battery CHEVROLET DYNASTY 1993 Owner's Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 278 of 2438

(6) Repeat steps 2 through 5 until a clear air free

flow of brake fluid is coming out of the Primary Ac-

cumulator bleeder screw. (7) Next select and actuate the RF Build/Decay

Valve. Again repeat steps 2 through 5 until a clean

air free flow of brake fluid is coming out of the Pri-

mary Accumulator bleeder screw.

4 SECONDARY ACCUMULATOR (1) Put a bleeder tube on the Secondary Accumu-

lator bleeder screw. (Fig. 1) (2) Use a pressure bleeder, or have an assistant,

apply light and constant pressure on the brake pedal.

Loosen the Secondary Accumulator bleeder screw

(Fig. 1). (3) Using the DRB II select the Actuate Valves

test mode. Then actuate the LF/RR Isolation Valve. (4) Bleed the Secondary Accumulator. Until a clear

air free flow of brake fluid is evident in the clear

hose and no air bubbles appear in the container, or

the brake pedal bottoms. (5) Tighten the bleeder screw and release the

brake pedal. (6) Repeat steps 2 through 5 until a clear air free

flow of brake fluid is coming out of the Secondary

Accumulator bleeder screw. (7) Next select and actuate the LF Build/Decay

Valve. Again repeat steps 2 through 5 until a clean

air free flow of brake fluid is coming out of the Pri-

mary Accumulator bleeder screw.PUMP/MOTOR SERVICE

On the Bendix Anti-Lock 6 Brake System the

Pump/Motor assembly can only be serviced as part of

Modulator Assembly.

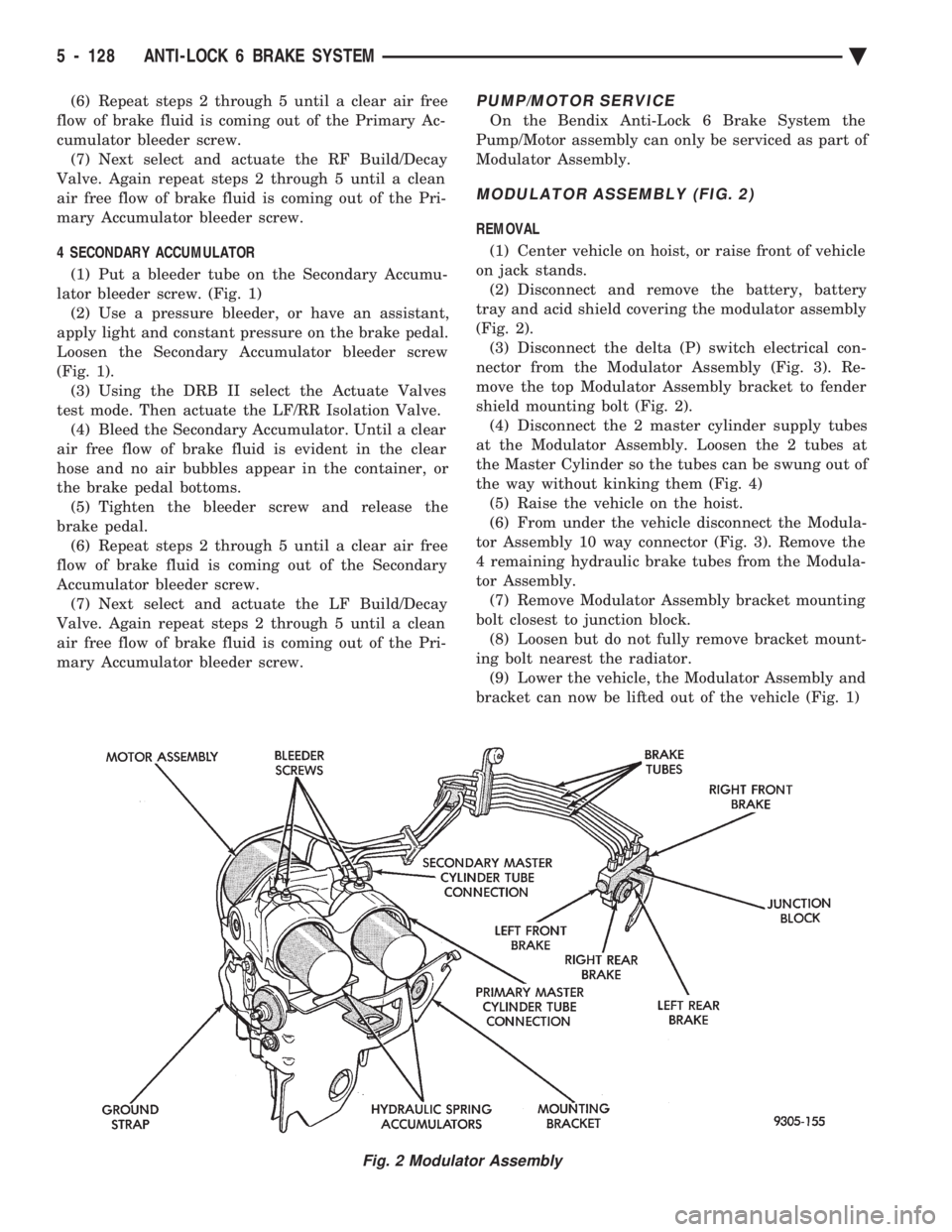

MODULATOR ASSEMBLY (FIG. 2)

REMOVAL

(1) Center vehicle on hoist, or raise front of vehicle

on jack stands. (2) Disconnect and remove the battery, battery

tray and acid shield covering the modulator assembly

(Fig. 2). (3) Disconnect the delta (P) switch electrical con-

nector from the Modulator Assembly (Fig. 3). Re-

move the top Modulator Assembly bracket to fender

shield mounting bolt (Fig. 2). (4) Disconnect the 2 master cylinder supply tubes

at the Modulator Assembly. Loosen the 2 tubes at

the Master Cylinder so the tubes can be swung out of

the way without kinking them (Fig. 4) (5) Raise the vehicle on the hoist.

(6) From under the vehicle disconnect the Modula-

tor Assembly 10 way connector (Fig. 3). Remove the

4 remaining hydraulic brake tubes from the Modula-

tor Assembly. (7) Remove Modulator Assembly bracket mounting

bolt closest to junction block. (8) Loosen but do not fully remove bracket mount-

ing bolt nearest the radiator. (9) Lower the vehicle, the Modulator Assembly and

bracket can now be lifted out of the vehicle (Fig. 1)

Fig. 2 Modulator Assembly

5 - 128 ANTI-LOCK 6 BRAKE SYSTEM Ä

Page 280 of 2438

junction block. Torque both lower mounting bracket

bolts to 28 N Im (250 in. lbs.)

(4) Reinstall the 4 hydraulic brake tubes to the

Modulator Assembly and torque the fittings to 16

N Im (145 in. lbs.).

(5) Reconnect the 10 way Modulator assembly con-

nector, and the delta P switch connector. (6) Lower the vehicle and install the 2 master cyl-

inder supply tubes to the Modulator Assembly.

Torque the Modulator Assembly fittings and the

master cylinder fittings to 16 N Im (145 in.lbs.).

(7) Torque the Modulator to fender splash shield

attaching bolt to 28 N Im (250 in. lbs.)

(8) Bleed the brake system. Refer to the Bleeding

Bendix Anti 6 Brake System in this section of the

manual for proper bleeding procedure. (9) Reinstall the acid shield and battery tray. Re-

install battery and connect battery cables.

MASTER CYLINDER AND POWER BOOSTER

REMOVAL AND INSTALLATION

If the Master Cylinder or the Power Booster need

to be serviced or replaced. Refer to Master Cylinder

or Power Brake Service section in this group of the

service manual. After servicing the Master Cylinder. Refer back to

this section of the service manual. For the appropri-

ate procedure and sequence, used to bleed the base

and ABS portion of the brake system

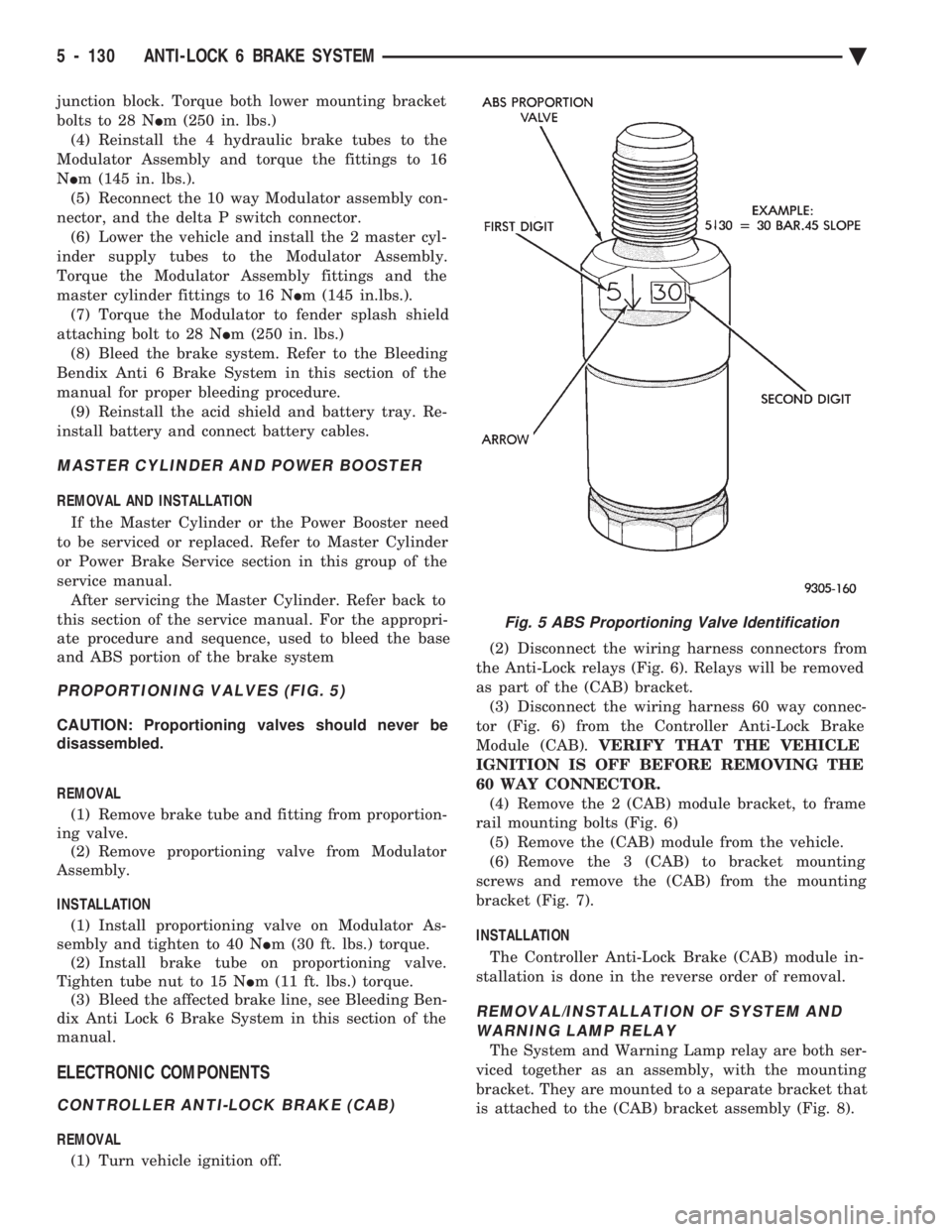

PROPORTIONING VALVES (FIG. 5)

CAUTION: Proportioning valves should never be

disassembled.

REMOVAL (1) Remove brake tube and fitting from proportion-

ing valve. (2) Remove proportioning valve from Modulator

Assembly.

INSTALLATION (1) Install proportioning valve on Modulator As-

sembly and tighten to 40 N Im (30 ft. lbs.) torque.

(2) Install brake tube on proportioning valve.

Tighten tube nut to 15 N Im (11 ft. lbs.) torque.

(3) Bleed the affected brake line, see Bleeding Ben-

dix Anti Lock 6 Brake System in this section of the

manual.

ELECTRONIC COMPONENTS

CONTROLLER ANTI-LOCK BRAKE (CAB)

REMOVAL

(1) Turn vehicle ignition off. (2) Disconnect the wiring harness connectors from

the Anti-Lock relays (Fig. 6). Relays will be removed

as part of the (CAB) bracket. (3) Disconnect the wiring harness 60 way connec-

tor (Fig. 6) from the Controller Anti-Lock Brake

Module (CAB). VERIFY THAT THE VEHICLE

IGNITION IS OFF BEFORE REMOVING THE

60 WAY CONNECTOR. (4) Remove the 2 (CAB) module bracket, to frame

rail mounting bolts (Fig. 6) (5) Remove the (CAB) module from the vehicle.

(6) Remove the 3 (CAB) to bracket mounting

screws and remove the (CAB) from the mounting

bracket (Fig. 7).

INSTALLATION

The Controller Anti-Lock Brake (CAB) module in-

stallation is done in the reverse order of removal.

REMOVAL/INSTALLATION OF SYSTEM AND WARNING LAMP RELAY

The System and Warning Lamp relay are both ser-

viced together as an assembly, with the mounting

bracket. They are mounted to a separate bracket that

is attached to the (CAB) bracket assembly (Fig. 8).

Fig. 5 ABS Proportioning Valve Identification

5 - 130 ANTI-LOCK 6 BRAKE SYSTEM Ä

Page 302 of 2438

(2) The voltage output from each of the wheel

speed sensors is verified to be within the correct op-

erating range. If a vehicle is not set in motion within 3 minutes

from the time the ignition switch is turned to the on

position. The solenoid valve test is bypassed but the

pump/motor is activated briefly to verify that it is op-

erating correctly.

WARNING SYSTEMS OPERATION

The ABS system uses an Amber Antilock Warning

Lamp, located in the instrument cluster. The purpose

of the warning lamp is discussed in detail below. The Amber Antilock Warning Light will turn on

whenever the CAB detects a condition which results

in a shutdown of the Antilock brake system. The

Amber Antilock Warning Lamp is normally on until

the CAB completes its self tests and turns the lamp

off (approximately 1-2 seconds). When the Amber

Antilock Warning Light is on, only the Antilock

brake function of the brake system if affected. The

standard brake system and the ability to stop the car

will not be affected when only the Amber Antilock

Warning Light is on.

NORMAL OPERATION OF WARNING LAMP

With ignition key turned to the Crank position, the

Red Brake Warning Lamp and Amber Antilock

Warning Lamp will turn on as a bulb check. The

Amber Antilock Warning Lamp will stay on for 1-2

seconds then turn off, once verification of Antilock

Brake System self diagnosis is completed.

ANTILOCK BRAKE SYSTEM COMPONENTS

The following is a detailed description of the Ben-

dix Antilock 4 Brake System components. For infor-

mation on servicing the Four Wheel Disc Brake

System, see the standard Brake section in the Front

Wheel Drive Car, chassis service manual.

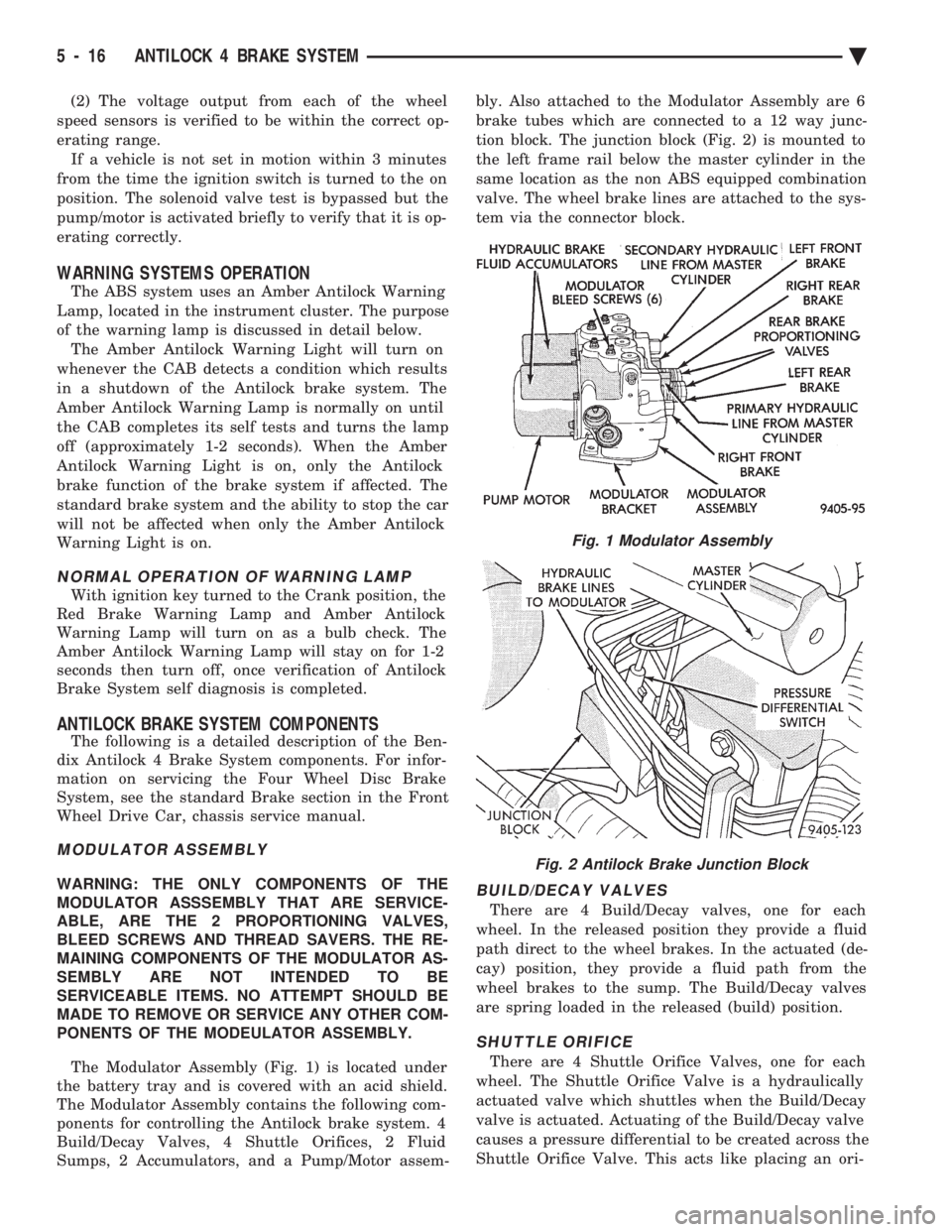

MODULATOR ASSEMBLY

WARNING: THE ONLY COMPONENTS OF THE

MODULATOR ASSSEMBLY THAT ARE SERVICE-

ABLE, ARE THE 2 PROPORTIONING VALVES,

BLEED SCREWS AND THREAD SAVERS. THE RE-

MAINING COMPONENTS OF THE MODULATOR AS-

SEMBLY ARE NOT INTENDED TO BE

SERVICEABLE ITEMS. NO ATTEMPT SHOULD BE

MADE TO REMOVE OR SERVICE ANY OTHER COM-

PONENTS OF THE MODEULATOR ASSEMBLY.

The Modulator Assembly (Fig. 1) is located under

the battery tray and is covered with an acid shield.

The Modulator Assembly contains the following com-

ponents for controlling the Antilock brake system. 4

Build/Decay Valves, 4 Shuttle Orifices, 2 Fluid

Sumps, 2 Accumulators, and a Pump/Motor assem- bly. Also attached to the Modulator Assembly are 6

brake tubes which are connected to a 12 way junc-

tion block. The junction block (Fig. 2) is mounted to

the left frame rail below the master cylinder in the

same location as the non ABS equipped combination

valve. The wheel brake lines are attached to the sys-

tem via the connector block.BUILD/DECAY VALVES

There are 4 Build/Decay valves, one for each

wheel. In the released position they provide a fluid

path direct to the wheel brakes. In the actuated (de-

cay) position, they provide a fluid path from the

wheel brakes to the sump. The Build/Decay valves

are spring loaded in the released (build) position.

SHUTTLE ORIFICE

There are 4 Shuttle Orifice Valves, one for each

wheel. The Shuttle Orifice Valve is a hydraulically

actuated valve which shuttles when the Build/Decay

valve is actuated. Actuating of the Build/Decay valve

causes a pressure differential to be created across the

Shuttle Orifice Valve. This acts like placing an ori-

Fig. 1 Modulator Assembly

Fig. 2 Antilock Brake Junction Block

5 - 16 ANTILOCK 4 BRAKE SYSTEM Ä

Page 309 of 2438

earlier in this service manual supplement. Then follow

the diagnostic procedures outlined in this section. Many conditions that generate customer complaints

may be normal operating conditions, but are judged to

be a problem due to not being familiar with the ABS

system. These conditions can be recognized without

performing extensive diagnostic work, given adequate

understanding of the operating principles and perfor-

mance characteristics of the ABS system.

DEFINITIONS

Several abbreviations are used in this manual. They

are presented here for reference.

² CABÐController Antilock Brake

² ABSÐAntilock Brake System

² PSIÐPounds per Square Inch (pressure)

² WSSÐWheel Speed Sensor

² ACÐAlternating Current

ABS COMPUTER SYSTEM SERVICE PRECAUTIONS

The ABS system uses an electronic control module,

the CAB. This module is designed to withstand normal

current draws associated with vehicle operation. How-

ever care must be taken to avoid overloading the CAB

circuits. In testing for open or short circuits, do

not ground or apply voltage to any of the circuits

unless instructed to do so by the appropriate

diagnostic procedure. These circuits should only be

tested using a high impedance multi-meter, special

tools or the DRB II tester as described in this section.

Power should never be removed or applied to any

control module with the ignition in the ON position.

Before removing or connecting battery cables, fuses, or

connectors, always turn the ignition to the OFF posi-

tion.

ABS GENERAL SERVICE PRECAUTIONS

TEST DRIVING ABS COMPLAINT VEHICLES

Most ABS complaints will require a test drive as a

part of the diagnostic procedure. The purpose of the

test drive is to duplicate the condition. Remember conditions that result in the turn-

ing on of the Red Brake Warning Lamp may

indicate reduced braking ability. The following

procedure should be used to test drive an ABS

complaint vehicle. Before test driving a brake complaint vehicle, note

whether the Red or Amber Brake Warning Lamp is

turned on. If the Red Brake Warning Lamp, is

turned on, refer to the base brake Control Valves

Section in the Front Wheel Drive, chassis service

manual. If the Amber Antilock Warning light was or

is on, read record and erase the faults. While the

Amber ABS Warning Lamp is on the ABS system is

not functional. The standard brake system and abil- ity to stop the car is not affected, if only the Amber

Antilock Warning Lamp is on.

(1) Turn ignition key to the off position and then

back to the on position. Note whether the Amber ABS

Warning Lamp continues to stay on. If it does refer to

the 1994 Bendix Antilock 4 Brake System Diagnostic

Manual for the required diagnostic test procedures. (2) If the Amber ABS Warning Lamp goes out, shift

vehicle into gear and drive car to a speed of 5 mph to

complete the ABS drive-off cycle. If at this time, the

Amber ABS Warning Lamp goes on refer to the 1994

Bendix Antilock 4 Brake System Diagnostic Manual. (3) If the Amber ABS Warning Lamp remains OUT,

continue to drive the vehicle a short distance. During

this test drive be sure that the vehicle achieves at least

25 mph. Brake to at least one complete stop and again

accelerate to 25 mph. (4) If a functional problem with the ABS system is

determined while test driving a vehicle. Refer to the

Bendix Antilock 4 Brake System Diagnostics Manual

for required diagnostic test procedures and proper use

of the DRB II tester.

ABS BRAKE SYSTEM ON VEHICLE SERVICE

The following are general precautions which

should be observed whenever servicing and or

diagnosing the ABS system and other vehicle

electronic systems. Failure to observe these pre-

cautions may result in ABS system damage. (1) If welding work is to be performed on a vehicle

using an arc welder. The wiring harness connector

should be disconnected from the CAB before beginning

any welding operation. (2) The CAB 60 way connector and modulator as-

sembly 10 way connector, should never be connected or

disconnected with the ignition in the on position. (3) Some components of Bendix Antilock 4 Brake

System assemblies can not be serviced separately from

the assembly and will require replacement of the

complete assembly for servicing. Do not disassemble

any component which is designated as non-serviceable.

CAUTION: Brake fluid will damage painted surfaces.

If brake fluid is spilled on any painted surfaces, wash

off with water immediately.

WHEEL SPEED SENSOR CABLES

Proper installation and routing of the Wheel Speed

Sensor Cables is critical to continued system opera-

tion. Be sure that cables are installed, routed and

clipped properly. Failure to install speed sensor ca-

bles as shown in the on car service section of this

Ä ANTILOCK 4 BRAKE SYSTEM 5 - 23

Page 312 of 2438

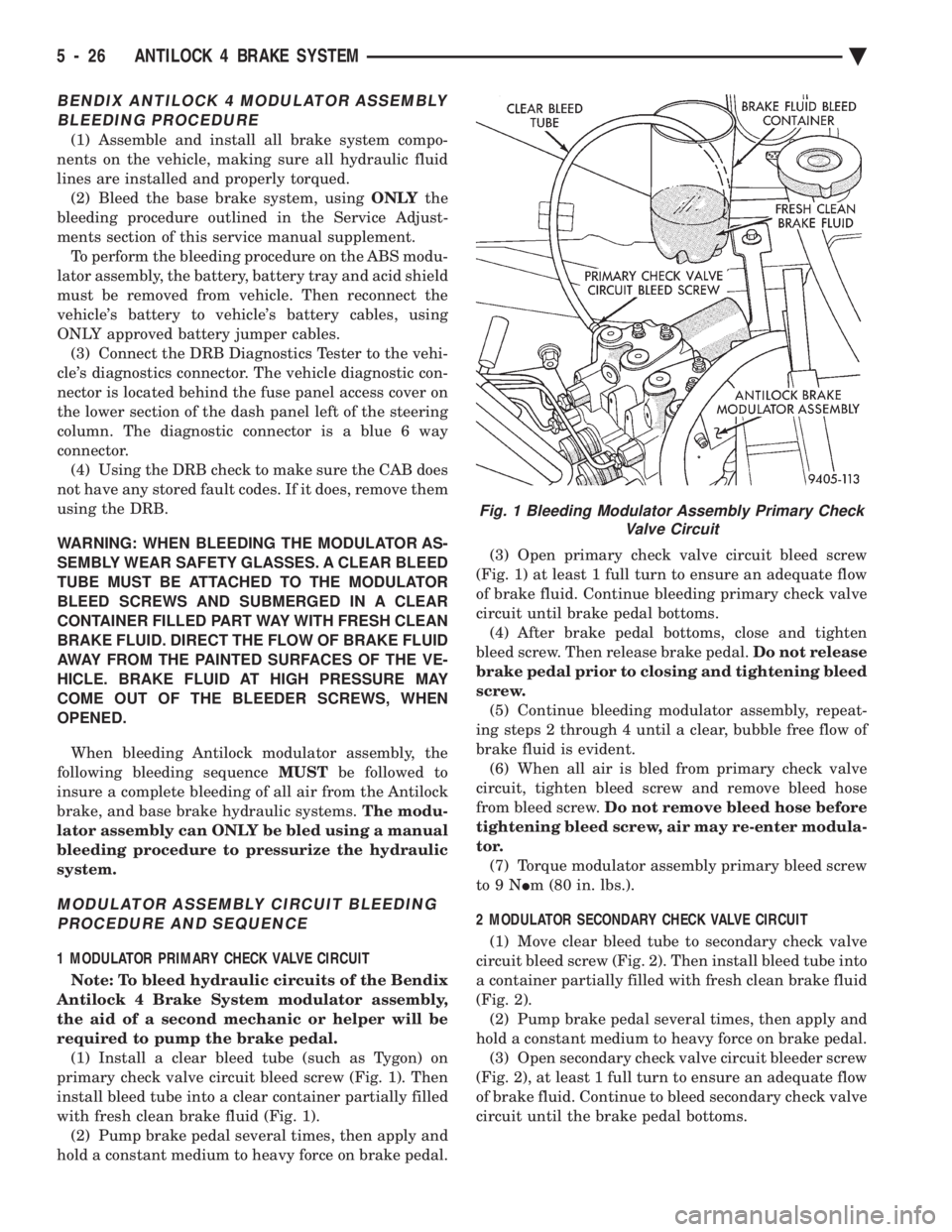

BENDIX ANTILOCK 4 MODULATOR ASSEMBLY BLEEDING PROCEDURE

(1) Assemble and install all brake system compo-

nents on the vehicle, making sure all hydraulic fluid

lines are installed and properly torqued. (2) Bleed the base brake system, using ONLYthe

bleeding procedure outlined in the Service Adjust-

ments section of this service manual supplement. To perform the bleeding procedure on the ABS modu-

lator assembly, the battery, battery tray and acid shield

must be removed from vehicle. Then reconnect the

vehicle's battery to vehicle's battery cables, using

ONLY approved battery jumper cables. (3) Connect the DRB Diagnostics Tester to the vehi-

cle's diagnostics connector. The vehicle diagnostic con-

nector is located behind the fuse panel access cover on

the lower section of the dash panel left of the steering

column. The diagnostic connector is a blue 6 way

connector. (4) Using the DRB check to make sure the CAB does

not have any stored fault codes. If it does, remove them

using the DRB.

WARNING: WHEN BLEEDING THE MODULATOR AS-

SEMBLY WEAR SAFETY GLASSES. A CLEAR BLEED

TUBE MUST BE ATTACHED TO THE MODULATOR

BLEED SCREWS AND SUBMERGED IN A CLEAR

CONTAINER FILLED PART WAY WITH FRESH CLEAN

BRAKE FLUID. DIRECT THE FLOW OF BRAKE FLUID

AWAY FROM THE PAINTED SURFACES OF THE VE-

HICLE. BRAKE FLUID AT HIGH PRESSURE MAY

COME OUT OF THE BLEEDER SCREWS, WHEN

OPENED.

When bleeding Antilock modulator assembly, the

following bleeding sequence MUSTbe followed to

insure a complete bleeding of all air from the Antilock

brake, and base brake hydraulic systems. The modu-

lator assembly can ONLY be bled using a manual

bleeding procedure to pressurize the hydraulic

system.

MODULATOR ASSEMBLY CIRCUIT BLEEDING PROCEDURE AND SEQUENCE

1 MODULATOR PRIMARY CHECK VALVE CIRCUIT

Note: To bleed hydraulic circuits of the Bendix

Antilock 4 Brake System modulator assembly,

the aid of a second mechanic or helper will be

required to pump the brake pedal. (1) Install a clear bleed tube (such as Tygon) on

primary check valve circuit bleed screw (Fig. 1). Then

install bleed tube into a clear container partially filled

with fresh clean brake fluid (Fig. 1). (2) Pump brake pedal several times, then apply and

hold a constant medium to heavy force on brake pedal. (3) Open primary check valve circuit bleed screw

(Fig. 1) at least 1 full turn to ensure an adequate flow

of brake fluid. Continue bleeding primary check valve

circuit until brake pedal bottoms. (4) After brake pedal bottoms, close and tighten

bleed screw. Then release brake pedal. Do not release

brake pedal prior to closing and tightening bleed

screw. (5) Continue bleeding modulator assembly, repeat-

ing steps 2 through 4 until a clear, bubble free flow of

brake fluid is evident. (6) When all air is bled from primary check valve

circuit, tighten bleed screw and remove bleed hose

from bleed screw. Do not remove bleed hose before

tightening bleed screw, air may re-enter modula-

tor. (7) Torque modulator assembly primary bleed screw

to9N Im (80 in. lbs.).

2 MODULATOR SECONDARY CHECK VALVE CIRCUIT (1) Move clear bleed tube to secondary check valve

circuit bleed screw (Fig. 2). Then install bleed tube into

a container partially filled with fresh clean brake fluid

(Fig. 2). (2) Pump brake pedal several times, then apply and

hold a constant medium to heavy force on brake pedal. (3) Open secondary check valve circuit bleeder screw

(Fig. 2), at least 1 full turn to ensure an adequate flow

of brake fluid. Continue to bleed secondary check valve

circuit until the brake pedal bottoms.

Fig. 1 Bleeding Modulator Assembly Primary Check Valve Circuit

5 - 26 ANTILOCK 4 BRAKE SYSTEM Ä

Page 316 of 2438

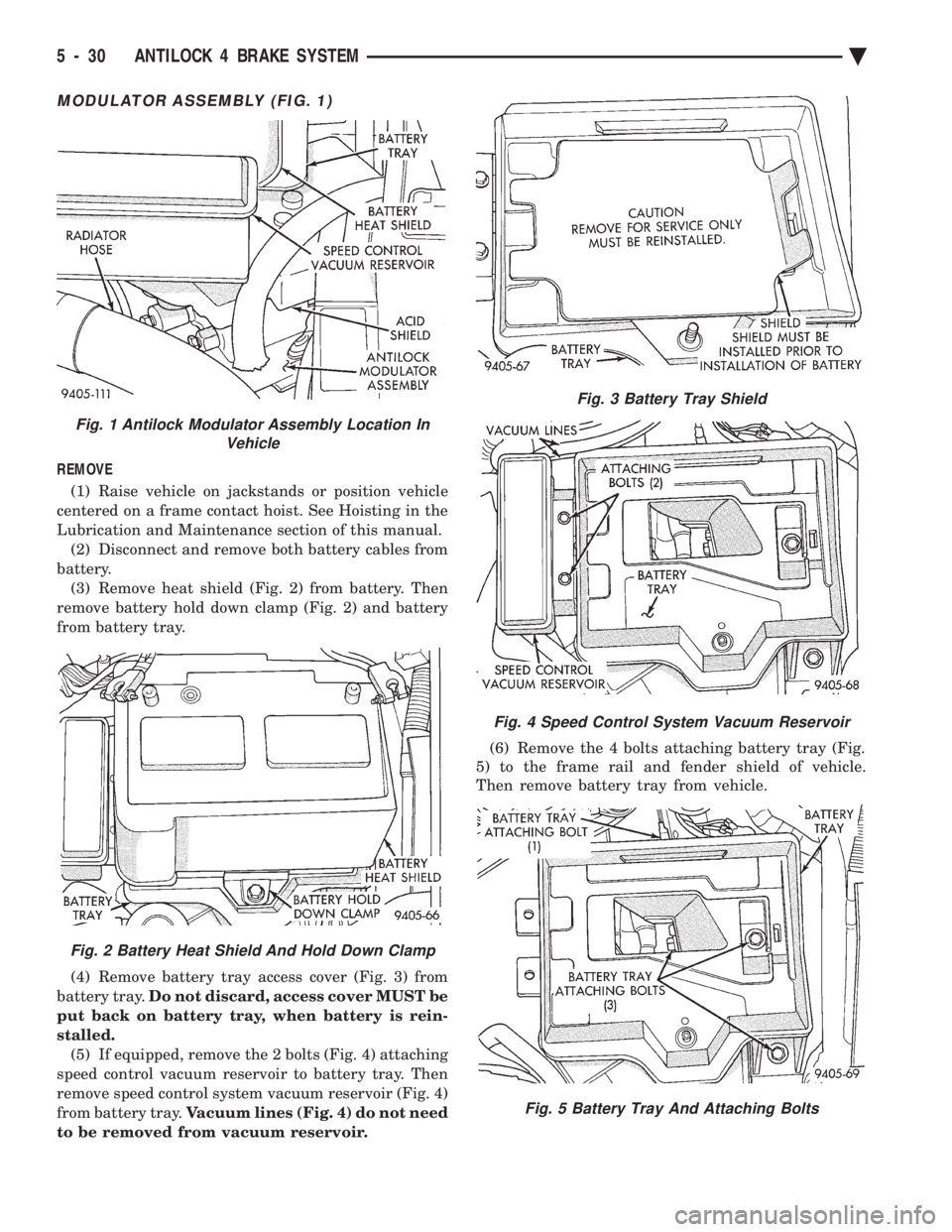

MODULATOR ASSEMBLY (FIG. 1)

REMOVE (1) Raise vehicle on jackstands or position vehicle

centered on a frame contact hoist. See Hoisting in the

Lubrication and Maintenance section of this manual. (2) Disconnect and remove both battery cables from

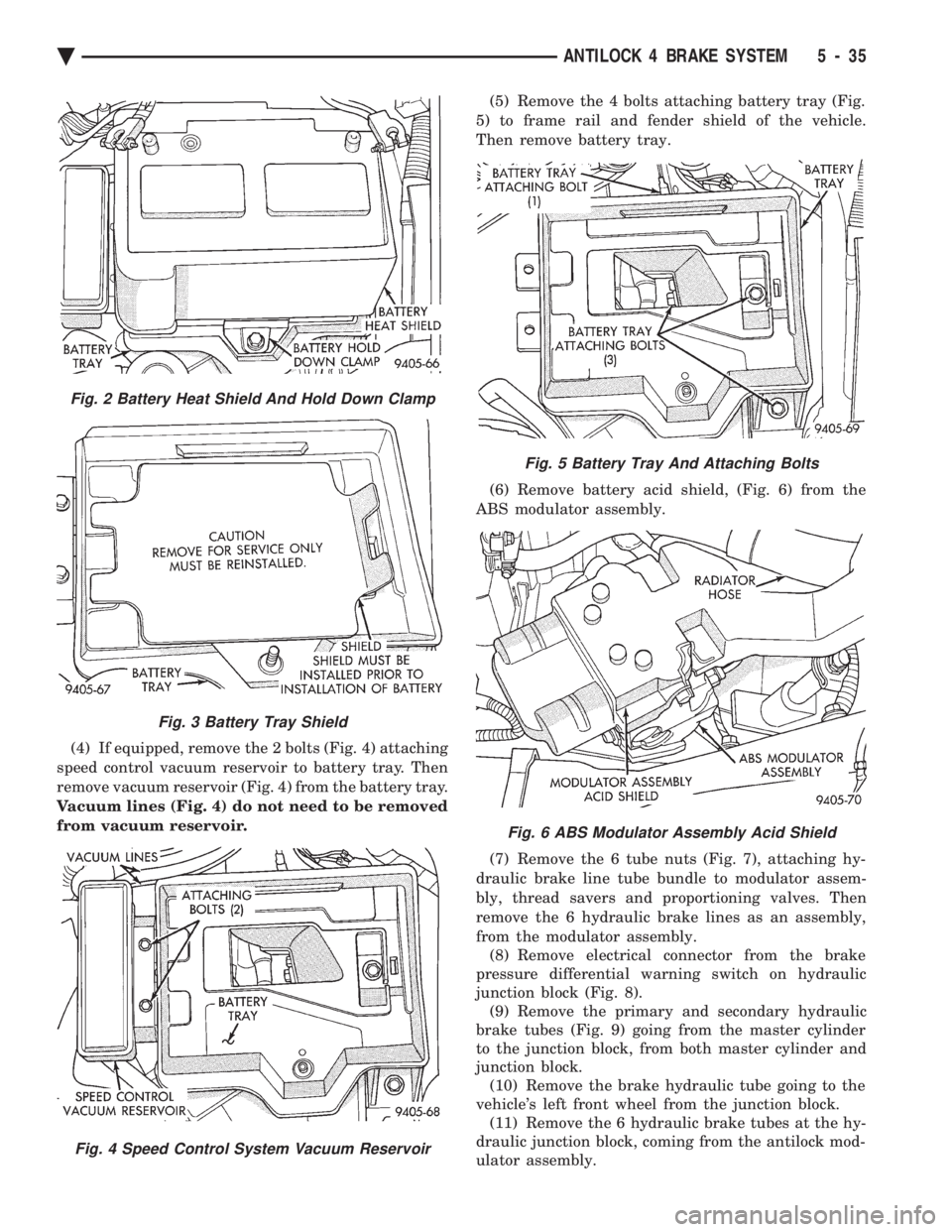

battery. (3) Remove heat shield (Fig. 2) from battery. Then

remove battery hold down clamp (Fig. 2) and battery

from battery tray.

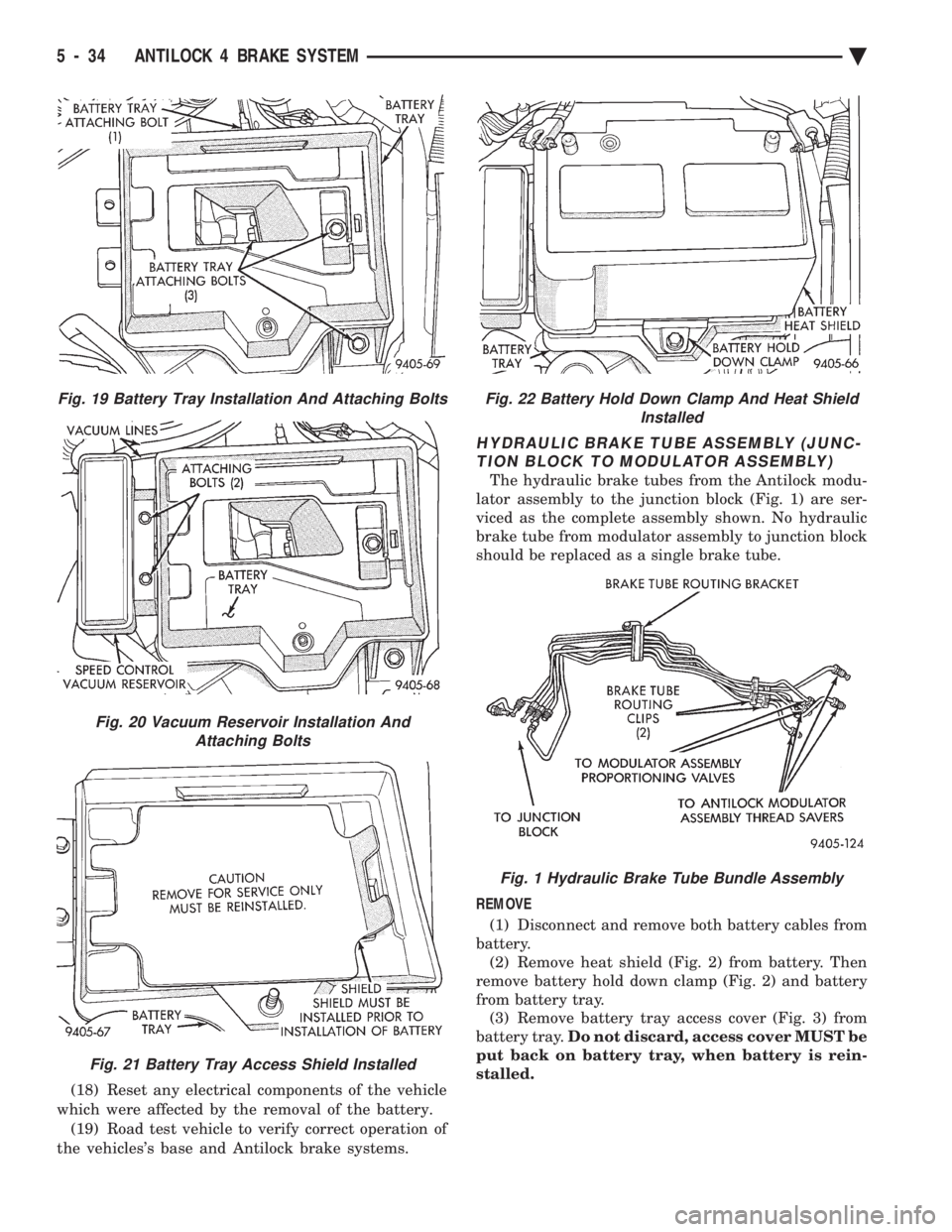

(4) Remove battery tray access cover (Fig. 3) from

battery tray. Do not discard, access cover MUST be

put back on battery tray, when battery is rein-

stalled. (5) If equipped, remove the 2 bolts (Fig. 4) attaching

speed control vacuum reservoir to battery tray. Then

remove speed control system vacuum reservoir (Fig. 4)

from battery tray. Vacuum lines (Fig. 4) do not need

to be removed from vacuum reservoir. (6) Remove the 4 bolts attaching battery tray (Fig.

5) to the frame rail and fender shield of vehicle.

Then remove battery tray from vehicle.

Fig. 3 Battery Tray Shield

Fig. 4 Speed Control System Vacuum Reservoir

Fig. 5 Battery Tray And Attaching Bolts

Fig. 1 Antilock Modulator Assembly Location In Vehicle

Fig. 2 Battery Heat Shield And Hold Down Clamp

5 - 30 ANTILOCK 4 BRAKE SYSTEM Ä

Page 317 of 2438

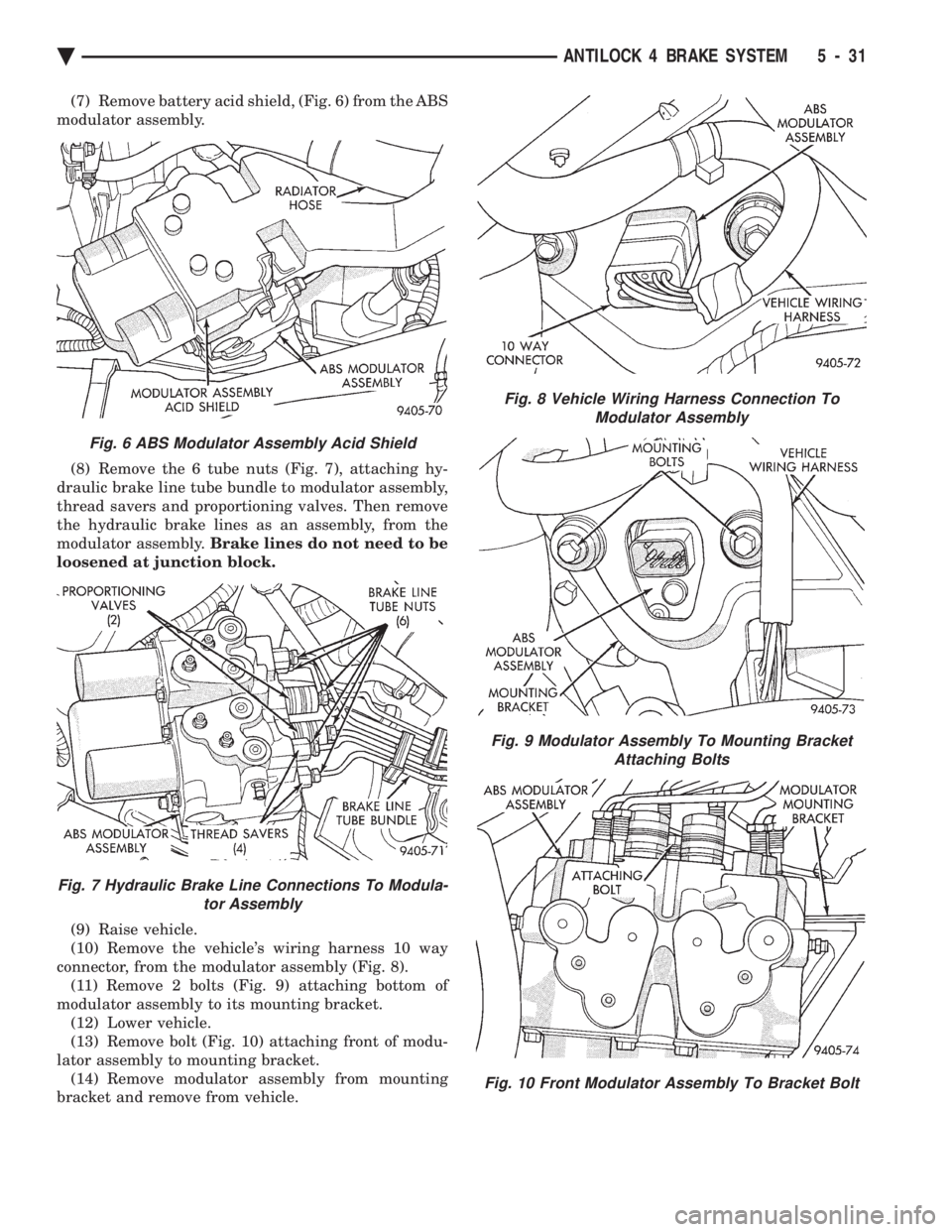

(7) Remove battery acid shield, (Fig. 6) from the ABS

modulator assembly.

(8) Remove the 6 tube nuts (Fig. 7), attaching hy-

draulic brake line tube bundle to modulator assembly,

thread savers and proportioning valves. Then remove

the hydraulic brake lines as an assembly, from the

modulator assembly. Brake lines do not need to be

loosened at junction block.

(9) Raise vehicle.

(10) Remove the vehicle's wiring harness 10 way

connector, from the modulator assembly (Fig. 8). (11) Remove 2 bolts (Fig. 9) attaching bottom of

modulator assembly to its mounting bracket. (12) Lower vehicle.

(13) Remove bolt (Fig. 10) attaching front of modu-

lator assembly to mounting bracket. (14) Remove modulator assembly from mounting

bracket and remove from vehicle.

Fig. 8 Vehicle Wiring Harness Connection To Modulator Assembly

Fig. 9 Modulator Assembly To Mounting Bracket Attaching Bolts

Fig. 10 Front Modulator Assembly To Bracket Bolt

Fig. 6 ABS Modulator Assembly Acid Shield

Fig. 7 Hydraulic Brake Line Connections To Modula- tor Assembly

Ä ANTILOCK 4 BRAKE SYSTEM 5 - 31

Page 319 of 2438

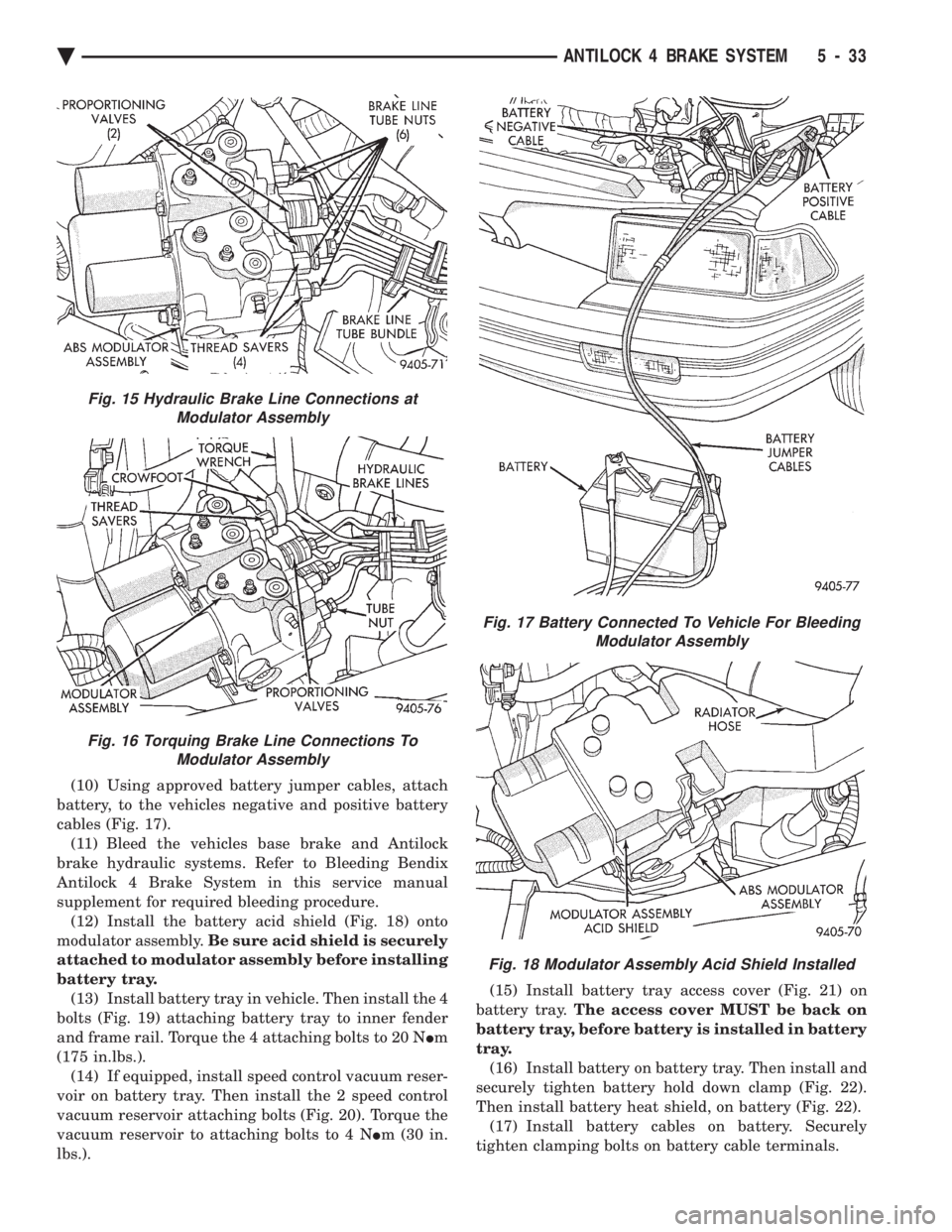

(10) Using approved battery jumper cables, attach

battery, to the vehicles negative and positive battery

cables (Fig. 17). (11) Bleed the vehicles base brake and Antilock

brake hydraulic systems. Refer to Bleeding Bendix

Antilock 4 Brake System in this service manual

supplement for required bleeding procedure. (12) Install the battery acid shield (Fig. 18) onto

modulator assembly. Be sure acid shield is securely

attached to modulator assembly before installing

battery tray. (13) Install battery tray in vehicle. Then install the 4

bolts (Fig. 19) attaching battery tray to inner fender

and frame rail. Torque the 4 attaching bolts to 20 N Im

(175 in.lbs.). (14) If equipped, install speed control vacuum reser-

voir on battery tray. Then install the 2 speed control

vacuum reservoir attaching bolts (Fig. 20). Torque the

vacuum reservoir to attaching bolts to 4 N Im (30 in.

lbs.). (15) Install battery tray access cover (Fig. 21) on

battery tray. The access cover MUST be back on

battery tray, before battery is installed in battery

tray. (16) Install battery on battery tray. Then install and

securely tighten battery hold down clamp (Fig. 22).

Then install battery heat shield, on battery (Fig. 22). (17) Install battery cables on battery. Securely

tighten clamping bolts on battery cable terminals.

Fig. 15 Hydraulic Brake Line Connections at Modulator Assembly

Fig. 16 Torquing Brake Line Connections To Modulator Assembly

Fig. 17 Battery Connected To Vehicle For Bleeding Modulator Assembly

Fig. 18 Modulator Assembly Acid Shield Installed

Ä ANTILOCK 4 BRAKE SYSTEM 5 - 33

Page 320 of 2438

(18) Reset any electrical components of the vehicle

which were affected by the removal of the battery. (19) Road test vehicle to verify correct operation of

the vehicles's base and Antilock brake systems.

HYDRAULIC BRAKE TUBE ASSEMBLY (JUNC- TION BLOCK TO MODULATOR ASSEMBLY)

The hydraulic brake tubes from the Antilock modu-

lator assembly to the junction block (Fig. 1) are ser-

viced as the complete assembly shown. No hydraulic

brake tube from modulator assembly to junction block

should be replaced as a single brake tube.

REMOVE (1) Disconnect and remove both battery cables from

battery. (2) Remove heat shield (Fig. 2) from battery. Then

remove battery hold down clamp (Fig. 2) and battery

from battery tray. (3) Remove battery tray access cover (Fig. 3) from

battery tray. Do not discard, access cover MUST be

put back on battery tray, when battery is rein-

stalled.

Fig. 19 Battery Tray Installation And Attaching Bolts

Fig. 20 Vacuum Reservoir Installation And Attaching Bolts

Fig. 21 Battery Tray Access Shield Installed

Fig. 22 Battery Hold Down Clamp And Heat Shield Installed

Fig. 1 Hydraulic Brake Tube Bundle Assembly

5 - 34 ANTILOCK 4 BRAKE SYSTEM Ä

Page 321 of 2438

(4) If equipped, remove the 2 bolts (Fig. 4) attaching

speed control vacuum reservoir to battery tray. Then

remove vacuum reservoir (Fig. 4) from the battery tray.

Vacuum lines (Fig. 4) do not need to be removed

from vacuum reservoir. (5) Remove the 4 bolts attaching battery tray (Fig.

5) to frame rail and fender shield of the vehicle.

Then remove battery tray.

(6) Remove battery acid shield, (Fig. 6) from the

ABS modulator assembly.

(7) Remove the 6 tube nuts (Fig. 7), attaching hy-

draulic brake line tube bundle to modulator assem-

bly, thread savers and proportioning valves. Then

remove the 6 hydraulic brake lines as an assembly,

from the modulator assembly. (8) Remove electrical connector from the brake

pressure differential warning switch on hydraulic

junction block (Fig. 8). (9) Remove the primary and secondary hydraulic

brake tubes (Fig. 9) going from the master cylinder

to the junction block, from both master cylinder and

junction block. (10) Remove the brake hydraulic tube going to the

vehicle's left front wheel from the junction block. (11) Remove the 6 hydraulic brake tubes at the hy-

draulic junction block, coming from the antilock mod-

ulator assembly.

Fig. 5 Battery Tray And Attaching Bolts

Fig. 6 ABS Modulator Assembly Acid Shield

Fig. 2 Battery Heat Shield And Hold Down Clamp

Fig. 3 Battery Tray Shield

Fig. 4 Speed Control System Vacuum Reservoir

Ä ANTILOCK 4 BRAKE SYSTEM 5 - 35