lock CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 425 of 1938

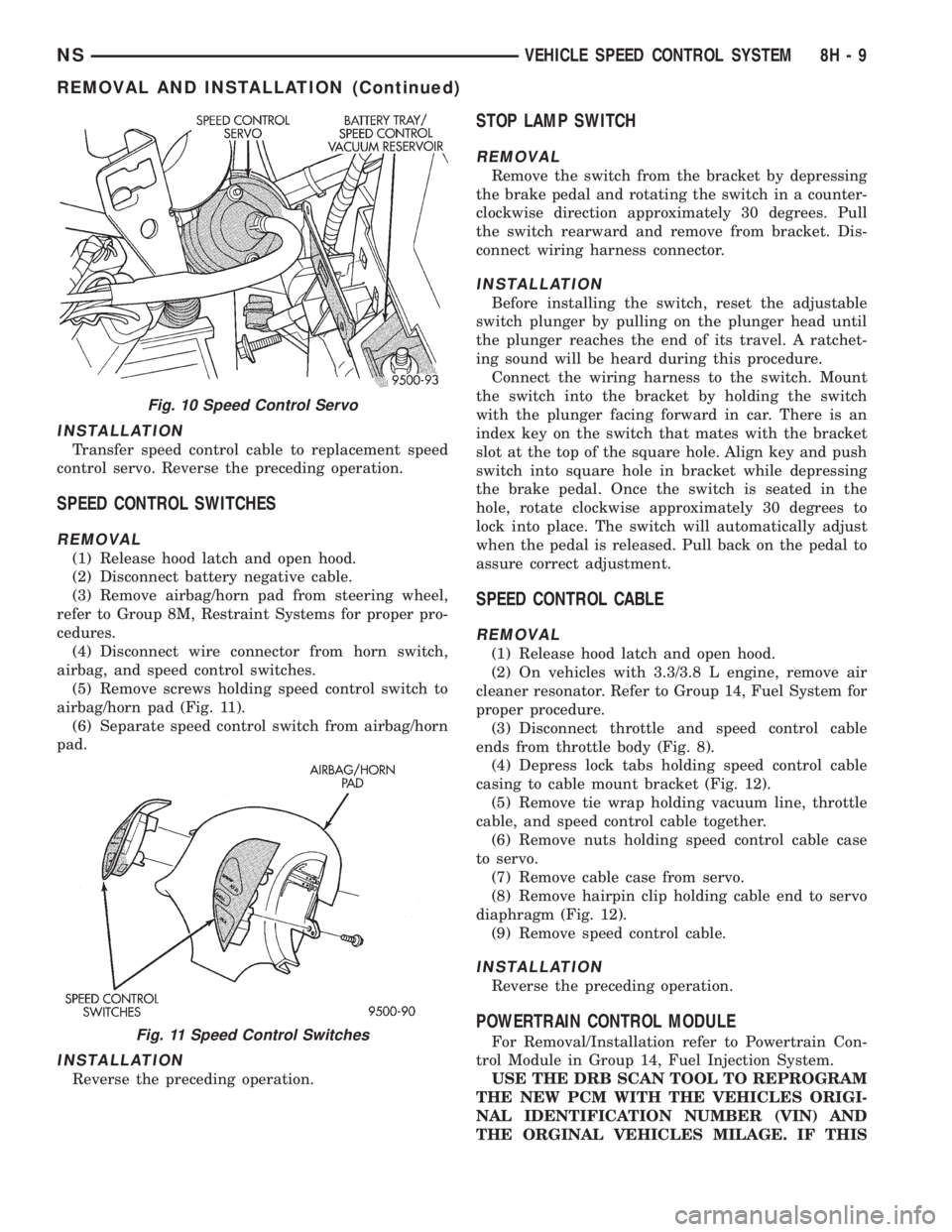

INSTALLATION

Transfer speed control cable to replacement speed

control servo. Reverse the preceding operation.

SPEED CONTROL SWITCHES

REMOVAL

(1) Release hood latch and open hood.

(2) Disconnect battery negative cable.

(3) Remove airbag/horn pad from steering wheel,

refer to Group 8M, Restraint Systems for proper pro-

cedures.

(4) Disconnect wire connector from horn switch,

airbag, and speed control switches.

(5) Remove screws holding speed control switch to

airbag/horn pad (Fig. 11).

(6) Separate speed control switch from airbag/horn

pad.

INSTALLATION

Reverse the preceding operation.

STOP LAMP SWITCH

REMOVAL

Remove the switch from the bracket by depressing

the brake pedal and rotating the switch in a counter-

clockwise direction approximately 30 degrees. Pull

the switch rearward and remove from bracket. Dis-

connect wiring harness connector.

INSTALLATION

Before installing the switch, reset the adjustable

switch plunger by pulling on the plunger head until

the plunger reaches the end of its travel. A ratchet-

ing sound will be heard during this procedure.

Connect the wiring harness to the switch. Mount

the switch into the bracket by holding the switch

with the plunger facing forward in car. There is an

index key on the switch that mates with the bracket

slot at the top of the square hole. Align key and push

switch into square hole in bracket while depressing

the brake pedal. Once the switch is seated in the

hole, rotate clockwise approximately 30 degrees to

lock into place. The switch will automatically adjust

when the pedal is released. Pull back on the pedal to

assure correct adjustment.

SPEED CONTROL CABLE

REMOVAL

(1) Release hood latch and open hood.

(2) On vehicles with 3.3/3.8 L engine, remove air

cleaner resonator. Refer to Group 14, Fuel System for

proper procedure.

(3) Disconnect throttle and speed control cable

ends from throttle body (Fig. 8).

(4) Depress lock tabs holding speed control cable

casing to cable mount bracket (Fig. 12).

(5) Remove tie wrap holding vacuum line, throttle

cable, and speed control cable together.

(6) Remove nuts holding speed control cable case

to servo.

(7) Remove cable case from servo.

(8) Remove hairpin clip holding cable end to servo

diaphragm (Fig. 12).

(9) Remove speed control cable.

INSTALLATION

Reverse the preceding operation.

POWERTRAIN CONTROL MODULE

For Removal/Installation refer to Powertrain Con-

trol Module in Group 14, Fuel Injection System.

USE THE DRB SCAN TOOL TO REPROGRAM

THE NEW PCM WITH THE VEHICLES ORIGI-

NAL IDENTIFICATION NUMBER (VIN) AND

THE ORGINAL VEHICLES MILAGE. IF THIS

Fig. 10 Speed Control Servo

Fig. 11 Speed Control Switches

NSVEHICLE SPEED CONTROL SYSTEM 8H - 9

REMOVAL AND INSTALLATION (Continued)

Page 429 of 1938

TURN SIGNAL AND FLASHERS

CONTENTS

page page

GENERAL INFORMATION

COMBINATION FLASHER.................. 1

INTRODUCTION......................... 1

DESCRIPTION AND OPERATION

COMBINATION FLASHER / DAYTIME

RUNNING LAMPS (DRL) MODULE......... 2

COMBINATION FLASHER FUNCTION......... 1DIAGNOSIS AND TESTING

COMBINATION FLASHER WITH / WITHOUT

DAYTIME RUNNING LAMPS MODULEÐ

CIRCUIT DIAGNOSTICS.................. 3

TURN SIGNAL MULTI-FUNCTION SWITCH.... 2

REMOVAL AND INSTALLATION

COMBINATION FLASHER WITH / WITHOUT

DRL MODULE........................ 11

MULTI-FUNCTION SWITCH............... 11

GENERAL INFORMATION

INTRODUCTION

The turn signals are actuated with a lever on the

left side of the steering column just ahead of the

steering wheel. The signals are automatically turned

off by a canceling cam (two lobes molded to the clock-

spring mechanism). The cam comes in contact with

the cancel actuator on the turn signal (multi-func-

tion) switch assembly. Either cam lobe, pushing on

the cancel actuator, returns the switch to the OFF

position.

Lane change signaling is actuated by applying par-

tial turn signal stalk movement toward the direction

desired until the indicator lamps flashes in the

instrument cluster. When the switch stalk is released

the stalk will spring back into the neutral position

turning OFF the turn signal.

With the ignition switch ON and the turn signal

switch stalk actuated left or right, current flows

through the:

²Combination flasher

²Multi-function switch

²Turn indicator lamp

²Front and rear turn signal bulbs.

A chime will sound after the vehicle has traveled a

distance of approximately 0.5 mile with the turn sig-

nal ON.

COMBINATION FLASHER

The Turn Signal/Hazard Warning Flasher is a

module providing the vehicle with turn signal and

hazard warning functions and has been designed

with internal relays to take advantage of low current

switching requirements in the vehicle. It is plugged

into the Junction Block at position 4 (Fig. 1), where

all wiring associated with its operation is terminated.The Junction Block is adjacent to and left of the

steering column of the vehicle.

To gain access to the flasher, remove the lower

steering column cover and knee blocker. Refer to

Group 8E, Instrument Panel and Systems for

removal procedures.

DESCRIPTION AND OPERATION

COMBINATION FLASHER FUNCTION

The Turn Signal/Hazard Warning Flasher is a

module providing turn signal, hazard warning func-

tions and has been designed with internal relays to

Fig. 1 Combination Flasher Location

NSTURN SIGNAL AND FLASHERS 8J - 1

Page 430 of 1938

take advantage of low current switching require-

ments in the vehicle. It is plugged into the Junction

Block at positions 4 (Fig. 1) where all wiring associ-

ated with its operation is terminated. The Junction

Block is adjacent to and left of the steering column of

the vehicle.

To gain access to the device, remove the lower

steering column cover and knee blocker, refer to

Group 8E, Instrument Panel and Systems.

The combination flasher may be operated in its

hazard warning mode either with or without the igni-

tion circuit being active. However, in order to operate

in the turn signal mode, the ignition circuit must be

completed to the module.

While the combination flasher is idle, there is no

current drawn through the module. The device does

not become active until a signal ground circuit is

supplied to either of the turn signal inputs or the

hazard warning input.

Typical flash rate for the flasher is 90 flashes per

minute.

When a lamp is burnt out for a given side of the

vehicle or a wire is open to a lamp, the flash rate will

increase to 180 flashes per minute when in the turn

signal mode. When in the hazard warning signal

mode the flash rate remains at 90 flashes per

minute.

Turn signal inputs that actuate the flasher are low

current grounds, each drawing a maximum of 300

mA., and are provided to the flasher through the

Junction Block from the multi-function switch that is

mounted to the steering column. The hazard warning

signal input is a low current ground drawing a max-

imum of 600 mA. through the multi-function switch.

COMBINATION FLASHER / DAYTIME RUNNING

LAMPS (DRL) MODULE

The Combination Flasher/DRL is a module provid-

ing turn signal, hazard warning, and daytime run-

ning light functions, and has been designed with

internal relays to take advantage of low current

switching requirements in the vehicle. It is plugged

into the junction block at positions 3 AND 4 (Fig. 2)

where all wiring associated with its operation is ter-

minated. The Junction Block is adjacent to and left of

the steering column of the vehicle.

To gain access to the device, remove the lower

steering column cover and knee blocker, refer to

Group 8E, Instrument Panel and Gauges.

The combination flasher/DRL may be operated in

its hazard warning mode either with or without the

ignition circuit being active. However, in order to

operate in the turn signal mode or the DRL mode,

the ignition circuit must be completed to the module.

While the combination flasher portion is idle, there

is no current drawn through the module. The devicedoes not become active in the turn signal or hazard

warning modes until a signal ground circuit is sup-

plied to either of the turn signal inputs or the hazard

warning input. With the ignition OFF, there is no

current drawn through the module.

While the ignition is ON, the front turn signal fil-

aments are illuminated steadily thus providing the

DRL function. The DRL function may be inhibited by

applying a signal ground input from either the park

brake circuit or the headlamp relay activation circuit.

Typical flash rate for the flasher is 90 flashes per

minute.

When a lamp is burnt out for a given side of the

vehicle or a wire is open to a lamp, the flash rate will

increase to 180 flashes per minute when in the turn

signal mode. When in the hazard warning signal

mode the flash rate remains at 90 flashes per

minute.

Turn signal inputs that actuate the flasher are low

current grounds, each could draw a maximum of 300

mA., and are provided to the flasher through the

Junction Block from the multi-function switch that is

mounted to the steering column. The hazard warning

signal input is a low current ground that could draw

a maximum of 600 mA. through the multi-function

switch.

DIAGNOSIS AND TESTING

TURN SIGNAL MULTI-FUNCTION SWITCH

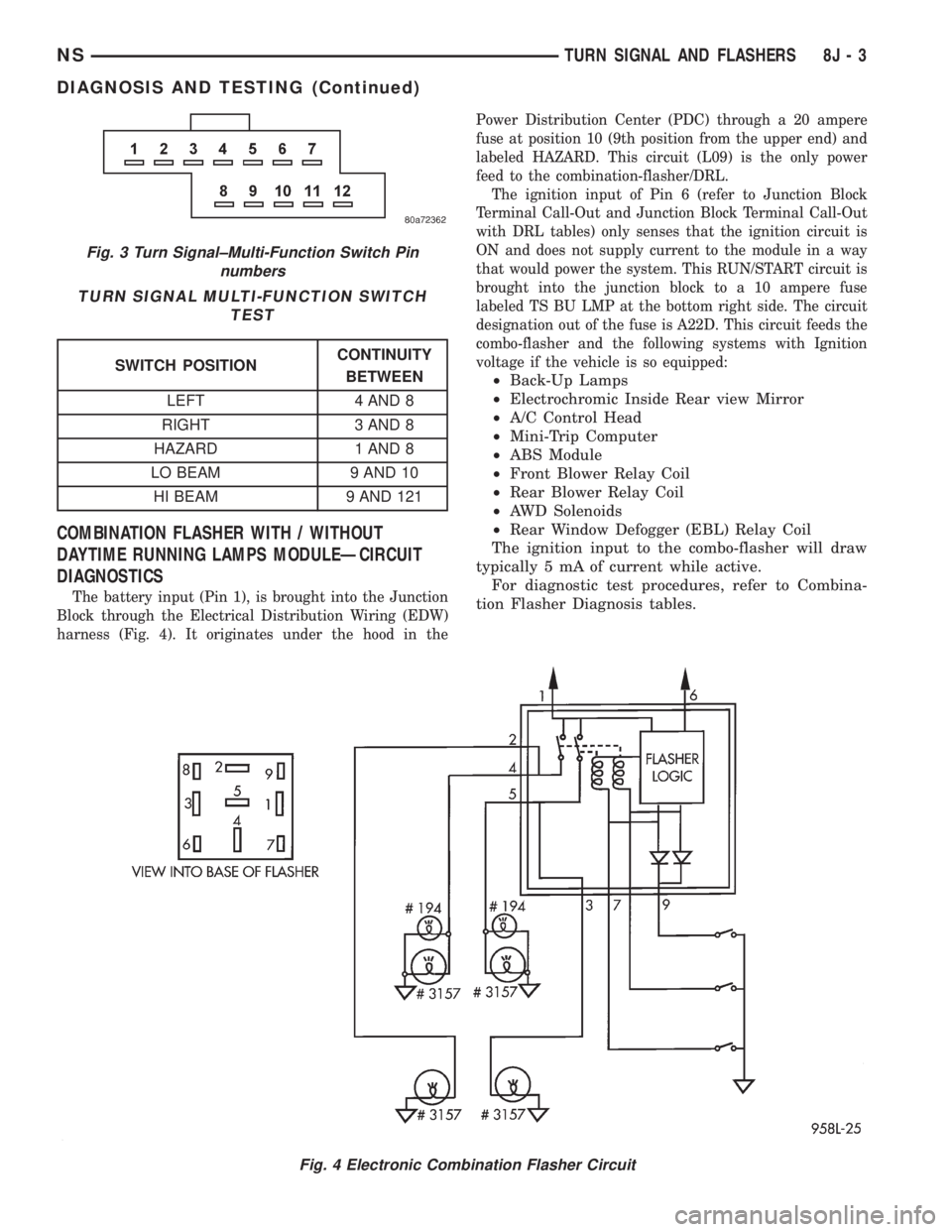

To test turn signal, headlamp beam select and opti-

cal horn portion of the multi-function switch:

(1) Remove the multi-function switch, refer to

removal procedures.

(2) Using an ohmmeter check continuity reading

between multi-function switch pins. Refer to (Fig. 3)

for proper pin numbers and Turn Signal Multi-Func-

tion Switch Test chart.

Fig. 2 Junction Block Terminal Pins

8J - 2 TURN SIGNAL AND FLASHERSNS

DESCRIPTION AND OPERATION (Continued)

Page 431 of 1938

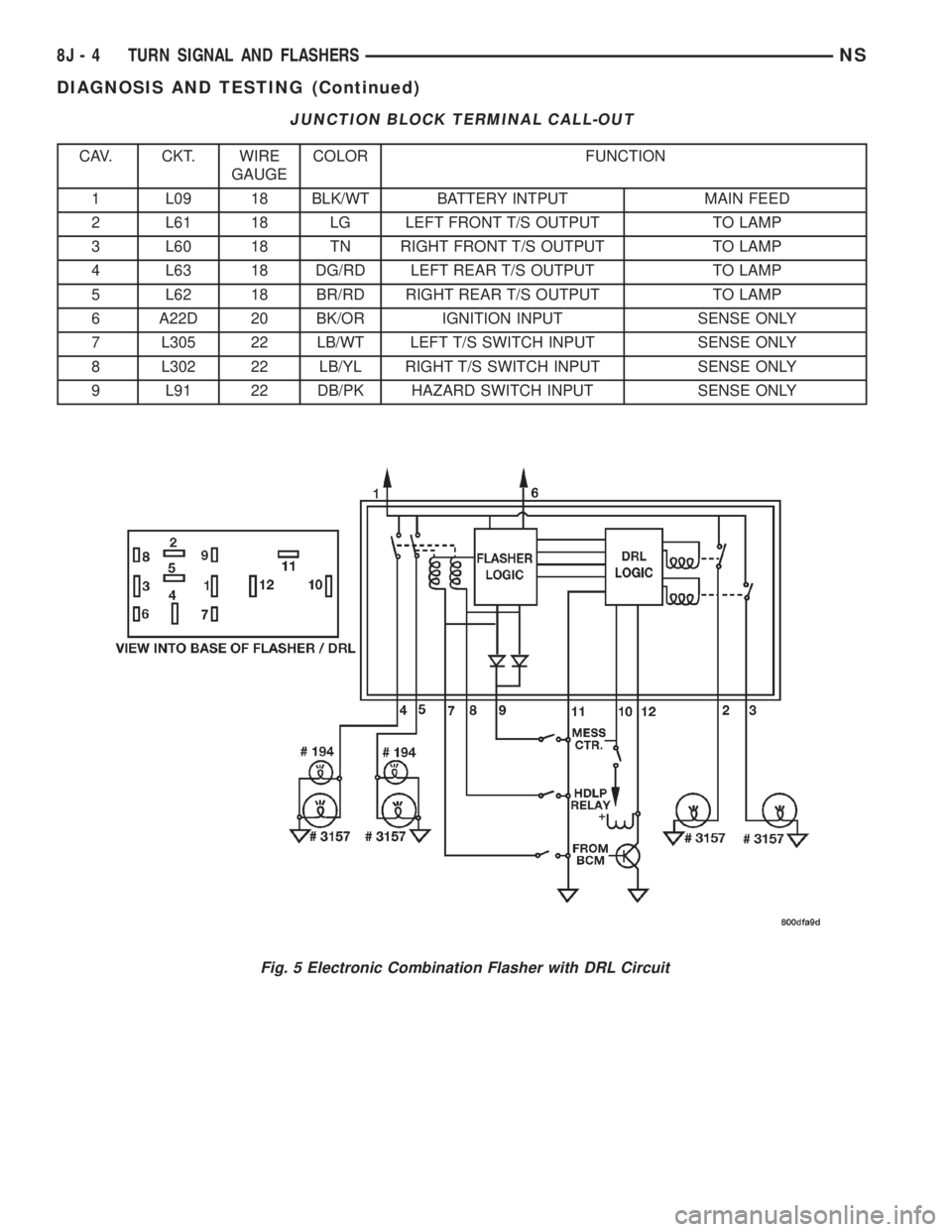

COMBINATION FLASHER WITH / WITHOUT

DAYTIME RUNNING LAMPS MODULEÐCIRCUIT

DIAGNOSTICS

The battery input (Pin 1), is brought into the Junction

Block through the Electrical Distribution Wiring (EDW)

harness (Fig. 4). It originates under the hood in thePower Distribution Center (PDC) through a 20 ampere

fuse at position 10 (9th position from the upper end) and

labeled HAZARD. This circuit (L09) is the only power

feed to the combination-flasher/DRL.

The ignition input of Pin 6 (refer to Junction Block

Terminal Call-Out and Junction Block Terminal Call-Out

with DRL tables) only senses that the ignition circuit is

ON and does not supply current to the module in a way

that would power the system. This RUN/START circuit is

brought into the junction block to a 10 ampere fuse

labeled TS BU LMP at the bottom right side. The circuit

designation out of the fuse is A22D. This circuit feeds the

combo-flasher and the following systems with Ignition

voltage if the vehicle is so equipped:

²Back-Up Lamps

²Electrochromic Inside Rear view Mirror

²A/C Control Head

²Mini-Trip Computer

²ABS Module

²Front Blower Relay Coil

²Rear Blower Relay Coil

²AWD Solenoids

²Rear Window Defogger (EBL) Relay Coil

The ignition input to the combo-flasher will draw

typically 5 mA of current while active.

For diagnostic test procedures, refer to Combina-

tion Flasher Diagnosis tables.

Fig. 4 Electronic Combination Flasher Circuit

Fig. 3 Turn Signal±Multi-Function Switch Pin

numbers

TURN SIGNAL MULTI-FUNCTION SWITCH

TEST

SWITCH POSITIONCONTINUITY

BETWEEN

LEFT 4 AND 8

RIGHT 3 AND 8

HAZARD 1 AND 8

LO BEAM 9 AND 10

HI BEAM 9 AND 121

NSTURN SIGNAL AND FLASHERS 8J - 3

DIAGNOSIS AND TESTING (Continued)

Page 432 of 1938

Fig. 5 Electronic Combination Flasher with DRL Circuit

JUNCTION BLOCK TERMINAL CALL-OUT

CAV. CKT. WIRE

GAUGECOLOR FUNCTION

1 L09 18 BLK/WT BATTERY INTPUT MAIN FEED

2 L61 18 LG LEFT FRONT T/S OUTPUT TO LAMP

3 L60 18 TN RIGHT FRONT T/S OUTPUT TO LAMP

4 L63 18 DG/RD LEFT REAR T/S OUTPUT TO LAMP

5 L62 18 BR/RD RIGHT REAR T/S OUTPUT TO LAMP

6 A22D 20 BK/OR IGNITION INPUT SENSE ONLY

7 L305 22 LB/WT LEFT T/S SWITCH INPUT SENSE ONLY

8 L302 22 LB/YL RIGHT T/S SWITCH INPUT SENSE ONLY

9 L91 22 DB/PK HAZARD SWITCH INPUT SENSE ONLY

8J - 4 TURN SIGNAL AND FLASHERSNS

DIAGNOSIS AND TESTING (Continued)

Page 433 of 1938

JUNCTION BLOCK TERMINAL CALL-OUT WITH DRL

CAV. CKT. WIRE

GAUGECOLOR FUNCTION

1 L09 18 BLK/WT BATTERY INTPUT MAIN FEED

2 L61 18 LG LEFT FRONT T/S OUTPUT TO LAMP

3 L60 18 TN RIGHT FRONT T/S OUTPUT TO LAMP

4 L63 18 DG/RD LEFT REAR T/S OUTPUT TO LAMP

5 L62 18 BR/RD RIGHT REAR T/S OUTPUT TO LAMP

6 A22D 20 BK/OR IGNITION INPUT SENSE ONLY

7 L305 22 LB/WT LEFT T/S SWITCH INPUT SENSE ONLY

8 L302 22 LB/YL RIGHT T/S SWITCH INPUT SENSE ONLY

9 L91 22 DB/PK HAZARD SWITCH INPUT SENSE ONLY

10 G09 22 GY/BK PARK BRAKE SWITCH INPUT SENSE ONLY

11 Z01 14 BK GROUND MAIN GRD.

12 L93 22 RD/YL HEADLAMP RELAY SWITCH

INPUTSENSE ONLY

NSTURN SIGNAL AND FLASHERS 8J - 5

DIAGNOSIS AND TESTING (Continued)

Page 434 of 1938

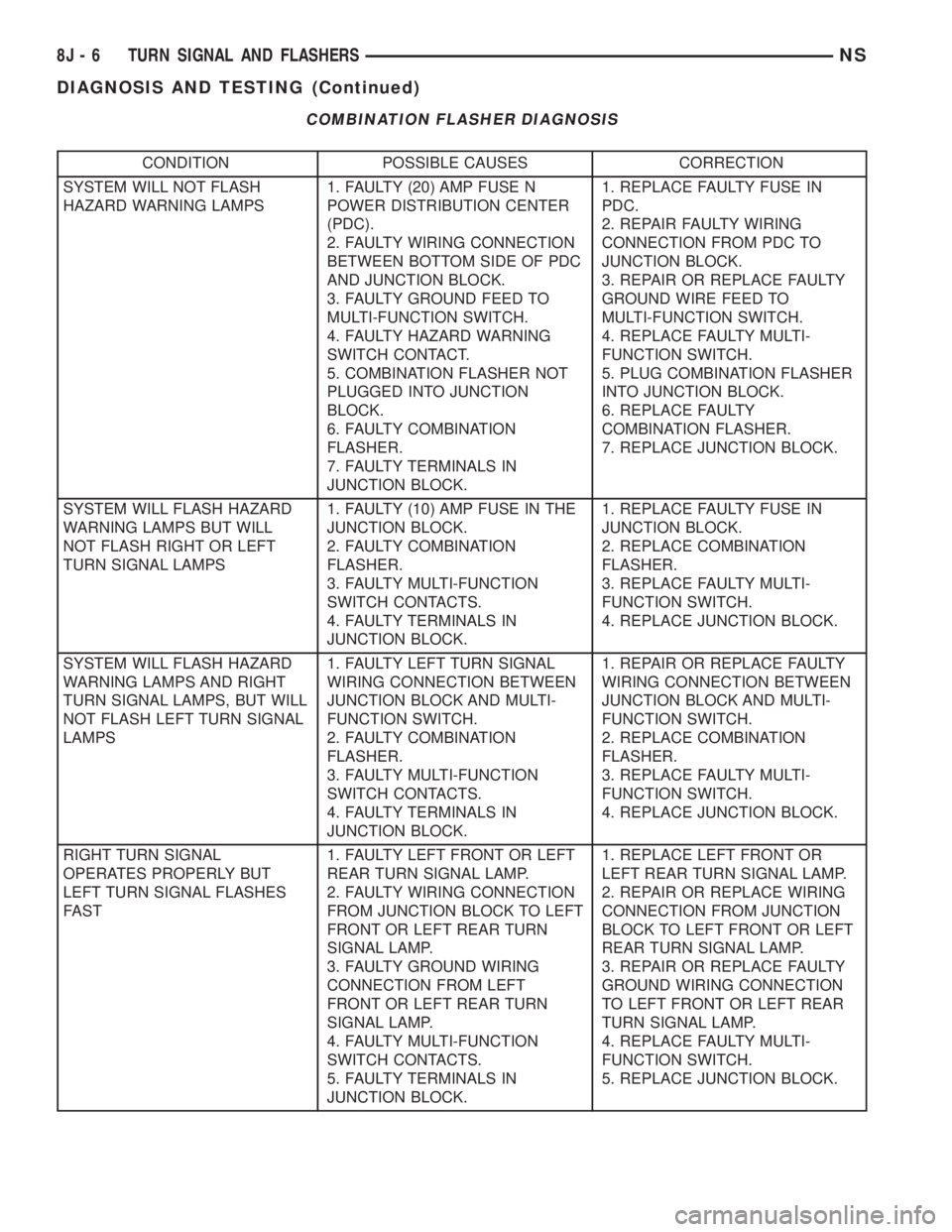

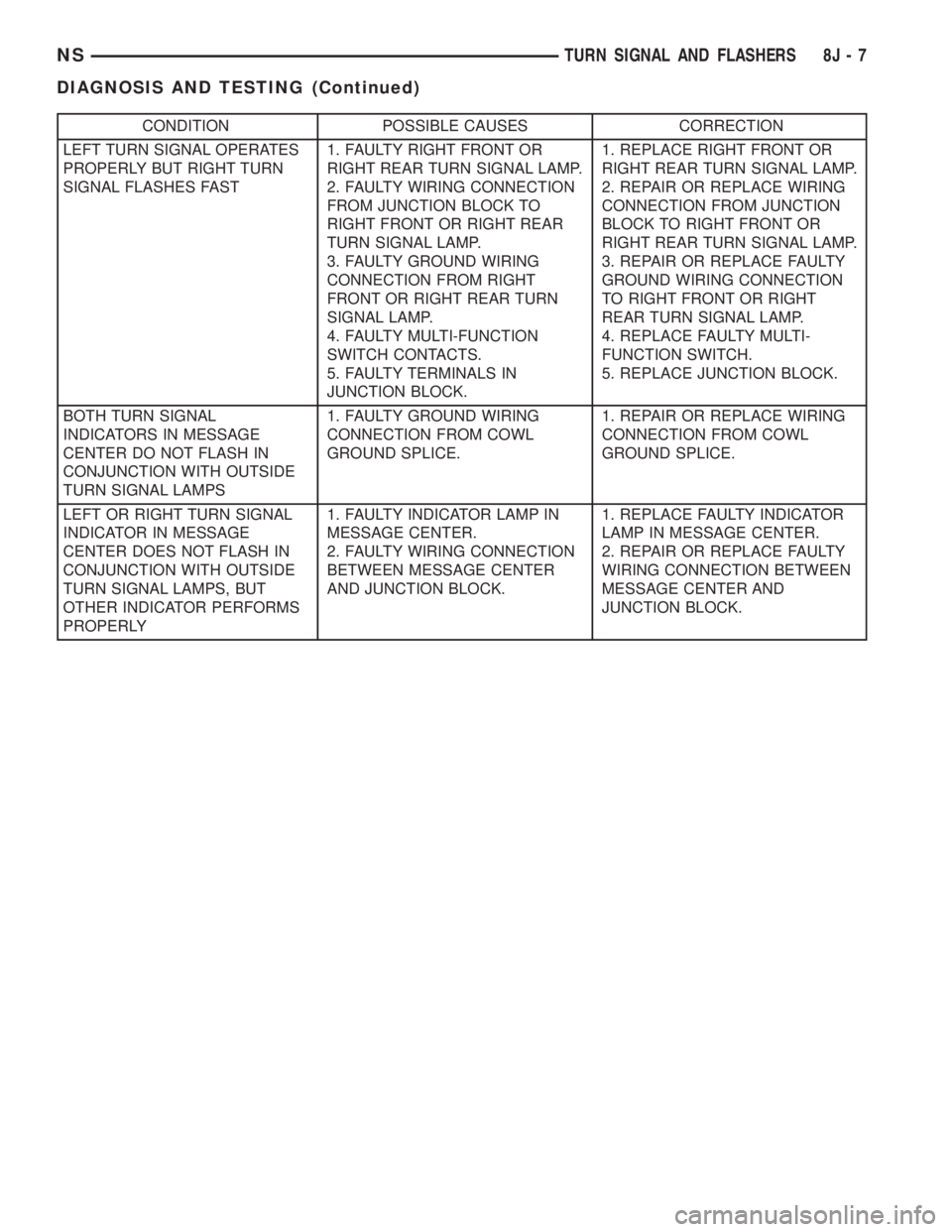

COMBINATION FLASHER DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

SYSTEM WILL NOT FLASH

HAZARD WARNING LAMPS1. FAULTY (20) AMP FUSE N

POWER DISTRIBUTION CENTER

(PDC).

2. FAULTY WIRING CONNECTION

BETWEEN BOTTOM SIDE OF PDC

AND JUNCTION BLOCK.

3. FAULTY GROUND FEED TO

MULTI-FUNCTION SWITCH.

4. FAULTY HAZARD WARNING

SWITCH CONTACT.

5. COMBINATION FLASHER NOT

PLUGGED INTO JUNCTION

BLOCK.

6. FAULTY COMBINATION

FLASHER.

7. FAULTY TERMINALS IN

JUNCTION BLOCK.1. REPLACE FAULTY FUSE IN

PDC.

2. REPAIR FAULTY WIRING

CONNECTION FROM PDC TO

JUNCTION BLOCK.

3. REPAIR OR REPLACE FAULTY

GROUND WIRE FEED TO

MULTI-FUNCTION SWITCH.

4. REPLACE FAULTY MULTI-

FUNCTION SWITCH.

5. PLUG COMBINATION FLASHER

INTO JUNCTION BLOCK.

6. REPLACE FAULTY

COMBINATION FLASHER.

7. REPLACE JUNCTION BLOCK.

SYSTEM WILL FLASH HAZARD

WARNING LAMPS BUT WILL

NOT FLASH RIGHT OR LEFT

TURN SIGNAL LAMPS1. FAULTY (10) AMP FUSE IN THE

JUNCTION BLOCK.

2. FAULTY COMBINATION

FLASHER.

3. FAULTY MULTI-FUNCTION

SWITCH CONTACTS.

4. FAULTY TERMINALS IN

JUNCTION BLOCK.1. REPLACE FAULTY FUSE IN

JUNCTION BLOCK.

2. REPLACE COMBINATION

FLASHER.

3. REPLACE FAULTY MULTI-

FUNCTION SWITCH.

4. REPLACE JUNCTION BLOCK.

SYSTEM WILL FLASH HAZARD

WARNING LAMPS AND RIGHT

TURN SIGNAL LAMPS, BUT WILL

NOT FLASH LEFT TURN SIGNAL

LAMPS1. FAULTY LEFT TURN SIGNAL

WIRING CONNECTION BETWEEN

JUNCTION BLOCK AND MULTI-

FUNCTION SWITCH.

2. FAULTY COMBINATION

FLASHER.

3. FAULTY MULTI-FUNCTION

SWITCH CONTACTS.

4. FAULTY TERMINALS IN

JUNCTION BLOCK.1. REPAIR OR REPLACE FAULTY

WIRING CONNECTION BETWEEN

JUNCTION BLOCK AND MULTI-

FUNCTION SWITCH.

2. REPLACE COMBINATION

FLASHER.

3. REPLACE FAULTY MULTI-

FUNCTION SWITCH.

4. REPLACE JUNCTION BLOCK.

RIGHT TURN SIGNAL

OPERATES PROPERLY BUT

LEFT TURN SIGNAL FLASHES

FAST1. FAULTY LEFT FRONT OR LEFT

REAR TURN SIGNAL LAMP.

2. FAULTY WIRING CONNECTION

FROM JUNCTION BLOCK TO LEFT

FRONT OR LEFT REAR TURN

SIGNAL LAMP.

3. FAULTY GROUND WIRING

CONNECTION FROM LEFT

FRONT OR LEFT REAR TURN

SIGNAL LAMP.

4. FAULTY MULTI-FUNCTION

SWITCH CONTACTS.

5. FAULTY TERMINALS IN

JUNCTION BLOCK.1. REPLACE LEFT FRONT OR

LEFT REAR TURN SIGNAL LAMP.

2. REPAIR OR REPLACE WIRING

CONNECTION FROM JUNCTION

BLOCK TO LEFT FRONT OR LEFT

REAR TURN SIGNAL LAMP.

3. REPAIR OR REPLACE FAULTY

GROUND WIRING CONNECTION

TO LEFT FRONT OR LEFT REAR

TURN SIGNAL LAMP.

4. REPLACE FAULTY MULTI-

FUNCTION SWITCH.

5. REPLACE JUNCTION BLOCK.

8J - 6 TURN SIGNAL AND FLASHERSNS

DIAGNOSIS AND TESTING (Continued)

Page 435 of 1938

CONDITION POSSIBLE CAUSES CORRECTION

LEFT TURN SIGNAL OPERATES

PROPERLY BUT RIGHT TURN

SIGNAL FLASHES FAST1. FAULTY RIGHT FRONT OR

RIGHT REAR TURN SIGNAL LAMP.

2. FAULTY WIRING CONNECTION

FROM JUNCTION BLOCK TO

RIGHT FRONT OR RIGHT REAR

TURN SIGNAL LAMP.

3. FAULTY GROUND WIRING

CONNECTION FROM RIGHT

FRONT OR RIGHT REAR TURN

SIGNAL LAMP.

4. FAULTY MULTI-FUNCTION

SWITCH CONTACTS.

5. FAULTY TERMINALS IN

JUNCTION BLOCK.1. REPLACE RIGHT FRONT OR

RIGHT REAR TURN SIGNAL LAMP.

2. REPAIR OR REPLACE WIRING

CONNECTION FROM JUNCTION

BLOCK TO RIGHT FRONT OR

RIGHT REAR TURN SIGNAL LAMP.

3. REPAIR OR REPLACE FAULTY

GROUND WIRING CONNECTION

TO RIGHT FRONT OR RIGHT

REAR TURN SIGNAL LAMP.

4. REPLACE FAULTY MULTI-

FUNCTION SWITCH.

5. REPLACE JUNCTION BLOCK.

BOTH TURN SIGNAL

INDICATORS IN MESSAGE

CENTER DO NOT FLASH IN

CONJUNCTION WITH OUTSIDE

TURN SIGNAL LAMPS1. FAULTY GROUND WIRING

CONNECTION FROM COWL

GROUND SPLICE.1. REPAIR OR REPLACE WIRING

CONNECTION FROM COWL

GROUND SPLICE.

LEFT OR RIGHT TURN SIGNAL

INDICATOR IN MESSAGE

CENTER DOES NOT FLASH IN

CONJUNCTION WITH OUTSIDE

TURN SIGNAL LAMPS, BUT

OTHER INDICATOR PERFORMS

PROPERLY1. FAULTY INDICATOR LAMP IN

MESSAGE CENTER.

2. FAULTY WIRING CONNECTION

BETWEEN MESSAGE CENTER

AND JUNCTION BLOCK.1. REPLACE FAULTY INDICATOR

LAMP IN MESSAGE CENTER.

2. REPAIR OR REPLACE FAULTY

WIRING CONNECTION BETWEEN

MESSAGE CENTER AND

JUNCTION BLOCK.

NSTURN SIGNAL AND FLASHERS 8J - 7

DIAGNOSIS AND TESTING (Continued)

Page 436 of 1938

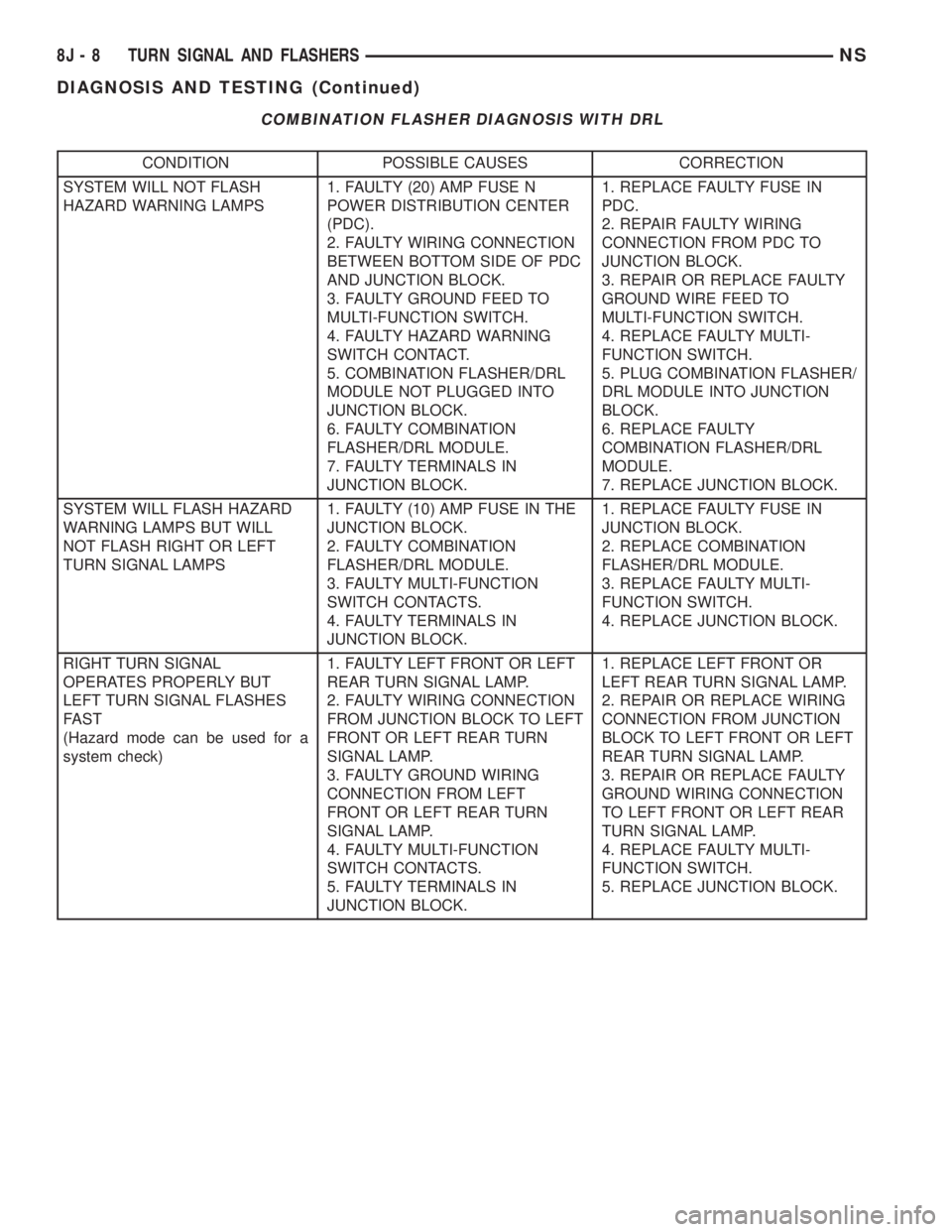

COMBINATION FLASHER DIAGNOSIS WITH DRL

CONDITION POSSIBLE CAUSES CORRECTION

SYSTEM WILL NOT FLASH

HAZARD WARNING LAMPS1. FAULTY (20) AMP FUSE N

POWER DISTRIBUTION CENTER

(PDC).

2. FAULTY WIRING CONNECTION

BETWEEN BOTTOM SIDE OF PDC

AND JUNCTION BLOCK.

3. FAULTY GROUND FEED TO

MULTI-FUNCTION SWITCH.

4. FAULTY HAZARD WARNING

SWITCH CONTACT.

5. COMBINATION FLASHER/DRL

MODULE NOT PLUGGED INTO

JUNCTION BLOCK.

6. FAULTY COMBINATION

FLASHER/DRL MODULE.

7. FAULTY TERMINALS IN

JUNCTION BLOCK.1. REPLACE FAULTY FUSE IN

PDC.

2. REPAIR FAULTY WIRING

CONNECTION FROM PDC TO

JUNCTION BLOCK.

3. REPAIR OR REPLACE FAULTY

GROUND WIRE FEED TO

MULTI-FUNCTION SWITCH.

4. REPLACE FAULTY MULTI-

FUNCTION SWITCH.

5. PLUG COMBINATION FLASHER/

DRL MODULE INTO JUNCTION

BLOCK.

6. REPLACE FAULTY

COMBINATION FLASHER/DRL

MODULE.

7. REPLACE JUNCTION BLOCK.

SYSTEM WILL FLASH HAZARD

WARNING LAMPS BUT WILL

NOT FLASH RIGHT OR LEFT

TURN SIGNAL LAMPS1. FAULTY (10) AMP FUSE IN THE

JUNCTION BLOCK.

2. FAULTY COMBINATION

FLASHER/DRL MODULE.

3. FAULTY MULTI-FUNCTION

SWITCH CONTACTS.

4. FAULTY TERMINALS IN

JUNCTION BLOCK.1. REPLACE FAULTY FUSE IN

JUNCTION BLOCK.

2. REPLACE COMBINATION

FLASHER/DRL MODULE.

3. REPLACE FAULTY MULTI-

FUNCTION SWITCH.

4. REPLACE JUNCTION BLOCK.

RIGHT TURN SIGNAL

OPERATES PROPERLY BUT

LEFT TURN SIGNAL FLASHES

FAST

(Hazard mode can be used for a

system check)1. FAULTY LEFT FRONT OR LEFT

REAR TURN SIGNAL LAMP.

2. FAULTY WIRING CONNECTION

FROM JUNCTION BLOCK TO LEFT

FRONT OR LEFT REAR TURN

SIGNAL LAMP.

3. FAULTY GROUND WIRING

CONNECTION FROM LEFT

FRONT OR LEFT REAR TURN

SIGNAL LAMP.

4. FAULTY MULTI-FUNCTION

SWITCH CONTACTS.

5. FAULTY TERMINALS IN

JUNCTION BLOCK.1. REPLACE LEFT FRONT OR

LEFT REAR TURN SIGNAL LAMP.

2. REPAIR OR REPLACE WIRING

CONNECTION FROM JUNCTION

BLOCK TO LEFT FRONT OR LEFT

REAR TURN SIGNAL LAMP.

3. REPAIR OR REPLACE FAULTY

GROUND WIRING CONNECTION

TO LEFT FRONT OR LEFT REAR

TURN SIGNAL LAMP.

4. REPLACE FAULTY MULTI-

FUNCTION SWITCH.

5. REPLACE JUNCTION BLOCK.

8J - 8 TURN SIGNAL AND FLASHERSNS

DIAGNOSIS AND TESTING (Continued)

Page 437 of 1938

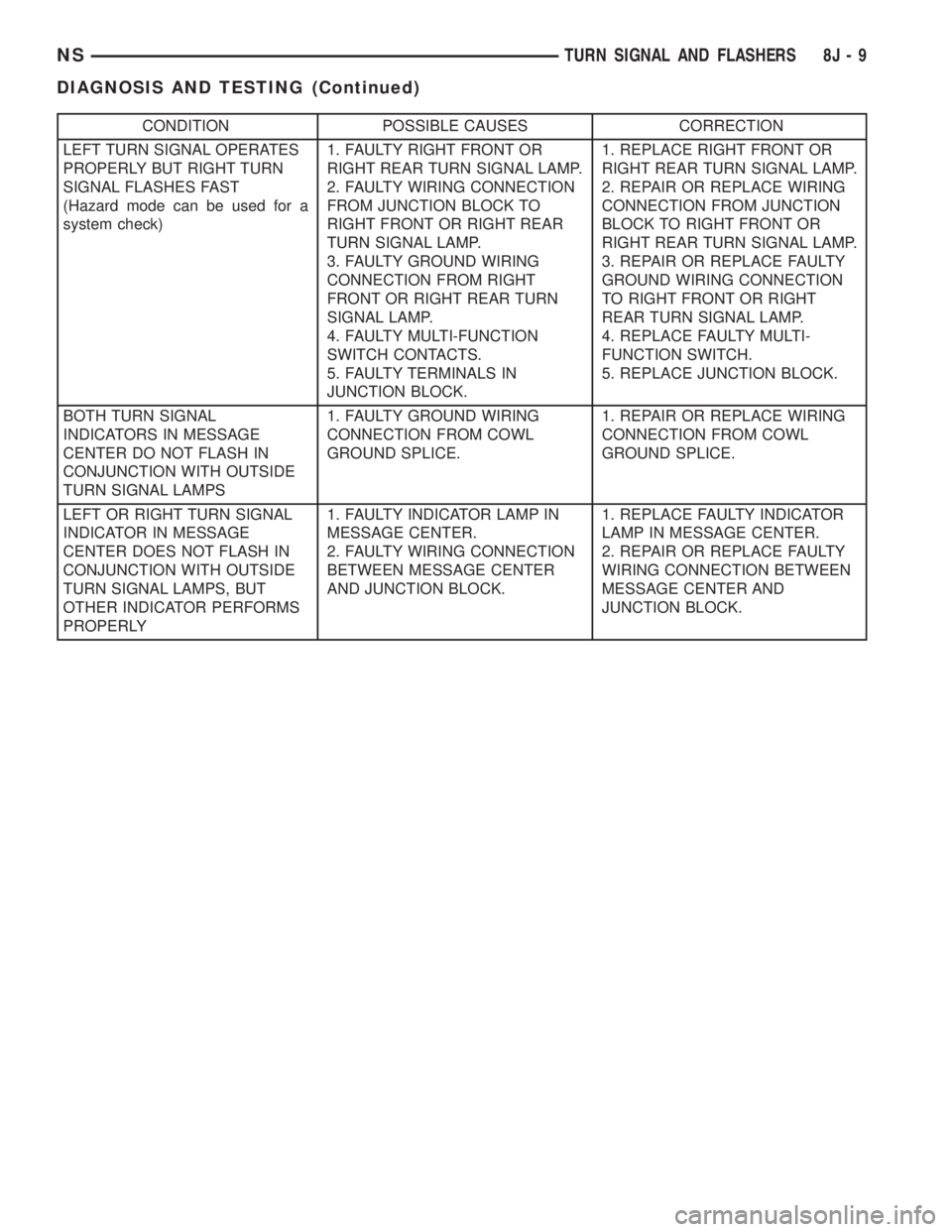

CONDITION POSSIBLE CAUSES CORRECTION

LEFT TURN SIGNAL OPERATES

PROPERLY BUT RIGHT TURN

SIGNAL FLASHES FAST

(Hazard mode can be used for a

system check)1. FAULTY RIGHT FRONT OR

RIGHT REAR TURN SIGNAL LAMP.

2. FAULTY WIRING CONNECTION

FROM JUNCTION BLOCK TO

RIGHT FRONT OR RIGHT REAR

TURN SIGNAL LAMP.

3. FAULTY GROUND WIRING

CONNECTION FROM RIGHT

FRONT OR RIGHT REAR TURN

SIGNAL LAMP.

4. FAULTY MULTI-FUNCTION

SWITCH CONTACTS.

5. FAULTY TERMINALS IN

JUNCTION BLOCK.1. REPLACE RIGHT FRONT OR

RIGHT REAR TURN SIGNAL LAMP.

2. REPAIR OR REPLACE WIRING

CONNECTION FROM JUNCTION

BLOCK TO RIGHT FRONT OR

RIGHT REAR TURN SIGNAL LAMP.

3. REPAIR OR REPLACE FAULTY

GROUND WIRING CONNECTION

TO RIGHT FRONT OR RIGHT

REAR TURN SIGNAL LAMP.

4. REPLACE FAULTY MULTI-

FUNCTION SWITCH.

5. REPLACE JUNCTION BLOCK.

BOTH TURN SIGNAL

INDICATORS IN MESSAGE

CENTER DO NOT FLASH IN

CONJUNCTION WITH OUTSIDE

TURN SIGNAL LAMPS1. FAULTY GROUND WIRING

CONNECTION FROM COWL

GROUND SPLICE.1. REPAIR OR REPLACE WIRING

CONNECTION FROM COWL

GROUND SPLICE.

LEFT OR RIGHT TURN SIGNAL

INDICATOR IN MESSAGE

CENTER DOES NOT FLASH IN

CONJUNCTION WITH OUTSIDE

TURN SIGNAL LAMPS, BUT

OTHER INDICATOR PERFORMS

PROPERLY1. FAULTY INDICATOR LAMP IN

MESSAGE CENTER.

2. FAULTY WIRING CONNECTION

BETWEEN MESSAGE CENTER

AND JUNCTION BLOCK.1. REPLACE FAULTY INDICATOR

LAMP IN MESSAGE CENTER.

2. REPAIR OR REPLACE FAULTY

WIRING CONNECTION BETWEEN

MESSAGE CENTER AND

JUNCTION BLOCK.

NSTURN SIGNAL AND FLASHERS 8J - 9

DIAGNOSIS AND TESTING (Continued)