light DATSUN 210 1979 Workshop Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 231 of 548

4

Install

stopper

pin

bolt

into

rear

extension

and

tighten

l

J

Tightening

torque

Stopper

pin

bolt

0

5

to

0

8

kg

m

3

6

to

5

8

ft

lb

Be

sure

to

apply

sealant

before

installation

Stopper

pin

bolt

Sealant

TM814

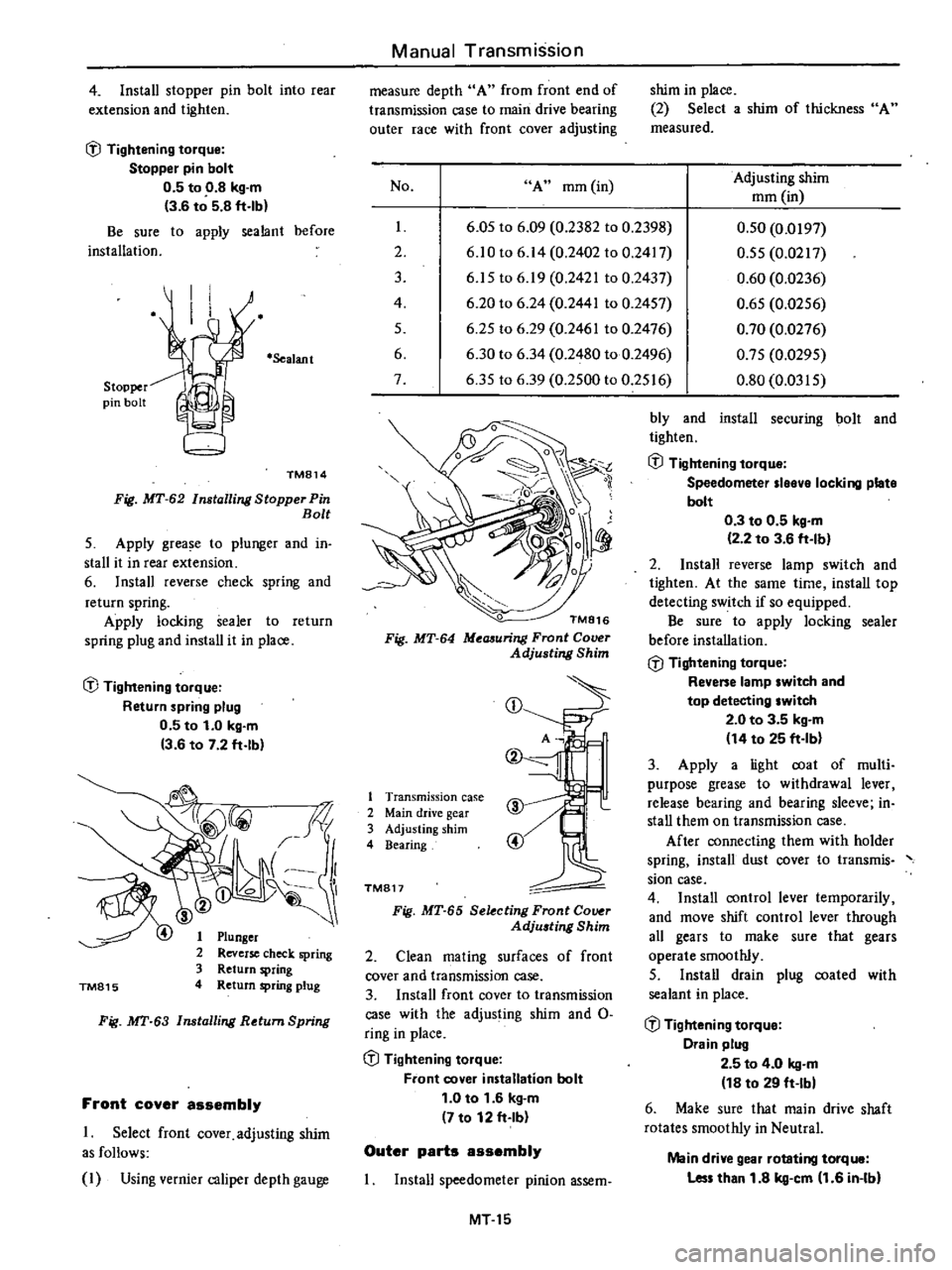

Fig

MT

62

Installing

Stopper

Pin

Bolt

5

Apply

grease

to

plunger

and

in

stall

it

in

rear

extension

6

Install

reverse

check

spring

and

return

spring

Apply

locking

sealer

to

return

spring

plug

and

install

it

in

place

l

J

Tightening

torque

Return

spring

plug

0

5

to

1

0

kg

m

3

6

to

7

2

ft

lb

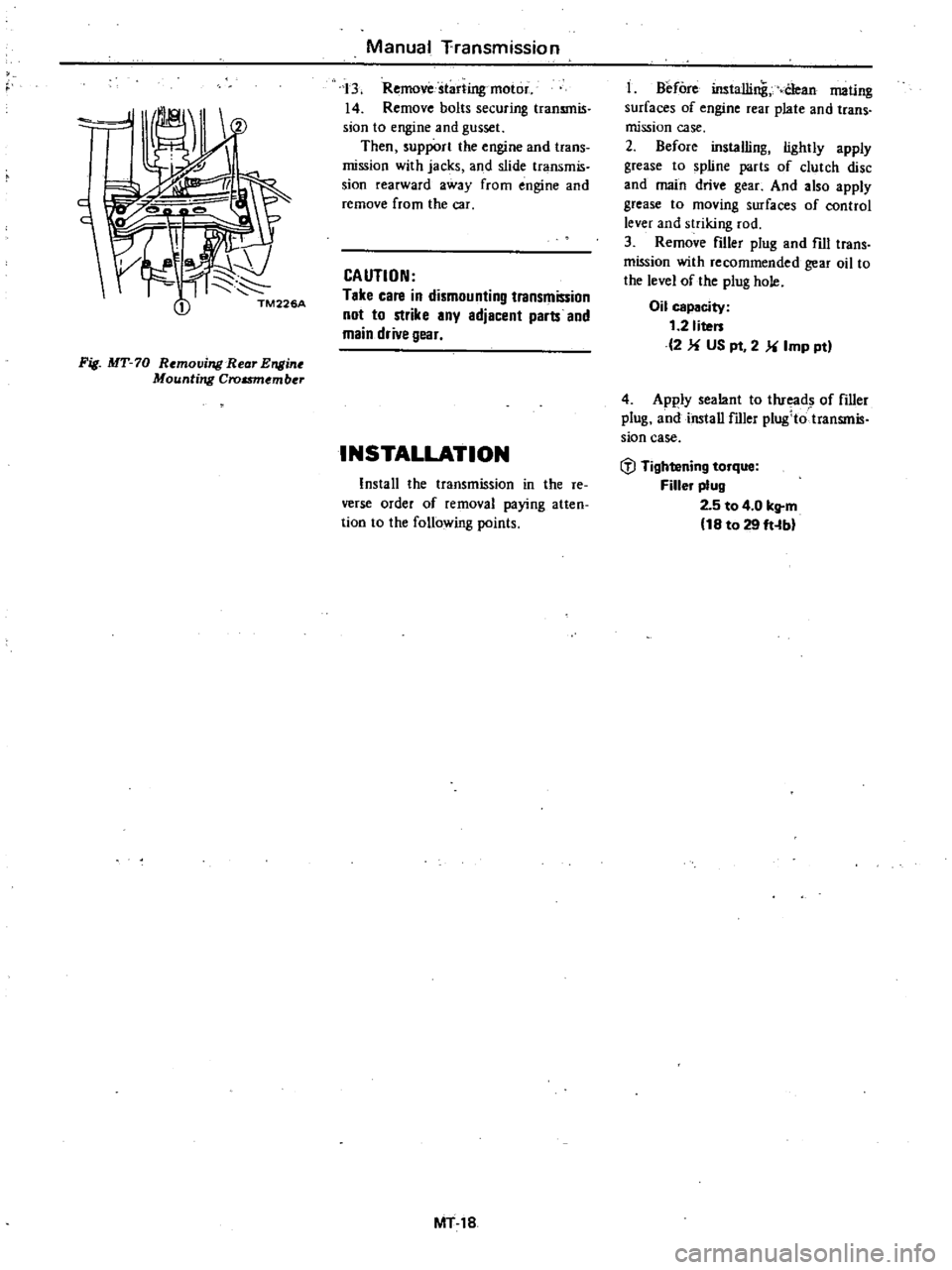

TM815

Plunger

Reverse

check

spring

Return

spring

Return

spring

plug

Fig

MT

63

Installing

Return

Spring

Front

cover

assembly

1

Select

front

cover

adjusting

shim

as

follows

I

Using

vernier

caliper

depth

gauge

Manual

Transmission

measure

depth

A

from

front

end

of

transmission

case

to

main

drive

bearing

outer

race

with

front

cover

adjusting

No

A

mm

in

I

2

3

4

5

6

7

shim

in

place

2

Select

a

shim

of

thickness

A

measured

Adjusting

shim

mm

in

6

05

to

6

09

0

2382

to

0

2398

6

10

to

6

14

0

2402

to

0

2417

6

15

to

6

19

0

2421

to

0

2437

6

20

to

6

24

0

2441

to

0

2457

6

25

to

6

29

0

2461

to

0

2476

6

30

to

6

34

0

2480

to

0

2496

6

35

to

6

39

0

2500

to

0

2516

0

50

0

0197

0

55

0

0217

0

60

0

0236

0

65

0

0256

0

70

0

0276

0

75

0

0295

0

80

0

0315

TM816

Fig

MT

64

Meaauring

Front

Cover

Adjusting

Shim

CD

1

Transmission

case

2

Main

drive

gear

3

Adjusting

shim

4

Bearing

TM817

Fig

MT

65

Selecting

Front

Co

r

Adju

ting

Shim

2

Clean

mating

surfaces

of

front

cover

and

transmission

case

3

Install

front

cover

to

transmission

case

with

the

adjusting

shim

and

0

ring

in

place

l

J

Tightening

torque

Front

cover

installation

bolt

1

0

to

1

6

kg

m

7

to

12

ft

Ib

Outer

parts

assembly

Install

speedometer

pinion

assem

MT15

bly

and

install

securing

bolt

and

tighten

l

J

Tightening

torque

Speedometer

Ieeve

locking

plate

bolt

0

3

to

0

5

kg

m

2

2

to

3

6

ft

Ib

2

Install

reverse

lamp

switch

and

tighten

At

the

same

time

install

top

detecting

switch

if

so

equipped

Be

sure

to

apply

locking

sealer

before

installation

l

J

Tightening

torque

Revene

lamp

switch

and

top

detecting

switch

2

0

to

3

5

kg

m

14

to

25

ft

Ib

3

Apply

a

light

coat

of

multi

purpose

grease

to

withdrawal

lever

release

bearing

and

bearing

sleeve

in

stall

them

on

transmission

case

After

connecting

them

with

holder

spring

install

dust

cover

to

transmis

sian

case

4

Install

control

lever

temporarily

and

move

shift

control

lever

through

all

gears

to

make

sure

that

gears

operate

smoothly

5

Install

drain

plug

coated

with

sealant

in

place

l

J

Tightening

torque

Drain

plug

2

5

to

4

0

kg

m

18

to

29

ft

Ibl

6

Make

sure

that

main

drive

shaft

rotates

smoothly

in

Neutral

Main

drive

gear

rotating

torque

Les

than

1

8

kg

cm

1

6

in

Ibl

Page 234 of 548

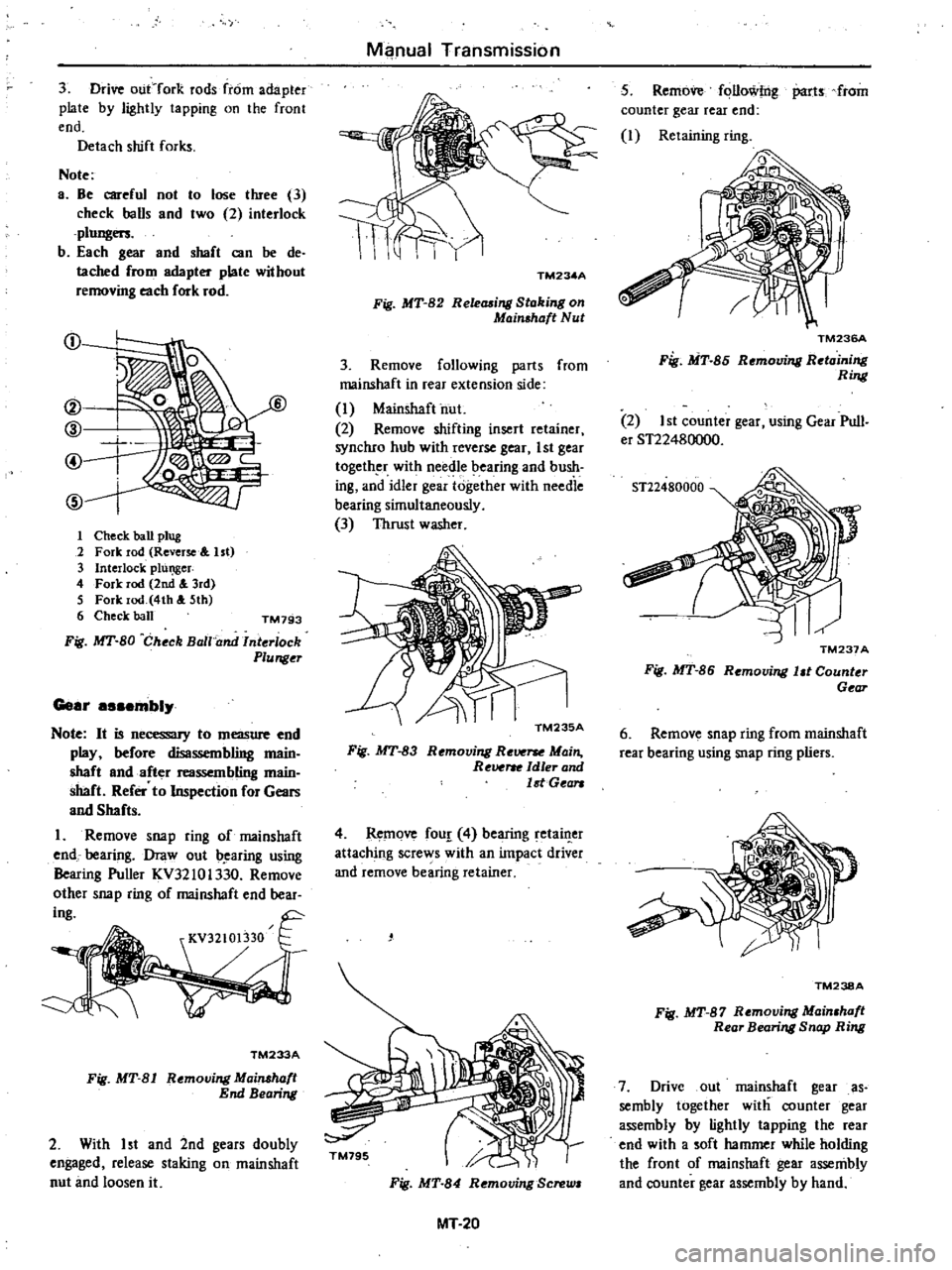

o

Fig

MT

70

R

movi7l

lB

ar

Ensi

Mounting

Croum

mber

Manual

Transmission

3

Remove

starting

motor

14

Remove

bolts

securing

transmis

sJon

to

engine

and

gusset

Then

support

the

engine

and

trans

mission

with

jacks

and

slide

transmis

sion

rearward

away

from

engine

and

remove

from

the

car

CAUTION

Take

cate

in

dismounting

transmission

not

to

strike

any

adjacenl

parts

and

main

drive

gear

INSTALLATION

Install

the

transmission

in

the

re

verse

order

of

removal

paying

atten

tion

to

the

following

points

MT18

t

Before

installing

Clean

mating

surfaces

of

engine

rear

plate

and

trans

mission

case

2

Before

installing

lightly

apply

grease

to

spline

parts

of

clutch

disc

and

main

drive

gear

And

also

apply

grease

to

moving

surfaces

of

control

lever

and

striking

rod

3

Remove

filler

plug

and

fill

trans

mission

with

recommended

gear

oil

to

the

level

of

the

plug

hole

Oil

capacity

t

2

liters

2

US

pt

2

Imp

ptl

4

Apply

sealant

to

thread

of

filler

plug

and

install

filler

plug

totransmis

sian

case

l

l

Tightening

torque

Filler

plug

2

5

to

4

0

kg

m

t8

to

29

ft

bl

Page 236 of 548

3

Drive

out

fork

rods

from

adapter

plate

by

lightly

tapping

on

the

front

end

Detach

shift

forks

Note

a

Be

careful

not

to

lose

three

3

check

balls

and

two

2

interlock

plungers

b

Each

gear

and

shaft

can

be

de

tached

from

ar1apter

plate

without

removing

each

fork

rod

CD

@

1

Check

ball

p1

8

2

Fork

rod

Reverse

Ist

3

Interlock

plu

er

4

Fork

rod

2nd

3rd

5

Fork

rod

4Ih

5th

6

Check

ball

TM793

Fig

MT

BO

Check

Ball

nd

Interlock

Plunger

Gear

a

embl

Note

It

is

necessary

to

measure

end

play

before

disassembling

main

shaft

and

after

reassembling

main

shaft

Refer

to

Inspection

for

Gears

and

Shafts

1

Remove

snap

ring

of

rnainshaft

end

bearing

Draw

out

b

aring

using

Bearing

Puller

KV32

10

1330

Remove

olher

sna

p

ring

of

rnainshaft

end

bear

ing

TM233A

Fig

MT

BI

Removing

Mainshaft

End

Bearing

2

With

1st

and

2nd

gears

doubly

engaged

release

staking

on

main

shaft

nut

and

loosen

it

Manual

Transmission

TM234A

Fig

MT

B2

Releaaing

Staking

on

Mainshaft

Nut

3

Remove

following

parts

from

mainshaft

in

rear

extension

side

I

Mainshaft

hut

2

Remove

shifting

insert

retainer

synchro

hub

with

reverse

gear

1st

gear

togeth

r

with

needle

bearing

and

bush

ing

and

idler

gear

together

with

needie

bearing

simultaneously

3

Thrust

washer

Fig

MT

83

Removing

Reverw

Main

Revere

Idler

and

1st

Gea

4

Remove

four

4

bearing

retai

er

attaching

screws

with

an

impact

driver

and

remove

bearing

retainer

Fig

MT

B4

Removing

Screw

MT

20

5

Remove

folloWIng

parts

from

counter

gear

rear

end

I

Retaining

ring

TM236A

Fig

ltiT

85

Removing

Retaining

Ring

2

1st

counter

gear

using

Gear

Pull

er

ST22480000

ST22480000

TM237A

Fig

MT

86

Remouing

l

t

Counter

Gear

6

Remove

snap

ring

from

mainshaft

rear

bearing

using

snap

ring

pliers

TM238A

Fig

MT

B7

Removing

Main

haft

Rear

Bearing

Snap

Ring

7

Drive

out

rnainshaft

gear

as

sembly

together

with

counter

gear

assembly

by

lightly

tapping

the

rear

end

with

a

sofl

hammer

while

holding

the

front

of

rnainshaft

gear

assembly

and

counter

gear

assembly

by

hand

Page 241 of 548

2

Install

needle

bearing

by

lightly

tapping

around

it

with

a

brass

drift

and

a

hammer

3

Install

reverse

idler

shaft

with

thrust

washer

in

adapter

plate

by

tapping

the

shaft

end

with

a

soft

hammer

TM243A

Fig

MT

I05

Installing

Re

Idler

Shaft

ASSEMBLY

OF

GEAR

ASSEMBLY

Clean

all

parts

in

solvent

and

dry

with

pressed

air

Synchronizer

1

2nd

3rd

41h

5th

speed

synchronizers

I

Place

synchro

hub

into

coupling

sleeve

2

Fit

shifIing

inserts

in

t1lree

grooves

in

synchronozer

hub

3

Install

spread

spring

to

inserts

so

that

insert

is

securely

attached

to

inner

side

of

coupling

sleeve

Install

Ihe

other

spread

spring

on

the

opposite

side

of

synchro

hub

Note

a

Be

careful

not

to

hook

front

and

rear

ends

of

the

spread

spring

to

the

same

insert

b

Be

sure

that

hub

and

sleeve

oper

ates

smoothly

and

correctly

by

hand

TM077

Fig

MT

I06

Enstalling

Spread

Spring

Manual

Transmission

TM131A

Fig

MT

I07

Installing

Spre

d

Spring

2

2

Ist

reverse

synchronizer

I

Position

shifting

insert

springs

and

shifting

inserts

in

three

3

slots

in

synchronizer

hub

2

Put

reverse

gear

on

synchronizer

hub

3

Install

shifting

insert

retainer

to

inserts

so

that

sert

is

securely

attach

ed

to

inner

side

of

reverse

gear

Mainshatt

I

Assemble

3rd

gear

needle

bearing

3rd

gear

baulk

ring

2nd

3rd

speed

synchronizer

assembly

2nd

gear

baulk

ring

2nd

gea

buihirig

needle

bearing

2nd

gea

and

thrust

washer

on

main

shaft

to

2

Press

mainshiift

bearing

onto

mainshaft

uSi

g

Mainshaft

Bearing

Drifl

ST22350000

L

ST22350000

TM711

Fig

MT

I08

Enstalling

Mainshaft

Bearing

Note

Assemble

2nd

3rd

speed

synchronizer

paying

attention

to

its

direction

MT

25

Front

hl

l

h2

2nd

gear

ide

3rd

gear

SIde

hi

h2

Fig

MT

109

Inslalling

2nd

3rd

Speed

Synchronizer

3

Position

5th

gear

needle

bearing

5th

gear

bawk

ring

and

4th

5th

synchronizer

assembly

on

the

front

side

of

mainshaft

4

Fit

a

new

suitable

snap

ring

in

place

so

that

there

exists

a

minimum

clearance

between

end

face

of

hub

and

ring

Note

Make

sure

snap

ring

fits

in

groove

Available

snap

rings

No

Thicknc

ss

mm

tin

2

1

55

to

1

60

0

0610

to

0

0630

1

60

to

1

65

0

0630

to

0

0650

1

65

to

1

70

0

0650

to

0

0669

3

TM798

Fig

MT

IlO

InslallingSnap

Ring

Main

drive

gear

1

Press

main

drive

gear

bearing

onto

shaft

of

main

drive

gear

using

Trans

mission

Drift

ST23800000

Make

sure

that

snap

ring

groove

on

shaft

clears

bearing

Page 242 of 548

H

ST23800000

M

TM714

Fig

MT

111

InstaUing

Main

Drive

Bearing

2

Place

main

drive

bearing

spacer

on

main

drive

bearing

and

secure

main

dtivebearing

with

a

new

tlii

er

snap

ring

that

will

eliminate

end

play

Note

Make

sure

snap

ring

fits

in

groove

1

Main

drive

gear

2

Snap

ring

3

Spacer

4

Main

drive

bearing

TM715

Fig

MT

112

In

talling

Snap

Ring

Available

snap

rings

No

Thickness

mm

in

2

1

34

to

I

40

0

0528

to

0

055

I

l40tol46

0

0551

to

0

0575

I

4610

1

52

0

0575100

0598

1

52101

58

0

0598

10

0

0622

1

58

to

1

64

0

0622

to

0

0646

1

64

to

I

70

0

0646

to

0

0669

I

70

to

I

76

0

0669

10

0

0693

3

4

5

6

7

Counter

cear

I

Install

a

counter

gear

thrust

washer

and

counter

gear

into

transmis

sian

case

and

select

counter

gear

Manual

Transmission

thrust

washer

of

proper

thiclmess

using

straight

edge

Select

washer

from

those

shown

in

the

following

table

so

that

end

play

of

counter

gear

is

specified

value

Standard

end

play

0

10

to

0

20

mm

0

0039

to

0

0079

inl

No

Thickness

mm

in

2

20

to

2

25

0

0866

to

0

0886

2

25

to

2

30

0

0886

to

0

0906

2

30

to

2

35

0

0906

to

0

0925

2

35

to

2

40

0

0925

to

0

0945

2

40

to

2

45

0

0945

to

0

0965

2

45

to

2

50

0

0965

to

0

0984

2

50

to

2

55

0

0984

to

0

1004

2

55

to

2

60

0

1004

to

0

024

2

3

4

5

6

7

8

Note

Be

sure

to

measure

at

two

or

more

positions

on

the

end

surface

of

counter

gear

rr

II

TM244A

Fig

MT

113

Measuring

Counter

Gear

End

Phly

2

Remove

counter

gear

from

the

transmission

case

Assembly

to

adapter

plate

I

Install

baulk

ring

on

main

dtive

gear

and

combine

with

mainshaft

to

complete

the

mainshaft

assembly

Note

l

e

sure

to

iJislall

pilot

bearing

in

place

when

combining

with

mainshaft

MT

26

2

Combine

mainshaft

assembly

with

counter

gear

assembly

and

place

them

into

adapter

plate

simulta

neously

Note

Be

careful

not

to

forget

to

install

thrust

washer

And

when

installing

throst

washer

note

front

1IIllIR

tt

djrections

Front

Thrust

side

Rear

Oil

groove

side

TM285A

Fig

MT

I14

Count

Gear

Thru

t

Washer

3

Pull

mainshaft

assembly

into

adapter

plate

using

Mainshaft

Puller

KV32100400

When

installing

main

shaft

assembly

carefully

hold

gears

by

hand

Install

counter

gear

assembly

together

with

mainshaft

assembly

by

applying

light

blows

with

a

soft

faced

hammer

Make

sure

that

snap

ring

groove

on

mainshaft

rear

bearing

clears

adapter

plate

CAUTION

a

Take

care

not

to

drop

geaB

on

floor

b

Take

care

not

tndamage

bearings

TM245A

Fig

MT

II5

Installing

Main

haft

A

6embly

4

Fit

snap

ring

to

groove

in

main

shaft

rear

bearing

with

snap

ring

pliers

TM23aA

Fig

MT

116

Fitting

Main

haft

Rear

Bearing

Snap

Ring

Page 245 of 548

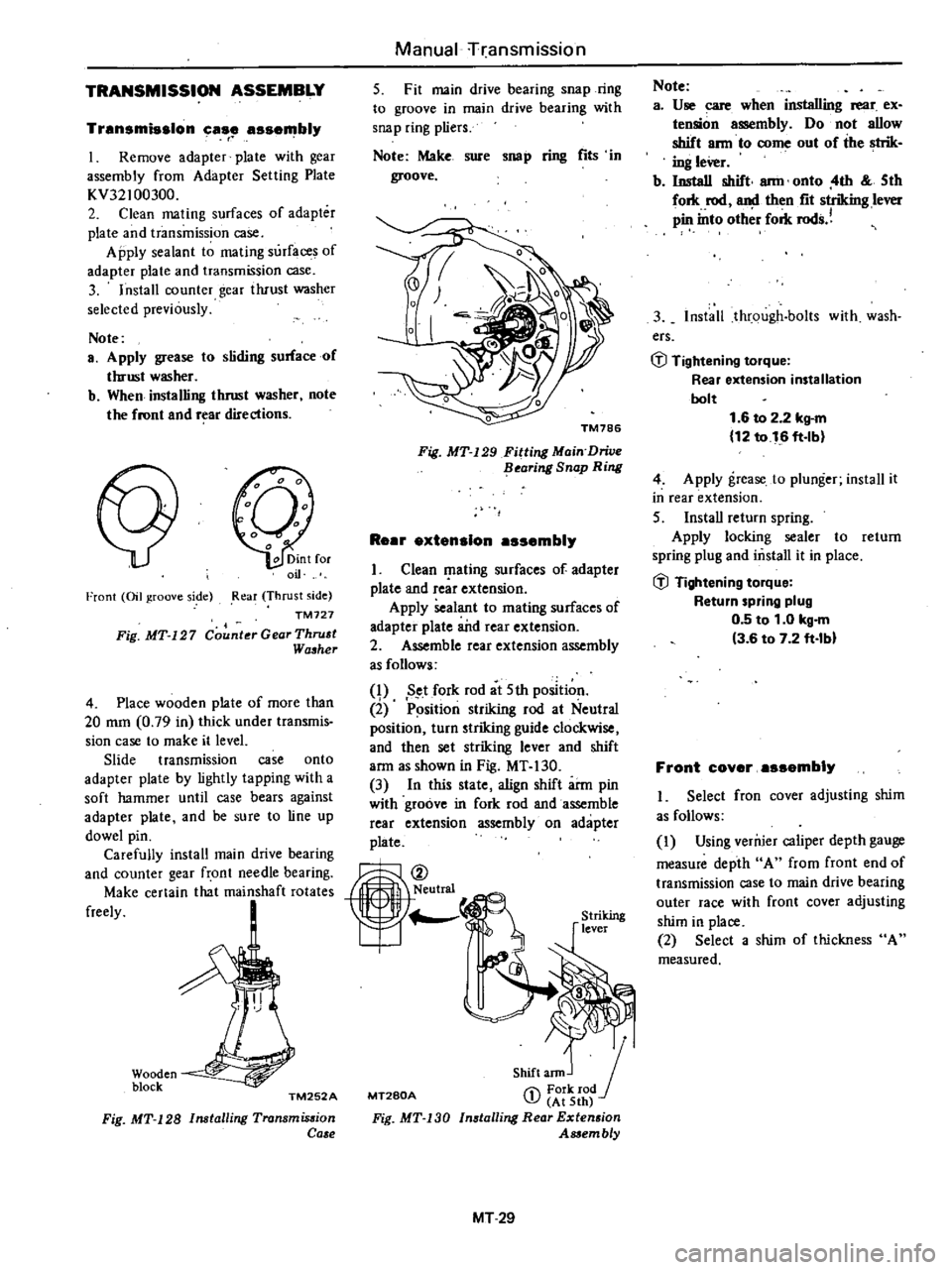

TRANSMISSION

ASSEMBLY

Transmission

case

assembly

r

I

Remove

adapter

plate

with

gear

assembly

from

Adapter

Setting

Plate

KV32100300

2

Clean

mating

surfaces

of

adapter

plate

and

transmission

case

Apply

sealant

to

mating

surfaces

of

adapter

plate

and

transmission

case

3

Install

counter

gear

tluust

washer

selected

previously

Note

a

Apply

grease

to

sliding

surface

of

thrust

washer

b

When

installing

thrust

washer

note

the

front

and

r

ar

directions

Front

Oil

groove

side

Rear

Thrust

side

TM727

Fig

MT

127

Counter

Gear

Thru

t

Wa

her

4

Place

wooden

plate

of

more

than

20

mm

0

79

in

thick

under

transmis

sion

case

to

make

it

level

Slide

transmission

case

onto

adapter

plate

by

lightly

tapping

with

a

soft

hammer

until

case

bears

against

adapter

plate

and

be

sure

to

line

up

dowel

pin

Carefully

install

main

drive

bearing

and

counter

gear

front

needle

bearing

Make

certain

that

mainshaft

rotates

freely

Wooden

block

TM252A

Fig

MT

128

Installing

Transmis

ion

Ca

e

Manual

rransmission

5

Fit

main

drive

bearing

snap

ring

to

groove

in

main

drive

bearing

with

snap

ring

pliers

Note

Make

sure

sno

p

ring

fits

in

groove

Fig

MT

129

Fitting

Main

Drive

flearing

Snap

Ring

ReBr

extension

assembly

I

Clean

I

lating

surfaces

of

adapter

plate

and

rcar

extension

Apply

sealant

to

mating

surfaces

of

adapter

plate

a

itd

rear

extension

2

Assemble

rear

extension

assembly

as

follows

q

Set

fork

rod

at

5th

position

2

P

sition

striking

rod

at

Neutral

position

turn

striking

guide

clockwise

and

then

set

striking

lever

and

shift

arm

as

shown

in

Fig

MT

130

3

In

this

state

align

shift

arm

pin

with

groove

in

fork

rod

and

assemble

rear

extension

assembly

on

adapter

plate

MT280A

Shift

ann

J

1

Fork

rod

J

At

5th

Installing

Rear

Extension

Assembly

Fig

MT

130

MT29

Note

a

Use

care

when

installing

rear

ex

tension

assembly

Do

not

allow

shift

ann

to

come

out

of

the

strik

ing

leVer

b

Install

shift

ann

onto

4th

5th

fork

rod

and

then

fit

striking

lever

pin

into

oth

r

fork

rods

3

Install

through

bolts

with

wash

ers

GJ

Tightening

torque

Rear

extension

installation

bolt

1

6

to

2

2

kg

m

12

to

16

ft

lb

4

Apply

grease

to

plunger

install

it

in

rear

extension

5

InstaU

return

spring

Apply

locking

sealer

to

return

spring

plug

and

mstall

it

in

place

GJ

Tightening

torque

Return

spring

plug

0

5

to

1

0

kg

m

3

6

to

7

2

ft

lbl

Front

coyer

assembly

I

Select

fron

cover

adjusting

shim

as

follows

I

Using

verruer

caliper

depth

gauge

measure

depth

A

from

front

end

of

transmission

case

to

main

drive

bearing

outer

race

with

front

cover

adjusting

shim

in

place

2

Select

a

shim

of

thickness

A

measured

Page 246 of 548

No

A

mm

in

Manual

Ttansniissio

n

Adjusting

shim

mm

in

0

50

0

0197

0

55

0

0217

0

60

0

0236

0

6

0

9756

0

70

0

0276

0

75

0

0295

0

80

0

0315

I

2

3

4

5

6

7

6

05

to

6

09

0

2382

to

0

2398

6

10to

6

14

0

2402

to

0

2417

6

15

to

6

19

0

2421

to

0

2437

6

20

to

6

2

4

9

1

41

t

19

2457

6

25

to

6

29

0

2461

to

0

2476

6

30

to

6

34

0

2480

to

0

2496

6

35

to

6

39

0

2500

to

0

2516

TM816

Fig

MT

131

MetuUring

Front

CoV

r

Adju

ting

Shim

1

Transmission

case

2

Main

drive

gear

3

Adjusting

shim

4

Bearing

TM817

Fig

MT

132

Selecting

Front

CoV

r

Adju

ti1l8

shim

2

Clean

maling

surfaces

of

front

cover

and

transmission

case

3

Install

front

cover

to

transmission

case

with

the

adjUsting

shim

and

0

ring

in

place

@

Tight

ning

torque

Front

co

erinstallation

bolt

1

0

to

1

6

kg

m

7

to

12

ft

Ib

Outer

parts

assembly

I

Install

speedometer

pinion

assem

bly

and

install

securing

bolt

and

tighten

@

Tightening

torque

Speedometer

sl

locking

plate

bolt

0

3

to

0

5

kg

m

2

2

to

3

6

ft

lb

2

Install

reverse

lamp

switch

and

tighten

At

the

same

time

install

top

detecting

switch

if

so

equipped

Be

sure

to

apply

locking

sealer

before

installation

MT30

@

Ti

ltening

torque

Rewene

lamp

switch

and

top

detecting

switch

2

0

to

3

5

kg

m

14

to

25

fHb

3

Apply

a

light

coat

of

multi

purpose

grease

to

withdrawal

lever

release

bearing

ahd

bearing

sleeve

in

stall

them

on

transmission

case

After

connecting

them

with

holder

spring

install

dust

cover

to

transmis

sion

case

4

Install

control

lever

temporarily

and

move

shift

coritrol

lever

through

all

gears

to

make

sure

that

gears

op

rate

smoothly

5

InstaU

draiiI

plug

coated

with

sealant

in

place

@

Tightening

torque

Drain

plug

2

5

to

4

0

kg

m

18

to

29

fHb

6

Make

sure

that

main

drive

shaft

rotates

smoothly

in

Neutral

v

Jin

drive

gear

routing

torque

less

than

1

8

leg

em

1

6

in

Ib

Page 255 of 548

Automatic

Transmission

HYDRAULIC

CONTROL

UNIT

AND

VALVES

The

hydraulic

or

a

tomatic

control

system

is

comprised

of

four

4

basic

groups

the

pressure

supply

system

the

pressure

regulating

system

the

flow

control

valves

and

the

friction

elements

PRESSURE

SUPPLY

SYSTEM

The

pressure

supply

system

consists

of

a

gear

type

oil

pwnp

driven

by

the

engine

through

the

torque

converter

The

pump

provides

pressure

for

aU

hydraulic

and

lubrication

needs

PRESSURE

REGULATOR

VALVES

The

pressure

regulating

valves

con

trol

the

output

pressure

of

the

oil

pump

Pre

ure

rellulator

valve

The

pressure

regulator

valve

con

trois

mainline

pressure

based

on

throttle

opening

for

the

operation

of

the

band

clutches

and

brake

Governor

valve

The

governor

valve

transmits

re

gulated

pressure

based

on

car

peed

to

the

shift

valves

to

control

upshifts

and

downshifts

Vacuum

throttle

valve

The

vacuum

throttle

valve

transmits

regulated

pressure

based

on

engine

load

vacuum

This

pressure

controls

the

pressure

regulator

valve

Also

this

pressure

is

applied

to

one

end

of

the

shift

valves

in

opposition

to

governor

pressure

which

acts

on

the

other

end

of

the

shift

valves

controlling

upshift

and

downshift

speeds

FLOW

CONTROL

VALVES

Manual

valve

The

manual

valve

is

moved

manual

Iy

by

the

car

operator

to

select

the

different

drive

ranges

1

2

ShHt

valve

The

1

2

shift

valve

automaticaIly

shifts

the

transmission

from

first

to

second

or

from

second

to

first

depend

ing

upon

governor

and

throttle

pres

sure

along

with

accelerator

position

solenoid

downshift

valve

See

Hy

draulic

Control

Circuits

Drive

2

2

3

ShHt

valve

The

2

3

shift

valve

automaticaIly

shifts

the

transmission

from

second

to

top

gear

or

from

top

to

second

de

pending

upon

governor

and

throttle

pressure

or

accelerator

position

sole

noid

downshift

valve

See

Hydraulic

Control

Circuits

Drive

3

Range

2

3

Tlmlnll

valve

For

2

3

shifts

a

restrictive

orifice

slows

the

application

fluid

to

the

front

clutch

while

the

slower

reacting

band

is

allowed

to

release

This

prevents

a

hard

2

3

or

3

2

shift

Under

heavy

load

however

the

engine

will

tend

to

run

away

during

the

2

3

or

3

2

shift

pause

therefore

a

2

3

timing

valve

using

throttle

and

governor

pressure

is

used

to

bypass

the

restrictive

orifice

during

such

heavy

load

conditions

Solenoid

down

hHt

valve

The

solenoid

downshift

valve

is

activated

electrically

when

the

ac

celerator

is

f1oor

d

causing

a

forced

downshift

from

top

to

second

top

to

first

or

second

to

first

gear

depending

upon

car

speed

governor

pressure

AT

3

Pre

ure

modified

valve

The

pressure

modifier

valve

assists

the

mainline

pressure

regulator

valve

in

lowering

mainline

pressure

during

high

speed

light

load

conditions

such

as

steady

speed

cruise

Governor

pres

sure

working

against

a

spring

opens

the

valve

which

aUows

modified

throt

tle

pressure

to

work

against

the

pres

sure

regulator

valve

spring

lowering

mainline

pressure

Lower

operating

pressure

under

light

load

reduces

oil

temperature

and

increases

transmis

sian

life

Throttle

back

up

valve

The

throttle

back

up

valve

assists

the

vacuum

throttle

valve

to

increase

line

pressure

when

the

manual

valve

is

shifted

either

to

2

or

I

range

Second

lock

valve

The

second

lock

valve

is

used

to

bypa

the

1

2

shift

valve

to

maintain

the

band

apply

pressure

in

2

posi

tion

The

valve

is

also

used

as

an

oil

passage

for

the

1

2

shift

valve

band

apply

pressure

in

D2

D3

and

12

Range

CLUTCHES

AND

BAND

SERVOS

The

servo

pistons

of

the

clutches

low

reverse

brake

and

band

are

moved

hydraulically

to

engage

the

clutches

brake

and

apply

the

band

The

clutch

and

brake

istons

are

released

by

spring

tension

and

band

piston

is

released

by

spring

tension

and

hy

draulic

pressure

Page 274 of 548

Automatic

Transmission

l

RANGE

LOW

AND

2ND

GEAR

second

12

afwvernor

preSsure

pre

vents

the

I

2

shift

valve

from

closing

The

range

1

position

is

used

to

lock

the

car

in

1st

gear

preventing

any

upshifts

If

the

selector

lever

is

moved

to

the

I

position

while

the

car

is

moving

at

high

speeds

the

transmis

sion

w

ill

not

shift

into

first

gear

until

car

speed

slows

to

approxiniately

55

km

h

35

mph

Instead

it

will

shift

to

Po

r

flow

The

power

flow

in

11

differs

slight

ly

from

01

in

that

the

low

and

reverse

band

is

applied

to

hold

the

rear

gear

set

planet

carrier

providing

engine

hraking

Power

flow

in

12

is

the

same

a

io02

Manual

Valve

Governor

Valve

15

Pressure

Modifier

Valve

I

Fluid

flow

Lolft

ar

Manual

pressure

passing

through

the

1

2

shift

valve

is

used

to

close

the

1

2

shift

valve

preventing

a

1

2

up

shift

Manual

pressure

pusing

through

the

downshift

valve

lock

the

2

3

siuit

valve

closed

along

with

applying

addi

tional

closing

pressure

to

the

I

2

shift

valve

2nd

3rd

Timing

Valve

2nd

3rd

Shift

Valve

lst

2ndSti

ft

Valve

1st

2nd

Shift

Valve

iRea

Clutcb

I

4

Solenoid

Downshift

Valve

13

I2nd

3rd

Shift

Valve

ht

2nd

Shift

Valve

Throttle

Back

up

Valve

5

C

1st

2nd

Shift

Valve

12

I

Throttle

Back

up

Valve

y

Low

Reverse

Bra1ce

I

Fluid

flow

2nd

ar

Manual

Valve

Governor

Valve

15

Preuurc

Modjfier

Valve

2nd

3rd

Timing

Valve

2nd

3rd

Shift

Valve

1st

2nd

Shift

Valve

8

1st

2nd

Shift

Valve

Second

Lock

Valve

9

I

Band

Servo

I

Apply

Side

4

t

Rear

Clutch

I

Solenoid

Downshift

Valve

13

I

2nd

3rd

Shift

Valve

ht

2nd

Shift

Valve

Throttle

Back

up

Valve

17

PreSlure

Modifier

Valve

2nd

3rd

Shift

Valve

2nd

3rd

Timing

Valve

Throttle

Drain

Valve

s

ht

2nd

Shift

Valve

Pressure

Regulator

Valve

AT

22

Page 278 of 548

4

Bolt

converter

to

drive

plate

Note

Align

chalk

mark

painted

a

cro5S

both

parts

during

disas

sembling

p

S

After

converter

is

installed

rotat

r

nkshait

veral

turns

and

check

to

be

sure

that

transmission

rotates

freely

without

binding

6

Pour

recommended

automatic

transmission

fluid

up

to

correct

level

through

oil

charge

pipe

7

Connect

manual

lever

to

shift

rod

Operation

should

be

carried

out

with

m

mual

and

selector

levers

in

N

8

Connect

inhibitor

switch

wires

Automatic

Transmission

NOte

a

Refer

to

page

AT40

for

Checking

and

Adjusting

Inhibitor

Switch

b

Inspect

end

edjust

switch

as

abo

whe

ever

it

has

to

be

removed

for

servi

e

9

Check

inhibitor

switch

for

op

eration

Starter

should

be

brought

into

op

eration

only

when

selector

lever

is

in

P

and

N

positions

it

should

not

be

started

when

lever

is

in

D

n

and

Ru

positions

Back

up

lamp

should

Iso

light

when

selector

lever

is

placed

in

R

position

10

Check

level

of

oil

in

transm

sion

For

detailed

procedure

see

page

AT39

AT

26

II

Move

selector

leve

through

all

positions

to

be

sure

that

transmission

operates

correctly

With

hand

brake

applied

rotate

engine

at

idling

Without

disturbing

the

above

seUlng

move

selector

lever

through

N

to

D

to

2

to

I

and

to

R

A

slight

shock

should

be

reU

by

handgripping

selector

each

time

transmission

is

shifted

Note

See

page

AT40

for

Checking

Engine

Idling

Revolution

12

Check

to

be

sure

that

line

pres

sure

is

correct

To

do

this

refer

to

page

AT

43

for

Line

Pressure

Test

13

Perform

stan

test

as

described

in

page

AT41