CHEVROLET CAMARO 1982 Repair Guide

Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 811 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 811

CAUTION

- NEVER hook the batteries up in a series circuit or the entire

electrical system will go up in smoke, including the starter!

Vehicles equipped with a diesel engine may utilize two 12 volt batteries. If so,

the batteries are connected in a parallel circuit (positive terminal to positive

terminal, negative terminal to negative te rminal). Hooking the batteries up in

parallel circuit increases battery cranki ng power without increasing total battery

voltage output. Output remains at 12 vo lts. On the other hand, hooking two 12

volt batteries up in a series circuit (positive terminal to negative terminal,

positive terminal to negative terminal) incr eases total battery output to 24 volts

(12 volts plus 12 volts).

JUMP STARTING PRECAUTIONS

• Be sure that both batteries are of t he same voltage. Vehicles covered by

this information and most vehicles on the road today utilize a 12 volt

charging system.

• Be sure that both batteries are of the same polarity (have the same

terminal, in most cases NEGATIVE grounded).

• Be sure that the vehicles are not touching or a short could occur.

• On serviceable batteries, be sure the v ent cap holes are not obstructed.

• Do not smoke or allow sparks anywhere near the batteries.

• In cold weather, make sure the battery electrolyte is not frozen. This can

occur more readily in a battery that has been in a state of discharge.

• Do not allow electrolyte to c ontact your skin or clothing.

JUMP STARTING PROCEDURE 1. Make sure that the voltages of the 2 batteries are the same. Most

batteries and charging systems are of the 12 volt variety.

2. Pull the jumping vehicle (with t he good battery) into a position so the

jumper cables can reach the dead battery and that vehicle's engine.

Make sure that the ve hicles do NOT touch.

3. Place the transmissions of both vehicles in Neutral (MT) or P (AT), as

applicable, then firmly set their parking brakes.

If necessary for safety reasons, the hazard lights on both vehicles may be

operated throughout the entir e procedure without significantly increasing the

difficulty of jumping the dead battery.

4. Turn all lights and accessories OFF on both vehicles. Make sure the ignition switches on both vehicles are turned to the OFF position.

5. Cover the battery cell caps with a rag, but do not cover the terminals.

6. Make sure the terminals on both batte ries are clean and free of corrosion

or proper electrical connection wil l be impeded. If necessary, clean the

battery terminals before proceeding.

7. Identify the positive (+) and negat ive (-) terminals on both batteries.

8. Connect the first jumper cable to the positive (+) terminal of the dead

battery, then connect the other end of that cable to the positive (+)

terminal of the booster (good) battery.

Page 812 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 812

9. Connect one end of the other jumper

cable to the negative (-) terminal on

the booster battery and the final cable clamp to an engine bolt head,

alternator bracket or ot her solid, metallic point on the engine with the

dead battery. Try to pick a ground on the engine that is positioned away

from the battery in order to minimi ze the possibility of the 2 clamps

touching should one l oosen during the procedure. DO NOT connect this

clamp to the negative (-) term inal of the bad battery.

CAUTION - Be very careful to keep the jum per cables away from moving parts

(cooling fan, belts, etc.) on both engines.

10. Check to make sure that the c ables are routed away from any moving

parts, then start the d onor vehicle's engine. Run the engine at moderate

speed for several minutes to allow the dead battery a chance to receive

some initial charge.

11. With the donor vehicle's engine still r unning slightly above idle, try to start

the vehicle with the dead battery. Crank the engine for no more than 10 \

seconds at a time and let the starter cool for at least 20 seconds between

tries. If the vehicl e does not start in 3 tries, it is likely that something else

is also wrong or that the battery needs additional time to charge.

12. Once the vehicle is star ted, allow it to run at idle for a few seconds to

make sure that it is operating properly.

13. Turn ON the headlight s, heater blower and, if equipped, the rear

defroster of both vehicles in order to reduce the severity of voltage spikes

and subsequent risk of dam age to the vehicles' electrical systems when

the cables are disconnected. This st ep is especially important to any

vehicle equipped with computer control modules.

14. Carefully disconnect the cables in the reverse order of connection. Star\

t with the negative cable that is attached to the engine ground, then the

negative cable on the donor battery. Di sconnect the positive cable from

the donor battery and finally, disconnect the positive cable from the

formerly dead battery. Be careful when disconnecting the cables from the

positive terminals not to allow the alli gator clips to touch any metal on

either vehicle or a short and sparks will occur.

JACKING

Your vehicle was supplied with a jack for emergency road repairs. This jack is

fine for changing a flat tire or other s hort term procedures not requiring you to

go beneath the vehicle. If it is used in an emergency situation, carefully follow

the instructions provided eit her with the jack or in your owner's manual. Do not

attempt to use the jack on any portions of the vehicle other than specified by the

vehicle manufacturer. Always block the diagonally opposite wheel when using a

jack.

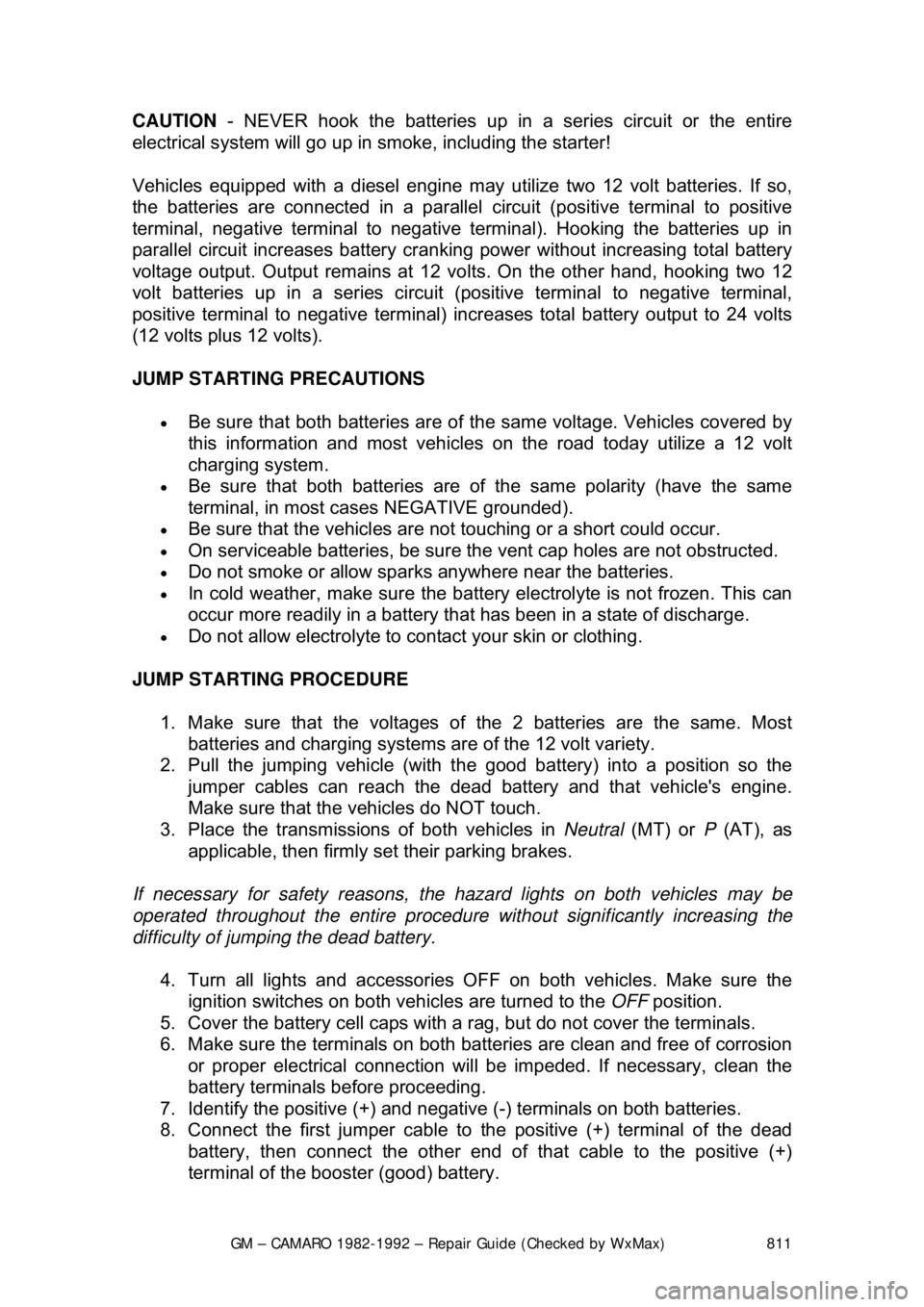

A more convenient way of jacking is the use of a garage or floor jack. You may

use the floor jack to raise the vehicle in the areas shown in the illustration .

Page 813 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 813

Fig. 1: Vehicle hoisting and jacking points

Never place the jack under the radiator , engine or transmission components.

Severe and expensive damage wil l result when the jack is raised. Additionally,

never jack under the floorpan or body work; the metal will deform.

Whenever you plan to work under the v ehicle, you must support it on jackstands

or ramps. Never use cinder blocks or st acks of wood to support the vehicle,

even if you're only going to be under it for a few minutes. Never crawl under the

vehicle when it is supported only by the tire-changing jack or other floor jack.

Always position a block of wood or smal l rubber pad on top of the jack or

jackstand to protect the lifting point's finish when lifting or supporting the vehicle.

Small hydraulic, screw, or sci ssors jacks are satisfactory for raising the vehicle.

Drive-on trestles or ramps are also a handy and safe way to both raise and

support the vehicle. Be careful though, some ramps may be too steep to drive

your vehicle onto without scraping t he front bottom panels. Never support the

vehicle on any suspension member (unless specifically instructed to do so by a

repair manual) or by an underbody panel.

JACKING PRECAUTIONS

The following safety points cannot be overemphasized:

• Always block the opposite wheel or wheels to keep the vehicle from

rolling off the jack.

• When raising the front of the vehicle, firmly apply the parking brake.

Page 814 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 814

•

When the drive wheels are to remain on the ground, leave the vehicle in

gear to help prevent it from rolling.

• Always use jackstands to support the vehicle when you are working

underneath. Place the stands beneath th e vehicle's jacking brackets.

Before climbing underneath, rock the vehicl e a bit to make sure it is firmly

supported.

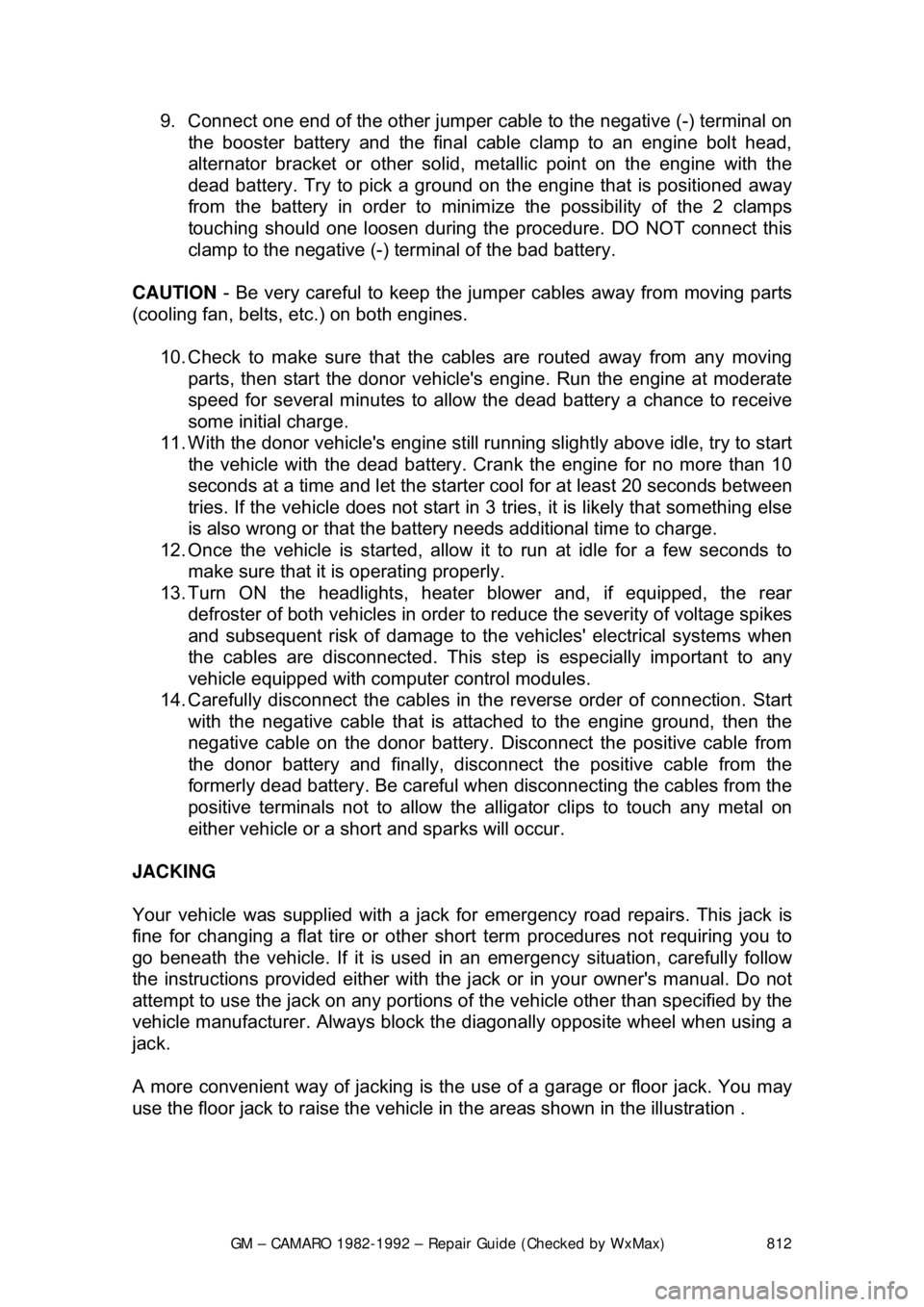

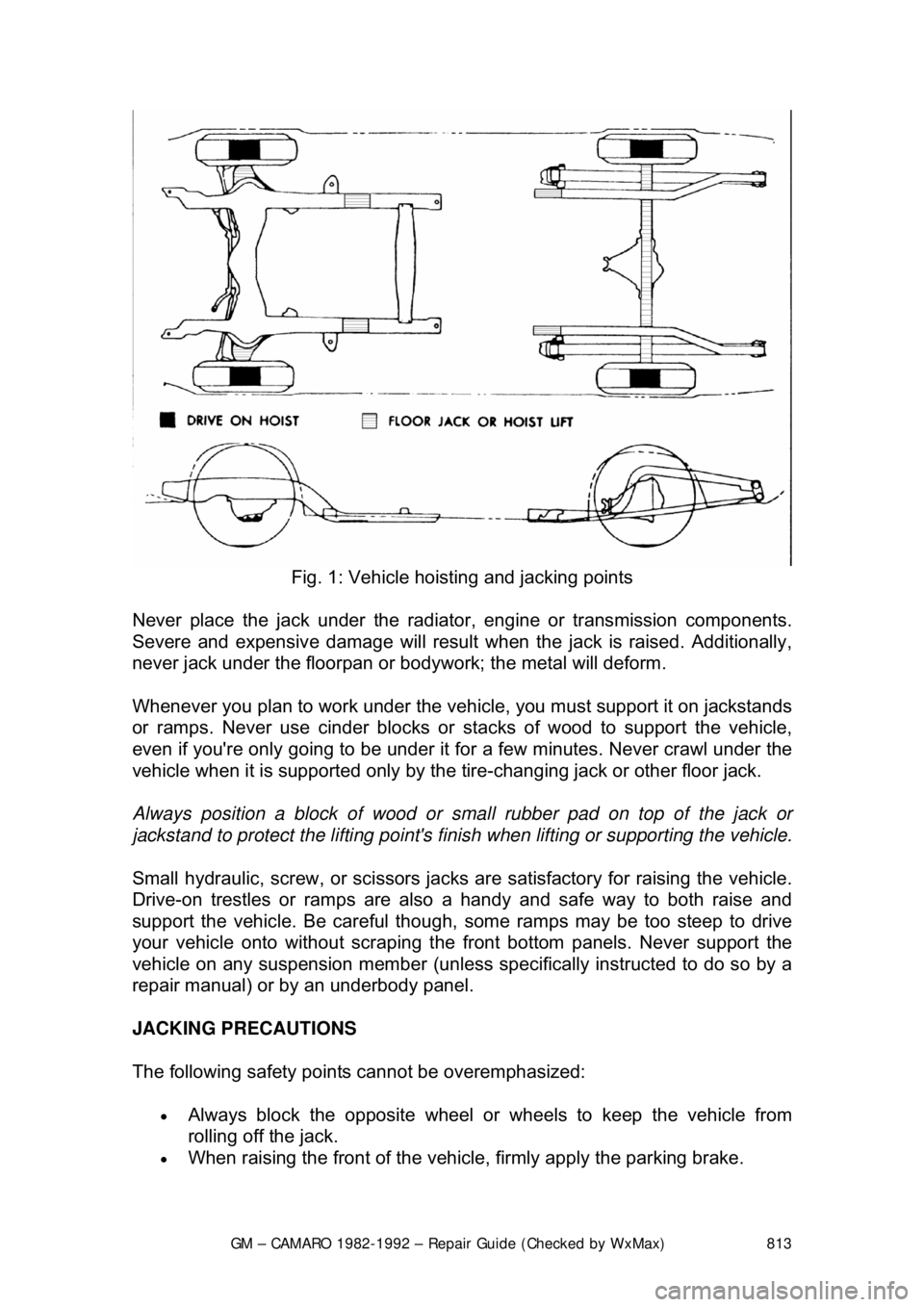

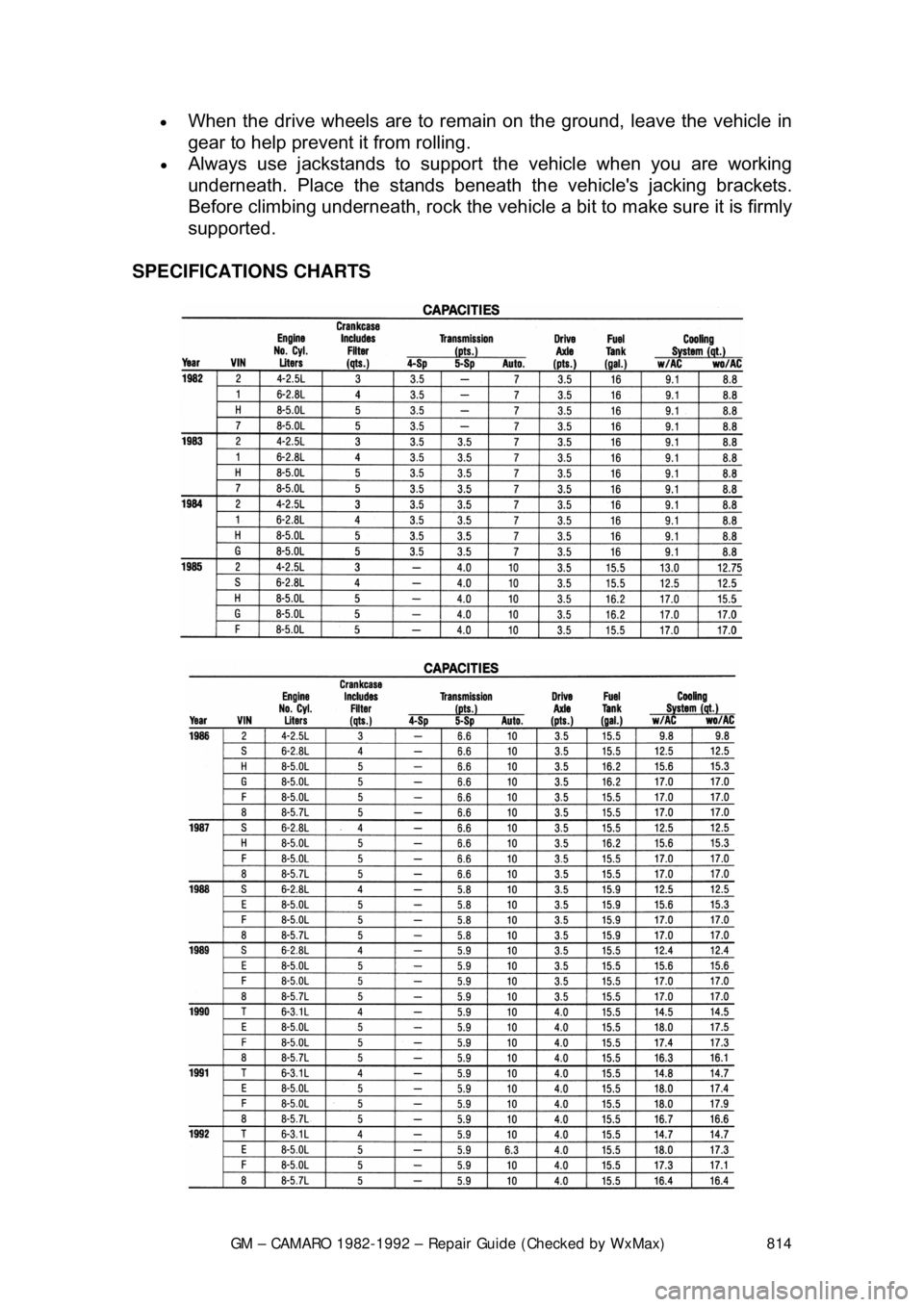

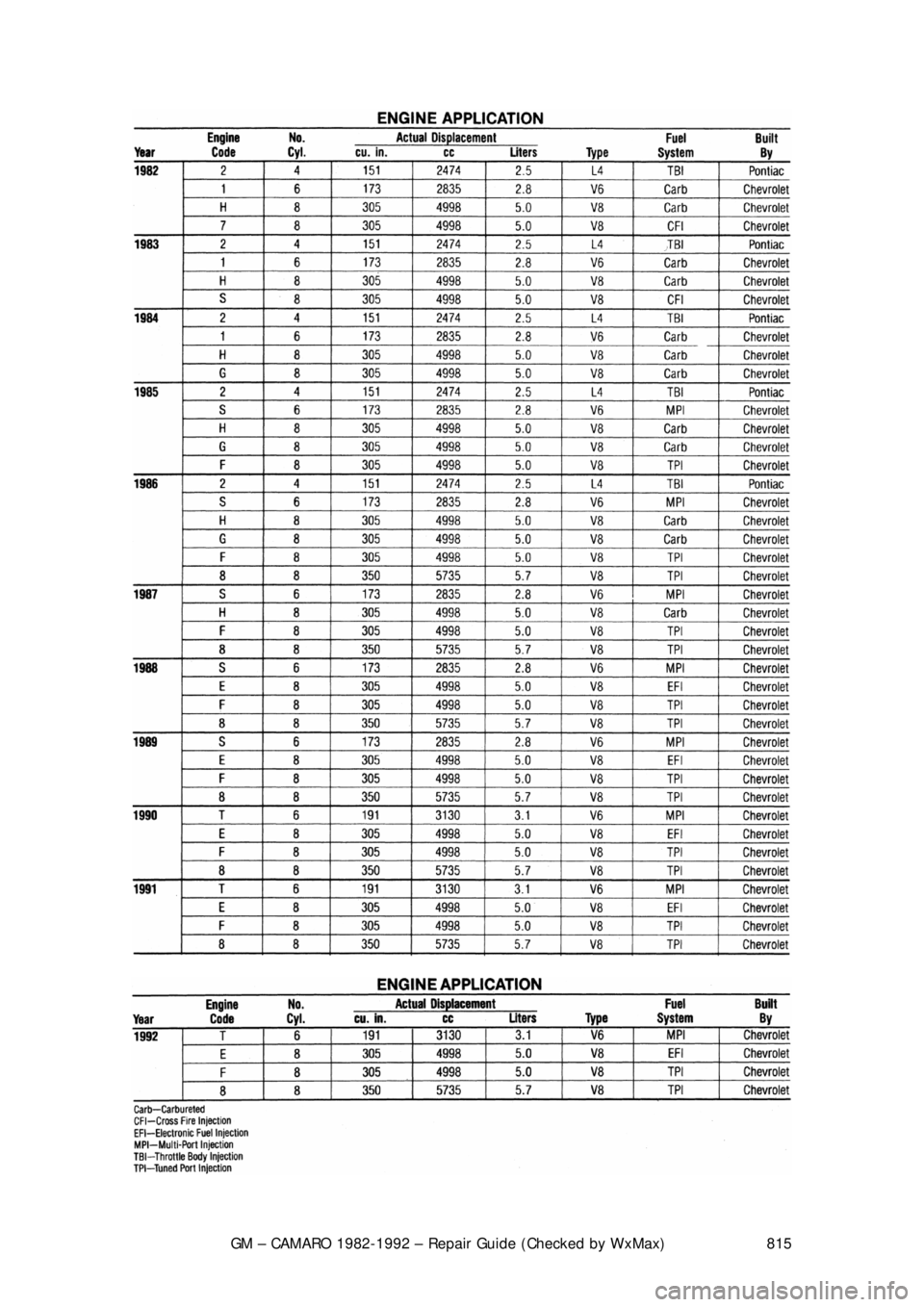

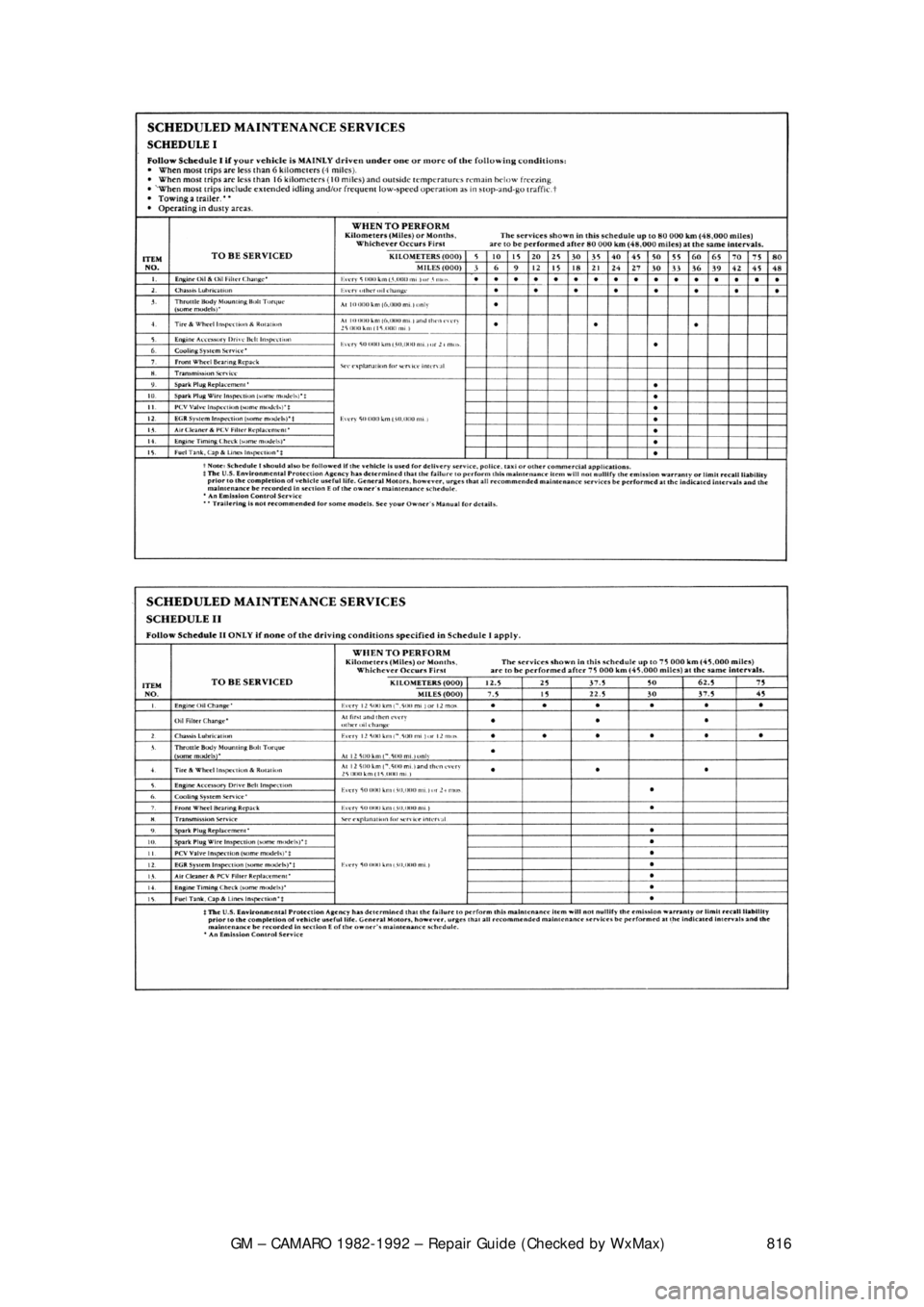

SPECIFICATIONS CHARTS

Page 815 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 815

Page 816 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 816

Page 817 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 817

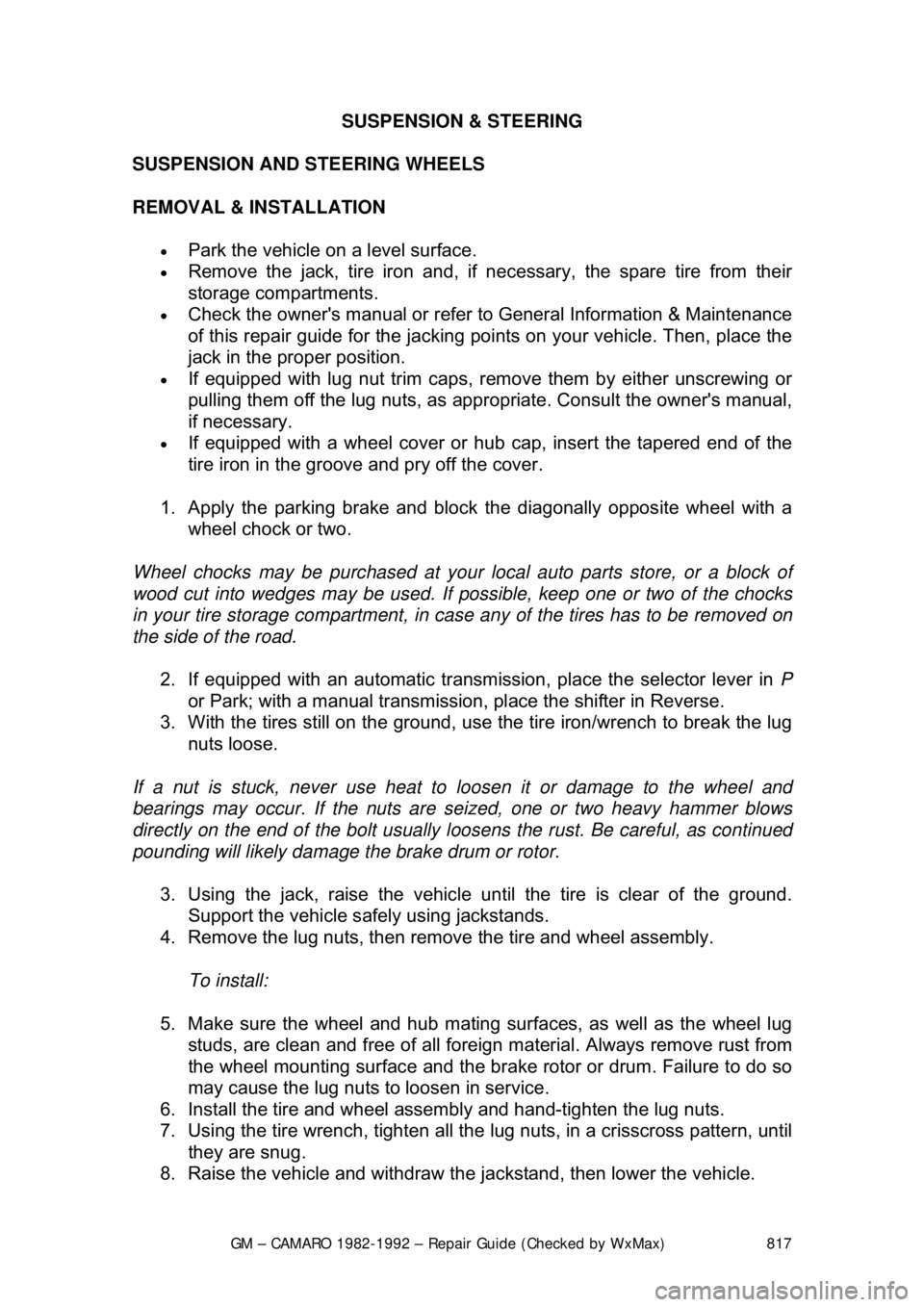

SUSPENSION & STEERING

SUSPENSION AND STEERING WHEELS

REMOVAL & INSTALLATION

• Park the vehicle on a level surface.

• Remove the jack, tire iron and, if nec essary, the spare tire from their

storage compartments.

• Check the owner's manual or refer to General Information & Maintenance

of this repair guide for the jacking poi nts on your vehicle. Then, place the

jack in the proper position.

• If equipped with lug nut trim caps, remo ve them by either unscrewing or

pulling them off the lug nuts, as appr opriate. Consult the owner's manual,

if necessary.

• If equipped with a wheel cover or hub c ap, insert the tapered end of the

tire iron in the groove and pry off the cover.

1. Apply the parking brake and block the diagonally opposite wheel with a

wheel chock or two.

Wheel chocks may be purchased at your lo cal auto parts store, or a block of

wood cut into wedges may be used. If possi ble, keep one or two of the chocks

in your tire storage compartment, in case any of the tires has to be removed on

the side of the road.

2. If equipped with an automatic transmi ssion, place the selector lever in P

or Park; with a manual transmission, place the shifter in Reverse.

3. With the tires still on the ground, use the tire iron/wrench to break the lug

nuts loose.

If a nut is stuck, never use heat to loosen it or damage to the wheel and

bearings may occur. If the nuts are seized, one or two heavy hammer blows

directly on the end of the bol t usually loosens the rust. Be careful, as continued

pounding will likely damage the brake drum or rotor.

3. Using the jack, raise the vehicle unt il the tire is clear of the ground.

Support the vehicle safely using jackstands.

4. Remove the lug nuts, then remove the tire and wheel assembly.

To install:

5. Make sure the wheel and hub mating su rfaces, as well as the wheel lug

studs, are clean and free of all foreign material. Always remove rust from

the wheel mounting surfac e and the brake rotor or drum. Failure to do so

may cause the lug nuts to loosen in service.

6. Install the tire and wheel asse mbly and hand-tighten the lug nuts.

7. Using the tire wrench, tighten all the lug nuts, in a crisscross pattern, until

they are snug.

8. Raise the vehicle and withdraw the jackstand, then lower the vehicle.

Page 818 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 818

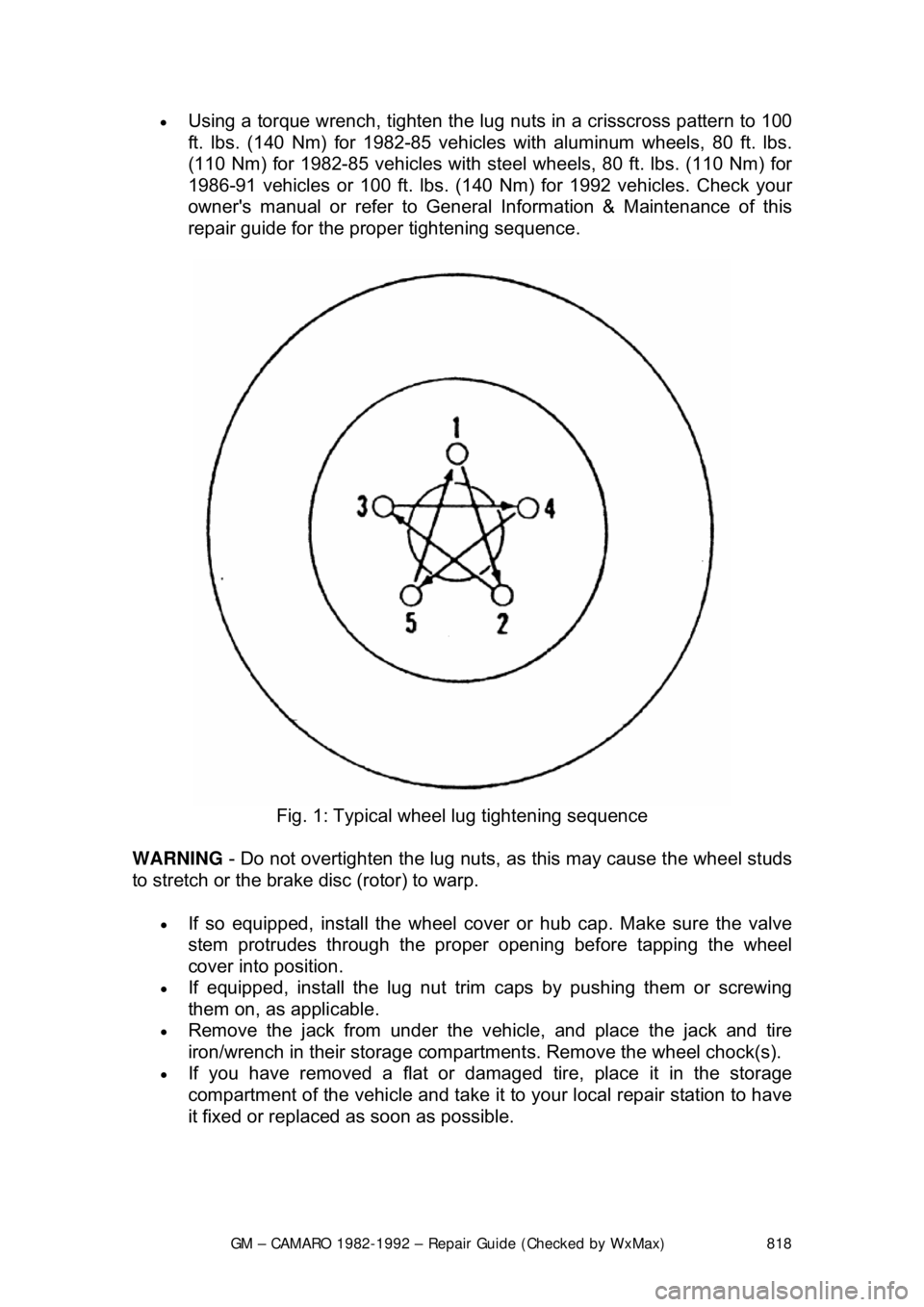

•

Using a torque wrench, tighten the lug nuts in a crisscross pattern to 100

ft. lbs. (140 Nm) for 1982-85 vehicles with aluminum wheels, 80 ft. lbs.

(110 Nm) for 1982-85 vehicles with st eel wheels, 80 ft. lbs. (110 Nm) for

1986-91 vehicles or 100 ft. lbs. (140 Nm) for 1992 vehicles. Check your

owner's manual or refer to General Information & Maintenance of this

repair guide for the proper tightening sequence.

Fig. 1: Typical wheel lug tightening sequence

WARNING - Do not overtighten the lug nuts, as this may cause the wheel studs

to stretch or the brake disc (rotor) to warp.

• If so equipped, install the wheel cover or hub cap. Make sure the valve

stem protrudes throu gh the proper opening bef ore tapping the wheel

cover into position.

• If equipped, install the lug nut trim caps by pushing them or screwing

them on, as applicable.

• Remove the jack from under the v ehicle, and place the jack and tire

iron/wrench in their storage compartment s. Remove the wheel chock(s).

• If you have removed a flat or damaged tire, place it in the storage

compartment of the vehicle and take it to your local repair station to have

it fixed or replaced as soon as possible.

Page 819 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 819

INSPECTION

Inspect the tires for lacerations, puncture

marks, nails and other sharp objects.

Repair or replace as necessary. Also check the tires for treadwear and air

pressure as outlined in General Information & Maintenance of this repair guide.

Check the wheel assemblies for dents, crac ks, rust and metal fatigue. Repair or

replace as necessary.

WHEEL LUG STUDS

REMOVAL & INSTALLATION

WITH DISC BRAKES

1. Raise and support the appropriate end of the vehicle safely using

jackstands, then remove the wheel.

2. Remove the brake pads and caliper. Support the caliper aside using wire

or a coat hanger. For details, please re fer to Brakes of this repair guide.

3. Remove the outer w heel bearing and lift off the rotor. For details on

wheel bearing removal, installation and adjustment, please refer to

General Information & Maintenan ce of this repair guide.

4. Properly support the rotor using pre ss bars, then drive the stud out using

an arbor press.

If a press is not available, CAREFULLY drive the old stud out using a blunt drift.

MAKE SURE the rotor is properly and ev enly supported or it may be damaged.

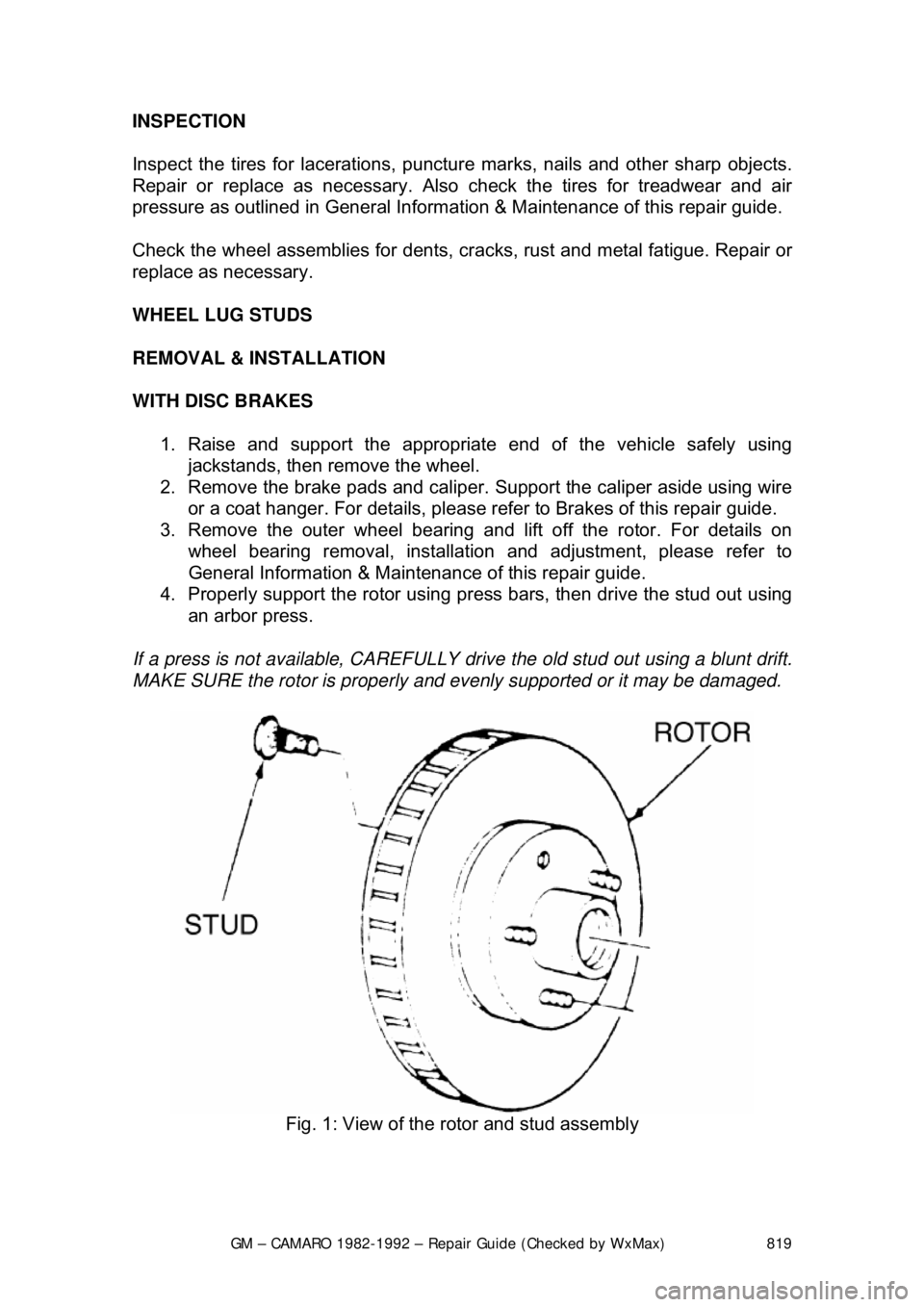

Fig. 1: View of the rotor and stud assembly

Page 820 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 820

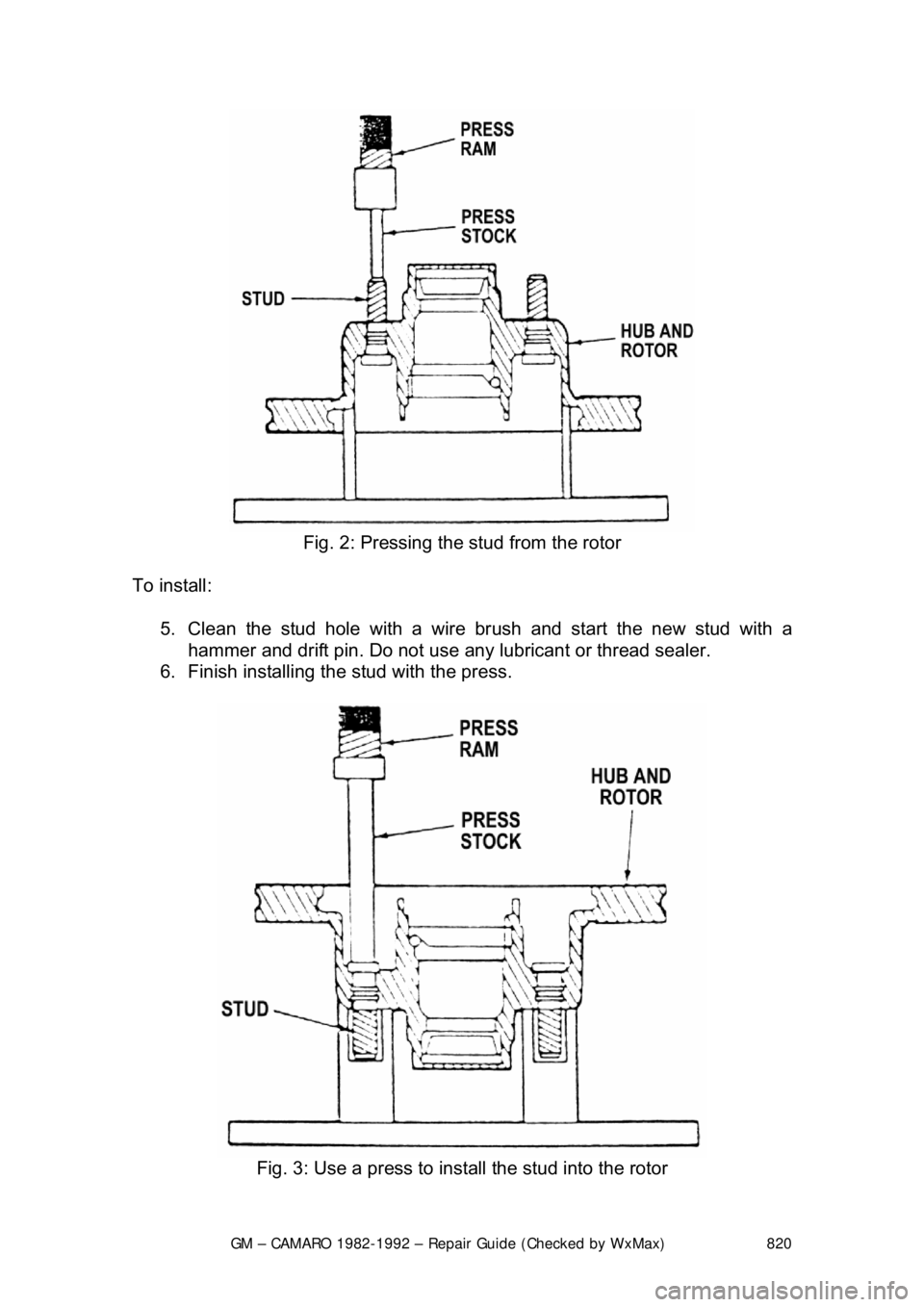

Fig. 2: Pressing the stud from the rotor

To install: 5. Clean the stud hole with a wire br ush and start the new stud with a

hammer and drift pin. Do not use any lubricant or thread sealer.

6. Finish installing t he stud with the press.

Fig. 3: Use a press to install the stud into the rotor