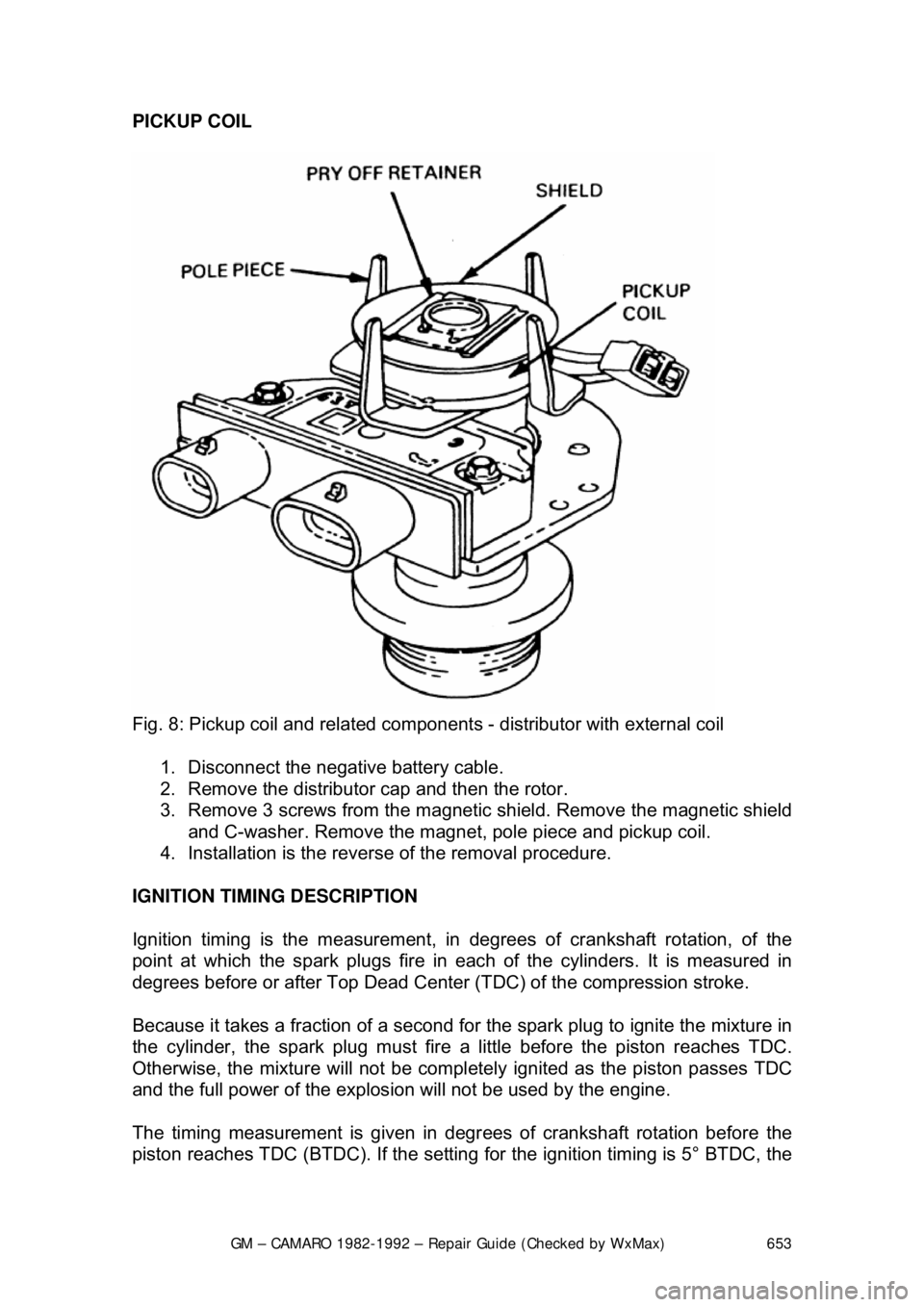

PICKUP COIL

Fig. 8: Pickup coil and related component s - distributor with external coil

1. Disconnect the negative battery cable.

2. Remove the distributor cap and then the rotor.

3. Remove 3 screws from the magnetic shield. Remove the magnetic shield

and C-washer. Remove the magnet, pole piece and pickup coil.

4. Installation is the revers e of the removal procedure.

IGNITION TIMING DESCRIPTION

Ignition timing is the measurement, in de grees of crankshaft rotation, of the

point at which the spark plugs fire in eac h of the cylinders. It is measured in

degrees before or after Top Dead Center (TDC) of the compression stroke.

Because it takes a fraction of a second for the spark plug to ignite the mixture in

the cylinder, the spark plug must fire a little before the piston reaches TDC.

Otherwise, the mixture will not be complete ly ignited as the piston passes TDC

and the full power of the explosion will not be used by the engine.

The timing measurement is given in degr ees of crankshaft rotation before the

piston reaches TDC (BTDC). If the setting fo r the ignition timing is 5° BTDC, the

Page 654 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 654

spark plug must fire 5° before each pist

on reaches TDC. This only holds true,

however, when the engine is at idle speed.

As the engine speed increases, the pist ons go faster. The spark plugs have to

ignite the fuel even sooner if it is to be completely ignited when the piston

reaches TDC.

If the ignition is set too far advanced (B TDC), the ignition and expansion of the

fuel in the cylinder will occu r too soon and try to force the piston down while it is

still traveling up. This causes engine ping. If the ignition spark is set too far

retarded, after TDC (ATDC), the pi ston will have already passed TDC and

started on its way down when the fuel is igni ted. This will cause the piston to be

forced down for only a portion of its trav el, resulting in poor engine performance

and lack of power.

When timing the engine, the Number 1 pl ug wire should be used to trigger the

timing light. On engines where timing is adjustable, the notch for the No. 1

cylinder is usually scribed across all th ree edges of the double sheaf pulley.

Another notch located 180° away from t he No. 1 cylinder notch is scribed only

across the center section of the pulley to make it distinguishable from the No. 1

cylinder notch.

There are two basic types of timing light s available. The first type of light

operates from the car's battery. Two al ligator clips connect to the battery

terminals, while a third wire connects to the spark plug with an adapter or to the

spark plug wire with an inductive pickup. This type of light is more expensive,

but the xenon bulb provides a nice bright flash which can even be seen in

sunlight. The second type replaces the battery source with 110-volt house

current. Some timing lights have other func tions built into them, such as dwell

meters, tachometers, or re mote starting switches. These are convenient, in that

they reduce the tangle of wires under t he hood, but may duplicate the functions

of tools you already have.

Because this car uses electronic ignition, you should use a timing light with an

inductive pickup. This pickup simply cl amps around the Number 1 spark plug

wire (in this case, the coil wire), elimin ating the adapter. It is not susceptible to

crossfiring or false triggering, which ma y occur with a conventional light due to

the greater voltages produc ed by these systems.

ADJUSTMENT

When adjusting the timing, refer to the instructions on the emission control

sticker inside the engine compartment. If th e instructions on the label disagree

with the procedure listed below, follo w the instructions on the label.

1982-87 VEHICLES 1. Locate the timing marks on the cran kshaft pulley and the front of the

engine.

Page 655 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 655

2. Clean off the marks and coat them wit

h white paint or chalk, if necessary,

so that they may be seen.

3. Run the engine until it reaches no rmal operating temperature, then shut

off the engine.

4. With the ignition OFF, connect a ta chometer to the distributor, and a

timing light with an inductive pickup lead to the No. 1 spark plug wire.

WARNING - Never pierce a secondary ignition wire in order to connect a timing

light. A pierced wire may lead to engine misfiring and driveability problems.

5. To properly set the ignition timing , the EST must be placed in the bypass

mode. a. On the 2.5L engine, refer to t he emission control label for the

procedure.

If the label is missing or unreadable, c ontact your Chevrolet dealer for a

replacement.

b. On 2.8L and 5.0L ca rbureted engines, disconnect the 4-wire EST

connector at the distributor. (Fault code 42 may be set in ECM memory,

and must be cleared once the procedur e is completed). Proceed to Step

7.

c. On 2.8L, 5.0L and 5.7L fuel inje cted engines, with the engine RUNNING

and all accessories off, use a jumper wire to connect diagnostic terminal

B and ground terminal A of the 12-terminal Assembly Line Diagnostic

Link (ALDL) usually located under t he left side of the instrument panel.

DO NOT disconnect the 4-wir e EST connector at the distributor. Aim the

timing light at the timing mark; the li ne on the balancer or pulley will line

up with the timing mark. Increase engine speed and check for timing

advance. If the timing still advances with engine speed, perform Step 6. If

timing does not advance with engi ne speed, proceed to Step 7.

If timing advances with engine speed, it will be necessary to disconnect the

single-wire Set Timing connector. (Faul t code 42 may be set in ECM memory,

and must be cleared once the procedure is completed).

6. Remove the jumper wire from t he ALDL, and shut off the ignition.

Disconnect the Set Timing connector, usually located under the plastic

cover above the heater unit, in the engi ne compartment. (The wire in this

connector is normally Tan/Black.)

7. With the engine running and all accessories off, aim the light at the timing

mark. The line on the balancer or pulle y will line up with the timing mark.

If a change in timing is necessary, loosen the hold-down clamp bolt at

the base of the distributor . While observing the timing mark, rotate the

distributor slightly unt il the line indicates the correct timing. Use the

timing specification on the emi ssion control label in the engine

compartment. If this label is missi ng or damaged, refer to the Tune-Up

Specifications chart in this Section.

Page 656 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 656

8. Once the timing is set to specific

ation, tighten the distributor hold-down

clamp. Recheck the timing to make su re it did not change while the bolt

was being tightened.

9. Remove the jumper wire from the ALDL connector, if applicable, with the

engine still running. (Usually, if this is performed before the engine is

shut off, no trouble codes will be stored.)

10. Turn the engine OFF, then remove the timing light and tachometer.

Reconnect the number 1 spark plug wire, if disconnected.

11. Attach the 4-wire EST connector at the distributor, or reconnect the Set

Timing connector, if applicable.

12. Check for fault code 42, and clear, if necessary, by disconnecting the

negative battery cable for at least 30 seconds.

To prevent ECM damage, the key must be in the OFF position when

disconnecting or reconnecting battery cables.

1988-90 VEHICLES

When adjusting the timing, refer to the instructions on the emission control

sticker inside the engine compartment. If th e instructions on the label disagree

with the procedure listed below, follo w the instructions on the label.

1. Locate the timing marks on the cran kshaft pulley and the front of the

engine.

2. Clean off the marks and coat them with white paint or chalk, so that they

may be easily seen.

3. Run the engine until it reaches no rmal operating temperature, then shut

off the engine.

4. With the ignition OFF, connect a ta chometer to the distributor, and a

timing light with an inductive pickup lead to the No. 1 spark plug wire.

WARNING - Never pierce a secondary ignition wire in order to connect a timing

light. A pierced wire may lead to engine misfiring and driveability problems.

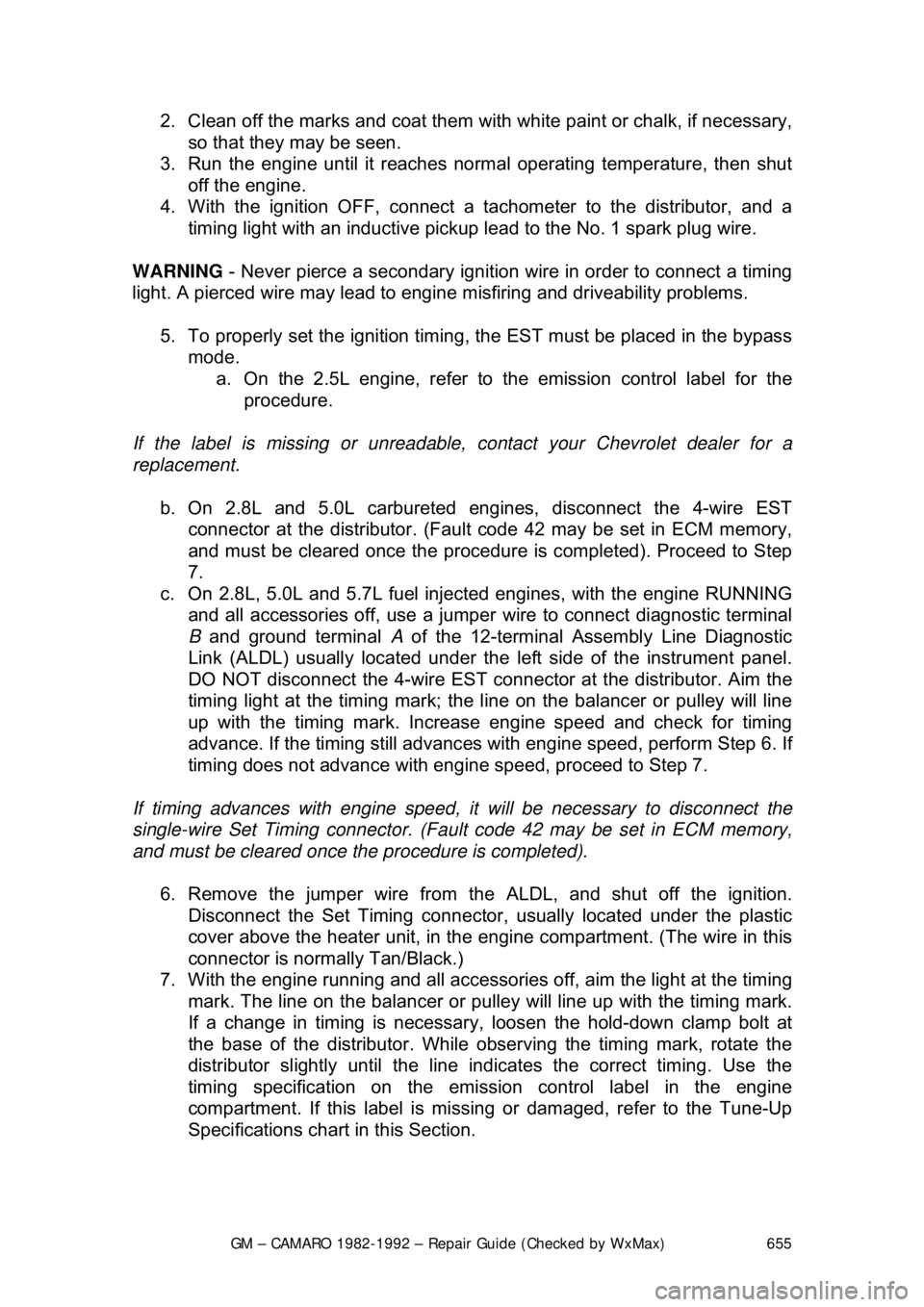

5. Start the engine. With the engine running and all accessories off, use a

jumper wire to connect diagnostic terminal B and ground terminal A of

the 12-terminal Assembly Line Diagnostic Link (ALDL), located under the

instrument panel.

If jumping the ALDL terminals does not prevent timing advance, the EST

bypass wire will have to be disconnected instead.

6. Aim the timing light at the timing mark. The line on the balancer or pulley

will line up with the timing mark. If a change in timing is necessary,

loosen the hold-down clamp bolt at t he base of the distributor. While

observing the timing mark, rotate the distributor slightly until the line

indicates the correct timing. Use t he timing specification on the emission

control label in the engine compartm ent. If this label is missing or

damaged, refer to the Tune- Up Specifications chart in this Section.

Page 657 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 657

7. Once the timing is set to specific

ation, tighten the distributor hold-down

clamp. Recheck the timing to make su re it did not change while the bolt

was being tightened.

8. With the engine still running, unground the diagnostic terminal.

(Ungrounding the diagnostic terminal while the engine is still running will

usually prevent trouble c odes from being stored.)

9. Turn the engine OFF and remove the timing light and tachometer.

Reconnect the number 1 spark plug wire, if disconnected.

Fig. 1: Grounding the diagnostic termi nal in order to set ignition timing

1991-92 VEHICLES

When adjusting the timing, refer to the instructions on the emission control

sticker inside the engine compartment. If th e instructions on the label disagree

with the procedure listed below, follo w the instructions on the label.

1. Locate the timing marks on the cran kshaft pulley and the front of the

engine.

2. Clean off the marks and coat them wit h white paint or chalk, if necessary,

so that they may be seen.

3. Run the engine until it reaches no rmal operating temperature, then shut

off the engine.

4. With the ignition OFF, connect a tachometer to the distributor, and the

pickup lead of an inductive timing li ght to the No. 1 spark plug wire.

Page 658 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 658

Connect the timing light power leads

according to the manufacturer's

instructions.

WARNING - Never pierce a secondary ignition wire in order to connect a timing

light. A pierced wire may lead to engine misfiring and driveability problems.

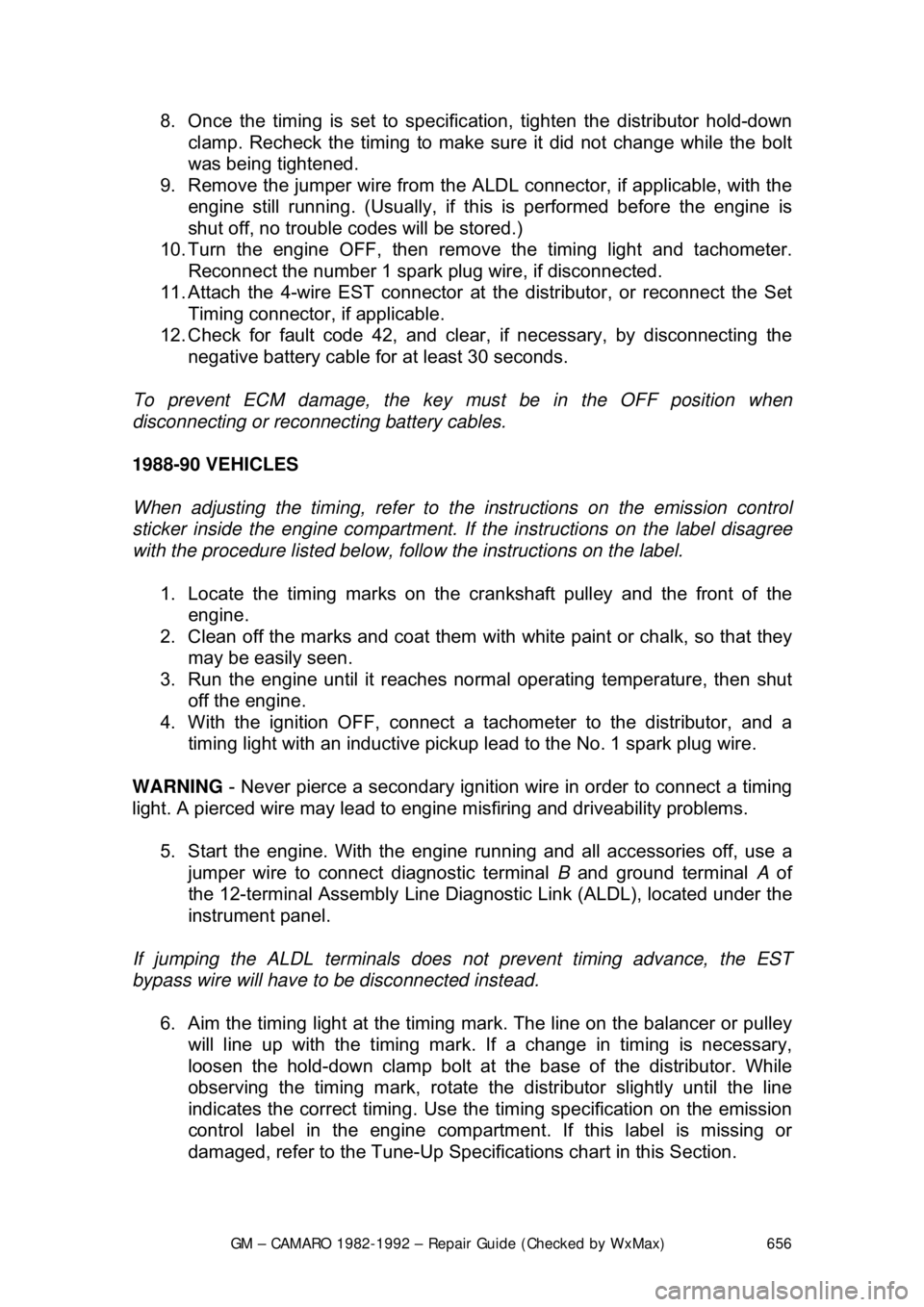

5. Start the engine. With the engine running at normal operating

temperature and all accessories OFF, disconnect the EST bypass

connector.

An ECM code will be set when the EST bypass connector is disconnected.

6. Aim the timing light at the timing mark. The line on the balancer or pulley

will line up with the timing mark. If a change in timing is necessary,

loosen the hold-down clamp bolt at t he base of the distributor. While

observing the timing mark, rotate the distributor slightly until the line

indicates the correct timing. Use t he timing specification on the emission

control label in the engine compartm ent. If this label is missing or

damaged, refer to the Tune- Up Specifications chart in this Section.

7. Tighten the distributor hold-down bolt and recheck the ignition timing to

make sure the distributor was not moved when the bolt was tightened.

8. Turn the engine OFF and remove the timing light and tachometer.

Reconnect the number 1 spark plug wire, if disconnected.

9. Connect the EST bypass connector , then check for and clear the ECM

code by disconnecting the negative battery cable for at least 30 seconds.

To prevent ECM damage, the key must be in the OFF position when

disconnecting or reconnecting battery cables.

Fig. 2: EST bypass connector

Page 659 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 659

VALVE LASH

All models utilize a hydraulic valve lifter system to obtain zero lash. No periodic

adjustment is necessary. An initial adjustm

ent is required anytime that the lifters

are removed or the valve tr ain is disturbed. This procedure is covered in Engine

& Engine Overhaul .

IDLE SPEED AND MIXTURE ADJUSTMENTS

Mixture adjustments are factory set and sealed; no adjustment attempt should

be made, except by an aut horized GM dealer or reputable shop equipped with

the necessary equipment.

IDLE SPEED

2-BBL CARBURETOR

WITHOUT AIR CONDITIONING

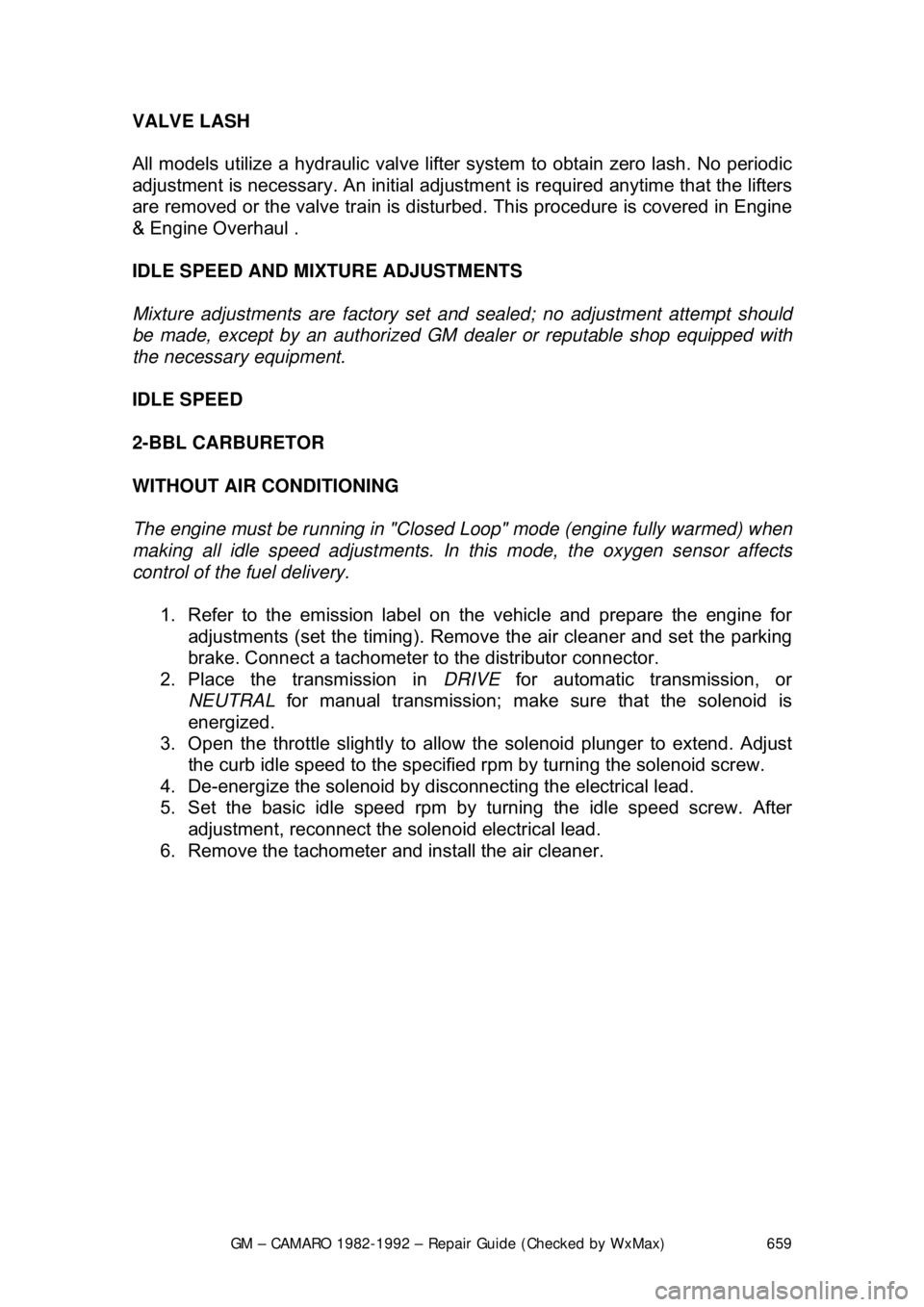

The engine must be running in "Closed Loop" mode (engine fully warmed) when

making all idle speed adjustments. In this mode, the oxygen sensor affects

control of the fuel delivery.

1. Refer to the emission label on the vehicle and prepare the engine for

adjustments (set the timing). Remove the air cleaner and set the parking

brake. Connect a tachometer to the distributor connector.

2. Place the transmission in DRIVE for automatic transmission, or

NEUTRAL for manual transmission; make sure that the solenoid is

energized.

3. Open the throttle slightly to allow the solenoid plunger to extend. Adjust

the curb idle speed to the specified rpm by turning the solenoid screw.

4. De-energize the solenoid by disconnecting the electrical lead.

5. Set the basic idle speed rpm by turning the idle speed screw. After

adjustment, reconnect the solenoid electrical lead.

6. Remove the tachometer and install the air cleaner.

Page 660 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 660

Fig. 1: Idle speed adjustm ents - 2-bbl carburetor (without air conditioning)

WITH AIR CONDITIONING

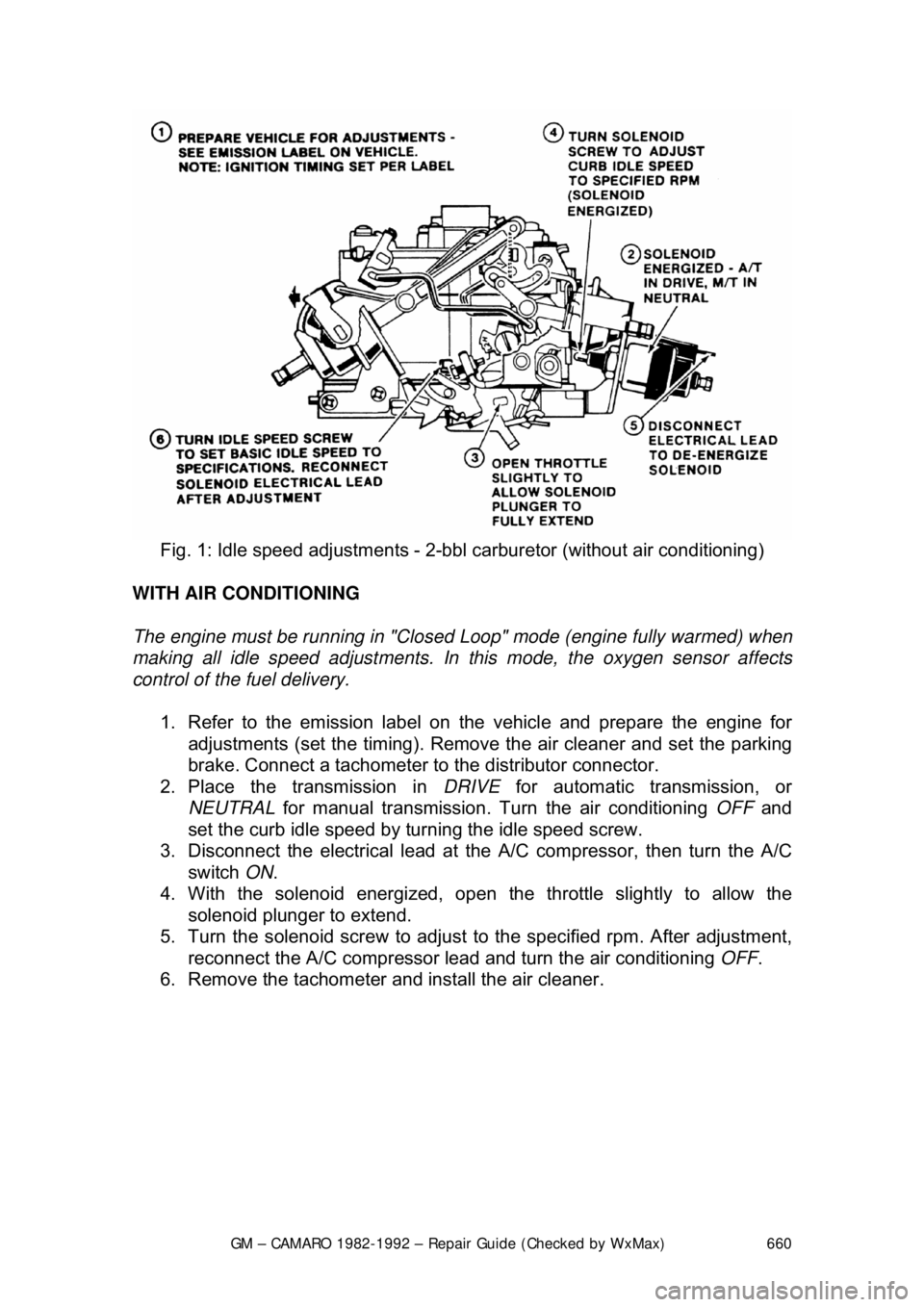

The engine must be running in "Closed Loop" mode (engine fully warmed) when

making all idle speed adjustments. In this mode, the oxygen sensor affects

control of the fuel delivery.

1. Refer to the emission label on the vehicle and prepare the engine for

adjustments (set the timing). Remove the air cleaner and set the parking

brake. Connect a tachometer to the distributor connector.

2. Place the transmission in DRIVE for automatic transmission, or

NEUTRAL for manual transmission. Tu rn the air conditioning OFF and

set the curb idle speed by turning the idle speed screw.

3. Disconnect the electrical lead at the A/C compressor, then turn the A/C

switch ON.

4. With the solenoid e nergized, open the throttle slightly to allow the

solenoid plunger to extend.

5. Turn the solenoid screw to adjust to the specified rpm. After adjustment,

reconnect the A/C compressor lead and turn the air conditioning OFF.

6. Remove the tachometer and install the air cleaner.