light DATSUN 210 1979 Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 363 of 548

6

Apply

P

B

C

grease

to

yoke

slid

ing

part

of

cylinder

Then

reposition

bias

ring

so

that

groove

of

bias

ring

coincides

with

yoke

7

Leaving

yoke

springs

inserted

lightly

into

cylinder

groove

assemble

cylinder

body

and

yoke

by

pushing

or

tapping

yoke

lightly

BA570

Fig

BR

19

A

embling

Yoke

and

Cylinder

8

Install

air

bleeder

valve

on

caliper

INSTAlLATION

1

Install

in

reverse

procedure

of

removal

CAUTION

When

installing

brake

tube

use

Flare

Nut

Torque

Wrench

6694310000

fJ

Tightening

tOlque

Calipel

securing

bolts

4

6

to

6

1

kll

m

33

to

44

ft

lb

Brake

tube

flere

nuts

1

5to

1

8

kg

m

11

to

13

ft

Ib

2

After

installing

pad

bleed

air

from

system

Brake

System

ROTOR

REMOVAL

Refer

to

Front

Axle

Section

FA

for

removal

Note

As

this

value

increases

wear

occurs

progressively

vibration

cor

responding

to

revolution

of

tire

may

often

be

tmnsmitted

to

in

terior

of

car

INSPECTION

Check

the

following

items

and

if

necessary

replace

Checks

can

be

made

by

removing

only

wheel

Sliding

surface

If

there

are

cracks

or

considerable

chips

replace

2

Runout

Adjust

wheel

bearing

correctly

Using

a

dial

gauge

measure

runout

at

the

center

of

rotor

pad

contact

sur

face

Runout

limit

less

than

0

12

mm

0

0047

in

Total

indicator

reading

BR025A

Fig

BR

20

Mecuuring

Runout

3

Parallelism

Measure

thickness

of

entire

periph

cry

of

rotor

using

a

micrometer

Parallelism

when

new

less

than

0

03

mm

0

0012

in

BR

9

Fig

BR

21

Measuring

Parallelism

4

Thickness

If

rotor

thickness

is

beyond

wear

limit

replace

rotor

When

correcting

thickness

be

sure

that

the

thickness

after

correction

does

not

exceed

the

limit

Standard

thickness

10

0

mm

0

394

in

Wear

limit

more

than

8

4

mm

0

331

in

INSTALLATION

Install

rotor

in

reverse

order

of

removal

Adjust

wheel

bearing

preload

correctly

Refer

to

Front

Axle

Sec

tion

FA

for

adjustment

ifl

Tightening

torque

Rotor

to

wheel

hub

3

9

to

5

3

kg

m

28

to

38

ft

rb

Page 369 of 548

Note

Front

cable

clevis

pin

and

cotter

pin

are

available

as

service

parts

Removal

of

eer

ceble

I

Disconnect

cable

adjuster

CD

from

front

cable

2

Remove

lock

plate

@

and

strap

00

at

axle

case

1

I

Rear

cable

adjuster

2

Lock

plate

3

Strap

BR037A

Fig

BR

37

Removing

Rear

Cable

Brake

System

3

Pull

off

return

spring

CD

and

disconnect

rear

cable

from

lever

by

removing

clevis

pin

@

@

I

Return

spring

2

Clevis

pin

6R122A

Fig

BR

38

Removing

Rear

Cable

BR

15

INSPECTION

I

Check

control

stem

and

lever

for

wear

or

other

damage

Replace

if

necessary

2

Replace

worn

or

fatigued

sprin

3

Check

wires

for

discontinuity

or

deterioration

Replace

ifheces

ary

4

Replace

malfunctioning

warning

light

or

switch

5

Check

parts

at

each

connection

and

if

found

defonned

or

damaged

replace

INSTALLATION

Install

hand

brake

assembly

in

the

reverse

procedure

of

removal

Page 375 of 548

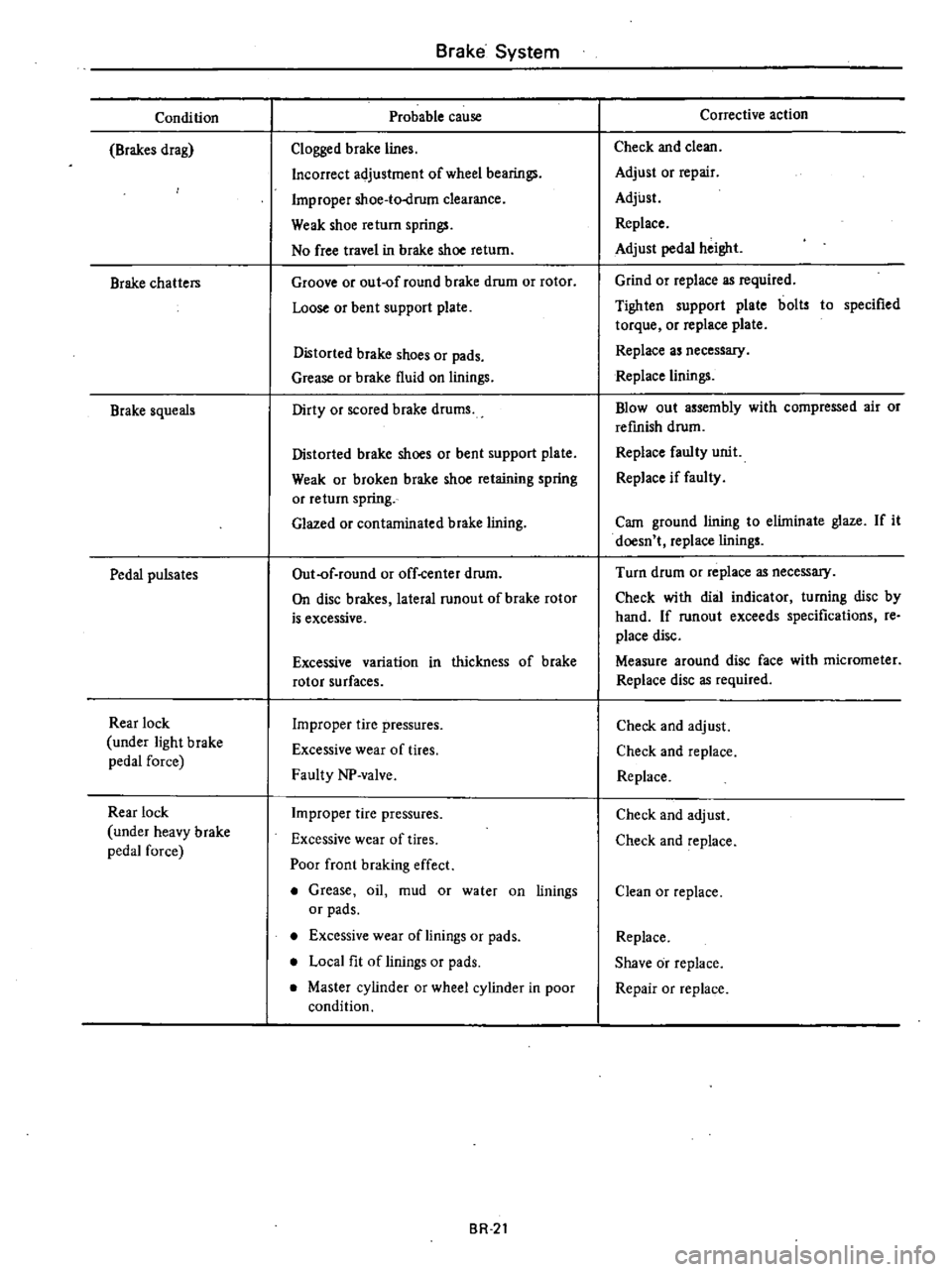

Condition

Brakes

drag

Brake

chatters

Brake

squeals

Pedal

pulsates

Rear

lock

under

light

brake

pedal

force

Rear

lock

under

heavy

brake

pedal

force

Brake

System

Probable

cause

Clogged

brake

lines

Incorrect

adjustment

of

wheel

bearings

Improper

shoe

to

drum

clearance

Weak

shoe

return

springs

No

free

travel

in

brake

shoe

return

Groove

or

out

of

round

brake

drum

or

rotor

Loose

or

bent

support

plate

Distorted

brake

shoes

or

pads

Grease

or

brake

fluid

on

linings

Dirty

or

scored

brake

drums

Distorted

brake

shoes

or

bent

support

plate

Weak

or

broken

brake

shoe

retaining

spring

or

return

spring

Glazed

or

contaminated

brake

lining

Out

of

round

or

off

center

drum

On

disc

brakes

lateral

runout

of

brake

rotor

is

excessive

Excessive

variation

in

thickness

of

brake

rotor

surfaces

Improper

tire

pressures

Excessive

wear

of

tires

Faulty

NP

valve

Improper

tire

pressures

Excessive

wear

of

tires

Poor

front

braking

effect

Grease

oil

mud

or

water

on

linings

or

pads

Excessive

wear

of

linings

or

pads

Local

fit

of

linings

or

pads

Master

cylinder

or

wheel

cylinder

in

poor

condition

BR

2t

Corrective

action

Check

and

clean

Adjust

or

repair

Adjust

Replace

Adjust

pedal

height

Grind

or

replace

as

required

Tighten

support

plate

bolts

to

specified

torque

or

replace

plate

Replace

as

necessary

Replace

linings

Blowout

assembly

with

compressed

air

or

refinish

drum

Replace

faulty

unit

Replace

if

faulty

Cam

ground

lining

to

elilninate

glaze

If

it

doesn

t

replace

linings

Turn

drum

or

replace

as

necessary

Check

with

dial

indicator

turning

disc

by

hand

If

runout

exceeds

specifications

re

place

disc

Measure

around

disc

face

with

micrometer

Replace

disc

as

required

Check

and

adjust

Check

and

replace

Replace

Check

and

adjust

Check

and

replace

Clean

or

replace

Replace

Shave

or

replace

Repair

or

replace

Page 379 of 548

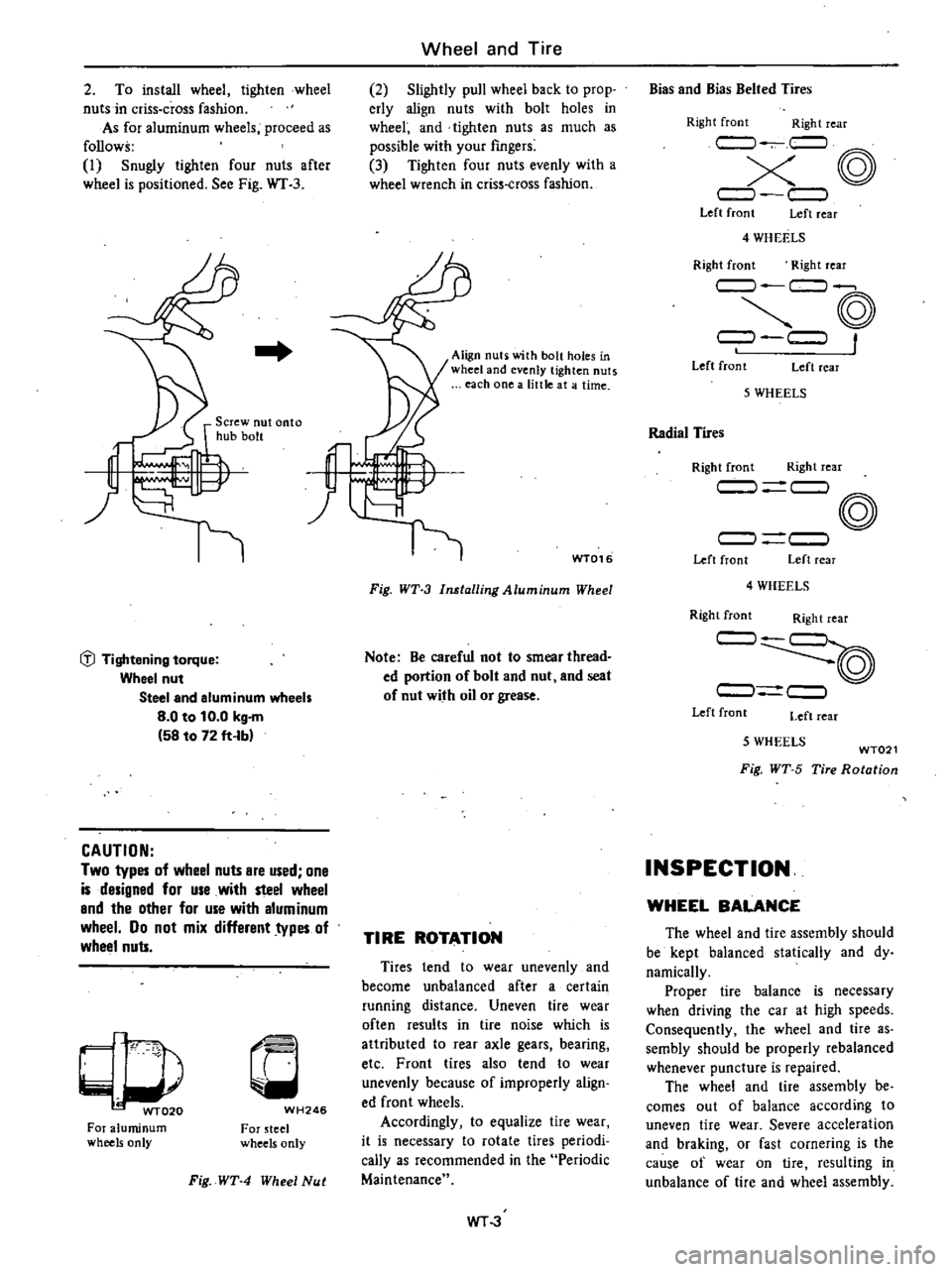

2

To

install

wheel

tighten

wheel

nuts

in

criss

cross

fashion

As

for

aluminum

wheels

proceed

as

follows

I

Snugly

tighten

four

nuts

after

wheel

is

positioned

See

Fig

WT

3

Iil

Tightening

torque

Wheel

nut

Steel

and

aluminum

wheels

8

0

to

10

0

kg

m

58

to

72

ft

Ibl

CAUTION

Two

types

of

wheel

nuts

Bre

used

one

is

designed

for

use

with

steel

wheel

Bnd

the

other

for

use

with

aluminum

wheel

Do

not

mix

different

types

of

wheel

nuts

p

WT020

For

aluminum

wheels

only

c

WH246

For

teel

wheels

only

Fig

WT

4

Wheel

Nut

Wheel

and

Tire

2

Slightly

pull

wheel

back

to

prop

erly

align

nuts

with

bolt

holes

in

wheel

and

tighten

nuts

as

much

as

possible

with

your

fingers

3

Tighten

four

nuts

evenly

with

a

wheel

wrench

in

criss

cross

fashion

f

WT016

Align

nuti

with

bolt

holes

in

wheel

and

evenly

tighten

nuts

each

one

a

little

at

a

time

Fig

WT

3

Installing

Aluminum

Wheel

Note

Be

careful

not

to

smear

thread

ed

portion

of

bolt

and

nut

and

seat

of

nut

with

oil

or

grease

TIRE

ROTATION

Tires

tend

to

wear

unevenly

and

become

unbalanced

after

a

certain

running

distance

Uneven

tire

wear

often

results

in

tire

noise

which

is

attributed

to

rear

axle

gears

bearing

etc

Front

tires

also

tend

to

wear

unevenly

because

of

improperly

align

ed

front

wheels

Accordingly

to

equalize

tire

wear

it

is

necessary

to

rotate

tires

periodi

cally

as

recommended

in

the

Periodic

Maintenance

WT

3

Bias

and

Bias

Belted

Tires

Right

front

Right

rear

c

J

c

l

X@

c

l

c

J

Left

front

Left

rear

4

WH

EELS

Right

front

Right

rear

c

J

c

l

@

9

c

J

Left

front

Left

rear

5

WHEELS

Radial

Tires

Right

front

Right

rear

c

J

c

l

@

c

l

c

J

Left

front

Left

rear

4

WHEELS

Right

front

Right

rear

c

J

c

J

c

l

Left

front

Left

rear

5

WHEELS

WT021

Fig

WT

5

Tire

Rotation

INSPECTION

WHEEL

BALANCE

The

wheel

and

tire

assembly

should

be

kept

balanced

statically

and

dy

namically

Proper

tire

balance

is

necessary

when

driving

the

car

at

high

speeds

Consequently

the

wheel

and

tire

as

sembly

should

be

properly

rebalanced

whenever

puncture

is

repaired

The

wheel

and

tire

assembly

be

comes

out

of

balance

according

to

uneven

tire

wear

Severe

acceleration

and

braking

or

fast

cornering

is

the

cause

of

wear

on

tire

resulting

in

unbalance

of

tire

and

wheel

assembly

Page 388 of 548

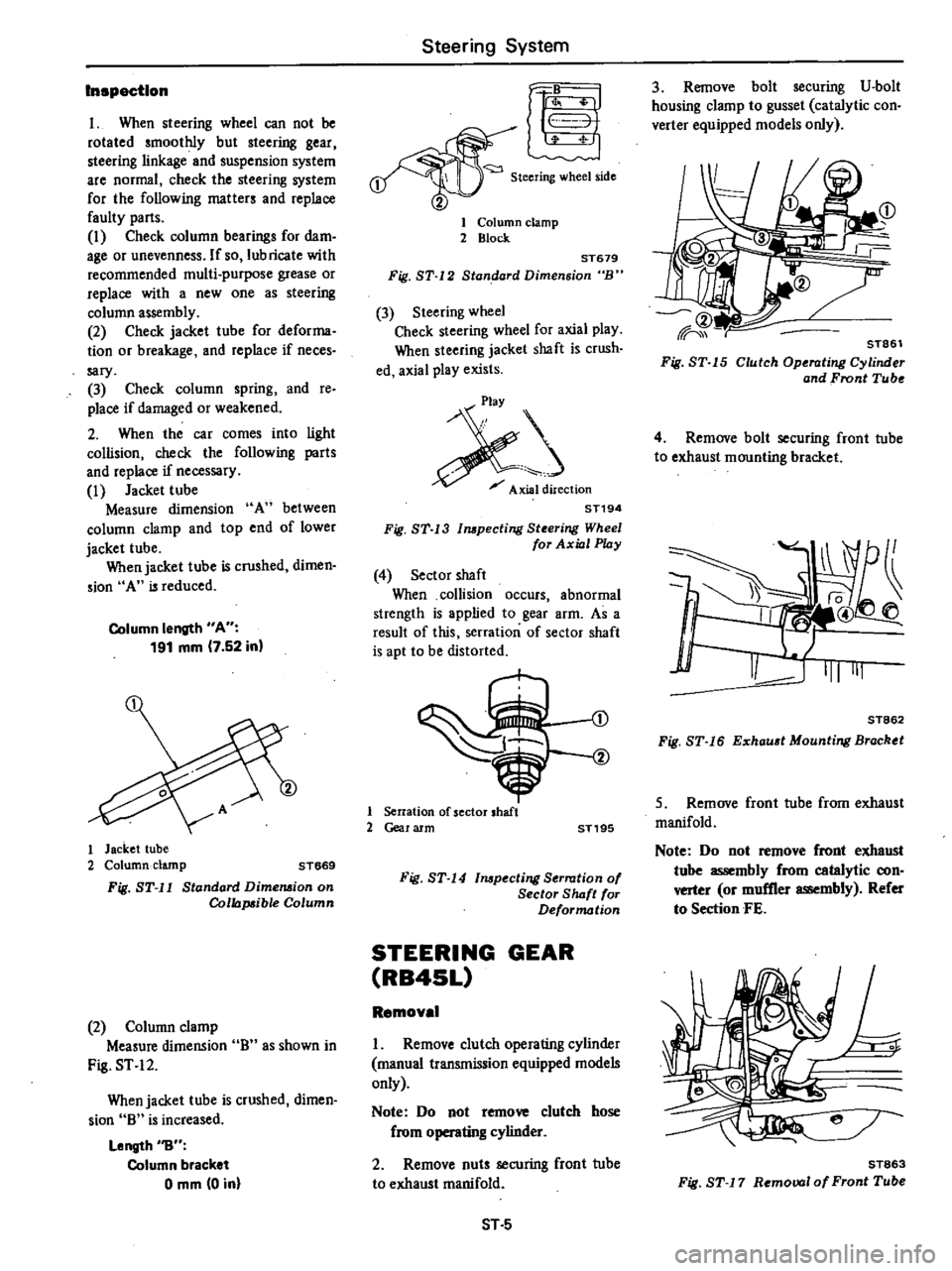

Inspection

I

When

steering

wheel

can

not

be

rotated

smoothly

but

steering

gear

steering

linkage

and

suspension

system

are

normal

check

the

steering

system

for

the

following

matters

and

replace

faulty

parts

I

Check

column

bearings

for

dam

age

or

unevenness

If

so

lubricate

with

recommended

multi

purpose

grease

or

replace

with

a

new

one

as

steering

column

assembly

2

Check

jacket

tube

for

deforma

tion

or

breakage

and

replace

if

neces

sary

3

Check

column

spring

and

re

place

if

damaged

or

weakened

2

When

the

car

comes

into

light

collision

check

the

following

parts

and

replace

if

necessary

I

Jacket

tube

Measure

dimension

A

between

column

clamp

and

top

end

of

lower

jacket

tube

When

jacket

tube

is

crushed

dimen

sion

A

is

reduced

Column

length

A

191

mm

7

52

in

1

Jacket

tube

2

Column

clamp

ST669

Fig

ST

l1

Standard

Dimension

on

Collapsible

Column

2

Column

clamp

Measure

dimension

0

as

shown

in

Fig

ST

12

When

jacket

tube

is

crushed

dimen

sion

0

is

increased

Length

1J

Column

bracket

o

mm

0

in

Steering

System

r

1

Steering

wheel

side

1

Column

clamp

2

Block

ST679

Fig

ST

12

Standard

Dimension

B

3

Steering

wheel

Check

steering

wheel

for

axial

play

When

steering

jacket

shaft

is

crush

ed

axial

play

exists

j

Axial

direction

ST194

Fig

ST

13

mpecting

Steering

Wheel

for

Axial

Play

4

Sector

shaft

When

collision

occurs

abnormal

strength

is

applied

to

gear

arm

As

a

result

of

this

serration

of

sector

shaft

is

apt

to

be

distorted

1

Serration

of

sector

shaft

2

Gear

arm

ST195

Fig

ST

14

mpeeting

Serration

of

Sector

S

IuJft

for

Deformation

STEERING

GEAR

RB4SL

Removal

I

Remove

clutch

operating

cylinder

manual

transmission

equipped

models

only

Note

Do

not

remove

clutch

hose

from

8

cylinder

2

Remove

nuts

securing

front

tube

to

exhaust

manifold

ST

5

3

Remove

bolt

securing

V

bolt

housing

clamp

to

gusset

catalytic

con

verter

equipped

models

only

STa6l

Fig

ST

5

Clutch

Operating

Cylinder

and

Front

Tube

4

Remove

bolt

securing

front

tube

to

exhaust

mounting

bracket

1

Q

I

II

@

J

111111

ST862

Fig

ST

16

Exhau

t

Mounting

Bracktt

5

Remove

front

tube

from

exhaust

manifold

Note

Do

not

remove

front

exhaust

tube

assembly

from

catalytic

con

verter

or

muffler

assembly

Refer

to

Section

FE

ST863

Fig

ST

7

Removal

of

Front

Tube

Page 391 of 548

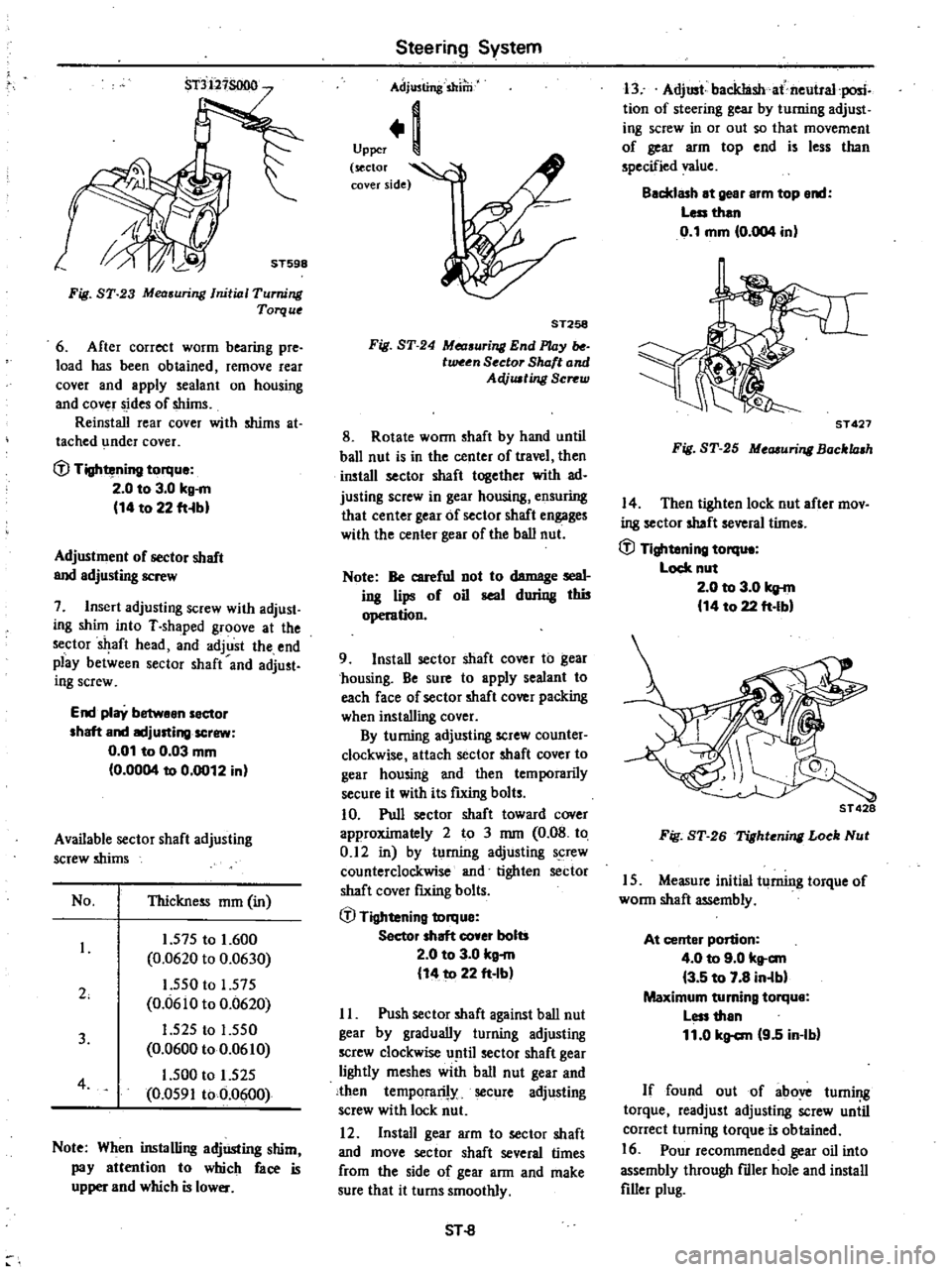

Fig

ST

23

Mea

uring

Initial

Turning

Torque

6

After

correct

worm

bearing

pre

load

has

been

obtained

remove

rear

cover

and

apply

sealant

on

housing

and

cover

sides

of

shims

Reinstall

rear

cover

with

shims

at

tached

under

cover

fJ

Tightening

torque

2

0

to

3

0

kg

m

14

to

22

fHbl

Adjustment

of

sector

shaft

and

adjusting

screw

7

Insert

adjusting

screw

with

adjust

ing

shUn

into

T

shaped

groove

at

the

sector

aft

head

and

adjust

the

end

play

between

sector

shaft

and

adjust

ing

screw

End

play

betwean

sector

shaft

and

IKljusting

screw

0

01

to

0

03

mm

0

0004

to

0

0012

in

Available

sector

shaft

adjusting

screw

shims

No

Thickness

mm

in

2

1

575

to

1

600

0

0620

to

0

0630

1

550

to

1

575

0

0610

to

0

0620

1

525

to

1

550

0

0600

to

0

0610

1

500

to

1

525

0

0591

to

0

0600

3

4

Note

When

installing

adjUsting

shim

pay

attention

to

which

face

is

upper

and

which

is

lower

Steering

System

Adjusting

shilli

Upper

1

sector

l

cover

side

ST258

Fig

ST

24

Measuri

End

l

UJy

tween

Sector

Shaft

and

AeVusting

Screw

8

Rotate

wonn

shaft

by

hand

until

ball

nut

is

in

the

center

of

travel

then

install

sector

shaft

together

with

ad

justing

screw

in

gear

housing

ensuring

that

center

gear

of

sector

shaft

engages

with

the

center

gear

of

the

ball

nut

Note

Be

careful

not

to

damage

seal

ing

lips

of

oil

seal

during

thi5

operation

9

Install

sector

shaft

cover

to

gear

chousing

Be

sure

to

apply

sealant

to

each

face

of

sector

shaft

cover

packing

when

installing

cover

By

turning

adjusting

screw

counter

clockwise

attach

sector

shaft

cover

to

gear

housing

and

then

temporarily

secure

it

with

its

futing

bolts

10

Pull

sector

shaft

toward

cover

approxUnately

2

to

3

mm

0

08

to

0

12

in

by

turning

adjusting

screw

counterclockwise

and

tighten

sector

shaft

cover

fIXing

bolts

fJ

Tightening

torque

Sector

shaft

co

er

bolts

2

0

to

3

0

kg

m

14

to

22

ft

Ib

II

Push

sector

shaft

against

ball

nut

gear

by

gradually

turning

adjusting

screw

clockwise

until

sector

shaft

gear

lightly

meshes

with

ball

nut

gear

and

then

temporarily

secure

adjusting

screw

with

lock

nut

12

Install

gear

arm

to

sector

shaft

and

move

sector

shaft

several

times

from

the

side

of

gear

ann

and

make

sure

that

it

turns

smoothly

SHl

13

Adjust

backIashat

neutral

posic

tion

of

steering

gear

by

turning

adjust

iog

screw

in

or

out

so

that

movement

of

gear

arm

top

end

is

less

than

specified

value

Backlash

at

gear

arm

top

end

Less

than

0

1

mm

0

004

in

ST

427

Fig

ST

25

Measuri

Bocklash

14

Then

tighten

lock

nut

after

mov

ing

sector

shaft

several

tUnes

fJ

Tightening

torqu

Lock

nut

2

0

to

3

0

kg

m

14

to

22

ft

Ibl

ST

428

Fig

ST

26

Tighteni

Loek

Nut

15

Measure

initial

turning

torque

of

wonn

shaft

assembly

At

center

portion

4

0

to

9

0

kt

c

m

3

5

to

7

8

in

lbl

Maximum

turning

torque

Less

than

11

0

kg

c

m

9

5

in

Ib

If

found

out

of

above

turning

torque

readjust

adjusting

screw

uniil

correct

turning

torque

is

obtained

16

Pour

recommended

gear

oil

into

assembly

through

fdler

hole

and

install

filler

plug

Page 407 of 548

Engine

Control

Fuel

Exhaust

Systems

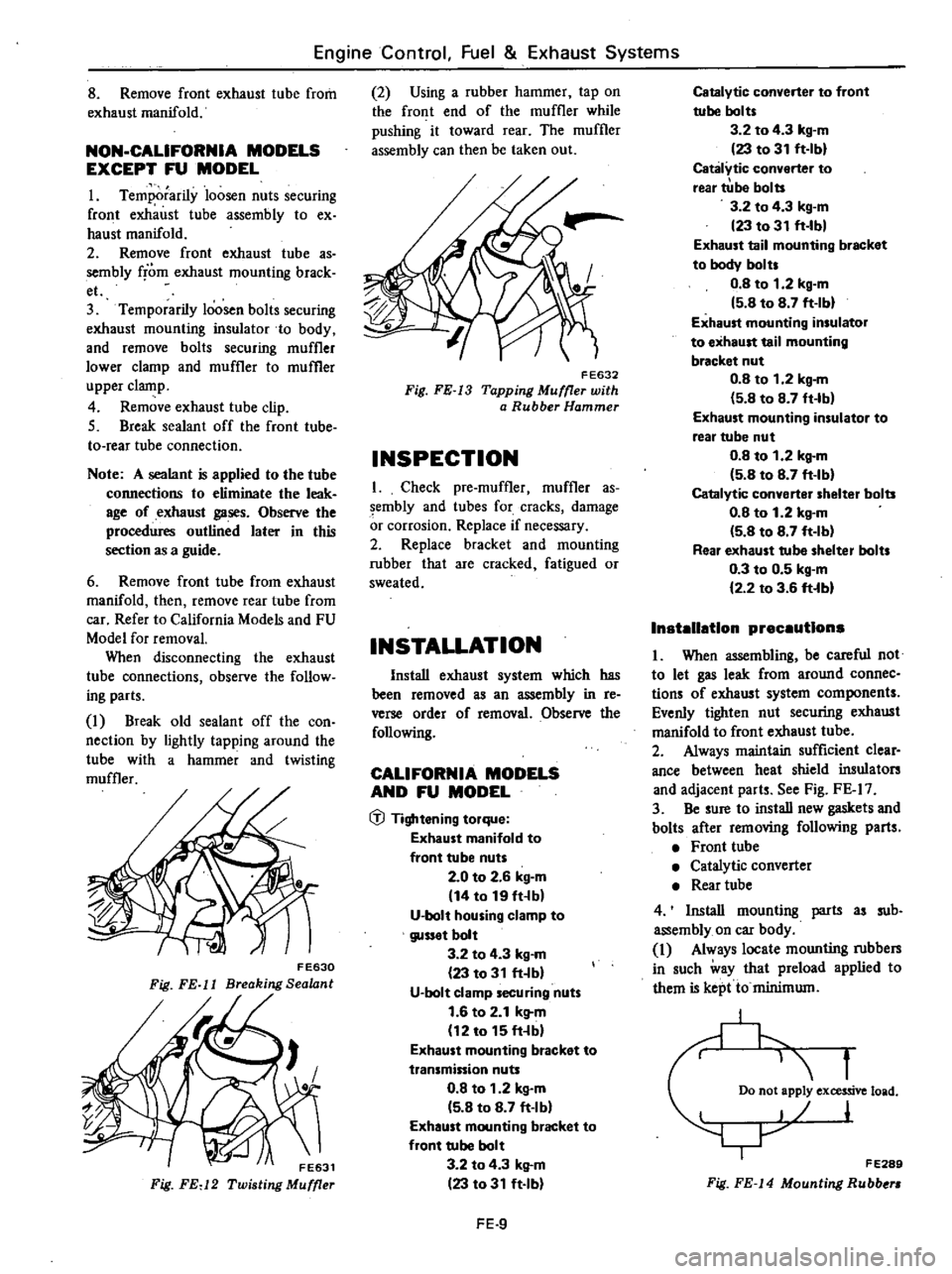

8

Remove

front

exhaust

tube

from

exhaust

manifold

NON

CALIFORNIA

MODELS

EXCEPT

FU

MODEL

I

Temporarily

loosen

nuts

securing

front

exhaust

tube

assembly

to

ex

haust

manifold

2

Remove

front

exhaust

tube

as

sembly

from

exhaust

mounting

brack

et

3

Temporarily

loosen

bolts

securing

exhaust

mounting

insulator

to

body

and

remove

bolts

securing

muffler

lower

clamp

and

muffler

to

muffler

upper

clamp

4

Remove

exhaust

tube

clip

5

Break

sealant

off

the

front

tube

to

rear

tube

connection

Note

A

sealant

is

applied

to

the

tube

connections

to

eliminate

the

leak

age

of

exhaust

gases

Observe

the

procedures

outlined

later

in

this

section

as

a

guide

6

Remove

front

tube

from

exhaust

manifold

then

remove

rear

tube

from

car

Refer

to

California

Models

and

FU

Model

for

removal

When

disconnecting

the

exhaust

tube

connections

observe

the

follow

ing

parts

I

Break

old

sealant

off

the

con

nection

by

lightly

tapping

around

the

tube

with

a

hammer

and

twisting

muffler

F

E630

Fig

FE

11

Breaking

Sealant

Fig

FEd

2

2

Using

a

rubber

hammer

tap

on

the

front

end

of

the

muffler

while

pushing

it

toward

rear

The

muffler

assembly

can

then

be

taken

out

FE632

Fig

FE

13

Tapping

Muffler

with

a

Rubber

Hammer

INSPECTION

I

Check

pre

muffler

muffler

as

sembly

and

tubes

for

cracks

damage

or

corrosion

Replace

if

necessary

2

Replace

bracket

and

mounting

rubber

that

are

cracked

fatigued

or

sweated

INSTALLATION

Install

exhaust

system

which

has

been

removed

as

an

assembly

in

re

verse

order

of

removal

Observe

the

following

CALIFORNIA

MODELS

AND

FU

MODEL

1Jl

Tightening

torque

Exhaust

manifold

to

front

tube

nuts

2

0

to

2

6

kg

m

14

to

19

fHb

U

bolt

housing

clamp

to

gusset

bolt

3

2

to

4

3

kg

m

23

to

31

ft

bl

U

bolt

clamp

securing

nuts

1

6

to

2

1

k

l

m

12

to

15

ft

bl

Exhaust

mounting

bracket

to

transmission

nuts

0

8

to

1

2

kg

m

5

8

to

8

7

ft

Ibl

Exhaust

mounting

bracket

to

front

tube

bolt

3

2

to

4

3

k

l

m

23

to

31

ft

Ib

FE

9

CatalytiC

converter

to

front

tube

bolts

3

2

to

4

3

kg

m

23

to

31

ft

Ibl

Catalytic

converter

to

rear

tUbe

bolts

3

2

to

4

3

kg

m

23

to

31

ft

Ibl

Exhaust

tail

mounting

bracket

to

body

bolts

0

8

to

1

2

kg

m

5

B

to

8

7

ft

Ibl

Exhaust

mounting

insulator

to

exhaust

tail

mounting

bracket

nut

0

8

to

1

2

kg

m

5

8

to

8

7

ft

Ib

Exhaust

mounting

insulator

to

rear

tube

nut

O

B

to

1

2

kg

m

5

8

to

8

7

ft

Ib

Catalytic

converter

shelter

bolts

O

B

to

1

2

kg

m

5

8

to

B

7

ft

Ib

Rear

exhaust

tube

shelter

bolts

0

3

to

0

5

kg

m

2

2

to

3

6

ft

bl

Installation

precautions

I

When

assembling

be

careful

not

to

let

gas

leak

from

around

connec

tions

of

exhaust

system

components

Evenly

tighten

nut

securing

exhaust

manifold

to

front

exhaust

tube

2

Always

maintain

sufficient

clear

ance

between

heat

shield

insulators

and

adjacent

parts

See

Fig

FE

I7

3

Be

sure

to

install

new

gaskets

and

bolts

after

removing

following

parts

Front

tube

Catalytic

converter

Rear

tube

4

Install

mounting

parts

as

sub

assembly

on

car

body

I

Always

locate

mounting

rubbers

in

such

way

that

preload

applied

to

them

is

kept

to

minimum

f

Do

not

apply

excessive

load

I

F

E289

Fig

FE

J4

Mounting

Rubbe

Page 441 of 548

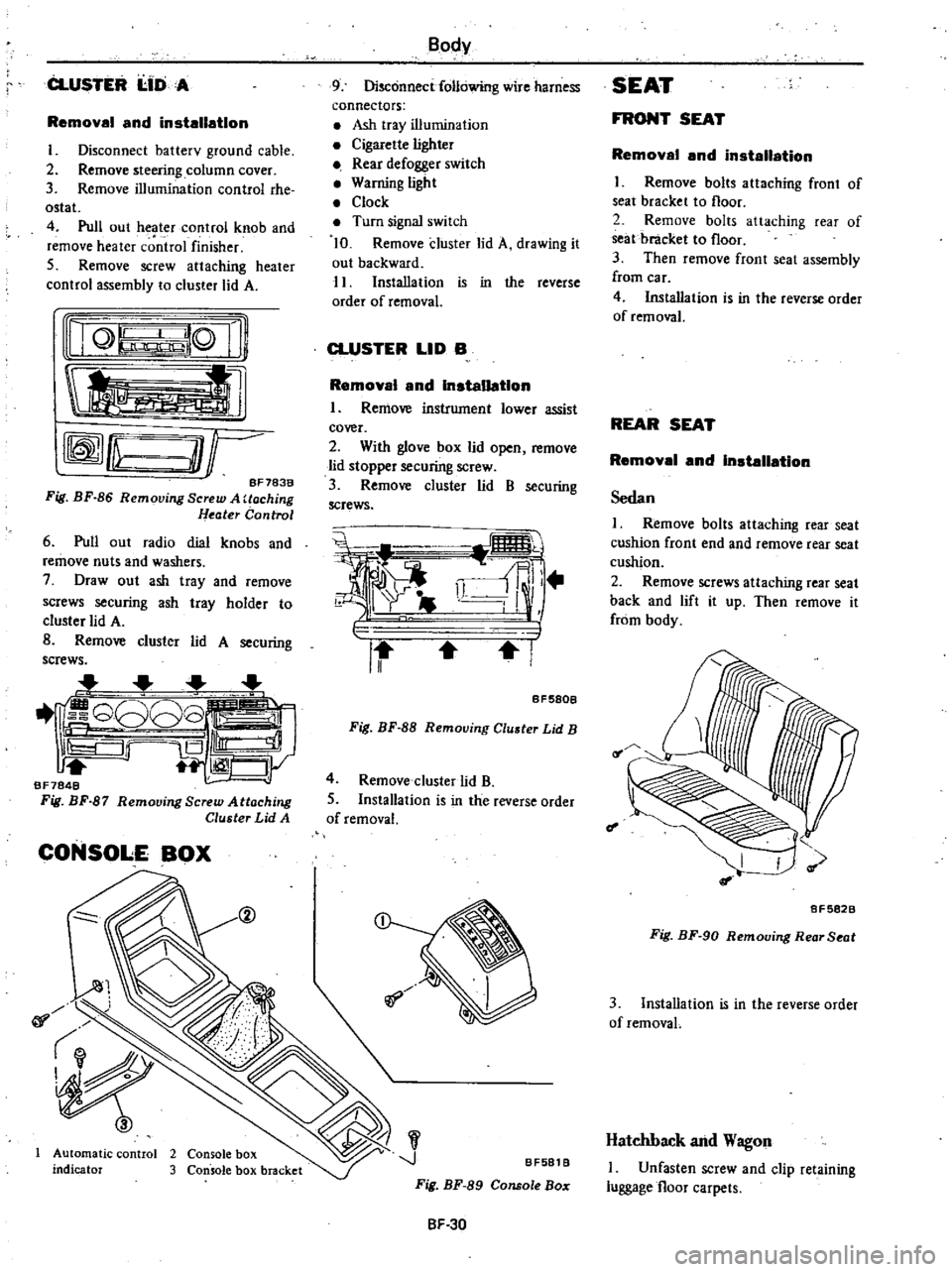

CLUSTER

I

IDA

Removal

and

installation

I

Disconnect

batterv

ground

cable

2

Remove

steering

column

cover

3

Remove

illumination

control

rhe

ostat

4

Pull

out

heater

control

knob

and

remove

heater

c

ntrol

finisher

5

Remove

screw

attaching

heater

control

assembly

to

cluster

lid

A

nQ

lQ

Ii

tl

rffmfLu

O

r

BF783B

Fig

BF

86

Removing

Screw

A

Uoching

Heater

Control

6

Pull

out

radio

dial

knobs

and

remove

nuts

and

washers

7

Draw

out

ash

tray

and

remove

screws

securing

ash

tray

holder

to

cluster

lid

A

B

Remove

cluster

lid

A

securing

screws

1

G808

iS

Ill

1

CJy

BF7848

Fig

BF

87

Remooing

Screw

Attaching

Cluster

Lid

A

CONSOLE

BOX

@

01

Automatic

control

2

Console

box

indicator

3

Console

box

bracket

Body

9

Disconnect

following

wire

harness

connectors

Ash

tray

illumination

Cigarette

lighter

Rear

defogger

switch

Warning

light

Clock

Turn

signal

switch

10

Remove

cluster

lid

A

drawing

it

out

backward

11

Installation

is

in

the

reverse

order

of

removal

CLUSTER

LID

B

Removal

and

Installation

I

Remove

instrument

lower

assist

cover

2

With

glove

box

lid

open

remove

lid

stopper

securing

screw

3

Remove

cluster

lid

B

securing

screws

i

i

ll

r

II

I

BF580B

Fig

BF

88

Removing

Cluster

Lid

B

4

Remove

cluster

lid

B

5

Installation

is

in

the

reverse

order

of

removal

J

BF581

B

Fig

BF

89

Console

Bo

SF

30

SEAT

FRONT

SEAT

Removal

and

installation

I

Remove

bolts

attaching

front

of

seat

bracket

to

floor

2

Remove

bolts

attaching

rear

of

seat

bracket

to

floor

3

Then

remove

front

seat

assembly

from

car

4

Installation

is

in

the

reverse

order

of

removal

REAR

SEAT

Removal

and

Installation

Sedan

I

Remove

bolts

attaching

rear

seat

cushion

front

end

and

remove

rear

seat

cushion

2

Remove

screws

attaching

rear

seat

back

and

lift

it

up

Then

remove

it

from

body

f

I

8F5828

Fig

BF

90

Removing

Rear

Seat

3

Installation

is

in

the

reverse

order

of

removaL

Hatchback

and

Wagon

I

Unfasten

screw

and

clip

retaining

luggage

floor

carpets

Page 443 of 548

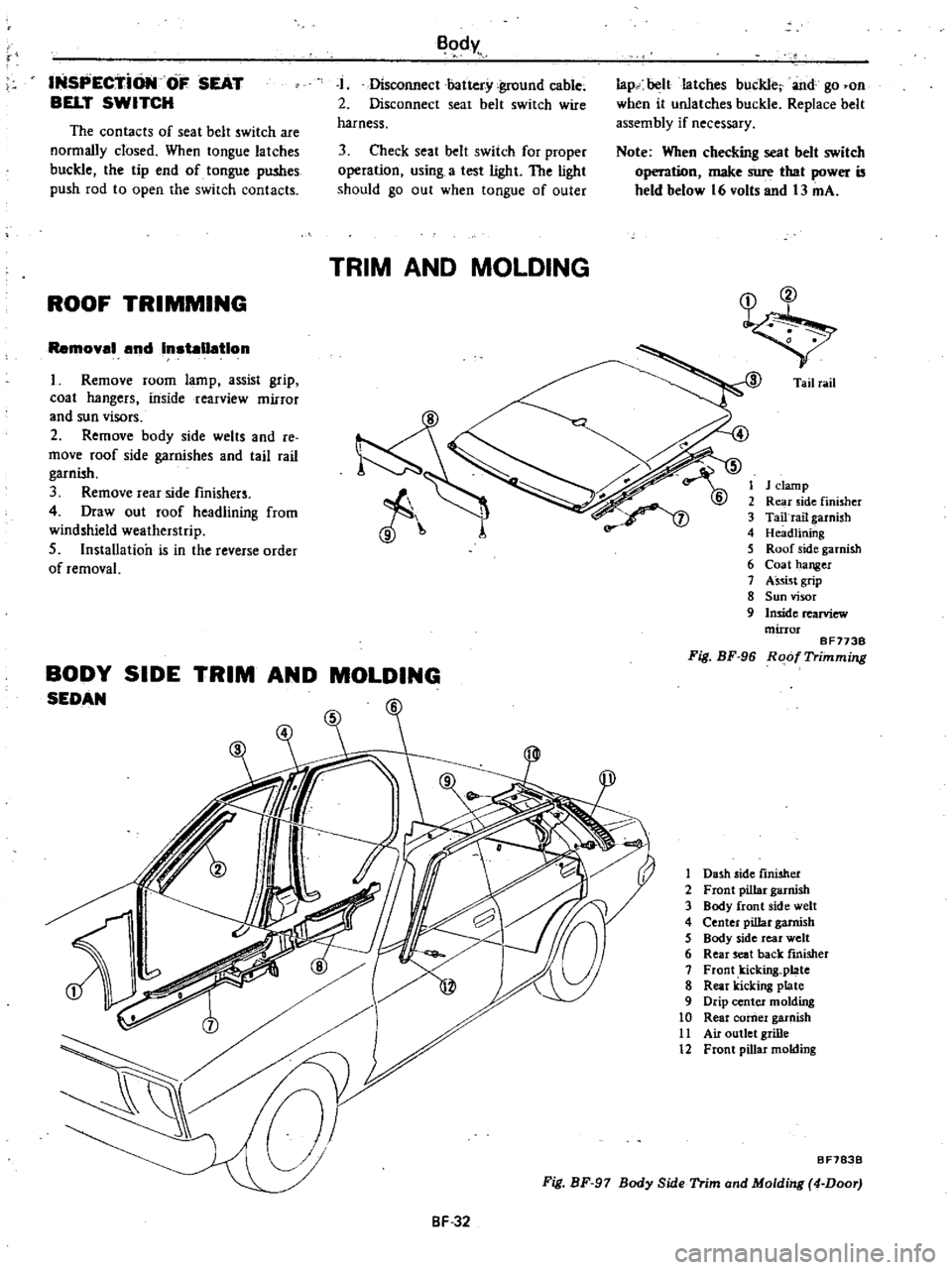

INSPECTiON

OF

SEAT

BELT

SWITCH

The

contacts

of

seat

belt

switch

are

normally

closed

When

tongue

latches

buckle

the

tip

end

of

tongue

pushes

push

rod

to

open

the

switch

contacts

ROOF

TRIMMING

Removel

end

Inetelletlon

l

Remove

room

lamp

assist

grip

coat

hangers

inside

rearview

mirror

and

sun

visors

2

Remove

body

side

welts

and

re

move

roof

side

garnishes

and

tail

rail

garnish

3

Remove

rear

side

finishers

4

Draw

out

roof

headlining

from

windshield

weatherstrip

5

Installation

is

in

the

reverse

order

of

removal

Body

u

I

Disconnectbatter

y

ground

cable

2

Disconnect

seat

belt

switch

wire

harness

lape

belt

latches

buckle

and

go

on

when

it

unlatches

buckle

Replace

belt

assembly

if

necessary

Note

When

checking

seat

belt

switch

operation

make

sure

that

power

held

below

16

volts

and

13

mA

3

Check

seat

belt

switch

for

proper

operation

using

a

test

light

The

light

should

go

out

when

tongue

of

outer

TRIM

AND

MOLDING

f

BODY

SIDE

TRIM

AND

MOLDING

SEDAN

T

S

Tail

rail

1

J

clamp

2

Rear

side

finisher

3

Tailrail

garnish

4

Headlining

5

Roof

side

garnish

6

Coat

hanger

7

Assist

grip

8

Sun

visor

9

Inside

rearview

mirror

BF173B

Fig

BF

96

Roof

Trimming

1

Dash

side

finisher

2

Front

pillar

garnish

3

Body

front

side

welt

4

Center

pillar

garnish

5

Body

side

rear

welt

6

Rear

seat

back

finisher

7

Front

kicking

plate

8

Rear

kicking

plate

9

Drip

center

molding

10

Rear

comer

garnish

11

Air

outlet

grille

12

Front

pillar

molding

Fig

BF

97

Body

Side

Trim

ond

Molding

4

Door

BF783B

BF

32

Page 446 of 548

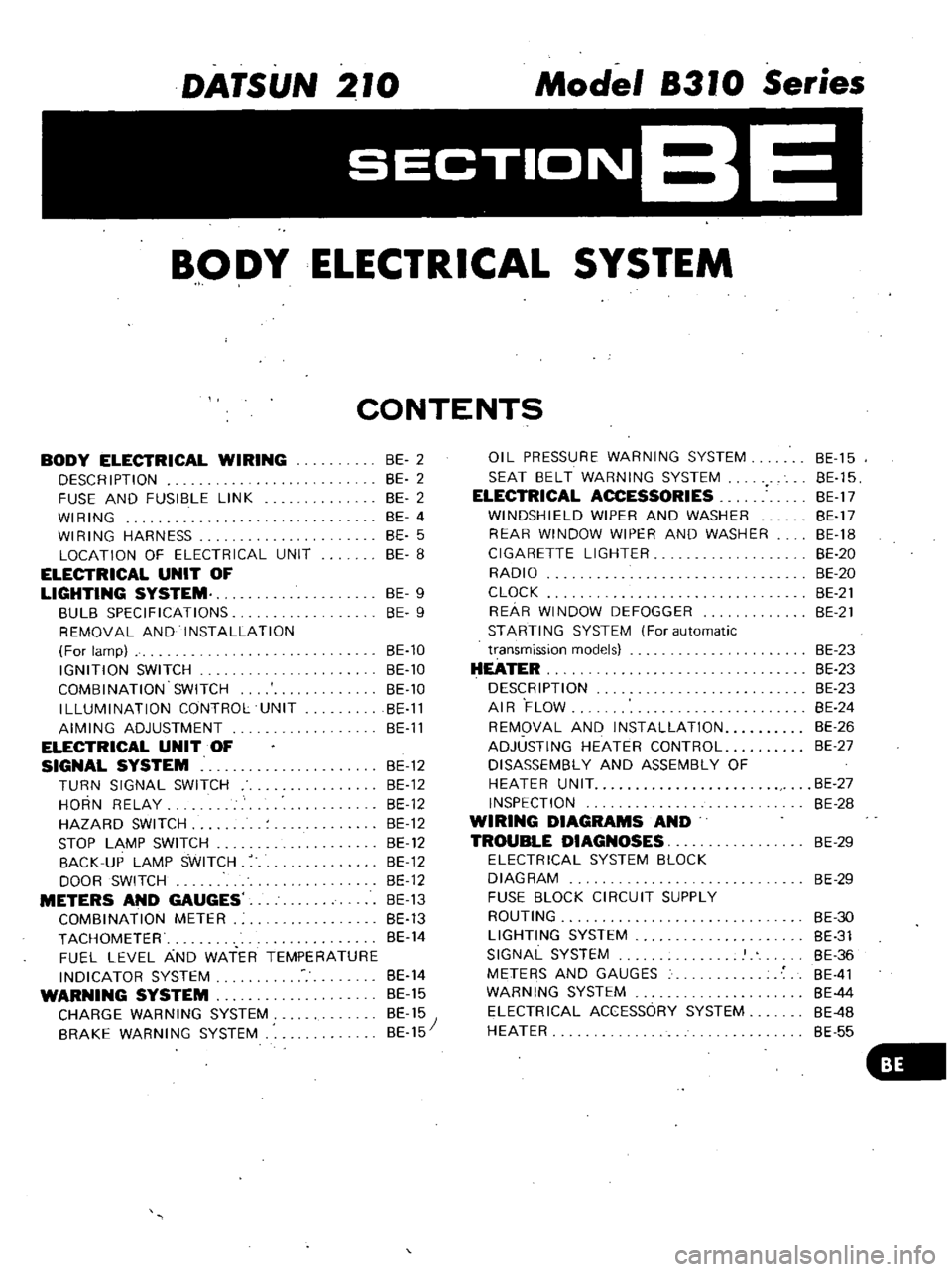

DATSUN

210

Model

8310

Series

SECTIONBE

BODY

ELECTRICAL

SYSTEM

CONTENTS

BODY

ELECTRICAL

WIRING

DESCRIPTION

FUSE

AND

FUSIBLE

LINK

WIRING

WIRING

HARNESS

LOCATION

OF

ELECTRICAL

UNIT

ELECTRICAL

UNIT

OF

LIGHTING

SYSTEM

BULB

SPECIFICATIONS

REMOVAL

AND

INSTALLATION

For

lamp

IGNITION

SWITCH

COMBINATION

SWITCH

ILLUMINATION

CONTROL

UNIT

AIMING

ADJUSTMENT

ELECTRICAL

UNIT

OF

SIGNAL

SYSTEM

BE

12

TURN

SIGNAL

SWITCH

BE

12

HORN

RELAY

BE

12

HAZARD

SWITCH

BE

12

STOP

LAMP

SWITCH

BE

12

BACK

UP

LAMP

SWITCH

BE

12

DOOR

SWITCH

BE

12

METERS

AND

GAUGES

BE

13

COMBINATION

METER

BE

13

TACHOMETER

BE

14

FUEL

LEVEL

AND

WATER

TEMPERATURE

INDICATOR

SYSTEM

BE

14

WARNING

SYSTEM

BE

15

CHARGE

WARNING

SYSTEM

BE

15

BRAKE

WARNING

SYSTEM

BE

15

BE

2

BE

2

BE

2

BE

4

BE

5

BE

8

BE

9

BE

9

BE

10

BE

10

BE

10

BE

11

BE

11

OIL

PRESSURE

WARNING

SYSTEM

SEAT

BELT

WARNING

SYSTEM

ELECTRICAL

ACCESSORIES

WINDSHIELD

WIPER

AND

WASHER

REAR

WINDOW

WIPER

AND

WASHER

CIGARETTE

LIGHTER

RADIO

CLOCK

REAR

WINDOW

DEFOGGER

STARTING

SYSTEM

For

automatic

transmission

models

HEATER

DESCRIPTION

AIR

FLOW

REMOVAL

AND

INSTALLATION

ADJUSTING

HEATER

CONTROL

DISASSEMBLY

AND

ASSEMBLY

OF

HEATER

UNIT

INSPECTION

WIRING

DIAGRAMS

AND

TROUBLE

DIAGNOSES

ELECTRICAL

SYSTEM

BLOCK

DIAGRAM

FUSE

BLOCK

CIRCUIT

SUPPLY

ROUTING

LIGHTING

SYSTEM

SIGNAL

SYSTEM

METERS

AND

GAUGES

WARNING

SYSTEM

ELECTRICAL

ACCESSORY

SYSTEM

HEATER

BE

15

BE

15

BE

17

BE

17

BE

18

BE

20

BE

20

BE

21

BE

21

BE

23

BE

23

BE

23

BE

24

BE

26

BE

27

BE

27

BE

28

BE

29

BE

29

BE

30

BE

31

BE

36

BE

41

BE

44

BE

4B

BE

55