light DATSUN 210 1979 Manual PDF

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 447 of 548

DESCRI

PTI

ON

Cabl

are

covered

with

color

coded

vinyl

for

easy

identification

In

the

wiring

diagram

olors

are

indicated

by

one

or

two

alphabetical

letters

It

is

recommended

that

the

battery

be

disconnected

before

performing

any

electrical

service

other

than

bulb

or

fuse

replacement

In

addition

to

fuses

a

fusible

link

has

been

installed

to

protect

wiring

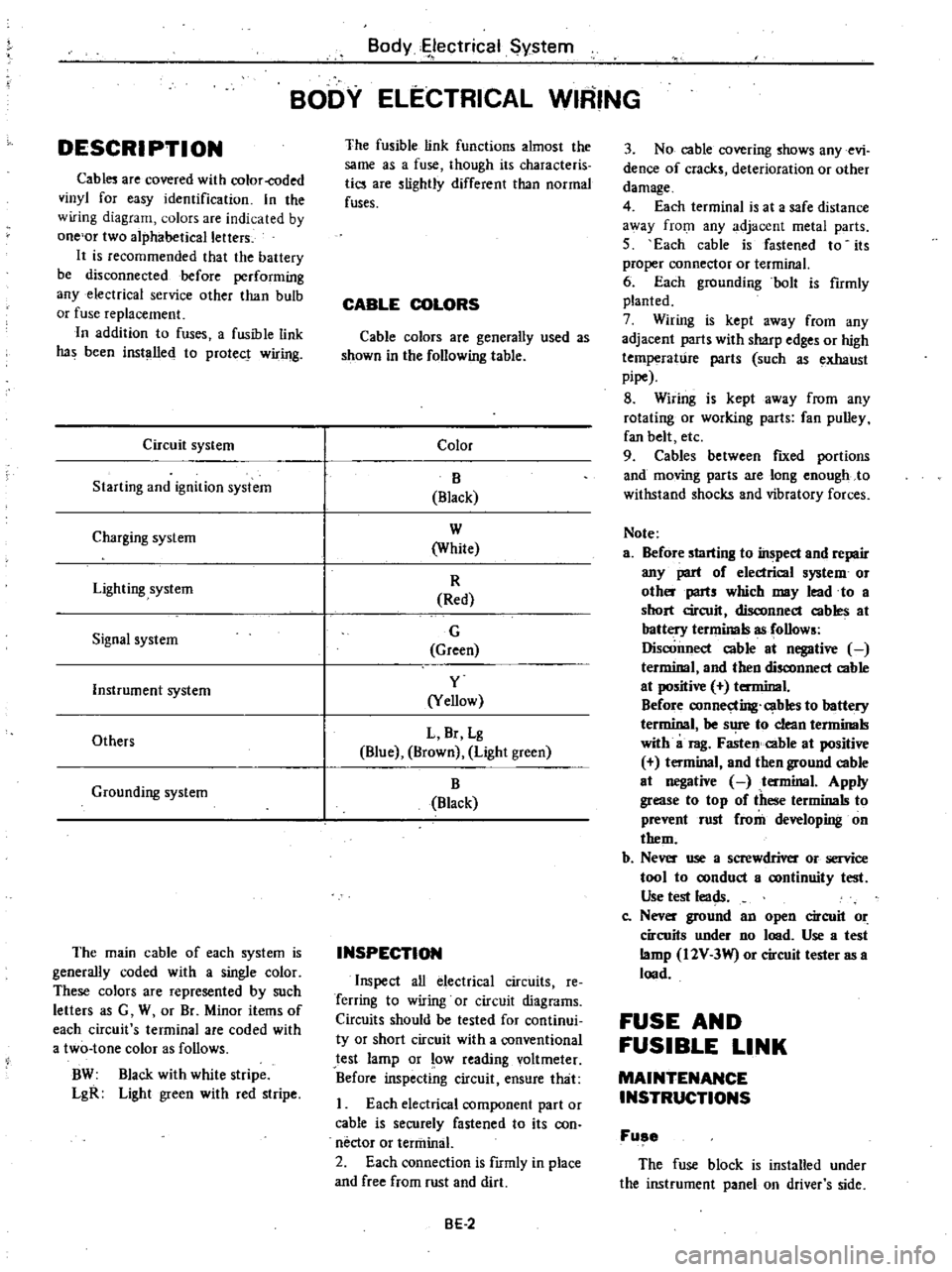

Circuit

system

Starting

and

ignition

system

Charging

system

Lighting

system

Signal

system

Instrument

system

Others

Grounding

system

The

main

cable

of

each

system

is

generally

coded

with

a

single

color

These

colors

are

represented

by

such

letters

as

G

W

or

Br

Minor

items

of

each

circuit

s

terminal

are

coded

with

a

two

tone

color

as

follows

BW

Black

with

white

stripe

LgR

Light

green

with

red

stripe

Body

ectrical

System

BODY

ELECTRICAL

WIRING

The

fusible

link

functions

almost

the

same

as

a

fuse

though

its

characteris

tics

are

slightly

different

than

normal

fuses

CABLE

COLORS

Cable

colors

are

generally

used

as

shown

in

the

following

table

Color

B

Black

W

White

R

Red

G

Green

y

Yellow

L

Br

Lg

Blue

Brown

Light

green

B

Black

INSPECTION

Inspect

all

electrical

circuits

Ie

Terring

to

wiring

or

circuit

diagrams

Circuits

should

be

tested

for

continui

ty

or

short

circuit

with

a

conventional

test

lamp

or

low

reading

voltmeter

Before

inspecting

circuit

ensure

that

I

Each

electrical

component

part

or

cable

is

securely

fastened

to

its

con

nector

or

tenninal

2

Each

connection

is

fIrmly

in

place

and

free

from

rust

and

dirt

BE

2

3

No

cable

covering

shows

any

evi

dence

of

cracks

deterioration

or

other

damage

4

Each

terminal

is

at

a

safe

distance

3

Vay

from

any

adjacent

metal

parts

5

Each

cable

is

fastened

to

its

proper

connector

or

terminal

6

Each

grounding

bolt

is

fumly

planted

7

Wiring

is

kept

away

from

any

adjacent

parts

with

sharp

edges

or

high

temperature

parts

such

as

exhaust

pipe

8

Wiring

is

kept

away

from

any

rotating

or

working

parts

fan

pulley

fan

belt

etc

9

Cables

between

fIXed

portions

and

moving

parts

are

long

enough

to

withstand

shocks

and

vibratory

forces

Note

a

Before

starting

to

inspect

and

repair

any

part

of

electrical

system

or

oth

parts

which

may

lead

to

a

short

circuit

disconnect

cables

at

battery

terminals

as

follows

Disconnect

cable

at

negative

terminal

and

then

disconnect

cable

at

positive

terminal

Before

connecting

cables

to

battery

terminal

be

s

1

to

clean

tenninals

with

a

rag

Fasten

cable

at

positive

t

minal

and

then

ground

cable

at

negative

tenninal

Apply

grease

to

top

of

these

terminals

to

prevent

rust

from

developing

on

them

b

Ne

use

a

screwdriver

or

service

tool

to

oonduct

a

oontinuity

test

Use

test

leads

Co

Nev

ground

an

open

circuit

or

circuits

under

no

lood

Use

a

test

lamp

I2V

3W

or

circuit

tester

as

a

lood

FUSE

AND

FUSIBLE

LINK

MAINTENANCE

INSTRUCTIONS

Fuse

The

fuse

block

is

installed

under

the

instrument

panel

on

driver

s

side

Page 450 of 548

m

c

n

to

l

l

I

g

iF

0

1

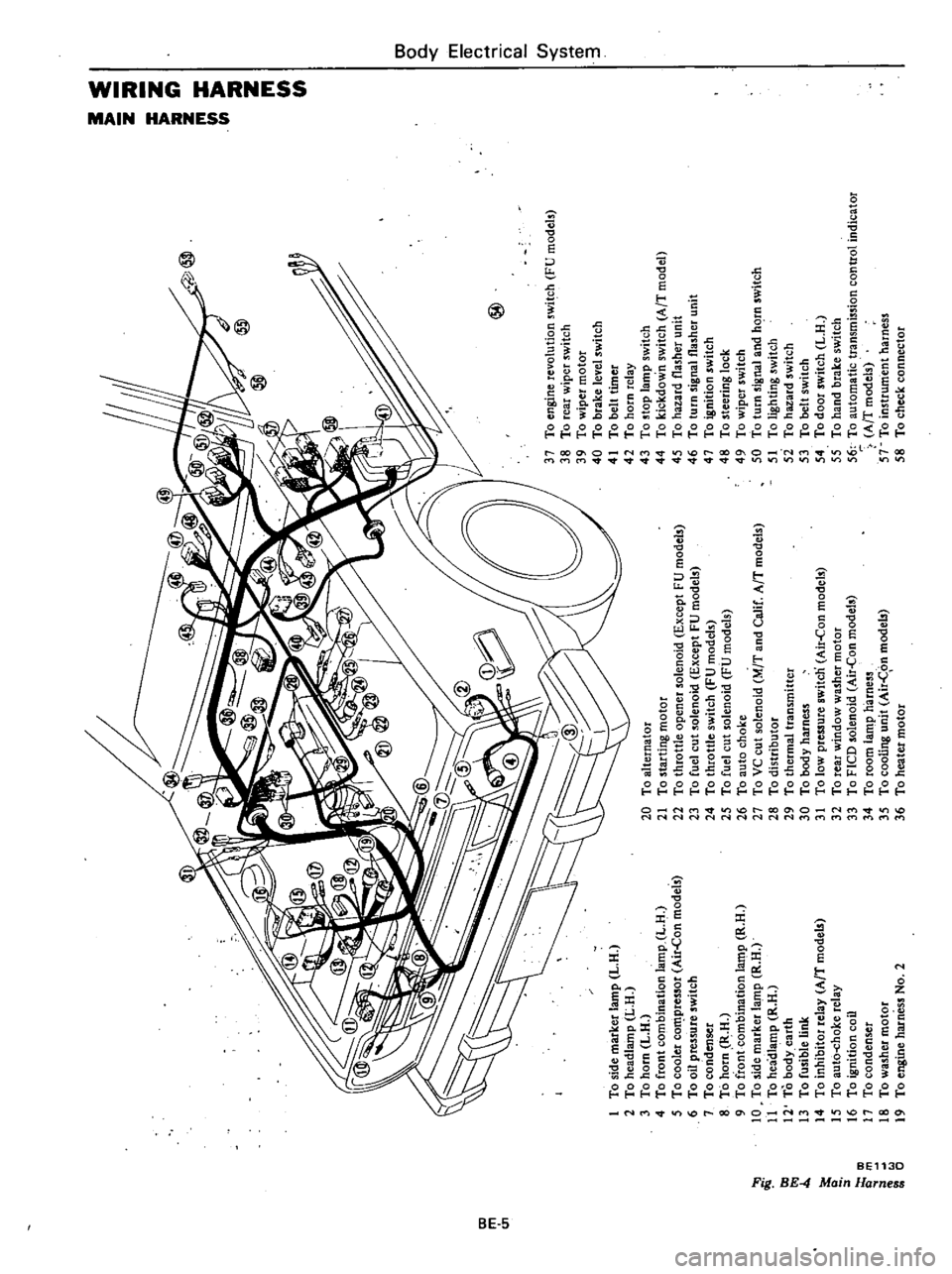

To

side

marker

lamp

L

H

2

To

headlamp

L

H

3

To

horn

L

H

4

To

front

combination

lamp

L

H

5

To

cooler

co

pressor

Air

Con

models

6

To

oil

pressure

switch

7

To

condenser

8

To

horn

R

H

9

To

front

combination

la

t11p

R

H

10

To

side

marker

lamp

R

H

11

To

headlamp

R

H

12

To

body

earth

13

To

fusible

link

14

To

inhibitor

relay

AfT

model

15

To

aut6

choke

relay

16

To

ignition

coil

17

To

condenser

18

To

washer

motor

19

To

engine

harness

No

2

@

20

To

alternator

21

To

starting

motor

22

To

throttle

opener

solenoid

Except

FU

models

23

To

fuel

cut

solenoid

Except

FU

models

24

To

throttle

switch

FU

models

25

To

fuel

cut

solenoid

FU

models

26

To

auto

choke

27

To

VC

cut

solenoid

M

T

and

Calif

AfT

models

28

To

distributor

29

To

thermal

transmitter

30

To

body

harness

31

To

low

pressure

switcn

Air

Con

models

32

To

rear

window

washer

motor

33

To

FICO

solenoid

Air

Con

models

34

To

room

lamp

harness

35

To

cooling

unit

Air

C

on

models

36

To

heater

motor

37

To

engine

revolution

switch

FU

models

38

To

rear

wiper

switch

39

To

wiper

motor

40

To

brake

level

switch

41

To

belt

timer

42

To

horn

relay

43

To

stop

lamp

switch

44

To

kickdown

switch

AfT

model

45

To

hazard

flasher

unit

46

To

turn

signal

flasher

unit

47

To

ignition

switch

48

To

steering

lock

49

To

wiper

switch

50

To

turn

signal

and

hC

rn

switch

51

To

lighting

switch

5i

To

hazard

switch

53

To

belt

switch

54

To

door

switch

L

H

55

To

hand

brake

switch

56

To

automatic

transmission

control

indicator

AfT

models

57

To

instrument

harness

58

To

check

connector

I

0

i

a

z

Z

G

z

tIl

tIl

a

Z

Il

I

to

o

Co

m

16

n

n

OJ

1

3

Page 451 of 548

BodyElectrital

System

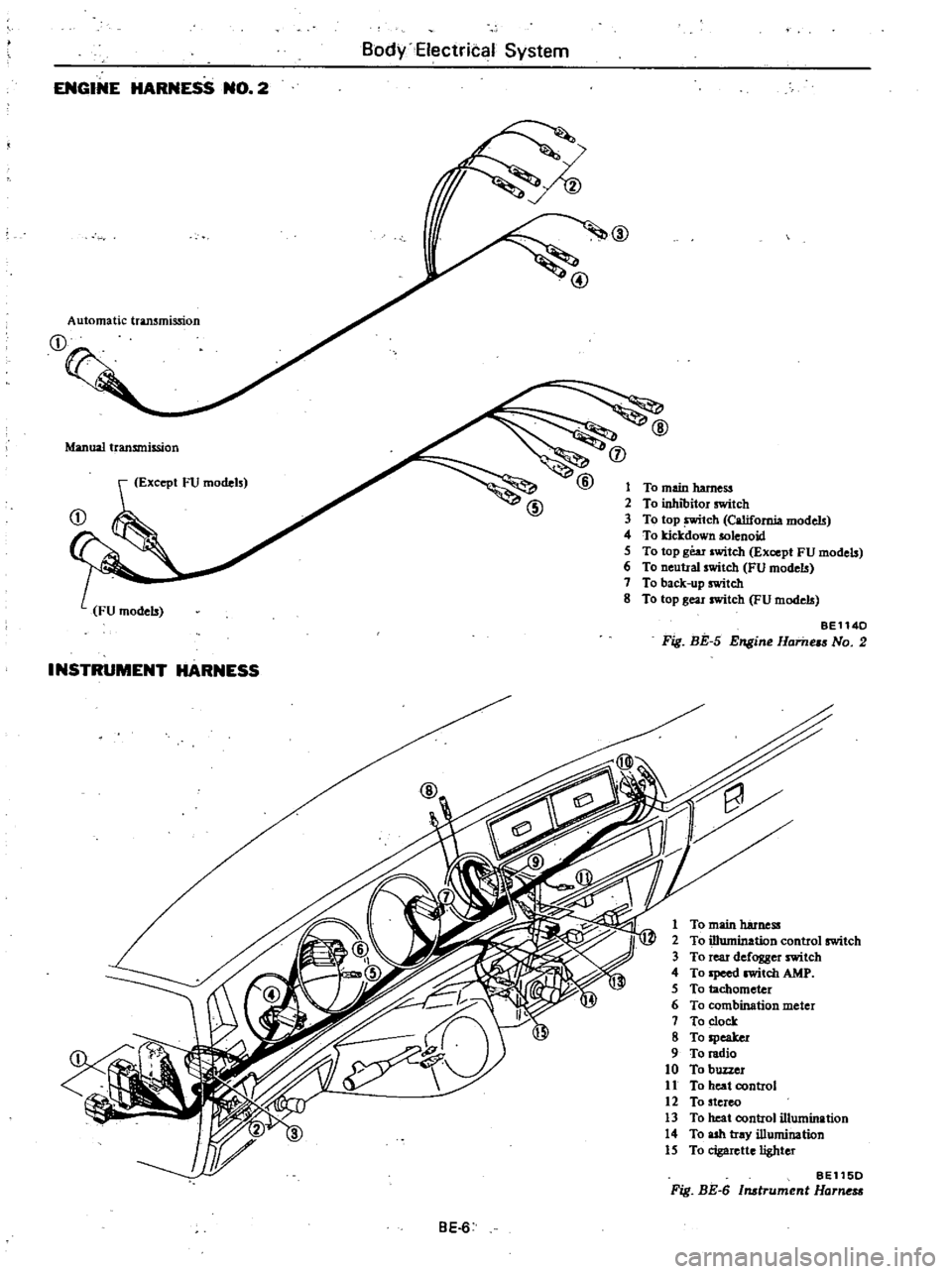

ENGINE

HARNESS

NO

2

@

Automatic

transmission

Manual

transmission

j

Except

FU

models

1

To

main

harness

2

To

inhibitor

switch

3

To

top

tch

California

models

4

To

kicJcdown

solenoid

5

To

top

gear

switch

Except

FU

models

6

To

neutral

switch

FU

models

7

To

back

up

switch

8

To

top

gear

switch

FU

models

BE1140

Fig

BE

5

Engine

Hame

No

2

INSTRUMENT

HARNESS

1

To

main

harness

2

To

illumination

control

switch

3

To

rear

defogger

switch

4

To

Ipeed

witch

AMP

5

To

tachometer

6

To

combination

meter

7

To

clock

8

To

speaker

9

To

radio

10

To

buzzer

11

To

heat

control

12

To

stereo

13

To

heat

control

illumination

14

To

ash

tray

illumination

15

To

cigarette

lighter

BE115D

Fig

BE

6

Instrument

Harne

BE

6

Page 454 of 548

Body

Electrical

System

ELECTRICAL

UNIT

OF

LIGHTING

SYSTEM

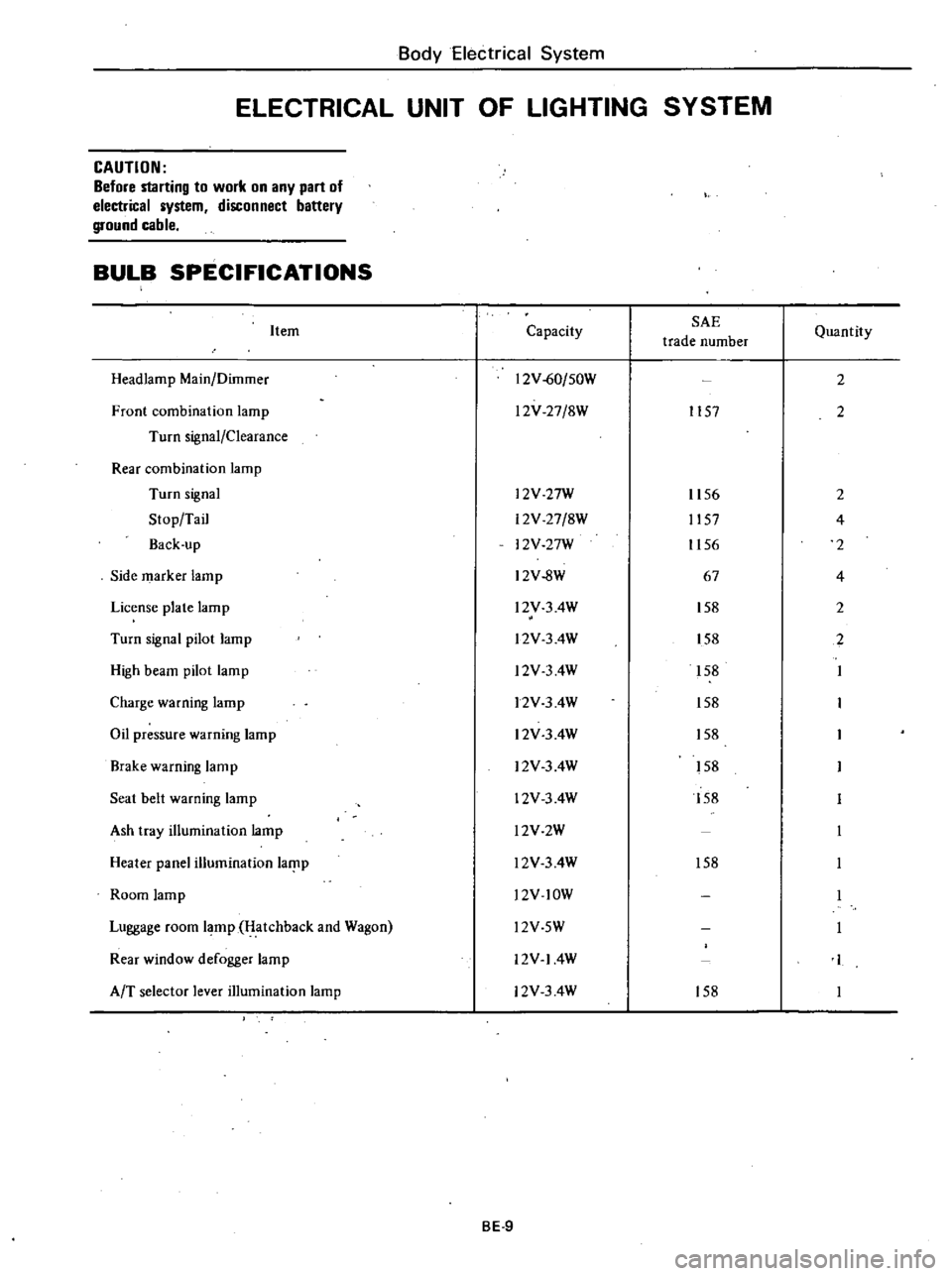

CAUTION

Before

starting

to

work

on

any

part

of

electrical

system

disconnect

battery

ground

cable

BULB

SPECIFICATIONS

Item

Headlamp

Main

Dilnmer

Front

combination

lamp

Turn

signal

Clearance

Rear

combination

lamp

Turn

signal

Stop

Tail

Back

up

Side

marker

lamp

License

plate

lamp

Turn

signal

pilot

lamp

High

beam

pilot

lamp

Charge

warning

lamp

Oil

pressure

warning

lamp

Brake

warning

lamp

Seat

belt

warning

lamp

Ash

tray

illumination

lamp

Heater

panel

illumination

laf

lp

Room

lamp

Luggage

room

lamp

Hatchback

and

Wagon

Rear

window

defogger

lamp

AfT

selector

lever

illumination

lamp

Capacity

SAE

trade

number

12V

60

50W

l2V

27

8W

1157

l2V

27W

12V

27

8W

12V

27W

12V

8W

l2V

3

4W

l2V

3

4W

l2V

3

4W

12V

3

4W

12V

3

4W

12V

3

4W

12V

3

4W

l2V2W

l2V

3

4W

l2V

lOW

Quantity

2

2

1156

2

1157

4

1156

2

67

4

158

2

158

2

158

158

158

158

158

158

l2V

5W

12V

14W

12V

3

4W

158

BE

9

Page 455 of 548

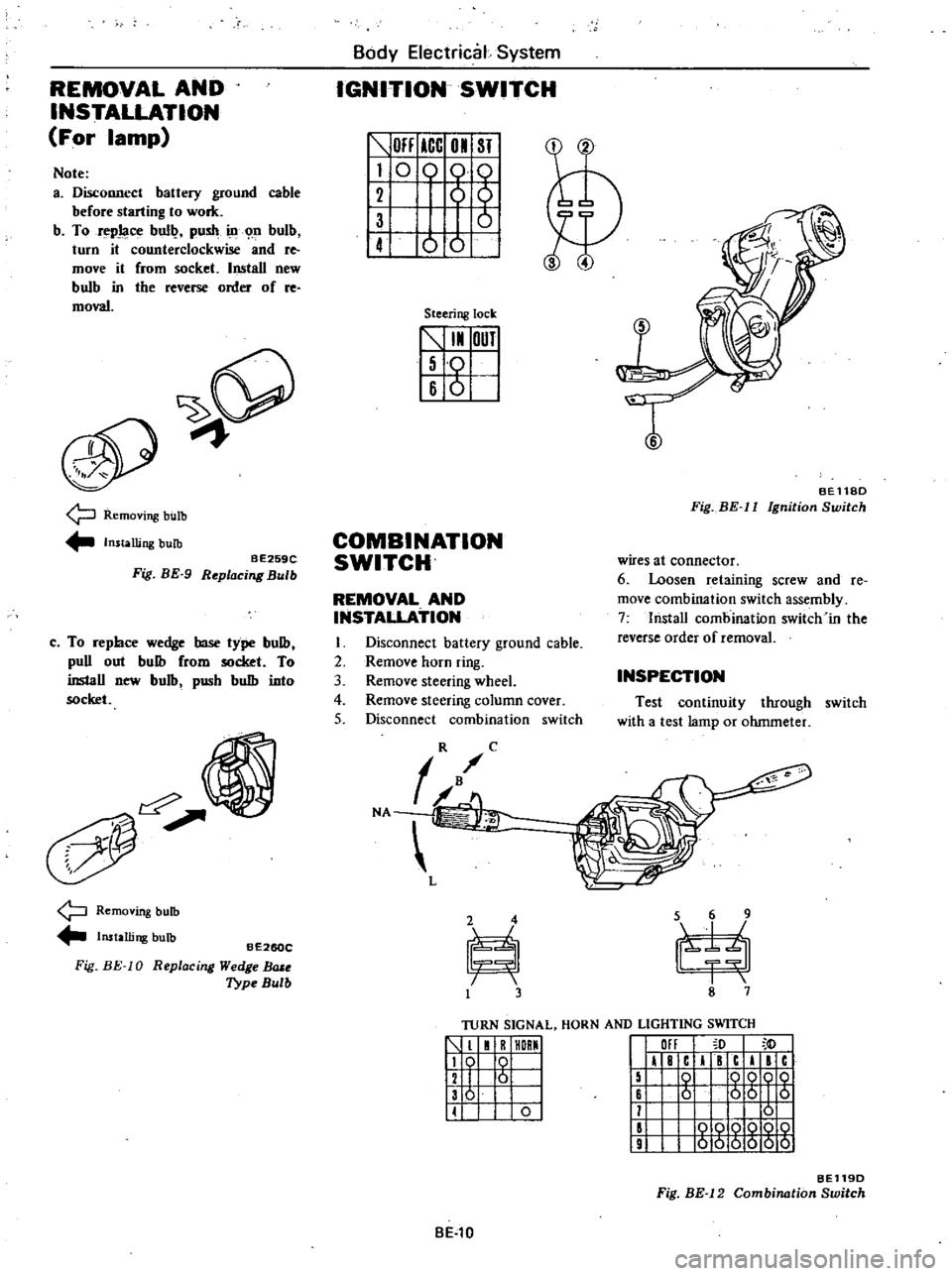

REMOVAL

AND

INSTALLATION

For

lamp

Note

a

Disconnect

battery

ground

cable

before

starting

to

work

b

To

repJaoe

bull

push

ill

n

bulb

turn

it

counterclockwise

and

re

move

it

from

socket

Install

new

bulb

in

tbe

reverse

order

of

re

moval

9

Removing

bulb

Installing

bulb

BE259C

Fig

BE

9

Replacing

Bulb

c

To

repbce

wedge

base

type

bulb

puD

out

bulb

from

socket

To

inslaD

new

bulb

pusb

bulb

into

socket

Removing

bulb

Installing

bulb

Fig

BE

10

BE260C

R

eplac

ing

Wedge

BlUe

Type

Bulb

Body

Electrical

System

IGNITION

SWITCH

OFF

ICC

01

ST

I

0

0

61

1

ot

Steering

lock

5

I

OUT

I

Iso

16

6

I

T

BEll8D

Fig

BE

II

Ignition

Switch

COMBINATION

SWITCH

wires

at

connector

6

Loosen

retaining

screw

and

Ie

move

combination

switch

assembly

7

lnstaD

combination

switch

in

the

reverse

order

of

removal

REMOVAL

AND

INSTALLATION

I

Disconnect

battery

ground

cable

2

Remove

horn

ring

3

Remove

steering

wheel

4

Remove

steering

column

cover

5

Disconnect

combination

switch

INSPECTION

Test

continuity

through

switch

with

a

test

lamp

or

ohmmeter

TURN

SIGNAL

HORN

AND

LIGHTING

SWITCH

1

1

R

HORMI

119

0

I

12

I

6

I

136

I

II

0

I

III

I

F

c

I

c

I

c

15

0

QQOQ

16

6

56

I

5

11

0

II

000Q

10

9

000000

BE119D

Fig

BE

12

Combination

Switch

BE

l0

Page 460 of 548

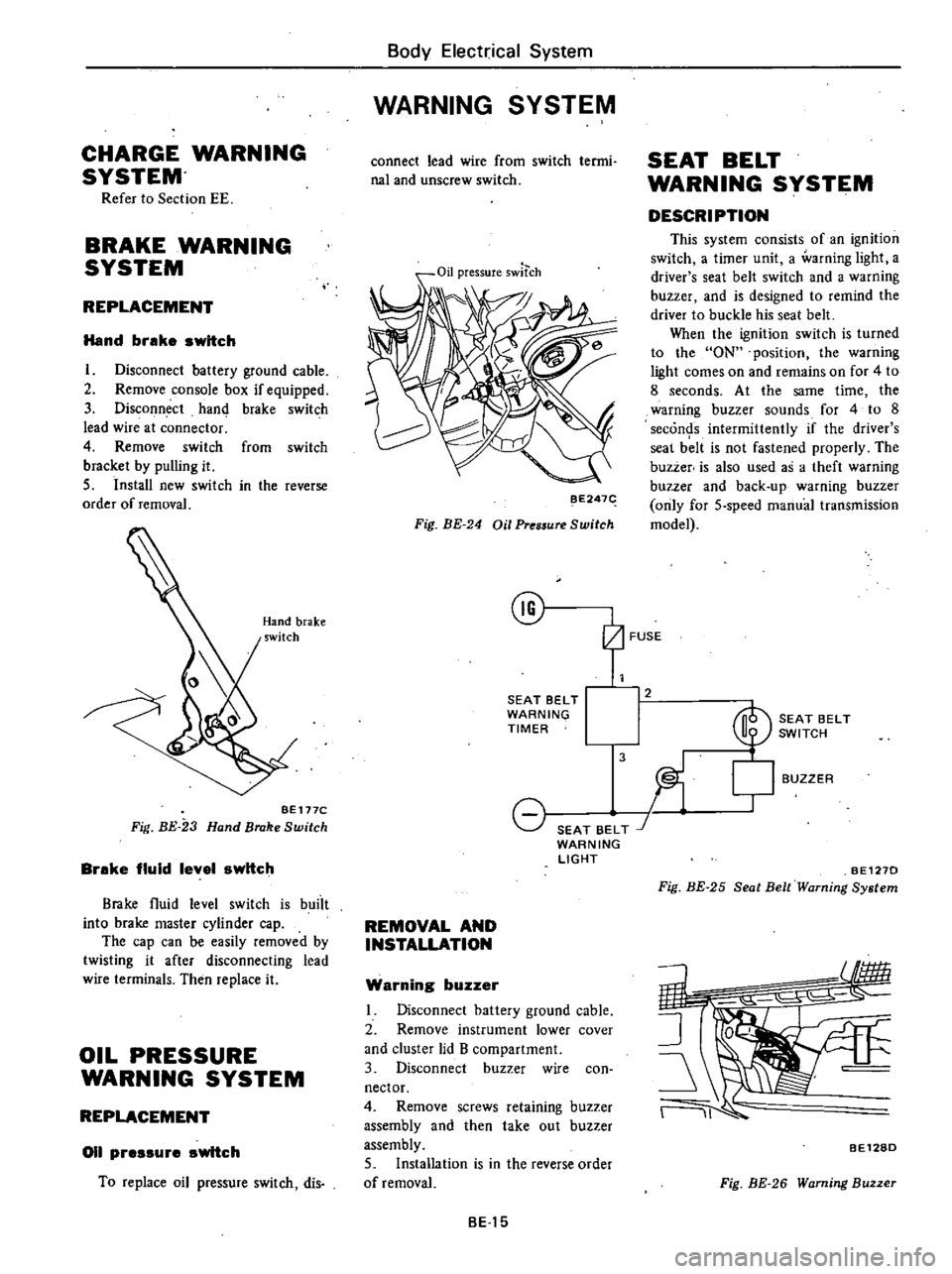

CHARGE

WARNING

SYSTEM

Refer

to

Section

EE

BRAKE

WARNING

SYSTEM

REPLACEMENT

Hand

brake

switch

I

Disconnect

battery

ground

cable

2

Remove

console

box

if

equipped

3

Disconnect

hand

brake

switch

lead

wire

at

connector

4

Remove

switch

from

switch

bracket

by

pulling

it

5

Install

new

switch

in

the

reverse

order

of

removal

BE

177C

Fig

BE

23

Hand

Brake

Switch

Brake

fluid

level

switch

Brake

fluid

level

switch

is

buiit

into

brake

master

cylinder

cap

The

cap

can

be

easily

removed

by

twisting

it

after

disconnecting

lead

wire

terminals

Then

replace

it

OIL

PRESSURE

WARNING

SYSTEM

REPLACEMENT

011

pressure

switch

To

replace

oil

pressure

switch

dis

Body

Electrical

System

WARNING

SYSTEM

connect

lead

wire

from

switch

termi

nal

and

unscrew

switch

Oil

pressureswltch

BE247

Fig

BE

24

Oil

Pres5ure

Switch

@

SEAT

BELT

WARNING

TIMER

8

SEAT

BELT

J

WARNING

LIGHT

REMOVAL

AND

INSTALLATION

Warning

buzzer

Disconnect

battery

ground

cable

2

Remove

instrument

lower

cover

and

cluster

lid

B

compartment

3

Disconnect

buzzer

wire

con

nector

4

Remove

screws

retaining

buzzer

assembly

and

then

take

out

buzzer

assembly

5

Installation

is

in

the

reverse

order

of

removal

BE15

SEAT

BELT

WARNING

SYSTEM

DESCRIPTION

This

system

consists

of

an

ignition

switch

a

timer

unit

a

warning

light

a

driver

s

seat

belt

switch

and

a

warning

buzzer

and

is

designed

to

remind

the

driver

to

buckle

his

seat

belt

When

the

ignition

switch

is

turned

to

the

ON

position

the

warning

light

comes

on

and

remains

on

for

4

to

8

seconds

At

the

same

time

the

warning

buzzer

sounds

for

4

to

8

seconds

intermittently

if

the

driver

s

seal

b

lt

is

not

fastened

properly

The

buzzer

is

also

used

as

a

theft

warning

buzzer

and

back

up

warning

buzzer

only

for

5

speed

manual

transmission

model

2

3

BUZZER

SEAT

BELT

SWITCH

l

BE1270

Fig

BE

25

Seat

Belt

Warning

System

11

BE128D

Fig

BE

26

Warning

Buzzer

Page 463 of 548

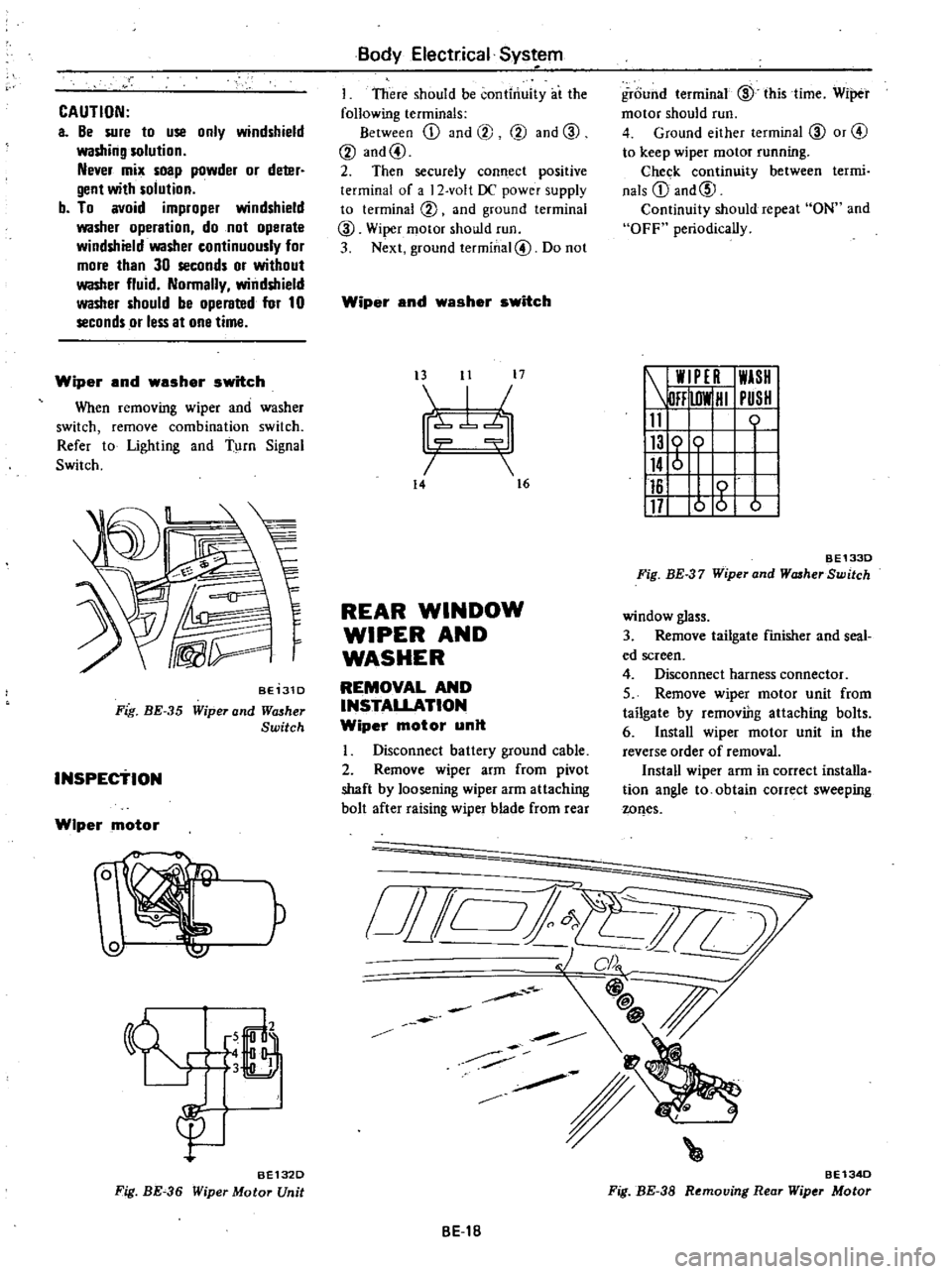

CAUTION

a

Be

sure

to

use

only

windshield

washing

solution

Never

mix

soap

powder

or

deter

gent

with

solution

b

To

avoid

improper

windshield

washer

operation

do

not

operate

windshield

washer

continuously

for

more

than

30

seconds

or

without

washer

fluid

Normally

windshield

washer

should

be

operated

for

10

seconds

or

less

at

one

time

Wiper

and

washer

switch

When

removing

wiper

and

washer

switch

remove

combination

switch

Refer

to

Lighting

and

Turn

Signal

Switch

BE131D

Fig

BE

35

Wiper

and

Wll5her

Switch

INSPEctiON

Wiper

motor

W

P

6

LJ

3

B

gu

BE132D

Fig

BE

36

Wiper

Motor

Unit

Body

Electrical

Sys

em

I

There

should

be

continuity

at

the

following

terminals

Between

ill

and

@

@

and

CID

@

and@

2

Then

securely

connect

positive

terminal

of

a

2

volt

DC

power

supply

to

terminal

@

and

ground

terminal

CID

Wiper

motor

should

run

3

Next

ground

terminal@

Do

not

Wiper

and

washer

switch

t3

11

17

I

7b

14

16

REAR

WINDOW

WIPER

AND

WASHER

REMOVAL

AND

INSTALLATION

Wiper

motor

unit

Disconnect

battery

ground

cable

2

Remove

wiper

arm

from

pivot

shaft

by

loosening

wiper

arm

attaching

bolt

after

raising

wiper

blade

from

rear

o

i

Jill

BE1B

ground

terminal

CID

this

time

Wiper

motor

should

run

4

Ground

either

terminal

CID

or

@

to

keep

wiper

motor

running

Chec

k

continuity

between

termi

nals

ill

and@

Continuity

should

repeat

ON

and

OFF

periodically

W

PE

I

WASH

DFF

lOW

HI

PUSH

11

0

116

117

o

g

b

BE1330

Fig

BE

37

Wiper

and

WcuherSwitch

window

glass

3

Remove

tailgate

finisher

and

seal

ed

screen

4

Disconnect

harness

connector

5

Remove

wiper

motor

unit

from

tailgate

by

removiDg

attaching

bolts

6

Install

wiper

motor

unit

in

the

reverse

order

of

removal

Install

wiper

arm

in

correct

installa

tion

angle

to

obtain

correct

sweeping

wQes

BE134D

Fig

BE

38

Removing

Rear

Wiper

Motor

Page 465 of 548

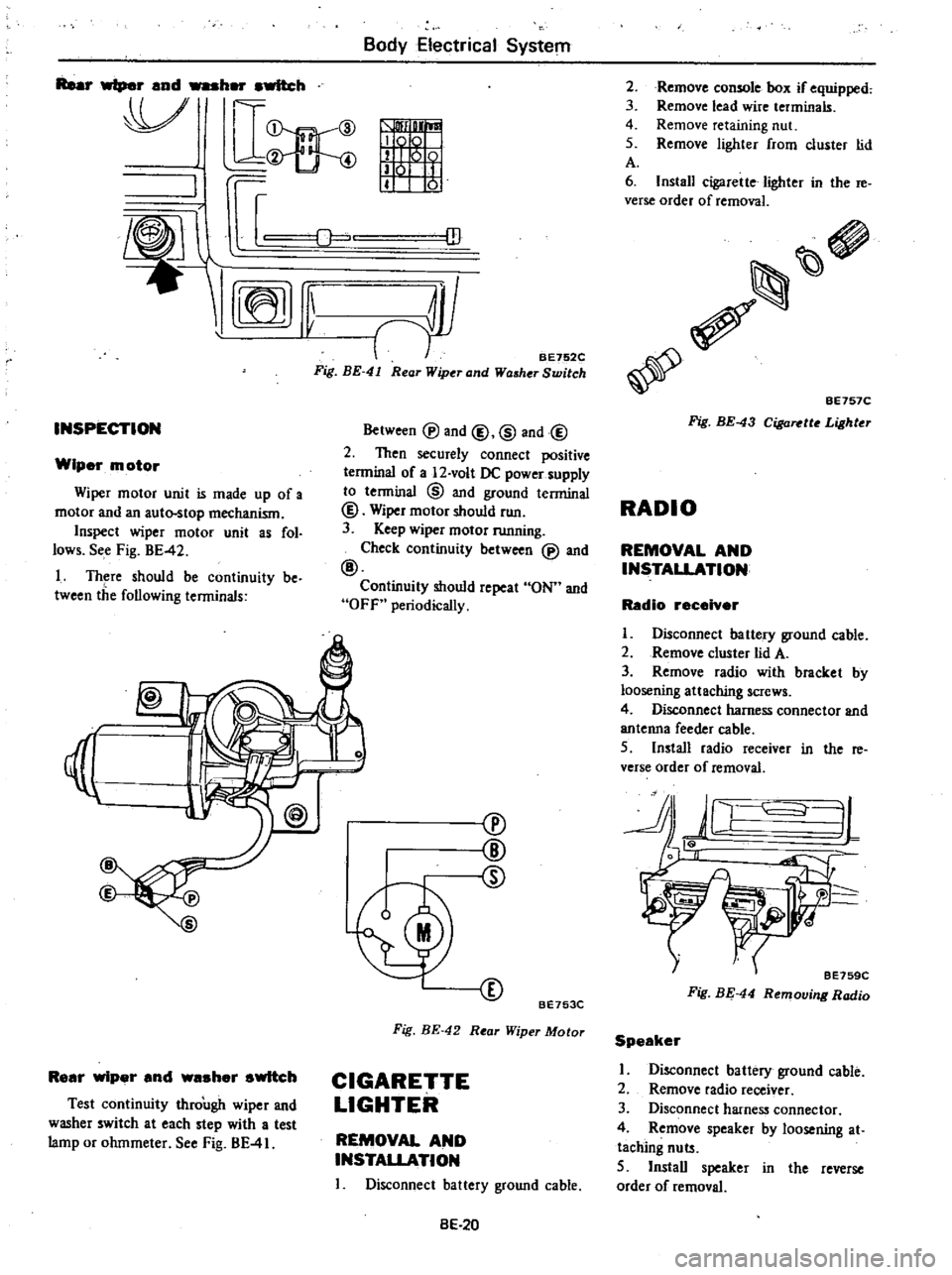

Rear

wiper

and

her

awltch

V

D

mn

ID

I

INSPECTION

Wiper

motor

Wiper

motor

unit

is

made

up

of

a

motor

and

an

auto

stop

mechanism

Inspect

wiper

motor

unit

as

fol

lows

See

Fig

BE

42

I

Th

re

should

be

continuity

be

tween

the

following

terminals

Body

Electrical

System

ill

BE752C

Fig

BE

41

Rear

Wiper

and

Washer

Switch

Between

@

and

@

@

and@

2

Then

securely

connect

positive

terminal

of

a

12

volt

DC

power

supply

to

tenninal

@

and

ground

terminal

@

Wiper

motor

should

run

3

Keep

wiper

motor

running

Check

continuity

between

@

and

@

Continuity

should

repeat

ON

and

OFf

periodically

I

Rear

wiper

and

waaher

switch

Test

continuity

through

wiper

and

washer

switch

at

each

step

with

a

test

lamp

or

ohmmeter

See

Fig

BE

41

cv

@

CD

BE753C

Fig

BE

42

Rear

Wiper

Motor

CIGARETTE

LIGHTER

REMOVAL

AND

INSTALLATION

I

Disconnect

battery

ground

cable

BE

20

Remove

comole

box

if

equipped

Remove

lead

wire

terminals

Remove

retaining

nut

Remove

lighter

from

cluster

lid

2

3

4

5

A

6

Install

cigarette

lighter

in

the

re

verse

order

of

removal

BE757C

Fig

BE

43

CiI

a

tto

Lighter

RADIO

REMOVAL

AND

INSTALLATION

Radio

receiver

I

Disconnect

battery

ground

cable

2

Remove

cluster

lid

A

3

Remove

radio

with

bracket

by

loosening

attaching

screws

4

DiscOnnect

harness

connector

and

antenna

feeder

cable

5

Install

radio

receiver

in

the

re

verse

order

of

removal

JL

J

tf

BE759C

Fig

BE

44

Removing

Radio

Speaker

I

Disconnect

battery

ground

cable

2

Remove

radio

receiver

3

Disconnect

harness

connector

4

Remove

speaker

by

loosening

at

taching

nuts

5

Install

speaker

in

the

reverse

order

of

removal

Page 467 of 548

B6

Y

Electrica

System

f

EIIII

I

I

I

11111111

111

777

Rea

window

1

j

glass

W

777

n

1

r7

U

u

T

t

I

I

I

j

T

cD

t

ID

3

BE537

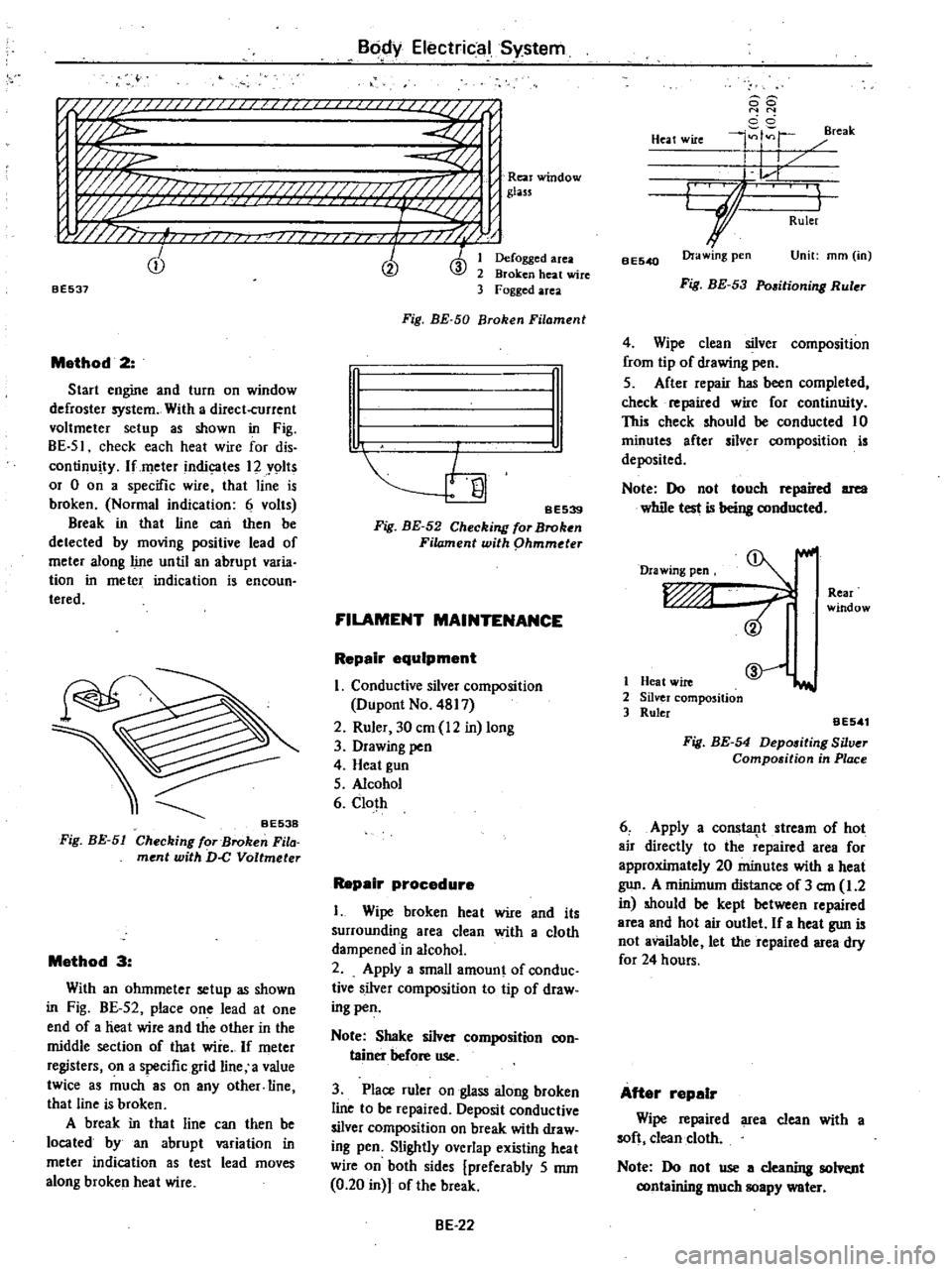

Method

2

Start

engine

and

turn

on

window

defroster

system

With

a

direct

current

voltmeter

setup

as

shown

in

Fig

BE

51

check

each

heat

wire

for

dis

continuity

lfmeter

indic

ates

12

Y9lts

or

0

on

a

specific

wire

that

line

is

broken

Normal

indication

6

volts

Break

in

that

line

can

then

be

detected

by

moving

positive

lead

of

meter

along

line

until

an

abrupt

varia

tion

in

meter

indication

is

encoun

teredo

Fig

BE

51

Method

3

With

an

ohmmeter

setup

as

shown

in

Fig

BE

52

place

one

lead

at

one

end

of

a

heat

wire

and

the

other

in

the

middle

section

of

that

wire

If

meter

registers

on

a

specific

grid

line

a

value

twice

as

much

8S

on

any

other

line

that

line

is

broken

A

break

in

tha

t

line

can

then

be

located

by

an

abrupt

variation

in

meter

indication

as

test

lead

moves

along

broken

heat

wire

Defogged

area

Broken

heat

wire

Fogged

area

Fig

BE

50

Broken

Filament

n

I

I

SE539

Fig

BE

52

Checking

for

Broken

Filament

with

phmmder

FILAMENT

MAINTENANCE

Repair

equipment

I

Conductive

silver

composition

Dupont

No

4817

2

Ruler

30

em

12

in

long

3

Drawing

pen

4

Heat

gun

5

Alcohol

6

Cloth

Repair

procedure

I

Wipe

broken

heat

wire

and

its

surrounding

area

clean

with

a

cloth

dampened

in

alcohol

2

Apply

a

small

amount

of

conduc

tive

silver

composition

to

tip

of

draw

ing

pen

Note

Shake

silver

composition

con

tainer

before

use

3

Place

ruler

on

glass

along

broken

line

to

be

repaired

Deposit

conductive

silver

composition

on

break

with

draw

ing

pen

Slightly

overlap

existing

heat

wire

on

both

sides

preferably

5

mm

0

20

in

of

the

break

BE

22

88

N

N

cci

4

r

reak

Heat

wire

I

I

L

r

GJ

I

Ruler

BE540

Ora

wing

pen

Unit

mm

in

Fig

BE

53

Pmitioning

Ruler

4

Wipe

clean

silver

composition

from

tip

of

drawing

pen

5

After

repair

has

been

completed

check

repaired

wire

for

continuity

This

check

should

be

conducted

10

minutes

after

silver

composition

is

deposited

Note

Do

not

touch

repaired

area

while

test

is

being

conducted

Drawing

pen

Rear

window

1

Heat

wire

2

Silver

composition

3

Ruler

@

iI

aE541

Fig

BE

54

Depositing

Silver

Compo

ition

in

Place

6

Apply

a

consla11t

stream

of

hot

air

directly

to

the

repaired

area

for

approxUnately

20

minutes

with

a

heat

gun

A

minilnum

distance

of

3

em

1

2

in

should

be

kept

between

repaired

area

and

hot

air

outlet

If

a

heat

gun

is

not

available

let

the

repaired

area

dry

for

24

hours

After

repair

Wipe

repaired

area

clean

with

a

soft

clean

cloth

Note

Do

not

use

a

cleaning

solvt

nt

containing

much

soapy

water

Page 471 of 548

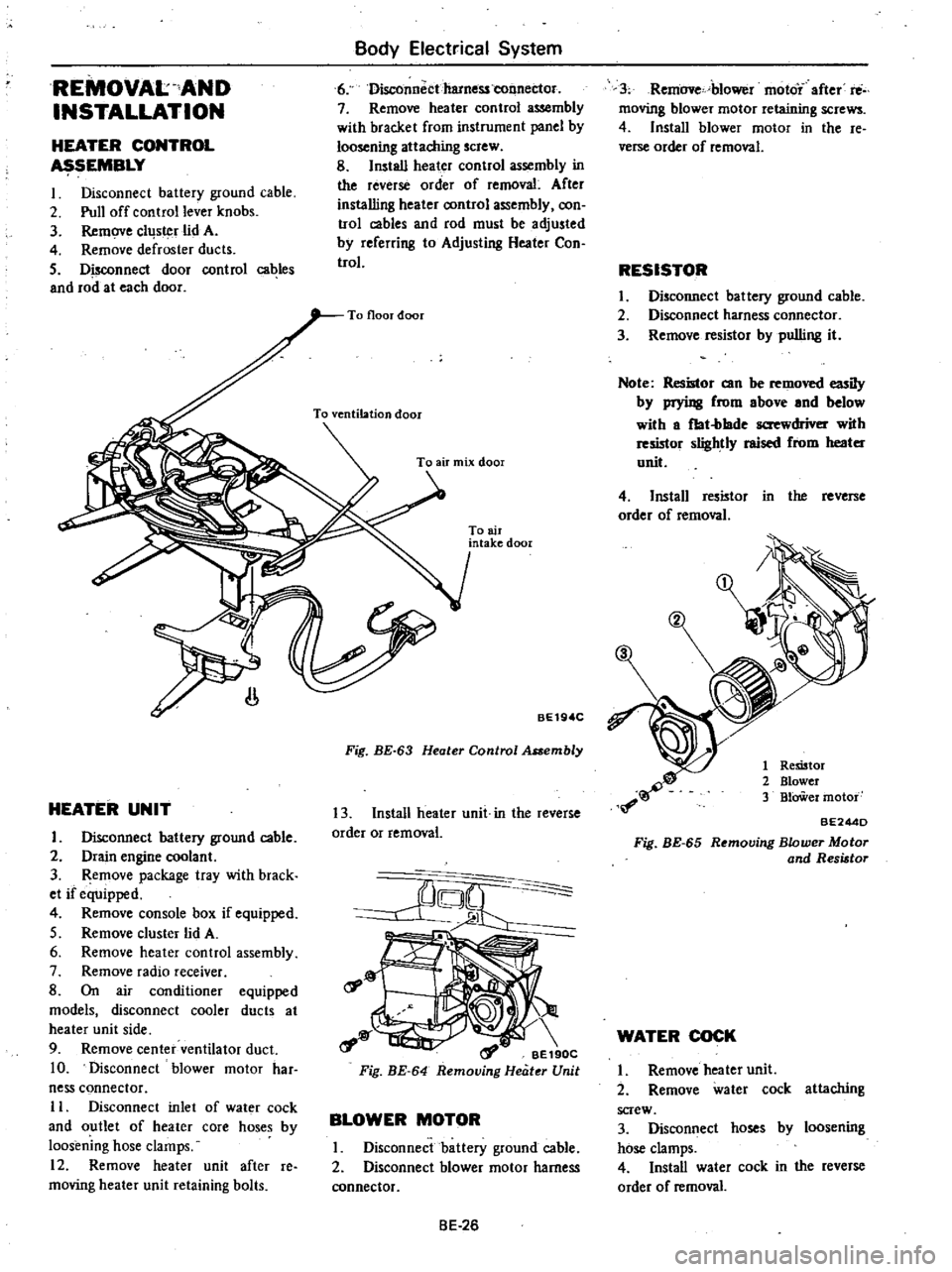

REMOVAL

AND

INSTALLATION

HEATER

CONTROL

SEMBLY

I

Disconnect

battery

ground

cable

2

Pull

off

control

lever

knobs

3

Remove

cllJs

r

lid

A

4

Remove

defroster

ducts

5

Disconnect

door

control

cables

and

rod

at

each

door

Body

Electrical

System

6

Disconnectharness

tonnec1or

7

Remove

heater

control

assembly

with

bracket

from

instrument

panel

by

loosening

attaching

screw

8

Install

heater

control

assembly

in

the

reverse

order

of

removal

After

installing

heater

oontrol

assembly

oon

trol

cables

and

rod

must

be

adjusted

by

referring

to

Adjusting

Heater

Con

trol

HEATER

UNIT

I

Disconnect

battery

ground

cable

2

Drain

engine

coolant

3

Remove

package

tray

with

brack

et

if

equipped

4

Remove

console

box

if

equipped

5

Remove

cluster

lid

A

6

Remove

heater

control

assembly

7

Remove

radio

receiver

8

On

air

conditioner

equipped

models

disconnect

cooler

ducts

at

heater

unit

side

9

Remove

center

ventilator

duct

10

Disconnect

blower

motor

har

ness

connector

II

Disconnect

inlet

of

wat

r

cock

and

outlet

of

heater

core

hoses

by

loosening

hose

clamps

12

Remove

heater

unit

after

re

moving

heater

unit

retaining

bolts

To

air

intake

door

BE19

C

Fig

BE

63

Heater

Control

Assembly

13

Install

heater

unit

in

the

reverse

order

or

removal

rf

o

t

a

1

BE190C

Fig

BE

64

Removing

Heater

Unit

BLOWER

MOTOR

I

Disconnect

battery

ground

cable

2

Disconnect

blower

motor

harness

connector

BE

26

3

Remove

blower

moto

after

rti

moving

blower

motor

retaining

screws

4

Install

blower

motor

in

the

re

verse

order

of

removal

RESISTOR

I

Disconnect

battery

ground

cable

2

Disconnect

harness

connector

3

Remove

resistor

by

pulling

it

Note

Resistor

can

be

removed

iIy

by

prying

from

above

and

below

with

a

fbt

blade

screwdriver

with

resmor

slightly

raised

from

heater

unit

4

Install

resistor

in

the

reverse

order

of

removal

1

Remtor

2

Blower

3

BlOWer

motor

BE244D

Fig

BE

65

Removing

Blower

Motor

and

Resistor

WATER

COCK

I

Remove

heater

unit

2

Remove

water

cock

attaching

screw

3

Disconnect

hoses

by

loosening

hose

clamps

4

Install

water

cock

in

the

reverse

order

of

removal