CITROEN CX 1988 Service Manual

Manufacturer: CITROEN, Model Year: 1988,

Model line: CX,

Model: CITROEN CX 1988

Pages: 648, PDF Size: 95.8 MB

CITROEN CX 1988 Service Manual

CX 1988

CITROEN

CITROEN

https://www.carmanualsonline.info/img/9/56874/w960_56874-0.png

CITROEN CX 1988 Service Manual

Trending: piston, wheel, checking oil, low oil pressure, bulb, mirror, steering wheel

Page 281 of 648

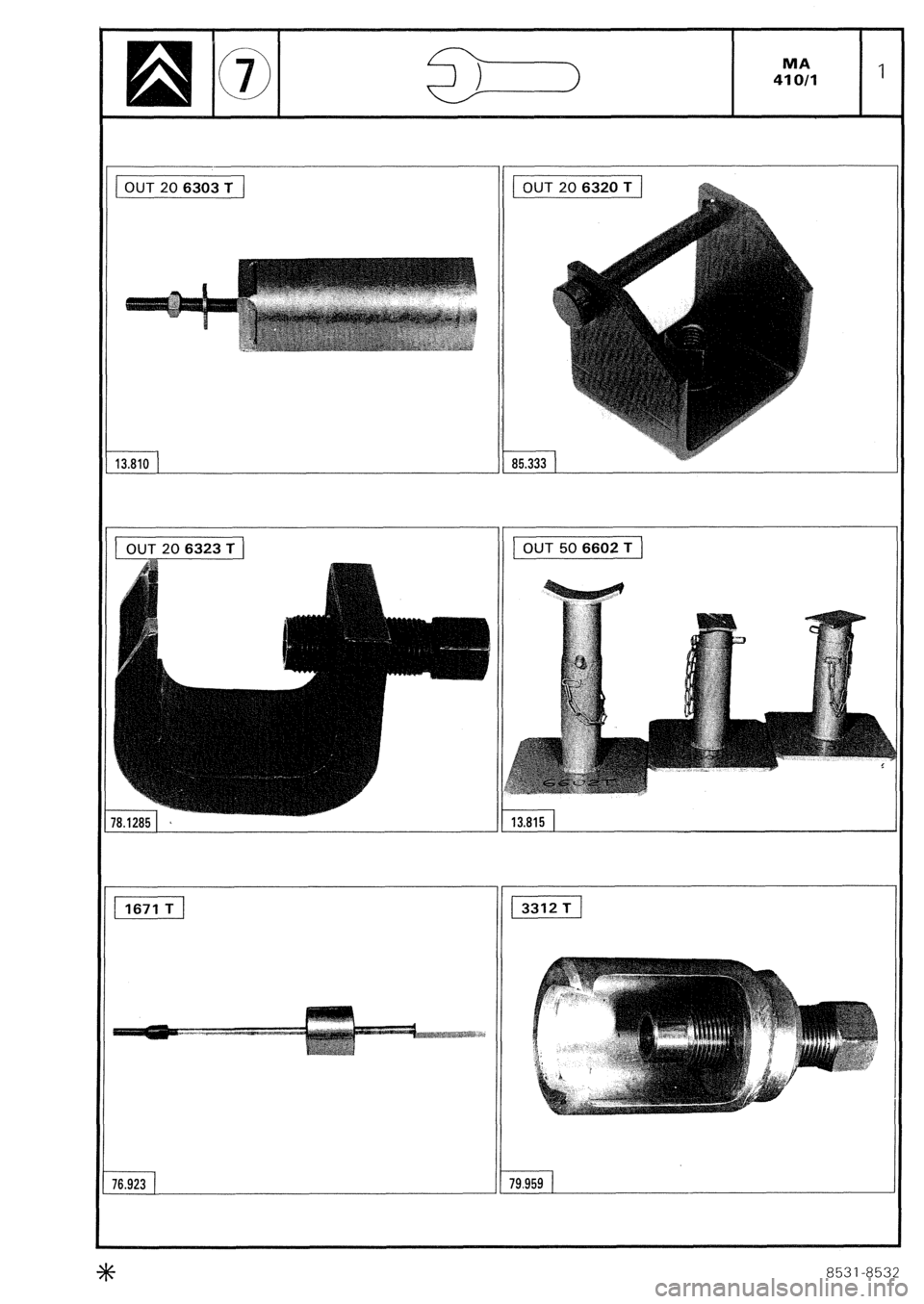

OUT 20 6303 T

13.810

76.923 79.959

8531-8532

Page 282 of 648

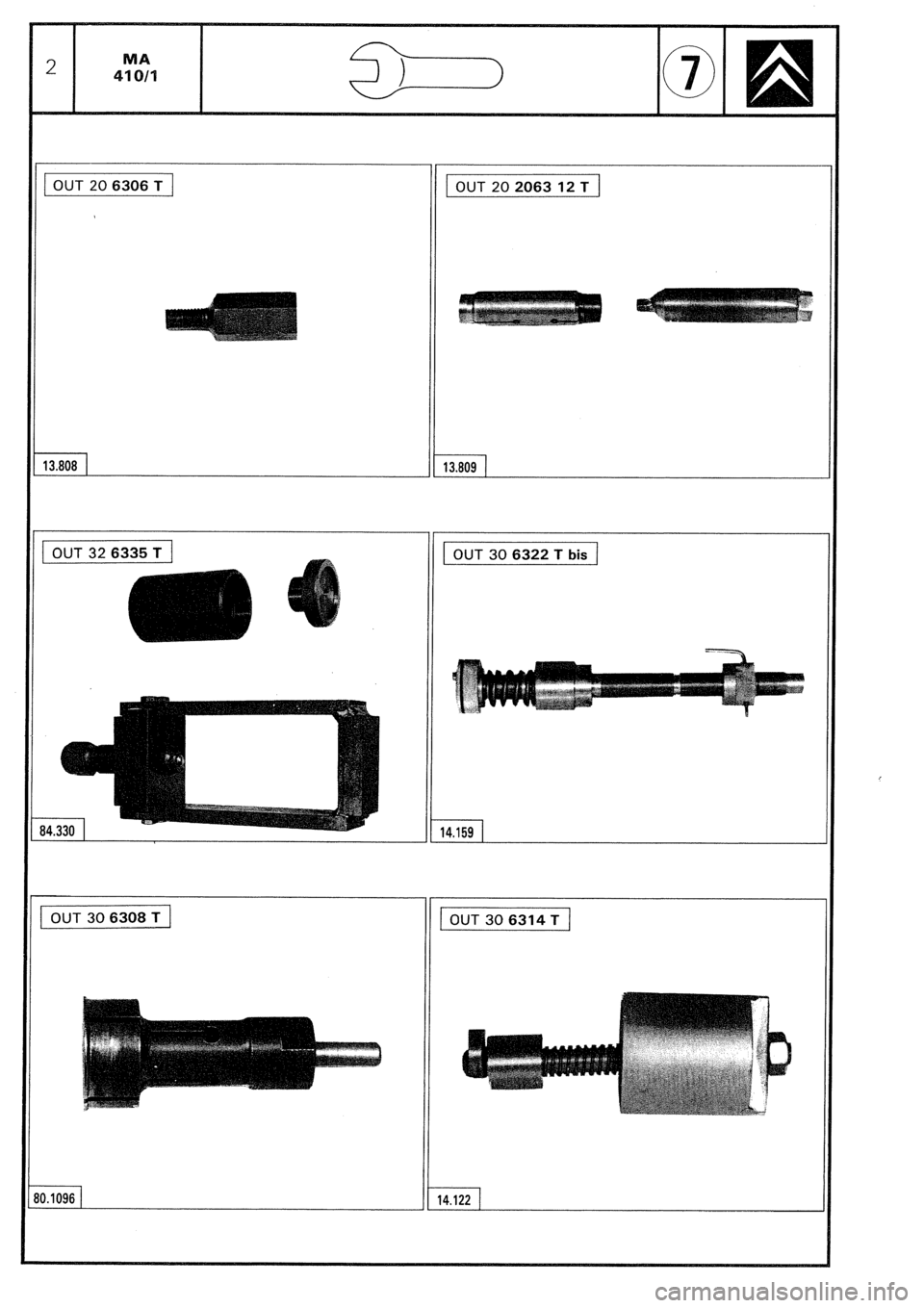

OUT 20 6306 T

OUT 20 2063 12 T 13.808

13.809

OUT 30 6322 T bis

14.159

OUT 30 6308 T

OUT306314T

3.1096 14.122

Page 283 of 648

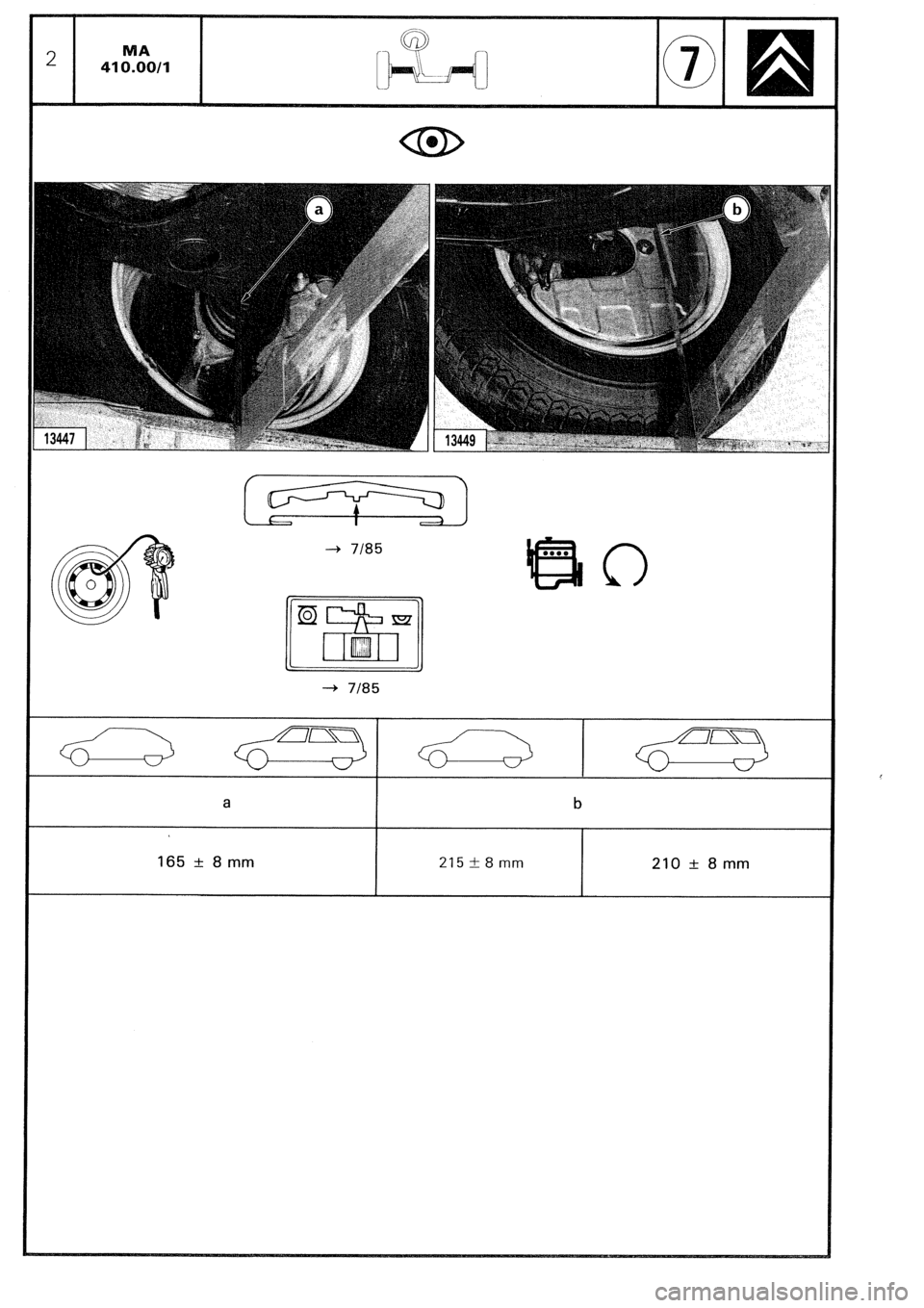

Page 284 of 648

--+ 7185

I a

I b

I

I

I

165 zt 8mm

I 215 +- 8 mm

I 210 + 8 mm

I

Page 285 of 648

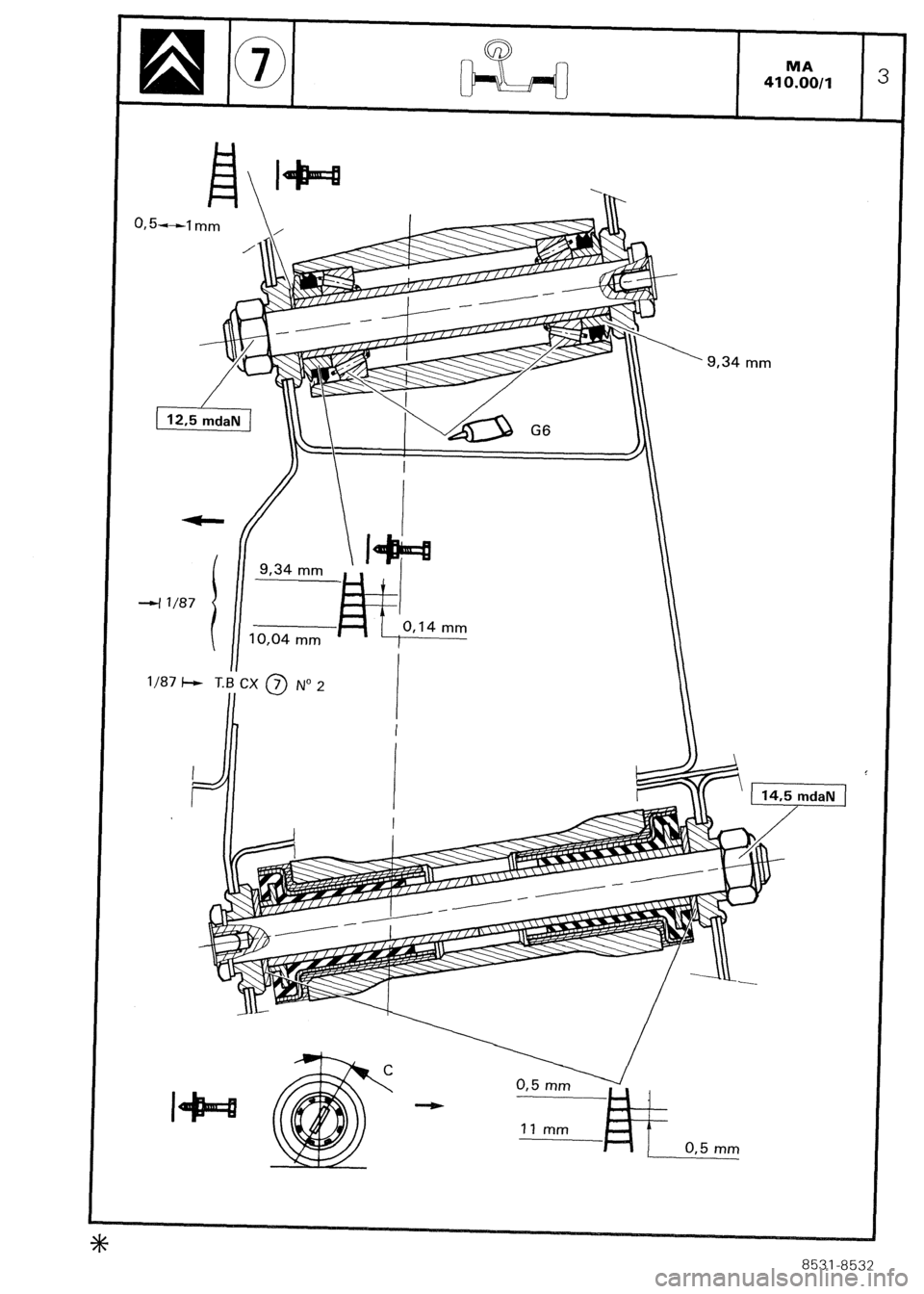

El

0,5

-1 mm

[ 12.5 mdaN 1

4 T/87

i Lmm j* \{

-9,

0,14 mm

---.

I- \

l/87

I

9,34 mm .

8531-8532

Page 286 of 648

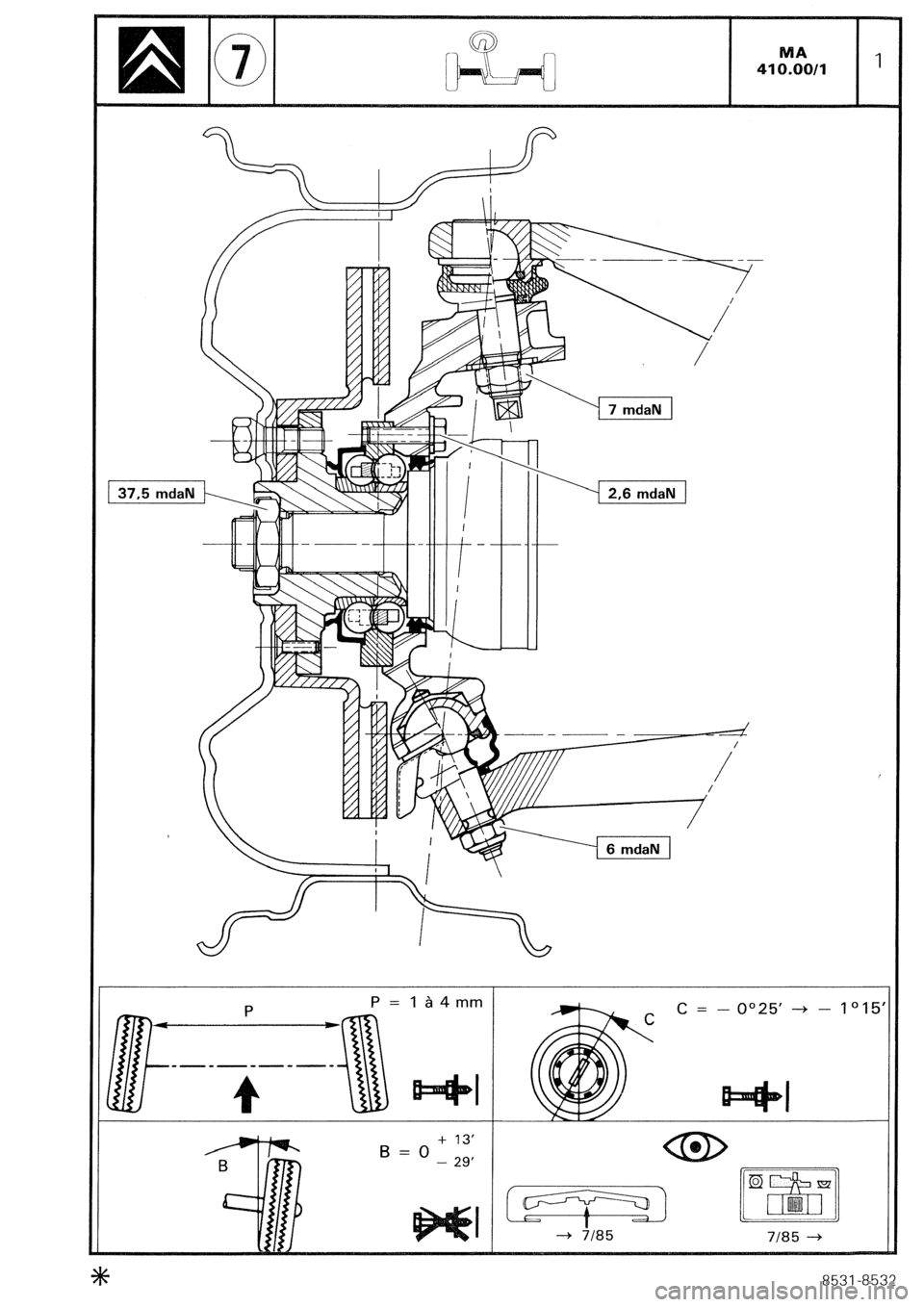

FRONT MA

412.1/l 1

RECOMMENDED TOOLS

6303-T.

Upper arm shaft extractor. 6320-T.

Anti-roll bar link rod extractor 6602-T.

Set of three stands.

REMOVING AND REFITTING

AN UPPER WHEEL ARM

8531-8532

Page 287 of 648

REMOVING AND REFITTING

AN UPPER WHEEL ARM

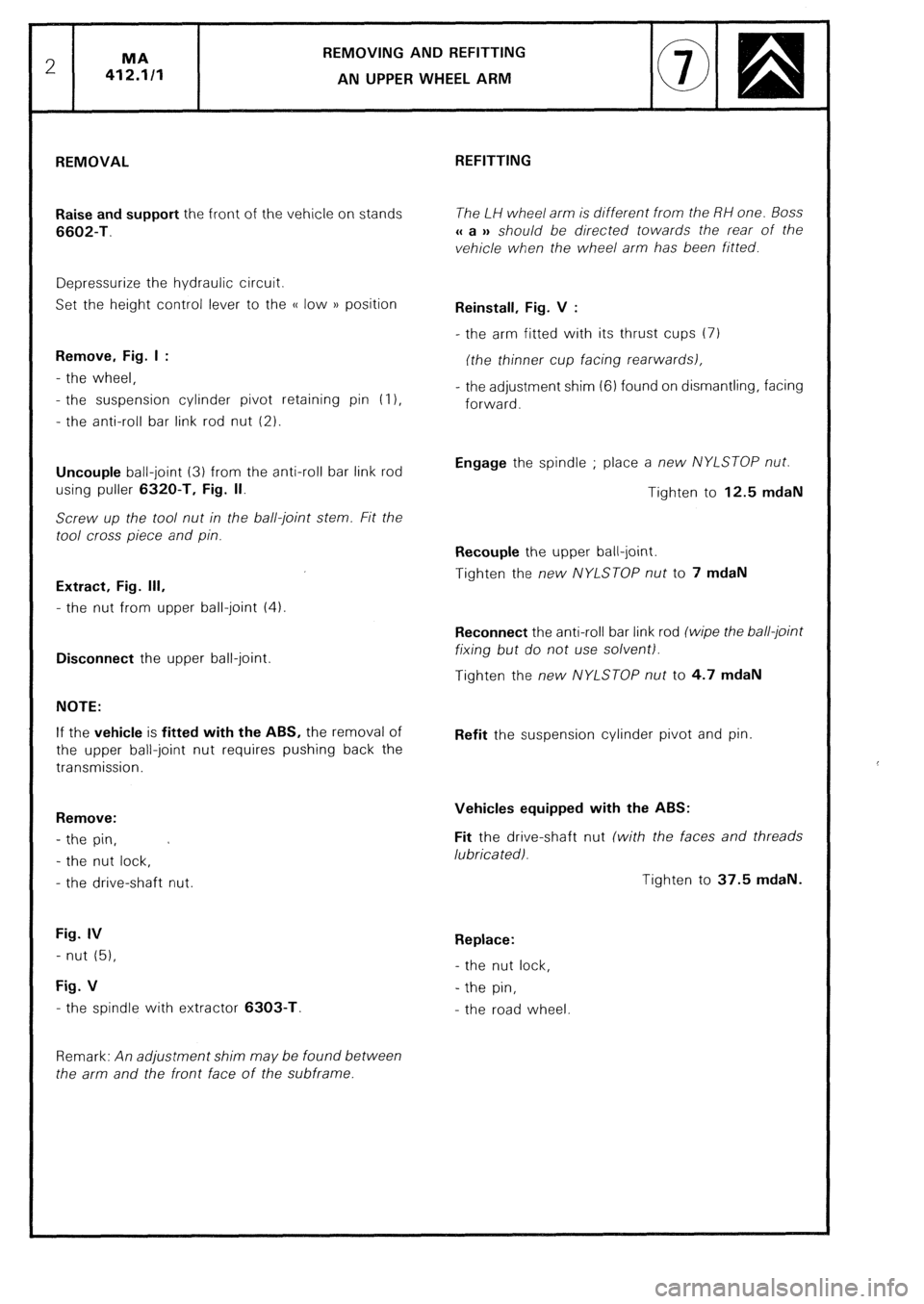

REMOVAL

Raise and support the front of the vehicle on stands

6602-T.

Depressurize the hydraulic circuit.

Set the height control lever to the (( low )) position

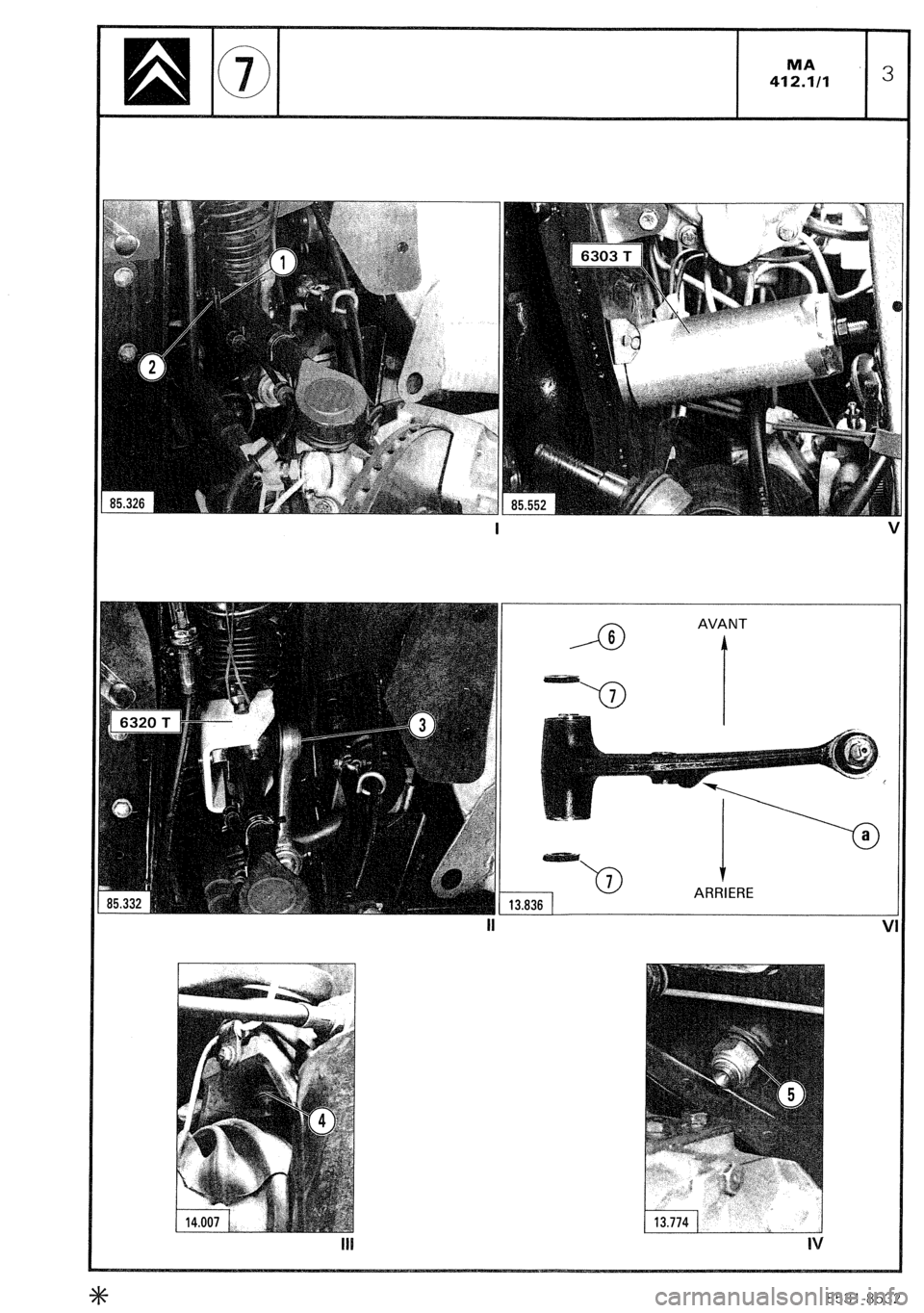

Remove, Fig. I :

- the wheel,

- the suspension cylinder pivot retaining pin (I 1,

- the anti-roll bar link rod nut (2).

Uncouple ball-joint (3) from the anti-roll bar link rod

using puller 6320-T. Fig. II.

Screw up the tool nut in the ball-joint stem. Fit the

tool cross piece and pin.

Extract, Fig. Ill,

- the nut from upper ball-joint (4).

Disconnect the upper ball-joint.

NOTE:

If the vehicle is fitted with the ABS, the removal of

the upper ball-joint nut requires pushing back the

transmission.

Remove:

- the pin, C

- the nut lock,

- the drive-shaft nut.

Fig. IV

- nut (51,

Fig. V

- the spindle with extractor 6303-T.

Remark: An adjustment shim may be found between

the arm and the front face of the subframe. REFITTING

The LH wheel arm is different from the RH one. Boss

u a )a should be directed towards the rear of the

vehicle when the wheel arm has been fitted.

Reinstall, Fig. V :

- the arm fitted with its thrust cups (7)

frhe thinner cup facing rearwardsl,

- the adjustment shim (6) found on dismantling, facing

forward.

Engage the spindle ; place a new NYLSTOP nut.

Tighten to 12.5 mdaN

Recouple the upper ball-joint.

Tighten the new NYLSTOP nut to 7 mdaN

Reconnect the anti-roll bar link rod (wipe the ball-joint

fixing but do nor use solventl.

Tighten the new NYLSTOP nut to 4.7 mdaN

Refit the suspension cylinder pivot and pin.

Vehicles equipped with the ABS:

Fit the drive-shaft nut (with the faces and threads

lubricated).

Tighten to 37.5 mdaN.

Replace:

- the nut lock,

- the pin,

- the road wheel

Page 288 of 648

I 1

AVANT

ARRIERE

13.836

II

8531-8532

Page 289 of 648

TOOLS TO BE USED

1671-T

3312-T

or 6323-T

6306-T

6312-T

6602-T

Inertia extractor

Lower wheel arm ball-joint extractor

with bosses.

Lower arm ball-joint extractor

with or without bosses.

Adaptor.

Expandable element to secure the lower

wheel arm fluid blocks.

Set of three stands

REMOVING AND REFITTING

A LOWER WHEEL ARM

8531-8532

Page 290 of 648

REMOVING AND REFITTING

REMOVAL

Support the front of the vehicle on stands 6602-T.

Release the pressure in the hydraulic system.

Set the height control lever to the (( low )) position.

Withdraw:

- the road wheel,

- the brake pad wear warning lamp harness holding

clips,

- the lower ball-joint nut.

Uncouple the lower ball-joint from the arm using puller

3312-T or 6323-T, Fig. I

Take off:

- the plastic trim cover,

- nut (I 1, Fig. II,

- spindle (2) with the help of inertia extractor

1671-T and adaptor 6306-T, Fig. Ill.

Mark adjustment shims (3) and (4) location, Fig. IV.

Remove the wheel arm. REFITTING

Note: the RH and LH arms are not alike.

If the wheel arm has been removed following an

impact, it will be necessary to readjust the caster

angle.

Place the expander of tool 6312-T in the wheel arm,

with screw A pointing rearwards, Fig V.

Bring tubes (5) and (6) into contact, Fig. V. In order

to do so:

Fig. VI :

- Grip the arm in a vice,

- Tighten the expandable element by means of

spanner B from tool 6312-T.

Trending: AUX, display, oil filter, remote start, air suspension, stop start, handbrake