light DATSUN 210 1979 Workshop Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 286 of 548

CD

@

I

I

TL

@

@

AT290

Assembl

I

Prior

to

assembly

dip

all

parts

in

clean

automatic

transmission

fluid

Reverse

disassembly

procedure

to

assemble

brake

2

Use

extreme

care

to

avoid

dam

aging

rubber

ring

when

installing

seal

lace

3

Blow

compressed

air

from

apply

side

of

piston

to

test

for

definite

piston

operation

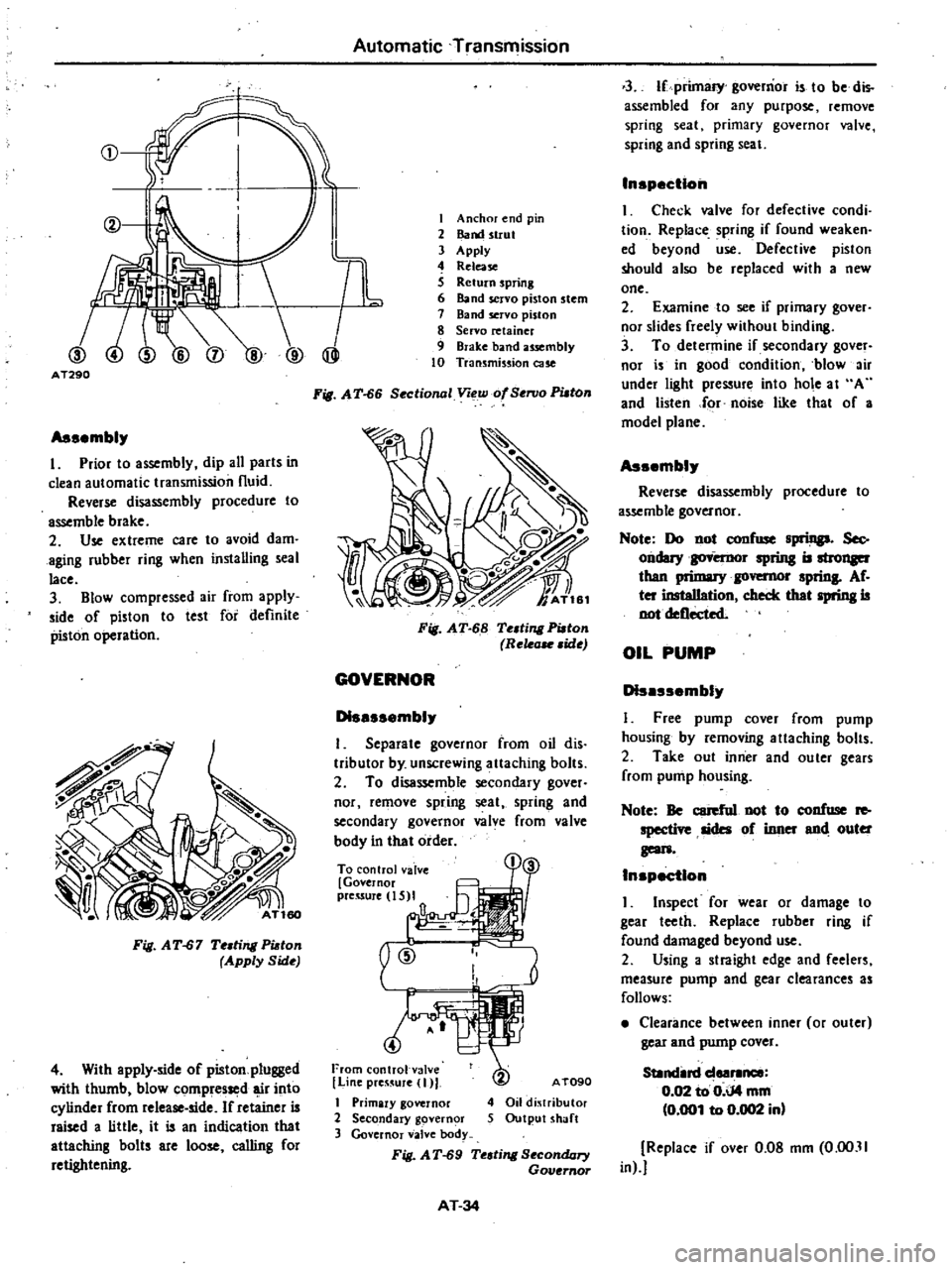

Fig

AT

67

Te

ling

Pi

ton

Apply

Side

4

With

apply

side

of

piston

plugged

with

thumb

blow

compressed

r

into

cylinder

from

release

side

If

retainer

is

raised

a

little

it

is

an

indication

that

attaching

bolts

are

loose

calling

for

retightening

Automatic

Transmission

I

Anchor

end

pin

2

Band

strut

3

Apply

4

Release

S

Return

spring

6

Band

servo

piston

stem

7

Band

servo

piston

8

Servo

retainer

9

Brake

band

usembly

10

Transmission

cue

Fig

A

T

66

Sectional

Voew

of

SenJo

PUlOn

Fig

AT

68

Te

ting

Pi

ton

Rele

ide

GOVERNOR

D1sessembl

I

Separate

governor

from

oil

dis

tributor

by

unscrewing

attaching

bolts

2

To

disassemble

secondary

gover

nor

remove

spring

seat

spring

and

secondary

governor

valve

from

valve

body

in

that

order

To

control

valve

Governor

preuure

IS

I

a

@

From

control

val

e

I

Line

preS

UJe

I

I

Primary

governor

2

Secondary

govern

r

3

Governor

valve

body

Fig

AT

69

Te

ling

SecondQry

Governor

AT090

4

Oil

dj

tributor

5

Output

shaft

AT

34

3

If

primary

governor

is

to

be

dis

assembled

for

any

purpose

remove

spring

seat

primary

governor

valve

spring

and

spring

seal

Inspection

I

Check

valve

for

defective

condi

tion

Replace

spring

if

found

weaken

ed

beyond

use

Defective

piston

should

also

be

replaced

with

a

new

one

2

Examine

to

see

if

primary

gover

nor

slides

freely

without

binding

3

To

determine

if

secondary

gover

nor

is

in

good

condition

blow

ir

under

light

pressure

into

hole

at

A

and

listen

for

noise

like

thaI

of

a

model

plane

Assembl

Reverse

disassembly

procedure

to

assemble

governor

Note

Do

not

confuse

spriDp

Sec

ondary

spring

is

than

1

governor

sprinS

Af

ter

insteIIation

check

thet

spring

is

not

deflected

OIL

PUMP

D1sessembl

I

Free

pump

cover

from

pump

housing

by

removing

allaching

bolts

2

Take

out

inner

and

ouler

gears

from

pump

housing

Note

Be

cerefnl

not

to

confuse

Ie

specti

sides

of

inner

end

outer

geon

Inspection

I

Inspect

for

wear

or

damage

to

gear

teeth

Replace

rub

bel

ring

if

found

damaged

beyond

use

2

Using

a

straight

edge

and

feelers

measure

pump

and

gear

clearances

as

follows

Clearance

between

inner

or

outer

gear

and

pump

cover

SUndin

deer1lnee

0

02

to

0

iJ4

mm

0

001

to

0

002

in

Replace

if

over

0

08

mm

0

00

11

in

Page 292 of 548

Place

the

vehicle

in

a

pit

and

by

sampling

the

lealeed

oil

deiermine

if

it

is

the

torque

converter

oil

The

torque

converter

oil

has

a

color

like

red

wine

so

it

is

easily

distinguished

from

engine

oil

or

gear

oil

Wipe

off

the

lealeing

oil

and

dust

and

detect

the

spot

of

ill

lell8e

nonflammable

organic

solvent

such

as

carbon

tetrachloride

for

wiping

Raise

the

oil

tcmperature

by

op

erating

the

engine

and

shift

the

lever

to

D

to

increase

the

oil

pressure

The

sp

Q

of

o

1

1I8

u

J1en

be

found

more

easily

Note

As

oil

leakage

from

the

breath

er

does

not

talee

place

except

when

running

at

high

peed

it

iSimpos

sible

to

ate

this

lealcage

with

vehicle

stationary

CHECKING

ENGINE

IDLING

REVOLunON

The

engine

idling

revolution

should

be

properly

adjusted

If

the

engine

revolution

is

too

low

the

e

gine

does

not

operate

smoothly

and

if

too

high

a

strong

shocle

or

creep

develops

when

changing

over

from

ON

to

Dn

or

R

CHECKING

AND

ADJUSTING

KICK

WN

SWITCH

AND

DOWNSH

FT

SOLENOID

When

the

Ieickdown

operation

is

not

made

properly

or

the

speed

chang

ingpoint

is

too

high

check

the

kick

down

switch

downshift

solenoid

and

wiring

between

them

When

the

igni

tion

Ieey

is

po

iti

ned

at

the

1st

stage

and

the

accelerator

pedal

is

depressed

deeply

the

switch

contact

hould

be

closed

and

the

solenoid

should

clicle

If

it

does

not

click

it

indicates

a

defect

Then

check

each

part

with

the

testing

inatrumen15

Auto

lT1atic

Transmissiqn

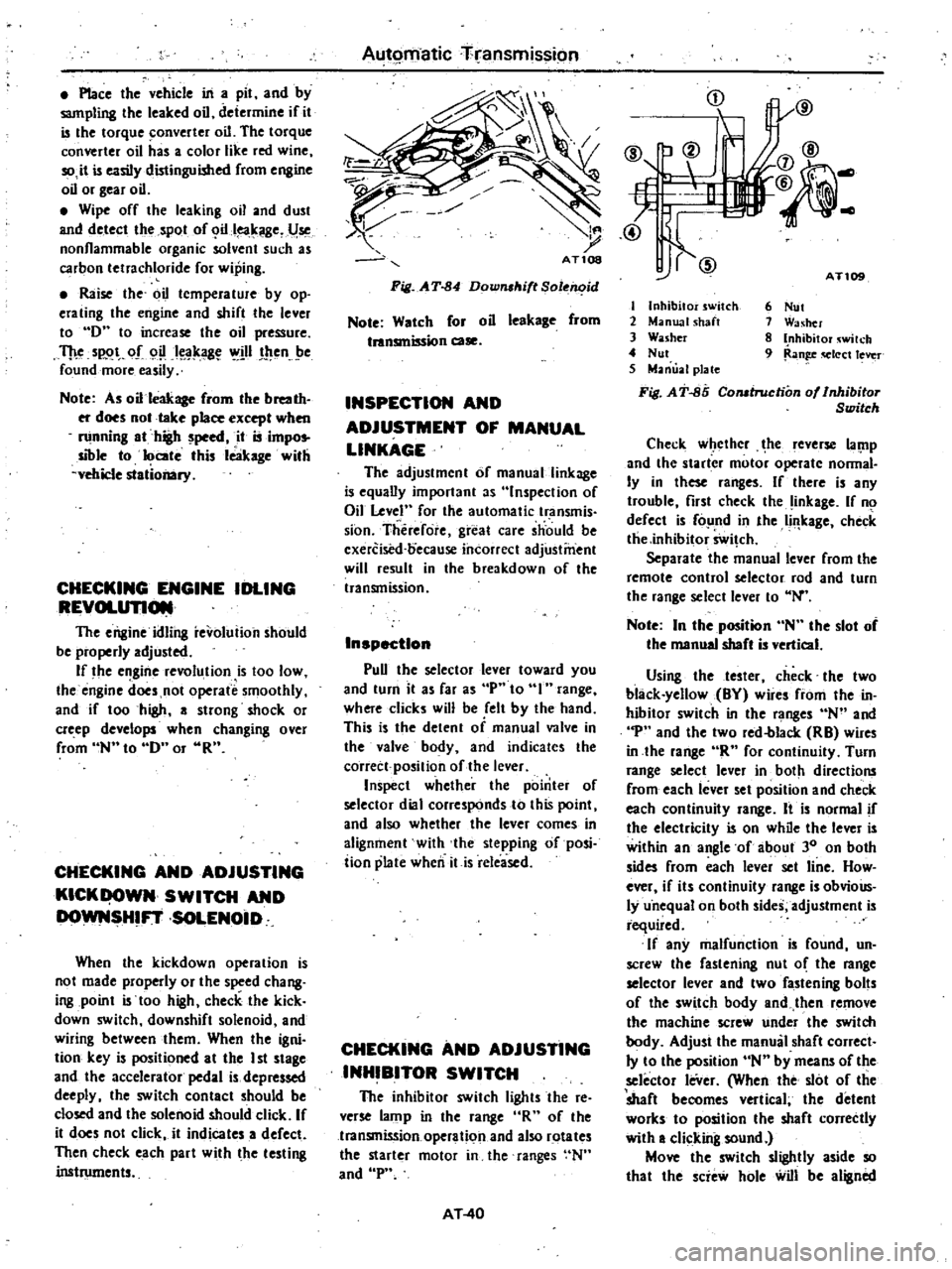

Fi

J

A

T

84

Down

ltift

Sole

id

Note

Watch

for

oil

leekage

from

tnnsmission

case

INSPECTION

AND

ADJUSTMENT

OF

MANUAL

LINKAGE

The

adjustmcnt

of

manual

linkage

i

equany

important

as

Inspection

of

Oil

Level

for

the

automatic

transmis

sion

Therefore

great

care

should

be

cxercised

oecause

incorrect

adjustment

will

result

in

the

breakdown

of

the

transmission

Inspection

pun

the

selector

lever

toward

you

and

turn

it

as

far

as

p

to

range

where

clicks

will

be

ell

by

the

hand

This

is

the

detent

of

manual

valve

in

the

valve

body

and

indicates

the

corrett

position

of

the

lever

Inspect

whether

the

pointer

of

selector

dial

corresponds

to

this

point

and

also

whether

the

lever

comes

in

alignment

with

the

stepping

of

posi

iion

plate

when

itis

released

CHECKING

AND

ADJUSTING

INHIBITOR

SWITCH

The

inhibitor

switch

lights

the

re

verse

lamp

in

the

range

R

of

the

transmission

operation

and

also

rotates

the

starter

motor

in

the

ranges

N

and

P

AT

40

i

j

tI

IlV

@

@

AT

I

Inhibitor

switch

2

Manual

shaft

3

Washer

4

Nut

5

Manual

plate

Fi

J

AT

85

Comtruction

of

Inhibitor

Switch

6

Nut

1

Washer

8

Inhibitor

wilch

9

Ran

q

Iect

lever

Check

w

ethcr

he

leverse

lal

1p

and

the

starter

motor

operate

nonnal

Iy

in

these

ranges

If

there

is

any

trouble

first

check

the

inkage

If

no

defect

is

fo

nd

in

the

Ii

leage

check

tlie

inhibitor

Swi

ch

Separate

the

manual

lever

from

the

remote

control

selector

rod

and

turn

the

range

select

lever

to

N

Note

In

the

position

N

the

slot

of

the

manual

shaft

is

vertical

Using

the

tester

check

the

two

black

yellow

BY

wire

from

the

in

hibitor

switch

in

the

ranges

N

and

p

and

the

two

red

blacle

RB

wires

in

the

lange

R

for

continuity

Turn

range

select

lever

in

both

directions

from

each

lever

set

position

and

check

each

continuity

range

It

is

normal

if

the

electricity

is

on

while

the

lever

is

within

an

angle

of

about

30

on

both

sides

from

each

lever

set

line

How

ever

if

its

continuity

range

is

obvioUs

ly

u

nequal

on

both

sides

adjustment

is

required

If

any

malfunction

is

found

un

screw

the

fastening

nut

o

the

range

selector

lever

and

two

fastening

bolts

of

the

switch

body

and

then

remove

the

machine

screw

under

the

switch

body

Adjust

the

manual

shaft

correct

Iy

to

the

position

N

by

means

of

the

selector

leVer

When

the

slot

of

the

shaft

becomes

vertical

the

detent

worles

to

position

the

shaft

correctly

with

a

clicking

sound

Move

the

switch

slightly

aside

so

that

the

scie

hole

will

be

aligned

Page 311 of 548

they

are

worn

damaged

or

otherwise

faulty

and

how

they

are

affected

Re

pair

or

replace

all

faulty

parts

which

ever

is

necessary

1

Check

gear

teeth

for

scoring

cracking

or

chipping

and

make

sure

that

tooth

contact

pattern

indicates

correct

meshing

depth

If

any

fault

is

evident

replace

parts

as

required

Note

Drive

pinion

and

ring

gear

are

supplied

for

replacement

as

a

set

therefore

should

either

part

be

damaged

replece

as

a

set

2

Check

pinion

shaft

and

pinion

mates

for

scores

and

signs

of

wear

and

replace

as

required

F

oUow

the

same

procedure

for

side

gear

and

their

seats

on

differential

case

3

Inspect

all

bearing

races

and

roU

ers

for

scoring

chipping

or

evidence

of

excessive

wear

They

should

be

in

tiptop

condition

such

as

not

worn

and

with

mirror

like

surfaces

Replace

if

there

is

a

shadow

of

doubt

on

their

efficiency

as

an

incorrect

bearing

op

eration

may

result

in

noises

and

gear

seizure

4

Inspect

thrust

washer

faces

SmaU

faults

can

be

corrected

with

sand

paper

If

pinion

mate

to

de

gear

backlash

exceeds

specified

value

re

place

thrust

washers

Pinion

mate

to

side

gear

backlash

0

10

to

0

20

mm

0

0039

to

0

0079

in

5

Inspect

gear

carrier

and

differ

ential

case

for

cracks

or

distortion

If

either

condition

is

evident

replace

Jaulty

parts

6

As

a

general

rule

oil

seal

should

be

replaced

at

each

disassembly

ASSEMBLY

AND

ADJUSTMENT

Assembly

can

be

done

in

the

reverse

order

of

disassembly

The

foUowing

directions

for

adjustment

and

usage

of

special

tools

enable

to

obtain

a

perfect

differential

operation

Propeller

Shaft

Differential

Carrier

PRECAUTIONS

IN

REASSEMBLY

I

Arrange

shims

washers

and

the

like

to

install

them

correctly

2

Thoroughly

clean

the

surfaces

on

which

shims

washers

bearings

and

bearing

caps

are

installed

3

Apply

gear

oil

when

installing

bearings

4

Pack

grease

cavity

between

lips

when

fitting

oil

seal

ASSEMBLY

OF

DIFFERENTIAL

CASE

1

Assemble

pinion

mates

side

gears

and

thrust

washers

in

differential

case

2

Fit

pinion

shaft

to

differential

case

so

that

it

meets

lock

pin

hole

3

Adjust

pinion

mate

to

ide

gear

backlash

or

the

clearance

between

the

rear

face

of

side

gear

and

thrust

washer

to

the

specified

value

by

selecting

side

gear

thrust

washer

Pinion

mate

to

side

gear

backlash

0

10

to

0

20

mm

10

0039

to

0

0079

in

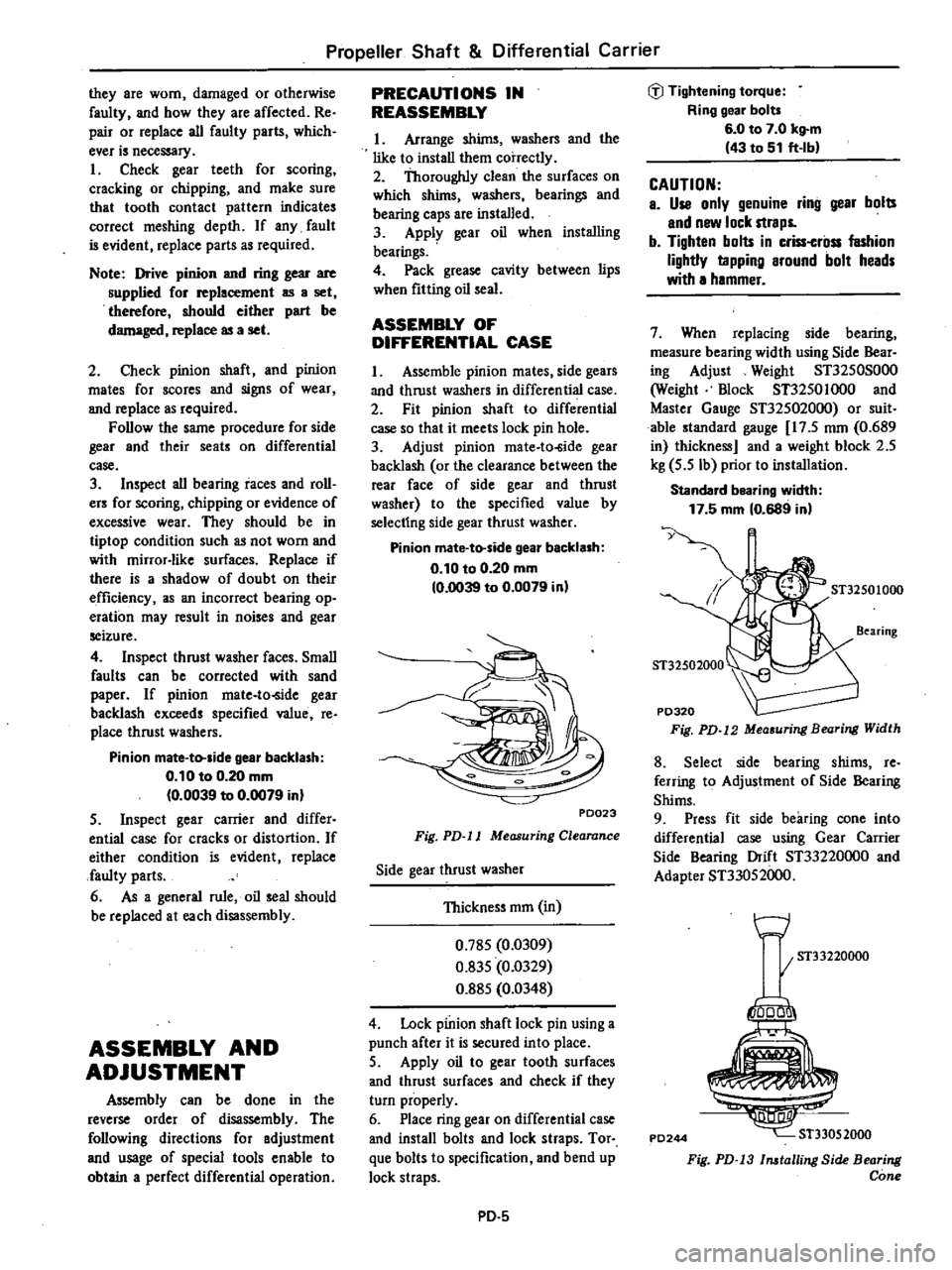

PD023

Fig

PD

l1

Measuring

Clearance

Side

gear

thrust

washer

Thickness

mm

in

0

785

0

0309

0

835

0

0329

0

885

0

0348

4

Lock

pinion

shaft

lock

pin

using

a

punch

after

it

is

secured

into

place

5

Apply

oil

to

gear

tooth

surfaces

and

thrust

surfaces

and

check

if

they

turn

properly

6

Place

ring

gear

on

differential

case

and

install

bolts

and

lock

straps

Tor

que

bolts

to

specification

and

bend

up

lock

straps

PO

5

tiJ

Tightening

torque

Ring

gear

bolt

6

0

to

7

0

kg

m

43

to

51

ft

Ib

CAUTION

e

Use

only

genuine

ring

gear

bolts

end

new

lock

straps

b

Tighten

bolts

in

criss

crilss

fashion

lightly

tapping

around

bolt

heads

with

a

hammer

7

When

replacing

side

bearing

measure

bearing

width

using

Side

Bear

ing

Adjust

Weight

ST3250S000

Weight

mock

ST3250

I

000

and

Master

Gauge

ST325020oo

or

suit

able

standard

gauge

17

5

nun

0

689

in

thickness

and

a

weight

block

2

5

kg

5

5

Ib

prior

to

installation

Standald

bearing

width

17

5

mm

10

689

in

y

ST32501000

8

Select

side

bearing

shims

re

ferring

to

Adjustment

of

Side

Bearing

Shims

9

Press

fit

side

bearing

cone

into

differential

case

using

Gear

Carrier

Side

Bearing

Drift

ST33220oo0

and

Adapter

ST33052000

w

I

ST33220000

PD244

1000

ST33052000

Fig

PD

13

lnatalling

Side

Bearing

Cone

Page 314 of 548

EX

2

A

0

B

3

C

I

D

2

E

O

I

F

0

08

H

I

Left

side

T

A

C

D

H

xO

OI

0

20

E

0

H

2

1

x

0

01

0

20

0

11

0

0

20

0

1

0

31

The

correct

shims

are

0

10

plus

lI

re

e

pi

ce

s

of

9

Q7

I

Il1I

thick

Right

side

T2

B

D

H

xO

OI

020

F

3

2

I

xO

01

0

20

0

08

0

02

0

20

0

08

0

30

The

correct

shims

are

0

10

plus

0

20

mm

thick

Note

If

w1ues

sigoifying

A

B

C

D

and

H

are

not

giVen

regard

them

as

zero

end

compote

After

essembly

clteek

to

see

that

preload

and

backlesb

ere

correct

If

not

readjust

Side

bearing

adjusting

shim

Thickness

mm

in

0

05

0

0020

0

07

0

0028

0

1

0

0

0039

0

20

0

0079

0

50

0

0197

2

Fit

determined

side

bearing

ad

justing

shim

on

differential

case

and

press

fit

left

and

right

side

bearing

inner

races

on

it

using

Side

Bearing

Drift

ST3322OO00

and

Adapter

ST33052000

3

Install

differential

case

assembly

into

gear

carrier

tapping

with

a

rubber

mallet

4

Align

mark

on

bearing

cap

with

that

on

gear

carrier

and

install

bearing

cap

on

carrier

And

tighten

bolts

to

specified

torque

Propeller

Shaft

Differential

Carrier

@Tightenirig

tOrque

Side

bealingcap

bolts

5

0

to

6

0

kg

m

36

to

43

ft

b

5

M

easure

L

dimension

between

left

and

right

bearing

cap

edges

with

a

micrometer

e

cljmension

153

40

to

153

45

mm

6

0394

to

6

0413

inl

PD271

Fig

PD

20

Measuring

L

Dimension

6

Measure

ring

gear

to

drive

pinion

backlash

If

backlash

is

too

smaU

decrease

thickness

of

left

shim

and

increase

thickness

of

right

shim

by

the

same

amount

If

backlash

is

too

great

reverse

the

above

procedure

Ring

gear

to

drive

pinion

backlash

0

10

to

0

15

mm

0

0039

to

0

0059

in

PD272

Fig

PD

21

Mea

uring

Backlash

7

At

the

same

time

check

side

bearing

preload

Bearing

preload

should

be

specified

torque

If

preload

does

not

accord

with

tJiis

specification

adjust

it

with

side

bear

ing

shims

PD

B

Side

bealing

preload

8

to

10

kg

cm

6

9

to

8

7

in

bl

At

ring

geer

bolt

1

5

to

1

9

kg

3

3

to

4

2

Ibl

8

Check

and

adjust

the

tooth

con

t

c

pattern

of

ring

gear

and

drive

pinion

I

Thoroughly

clean

ring

and

drive

pinion

gear

teeth

2

Paint

ring

gear

teeth

lightly

and

evenly

with

a

mixture

of

recommend

ed

powder

and

oil

of

a

suitable

consist

ency

to

produce

a

contactpaUern

3

Rotate

pinion

through

several

revolutions

in

the

forward

and

reverse

direction

until

a

definite

contact

pat

tern

i

developed

on

ring

gear

4

When

contact

pattern

is

in

correct

readjust

thickness

oLadjust

ing

shim

Be

sure

to

wipe

off

powder

com

pletely

upon

completion

of

adjust

ment

5

Incorrect

contact

pattern

of

teeth

can

be

adjusted

in

the

foUowing

manner

Contact

pettern

a

Heel

contact

To

correct

increase

thickness

of

drive

pinion

adjusting

washer

in

order

to

bring

drive

pinion

close

to

ring

gear

P0193

Fig

PD

22

Heel

Contact

b

Toe

contact

To

correct

reduce

thickness

of

drive

pinion

adjusting

washer

in

order

to

make

drive

pinion

go

away

from

ring

gear

t

PD194

Fig

PD

23

Toe

Contact

Page 324 of 548

Front

Axle

Front

Suspension

INSPECTION

AND

ADJUSTIVIENT

INSPECTION

Inspect

in

accordance

with

periodic

maintenance

schedule

Block

rear

wheels

with

chocks

2

Jack

up

the

front

of

car

and

support

it

with

safety

stands

Refer

to

Section

GI

for

lifting

points

and

towing

3

Shaking

each

fiont

wheel

by

grasping

the

upper

and

lower

surfaces

of

the

tires

check

suspension

parts

for

looseness

wear

or

damage

Tighten

aU

loose

bolts

and

nuts

to

the

specified

torque

Replace

all

worn

parts

as

described

under

Front

Suspension

4

Check

wheel

bearings

If

there

is

any

axial

end

play

adjust

bearings

to

specifications

Replace

worn

or

damaged

bearings

as

described

under

Front

Axle

S

Check

strut

for

oil

leakage

or

damage

ADJUSTMENT

WHEEL

BEARING

Block

rear

wheels

with

chocks

2

Jack

up

the

front

of

car

and

support

it

with

safety

stands

3

Remove

brake

pads

Refer

to

Section

BR

for

pad

replacement

4

Remove

hub

cap

cotter

pin

ad

justing

cap

and

wheel

bearing

nut

S

Sparingly

apply

recommended

multi

purpose

grease

to

threaded

por

tion

of

spindle

and

contact

surface

between

wheel

bearing

washer

and

outer

wheel

bearing

6

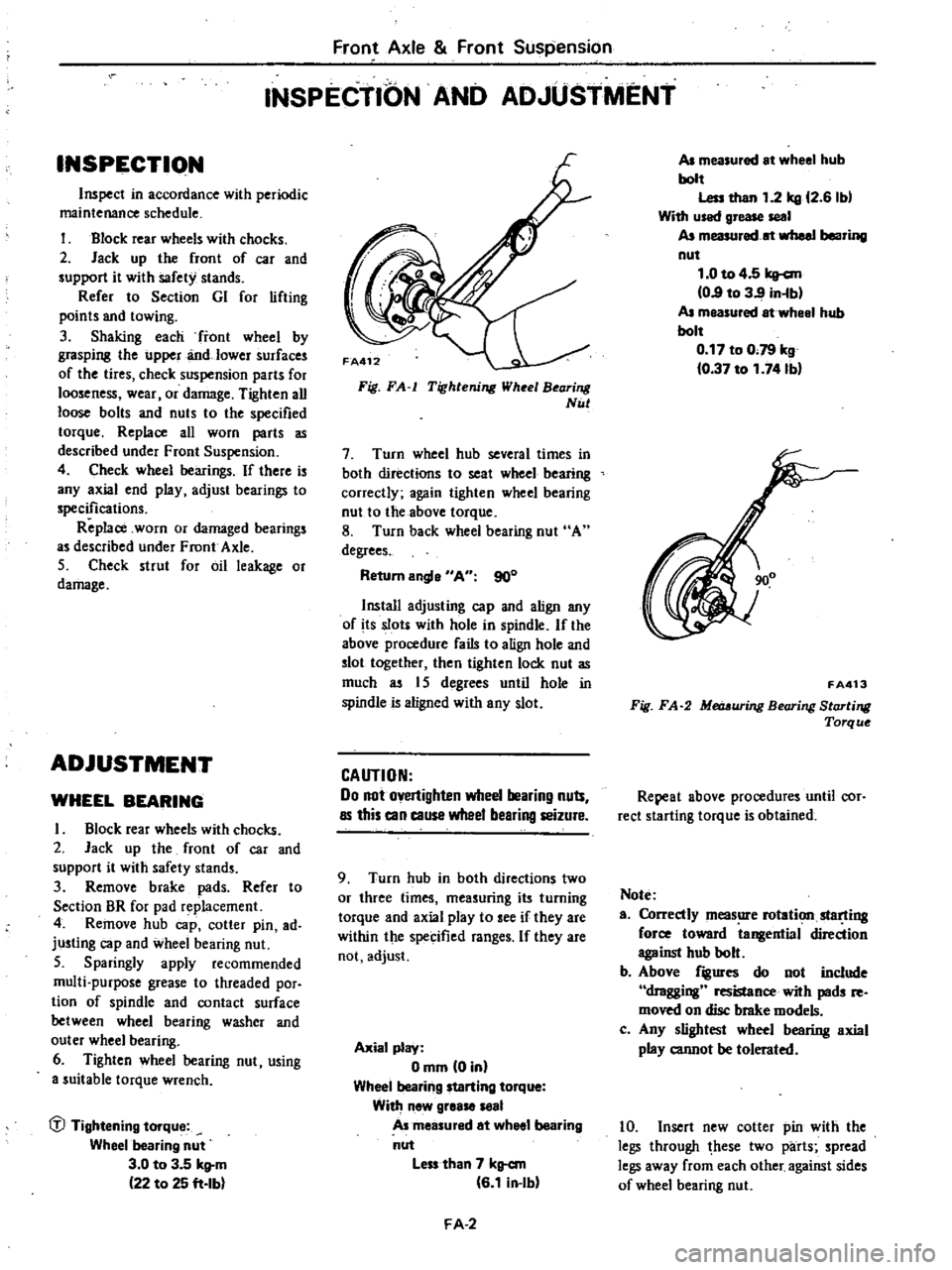

Tighten

wheel

bearing

nut

using

a

suitable

torque

wrench

P

Tightening

torque

Wheel

bearing

nut

3

0

to

3

5

kll

m

22

to

25

ft

Ibl

Fig

FA

Tighlening

Wheel

Bearing

Nul

7

Turn

wheel

hub

several

times

in

both

directions

to

seat

wheel

bearing

correctly

again

tighten

wheel

bearing

nut

to

the

above

torque

8

Turn

back

wheel

bearing

nut

A

degrees

Return

engle

AU

900

Install

adjusting

cap

and

align

any

of

its

slots

with

hole

in

spindle

If

the

above

procedure

fails

to

align

hole

and

slot

together

then

tighten

lock

nut

as

much

as

I

S

degrees

until

hole

in

spindle

is

aligned

with

eny

slot

CAUTION

00

not

overtighten

wheel

bearing

nuts

as

this

can

cause

wheel

bearing

seizure

9

Turn

hub

in

both

directions

two

or

three

times

measuring

its

turning

torque

and

axial

play

to

ee

if

they

are

within

the

specified

range

If

they

are

not

adjust

Axial

play

Omm

Din

Wheel

bealing

starting

torque

With

new

gleaS8

l8al

A

measured

et

wheel

bearing

nut

less

than

7

kg

cm

G

1

in

Ibl

FA

2

AJ

measuled

et

wheel

hub

bolt

Less

then

1

2

kg

12

G

Ibl

With

u

ed

gr

seal

AJ

measured

at

wheel

bealing

nut

1

0

to

4

5

kg

cm

0

9

to

3

9

in

b

AJ

measuled

at

wheel

hub

bolt

0

17

to

0

79

kg

0

37

to

1

741bl

FA413

Fig

FA

2

Metr

uring

Bearing

Starting

Torq

ue

Repeat

above

procedures

until

cor

rect

starting

torque

is

obtained

Note

a

Correctly

meas

e

rotation

slar

ting

force

toward

tangential

direction

against

hub

bolt

b

Above

figures

do

not

include

dragging

resistance

with

pads

re

moved

on

disc

brake

models

c

Any

slightest

wheel

bearing

axial

play

cannot

be

tolerated

10

Insert

new

cotter

pin

with

the

legs

through

hese

two

parts

spread

legs

away

from

each

other

against

sides

of

wheel

bearing

nut

Page 339 of 548

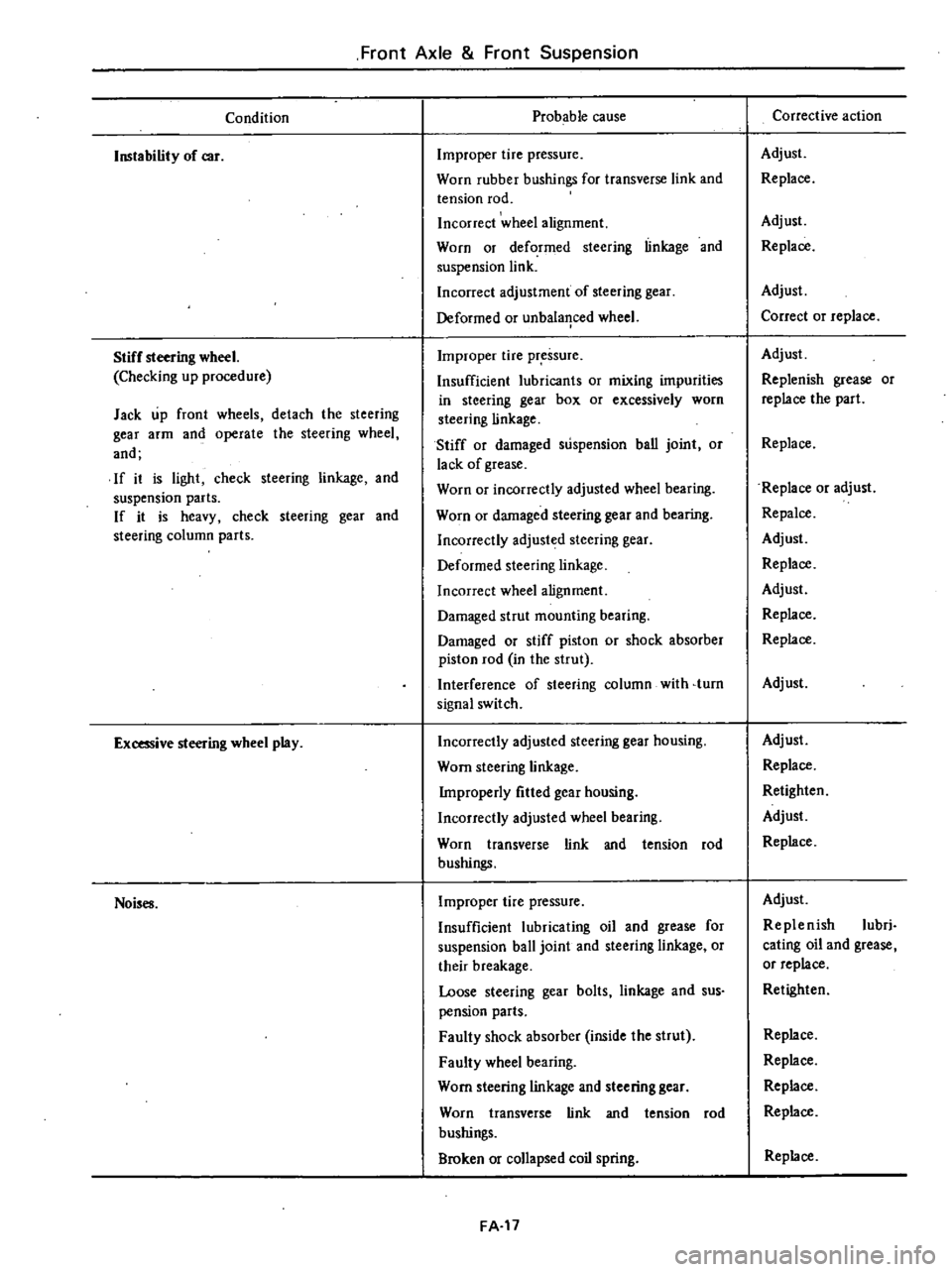

Front

Axle

Front

Suspension

Condition

Instability

of

car

Stiff

steering

wheel

Checking

up

procedure

Jack

up

front

wheels

detach

the

steering

gear

arm

and

operate

the

steering

wheel

and

If

it

is

light

check

steering

linkage

and

suspension

parts

If

it

is

heavy

check

steering

gear

and

steering

column

parts

Excessive

steering

wheel

play

Noises

Probable

cause

Improper

tire

pressure

Worn

rubber

bushings

for

transverse

link

and

tension

rod

Incorrect

wheel

alignment

Worn

or

deformed

steering

linkage

and

suspension

link

Incorrect

adjustment

of

steering

gear

Deformed

or

unbala

1ced

wheel

Improper

tire

pressure

Insufficient

lubricants

or

mixing

impurities

in

steering

gear

box

or

excessively

worn

steering

linkage

Stiff

or

damaged

suspension

ban

joint

or

lack

of

grease

Worn

or

incorrectly

adjusted

wheel

bearing

Worn

or

damaged

steering

gear

and

bearing

Incorrectly

adjusted

steering

gear

Deformed

steering

linkage

Incorrect

wheel

alignment

Damaged

strut

mounting

bearing

Damaged

or

stiff

piston

or

shock

absorber

piston

rod

in

the

strut

Interference

of

steering

column

with

turn

signal

switch

Incorrectly

adjusted

steering

gear

housing

Worn

steering

linkage

Improperly

fitted

gear

housing

Incorrectly

adjusted

wheel

bearing

Worn

transverse

link

and

tension

rod

bushings

Improper

tire

pressure

Insufficient

lubricating

oil

and

grease

for

suspension

ball

joint

and

steering

linkage

or

their

breakage

Loose

steering

gear

bolts

linkage

and

sus

pension

parts

Faulty

shock

absorber

inside

the

strut

Faulty

wheel

bearing

Worn

steering

linkage

and

steering

gear

Worn

transverse

link

and

tension

rod

bushings

Broken

or

collapsed

coil

spring

FA

17

Corrective

action

Adjust

Replace

Adjust

Replace

Adjust

Correct

or

replace

Adjust

Replenish

grease

or

replace

the

part

Replace

Replace

or

adjust

Repalce

Adjust

Replace

Adjust

Replace

Replace

Adjust

Adjust

Replace

Retighten

Adjust

Replace

Adjust

Replenish

lubri

cating

oil

and

grease

or

replace

Retighten

Replace

Replace

Replace

Replace

Replace

Page 354 of 548

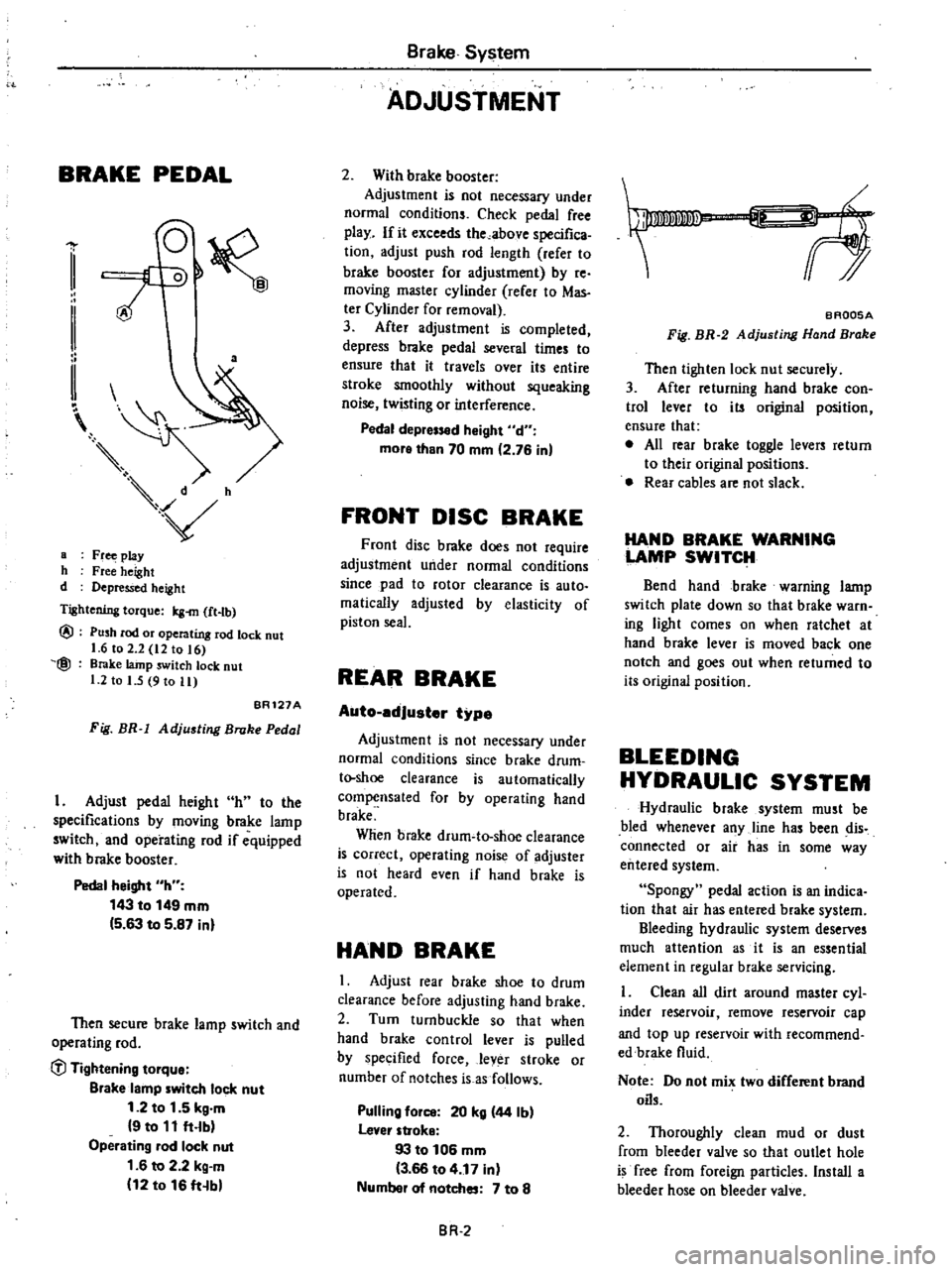

BRAKE

PEDAL

a

a

Fr

play

h

Free

height

d

Depressed

height

Tightening

torque

Icg

m

ft

tb

@

@

Push

rod

or

operating

rod

lock

nut

1

6

to

2

2

12

to

16

Brake

lainp

switch

lock

nut

1

2

to

I

5

9

to

11

BR121A

Fig

BR

1

Adjusting

Broke

Pedal

I

Adjust

pedal

height

h

to

the

specifications

by

moving

brake

lamp

switch

and

operating

rod

if

equipped

with

brake

booster

Pedal

height

h

143

to

149

mm

5

63

to

5

87

inl

Then

secure

brake

lamp

switch

and

operating

rod

C

l

Tightening

tOlque

Blake

lamp

witch

lock

nut

1

2

to

1

5

kg

m

9

to

11

ft

lb

Operating

lad

lock

nut

1

6

to

2

2

kg

m

12

to

16

ft

b

Brake

System

ADJUSTMENT

2

With

brake

booster

Adjustment

is

not

necessary

under

normal

conditions

Check

pedal

free

play

If

it

exceeds

the

above

specifica

tion

adjust

push

rod

length

refer

to

brake

booster

for

adjustment

by

re

moving

master

cylinder

rerer

to

Mas

ter

Cylinder

for

removal

3

After

adjustment

is

completed

depress

brake

pedal

several

times

to

ensure

that

it

travels

over

its

entire

stroke

smoothly

without

squeaking

noise

twisting

or

interference

Pedal

depr

d

Might

d

more

than

70

mm

2

76

in

FRONT

DISC

BRAKE

Front

disc

brake

does

not

require

adjustment

under

normal

conditions

since

pad

to

rotor

clearance

is

auto

malically

adjusted

by

elasticity

of

piston

seal

REAR

BRAKE

Auto

edJuster

type

Adjustment

is

not

necessary

under

normal

conditions

since

brake

drum

t

shoe

clearance

is

automatically

compensated

for

by

operating

hand

brake

Wlien

brake

drum

to

shoe

clearance

is

correct

operating

noise

of

adjuster

is

not

heard

even

if

hand

brake

is

operated

HAND

BRAKE

I

Adjust

rear

brake

shoe

to

drum

clearance

before

adjusting

hand

brake

2

Turn

turnbuckle

so

that

when

hand

brake

control

lever

is

pulled

by

specified

force

lever

stroke

or

number

of

notches

is

as

follows

Pulling

fOil

20

kg

44

Ib

lever

stroke

93

to

106

mm

3

66

to

4

17

in

Numbel

of

notches

7

to

8

BR

2

f

BAQ05A

Fig

BR

2

Adjusting

Hand

Brake

Then

tighten

lock

nut

securely

3

After

returning

hand

brake

con

trol

lever

to

its

original

position

ensure

that

e

All

rear

brake

toggle

levers

return

to

their

original

positions

Rear

cables

are

not

slack

HAND

BRAKE

WARNING

LAMP

SWITCH

Bend

hand

brake

warning

lamp

switch

plate

down

so

that

brake

warn

ing

light

comes

on

when

ratchet

at

hand

brake

lever

is

moved

back

one

notch

and

goes

out

when

returned

to

its

original

position

BLEEDING

HYDRAULIC

SYSTEM

Hydraulic

brake

system

must

be

bled

whenever

any

line

has

been

dis

connected

or

air

has

in

some

way

entered

system

Spongy

pedal

action

is

an

indica

tion

that

air

has

entered

brake

system

Bleeding

hydraulic

system

deserves

much

attention

as

it

is

an

essential

element

in

regular

brake

servicing

Clean

all

dirt

around

master

cyl

inder

reservoir

remove

reservoir

cap

and

top

up

reservoir

with

recommend

edbrake

fluid

Note

Do

not

mix

two

different

brand

oils

2

Thoroughly

clean

mud

or

dust

from

bleeder

valve

so

that

outlet

hole

is

free

from

foreign

particles

Install

a

bleeder

hose

on

bleeder

valve

Page 360 of 548

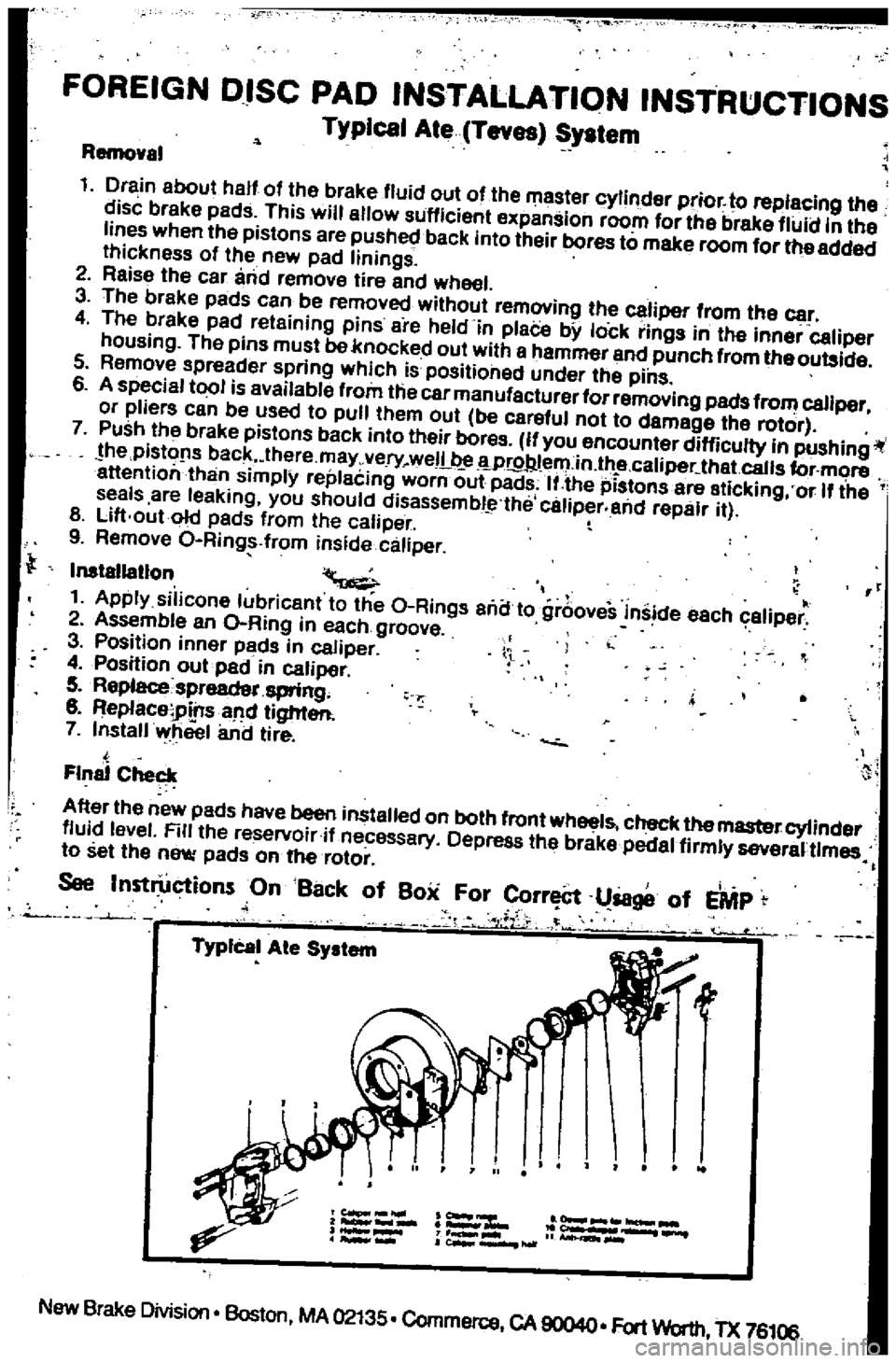

FOREIGN

DISC

PAD

INSTALLATION

INSTRUCTIONS

Typical

Ate

Teves

System

Removel

1

Drain

about

half

of

the

brake

fluid

out

of

the

master

cylinder

prior

to

replacing

the

disc

brake

pads

This

will

allow

sufficient

expansion

room

for

the

brake

fluid

in

the

lines

when

the

pistons

are

pushed

back

into

their

bores

to

make

room

for

the

added

Ihickness

of

the

new

pad

linings

2

Reise

the

car

and

lemove

tire

and

wheel

3

The

breke

pads

can

be

removed

without

lemovinll

the

caliper

from

the

car

4

The

brake

pad

reteining

pins

are

held

in

plaCe

bY

lock

rinlls

in

Ihe

inner

caliper

housing

The

pins

must

be

knocked

out

with

e

hammel

end

punch

from

theoulllide

5

Remove

spreader

spring

which

is

positioned

under

the

pins

6

A

special

tool

is

available

flom

the

car

manufacturer

forremoving

pads

from

caliper

or

pliers

can

be

used

to

pull

them

oul

be

careful

not

to

damage

the

rotor

7

Push

Ihe

brake

pistons

back

into

their

boros

If

you

encounter

difficulty

in

pushingil

he

pistofls

back

lhere

may

very

weIL

Wr9Jl

l

ern

in

lh

e

caliper

that

calls

for

more

attention

than

simplY

replecing

worn

out

pads

IUhe

pistons

are

eticking

or

If

the

seals

are

leaking

you

should

disassembl

the

caliper

and

repair

il

8

Lift

out

old

pads

from

Ihe

caliper

9

Remove

O

Ring

from

inside

caliper

Inslallatlon

II

1

Apply

silicone

lubricanl

to

Ihe

O

Rings

ana

to

grooveS

inside

each

caliper

2

Assemble

an

O

Ring

in

each

groove

3

Position

innor

pads

in

caliper

4

Position

oulpad

in

caliper

5

Replacespreadet

spring

8

ReplaceiPtnsaM

lighter

7

Install

wheel

and

lire

l

Final

Checl

A

Iter

Ihe

new

padS

have

been

installed

on

bolh

front

wheel

check

the

master

cylinder

fluid

level

Rlllhe

reservoiril

necessary

Depress

Ihe

brake

pedal

firmly

severaUlmes

to

sellhe

new

pads

on

he

rotor

i

See

Inst

ctionsOnBat

k

of

Box

For

rr

l8ge

of

EMP

l

iL

1

f

J

TypIcal

Ale

System

New

Brake

Division

Boston

MA

02135

Commerce

CA

90040

Fort

Worth

TX

76106

Page 361 of 548

BR563

Fig

BR

10

Removing

Pad

Inspection

Clean

pads

with

cleaning

solvent

CAUTION

Use

brake

fluid

to

clean

Never

use

mineral

oil

2

When

pads

are

heavily

fouled

with

oil

or

grease

or

when

pad

is

deteriorated

or

deformed

replace

it

3

If

pad

is

worn

to

less

than

the

specified

value

replace

Pad

wear

limit

Minimum

thickness

t

6

mm

0

063

in

Note

Always

replace

pads

in

pad

kit

four

pads

two

clips

four

pad

pins

and

four

pad

springs

4

Check

rotor

referring

to

Rotor

for

inspection

Installetlon

I

Clean

and

apply

P

RC

grease

on

yoke

guide

groove

of

cylinder

body

sliding

contact

portions

of

yoke

and

end

surface

of

piston

Note

a

Do

not

use

common

brake

grease

b

Be

careful

not

to

get

brake

grease

on

rotor

and

pads

2

Loosen

air

bleeder

and

push

pis

ton

B

outer

piston

in

cylinder

until

end

surface

of

piston

B

coincides

with

end

surface

of

retaining

ring

on

boot

Then

inner

pad

can

be

installed

Brake

System

BR564

Fig

BR

11

Pushing

Piston

CAUTION

Piston

can

be

easily

pushed

in

by

hand

but

if

pushed

too

far

groove

of

piston

will

go

inside

of

piston

seal

as

shown

in

Fig

BR

12

At

this

point

if

piston

is

pressured

or

moved

piston

seal

will

be

damaged

If

piston

has

been

pushed

in

too

far

remove

brake

assembly

and

disassemble

it

Then

push

piston

out

in

the

direction

shown

by

arrow

Assemble

it

again

referring

to

follow

ing

section

00

I

Normal

I

position

L

BR409

Fig

BR

12

Position

for

Pushing

Piston

3

Push

piston

A

inner

piston

in

cylinder

by

pulling

yoke

as

shown

The

outer

pad

can

then

be

installed

BRS6S

Fig

BR

13

Pulling

in

Piston

A

BR

7

4

After

installing

pads

depress

brake

pedal

several

times

and

pads

will

settle

into

proper

position

Note

When

worn

out

pads

are

re

placed

with

new

ones

brake

fluid

may

overflow

reservoir

While

re

placing

pads

keep

loosening

bleeder

to

release

brake

fluid

5

Install

wheels

and

lower

car

to

ground

REMOVAL

I

Remove

pads

Refer

to

Pad

Re

placement

2

Remove

brake

tube

from

caliper

assembly

CAUTION

When

removing

brake

tube

use

suit

able

tube

wrench

Never

use

open

end

or

adjustable

wrench

Note

Plug

up

hole

in

caliper

so

that

brake

fluid

does

not

flow

out

from

cylinder

body

3

Loosen

bolts

securing

cylinder

body

to

knuckle

spindle

and

remove

caliper

assembly

from

strut

DISASSEMBLY

I

Drain

brake

fluid

from

top

hole

of

cylinder

body

2

Push

both

pistons

A

and

B

into

cylinder

Refer

to

Pad

Replacement

3

Tap

cylinder

body

lightly

with

a

plastic

hammer

Cylinder

will

then

separate

from

yoke

BR115A

Fig

BR

14

Tapping

Cylinder

Block

Page 362 of 548

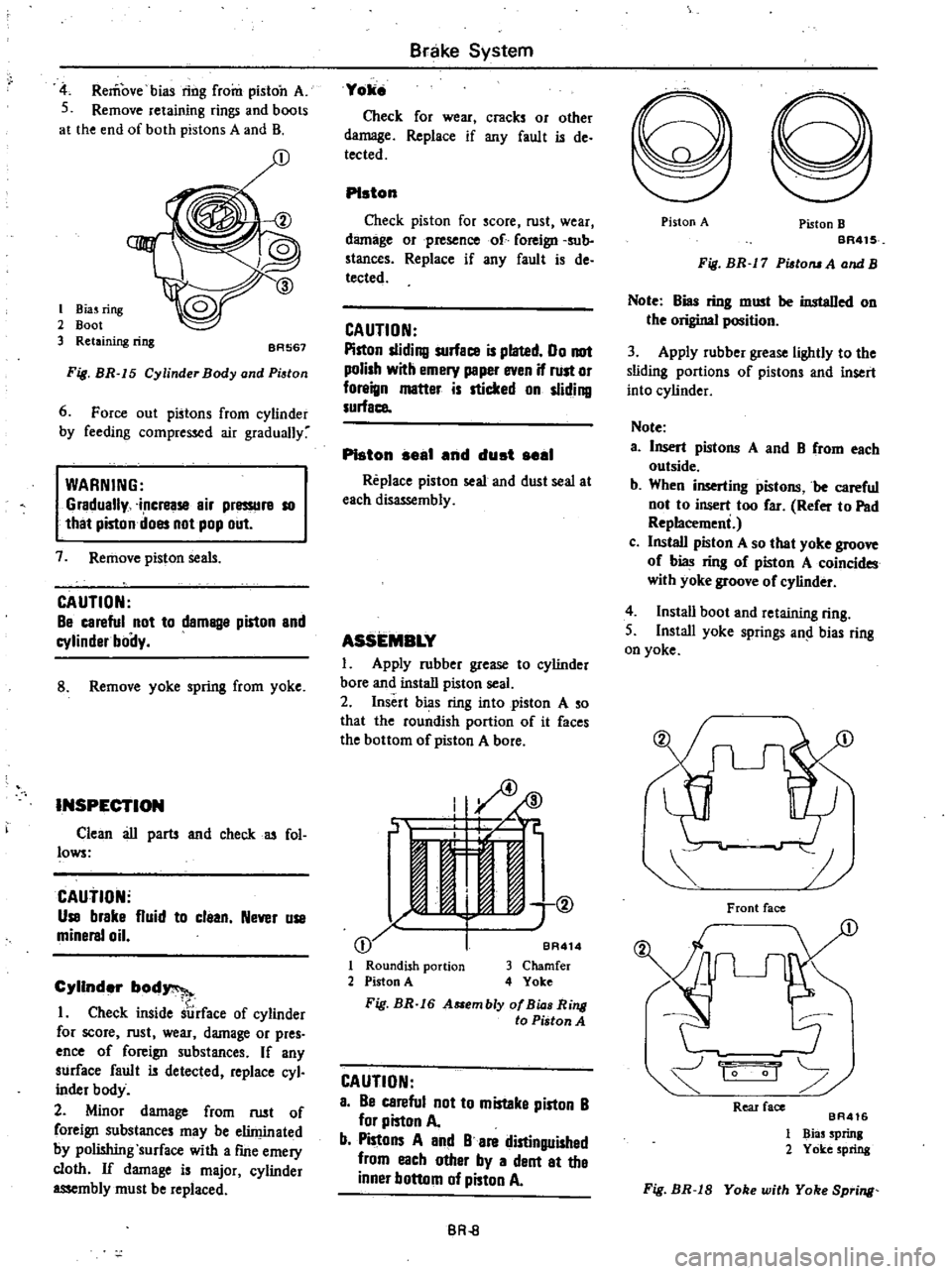

Remove

bias

ring

from

piston

A

S

Remove

retaining

rings

and

boots

at

the

end

of

both

pistons

A

and

B

I

Biuring

2

Boot

3

Retaining

ring

BA567

Fig

BR

15

Cylinder

Body

and

Pi

tan

6

Force

out

pistons

from

cylinder

by

feeding

compressed

air

gradually

WARNING

Gradually

increase

air

pressurs

10

that

piston

does

not

pop

out

7

Remove

piston

seals

CAUTION

Be

careful

not

to

damBlle

piston

and

cylinder

boily

8

Remove

yoke

spring

from

yoke

INSPECTION

Clean

au

parts

and

check

u

fol

lows

CAutiON

Use

brake

fluid

to

claan

Never

use

minersl

oil

Cylinder

bod

1

Check

inside

surface

of

cylinder

for

score

rust

wear

damage

or

pres

ence

of

foreign

substances

If

any

surface

fault

is

detected

replace

cyl

inder

body

2

Minor

damage

from

rust

of

foreign

substances

may

be

eliminated

by

polishing

surface

with

a

fme

emery

cloth

If

damage

is

major

cylinder

assembly

must

be

replaced

Brake

System

Yoke

Check

for

wear

cracks

or

other

damage

Replace

if

any

fault

is

de

tected

PIston

Check

piston

for

score

rust

wear

damage

orpresenco

of

foreign

sub

stances

Replace

if

any

fault

is

de

tected

CAUTION

Piston

sliding

surface

is

plated

00

not

polish

with

emery

peper

even

if

rust

or

foreign

matter

is

sticked

on

sliding

surface

PIston

seal

end

dust

seel

Replace

piston

seal

and

dust

seal

at

each

dis

mbly

ASSEMBLY

1

Apply

rubber

grease

to

cylinder

bore

and

install

piston

seal

2

Insert

bias

ring

into

piston

A

so

that

the

roundish

portion

of

it

faces

the

bottom

of

piston

A

bore

I

ID

J

if

C

jt

11

e

1

@

I

j

BA

I

Roundish

portion

3

Chamfer

2

Piston

A

4

Yoke

Fig

BR

16

A

embly

af

Bia

Ring

to

Piston

A

CAUTION

a

Be

careful

not

to

mistaka

piston

B

for

piston

A

b

Pistons

A

and

B

are

distinguished

from

each

other

by

a

dent

at

the

inner

bottom

of

piston

A

BR

8

Piston

A

Piston

B

BR41S

Fig

BR

17

Pisto

A

and

B

Note

Bias

ring

must

be

instaDed

on

the

original

position

3

Apply

rubber

grease

lightly

to

the

sliding

portions

of

pistons

and

insert

into

cylinder

Note

a

Insert

pistons

A

and

B

from

each

outside

b

When

inserting

pistons

be

careful

not

to

insert

too

far

Refer

to

Pad

Replacemeni

c

Install

piston

A

so

that

yoke

groove

of

bias

ring

of

piston

A

coincides

with

yoke

groove

of

cylinder

4

Instau

boot

and

retaining

ring

S

Install

yoke

springs

an

bias

ring

on

yoke

Front

face

1

1

0

Rear

face

BA416

1

Bias

Sprinl

2

Yoke

spring

Fig

BR

18

Yoke

with

Yoke

Spring