CHRYSLER VOYAGER 2001 Service Manual

Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 2071 of 4284

NOTE: The following tests may not prove conclu-

sive in the diagnosis of this system. The most reli-

able, efficient, and accurate means to diagnose the

Sentry Key Immobilizer System involves the use of

a DRB IIITscan tool. Refer to the proper Body Diag-

nostic Procedures Manual.

The Sentry Key Immobilizer System (SKIS) and

the Programmable Communication Interface (PCI)

bus network should be diagnosed using a DRB IIIt

scan tool. The DRB IIItwill allow confirmation that

the PCI bus is functional, that the Sentry Key Immo-

bilizer Module (SKIM) is placing the proper messages

on the PCI bus, and that the Powertrain Control

Module (PCM) is receiving the PCI bus messages.

Refer to the proper Body Diagnostic Procedures man-

ual, and Wiring Diagrams for complete circuit

descriptions and diagrams.

(1) Check the fuses in the Integrated Power Mod-

ule (IPM). If OK, go to Step 2. If not OK, repair the

shorted circuit or component as required and replace

the faulty fuse.

(2) Disconnect and isolate the battery negative

remote cable from the remote terminal. Unplug the

wire harness connector at the SKIM. Check for con-

tinuity between the ground circuit cavity of the

SKIM wire harness connector and a good ground.

There should be continuity. If OK, go to Step 3. If not

OK, repair the open circuit to ground as required.

(3) Connect the battery negative cable. Check for

battery voltage at the fused B(+) circuit cavity of the

SKIM wire harness connector. If OK, go to Step 4. If

not OK, repair the open circuit to the fuse in the

IPM as required.

(4) Turn the ignition switch to the ON position.

Check for battery voltage at the fused ignition switch

output (run/start) circuit cavity of the SKIM wire

harness connector. If OK, use a DRB IIItscan tool

and the proper Body Diagnostic Procedures manual

to complete the diagnosis of the SKIS. If not OK,

repair the open circuit to the fuse in the IPM as

required.

DIAGNOSIS AND TESTING - VEHICLE THEFT

SECURITY SYSTEM

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, further details

on wire harness routing and retention, as well as

pin-out and location views for the various wire har-

ness connectors, splices and grounds. Using a DRB

IIItscan tool. Refer to the proper Body Diagnostic

Procedures Manual for test procedures.

HOOD AJAR SWITCH

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Using a small flat blade screwdriver, pry trig-

ger switch from the bracket on the left fender well.

(3) Disconnect the hood ajar switch from the wire

connector and remove from vehicle.

INSTALLATION

(1) Connect the hood ajar switch to the wire conec-

tor.

(2) Press the hood ajar switch into position on the

bracket located on the left inner fender well.

(3) Reconnect the battery negative cable.

(4) Close the hood and check for proper operation.

TRANSPONDER KEY

DESCRIPTION

The Sentry Key Immobilizer System (SKIS) uses a

transponder chip that is integral to each ignition key

(Fig. 1) to communicate with the Sentry Key Immo-

bilizer Module (SKIM). Ignition keys are supplied

with the vehicle when it is shipped from the factory.

The transponder chip is undermolded within the

head of the key. This undermold is hidden beneath

an overmolded rubber cap.

Fig. 1 TRANSPONDER KEY - TYPICAL

1 - MOLDED CAP

2 - TRANSPONDER

3 - MOLDED CAP REMOVED

4 - SENTRY KEY

RSVEHICLE THEFT SECURITY8Q-3

VEHICLE THEFT SECURITY (Continued)

Page 2072 of 4284

OPERATION

Each Sentry Key has a unique transponder identi-

fication code permanently programmed into it by the

manufacturer. Likewise, the SKIM has a unique

9Secret Key9code programmed into it by the manu-

facturer as well. When a Sentry Key is programmed

into the memory of the SKIM, the SKIM stores the

transponder identification code from the Sentry Key,

and the Sentry Key learns the9Secret Key9code from

the SKIM. Once the Sentry Key learns the9Secret

Key9code of the SKIM, it is also permanently pro-

grammed into the transponder's memory. Therefore,

blank keys for the SKIS must be programmed by the

SKIM in addition to being cut to match the mechan-

ical coding of the ignition lock cylinder. Refer to Elec-

trical, Vehicle Theft Security, Transponder Key,

Standard Procedure - Transponder Programming.

The Sentry Key's transponder is within the range

of the SKIM's transceiver antenna ring when it is

inserted into the ignition lock cylinder. When the

ignition switch is turned to the ON position, the

SKIM communicates with the Sentry Key via a radio

frequency (RF) signal. The SKIM determines if a

valid key is present based on the information it

receives from the Sentry Key. If a valid key is

detected, that fact is communicated to the PCM via

the PCI bus and the vehicle is allowed to continue

running. If an invalid key is received by the PCM or

no status at all is communicated, the vehicle will

stall after two (2) seconds of running. The indicator

light will be flashing at this point. The Sentry Key's

transponder can not be repaired. If it is faulty or

damaged, it must be replaced.

Common communication problems:

²Two transponder keys too close together.

²Speed Pass too close to transponder key.

Solid indicator that there is a system failure.

²Loss of PCM communication.

²Failed antenna circuit.

STANDARD PROCEDURE - TRANSPONDER

PROGRAMMING

USING A DRB IIITSCAN TOOL

All Sentry Keys included with the vehicle are pre-

programmed to work with the Sentry Key Immobi-

lizer System (SKIS) when it is shipped from the

factory. The Sentry Key Immobilizer Module (SKIM)

can be programmed to recognize up to a total of eight

Sentry Keys. When programming a blank Sentry Key

transponder, the key must first be cut to match the

ignition lock cylinder of the vehicle for which it will

be used. The vehicle's four digit PIN code will be

required to complete this task since you will need it

to enter the Secured Access Mode in the SKIM. Thefollowing steps must be completed using a DRB IIIt

scan tool:

(1) Insert the blank key into the ignition and turn

it to the RUN position.

(2) Using a DRB IIItscan tool, select9Theft

Alarm,99SKIM,99Miscellaneous,9and then9Program

New Key.9

(3) Enter the four digit PIN code using the DRB

IIItscan tool. When programming is completed, the

SKIM will exit Secured Access Mode and the DRB

IIItscan tool will display the results of your attempt

to program the key. One of five distinct results may

be displayed. All five are listed below:

²(Programming Successful(is displayed if the

Sentry Key programming is successful.

²(Learned Key in Ignition(is displayed if the

key in the ignition has already been programmed

into that vehicle's SKIM.

²(Eight Keys Already Learned (At The Maxi-

mum) Programming Not Done(is displayed if

eight keys have already been programmed into the

SKIM. In this case, if a new key needs to be added

due to a lost or defective key, the9Erase All Keys9

command (which requires entering the Secured

Access Mode) has to be performed. Following the

9Erase All Keys9command, all keys that will be used

to operate the vehicleMUSTbe reprogrammed to

the SKIM.

²(Programming Not Attempted(is displayed

after an9Erase All Keys9function is executed.

²(Programming Key Failed(is displayed if fur-

ther diagnosis is required.

To learn additional keys, turn the ignition OFF,

remove the learned key, insert the next new blank

key, and repeat the steps from the beginning.

ªCUSTOMER LEARNº MODE

This feature is only available on domestic vehicles

or those which have a U.S. country code designator.

This procedure requires access to at least two valid

Sentry Keys. If two valid Sentry Keys are not avail-

able, Sentry Key programming will require the use of

a DRB IIItscan tool.

The steps required to program Sentry Keys with

two valid Sentry Keys follows:

(1) Obtain the blank Sentry Key(s) that need to be

programmed. Cut the keys to match the ignition lock

cylinder mechanical key codes.

(2) Insert one of the two valid Sentry Keys into the

ignition switch and turn the ignition switch to the

ON position.

(3) After the ignition switch has been in the ON

position for longer than three seconds, but no more

than fifteen seconds, cycle the ignition switch back to

8Q - 4 VEHICLE THEFT SECURITYRS

TRANSPONDER KEY (Continued)

Page 2073 of 4284

the OFF position. Replace the first valid Sentry Key

in the ignition lock cylinder with the second valid

Sentry Key and turn the ignition switch back to the

ON position. The second valid Sentry Key must be

inserted within 15 seconds of removing the first valid

Sentry key.

(4) About ten seconds after the completion of Step

3, the indicator light will start to flash and a single

audible chime tone will sound to indicate that the

system has entered the9Customer Learn9program-

ming mode.

(5) Within sixty seconds of entering the9Customer

Learn9programming mode, turn the ignition switch

to the OFF position, replace the valid Sentry Key

with a blank Sentry Key transponder, and turn the

ignition switch back to the ON position.

(6) About ten seconds after the completion of Step

5, a single audible chime tone will sound and the

indicator light will stop flashing and stay on solid for

three seconds and then turn off to indicate that the

blank Sentry Key has been successfully programmed.

The SKIS will immediately exit the9Customer

Learn9programming mode and the vehicle may be

started using the newly programmed Sentry Key.

These steps must be completed in their entirety for

each additional Sentry Key to be programmed. If any

of the above steps are not completed in the given

sequence, or within the allotted time, the SKIS will

exit the9Customer Learn9programming mode and

the programming will be unsuccessful. The SKIS will

also automatically exit the9Customer Learn9pro-

gramming mode if:

²It sees a non-blank Sentry Key when it should

see a blank.

²If it has already programmed eight (8) valid

Sentry Keys.

²If the ignition switch is turned to the OFF posi-

tion for more than about fifty (50) seconds.

NOTE: If you attempt to start the vehicle while in

ªCustomer Learnº mode (LED flashing), the vehicle

will behave as though an invalid key is being used

(i.e. the engine will stall after two (2) seconds of

running). No faults will be logged.

NOTE: Once a Sentry Key has been programmed to

a particular vehicle, it cannot be used on any other

vehicle.VTSS/SKIS INDICATOR LAMP

DESCRIPTION

The Sentry Key Immobilizer System (SKIS) uses

an indicator light to convey information on the status

of the system to the customer. This light is shared

with the Vehicle Theft Security System (VTSS). The

light is located in the Message Center. The indicator

light is controlled by the Body Control Module (BCM)

based upon messages it receives from the Sentry Key

Immobilizer Module (SKIM) on the PCI bus.

OPERATION

The BCM performs a four second bulb check,

regardless of SKIM messages. After the bulb check,

the lamp is controlled according to SKIM messages.

Then, the SKIM sends messages to the BCM to oper-

ate the light based upon the results of the SKIS self

tests. The light may be actuated in two possible

ways, flashing or on solid. If the light comes on and

stays on solid after a power-up test, this indicates

that the SKIM has detected a system malfunction. If

the SKIM detects an invalid key when the ignition

switch is moved to the ON position, it sends a mes-

sage on the PCI bus to the BCM, to flash the light.

The SKIM can also send a message to flash the light

and generate a single audible chime at the same

time. These two events occurring simultaneously

indicate that the SKIS has been placed into the9Cus-

tomer Learn9mode. Refer to Electrical, Vehicle Theft

Security, Transponder Key, Standard Procedure -

Transponder Programming for more information on

the9Customer Learn9mode. If the light comes on

and stays on after the power-up test, diagnosis of the

SKIS should be performed using a DRB IIItscan tool

and the appropriate Body Diagnostic Procedures

manual. The light is not a serviceable component.

RSVEHICLE THEFT SECURITY8Q-5

TRANSPONDER KEY (Continued)

Page 2074 of 4284

Page 2075 of 4284

WIPERS/WASHERS

TABLE OF CONTENTS

page page

WIPERS/WASHERS

DESCRIPTION............................1

OPERATION.............................1

DIAGNOSIS AND TESTING..................2

FRONT WIPER SYSTEM..................2

REAR WIPER SYSTEM...................2

FRONT WIPER/WASHER SWITCH...........2

FAILED PARK SWITCH...................2

FRONT WIPER ARMS

REMOVAL...............................4

INSTALLATION............................4

ADJUSTMENTS...........................4

FRONT WIPER MOTOR

REMOVAL...............................5

INSTALLATION............................5

FRONT WIPER UNIT

REMOVAL...............................5

INSTALLATION............................6

REAR WIPER ARM

REMOVAL...............................6

INSTALLATION............................7

REAR WIPER MOTOR

REMOVAL...............................7INSTALLATION............................7

REAR WIPER/WASHER SWITCH

DESCRIPTION............................7

OPERATION.............................7

WASHER HOSES

REMOVAL...............................7

INSTALLATION............................8

WASHER RESERVOIR

REMOVAL...............................8

INSTALLATION............................8

WIPER BLADES

REMOVAL...............................9

CLEANING...............................9

INSTALLATION............................9

WIPER BLADE ELEMENTS

REMOVAL...............................9

INSTALLATION...........................10

WIPER LINKAGE

REMOVAL..............................10

INSTALLATION...........................10

WIPERS/WASHERS

DESCRIPTION

FRONT WIPER/WASHER SYSTEM

The windshield wipers can be operated with the

windshield wiper switch when the ignition switch is

in the RUN or ACCESSORY positions. The wind-

shield wiper system is protected by a 30 amp fuse (9)

located in the Power Distribution Center (PDC) part

of the Integrated Power Module (IPM) in the engine

compartment. The wiper/washer switch is integral to

the multi-function switch. It is a resistive MUX

switch that sends inputs to the BCM to operate the

wiper/washer system.

REAR WIPER/WASHER SYSTEM

The rear windshield wiper and washers can be

operated when the ignition switch is in the RUN or

ACCESSORY positions.

OPERATION

FRONT WIPER/WASHER SYSTEM

The windshield washer circuit is protected by a 9

amp PTC located in the Junction Block. The wiper

motor has permanent magnetic fields. The speeds are

determined by current flow to the appropriate set of

brushes inside the motor. The current flow is con-

trolled by the multi-function switch stalk mounted

wiper switch, high speed/low speed relays located in

the Power Distribution Center (PDC) part of the

Integrated Power Module (IPM) in the engine com-

partment. The speed sensitive intermittent wiper is

controlled by the Body Control Module (BCM). The

intermittent mode, with the vehicle traveling greater

than 10.4 mph, has a range of 0.5 to 18 seconds.

With the vehicle traveling less than 10.4 mph, and

the time delay is not adjusted, time delay doubles to

a range of 1 to 36 seconds. The wiper arms will park

at the base of the windshield just above the cowl

cover after the wiper switch is turned OFF.

RSWIPERS/WASHERS8R-1

Page 2076 of 4284

The windshield wiper motor and linkage is located

in an integral wiper unit at the rear of the engine

compartment. The wiper unit must be removed to

gain access to the wiper motor.

REAR WIPER/WASHER SYSTEM

When continuous rear wiper operation is required,

the Body Control Module (BCM) will provide ignition

ON voltage to the rear wiper motor. When the wiper

switch is turned OFF, the BCM provides circuit

ground to operate the motor until the wipe cycle is

complete and the wiper arm returns to the base of

the rear window.

When intermittent rear wiper mode is selected, the

wiper motor will cycle every 7 seconds. The intermit-

tent delay time is also adjusted based upon vehicle

speed. With the vehicle traveling greater at 50 mph,

the cycle changes to every 5 seconds. DIAGNOSIS

AND TESTING

DIAGNOSIS AND TESTING - FRONT WIPER

SYSTEM

The windshield wiper system operates in several

modes:

²Low and high speed normal wipe

²Speed sensitive intermittent wipe

²Wipe after wash

²Pulse wipe

²Park (switch OFF)

The windshield wiper circuits are continuously

monitored and controlled by the Body Control Mod-

ule (BCM). If a problem occurs in the electronic com-

ponents, wiring, switch (except integral motor park

switch) and wiper motor a Diagnostic Trouble Code

(DTC) will be stored in the BCM memory. DTC's can

be retrieved using a DRB IIItscan tool. Refer to the

proper Body Diagnostic Procedures manual for DTC

descriptions and retrieval information.

The windshield wiper park switch and circuit is

monitored by the BCM. The park switch and circuit

can be tested using the Wiper System Diagnosis

table.

DIAGNOSIS AND TESTING - REAR WIPER

SYSTEM

The rear window wiper system operates in several

modes:

²Continuous wipe

²Intermittent wipe

²Wash

²Wipe after wash

The windshield wiper circuits are continuously

monitored and controlled by the Body Control Mod-

ule (BCM). If a problem occurs in the electronic com-

ponents, wiring, switch (except integral motor parkswitch) and wiper motor a Diagnostic Trouble Code

(DTC) will be stored in the BCM memory. The

DTC(s) can be retrieved using a DRB IIItscan tool.

DIAGNOSIS AND TESTING - FRONT

WIPER/WASHER SWITCH

To test the front wiper/washer portion of the multi-

function switch:

(1) Remove the multi-function switch (Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

MULTI-FUNCTION SWITCH - REMOVAL).

(2) Using an ohmmeter check continuity reading

between switch pins. See (Fig. 1) and the table.

WIPER/WASHER SWITCH CONTINUITY

SWITCH POSITION RESISTANCE VALUE

BETWEEN

OFF 6 AND 7 = OPEN CIRCUIT

DELAY POSITION

1ST 6AND7=8KV680V

2ND 6AND7=6KV660V

3RD 6 AND 7 = 4.5 KV645V

4TH 6 AND 7 = 3.5 KV635V

5TH 6 AND 7 = 2.5 KV625V

6TH 6 AND 7 = 1.5 KV615V

LOW 6AND7=1KV610V

HIGH 6 AND7=1KV610V

WASH 6 AND 11 = CONTINUITY

DIAGNOSIS AND TESTING - FAILED PARK

SWITCH

If the wiper park switch has failed the windshield

wipers will operate as follows:

²SWITCH OFF- Wipers stop in current location

regardless of the park signal.

²INTERMITTENT MODE- Wipers operate at

low speed for one or more extra wipes or continu-

ously.

Fig. 1 WIPER/WASHER SWITCH PIN CALL OUT

8R - 2 WIPERS/WASHERSRS

WIPERS/WASHERS (Continued)

Page 2077 of 4284

²LOW SPEED- Wipers operate at low speed.

²HIGH SPEED- Wipers operate at high speed.

²PULSE WIPE- Wipers will not operate.

²WIPE AFTER WASH- Wipers operate at low

speed in any mode setting. Wipers operate only whilewash button is depressed with switch in OFF mode,

wipers stop in mid-cycle when button is released.

The windshield wiper park switch and circuit is

monitored by the BCM. The park switch and circuit

can be tested using the table.

WIPER SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

WIPER BLADES DO NOT

PARK PROPERLY1. WIPER ARMS IMPROPERLY

PARKED.

2. WIPER ARMS ARE LOOSE ON

PIVOT SHAFT.

3. MOTOR CRANK LOOSE AT

OUTPUT SHAFT.1. REMOVE WIPER ARMS AND REPARK.

REFER TO WIPER ARM REMOVAL AND

INSTALLATION.

2. REMOVE WIPER ARM AND REPARK.

REFER TO WIPER ARM REMOVAL AND

INSTALLATION.

3. REMOVE WIPER ARM, RUN WIPER

MOTOR TO PARK POSITION AND

REMOVE THE MODULE. WITHOUT

ROTATING THE MOTOR OUTPUT SHAFT,

REMOVE THE CRANK AND CLEAN ANY

FOREIGN MATTER FROM THE MOTOR

SHAFT. INSTALL THE MOTOR CRANK IN

ITS ORIGINAL POSITION.

MOTOR STOPS IN ANY

POSITION WHEN THE

SWITCH IS TURNED OFF1. OPEN PARK CIRCUIT. 1. CHECK PARK SWITCH BY

DISCONNECTING THE WIRE

CONNECTOR AND APPLY BATTERY

VOLTAGE TO PIN 4. PLACE A JUMPER

WIRE FROM PIN 2 TO PIN 3 AND THEN

TO AN EXTERNAL GROUND. REPLACE

MOTOR IF IT DOES NOT PARK.

MOTOR WILL NOT STOP

WHEN THE SWITCH IS

TURNED OFF1. FAULTY SWITCH.

2. LACK OF DYNAMIC BRAKE ON

WET GLASS.1. CHECK SWITCH IN LOW, HIGH AND

INTERMITTENT POSITION.

2. ENSURE PARK SWITCH HAS CLEAN

GROUND.

WIPER BLADES SLAP

AGAINST COWL SCREEN

OR WINDOW MOLDINGS.1. WIPER ARMS ARE PARKED

INCORRECTLY.1. PARK WIPER ARMS. REFER TO

WIPER ARM ADJUSTMENT.

BLADES CHATTER 1. FOREIGN SUBSTANCE SUCH

AS POLISH ON GLASS OR

BLADES.

2. ARMS TWISTED, BLADE AT

WRONG ANGLE ON GLASS.

3. BLADE STRUCTURE BENT.

4. BLADE ELEMENT HAS

PERMANENT SET.1. CLEAN GLASS AND BLADE ELEMENT

WITH NON-ABRASIVE CLEANER.

2. REPLACE ARM.

3. REPLACE BLADE.

4. REPLACE BLADE ELEMENT.

WIPER KNOCK AT

REVERSAL1. LINKAGE BUSHINGS WORN.

2. ARMATURE ENDPLAY IN

MOTOR.1. REPLACE WORN LINK. REFER TO

WIPER LINKAGE REMOVAL AND

INSTALLATION.

2. REPLACE WIPER MOTOR. REFER TO

WIPER MOTOR REMOVAL AND

INSTALLATION.

RSWIPERS/WASHERS8R-3

WIPERS/WASHERS (Continued)

Page 2078 of 4284

CONDITION POSSIBLE CAUSES CORRECTION

WIPER MOTOR WILL NOT

RUN1. BLOWN FUSE.

2. NEW FUSE BLOWS.

3. NEW FUSE BLOWS.

4. NO VOLTAGE AT MOTOR.

5. POOR GROUND.1. REPLACE FUSE, AND RUN SYSTEM.

2. CHECK FOR SHORT IN WIRING OR

SWITCH.

3. REPLACE FUSE, REMOVE MOTOR

CONNECTOR, TURN SWITCH ON, FUSE

DOES NOT BLOW, REPLACE MOTOR.

4. CHECK SWITCH AND WIRING

HARNESS. REFER TO WIRING

DIAGRAMS.

5. REPAIR GROUND WIRE CONNECTION

AS NECESSARY.

FRONT WIPER ARMS

REMOVAL

CAUTION: The driver side wiper arm must be

parked above the passenger side. Failure to do so

will result in damage to the arms, blades or system.

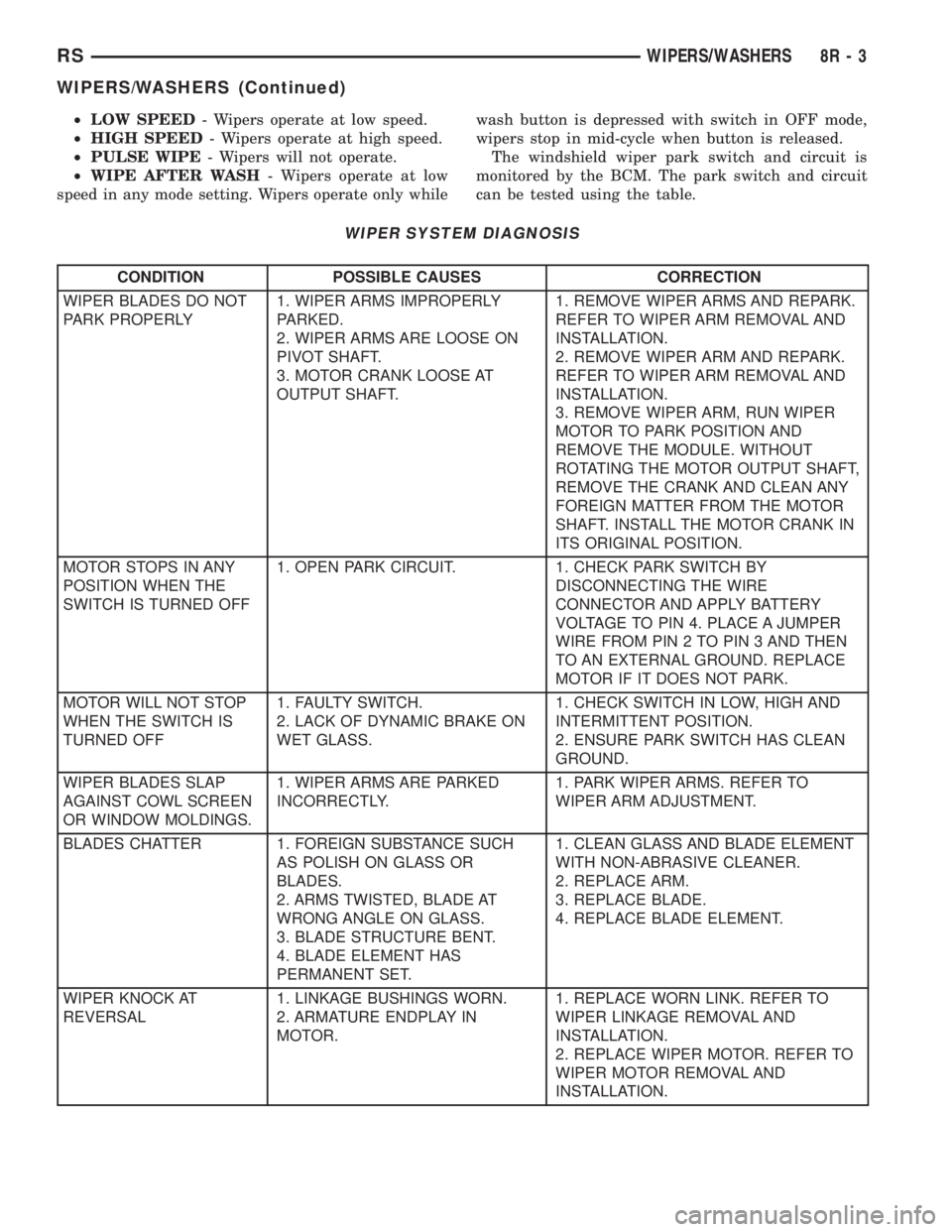

(1) Disengage the clip holding outside end of the

wiper arm pivot cover to the wiper arm.

(2) Lift the arm cap upward.

(3) Remove the nut holding wiper arm to the wiper

pivot.

(4) Using a suitable two jaw puller, separate the

wiper arm from the wiper pivot (Fig. 2).

INSTALLATION

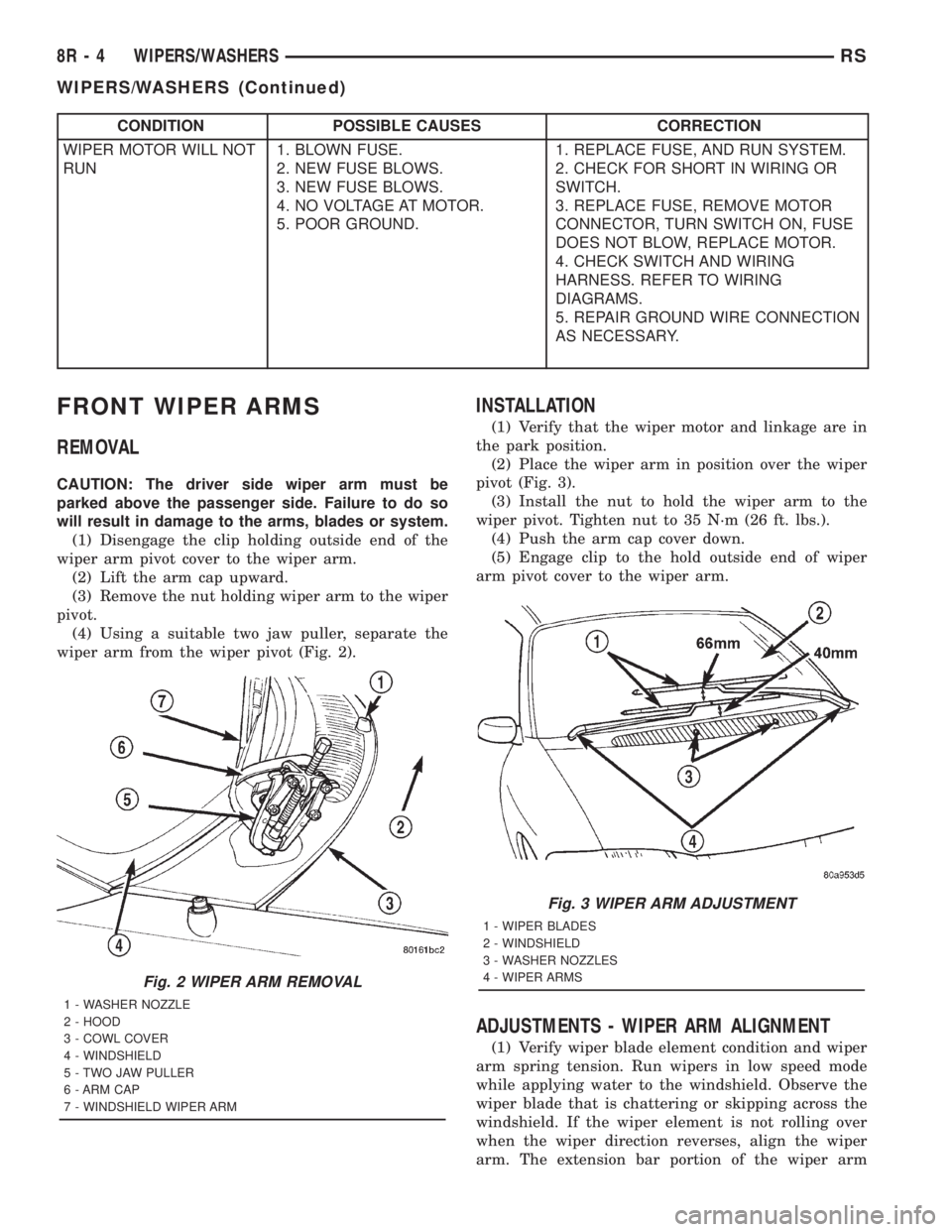

(1) Verify that the wiper motor and linkage are in

the park position.

(2) Place the wiper arm in position over the wiper

pivot (Fig. 3).

(3) Install the nut to hold the wiper arm to the

wiper pivot. Tighten nut to 35 N´m (26 ft. lbs.).

(4) Push the arm cap cover down.

(5) Engage clip to the hold outside end of wiper

arm pivot cover to the wiper arm.

ADJUSTMENTS - WIPER ARM ALIGNMENT

(1) Verify wiper blade element condition and wiper

arm spring tension. Run wipers in low speed mode

while applying water to the windshield. Observe the

wiper blade that is chattering or skipping across the

windshield. If the wiper element is not rolling over

when the wiper direction reverses, align the wiper

arm. The extension bar portion of the wiper arm

Fig. 2 WIPER ARM REMOVAL

1 - WASHER NOZZLE

2 - HOOD

3 - COWL COVER

4 - WINDSHIELD

5 - TWO JAW PULLER

6 - ARM CAP

7 - WINDSHIELD WIPER ARM

Fig. 3 WIPER ARM ADJUSTMENT

1 - WIPER BLADES

2 - WINDSHIELD

3 - WASHER NOZZLES

4 - WIPER ARMS

8R - 4 WIPERS/WASHERSRS

WIPERS/WASHERS (Continued)

Page 2079 of 4284

must be twisted in the proper direction to allow the

wiper element to roll over when the direction

reverses.

(2) Place two small adjustable wrenches placed 50

mm (2 in.) apart on the wiper arm extension rod.

(3) Twist the extension rod slightly in the opposite

direction that the element is laying on the wind-

shield while holding the wrench closest to the pivot

stationary.

(4) Repeat step Step 1, and align as necessary

until wiper stops chattering and wipes the wind-

shield clear.

FRONT WIPER MOTOR

REMOVAL

(1) Remove wiper unit from vehicle. (Refer to 8 -

ELECTRICAL/WIPERS/WASHERS/WIPER MOD-

ULE - REMOVAL).

(2) Remove wiper linkage and motor mount plate

from wiper unit.

(3) Disconnect wire connectors from back of wiper

motor (Fig. 18).

(4) Remove wiper linkage from motor crank. Do

NOT remove crank from motor.

(5) Remove bolts holding wiper motor to mount

plate and remove motor (Fig. 4) and (Fig. 5).

INSTALLATION

(1) Place wiper unit on a suitable work surface.

(2) Place wiper motor in position on mount plate.

(3) Install bolts to hold wiper motor to mount

plate.(4) Install wiper linkage and motor mount plate

into wiper unit.

(5) Connect wire connectors to wiper motor (Fig.

18).

(6) Place the wiper unit into engine compartment

and connect wiper unit wire connector to engine wire

harness (Fig. 6).

(7) Operate wiper motor and verify that the wiper

motor parks when wiper switch is turned OFF.

FRONT WIPER UNIT

REMOVAL

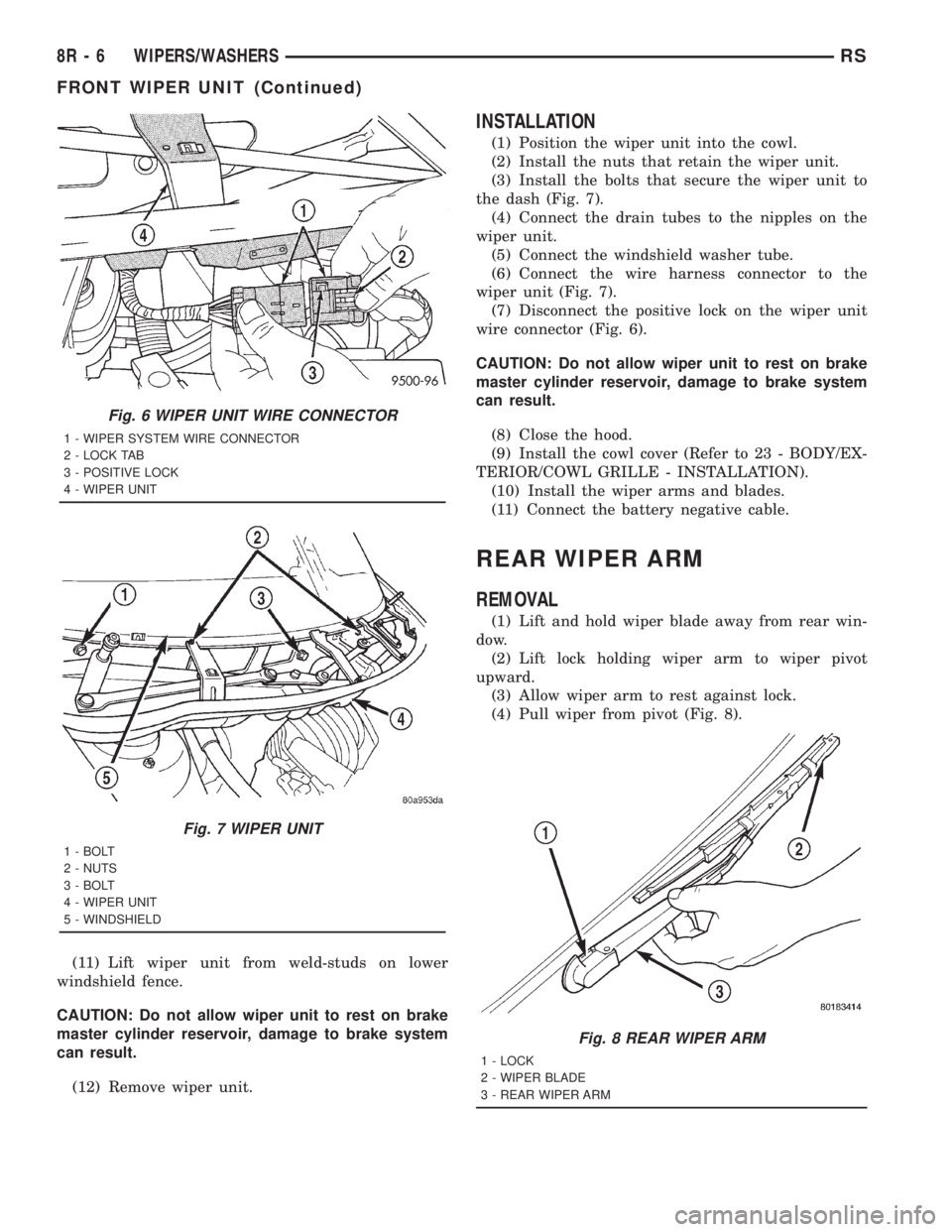

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the wiper arms.

(3) Remove the cowl cover (Refer to 23 - BODY/

EXTERIOR/COWL GRILLE - REMOVAL).

(4) Release the hood latch and open hood.

(5) Disconnect the positive lock on the wiper unit

wire connector (Fig. 6).

(6) Disconnect the wiper unit wire connector from

the engine compartment wire harness.

(7) Disconnect the windshield washer hose from

coupling inside unit.

(8) Disconnect the drain tubes from nipples on bot-

tom of the wiper unit.

(9) Remove nuts holding wiper unit to lower wind-

shield fence.

(10) Remove bolts holding the wiper unit to the

dash panel (Fig. 7).

Fig. 4 WIPER MOTOR CRANK

1 - WIPER MOTOR

2 - MOTOR MOUNT PLATE

3 - CRANK

4 - LINKAGE

5 - MOUNTING BOLTS

Fig. 5 WIPER MOTOR

1 - MOTOR MOUNT PLATE

2 - WIPER MOTOR

RSWIPERS/WASHERS8R-5

FRONT WIPER ARMS (Continued)

Page 2080 of 4284

(11) Lift wiper unit from weld-studs on lower

windshield fence.

CAUTION: Do not allow wiper unit to rest on brake

master cylinder reservoir, damage to brake system

can result.

(12) Remove wiper unit.

INSTALLATION

(1) Position the wiper unit into the cowl.

(2) Install the nuts that retain the wiper unit.

(3) Install the bolts that secure the wiper unit to

the dash (Fig. 7).

(4) Connect the drain tubes to the nipples on the

wiper unit.

(5) Connect the windshield washer tube.

(6) Connect the wire harness connector to the

wiper unit (Fig. 7).

(7) Disconnect the positive lock on the wiper unit

wire connector (Fig. 6).

CAUTION: Do not allow wiper unit to rest on brake

master cylinder reservoir, damage to brake system

can result.

(8) Close the hood.

(9) Install the cowl cover (Refer to 23 - BODY/EX-

TERIOR/COWL GRILLE - INSTALLATION).

(10) Install the wiper arms and blades.

(11) Connect the battery negative cable.

REAR WIPER ARM

REMOVAL

(1) Lift and hold wiper blade away from rear win-

dow.

(2) Lift lock holding wiper arm to wiper pivot

upward.

(3) Allow wiper arm to rest against lock.

(4) Pull wiper from pivot (Fig. 8).

Fig. 6 WIPER UNIT WIRE CONNECTOR

1 - WIPER SYSTEM WIRE CONNECTOR

2 - LOCK TAB

3 - POSITIVE LOCK

4 - WIPER UNIT

Fig. 7 WIPER UNIT

1 - BOLT

2 - NUTS

3 - BOLT

4 - WIPER UNIT

5 - WINDSHIELD

Fig. 8 REAR WIPER ARM

1 - LOCK

2 - WIPER BLADE

3 - REAR WIPER ARM

8R - 6 WIPERS/WASHERSRS

FRONT WIPER UNIT (Continued)