window CHRYSLER VOYAGER 2001 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 1095 of 4284

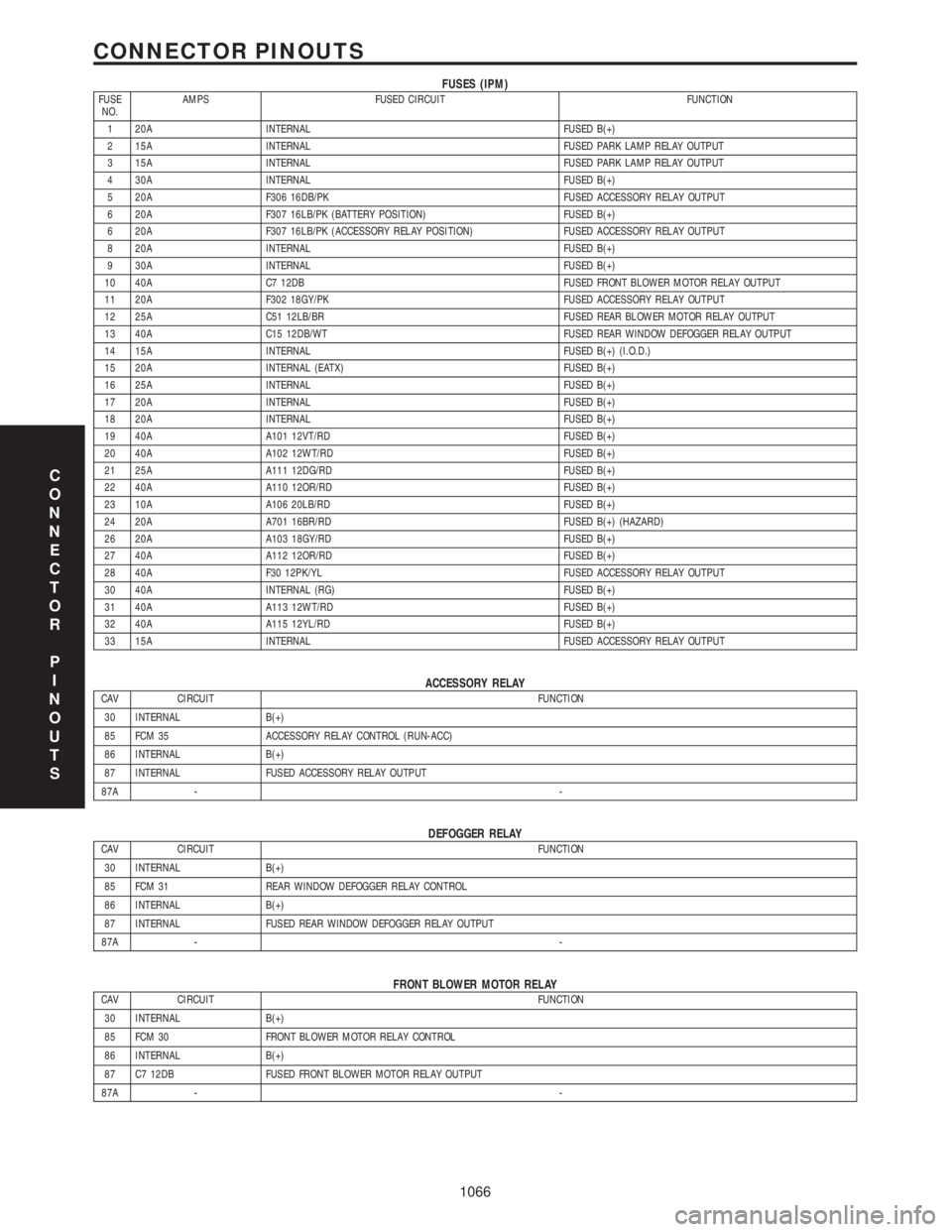

FUSES (IPM)FUSE

NO.AMPS FUSED CIRCUIT FUNCTION

1 20A INTERNAL FUSED B(+)

2 15A INTERNAL FUSED PARK LAMP RELAY OUTPUT

3 15A INTERNAL FUSED PARK LAMP RELAY OUTPUT

4 30A INTERNAL FUSED B(+)

5 20A F306 16DB/PK FUSED ACCESSORY RELAY OUTPUT

6 20A F307 16LB/PK (BATTERY POSITION) FUSED B(+)

6 20A F307 16LB/PK (ACCESSORY RELAY POSITION) FUSED ACCESSORY RELAY OUTPUT

8 20A INTERNAL FUSED B(+)

9 30A INTERNAL FUSED B(+)

10 40A C7 12DB FUSED FRONT BLOWER MOTOR RELAY OUTPUT

11 20A F302 18GY/PK FUSED ACCESSORY RELAY OUTPUT

12 25A C51 12LB/BR FUSED REAR BLOWER MOTOR RELAY OUTPUT

13 40A C15 12DB/WT FUSED REAR WINDOW DEFOGGER RELAY OUTPUT

14 15A INTERNAL FUSED B(+) (I.O.D.)

15 20A INTERNAL (EATX) FUSED B(+)

16 25A INTERNAL FUSED B(+)

17 20A INTERNAL FUSED B(+)

18 20A INTERNAL FUSED B(+)

19 40A A101 12VT/RD FUSED B(+)

20 40A A102 12WT/RD FUSED B(+)

21 25A A111 12DG/RD FUSED B(+)

22 40A A110 12OR/RD FUSED B(+)

23 10A A106 20LB/RD FUSED B(+)

24 20A A701 16BR/RD FUSED B(+) (HAZARD)

26 20A A103 18GY/RD FUSED B(+)

27 40A A112 12OR/RD FUSED B(+)

28 40A F30 12PK/YL FUSED ACCESSORY RELAY OUTPUT

30 40A INTERNAL (RG) FUSED B(+)

31 40A A113 12WT/RD FUSED B(+)

32 40A A115 12YL/RD FUSED B(+)

33 15A INTERNAL FUSED ACCESSORY RELAY OUTPUT

ACCESSORY RELAYCAV CIRCUIT FUNCTION

30 INTERNAL B(+)

85 FCM 35 ACCESSORY RELAY CONTROL (RUN-ACC)

86 INTERNAL B(+)

87 INTERNAL FUSED ACCESSORY RELAY OUTPUT

87A --

DEFOGGER RELAYCAV CIRCUIT FUNCTION

30 INTERNAL B(+)

85 FCM 31 REAR WINDOW DEFOGGER RELAY CONTROL

86 INTERNAL B(+)

87 INTERNAL FUSED REAR WINDOW DEFOGGER RELAY OUTPUT

87A --

FRONT BLOWER MOTOR RELAYCAV CIRCUIT FUNCTION

30 INTERNAL B(+)

85 FCM 30 FRONT BLOWER MOTOR RELAY CONTROL

86 INTERNAL B(+)

87 C7 12DB FUSED FRONT BLOWER MOTOR RELAY OUTPUT

87A --

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

1066

CONNECTOR PINOUTS

Page 1096 of 4284

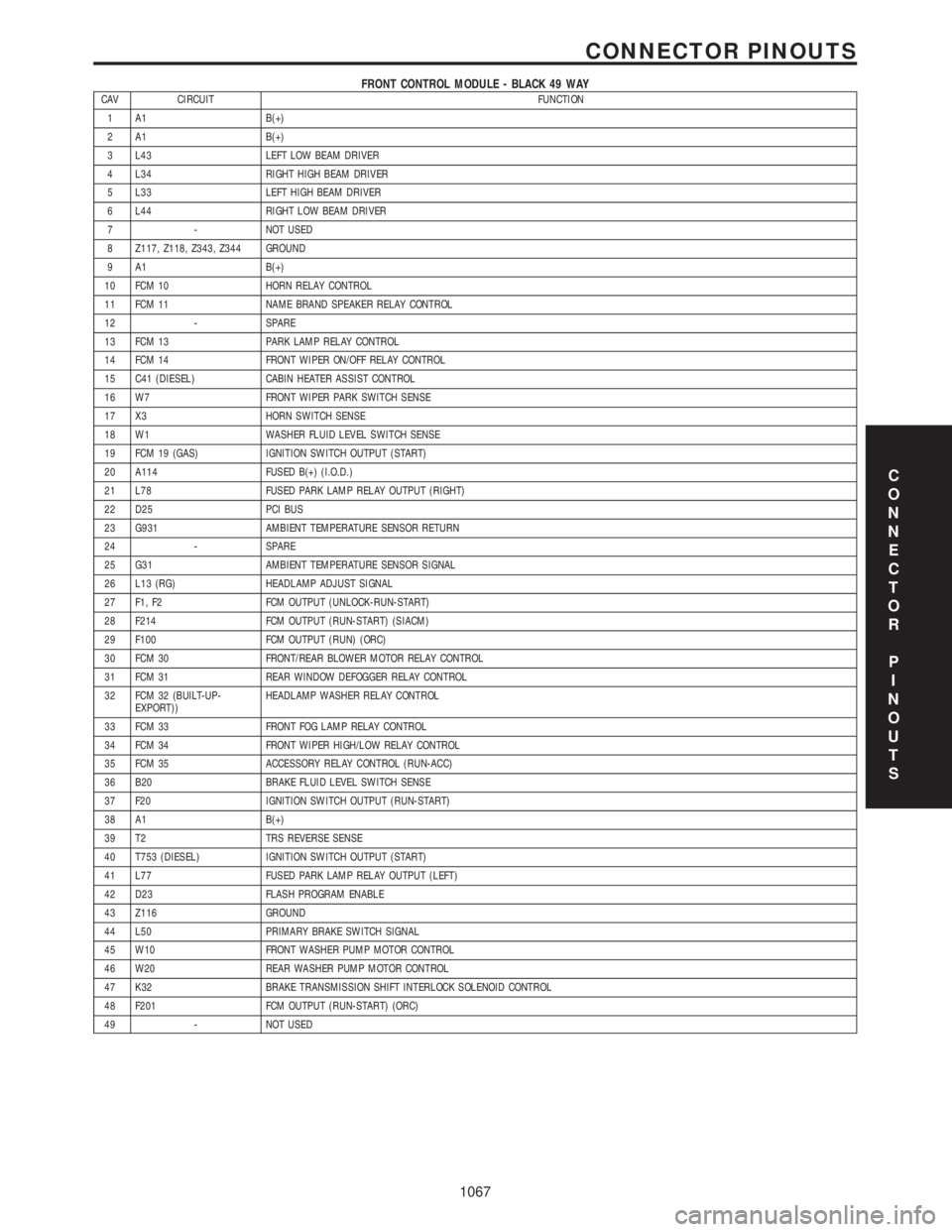

FRONT CONTROL MODULE - BLACK 49 WAYCAV CIRCUIT FUNCTION

1 A1 B(+)

2 A1 B(+)

3 L43 LEFT LOW BEAM DRIVER

4 L34 RIGHT HIGH BEAM DRIVER

5 L33 LEFT HIGH BEAM DRIVER

6 L44 RIGHT LOW BEAM DRIVER

7 - NOT USED

8 Z117, Z118, Z343, Z344 GROUND

9 A1 B(+)

10 FCM 10 HORN RELAY CONTROL

11 FCM 11 NAME BRAND SPEAKER RELAY CONTROL

12 - SPARE

13 FCM 13 PARK LAMP RELAY CONTROL

14 FCM 14 FRONT WIPER ON/OFF RELAY CONTROL

15 C41 (DIESEL) CABIN HEATER ASSIST CONTROL

16 W7 FRONT WIPER PARK SWITCH SENSE

17 X3 HORN SWITCH SENSE

18 W1 WASHER FLUID LEVEL SWITCH SENSE

19 FCM 19 (GAS) IGNITION SWITCH OUTPUT (START)

20 A114 FUSED B(+) (I.O.D.)

21 L78 FUSED PARK LAMP RELAY OUTPUT (RIGHT)

22 D25 PCI BUS

23 G931 AMBIENT TEMPERATURE SENSOR RETURN

24 - SPARE

25 G31 AMBIENT TEMPERATURE SENSOR SIGNAL

26 L13 (RG) HEADLAMP ADJUST SIGNAL

27 F1, F2 FCM OUTPUT (UNLOCK-RUN-START)

28 F214 FCM OUTPUT (RUN-START) (SIACM)

29 F100 FCM OUTPUT (RUN) (ORC)

30 FCM 30 FRONT/REAR BLOWER MOTOR RELAY CONTROL

31 FCM 31 REAR WINDOW DEFOGGER RELAY CONTROL

32 FCM 32 (BUILT-UP-

EXPORT))HEADLAMP WASHER RELAY CONTROL

33 FCM 33 FRONT FOG LAMP RELAY CONTROL

34 FCM 34 FRONT WIPER HIGH/LOW RELAY CONTROL

35 FCM 35 ACCESSORY RELAY CONTROL (RUN-ACC)

36 B20 BRAKE FLUID LEVEL SWITCH SENSE

37 F20 IGNITION SWITCH OUTPUT (RUN-START)

38 A1 B(+)

39 T2 TRS REVERSE SENSE

40 T753 (DIESEL) IGNITION SWITCH OUTPUT (START)

41 L77 FUSED PARK LAMP RELAY OUTPUT (LEFT)

42 D23 FLASH PROGRAM ENABLE

43 Z116 GROUND

44 L50 PRIMARY BRAKE SWITCH SIGNAL

45 W10 FRONT WASHER PUMP MOTOR CONTROL

46 W20 REAR WASHER PUMP MOTOR CONTROL

47 K32 BRAKE TRANSMISSION SHIFT INTERLOCK SOLENOID CONTROL

48 F201 FCM OUTPUT (RUN-START) (ORC)

49 - NOT USED

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

1067

CONNECTOR PINOUTS

Page 1097 of 4284

FRONT FOG LAMP RELAYCAV CIRCUIT FUNCTION

30 INTERNAL FUSED B(+)

85 FCM 33 FRONT FOG LAMP RELAY CONTROL

86 INTERNAL FUSED B(+)

87 INTERNAL FRONT FOG LAMP RELAY OUTPUT

87A --

HEADLAMP WASHER RELAY (BUILT-UP-EXPORT)CAV CIRCUIT FUNCTION

30 INTERNAL FUSED B(+)

57 T55 20YL/VT (AUTOSTICK)

85 FCM 32 HEADLAMP WASHER RELAY CONTROL

86 INTERNAL FUSED B(+)

87 V53 12BR/OR HEADLAMP WASHER RELAY OUTPUT

87A - No Function Defined

NAME BRAND SPEAKER RELAYCAV CIRCUIT FUNCTION

30 INTERNAL FUSED B(+) (I.O.D.)

85 FCM 11 NAME BRAND SPEAKER (NBS) RELAY CONTROL

86 INTERNAL FUSED B(+) (I.O.D.)

87 X1 16DG/BR NAME BRAND SPEAKER (NBS) RELAY OUTPUT

87A --

PARK LAMP RELAYCAV CIRCUIT FUNCTION

30 INTERNAL B(+)

85 FCM 13 PARK LAMP RELAY CONTROL

86 INTERNAL B(+)

87 INTERNAL PARK LAMP RELAY OUTPUT

87A --

POSITIVE TEMPERATURE COEFFICIENTSFUSE

NO.AMPS FUSED CIRCUIT FUNCTION

4 8A C16 18DB/GY FUSED REAR WINDOW DEFOGGER RELAY OUTPUT

7 13A A105 18DB/RD FUSED B(+)

REAR BLOWER MOTOR RELAYCAV CIRCUIT FUNCTION

30 INTERNAL B(+)

85 FCM 30 REAR BLOWER MOTOR RELAY CONTROL

86 INTERNAL B(+)

87 C51 12LB/BR FUSED REAR BLOWER MOTOR RELAY OUTPUT

87A --

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

1068

CONNECTOR PINOUTS

Page 1109 of 4284

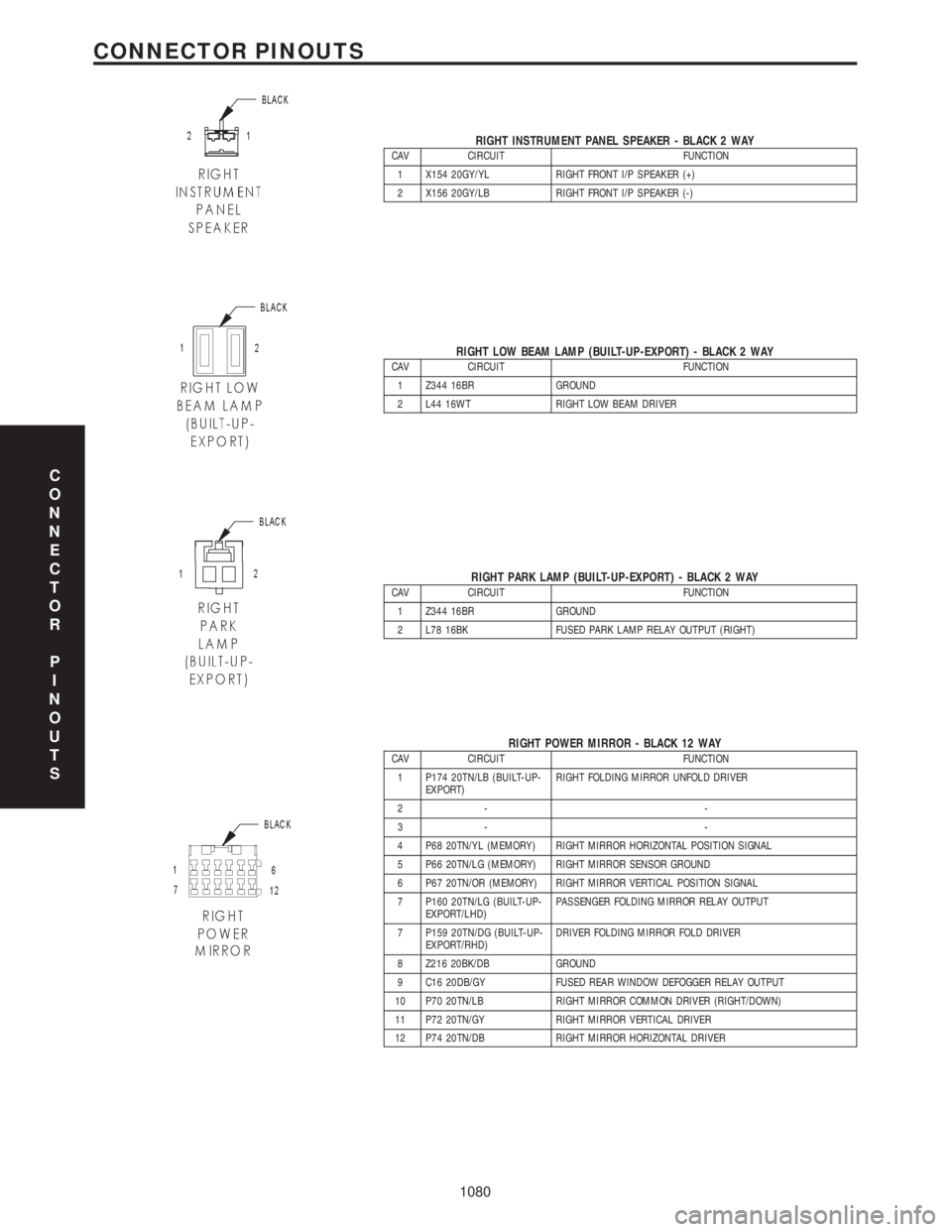

RIGHT INSTRUMENT PANEL SPEAKER - BLACK 2 WAYCAV CIRCUIT FUNCTION

1 X154 20GY/YL RIGHT FRONT I/P SPEAKER (+)

2 X156 20GY/LB RIGHT FRONT I/P SPEAKER (-)

RIGHT LOW BEAM LAMP (BUILT-UP-EXPORT) - BLACK 2 WAYCAV CIRCUIT FUNCTION

1 Z344 16BR GROUND

2 L44 16WT RIGHT LOW BEAM DRIVER

RIGHT PARK LAMP (BUILT-UP-EXPORT) - BLACK 2 WAYCAV CIRCUIT FUNCTION

1 Z344 16BR GROUND

2 L78 16BK FUSED PARK LAMP RELAY OUTPUT (RIGHT)

RIGHT POWER MIRROR - BLACK 12 WAYCAV CIRCUIT FUNCTION

1 P174 20TN/LB (BUILT-UP-

EXPORT)RIGHT FOLDING MIRROR UNFOLD DRIVER

2- -

3- -

4 P68 20TN/YL (MEMORY) RIGHT MIRROR HORIZONTAL POSITION SIGNAL

5 P66 20TN/LG (MEMORY) RIGHT MIRROR SENSOR GROUND

6 P67 20TN/OR (MEMORY) RIGHT MIRROR VERTICAL POSITION SIGNAL

7 P160 20TN/LG (BUILT-UP-

EXPORT/LHD)PASSENGER FOLDING MIRROR RELAY OUTPUT

7 P159 20TN/DG (BUILT-UP-

EXPORT/RHD)DRIVER FOLDING MIRROR FOLD DRIVER

8 Z216 20BK/DB GROUND

9 C16 20DB/GY FUSED REAR WINDOW DEFOGGER RELAY OUTPUT

10 P70 20TN/LB RIGHT MIRROR COMMON DRIVER (RIGHT/DOWN)

11 P72 20TN/GY RIGHT MIRROR VERTICAL DRIVER

12 P74 20TN/DB RIGHT MIRROR HORIZONTAL DRIVER

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

1080

CONNECTOR PINOUTS

Page 1208 of 4284

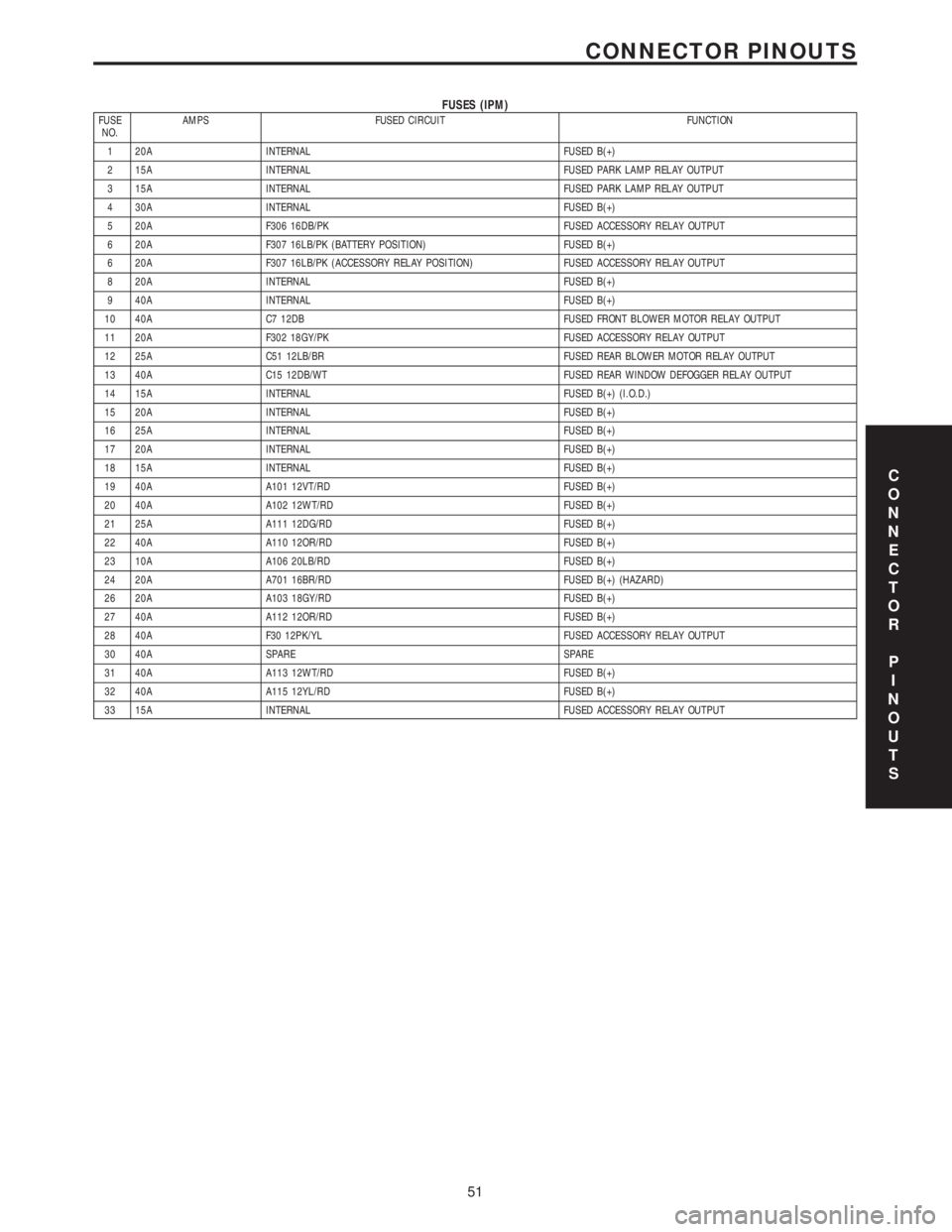

FUSES (IPM)FUSE

NO.AMPS FUSED CIRCUIT FUNCTION

1 20A INTERNAL FUSED B(+)

2 15A INTERNAL FUSED PARK LAMP RELAY OUTPUT

3 15A INTERNAL FUSED PARK LAMP RELAY OUTPUT

4 30A INTERNAL FUSED B(+)

5 20A F306 16DB/PK FUSED ACCESSORY RELAY OUTPUT

6 20A F307 16LB/PK (BATTERY POSITION) FUSED B(+)

6 20A F307 16LB/PK (ACCESSORY RELAY POSITION) FUSED ACCESSORY RELAY OUTPUT

8 20A INTERNAL FUSED B(+)

9 40A INTERNAL FUSED B(+)

10 40A C7 12DB FUSED FRONT BLOWER MOTOR RELAY OUTPUT

11 20A F302 18GY/PK FUSED ACCESSORY RELAY OUTPUT

12 25A C51 12LB/BR FUSED REAR BLOWER MOTOR RELAY OUTPUT

13 40A C15 12DB/WT FUSED REAR WINDOW DEFOGGER RELAY OUTPUT

14 15A INTERNAL FUSED B(+) (I.O.D.)

15 20A INTERNAL FUSED B(+)

16 25A INTERNAL FUSED B(+)

17 20A INTERNAL FUSED B(+)

18 15A INTERNAL FUSED B(+)

19 40A A101 12VT/RD FUSED B(+)

20 40A A102 12WT/RD FUSED B(+)

21 25A A111 12DG/RD FUSED B(+)

22 40A A110 12OR/RD FUSED B(+)

23 10A A106 20LB/RD FUSED B(+)

24 20A A701 16BR/RD FUSED B(+) (HAZARD)

26 20A A103 18GY/RD FUSED B(+)

27 40A A112 12OR/RD FUSED B(+)

28 40A F30 12PK/YL FUSED ACCESSORY RELAY OUTPUT

30 40A SPARE SPARE

31 40A A113 12WT/RD FUSED B(+)

32 40A A115 12YL/RD FUSED B(+)

33 15A INTERNAL FUSED ACCESSORY RELAY OUTPUT

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

51

CONNECTOR PINOUTS

Page 1473 of 4284

FASTENER IDENTIFICATION

DESCRIPTION

The SAE bolt strength grades range from grade 2

to grade 8. The higher the grade number, the greater

the bolt strength. Identification is determined by the

line marks on the top of each bolt head. The actual

bolt strength grade corresponds to the number of line

marks plus 2. The most commonly used metric bolt

strength classes are 9.8 and 10.9. The metric

strength class identification number is imprinted on

the head of the bolt. The higher the class number,

the greater the bolt strength. Some metric nuts are

imprinted with a single-digit strength class on the

nut face. Refer to the Fastener Identification and

Fastener Strength Charts.

FASTENER USAGE

DESCRIPTION - FASTENER USAGE

WARNING: USE OF AN INCORRECT FASTENER

MAY RESULT IN COMPONENT DAMAGE OR PER-

SONAL INJURY.

Figure art, specifications and torque references in

this Service Manual are identified in metric and SAE

format.

During any maintenance or repair procedures, it is

important to salvage all fasteners (nuts, bolts, etc.)

for reassembly. If the fastener is not salvageable, a

fastener of equivalent specification must be used.

International Symbols

1 High Beam 13 Rear Window Washer

2 Fog Lamps 14 Fuel

3 Headlamp, Parking Lamps, Panel Lamps 15 Engine Coolant Temperature

4 Turn Warning 16 Battery Charging Condition

5 Hazard Warning 17 Engine Oil

6 Windshield Washer 18 Seat Belt

7 Windshield Wiper 19 Brake Failure

8 Windshield Wiper and Washer 20 Parking Brake

9 Windscreen Demisting and Defrosting 21 Front Hood

10 Ventilating Fan 22 Rear hood (Decklid)

11 Rear Window Defogger 23 Horn

12 Rear Window Wiper 24 Lighter

RSINTRODUCTION5

INTERNATIONAL SYMBOLS (Continued)

Page 1483 of 4284

FASTENER USAGE

DESCRIPTION

WARNING: USE OF AN INCORRECT FASTENER

MAY RESULT IN COMPONENT DAMAGE OR PER-

SONAL INJURY.

Figure art, specifications and torque references in

this Service Manual are identified in metric and SAE

format.

During any maintenance or repair procedures, it is

important to salvage all fasteners (nuts, bolts, etc.)

for reassembly. If the fastener is not salvageable, a

fastener of equivalent specification must be used.

THREADED HOLE REPAIR

DESCRIPTION

Most stripped threaded holes can be repaired using

a Helicoilt. Follow the vehicle or Helicoiltrecommen-

dations for application and repair procedures.

INTERNATIONAL VEHICLE

CONTROL & DISPLAY

SYMBOLS

DESCRIPTION

The graphic symbols illustrated in the following

International Control and Display Symbols Chart

(Fig. 4) are used to identify various instrument con-

trols. The symbols correspond to the controls and dis-

plays that are located on the instrument panel.

Fig. 4 INTERNATIONAL CONTROL AND DISPLAY SYMBOLS

1 High Beam 13 Rear Window Washer

2 Fog Lamps 14 Fuel

3 Headlamp, Parking Lamps, Panel Lamps 15 Engine Coolant Temperature

4 Turn Warning 16 Battery Charging Condition

5 Hazard Warning 17 Engine Oil

6 Windshield Washer 18 Seat Belt

7 Windshield Wiper 19 Brake Failure

8 Windshield Wiper and Washer 20 Parking Brake

9 Windscreen Demisting and Defrosting 21 Front Hood

10 Ventilating Fan 22 Rear hood (Decklid)

11 Rear Window Defogger 23 Horn

12 Rear Window Wiper 24 Lighter

RGINTRODUCTION5a

Page 1817 of 4284

AUDIO

TABLE OF CONTENTS

page page

QUARTER GLASS INTEGRAL ANTENNA

DESCRIPTION............................1

OPERATION.............................1

DIAGNOSIS AND TESTING..................1

QUARTER GLASS INTEGRAL ANTENNA......1

ANTENNA MODULE

DESCRIPTION............................2OPERATION.............................2

DIAGNOSIS AND TESTING..................2

ANTENNA MODULE......................2

REMOVAL...............................2

INSTALLATION............................2

QUARTER GLASS INTEGRAL

ANTENNA

DESCRIPTION

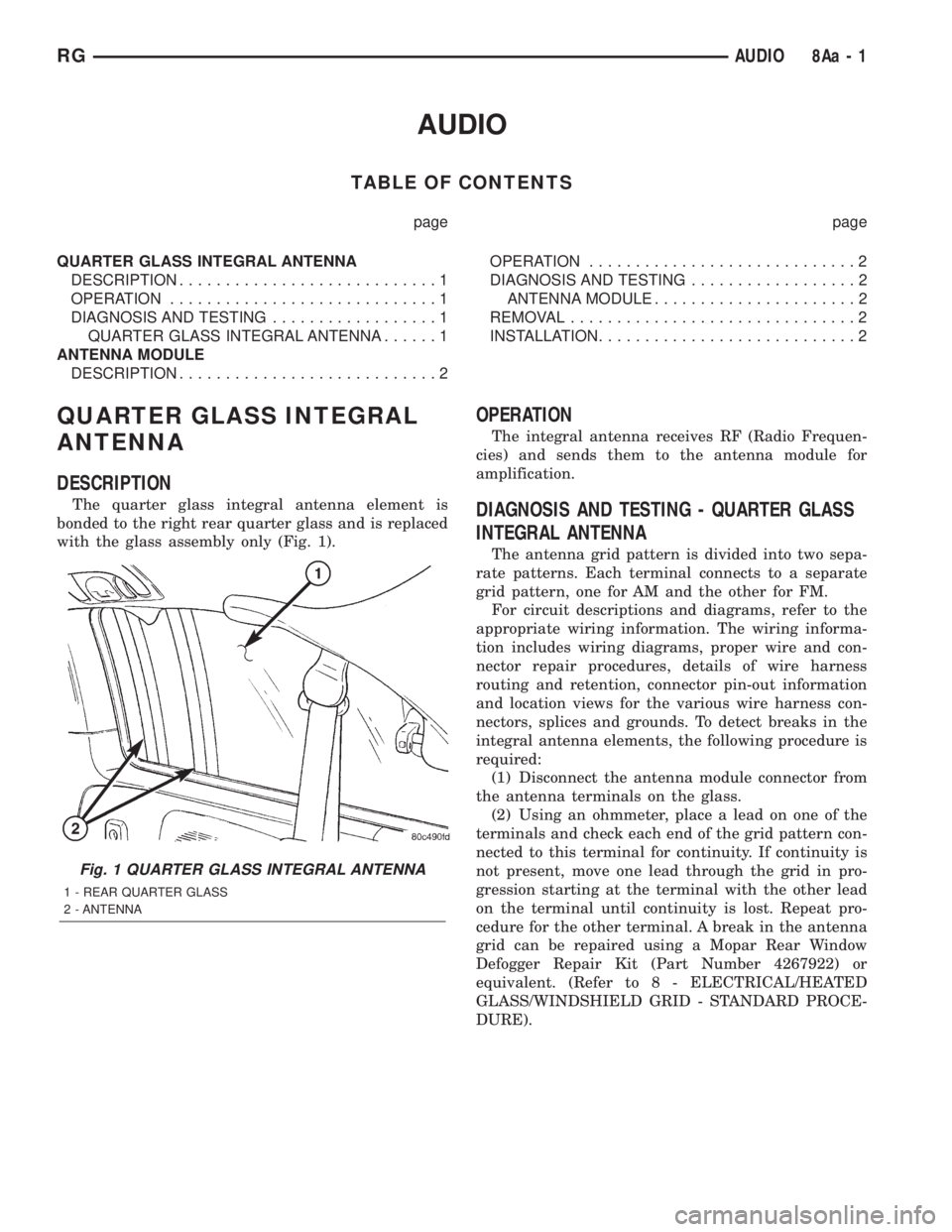

The quarter glass integral antenna element is

bonded to the right rear quarter glass and is replaced

with the glass assembly only (Fig. 1).

OPERATION

The integral antenna receives RF (Radio Frequen-

cies) and sends them to the antenna module for

amplification.

DIAGNOSIS AND TESTING - QUARTER GLASS

INTEGRAL ANTENNA

The antenna grid pattern is divided into two sepa-

rate patterns. Each terminal connects to a separate

grid pattern, one for AM and the other for FM.

For circuit descriptions and diagrams, refer to the

appropriate wiring information. The wiring informa-

tion includes wiring diagrams, proper wire and con-

nector repair procedures, details of wire harness

routing and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds. To detect breaks in the

integral antenna elements, the following procedure is

required:

(1) Disconnect the antenna module connector from

the antenna terminals on the glass.

(2) Using an ohmmeter, place a lead on one of the

terminals and check each end of the grid pattern con-

nected to this terminal for continuity. If continuity is

not present, move one lead through the grid in pro-

gression starting at the terminal with the other lead

on the terminal until continuity is lost. Repeat pro-

cedure for the other terminal. A break in the antenna

grid can be repaired using a Mopar Rear Window

Defogger Repair Kit (Part Number 4267922) or

equivalent. (Refer to 8 - ELECTRICAL/HEATED

GLASS/WINDSHIELD GRID - STANDARD PROCE-

DURE).

Fig. 1 QUARTER GLASS INTEGRAL ANTENNA

1 - REAR QUARTER GLASS

2 - ANTENNA

RGAUDIO8Aa-1

Page 1818 of 4284

ANTENNA MODULE

DESCRIPTION

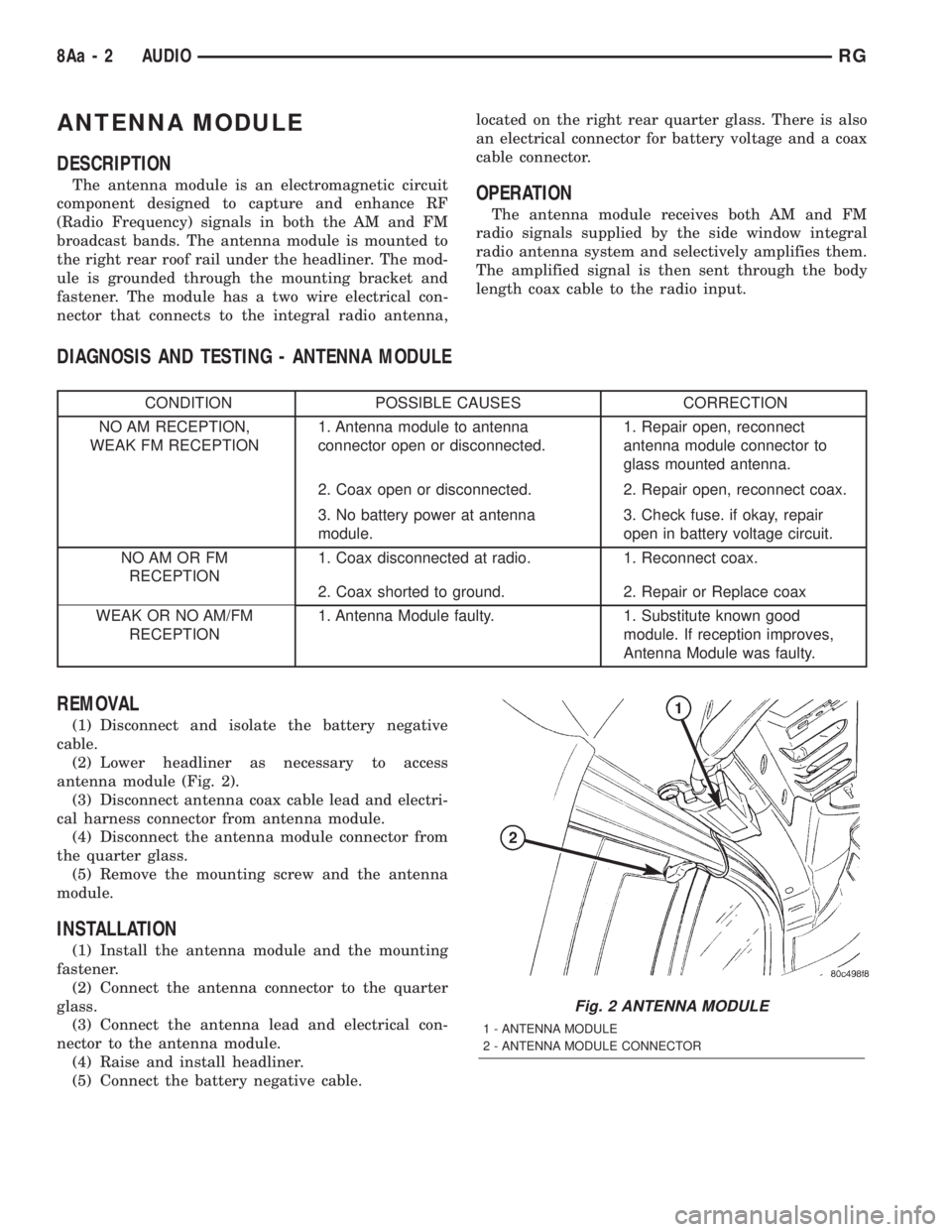

The antenna module is an electromagnetic circuit

component designed to capture and enhance RF

(Radio Frequency) signals in both the AM and FM

broadcast bands. The antenna module is mounted to

the right rear roof rail under the headliner. The mod-

ule is grounded through the mounting bracket and

fastener. The module has a two wire electrical con-

nector that connects to the integral radio antenna,located on the right rear quarter glass. There is also

an electrical connector for battery voltage and a coax

cable connector.OPERATION

The antenna module receives both AM and FM

radio signals supplied by the side window integral

radio antenna system and selectively amplifies them.

The amplified signal is then sent through the body

length coax cable to the radio input.

DIAGNOSIS AND TESTING - ANTENNA MODULE

CONDITION POSSIBLE CAUSES CORRECTION

NO AM RECEPTION,

WEAK FM RECEPTION1. Antenna module to antenna

connector open or disconnected.1. Repair open, reconnect

antenna module connector to

glass mounted antenna.

2. Coax open or disconnected. 2. Repair open, reconnect coax.

3. No battery power at antenna

module.3. Check fuse. if okay, repair

open in battery voltage circuit.

NO AM OR FM

RECEPTION1. Coax disconnected at radio. 1. Reconnect coax.

2. Coax shorted to ground. 2. Repair or Replace coax

WEAK OR NO AM/FM

RECEPTION1. Antenna Module faulty. 1. Substitute known good

module. If reception improves,

Antenna Module was faulty.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Lower headliner as necessary to access

antenna module (Fig. 2).

(3) Disconnect antenna coax cable lead and electri-

cal harness connector from antenna module.

(4) Disconnect the antenna module connector from

the quarter glass.

(5) Remove the mounting screw and the antenna

module.

INSTALLATION

(1) Install the antenna module and the mounting

fastener.

(2) Connect the antenna connector to the quarter

glass.

(3) Connect the antenna lead and electrical con-

nector to the antenna module.

(4) Raise and install headliner.

(5) Connect the battery negative cable.

Fig. 2 ANTENNA MODULE

1 - ANTENNA MODULE

2 - ANTENNA MODULE CONNECTOR

8Aa - 2 AUDIORG

Page 1897 of 4284

HEATED SYSTEMS

TABLE OF CONTENTS

page page

HEATED GLASS........................... 1

HEATED MIRRORS......................... 5HEATED SEAT SYSTEM..................... 7

HEATED GLASS

TABLE OF CONTENTS

page page

HEATED GLASS

DESCRIPTION............................1

OPERATION.............................2

DEFOGGER RELAY

DESCRIPTION............................2

REAR WINDOW DEFOGGER GRID

STANDARD PROCEDURE...................2

GRID LINE REPAIR-REAR.................2REAR WINDOW DEFOGGER SWITCH

DESCRIPTION............................2

OPERATION.............................2

WINDSHIELD GRID

DIAGNOSIS AND TESTING..................3

SYSTEM TEST..........................3

STANDARD PROCEDURE...................3

GRID LINE AND TERMINAL REPAIR.........3

HEATED GLASS

DESCRIPTION

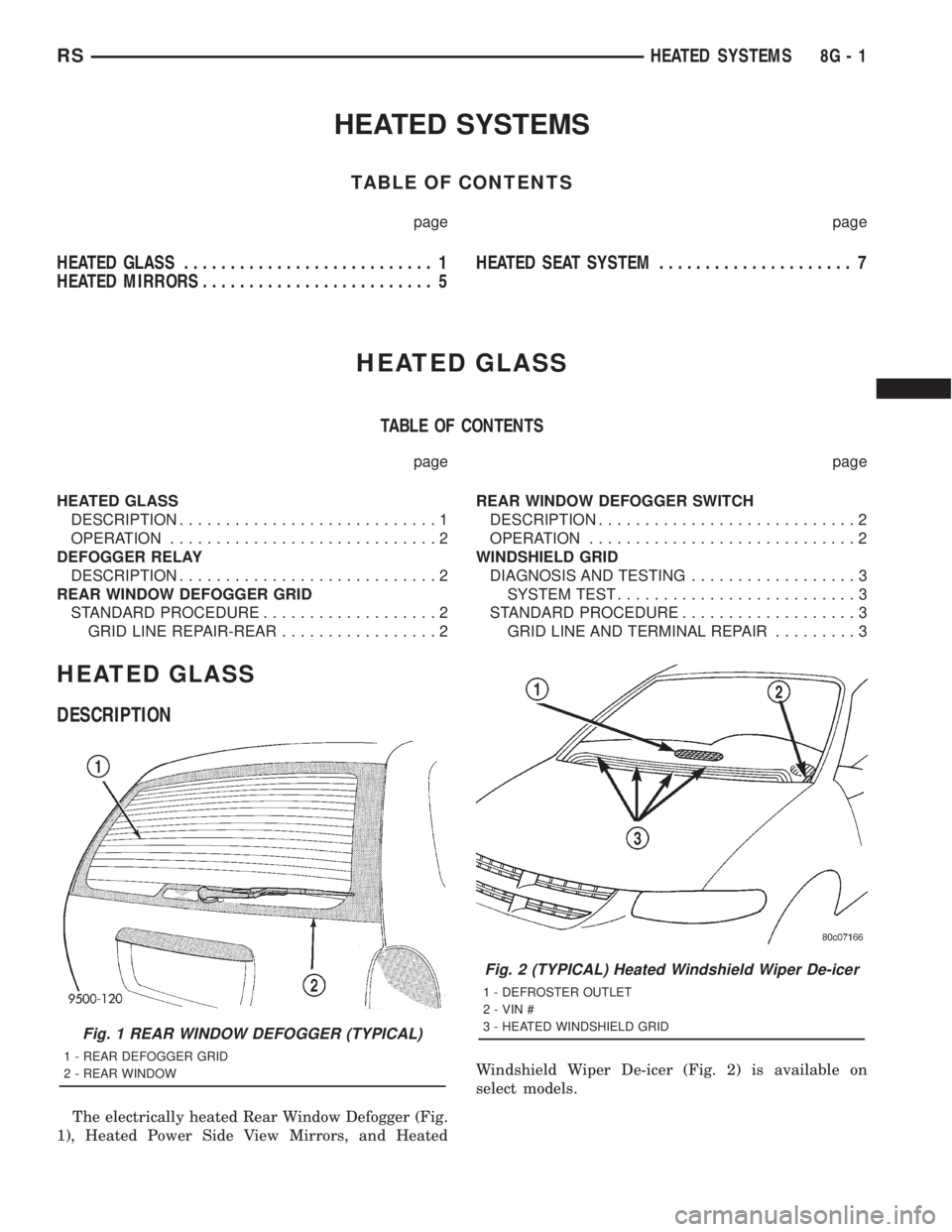

The electrically heated Rear Window Defogger (Fig.

1), Heated Power Side View Mirrors, and HeatedWindshield Wiper De-icer (Fig. 2) is available on

select models.

Fig. 1 REAR WINDOW DEFOGGER (TYPICAL)

1 - REAR DEFOGGER GRID

2 - REAR WINDOW

Fig. 2 (TYPICAL) Heated Windshield Wiper De-icer

1 - DEFROSTER OUTLET

2 - VIN #

3 - HEATED WINDSHIELD GRID

RSHEATED SYSTEMS8G-1