ECO DATSUN PICK-UP 1977 Owners Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 308 of 537

Fig

AT

96

Measuring

clearanc

Automatic

Transmission

6

u

ST255801JOO

AT264

Fig

AT

99

Measuring

runout

5

Tighten

pump

securing

bolts

to

specified

torque

0

6

to

0

8

kg

m

4

to

6

ft

Ib

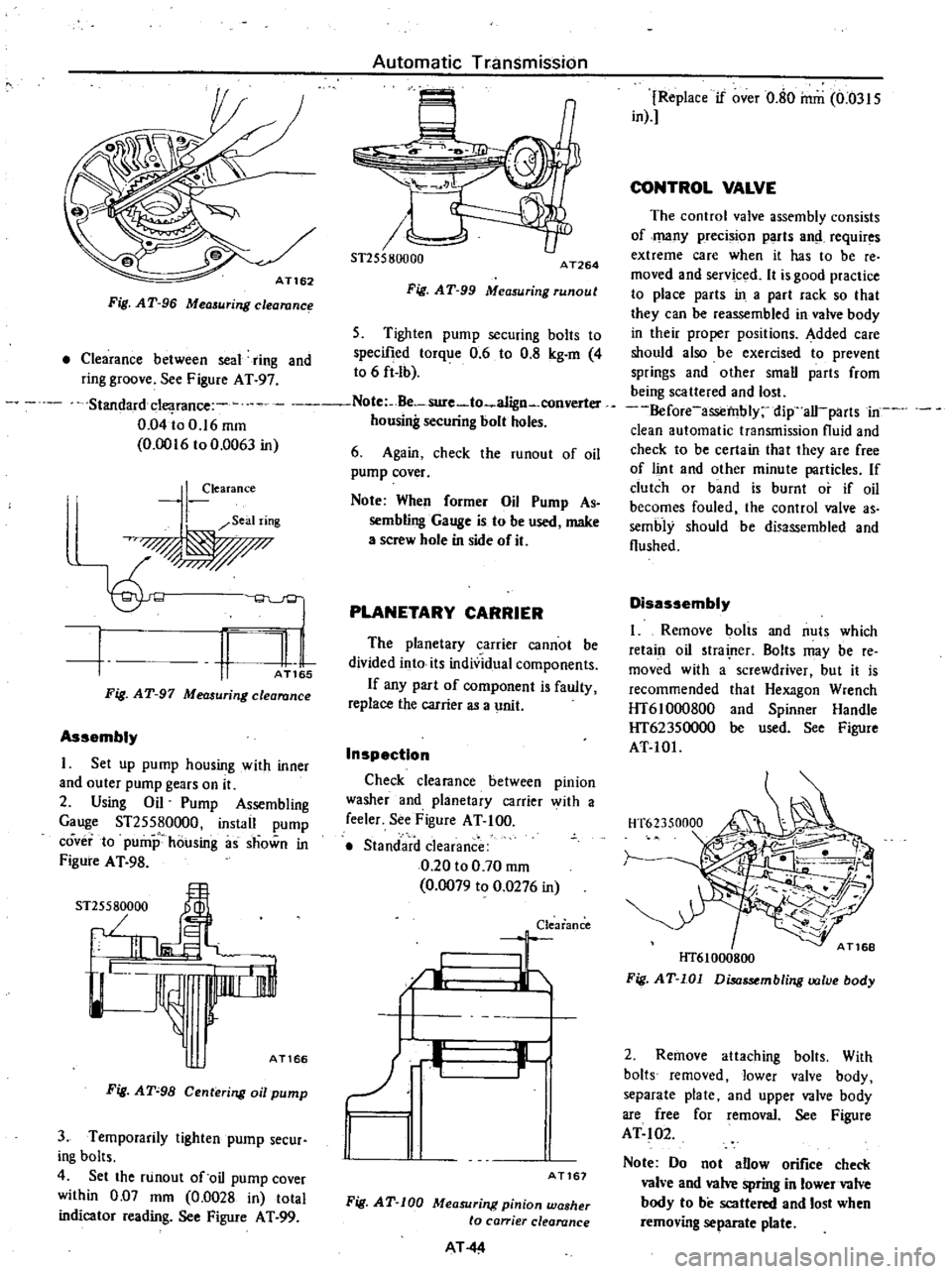

Clearance

between

seal

ring

and

ring

groove

See

Figure

AT

97

Standarddearance

Note

Be

sure

to

a1ign

converter

0

04

io

0

16

mm

housing

securing

bolt

holes

0

0016

to

0

0063

in

6

Again

check

the

runout

of

oil

pump

cover

I

learance

Seal

ring

q

I

n

l

1

AT

5

Fig

AT

97

Measuring

clearance

Assembly

I

Set

up

pump

housing

with

inner

and

outer

pump

gears

on

it

2

Using

Oil

Pump

Assembling

Gauge

ST25580000

instail

pump

coverta

pump

housing

as

shown

in

Figure

A

T

98

ST

5

000

J

I

I

JL

AT166

Fig

AT

98

Centering

oil

pump

3

Temporarily

lighten

pump

secur

ing

bolts

4

Set

the

runout

of

oil

pump

cover

within

0

D7

mm

0

0028

in

total

indicator

reading

See

Figure

AT

99

Note

When

former

Oil

Pump

As

sembling

Gauge

is

to

be

used

make

a

screw

hole

in

side

of

it

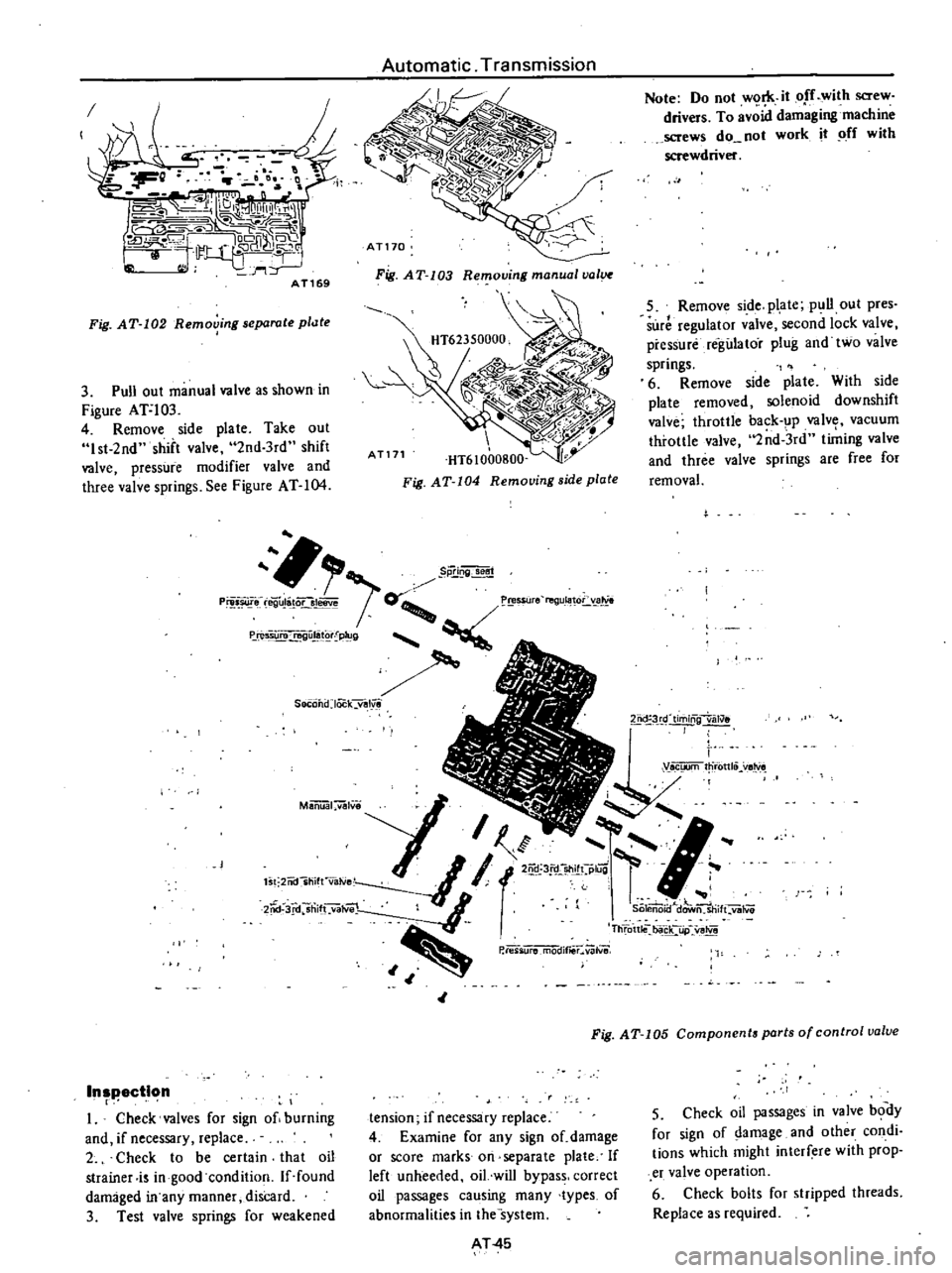

PLANETARY

CARRIER

The

planetary

carrier

cannot

be

divided

into

its

individual

components

If

any

part

of

component

is

faulty

replace

the

carrier

as

a

unit

Inspection

Check

clearance

between

pinion

washer

and

planetary

carrier

with

a

feeler

See

Figure

AT

100

Standard

clearance

0

20

to

0

70

mm

0

0079

to

0

0276

in

Clearance

I

Jr

I

1

11

r

AT167

Fig

AT

100

Measuring

pinion

washer

to

ca

ier

clearance

AT

44

Replace

if

over

0

80

mm

0

0315

in

CONTROL

VALVE

The

control

valve

assembly

consists

of

many

preci

ion

parts

and

requir

s

extreme

care

when

it

has

to

be

reo

moved

and

serviced

It

is

good

practice

to

place

parts

in

a

part

rack

so

that

they

can

be

reassembled

in

valve

body

in

their

proper

positions

Added

care

should

also

be

exercised

to

prevent

springs

and

other

small

parts

from

being

scattered

and

lo

t

Before

assembly

dip

all

parts

in

clean

automatic

transmission

fluid

and

check

to

be

certain

that

they

are

free

of

lint

and

other

minute

particles

If

clutch

or

band

is

burnt

or

if

oil

becomes

fouled

the

control

valve

as

sembly

should

be

di

ssembled

and

flushed

Disassembly

I

Remove

bolts

and

nuts

which

retain

oil

trainer

Bolts

may

be

re

moved

with

a

screwdriver

but

it

is

recommended

that

Hexagon

Wrench

HT610oo800

and

Spinner

Handle

HT62350000

be

used

See

Figure

AT

101

HT61000800

Fig

AT

101

Disassembling

valve

body

2

Remove

attaching

bolts

With

bolts

removed

lower

valve

body

separate

plate

and

upper

valve

body

are

free

for

removal

See

Figure

AT

102

Note

Do

not

allow

orifice

check

vah

e

and

valve

spring

in

lower

valve

body

to

be

scattered

and

lost

when

removing

separate

plate

Page 309 of 537

I

F

1

D

t

l

a

J

n

f

19l1

Ull

IU

P

C

o

J

CJ

IODrR

CC

t

LL6

SJQIl2J

lhl

fB

rt

AT169

Fig

AT

102

Removing

separate

pllJte

3

Pull

out

manual

valve

as

shown

in

Figure

Ar103

4

Remove

side

plate

Take

out

1st

2nd

shift

valve

2nd

3rd

shift

valve

pressure

modifier

valve

and

three

valve

springs

See

Figure

AT

104

Automatic

Transmission

Fig

AT

103

Removing

manual

val

AT1

1

HT61000800

Fig

AT

104

Removing

side

plate

g

p

e

eguJa

Of

le6Ve

or

r

essure

reguJl

oL

@iO

I

f

g

SecOni

J

lOCltvalYi

y

h

l

l

2I

r

JI

Io

J

l

j

t

1

i

S

r

0

x

t

i

3

1

Note

Do

not

w

it

off

with

screw

drivers

To

avoid

darnagingmachine

screws

do

not

work

it

ff

with

screwdriver

5

Remove

side

plate

pull

out

pres

sure

regulator

valve

second

lock

valve

pressure

regi1lator

plug

and

two

valve

springs

6

Remove

side

plate

With

side

plate

removed

solenoid

downshift

valve

throttle

back

up

valve

vacuum

throttle

valve

2

d

3rd

t

ing

valve

and

three

valve

springs

are

free

for

removal

2nd

3rd

timing

talve

r

en

i

C1iJrilth

rottle

lI

lY

e

M

a

alVSY

I

j1

f

I

1

f

Iv

I

f

2i

3

CP

g

f

st

2nd

S

t

a

el

2i1d

3

d

St1itLvalv

so

iit

a

stiift

V81v

i

hrottle

f

iicnjp

VB

y

i

P

ie

mo

i

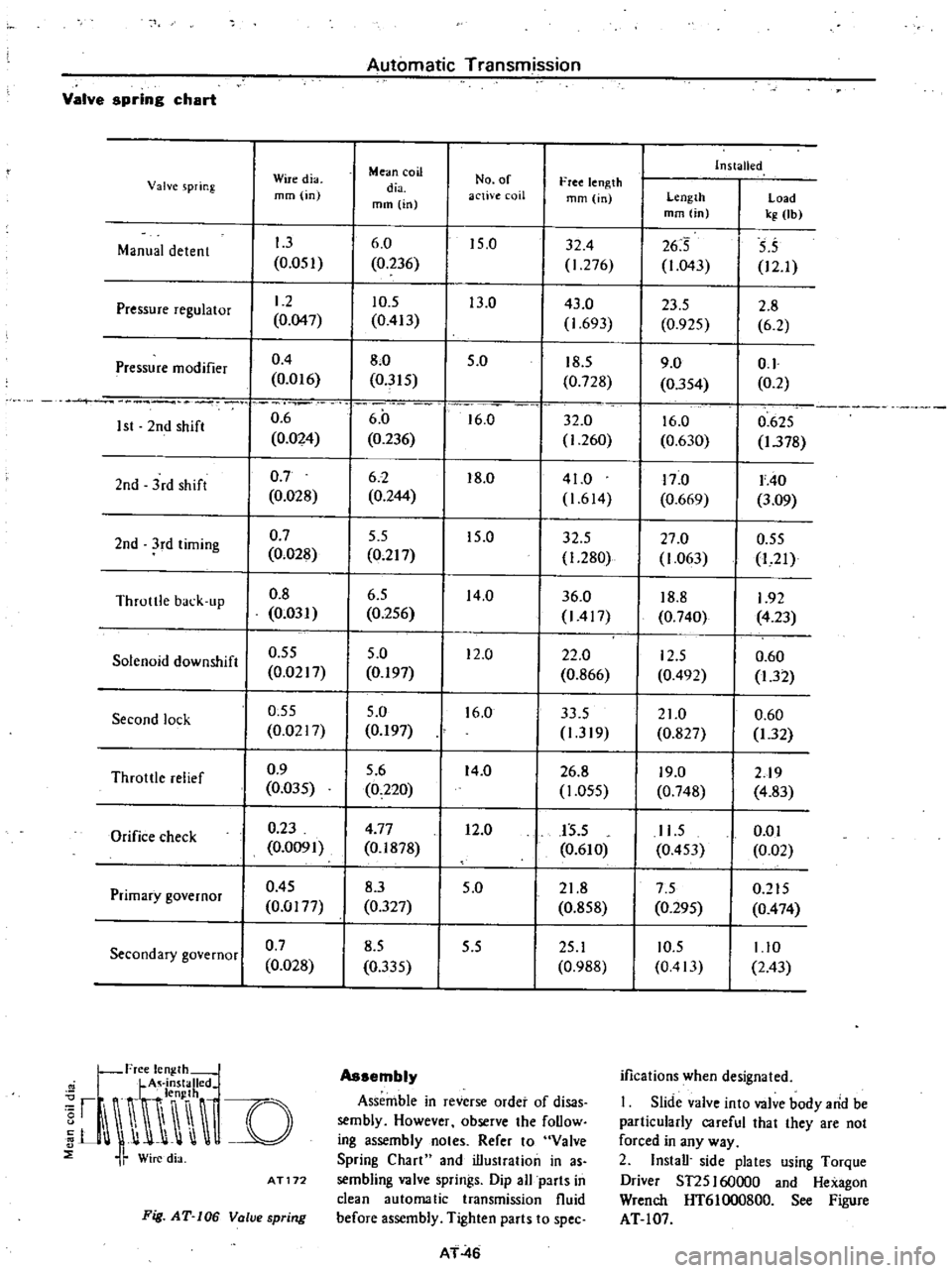

Inspection

r

I

Check

valves

for

sign

of

burning

and

if

necessary

replace

2

Check

to

be

certain

that

oil

strainer

is

in

good

condition

If

found

damaged

in

any

manner

disCard

3

Test

valve

springs

for

weakened

Fig

AT

105

Components

ports

of

control

uolue

tension

if

necessary

replace

4

Examine

for

any

sign

oLdamage

or

score

marks

on

separate

plate

If

left

unheedcd

oiL

will

bypass

correct

oil

passages

causing

many

types

of

abnormalities

in

thesystem

AT45

5

Check

oil

passages

in

valve

b

dy

for

sign

of

damage

and

other

condi

tions

which

might

interfere

with

prop

er

valve

operation

6

Check

bolts

for

stripped

threads

Replace

as

required

Page 310 of 537

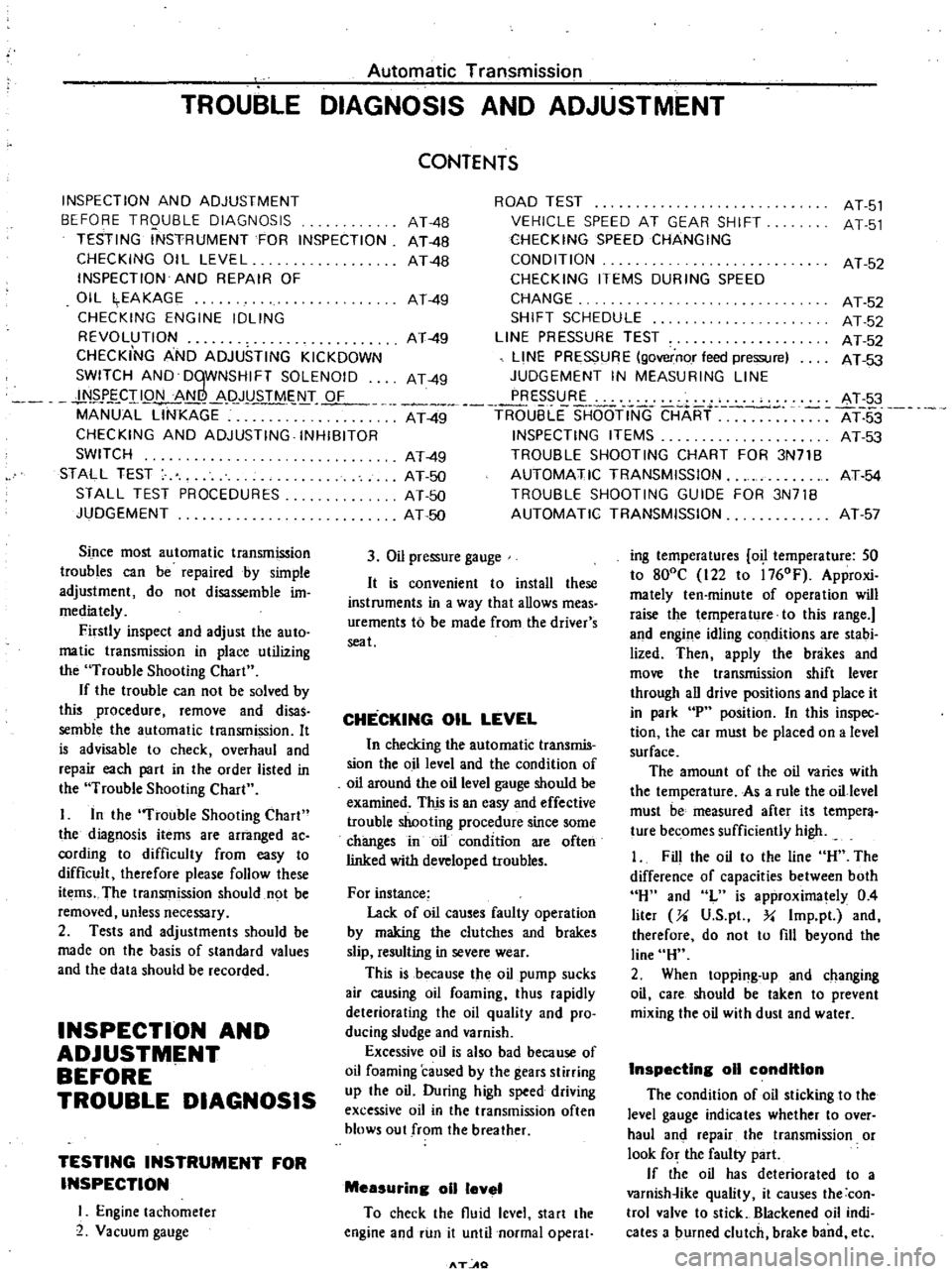

Automatic

Transmission

Valve

spring

chart

Mean

coil

Installed

Valve

spring

Wiredia

dia

No

of

free

length

mm

in

mm

in

active

coil

mm

in

Length

Load

mm

in

kg

lb

Manual

detent

1

3

6

0

15

0

32

4

26

5

5

5

0

051

0

236

1

276

1

043

12

1

Pressure

regulator

1

2

10

5

13

0

43

0

23

5

2

8

0

047

0

413

1

693

0

925

6

2

Pressure

modifier

0

4

8

0

5

0

18

5

9

0

0

1

0

016

0

315

0

728

0

354

0

2

1st

2nd

shift

0

6

6

0

6

0

32

0

16

0

0

625

0

024

0

236

1

260

0

630

1

378

2nd

3rd

shifl

0

7

6

2

8

0

41

0

17

0

1

40

0

028

0

244

1

614

0

669

3

09

2nd

3rd

timing

0

7

5

5

15

0

32

5

27

0

0

55

0

028

0

217

1

280

1

063

1

21

Throule

back

lIP

0

8

6

5

14

0

36

0

18

8

1

92

0

031

0

256

1417

0

740

4

23

Solenoid

downshift

0

55

5

0

12

0

22

0

12

5

0

60

0

0217

0

197

0

866

0

492

1

32

Second

lock

0

55

5

0

16

0

33

5

21

0

0

60

0

0217

0

197

1

319

0

827

1

32

Throule

relief

0

9

5

6

14

0

26

8

19

0

2

9

0

035

0

220

1

055

0

748

4

83

Orifice

check

0

23

4

77

12

0

J5

5

11

5

0

01

0

0091

0

1878

0

610

0

453

0

02

Primary

governor

0

45

8

3

5

0

21

8

7

5

0

215

0

0177

0

327

0

858

0

295

0

474

Secondary

governor

0

7

8

5

5

5

25

1

10

5

I

10

0

028

0

335

0

988

0

413

2

43

Free

lenglhm

A

installed

f

n

ri

DO

n

i

Wire

dia

AT172

Assembly

Assemble

in

reverse

order

of

disas

sembly

However

observe

the

follow

ing

assembly

noles

Refer

to

Valve

Spring

Chart

and

illustralion

in

as

sembling

valve

springs

Dip

all

parts

in

clean

automatic

transmission

fluid

before

assembly

Tighten

parts

to

spec

ifications

when

designated

I

Slide

valve

into

valve

body

arid

be

particularly

careful

that

they

are

not

forced

in

any

way

2

Install

side

plates

using

Torque

Driver

ST25160000

and

Hexagon

Wrench

HT6

I

000800

See

Figure

AT

l

07

Fig

AT

106

Value

spring

AT

46

Page 312 of 537

Automatic

Transmission

TROUBLE

DIAGNOSIS

AND

ADJUSTMENT

INSPECTION

AND

ADJUSTMENT

BEFORE

TRQUBLE

DIAGNOSIS

TESTING

INSTRUMENT

FOR

INSPECTION

CHECKING

OIL

LEVEL

INSPECTION

AND

REPAIR

OF

OIL

EAKAGE

CHECKING

ENGINE

IDLING

REVOLUTION

CHECKING

AND

ADJUSTING

KICKDOWN

SWITCH

AND

DqWNSHIFT

SOLENOID

N

J

J

CII

Q

t

L

8li

p

JYSTMs

T

OF

MANUAL

LINKAGE

CHECKING

AND

ADJUSTING

INHIBITOR

SWITCH

STALL

TEST

STALL

TEST

PROCEDURES

JUDGEMENT

Since

most

automatic

transmission

troubles

can

be

repaired

by

simple

adjustment

do

not

disassemble

im

mediately

Firstly

inspect

and

adjust

the

auto

matic

transmission

in

place

utilizing

the

Trouble

Shooting

Chart

If

the

trouble

can

not

be

solved

by

this

procedure

remove

and

disas

semble

the

automatic

transmission

It

is

advisable

to

check

overhaul

and

repair

each

part

in

the

order

listed

in

the

Trouble

Shooting

Chart

I

In

the

Trouble

Shooting

Chart

the

diagnosis

items

are

arranged

ac

cording

to

difficulty

from

easy

to

difficult

therefore

please

follow

these

items

The

transmission

should

not

be

removed

unless

necessary

2

Tests

and

adjustments

should

be

made

on

the

basis

of

standard

values

and

the

data

should

be

recorded

INSPECTION

AND

ADJUSTMENT

BEFORE

TROUBLE

DIAGNOSIS

TESTING

INSTRUMENT

FOR

INSPECTION

I

Engine

tachometer

2

Vacuum

gauge

ROAD

TEST

VEHICLE

SPEED

AT

GEAR

SHIFT

CHECKING

SPEED

CHANGING

CONDITION

CHECKING

ITEMS

DURING

SPEED

CHANGE

SHIFT

SCHEDULE

LINE

PRESSURE

TEST

LINE

PRESSURE

governor

feed

pressure

JUDGEMENT

IN

MEASURING

LINE

PRESSURE

At

49

TR6

uBLE

SHOOTINC

CHART

INSPECTING

ITEMS

TROUBLE

SHOOTING

CHART

FOR

3N71B

AUTOMATIC

TRANSMISSION

TROUBLE

SHOOTING

GUIDE

FOR

3N71B

AUTOMATIC

TRANSMISSION

CONTENTS

AT

4B

AT

48

AT

4B

AT

49

AT

49

AT

49

AT

49

AT

50

AT

50

AT

50

3

Oil

pressure

gauge

It

is

convenient

to

install

these

instruments

in

a

way

that

allows

meas

urements

to

be

made

from

the

driver

s

seat

CHECKING

OIL

LEVEL

In

checking

the

automatic

transmis

sion

the

o

illevel

and

the

condition

of

oil

around

the

oil

level

gauge

should

be

examined

This

is

an

easy

and

effective

trouble

shooting

procedure

since

some

changes

in

oil

condition

are

often

linked

with

developed

troubles

For

instance

Lack

of

oil

causes

faulty

operation

by

making

the

clutches

and

brakes

slip

resulting

in

severe

wear

This

is

because

the

oil

pump

sucks

air

causing

oil

foaming

thus

rapidly

deteriorating

the

oil

quality

and

pro

ducing

sludge

and

varnish

Excessive

oil

is

also

bad

because

of

oil

foaming

caused

by

the

gears

stirring

up

the

oil

During

high

speed

driving

excessive

oil

in

the

transmission

often

blows

out

from

the

breather

Measuring

011

level

To

check

the

fluid

level

start

the

engine

and

run

it

until

normal

operat

T

AO

AT

51

AT

51

AT

52

AT

52

AT

52

AT

52

AT

53

AT

3

AT

53

AT

53

AT

54

AT

57

ing

temperatures

o

temperature

SO

to

800C

122

to

l760F

Approxi

mately

ten

minute

of

operation

will

raise

the

temperature

to

this

range

and

engine

idling

conditions

are

stabi

lized

Then

apply

the

brakes

and

move

the

transmission

shift

lever

through

all

drive

positions

and

place

it

in

park

P

position

In

this

inspec

tion

the

car

must

be

placed

on

a

level

surface

The

amount

of

the

oil

varies

with

the

temperature

As

a

rule

the

oil

level

must

be

measured

after

its

temper

ture

becomes

sufficiently

high

1

Fill

the

oil

to

the

line

H

The

difference

of

capacities

between

both

H

and

L

is

approximately

0

4

liter

Ji

V

S

p

Y

Imp

pl

and

therefore

do

not

to

fill

beyond

the

line

H

2

When

topping

up

and

changing

oil

care

should

be

taken

to

prevent

mixing

the

oil

with

dust

and

water

InspectIng

011

condition

The

condition

of

oil

sticking

to

the

level

gauge

indicates

whether

to

over

haul

and

repair

the

transmission

or

look

for

the

faulty

part

If

the

oil

has

deteriorated

to

a

varnish

ike

quality

it

causes

the

con

trol

valve

to

stick

Blackened

oil

indi

cates

a

burned

clutch

brake

band

etc

Page 314 of 537

Using

the

tester

check

the

two

black

yellow

BY

wires

from

the

in

hibitor

switch

in

the

ranges

N

and

I

and

the

tw

re

d

black

RBj

wir

s

in

the

range

R

for

continuity

Turn

range

select

lever

in

both

directions

from

each

lever

set

position

and

check

each

continuity

range

It

is

normal

if

the

electricity

is

on

while

the

lever

is

within

an

angle

of

about

30

on

both

sides

from

each

lever

set

line

How

ever

if

its

continl

ity

range

is

obvious

ly

unequal

on

both

sides

adjustment

is

required

If

any

malfunction

is

found

un

screw

the

fastening

nut

of

the

range

selector

lever

and

two

fastening

bolts

of

the

switch

body

and

then

remove

the

machine

screw

under

the

switch

body

Adjust

the

manual

shaft

correct

ly

to

the

position

N

by

means

of

the

selector

lever

When

the

slot

of

the

shaft

becomes

vertical

the

detent

works

to

position

the

shaft

correctly

with

a

clicking

sound

MSlVe

the

switch

slightly

asj

Je

so

that

the

screw

hole

will

be

aligned

with

the

pin

hole

of

the

internal

rotor

combined

with

the

manual

shaft

and

check

their

alignment

by

inserting

a

1

5

mm

0

059

in

diameter

pin

into

the

holes

If

the

alignment

is

correct

fasten

the

switch

body

with

the

bolts

pull

out

the

pin

tighten

up

the

screw

in

the

hole

and

fasten

the

selector

lever

as

before

Check

the

continuity

again

with

the

tester

If

the

malfunc

tion

still

remains

replace

the

inhibitor

switch

Chcck

whether

the

reverse

lamp

and

the

starter

motor

operate

normal

ly

in

these

ranges

If

Ihere

is

any

lrouble

first

check

the

linkage

If

no

fault

is

found

in

the

linkage

check

the

inhibitor

switch

Separate

the

manual

lever

from

Ihe

remote

control

selector

rod

and

turn

the

range

selcct

lever

to

N

Note

In

the

position

N

the

slot

of

the

manual

shaft

is

vertical

STALL

TEST

The

purpose

of

this

test

is

to

check

the

transmission

and

engine

for

trou

ble

by

measuring

the

maximum

num

bers

of

revolutions

of

the

engine

while

Automatic

Transmission

vehicle

is

held

in

a

stalled

condition

The

carburctor

is

in

full

throttle

opera

tion

with

the

selector

lever

in

ranges

f

2

and

I

respectively

Com

pare

the

measured

results

with

the

slandard

values

Components

to

be

tested

and

test

items

I

Clutches

brake

and

band

in

trans

mission

for

slipping

2

Torque

converter

for

proper

fune

tioning

3

Engine

for

overall

properly

STALL

TEST

PROCEDURES

Before

Icsting

c

heck

the

engine

oil

and

torque

converter

oil

warm

up

the

engine

cooling

water

to

suitable

tem

perature

by

running

at

1

200

rpm

with

the

selector

lever

in

the

range

P

for

several

minutes

Warm

up

the

torque

converter

oil

to

suitable

temperature

6010

1000C

140

to

2l20F

I

Mount

the

engine

tachometer

at

a

location

that

allows

good

visibility

fro

the

dri

er

s

seat

and

put

a

mark

on

specified

revolutions

on

the

meter

2

Secure

the

front

and

rear

wheels

with

chocks

and

apply

the

hand

brake

Be

sure

to

depress

the

brake

pedal

fumly

with

the

left

foot

before

de

pressing

the

accelerator

pedal

3

Throw

the

selector

lever

into

the

range

1

4

Slowly

depress

the

accelerator

pedal

until

the

throttle

valvc

is

fully

opened

Quickly

read

and

record

the

engine

revolution

when

the

engine

begins

to

rotate

steadily

and

then

release

the

accelerator

pedal

5

Shift

the

selector

lever

to

N

and

operate

the

engine

at

approxi

mately

1

200

rpm

for

more

than

one

minute

to

cool

down

the

torque

con

ver

ter

oil

and

coolant

6

Make

similar

stall

tests

in

ranges

2

I

and

RIO

Note

The

stall

test

operation

as

speci

f

d

in

item

4

should

be

I

l3de

wiihin

five

seconds

If

it

takes

too

long

the

oil

deteriorates

an

the

clutches

brake

and

band

are

ad

versely

affected

Sufficient

cooling

time

should

be

given

between

each

AT

5O

test

for

the

four

ranges

0

2

I

and

R

JUDGEMENT

High

stall

revolution

more

than

standard

revolution

If

the

engine

revolution

in

stall

condition

is

higher

than

the

standard

values

it

indicates

that

one

or

more

clutches

in

the

transmission

are

slipping

and

therefore

no

further

test

is

required

For

the

following

abnormalities

the

respective

causes

are

presumed

High

rpm

in

all

ranges

low

Iine

pressure

High

rpm

in

D

2

and

I

and

normal

rpm

in

R

Rear

clutch

slipping

High

rpm

in

0

and

normal

rpm

in

I

clutch

slipping

High

rpm

in

R

only

Front

clutch

or

low

and

reverse

brake

slipping

To

determine

which

is

slipping

front

clutch

or

low

and

reverse

brake

a

road

test

is

nceded

If

whilc

coasting

after

starting

with

the

lever

in

1

range

engine

braking

does

not

work

properly

the

low

and

reverse

brake

is

slipping

Otherwise

the

front

clutch

is

slipping

Slipping

of

the

band

brake

is

diffi

cult

to

ascertain

However

if

it

occurs

with

the

lever

in

2

range

engine

revolution

increases

Jp

to

thesarne

level

as

in

I

strange

It

is

impossible

to

check

it

in

the

stall

test

2

and

One

way

2

Standard

stall

revolution

If

the

engine

revolution

in

stall

condition

is

within

the

standard

values

the

control

elements

are

nor

mally

operating

in

the

ranges

0

2

I

and

R

Also

tIle

engine

and

one

way

clutch

of

the

torque

converter

are

normal

in

performance

and

operation

The

one

way

clutch

of

the

torque

converter

however

sometimes

sticks

This

is

determined

in

the

road

test

3

Lower

stall

revolution

than

stand

ard

revolution

If

the

engine

revolution

in

stall

condition

is

lower

than

the

standard

Page 315 of 537

values

it

indicates

that

the

engine

is

in

abnormal

condition

or

the

torque

con

verter

s

one

way

clutch

is

slipping

4

Others

1

If

the

accelerating

performance

is

poor

until

vehicle

speed

of

approxi

mately

50

km

h

30

MPH

is

attained

and

then

normal

beyond

that

speed

it

can

be

judged

that

the

torque

con

verter

s

one

way

clutch

is

slipping

Automatic

Transmission

2

If

the

torque

converter

s

one

way

clutch

sticks

vehicle

speed

can

not

exceed

approximately

80

km

h

50

MPH

in

the

road

test

In

such

a

case

the

torque

converter

oil

tem

perature

rises

abnormally

and

so

special

care

is

required

3

If

the

transmission

does

not

op

erate

properly

at

all

vehicle

speeds

it

indicates

poor

engine

performance

VEHICLE

SPEED

AT

GEAR

SHIFT

Throttle

opening

mmHg

Kickdown

0

Half

throttle

200

Fuol

throttle

0

Minimum

throttle

450

ROAD

TEST

An

accurate

knowledge

of

the

auto

JT

l

ltic

transmission

is

required

for

an

exact

diagnosis

It

is

recommended

that

a

diagnosis

guide

chart

with

the

standard

vehicle

speeds

for

each

stage

of

the

up

and

down

shiftings

be

prepared

Measured

vehicle

speeds

are

to

be

filled

in

the

adjoining

column

after

each

testing

Also

it

is

advisable

to

mount

a

stopper

for

positioning

the

throttle

opening

Gear

shift

Vehicle

speed

km

h

MPH

Propeller

shaft

rpm

Dl

D2

51

to

65

32

to

40

1

840

to

2

340

D2

D3

92

to

106

57

to

66

3

340

to

3

840

D3

D2

96

to

82

60

to

51

3

460

to

2

960

D2

Dl

49

to

36

30

to

22

1

790

to

1

290

Dl

D2

9t023

6toI4

330to

830

D2

D3

48

to

61

30

to

38

1

720

to

2

220

D3

D2

or

D3

Dl

37

to

24

23

to

15

1

350

to

850

D2

Dl

19

12

700

Max

12

I

51

to

38

32

to

24

1

860

to

1

360

1

12

I

51

to

38

32

to

24

1

860

to

1

360

1

Reduce

the

speed

by

shifting

to

I

range

from

D

range

output

shaft

2

000

rpm

Vehicle

speed

can

be

calculated

by

the

following

formula

V

2

x

1f

x

r

x

Np

x

60

RF

x

1

000

V

Vehicle

speed

km

h

Np

Propeller

shaft

revolution

rpm

R

Final

gear

ratio

r

Tire

effective

radius

m

TT

The

ratio

of

circumference

of

a

circle

to

its

diameter

3

14

Note

where

RF

4

375

r

0

321

6

00

14

AT

51

Page 316 of 537

CHECKING

SPEED

CHANGING

CONDITION

The

driver

s

feeling

during

gear

changes

should

also

be

checkedatten

tively

I

A

sharp

shock

or

unSffioothness

is

felt

during

a

gear

change

2

A

gear

change

is

made

with

a

long

and

dragging

feeling

These

indicate

that

the

tIuottle

pressure

is

too

low

or

some

valve

connected

to

the

throttle

is

faulty

h

k

100

1

1

2

I

2

J

I

1

2

I

I

I

2

3

oo

I

c

I

E

I

I

300

I

Z

5

L

mmHg

t

1

400

I

I

1

Output

shaft

speed

rpm

20

30

40

50

60

70

80

90100

00

io

3

0

40

0

60

Vehicle

speed

R

4

315

r

0

321

6

00

14

ATll0

Fig

AT

111

Shift

IChedule

Automatic

Transmission

SHI

SCHEDULE

500

CHECKING

ITEMS

DURING

km

hO

1O

SPEED

CHANGE

I

In

D

range

gear

changes

DI

D2

D3

are

effected

In

R

range

the

speed

does

not

increase

2

The

kickdown

operates

properly

3

By

moving

the

lever

from

D

to

I

gear

changes

D

2

1

2

1

are

effected

In

the

ranges

12

and

I

the

engine

braking

works

prop

erly

4

In

I

the

speed

does

not

in

crease

5

Should

be

quickly

fixed

at

2

range

6

In

P

vehicle

can

he

parked

properly

If

any

malfunction

occurs

in

second

gear

during

the

road

test

that

is

if

vehicle

shakes

drags

or

slings

while

shifting

up

from

D

directly

to

D

or

in

shifting

up

from

D

to

D2

the

brake

band

should

be

ad

justed

If

these

troubles

remain

after

the

brake

band

is

adjusted

check

the

servo

piston

seal

for

oil

leakage

MPH

Ii

io

LINE

PRESSURE

TEST

When

any

slipping

occurs

in

clutch

or

brake

or

the

feeling

during

a

speed

change

is

not

correct

the

line

pressure

must

be

checked

Measuring

line

pressure

is

done

by

a

pressure

gauge

attached

to

two

pres

sure

measuring

holes

after

removing

blind

plugs

located

at

transmission

case

See

Figure

AT

112

The

line

pressure

measurement

is

begun

at

idling

and

taken

step

by

step

by

enlarging

the

throttle

opening

I

A

sharp

shock

in

up

shifting

or

too

high

changing

speeds

are

caused

mostly

by

too

high

throttle

pressure

2

Slipping

or

incapability

of

opera

tion

is

mostly

due

to

oil

pressure

leakage

within

the

gear

trains

or

spool

valve

AT

S2

3

3SA

000

t

I

1

I

c

l

1

c

7

D

jf

o

CV

ATl13

1

Lige

pressure

2

Governor

feed

3

SerVo

release

pressure

Fig

AT

112

MeCJ

uring

line

preuure

Page 321 of 537

Automatic

Transmission

TROUBLE

SHOOTING

GUIDE

FOR

3N71B

AUTOMATIC

TRANSMISSION

Order

Test

item

Checking

Oil

level

gauge

2

Downshift

solenoid

3

Manuallinkage

L

4

Inhibitor

switch

5

Engine

idling

rpm

6

Vacuum

pressure

of

vacuum

pipe

7

Operation

in

each

range

8

Creep

of

vehicle

Stall

test

I

Oil

pressure

before

tesling

1

2

Stall

test

3

Oil

pressure

after

testing

Road

test

Slow

acceleration

I

st

2nd

2nd

3rd

2

Quick

acceleration

lst

2nd

2nd

3rd

3

Kick

down

operation

3rd

2nd

or

2nd

1st

Procedure

Check

gauge

for

oil

level

and

leakage

before

and

after

each

test

Check

for

sound

of

operating

solenoid

when

depressing

accelerator

pedal

fully

with

ignition

key

ON

Check

by

shifting

into

P

lR

IN

D

2

and

I

ranges

with

selector

lever

Check

whether

starter

operates

in

N

and

p

ranges

only

and

whether

reverse

lamp

operates

in

R

range

only

Check

whelher

idling

rpm

meet

standard

Check

whether

vacuum

pressure

is

more

than

450

mmHg

in

idling

and

whether

it

decreases

with

increasing

rpm

Check

whether

transmission

engages

positively

by

shifting

N

0

N

2

N

l

I

and

N

R

range

while

idling

with

brake

applied

Check

whether

there

is

any

creep

in

D

2

R

ranges

and

Measure

line

pressures

in

D

2

I

and

R

range

while

idling

Measure

engine

rpm

and

line

pressure

in

D

2

I

and

R

ranges

during

full

throttle

operati

n

Notes

a

Temperature

of

torque

converter

oil

used

in

test

should

be

from

600

to

1000C

1400

to

2120F

i

e

sufficiently

warmed

up

but

not

overheated

b

To

cool

oil

between

each

stall

test

for

D

2

I

and

R

ranges

idle

engine

i

e

rpm

at

about

1

200

rpm

for

more

than

1

minute

in

P

range

Measurement

time

must

not

be

more

than

5

seconds

Same

as

item

I

Check

vehide

speeds

and

engine

cpm

in

shifting

up

Ist

2nd

range

and

2nd

Jo3rd

range

while

running

with

lever

in

D

range

and

engine

vacuum

pressure

of

about

200

I11I1lHg

Same

as

item

1

above

except

with

engine

vacuum

pressure

of

0

mmHg

i

e

in

position

just

before

kickdown

Check

whether

the

kickdown

operates

and

measure

the

time

delays

while

running

at

30

40

50

60

70

km

h

18

25

30

37

43

MPH

in

D3

range

AT

57

Page 322 of 537

Automatic

Transmission

Order

Test

item

4

Shift

down

Dr

O2

0

5

Shift

down

DJ

12

1

6

Shift

down

DJ

2

7

Shift

up

I

12

8

Shift

up

or

down

when

start

iog

in

2

range

9

Parking

Others

Abnormal

shock

oil

leakage

Procedure

Check

vehicle

speeds

and

engine

rpm

in

shifting

down

from

3rd

2nd

I

st

sequentially

while

coasting

with

accelerater

pedal

released

in

D3

range

and

engine

vacuum

pressure

of

about

450

mmHg

Check

for

shifting

down

OJ

12

and

engine

braking

and

further

for

shifting

down

12

I

and

engine

braking

after

shifting

the

lever

into

I

range

with

the

accelerator

pedal

released

and

the

engine

vacuum

pressure

of

0

mmHg

while

driving

at

about

50

km

h

30

MPH

in

OJ

range

Check

for

quick

shifting

down

0

2

and

engine

biaking

after

shifting

the

lever

into

2

range

while

driving

at

about

50

km

h

30

MPH

in

OJ

range

Further

check

for

locking

of

the

transmission

in

2nd

gear

ratio

regardless

of

vehicle

speed

Check

for

failure

of

the

transmission

to

shift

up

during

acceleration

when

starting

in

I

range

Check

the

transmission

for

not

shifting

up

or

down

during

acceleration

or

deceleration

when

starting

in

2

rang

Confirm

that

vehicle

will

not

move

on

grade

when

shifting

to

P

range

Enter

into

record

conditions

observed

during

these

tests

such

as

gear

noise

abnormal

clutch

noise

and

acceleration

performance

AT

58

Page 331 of 537

PROPELLER

SHAFT

DIFFERENTIAL

CARRIER

Watch

for

oil

leakage

from

trans

mission

end

Notes

a

Remove

propeller

shaft

carefully

so

as

not

to

damage

spline

sleeve

yoke

and

rear

oil

seal

b

Plug

up

the

opening

in

the

rear

of

rear

extension

housing

to

prevent

oil

from

flowing

out

To

install

reverse

the

foregoing

removal

procedure

1

Align

propeller

shaft

with

com

panion

flange

using

reference

marks

prescribed

in

removal

procedure

and

assemble

with

bolts

Tightening

torque

2

4

to

3

3

kg

m

17

to

24

ft

Ib

2

Insert

bolts

through

the

holes

of

center

beariug

bracket

and

torque

nuts

to

retain

center

bearing

on

cross

member

Tightening

torque

1

6

to

2

2

kg

m

12

to

16

ft

Ib

DISASSEMBLY

AND

ASSEMBLY

Primarily

do

not

disassemble

pro

peller

shaft

because

it

is

balanced

as

an

assembly

However

check

propeller

shaft

with

journal

for

movement

When

journal

does

not

move

smoothly

dis

assemble

1

Mark

propeller

shaft

and

journal

so

that

the

original

combination

can

be

restored

at

assembly

2

Remove

snap

ring

with

a

standard

screwdriver

3

Lightly

tap

base

of

yoke

with

a

hammer

and

withdraw

bearing

race

See

Figure

PD

4

PDOO5

Fig

PD

4

Remo

i

bearing

Note

When

removing

journal

from

yoke

be

careful

not

to

damage

journal

and

yoke

bole

When

disassembling

and

repairing

center

bearing

are

required

the

follow

ing

procedures

are

applied

1

Put

match

marks

on

flange

and

front

propeller

shaft

Remove

bolts

connecting

flange

yoke

to

companion

flange

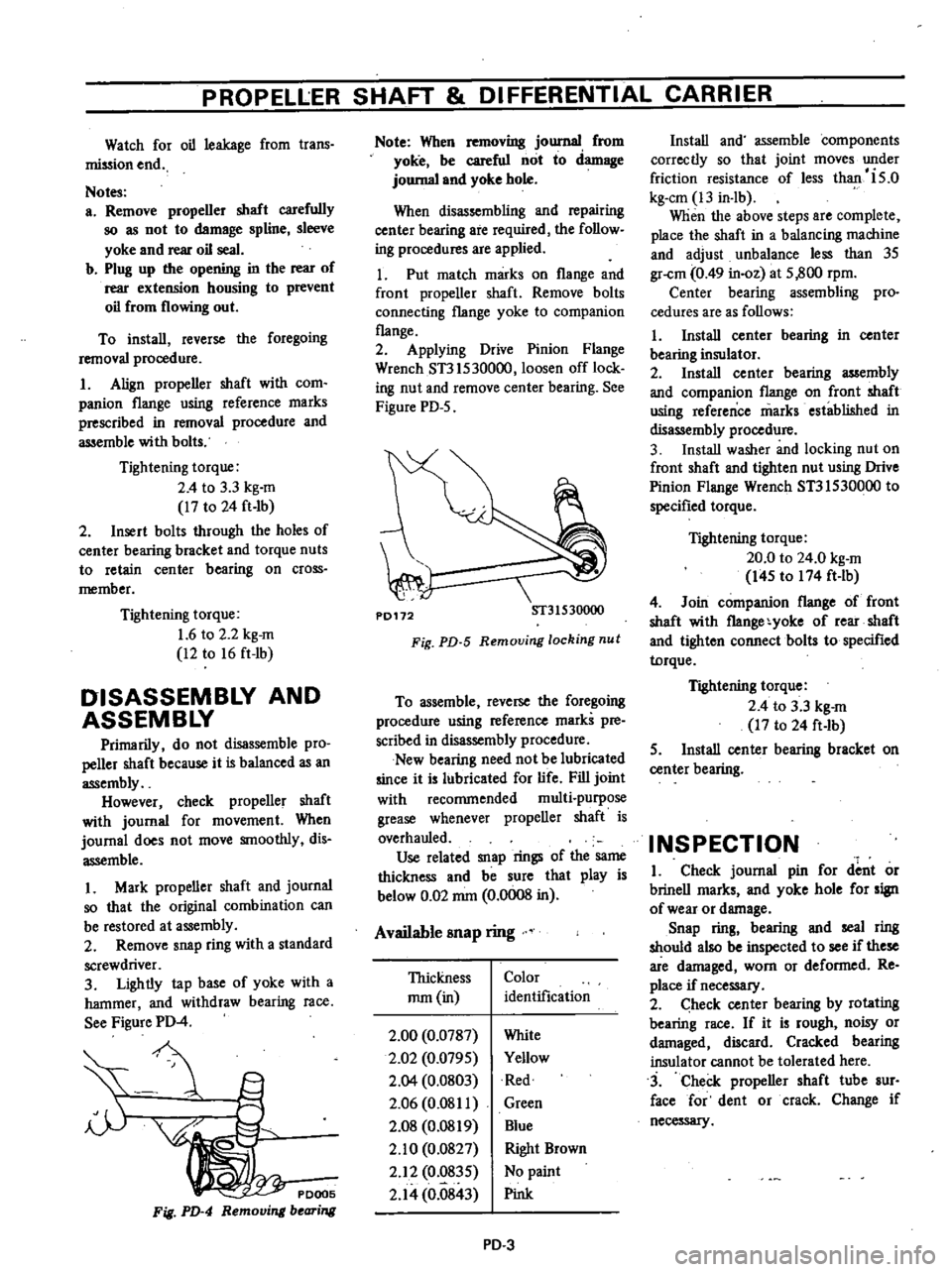

2

Applying

Drive

Pinion

Flange

Wrench

ST3lS30000

loosen

off

lock

ing

nut

and

remove

center

bearing

See

Figure

PD

5

P0172

ST31530000

Fig

PD

5

Remouing

locking

nut

To

assemble

reverse

the

foregoing

procedure

using

reference

marks

pre

scribed

in

disassembly

procedure

New

bearing

need

not

be

lubricated

since

it

is

lubricated

for

life

Fill

joint

with

recommended

multi

purpose

grease

whenever

propeller

shaft

is

overhauled

Use

related

snap

rings

of

the

same

thickness

and

be

sure

that

play

is

below

0

02

mm

0

0008

in

Available

snap

ring

Thickness

mm

in

Color

identification

2

00

0

0787

2

02

0

079S

2

Q4

0

0803

2

06

0

08

II

2

08

0

0819

2

10

0

0827

2

12

0

83S

2

14

0

0843

White

Yellow

Red

Green

Blue

Right

Brown

No

paint

Pink

PD

3

Install

and

assemble

components

correctly

so

that

joint

moves

under

friction

resistance

of

less

than

is

o

kg

em

13

in

lb

When

the

above

steps

are

complete

place

the

shaft

in

a

balancing

machine

and

adjust

unbalance

less

than

3S

gr

cm

0

49

in

oz

at

S

800

rpm

Center

bearing

assembling

pro

cedures

are

as

follows

I

Install

center

bearing

in

center

bearing

insulator

2

Install

center

bearing

assembly

and

companion

flange

on

front

shaft

usiug

reference

marks

established

in

disassembly

procedure

3

Install

washer

and

locking

nut

on

front

shaft

and

tighten

nut

using

Drive

Pinion

Flange

Wrench

ST3IS30000

to

specified

torque

Tightening

torque

20

0

to

24

0

kg

m

I4S

to

174

ft

lb

4

Join

companion

flange

of

front

shaft

with

f1ange

yoke

of

rear

shaft

and

tighten

connect

bolts

to

specified

torque

Tightening

torque

2

4

to

3

3

kg

m

17

to

24

ft

Ib

S

Install

center

bearing

bracket

on

center

bearing

INSPECTION

I

Check

journal

pin

for

dent

or

brinell

marks

and

yoke

hole

for

sign

of

wear

or

damage

Snap

ring

bearing

and

seal

ring

should

also

be

inspected

to

see

if

these

are

damaged

worn

or

deformed

Re

place

if

necessary

2

heck

center

bearing

by

rotating

bearing

race

If

it

is

rough

noisy

or

damaged

discard

Cracked

bearing

insulator

cannot

be

tolerated

here

3

Check

propeller

shaft

tube

sur

face

for

dent

or

crack

Change

if

necessary