CHEVROLET CAMARO 1982 Repair Guide

Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 641 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 641

If, however, there is no spark or a weak

spark, then further ignition system

testing will have to be done. Troubleshooting techniques fall into various

categories, depending on t he nature of the problem and the system being

tested. Categories will include symptom s such as the engine cranks, but will not

start or the engine runs rough.

HEI SYSTEM

When testing the HEI system, there are 2 major categories of problems, (1)

Engine cranks, but will not star t or (2) Engine runs, but runs rough or cuts out.

If the engine will not start, perform a spar k test as described earlier. This will

narrow the problem area down considerab ly. If no spark occurs, check for the

presence of normal battery voltage at the battery ( BAT) terminal on the ignition

coil. The ignition switch must be in the ON position for this test. Either a

voltmeter or a test light wire may be us ed for this test. Connect the test light

wire to ground and the probe end to the BAT terminal at the coil. If the light

comes on, you have voltage to the distribut or and/or spark plug wires. If the light

fails to come on, this indicates an open circuit in the ignition primary wiring

leading to the distributor. In this case , you will have to check wiring continuity

back to the ignition switch using a test li ght. If there is battery voltage at the BAT

terminal, but no spark at the plugs, t hen the problem probably lies within the

distributor assembly.

If, on the other hand, the engine starts, but runs roughly or cuts out, make sure

the plug wires are in good shape first. There should be no obvious cracks or

breaks. You can check the plug wires with an ohmmeter, but do not pierce the

wires with a probe. Check the chart for th e correct plug wire resistance. If the

plug wires are OK, remove the cap asse mbly and check for moisture, cracks,

chips, or carbon tracks, or any other hi gh voltage leads or failures. Replace the

cap if any defects are found. Make su re the timer wheel rotates when the

engine is cranked.

If the trouble has been narrowed down to t he units within the distributor, the

following tests can help pinpoint the defective component. An ohmmeter with

both high and low ranges shou ld be used. These tests are made with the cap

assembly removed and the battery wir e disconnected. If a tachometer is

connected to the TACH terminal, disconnect it before making these tests.

IGNITION COIL

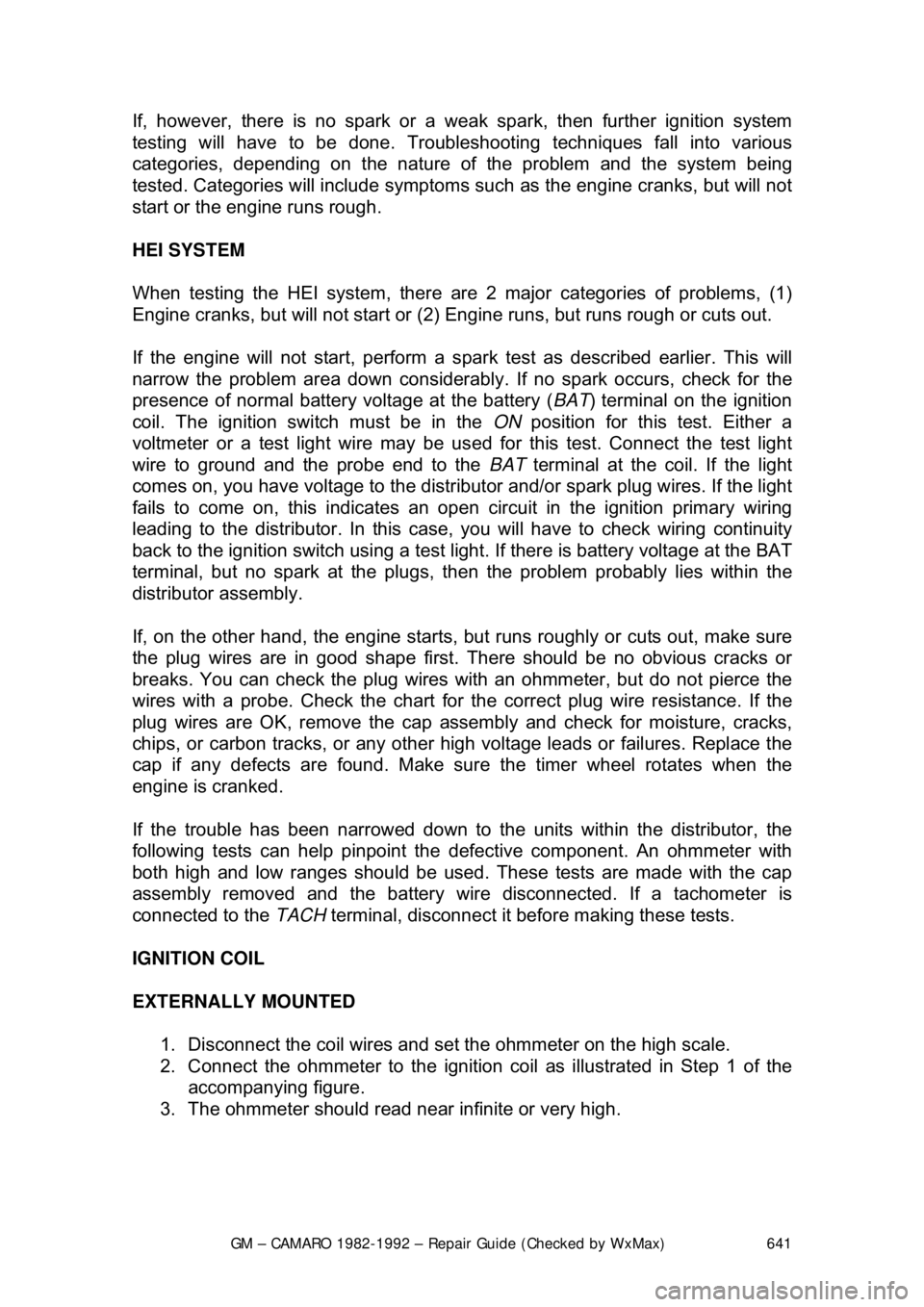

EXTERNALLY MOUNTED 1. Disconnect the coil wires and se t the ohmmeter on the high scale.

2. Connect the ohmmeter to the ignition co il as illustrated in Step 1 of the

accompanying figure.

3. The ohmmeter should read near infinite or very high.

Page 642 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 642

Fig. 1: Testing exte rnal ignition coil

4. Next, set the ohmmete r to the low scale and connect test leads as

illustrated in Step 2 of t he accompanying figure.

5. The reading should be very low or zero.

6. Now set the ohmmeter on the high scale and connect test leads as illustrated in Step 3 of the accom panying figure. The ohmmeter should

not read infinity.

Page 643 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 643

7. If any results of the 3 tests lis

ted above do not agree with the desired

readings, replace the ignition coil.

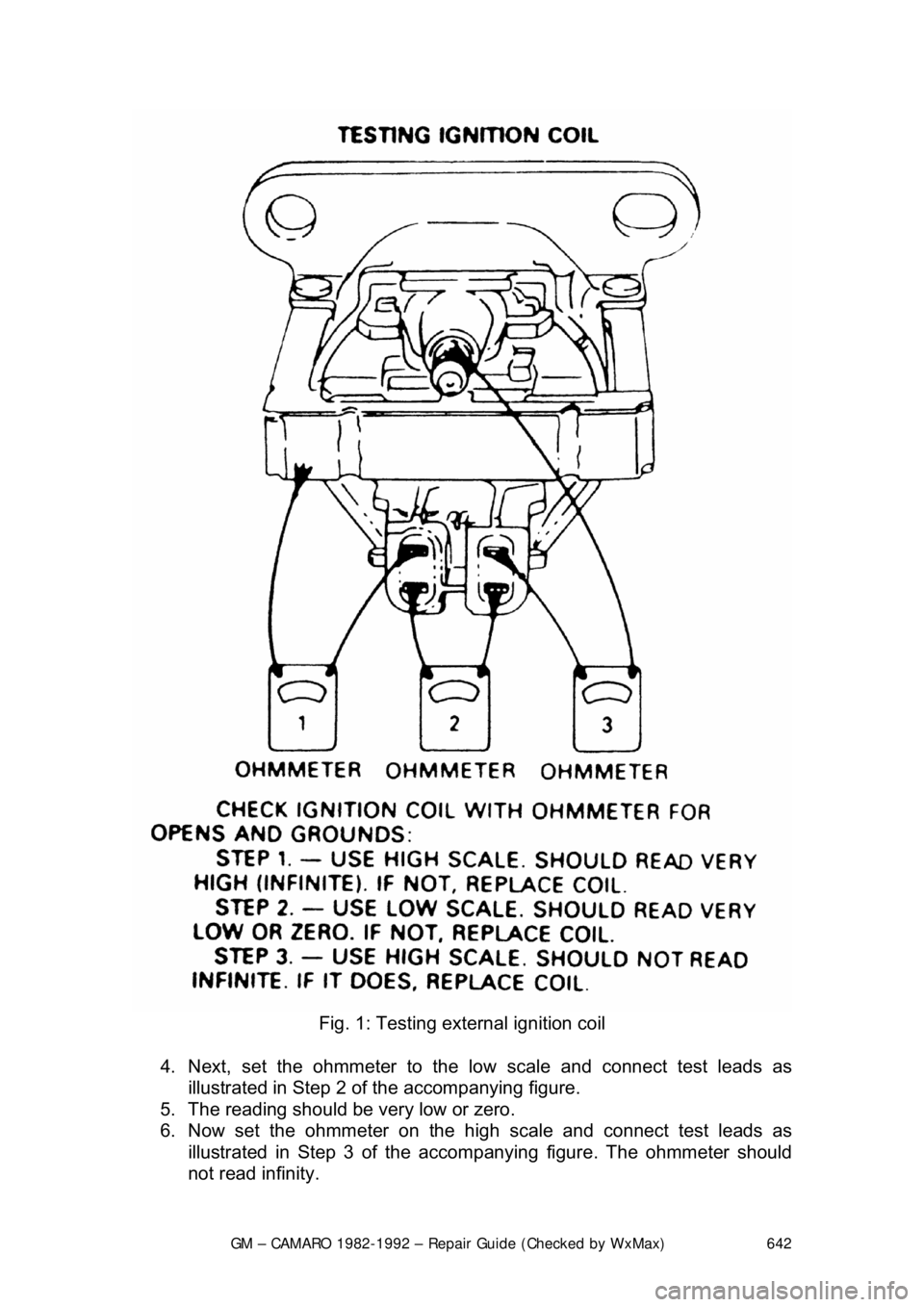

INTERNALLY MOUNTED 1. Connect an ohmmeter between the TACH and BAT terminals on the

ignition coil. The primary coil resi stance should be less than ohms;.

2. To check the coil secondary resistance, connect an ohmmeter between the high tension terminal and the BAT terminal. Note the reading.

Connect the ohmmeter between the high tension terminal and the TACH

terminal. Note the reading. The resi stance in both cases should be

6,000-30,000 ω. Be sure to test between the high tension terminal and

both the BAT and TACH terminals.

3. Replace the coil only if the reading s in Step 1 and Step 2 are infinite.

These resistance checks will not disclose shorted coil windings. This condition

can only be detected with scope analysis or a suitably designed coil tester. If

these instruments are unavaila ble, replace the coil with a known good coil as a

final coil test.

Fig. 2: Testing interna lly mounted ignition coil

Page 644 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 644

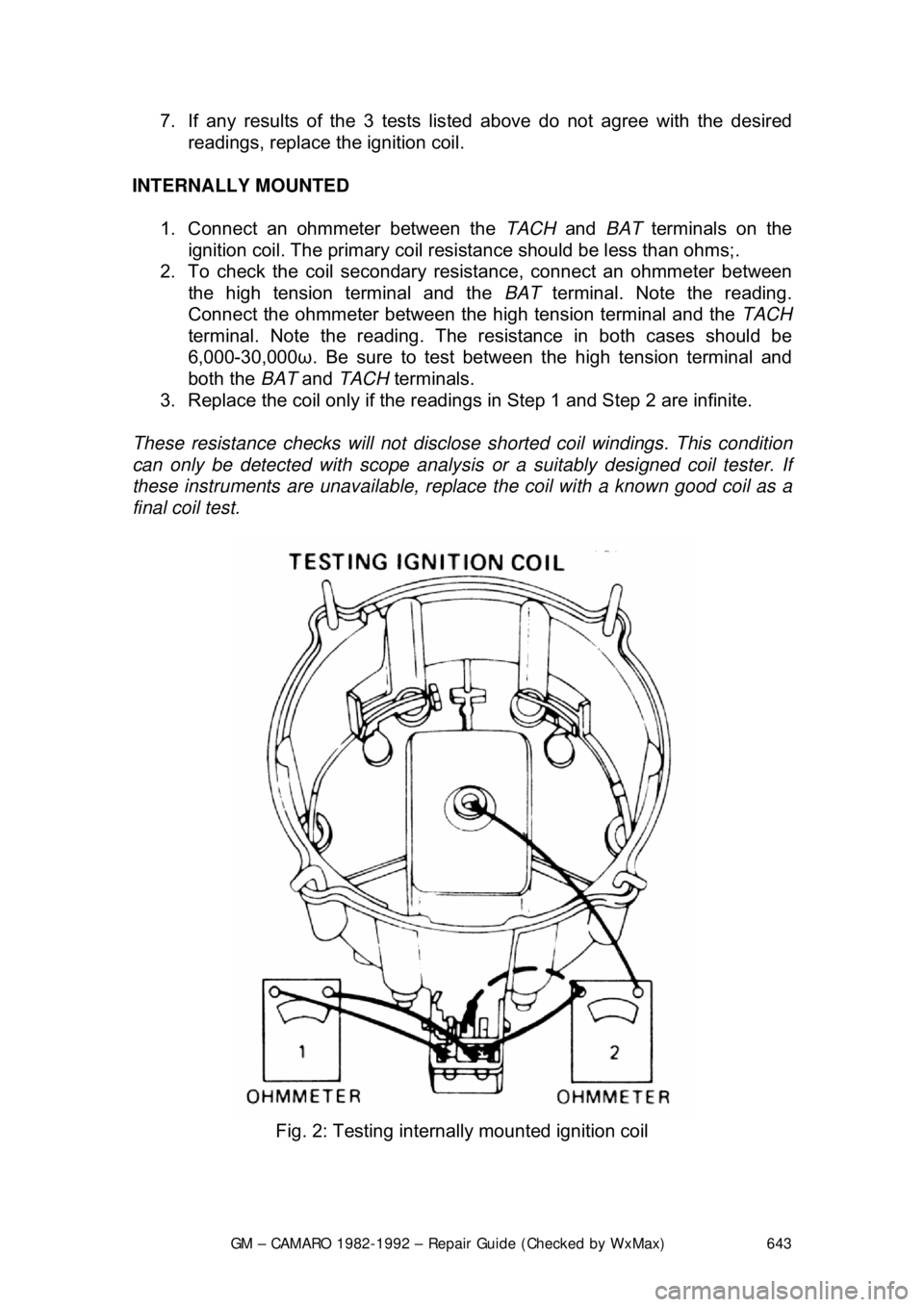

PICKUP COIL

1. To test the pickup coil, firs t disconnect the white and green module

leads. Set the ohmmeter on the high scale and connect it between a

ground and either the wh ite or green lead. Any resistance measurement

less than infinity requires repl acement of the pickup coil.

Fig. 3: Testing Pickup coil - Test 1 should read infinite at all times. Test 2 should

read a steady value of 500-1500 ohms.

2. Pickup coil continuity is test ed using an ohmmeter (on low range)

between the white and gr een leads. Normal resistance is 500-1,500ω. If

a vacuum unit is used, move the vacuum advance arm while performing

this test. This will detect any break in coil continuity. Such a condition can

cause intermittent misfiring. Replac e the pickup coil if the reading is

outside the specified limits.

Page 645 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 645

3. If no defects have been found at this

time, and you still have a problem,

then the module will have to be che cked. If you do not have access to a

module tester, the only possible alter native is a substitution test. If the

module fails the substitution test, replace it.

COMPONENT REPLACEMENT

CAUTION - When handling secondar y spark plug leads with the engine running

or starting, insulated pliers must be used and care exercised to prevent a

possible electrical shock.

HEI SYSTEM

IGNITION COIL

EXTERNALLY MOUNTED

1. Disconnect the negative battery cable.

2. Disconnect the ignition coil wire from the coil. Do so by pulling on the

boot of the wire while twisting it.

3. Disconnect the harness connecto r from the ignition coil.

4. Remove the coil mounting screws and the ignition coil. If necessary, drill

out and remove the rivets holding the coil to the bracket.

To install: 5. Place the ignition coil in position on the mounting bracket and install the

mounting screws.

6. Reconnect the harness connectors to the ignition coil. Confirm that the

harness connectors are firmly attached to the coil.

7. Install the secondary coil wire to the coil tower.

8. Connect the negative battery cable.

Page 646 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 646

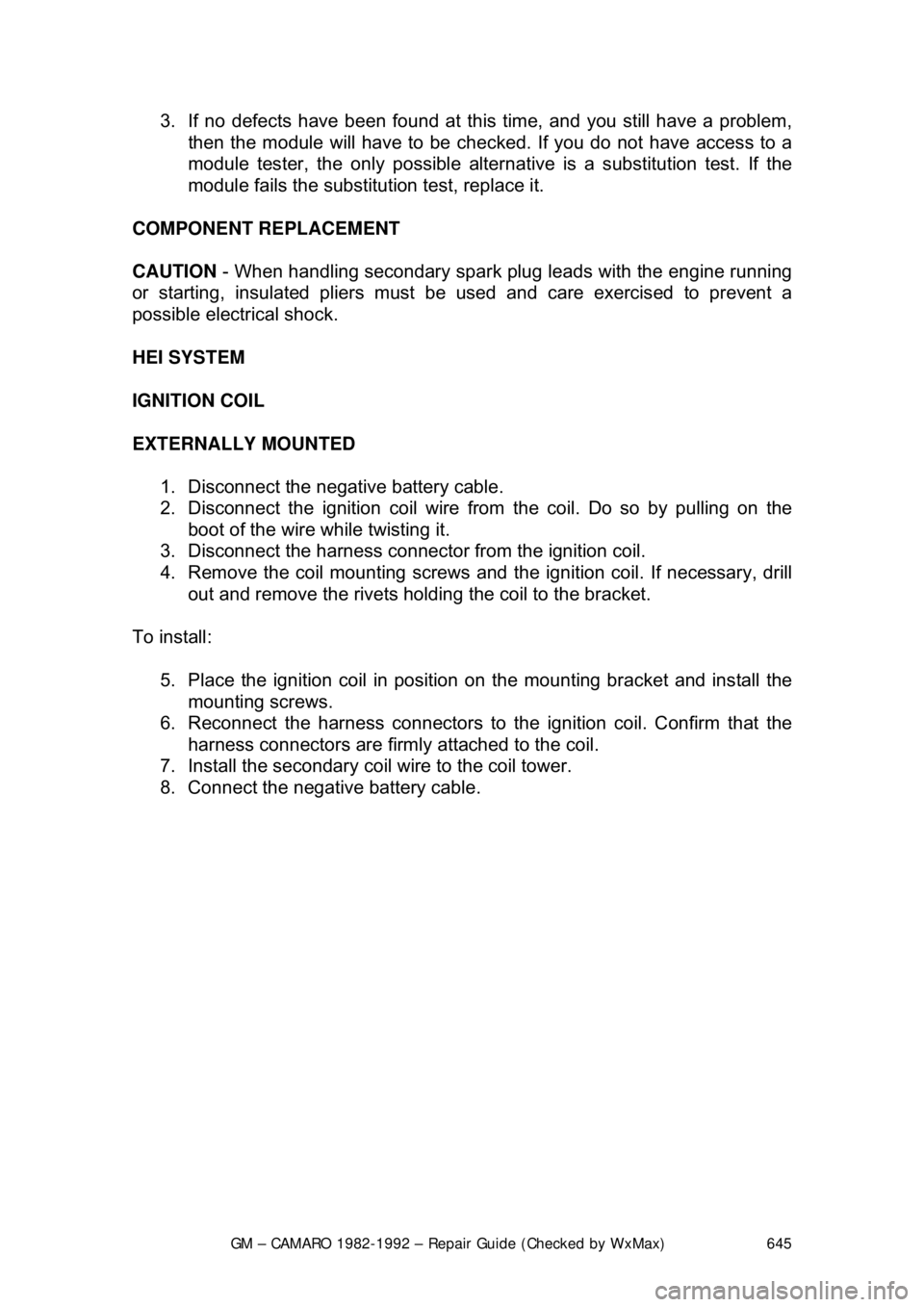

Fig. 1: Distributor with external ignition coil

Page 647 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 647

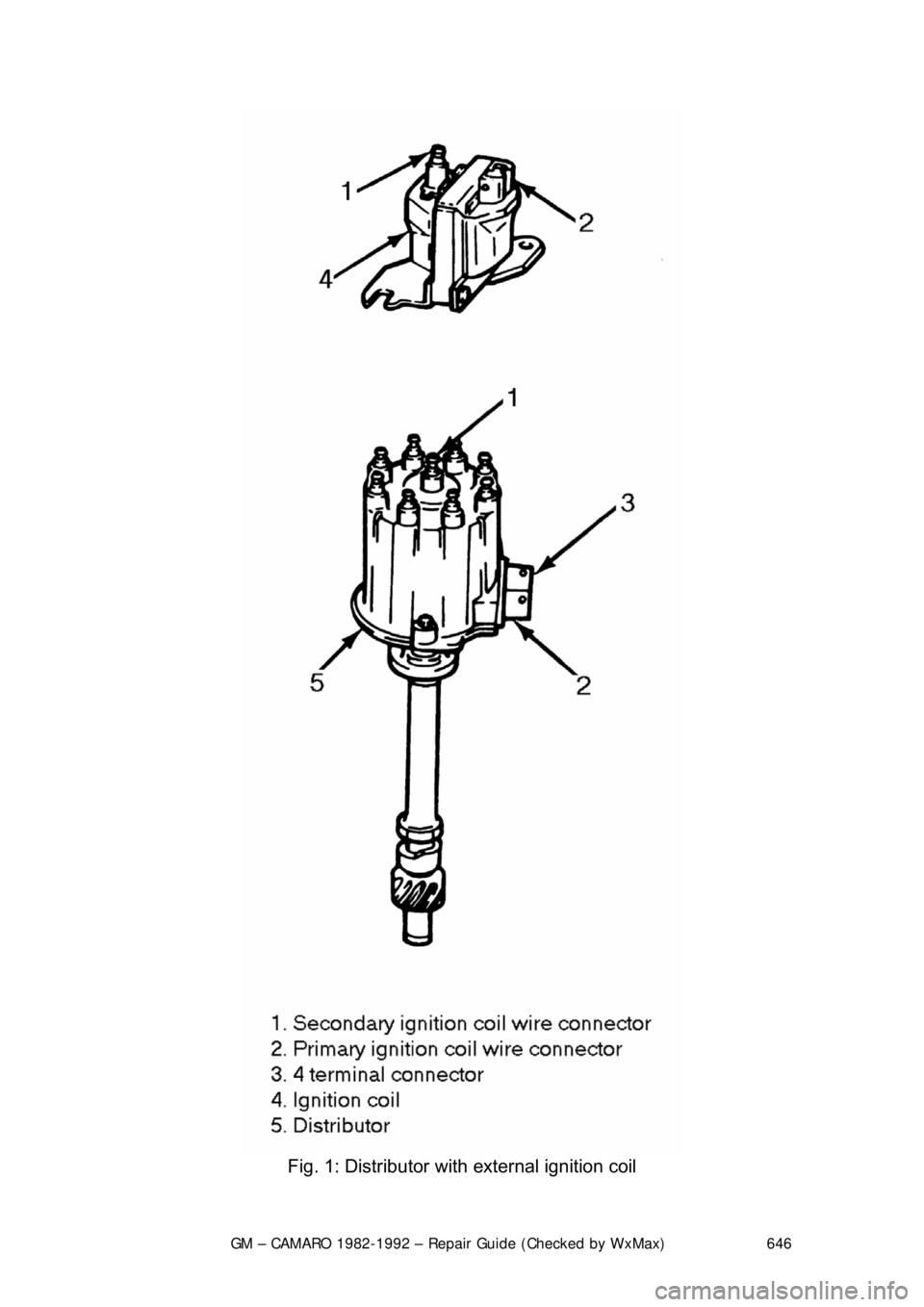

Fig. 2: Release the locking tab and remo ve the harness connector from the coil

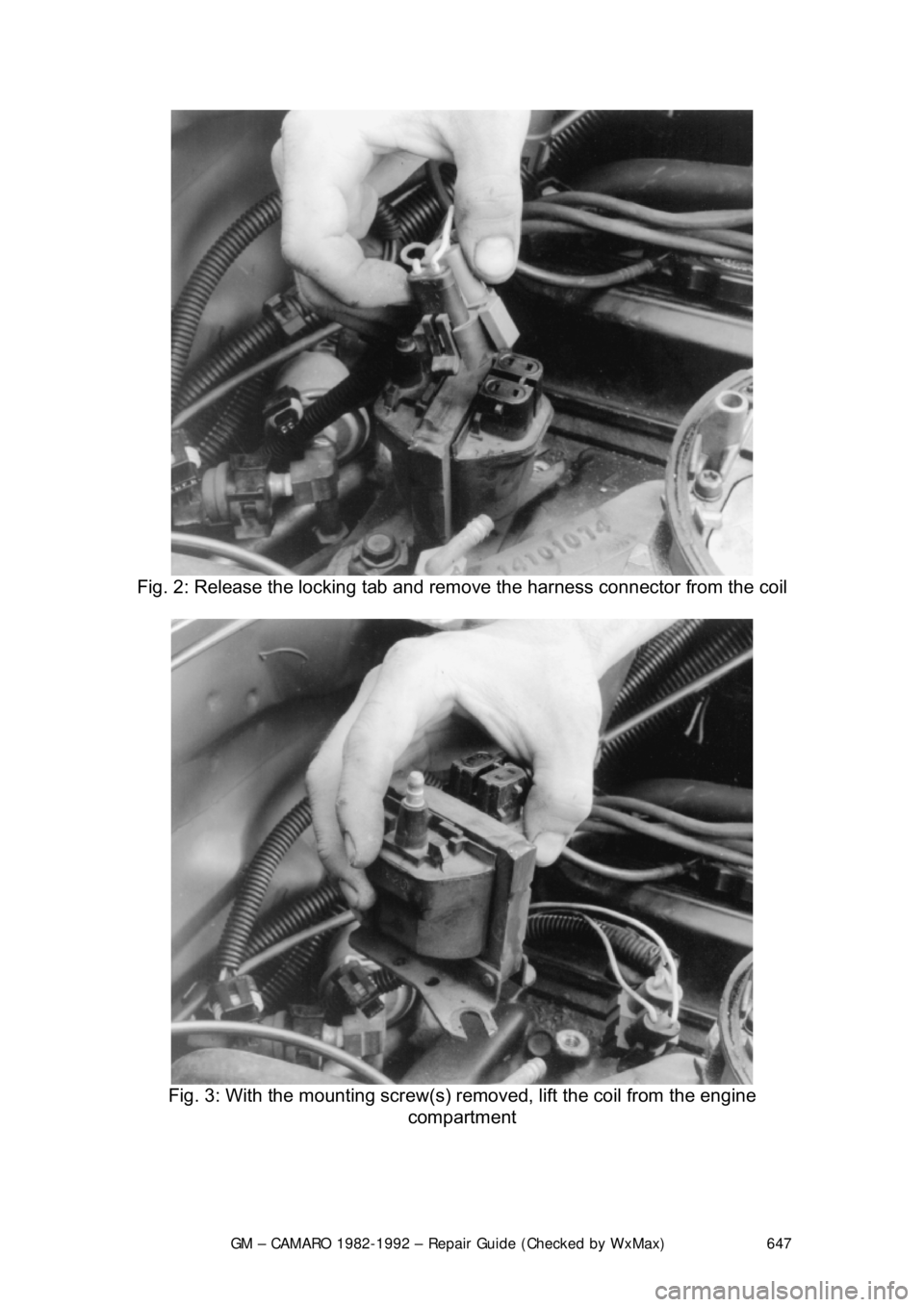

Fig. 3: With the mounting screw(s) re moved, lift the coil from the engine

compartment

Page 648 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 648

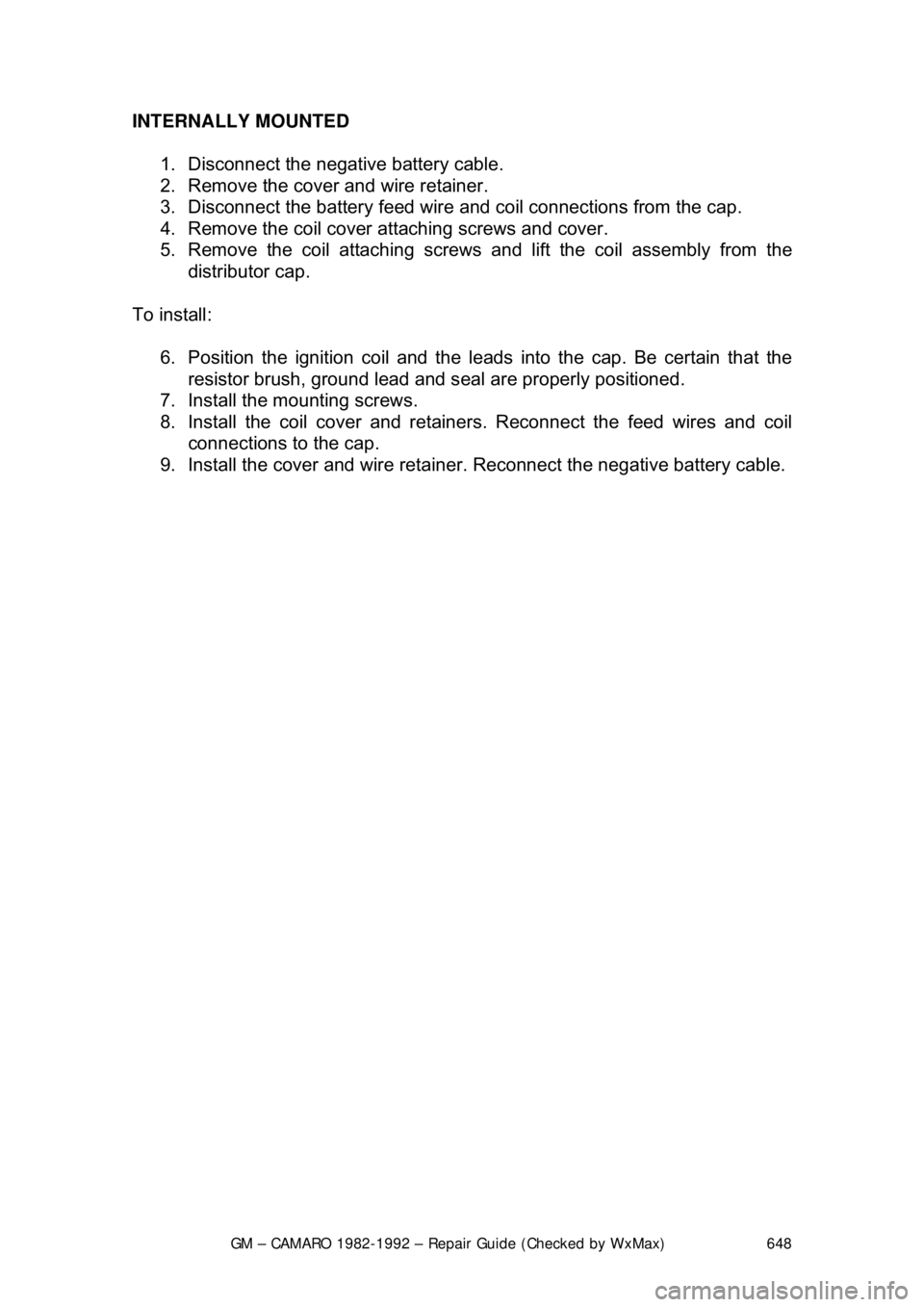

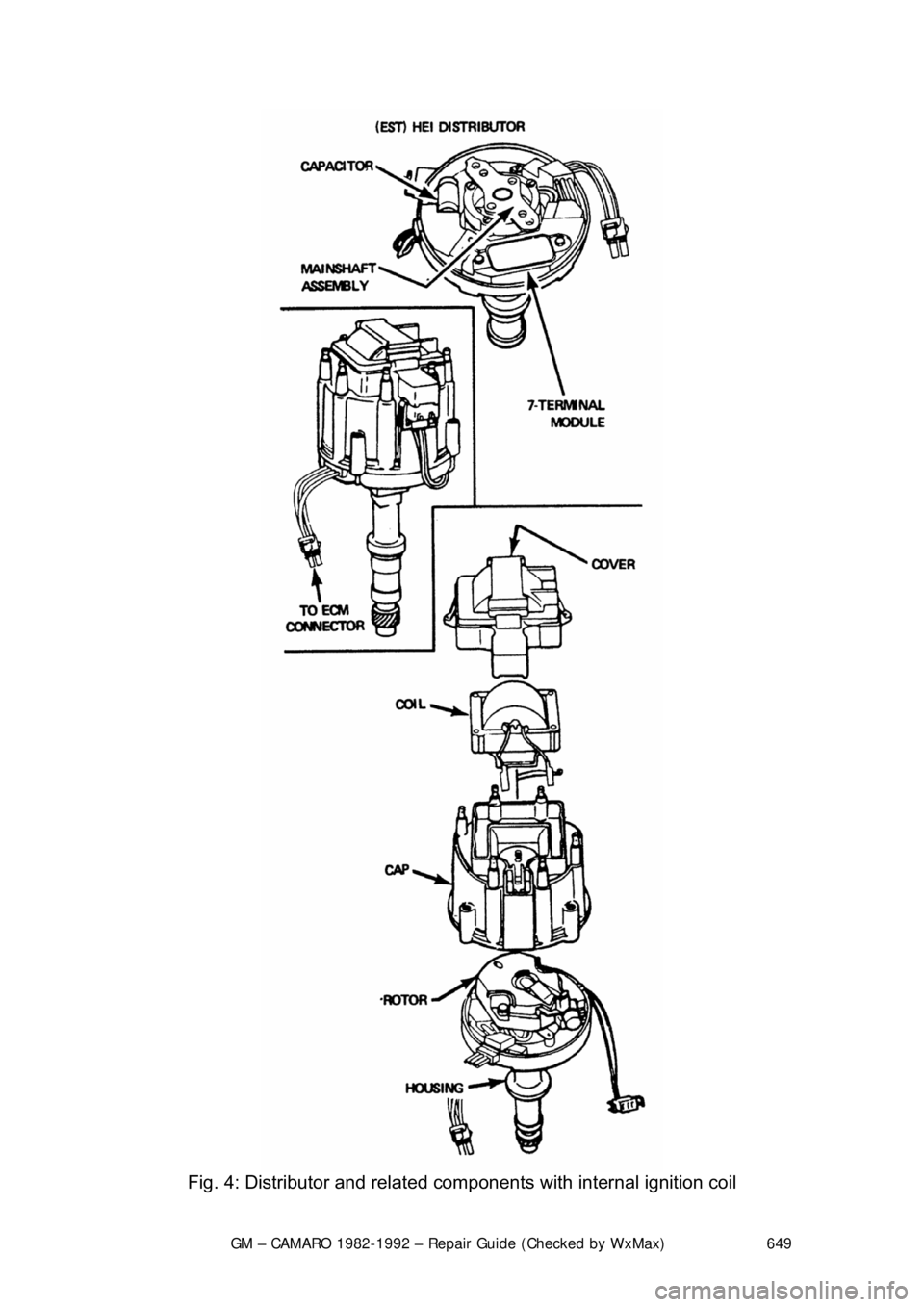

INTERNALLY MOUNTED

1. Disconnect the negative battery cable.

2. Remove the cover and wire retainer.

3. Disconnect the battery feed wire and coil connections from the cap.

4. Remove the coil cover attaching screws and cover.

5. Remove the coil attaching screws and lift the coil assembly from the

distributor cap.

To install: 6. Position the ignition coil and the leads into the cap. Be certain that the

resistor brush, ground lead and s eal are properly positioned.

7. Install the mounting screws.

8. Install the coil cove r and retainers. Reconnec t the feed wires and coil

connections to the cap.

9. Install the cover and wire retainer. Reconnect the negative battery cable.

Page 649 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 649

Fig. 4: Distributor and related com ponents with internal ignition coil

Page 650 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 650

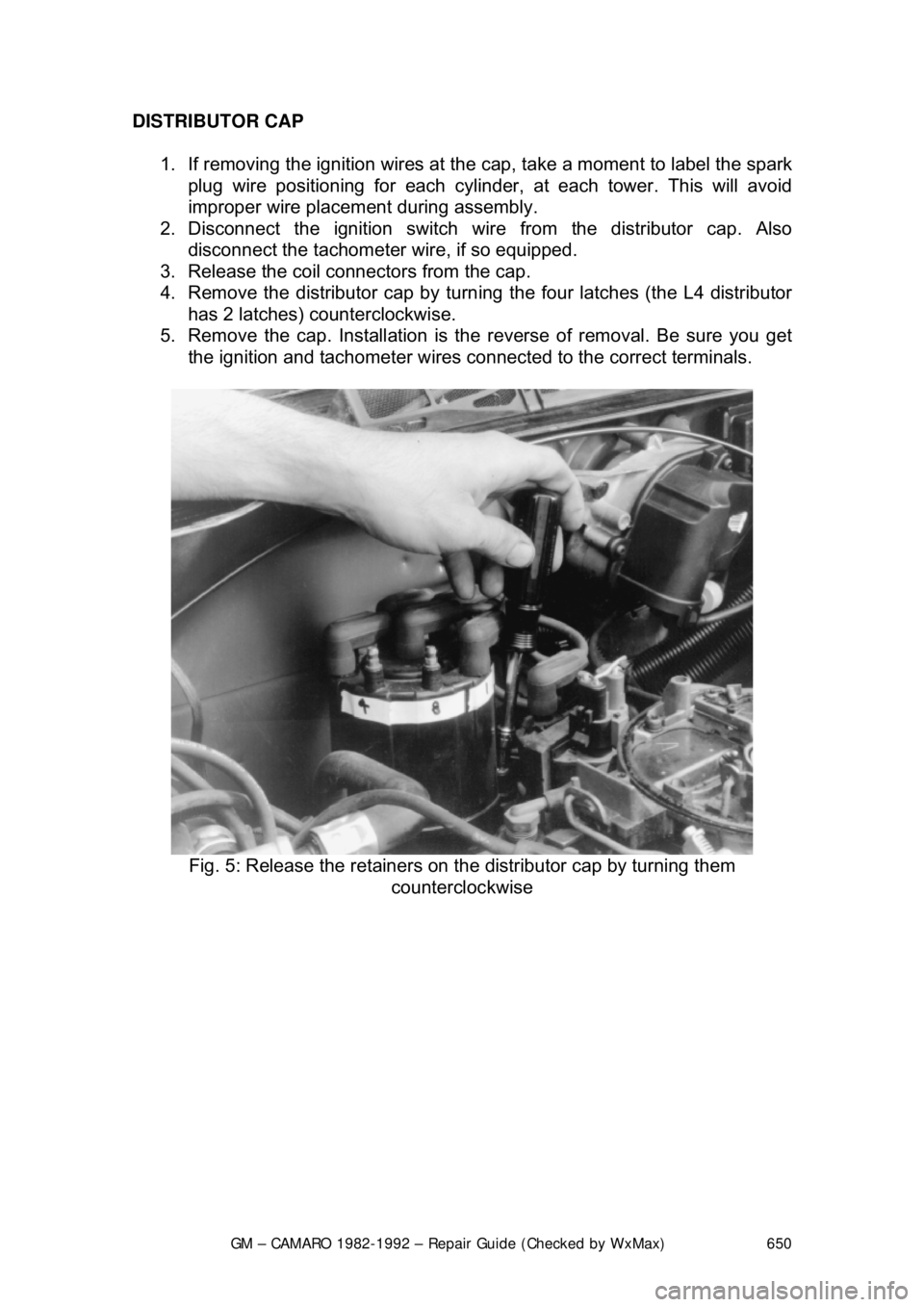

DISTRIBUTOR CAP

1. If removing the ignition wires at the cap, take a moment to label the spark

plug wire positioning for each cylinder, at each tower. This will avoid

improper wire placement during assembly.

2. Disconnect the ignition switch wir e from the distributor cap. Also

disconnect the tachometer wire, if so equipped.

3. Release the coil connec tors from the cap.

4. Remove the distributor cap by turn ing the four latches (the L4 distributor

has 2 latches) counterclockwise.

5. Remove the cap. Installation is the reverse of removal. Be sure you get

the ignition and tachometer wires c onnected to the correct terminals.

Fig. 5: Release the retainers on t he distributor cap by turning them

counterclockwise