torque CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1132 of 1938

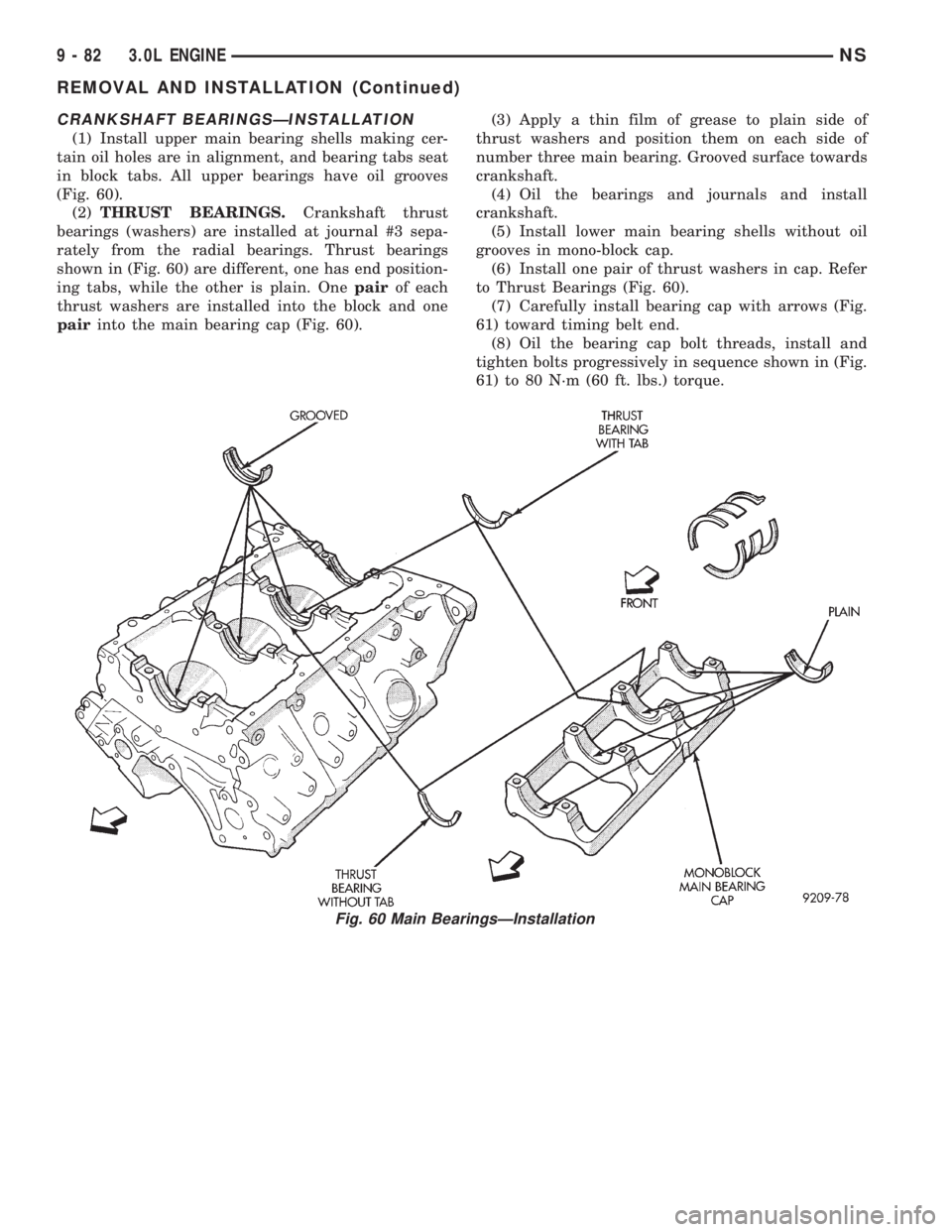

CRANKSHAFT BEARINGSÐINSTALLATION

(1) Install upper main bearing shells making cer-

tain oil holes are in alignment, and bearing tabs seat

in block tabs. All upper bearings have oil grooves

(Fig. 60).

(2)THRUST BEARINGS.Crankshaft thrust

bearings (washers) are installed at journal #3 sepa-

rately from the radial bearings. Thrust bearings

shown in (Fig. 60) are different, one has end position-

ing tabs, while the other is plain. Onepairof each

thrust washers are installed into the block and one

pairinto the main bearing cap (Fig. 60).(3) Apply a thin film of grease to plain side of

thrust washers and position them on each side of

number three main bearing. Grooved surface towards

crankshaft.

(4) Oil the bearings and journals and install

crankshaft.

(5) Install lower main bearing shells without oil

grooves in mono-block cap.

(6) Install one pair of thrust washers in cap. Refer

to Thrust Bearings (Fig. 60).

(7) Carefully install bearing cap with arrows (Fig.

61) toward timing belt end.

(8) Oil the bearing cap bolt threads, install and

tighten bolts progressively in sequence shown in (Fig.

61) to 80 N´m (60 ft. lbs.) torque.

Fig. 60 Main BearingsÐInstallation

9 - 82 3.0L ENGINENS

REMOVAL AND INSTALLATION (Continued)

Page 1134 of 1938

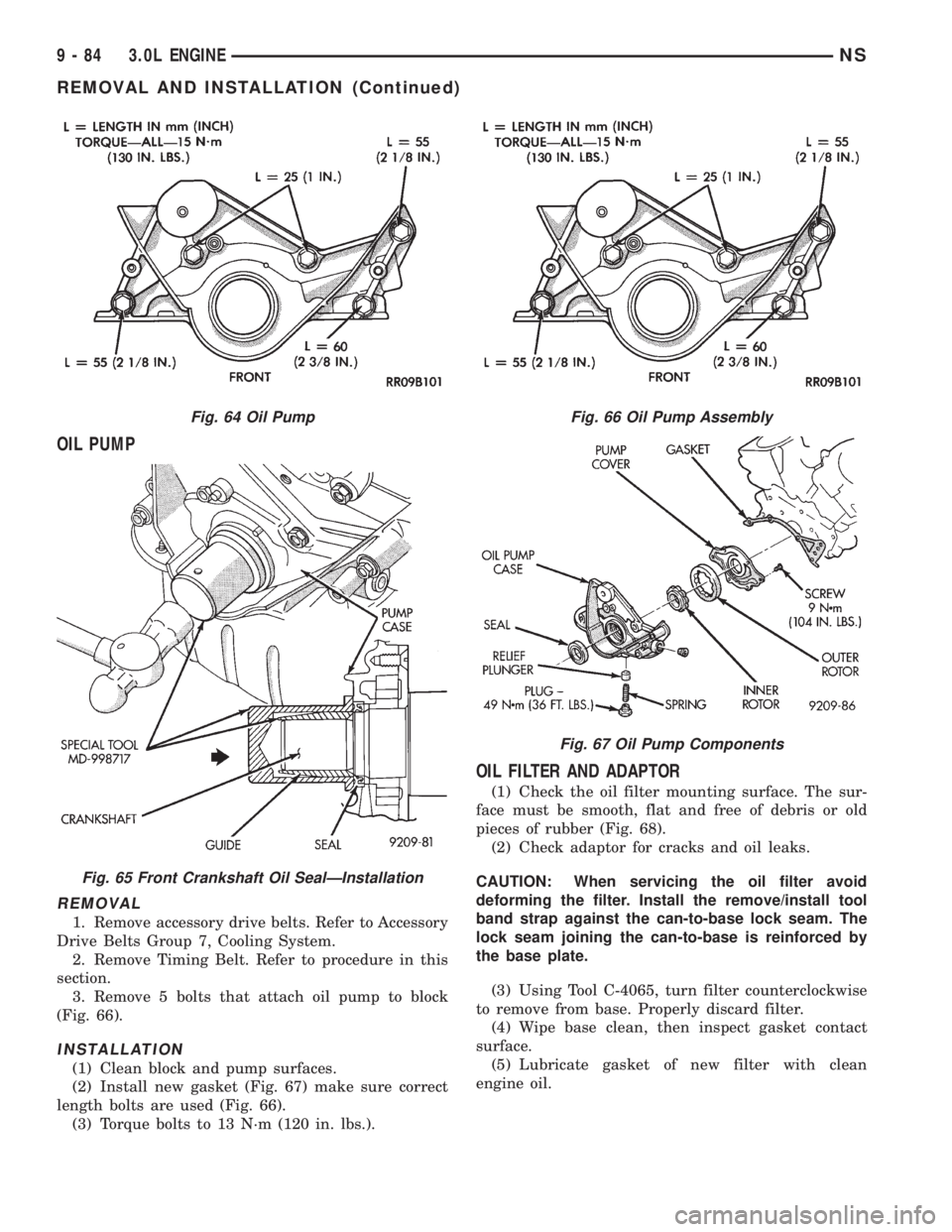

OIL PUMP

REMOVAL

1. Remove accessory drive belts. Refer to Accessory

Drive Belts Group 7, Cooling System.

2. Remove Timing Belt. Refer to procedure in this

section.

3. Remove 5 bolts that attach oil pump to block

(Fig. 66).

INSTALLATION

(1) Clean block and pump surfaces.

(2) Install new gasket (Fig. 67) make sure correct

length bolts are used (Fig. 66).

(3) Torque bolts to 13 N´m (120 in. lbs.).

OIL FILTER AND ADAPTOR

(1) Check the oil filter mounting surface. The sur-

face must be smooth, flat and free of debris or old

pieces of rubber (Fig. 68).

(2) Check adaptor for cracks and oil leaks.

CAUTION: When servicing the oil filter avoid

deforming the filter. Install the remove/install tool

band strap against the can-to-base lock seam. The

lock seam joining the can-to-base is reinforced by

the base plate.

(3) Using Tool C-4065, turn filter counterclockwise

to remove from base. Properly discard filter.

(4) Wipe base clean, then inspect gasket contact

surface.

(5) Lubricate gasket of new filter with clean

engine oil.

Fig. 64 Oil Pump

Fig. 65 Front Crankshaft Oil SealÐInstallation

Fig. 66 Oil Pump Assembly

Fig. 67 Oil Pump Components

9 - 84 3.0L ENGINENS

REMOVAL AND INSTALLATION (Continued)

Page 1140 of 1938

Service Limit.............0.15 mm (0.006 in.)

Valve Guide

Overall Length±Intake........44mm(1.732 in.)

Overall Length±Exhaust.......48mm(1.889 in.)

Outside Diameter...........13.055 - 13.065 mm

(0.514 - 0.5143 in.)

Inside Diameter..............8.000 - 8.018 mm

(0.314 - 315 in.)

Valve Springs

Free Length (Approx.).......49.8 mm (1.960 in.)

Service Limit............48.8 mm (1.9213 in.)

Loaded Height...............40.4 mm @ 33 kg

(1.59 in. @73 lbs.)

Perpendicularity±Intake and Exhaust . . .2É (Max.)

Service Limit.....................4É(Max.)

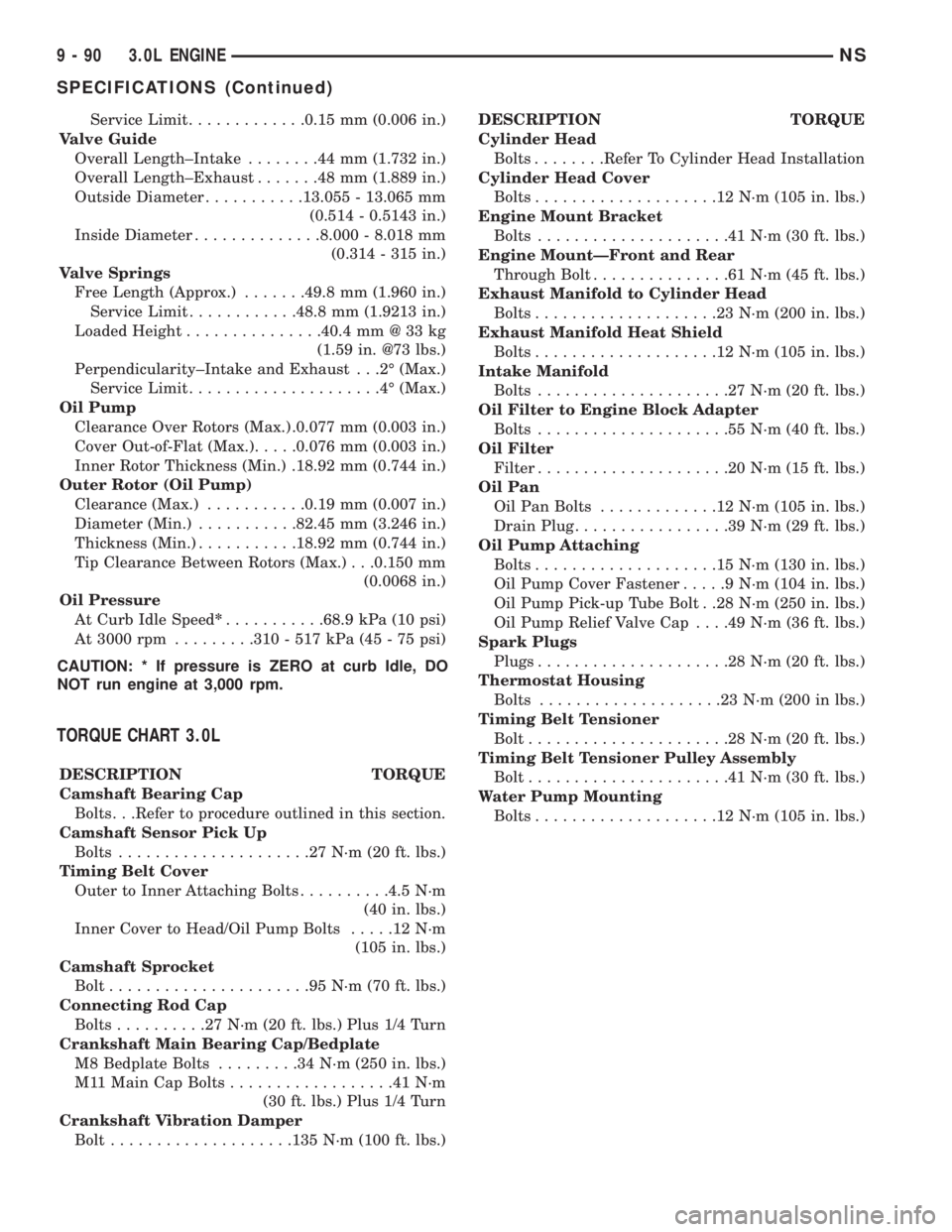

Oil Pump

Clearance Over Rotors (Max.) .0.077 mm (0.003 in.)

Cover Out-of-Flat (Max.).....0.076 mm (0.003 in.)

Inner Rotor Thickness (Min.) .18.92 mm (0.744 in.)

Outer Rotor (Oil Pump)

Clearance (Max.)...........0.19 mm (0.007 in.)

Diameter (Min.)...........82.45 mm (3.246 in.)

Thickness (Min.)...........18.92 mm (0.744 in.)

Tip Clearance Between Rotors (Max.) . . .0.150 mm

(0.0068 in.)

Oil Pressure

At Curb Idle Speed*...........68.9 kPa (10 psi)

At 3000 rpm.........310 - 517 kPa (45 - 75 psi)

CAUTION: * If pressure is ZERO at curb Idle, DO

NOT run engine at 3,000 rpm.

TORQUE CHART 3.0L

DESCRIPTION TORQUE

Camshaft Bearing Cap

Bolts. . .Refer to procedure outlined in this section.

Camshaft Sensor Pick Up

Bolts.....................27N´m(20ft.lbs.)

Timing Belt Cover

Outer to Inner Attaching Bolts..........4.5 N´m

(40 in. lbs.)

Inner Cover to Head/Oil Pump Bolts.....12N´m

(105 in. lbs.)

Camshaft Sprocket

Bolt......................95N´m(70ft.lbs.)

Connecting Rod Cap

Bolts..........27N´m(20ft.lbs.) Plus 1/4 Turn

Crankshaft Main Bearing Cap/Bedplate

M8 Bedplate Bolts.........34N´m(250 in. lbs.)

M11 Main Cap Bolts..................41N´m

(30 ft. lbs.) Plus 1/4 Turn

Crankshaft Vibration Damper

Bolt....................135 N´m (100 ft. lbs.)DESCRIPTION TORQUE

Cylinder Head

Bolts........Refer To Cylinder Head Installation

Cylinder Head Cover

Bolts....................12N´m(105 in. lbs.)

Engine Mount Bracket

Bolts.....................41N´m(30ft.lbs.)

Engine MountÐFront and Rear

Through Bolt...............61N´m(45ft.lbs.)

Exhaust Manifold to Cylinder Head

Bolts....................23N´m(200 in. lbs.)

Exhaust Manifold Heat Shield

Bolts....................12N´m(105 in. lbs.)

Intake Manifold

Bolts.....................27N´m(20ft.lbs.)

Oil Filter to Engine Block Adapter

Bolts.....................55N´m(40ft.lbs.)

Oil Filter

Filter.....................20N´m(15ft.lbs.)

Oil Pan

Oil Pan Bolts.............12N´m(105 in. lbs.)

Drain Plug.................39N´m(29ft.lbs.)

Oil Pump Attaching

Bolts....................15N´m(130 in. lbs.)

Oil Pump Cover Fastener.....9N´m(104 in. lbs.)

Oil Pump Pick-up Tube Bolt . .28 N´m (250 in. lbs.)

Oil Pump Relief Valve Cap. . . .49 N´m (36 ft. lbs.)

Spark Plugs

Plugs.....................28N´m(20ft.lbs.)

Thermostat Housing

Bolts....................23N´m(200 in lbs.)

Timing Belt Tensioner

Bolt......................28N´m(20ft.lbs.)

Timing Belt Tensioner Pulley Assembly

Bolt......................41N´m(30ft.lbs.)

Water Pump Mounting

Bolts....................12N´m(105 in. lbs.)

9 - 90 3.0L ENGINENS

SPECIFICATIONS (Continued)

Page 1143 of 1938

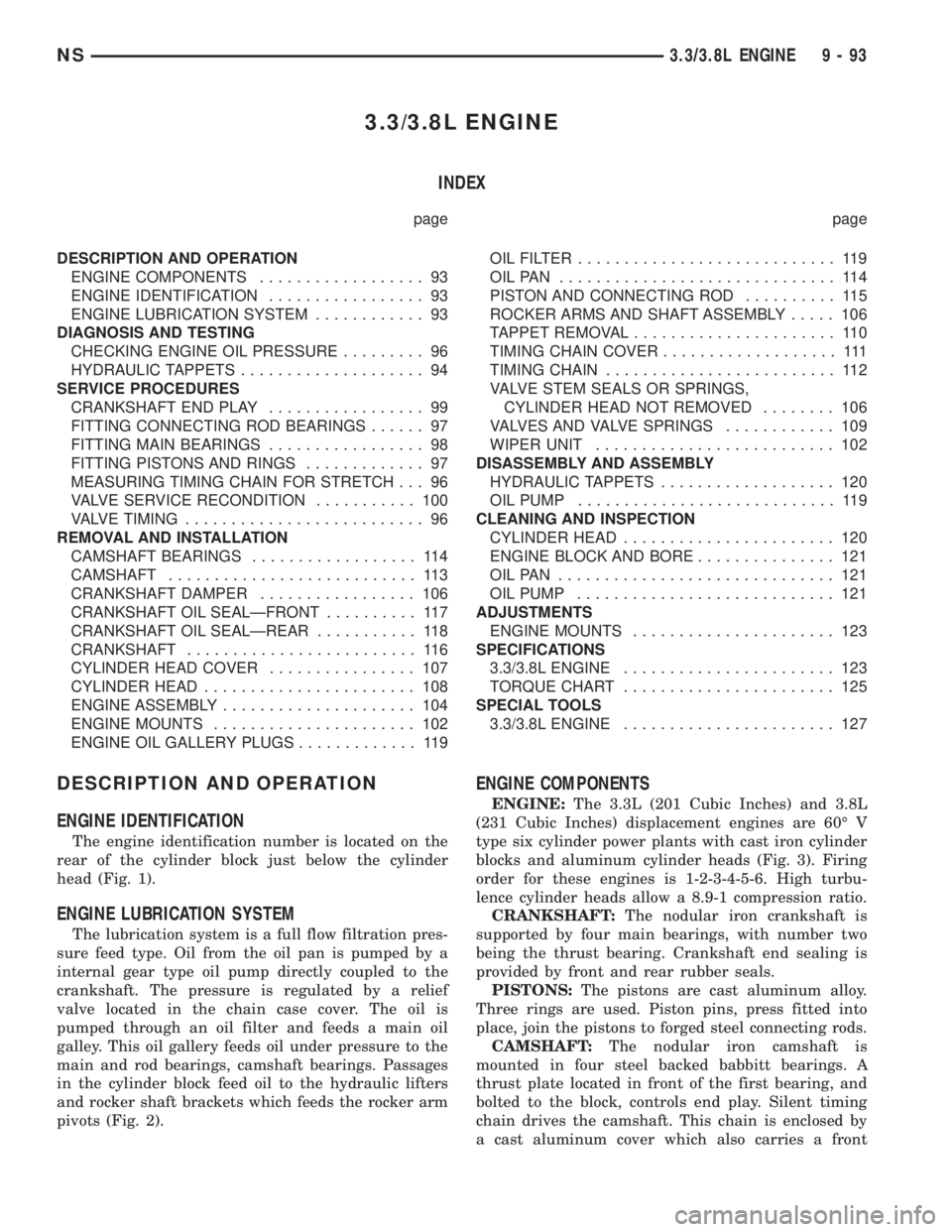

3.3/3.8L ENGINE

INDEX

page page

DESCRIPTION AND OPERATION

ENGINE COMPONENTS.................. 93

ENGINE IDENTIFICATION................. 93

ENGINE LUBRICATION SYSTEM............ 93

DIAGNOSIS AND TESTING

CHECKING ENGINE OIL PRESSURE......... 96

HYDRAULIC TAPPETS.................... 94

SERVICE PROCEDURES

CRANKSHAFT END PLAY................. 99

FITTING CONNECTING ROD BEARINGS...... 97

FITTING MAIN BEARINGS................. 98

FITTING PISTONS AND RINGS............. 97

MEASURING TIMING CHAIN FOR STRETCH . . . 96

VALVE SERVICE RECONDITION........... 100

VALVE TIMING.......................... 96

REMOVAL AND INSTALLATION

CAMSHAFT BEARINGS.................. 114

CAMSHAFT........................... 113

CRANKSHAFT DAMPER................. 106

CRANKSHAFT OIL SEALÐFRONT.......... 117

CRANKSHAFT OIL SEALÐREAR........... 118

CRANKSHAFT......................... 116

CYLINDER HEAD COVER................ 107

CYLINDER HEAD....................... 108

ENGINE ASSEMBLY..................... 104

ENGINE MOUNTS...................... 102

ENGINE OIL GALLERY PLUGS............. 119OILFILTER ............................ 119

OILPAN .............................. 114

PISTON AND CONNECTING ROD.......... 115

ROCKER ARMS AND SHAFT ASSEMBLY..... 106

TAPPET REMOVAL...................... 110

TIMING CHAIN COVER................... 111

TIMING CHAIN......................... 112

VALVE STEM SEALS OR SPRINGS,

CYLINDER HEAD NOT REMOVED........ 106

VALVES AND VALVE SPRINGS............ 109

WIPER UNIT.......................... 102

DISASSEMBLY AND ASSEMBLY

HYDRAULIC TAPPETS................... 120

OIL PUMP............................ 119

CLEANING AND INSPECTION

CYLINDER HEAD....................... 120

ENGINE BLOCK AND BORE............... 121

OILPAN .............................. 121

OIL PUMP............................ 121

ADJUSTMENTS

ENGINE MOUNTS...................... 123

SPECIFICATIONS

3.3/3.8L ENGINE....................... 123

TORQUE CHART....................... 125

SPECIAL TOOLS

3.3/3.8L ENGINE....................... 127

DESCRIPTION AND OPERATION

ENGINE IDENTIFICATION

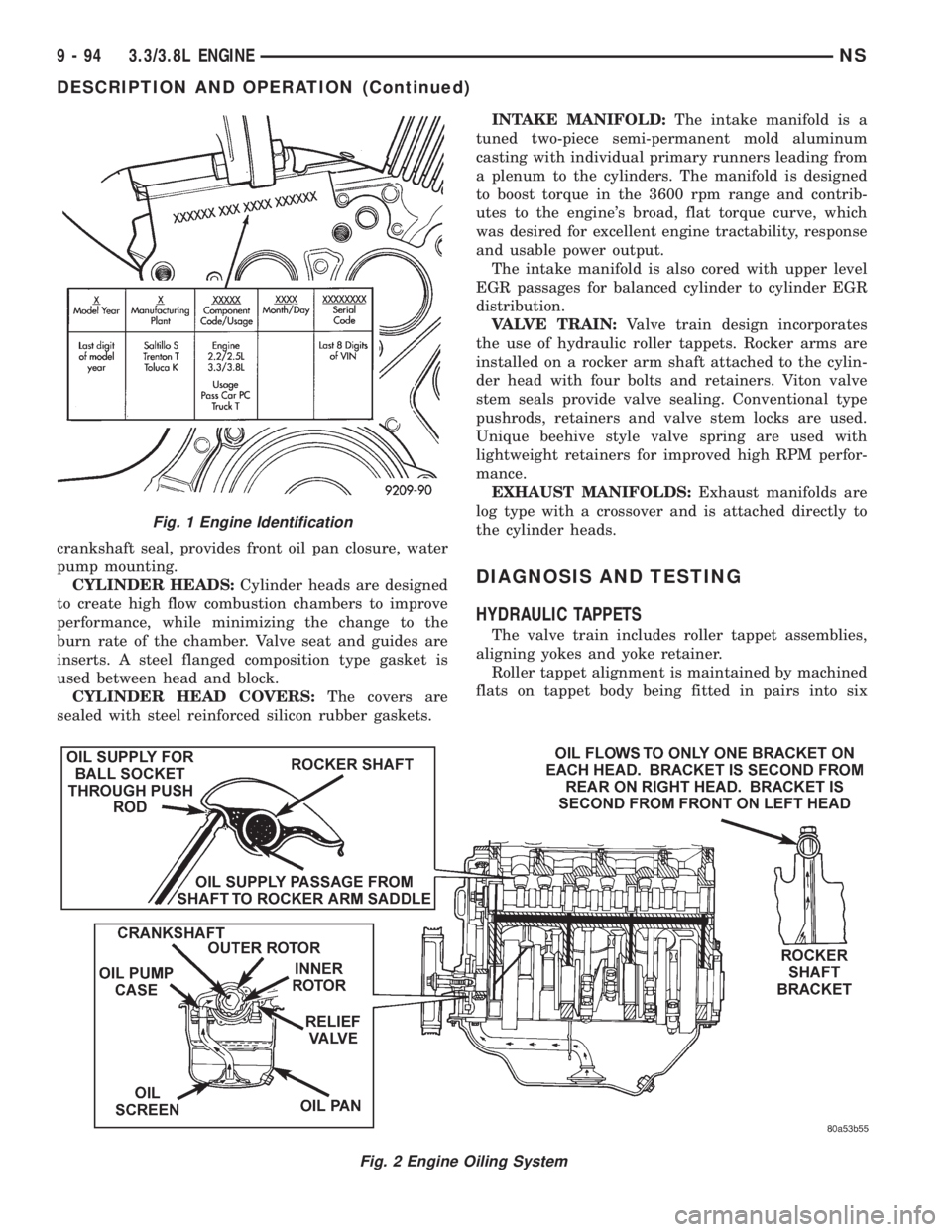

The engine identification number is located on the

rear of the cylinder block just below the cylinder

head (Fig. 1).

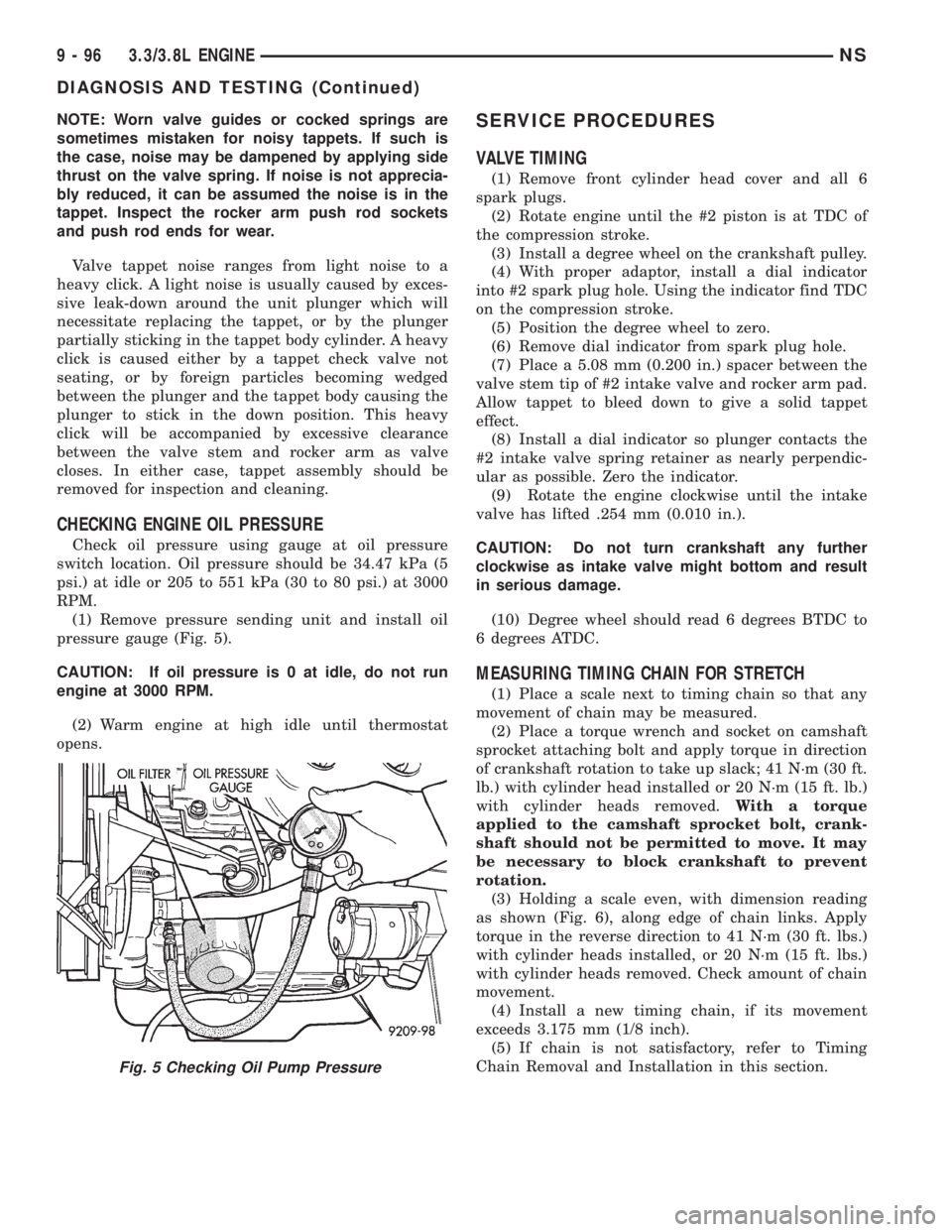

ENGINE LUBRICATION SYSTEM

The lubrication system is a full flow filtration pres-

sure feed type. Oil from the oil pan is pumped by a

internal gear type oil pump directly coupled to the

crankshaft. The pressure is regulated by a relief

valve located in the chain case cover. The oil is

pumped through an oil filter and feeds a main oil

galley. This oil gallery feeds oil under pressure to the

main and rod bearings, camshaft bearings. Passages

in the cylinder block feed oil to the hydraulic lifters

and rocker shaft brackets which feeds the rocker arm

pivots (Fig. 2).

ENGINE COMPONENTS

ENGINE:The 3.3L (201 Cubic Inches) and 3.8L

(231 Cubic Inches) displacement engines are 60É V

type six cylinder power plants with cast iron cylinder

blocks and aluminum cylinder heads (Fig. 3). Firing

order for these engines is 1-2-3-4-5-6. High turbu-

lence cylinder heads allow a 8.9-1 compression ratio.

CRANKSHAFT:The nodular iron crankshaft is

supported by four main bearings, with number two

being the thrust bearing. Crankshaft end sealing is

provided by front and rear rubber seals.

PISTONS:The pistons are cast aluminum alloy.

Three rings are used. Piston pins, press fitted into

place, join the pistons to forged steel connecting rods.

CAMSHAFT:The nodular iron camshaft is

mounted in four steel backed babbitt bearings. A

thrust plate located in front of the first bearing, and

bolted to the block, controls end play. Silent timing

chain drives the camshaft. This chain is enclosed by

a cast aluminum cover which also carries a front

NS3.3/3.8L ENGINE 9 - 93

Page 1144 of 1938

crankshaft seal, provides front oil pan closure, water

pump mounting.

CYLINDER HEADS:Cylinder heads are designed

to create high flow combustion chambers to improve

performance, while minimizing the change to the

burn rate of the chamber. Valve seat and guides are

inserts. A steel flanged composition type gasket is

used between head and block.

CYLINDER HEAD COVERS:The covers are

sealed with steel reinforced silicon rubber gaskets.INTAKE MANIFOLD:The intake manifold is a

tuned two-piece semi-permanent mold aluminum

casting with individual primary runners leading from

a plenum to the cylinders. The manifold is designed

to boost torque in the 3600 rpm range and contrib-

utes to the engine's broad, flat torque curve, which

was desired for excellent engine tractability, response

and usable power output.

The intake manifold is also cored with upper level

EGR passages for balanced cylinder to cylinder EGR

distribution.

VALVE TRAIN:Valve train design incorporates

the use of hydraulic roller tappets. Rocker arms are

installed on a rocker arm shaft attached to the cylin-

der head with four bolts and retainers. Viton valve

stem seals provide valve sealing. Conventional type

pushrods, retainers and valve stem locks are used.

Unique beehive style valve spring are used with

lightweight retainers for improved high RPM perfor-

mance.

EXHAUST MANIFOLDS:Exhaust manifolds are

log type with a crossover and is attached directly to

the cylinder heads.

DIAGNOSIS AND TESTING

HYDRAULIC TAPPETS

The valve train includes roller tappet assemblies,

aligning yokes and yoke retainer.

Roller tappet alignment is maintained by machined

flats on tappet body being fitted in pairs into six

Fig. 2 Engine Oiling System

Fig. 1 Engine Identification

9 - 94 3.3/3.8L ENGINENS

DESCRIPTION AND OPERATION (Continued)

Page 1146 of 1938

NOTE: Worn valve guides or cocked springs are

sometimes mistaken for noisy tappets. If such is

the case, noise may be dampened by applying side

thrust on the valve spring. If noise is not apprecia-

bly reduced, it can be assumed the noise is in the

tappet. Inspect the rocker arm push rod sockets

and push rod ends for wear.

Valve tappet noise ranges from light noise to a

heavy click. A light noise is usually caused by exces-

sive leak-down around the unit plunger which will

necessitate replacing the tappet, or by the plunger

partially sticking in the tappet body cylinder. A heavy

click is caused either by a tappet check valve not

seating, or by foreign particles becoming wedged

between the plunger and the tappet body causing the

plunger to stick in the down position. This heavy

click will be accompanied by excessive clearance

between the valve stem and rocker arm as valve

closes. In either case, tappet assembly should be

removed for inspection and cleaning.

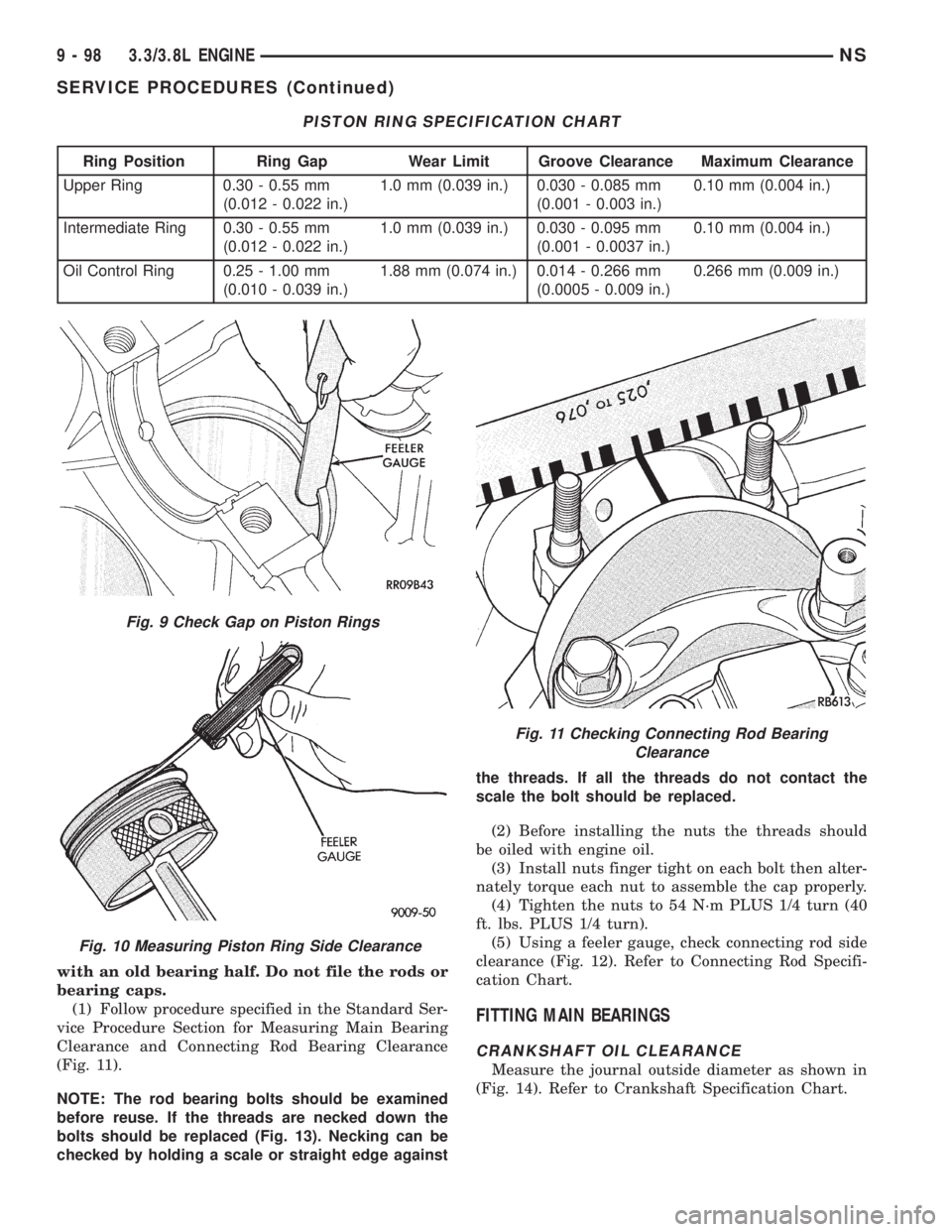

CHECKING ENGINE OIL PRESSURE

Check oil pressure using gauge at oil pressure

switch location. Oil pressure should be 34.47 kPa (5

psi.) at idle or 205 to 551 kPa (30 to 80 psi.) at 3000

RPM.

(1) Remove pressure sending unit and install oil

pressure gauge (Fig. 5).

CAUTION: If oil pressure is 0 at idle, do not run

engine at 3000 RPM.

(2) Warm engine at high idle until thermostat

opens.

SERVICE PROCEDURES

VALVE TIMING

(1) Remove front cylinder head cover and all 6

spark plugs.

(2) Rotate engine until the #2 piston is at TDC of

the compression stroke.

(3) Install a degree wheel on the crankshaft pulley.

(4) With proper adaptor, install a dial indicator

into #2 spark plug hole. Using the indicator find TDC

on the compression stroke.

(5) Position the degree wheel to zero.

(6) Remove dial indicator from spark plug hole.

(7) Place a 5.08 mm (0.200 in.) spacer between the

valve stem tip of #2 intake valve and rocker arm pad.

Allow tappet to bleed down to give a solid tappet

effect.

(8) Install a dial indicator so plunger contacts the

#2 intake valve spring retainer as nearly perpendic-

ular as possible. Zero the indicator.

(9) Rotate the engine clockwise until the intake

valve has lifted .254 mm (0.010 in.).

CAUTION: Do not turn crankshaft any further

clockwise as intake valve might bottom and result

in serious damage.

(10) Degree wheel should read 6 degrees BTDC to

6 degrees ATDC.

MEASURING TIMING CHAIN FOR STRETCH

(1) Place a scale next to timing chain so that any

movement of chain may be measured.

(2) Place a torque wrench and socket on camshaft

sprocket attaching bolt and apply torque in direction

of crankshaft rotation to take up slack; 41 N´m (30 ft.

lb.) with cylinder head installed or 20 N´m (15 ft. lb.)

with cylinder heads removed.With a torque

applied to the camshaft sprocket bolt, crank-

shaft should not be permitted to move. It may

be necessary to block crankshaft to prevent

rotation.

(3) Holding a scale even, with dimension reading

as shown (Fig. 6), along edge of chain links. Apply

torque in the reverse direction to 41 N´m (30 ft. lbs.)

with cylinder heads installed, or 20 N´m (15 ft. lbs.)

with cylinder heads removed. Check amount of chain

movement.

(4) Install a new timing chain, if its movement

exceeds 3.175 mm (1/8 inch).

(5) If chain is not satisfactory, refer to Timing

Chain Removal and Installation in this section.

Fig. 5 Checking Oil Pump Pressure

9 - 96 3.3/3.8L ENGINENS

DIAGNOSIS AND TESTING (Continued)

Page 1148 of 1938

with an old bearing half. Do not file the rods or

bearing caps.

(1) Follow procedure specified in the Standard Ser-

vice Procedure Section for Measuring Main Bearing

Clearance and Connecting Rod Bearing Clearance

(Fig. 11).

NOTE: The rod bearing bolts should be examined

before reuse. If the threads are necked down the

bolts should be replaced (Fig. 13). Necking can be

checked by holding a scale or straight edge againstthe threads. If all the threads do not contact the

scale the bolt should be replaced.

(2) Before installing the nuts the threads should

be oiled with engine oil.

(3) Install nuts finger tight on each bolt then alter-

nately torque each nut to assemble the cap properly.

(4) Tighten the nuts to 54 N´m PLUS 1/4 turn (40

ft. lbs. PLUS 1/4 turn).

(5) Using a feeler gauge, check connecting rod side

clearance (Fig. 12). Refer to Connecting Rod Specifi-

cation Chart.

FITTING MAIN BEARINGS

CRANKSHAFT OIL CLEARANCE

Measure the journal outside diameter as shown in

(Fig. 14). Refer to Crankshaft Specification Chart.

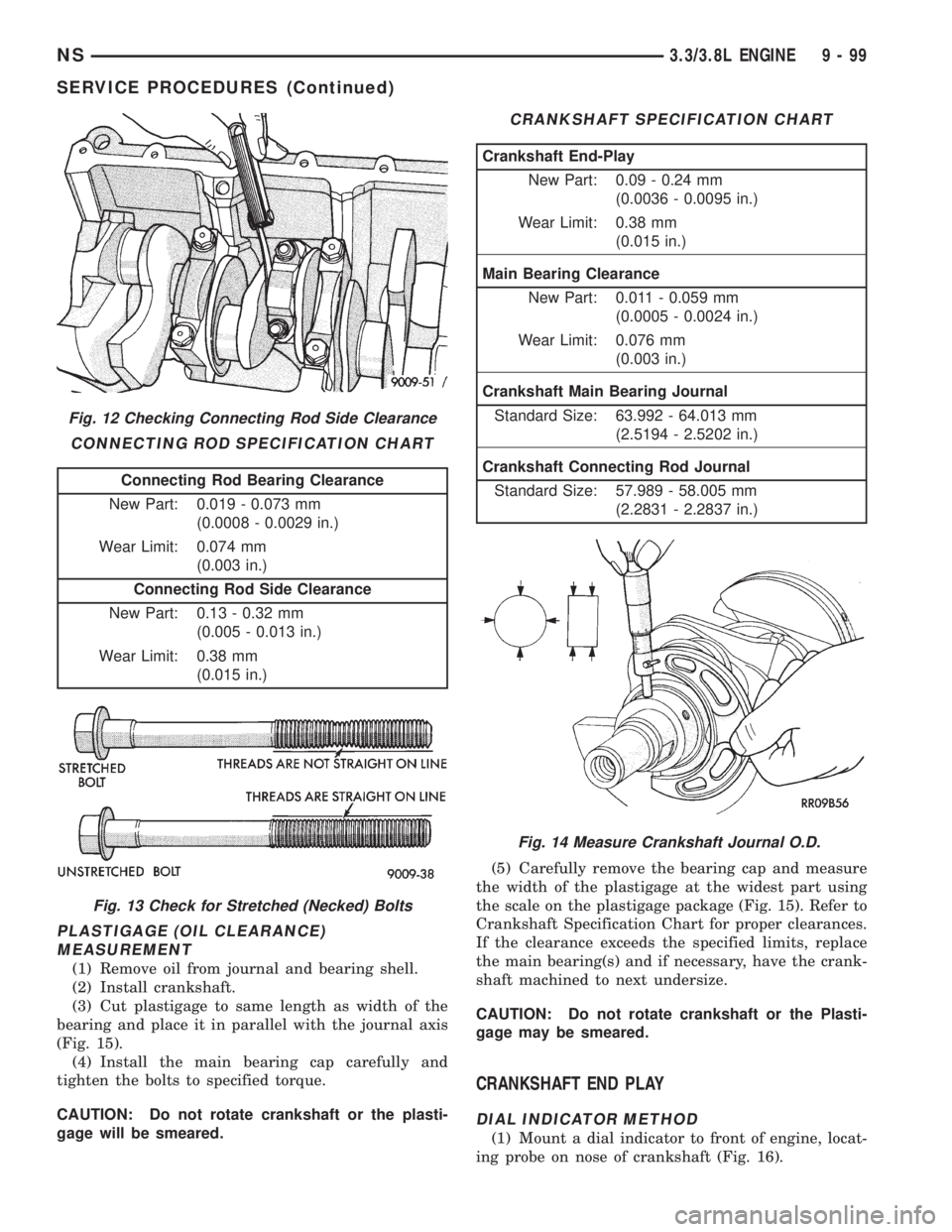

PISTON RING SPECIFICATION CHART

Ring Position Ring Gap Wear Limit Groove Clearance Maximum Clearance

Upper Ring 0.30 - 0.55 mm

(0.012 - 0.022 in.)1.0 mm (0.039 in.) 0.030 - 0.085 mm

(0.001 - 0.003 in.)0.10 mm (0.004 in.)

Intermediate Ring 0.30 - 0.55 mm

(0.012 - 0.022 in.)1.0 mm (0.039 in.) 0.030 - 0.095 mm

(0.001 - 0.0037 in.)0.10 mm (0.004 in.)

Oil Control Ring 0.25 - 1.00 mm

(0.010 - 0.039 in.)1.88 mm (0.074 in.) 0.014 - 0.266 mm

(0.0005 - 0.009 in.)0.266 mm (0.009 in.)

Fig. 9 Check Gap on Piston Rings

Fig. 10 Measuring Piston Ring Side Clearance

Fig. 11 Checking Connecting Rod Bearing

Clearance

9 - 98 3.3/3.8L ENGINENS

SERVICE PROCEDURES (Continued)

Page 1149 of 1938

PLASTIGAGE (OIL CLEARANCE)

MEASUREMENT

(1) Remove oil from journal and bearing shell.

(2) Install crankshaft.

(3) Cut plastigage to same length as width of the

bearing and place it in parallel with the journal axis

(Fig. 15).

(4) Install the main bearing cap carefully and

tighten the bolts to specified torque.

CAUTION: Do not rotate crankshaft or the plasti-

gage will be smeared.(5) Carefully remove the bearing cap and measure

the width of the plastigage at the widest part using

the scale on the plastigage package (Fig. 15). Refer to

Crankshaft Specification Chart for proper clearances.

If the clearance exceeds the specified limits, replace

the main bearing(s) and if necessary, have the crank-

shaft machined to next undersize.

CAUTION: Do not rotate crankshaft or the Plasti-

gage may be smeared.

CRANKSHAFT END PLAY

DIAL INDICATOR METHOD

(1) Mount a dial indicator to front of engine, locat-

ing probe on nose of crankshaft (Fig. 16).

Fig. 12 Checking Connecting Rod Side Clearance

CONNECTING ROD SPECIFICATION CHART

Connecting Rod Bearing Clearance

New Part: 0.019 - 0.073 mm

(0.0008 - 0.0029 in.)

Wear Limit: 0.074 mm

(0.003 in.)

Connecting Rod Side Clearance

New Part: 0.13 - 0.32 mm

(0.005 - 0.013 in.)

Wear Limit: 0.38 mm

(0.015 in.)

Fig. 13 Check for Stretched (Necked) Bolts

CRANKSHAFT SPECIFICATION CHART

Crankshaft End-Play

New Part: 0.09 - 0.24 mm

(0.0036 - 0.0095 in.)

Wear Limit: 0.38 mm

(0.015 in.)

Main Bearing Clearance

New Part: 0.011 - 0.059 mm

(0.0005 - 0.0024 in.)

Wear Limit: 0.076 mm

(0.003 in.)

Crankshaft Main Bearing Journal

Standard Size: 63.992 - 64.013 mm

(2.5194 - 2.5202 in.)

Crankshaft Connecting Rod Journal

Standard Size: 57.989 - 58.005 mm

(2.2831 - 2.2837 in.)

Fig. 14 Measure Crankshaft Journal O.D.

NS3.3/3.8L ENGINE 9 - 99

SERVICE PROCEDURES (Continued)

Page 1152 of 1938

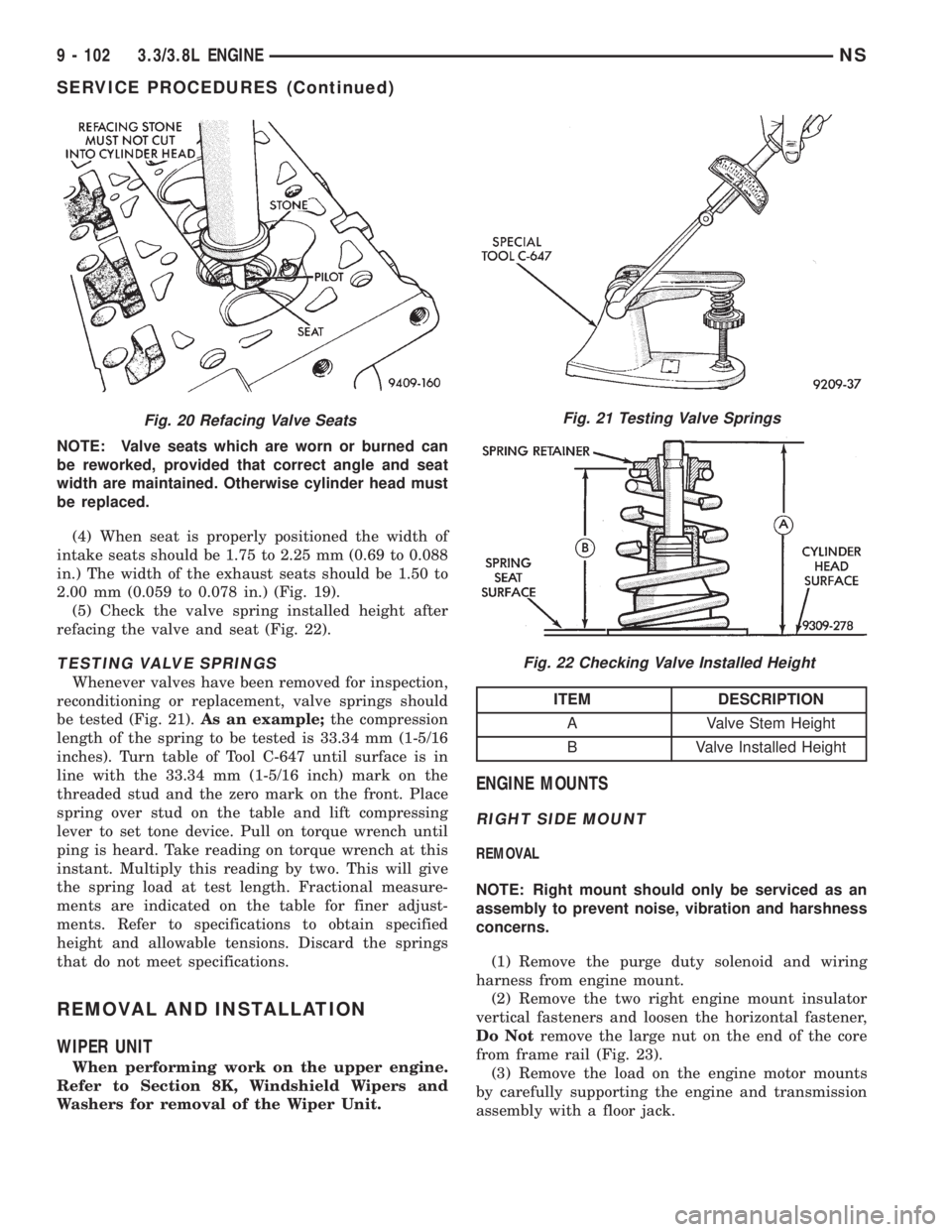

NOTE: Valve seats which are worn or burned can

be reworked, provided that correct angle and seat

width are maintained. Otherwise cylinder head must

be replaced.

(4) When seat is properly positioned the width of

intake seats should be 1.75 to 2.25 mm (0.69 to 0.088

in.) The width of the exhaust seats should be 1.50 to

2.00 mm (0.059 to 0.078 in.) (Fig. 19).

(5) Check the valve spring installed height after

refacing the valve and seat (Fig. 22).

TESTING VALVE SPRINGS

Whenever valves have been removed for inspection,

reconditioning or replacement, valve springs should

be tested (Fig. 21).As an example;the compression

length of the spring to be tested is 33.34 mm (1-5/16

inches). Turn table of Tool C-647 until surface is in

line with the 33.34 mm (1-5/16 inch) mark on the

threaded stud and the zero mark on the front. Place

spring over stud on the table and lift compressing

lever to set tone device. Pull on torque wrench until

ping is heard. Take reading on torque wrench at this

instant. Multiply this reading by two. This will give

the spring load at test length. Fractional measure-

ments are indicated on the table for finer adjust-

ments. Refer to specifications to obtain specified

height and allowable tensions. Discard the springs

that do not meet specifications.

REMOVAL AND INSTALLATION

WIPER UNIT

When performing work on the upper engine.

Refer to Section 8K, Windshield Wipers and

Washers for removal of the Wiper Unit.

ENGINE MOUNTS

RIGHT SIDE MOUNT

REMOVAL

NOTE: Right mount should only be serviced as an

assembly to prevent noise, vibration and harshness

concerns.

(1) Remove the purge duty solenoid and wiring

harness from engine mount.

(2) Remove the two right engine mount insulator

vertical fasteners and loosen the horizontal fastener,

Do Notremove the large nut on the end of the core

from frame rail (Fig. 23).

(3) Remove the load on the engine motor mounts

by carefully supporting the engine and transmission

assembly with a floor jack.

Fig. 20 Refacing Valve SeatsFig. 21 Testing Valve Springs

Fig. 22 Checking Valve Installed Height

ITEM DESCRIPTION

A Valve Stem Height

B Valve Installed Height

9 - 102 3.3/3.8L ENGINENS

SERVICE PROCEDURES (Continued)

Page 1155 of 1938

(20) Remove rear transmission mount and bracket.

(21) Remove power steering pump and bracket

assembly.

(22) Remove wiring harness and connectors from

front of engine.

(23) Remove bending braces and install tool num-

ber 6912 on engine.

(24) Remove transmission inspection cover and

mark flexplate to torque converter.

(25) Remove driveplate to torque converter bolts.

(26) Lower the vehicle.

(27) Remove ground straps to body.

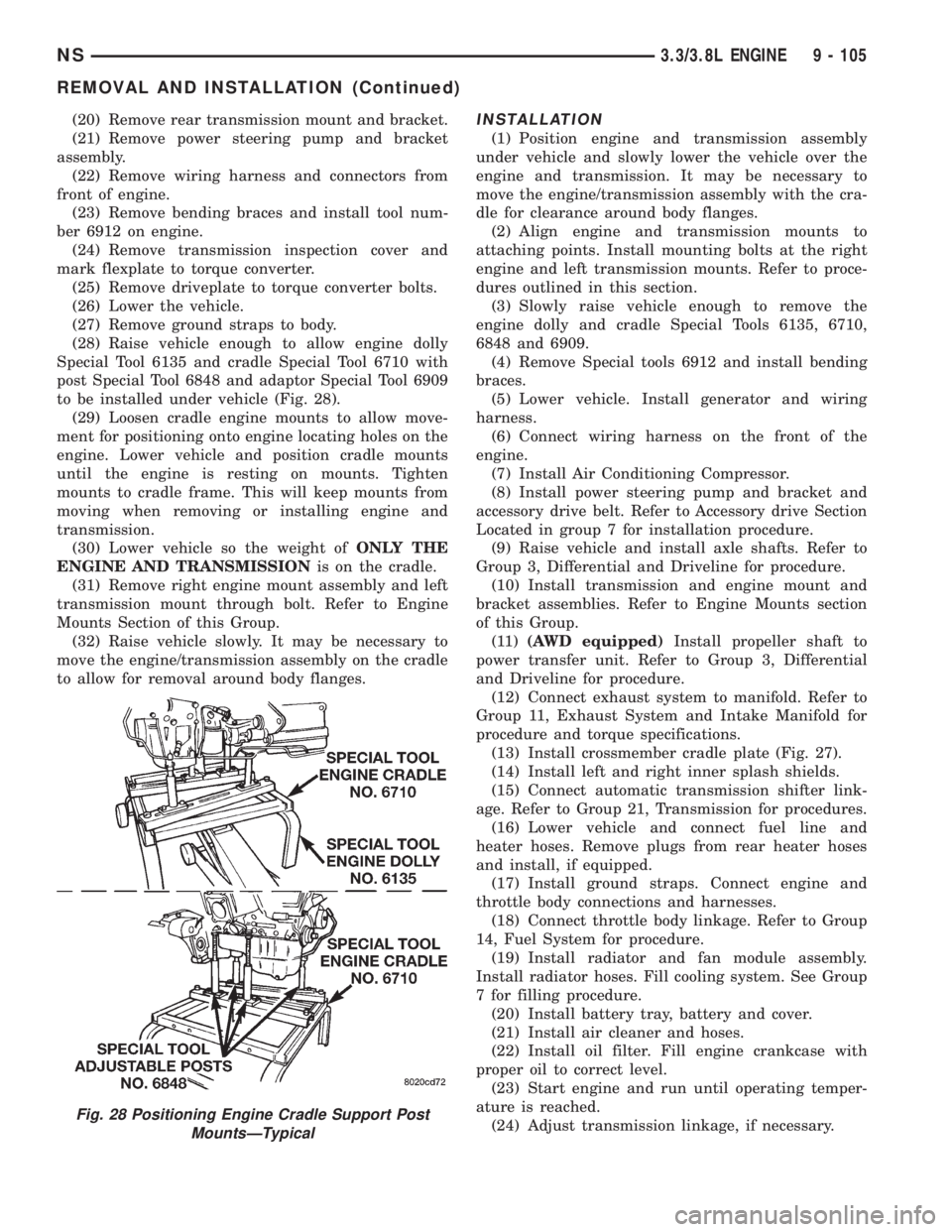

(28) Raise vehicle enough to allow engine dolly

Special Tool 6135 and cradle Special Tool 6710 with

post Special Tool 6848 and adaptor Special Tool 6909

to be installed under vehicle (Fig. 28).

(29) Loosen cradle engine mounts to allow move-

ment for positioning onto engine locating holes on the

engine. Lower vehicle and position cradle mounts

until the engine is resting on mounts. Tighten

mounts to cradle frame. This will keep mounts from

moving when removing or installing engine and

transmission.

(30) Lower vehicle so the weight ofONLY THE

ENGINE AND TRANSMISSIONis on the cradle.

(31) Remove right engine mount assembly and left

transmission mount through bolt. Refer to Engine

Mounts Section of this Group.

(32) Raise vehicle slowly. It may be necessary to

move the engine/transmission assembly on the cradle

to allow for removal around body flanges.INSTALLATION

(1) Position engine and transmission assembly

under vehicle and slowly lower the vehicle over the

engine and transmission. It may be necessary to

move the engine/transmission assembly with the cra-

dle for clearance around body flanges.

(2) Align engine and transmission mounts to

attaching points. Install mounting bolts at the right

engine and left transmission mounts. Refer to proce-

dures outlined in this section.

(3) Slowly raise vehicle enough to remove the

engine dolly and cradle Special Tools 6135, 6710,

6848 and 6909.

(4) Remove Special tools 6912 and install bending

braces.

(5) Lower vehicle. Install generator and wiring

harness.

(6) Connect wiring harness on the front of the

engine.

(7) Install Air Conditioning Compressor.

(8) Install power steering pump and bracket and

accessory drive belt. Refer to Accessory drive Section

Located in group 7 for installation procedure.

(9) Raise vehicle and install axle shafts. Refer to

Group 3, Differential and Driveline for procedure.

(10) Install transmission and engine mount and

bracket assemblies. Refer to Engine Mounts section

of this Group.

(11)(AWD equipped)Install propeller shaft to

power transfer unit. Refer to Group 3, Differential

and Driveline for procedure.

(12) Connect exhaust system to manifold. Refer to

Group 11, Exhaust System and Intake Manifold for

procedure and torque specifications.

(13) Install crossmember cradle plate (Fig. 27).

(14) Install left and right inner splash shields.

(15) Connect automatic transmission shifter link-

age. Refer to Group 21, Transmission for procedures.

(16) Lower vehicle and connect fuel line and

heater hoses. Remove plugs from rear heater hoses

and install, if equipped.

(17) Install ground straps. Connect engine and

throttle body connections and harnesses.

(18) Connect throttle body linkage. Refer to Group

14, Fuel System for procedure.

(19) Install radiator and fan module assembly.

Install radiator hoses. Fill cooling system. See Group

7 for filling procedure.

(20) Install battery tray, battery and cover.

(21) Install air cleaner and hoses.

(22) Install oil filter. Fill engine crankcase with

proper oil to correct level.

(23) Start engine and run until operating temper-

ature is reached.

(24) Adjust transmission linkage, if necessary.

Fig. 28 Positioning Engine Cradle Support Post

MountsÐTypical

NS3.3/3.8L ENGINE 9 - 105

REMOVAL AND INSTALLATION (Continued)