tires DATSUN PICK-UP 1977 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 342 of 537

PROPELLER

SHAFT

DIFFERENTIAl

CARRIER

TROUBLE

DIAGNOSES

AND

CORRECTIONS

When

a

differential

carrier

is

sus

pected

of

being

noisy

it

is

advisable

to

make

a

thorough

lest

to

determine

whether

the

noise

originates

in

the

Condition

Noise

on

drive

coast

and

float

Noise

on

turn

Knocking

sound

during

starting

or

gear

shifting

tires

road

surface

exhaust

universal

joint

propeller

shaft

wheel

bearings

engine

transmission

or

differential

carrier

Noise

which

originates

in

other

Probable

cause

Shortage

of

oil

Incorrect

tooth

contact

between

ring

gear

and

drive

pinion

Incorrect

backlash

between

ring

gear

and

drive

pinion

Seized

up

or

damaged

ring

gear

and

drive

pinion

Seized

up

damaged

or

broken

drive

pinion

bearing

Seized

up

damaged

or

broken

side

bearing

Loose

bolts

or

nuts

fIXing

ring

gear

bearing

cap

etc

Seized

up

damaged

or

broken

side

and

pinion

mate

Seized

up

damaged

or

broken

side

gear

and

pinion

thrust

washer

Pinion

mates

too

tight

on

their

shaft

Excessive

backlash

Incorrect

backlash

ring

ar

to

drive

pinion

or

side

gear

to

pinionmate

Worn

gears

or

case

Worn

rear

axle

shaft

and

side

gear

spline

Drjve

pinion

bearing

under

p

reload

Loose

drive

pinion

nut

Loose

bolts

or

nuts

ftxing

ring

gear

bearing

cap

etc

PD

14

places

cannot

be

corrected

by

adjust

ment

or

replacement

of

parts

in

dif

ferential

carrier

Corrective

action

Supply

gear

oil

Rebuild

gear

carrier

if

necessary

Adjust

tooth

contact

or

replace

the

hypoid

gear

set

Adjust

backlash

or

replace

the

hypoid

gear

set

if

necessary

Replace

the

hypoid

gear

set

Replace

the

pinion

bearing

and

faulty

parts

Replace

the

side

bearing

and

faulty

parts

Clamp

them

to

specified

torque

and

replace

faulty

parts

Replace

faulty

parts

Replace

faulty

parts

Replace

faulty

parts

Adjust

backlash

Replace

worn

parts

Replace

worn

parts

Adjust

preload

Repair

or

replace

Clamp

them

or

replace

if

necessary

Page 361 of 537

WHEEL

ALIGNMENT

Correct

front

wheel

alignment

attains

proper

vehicle

handling

charac

teristics

and

the

least

steering

effort

with

a

minimum

amount

of

tire

wear

Before

adjusting

front

wheel

align

ment

make

sure

to

carry

out

a

pre

liminary

inspection

of

the

front

end

parts

for

the

following

conditions

1

Tire

pressure

and

balance

2

Wheel

bearings

and

nuts

3

Steering

gear

play

4

Steering

gear

housing

at

frame

S

Steering

linkage

and

connections

6

Shock

absorber

action

When

using

the

equipment

for

front

wheel

alignment

inspection

follow

the

inst

c

tions

furnished

with

the

equip

ment

Furthennore

the

inspection

should

be

made

with

the

vehicle

level

and

at

curb

weight

Camber

and

caster

Measure

camber

and

caster

and

adjust

them

in

accordance

with

the

following

procedures

if

necessary

Both

camber

and

caster

are

ad

justed

by

increasing

and

decreasing

thickness

of

adjust

shim

inserted

be

tween

upper

link

spindle

and

upper

link

mounting

bracket

To

adjust

caster

make

a

difference

between

thickness

of

front

and

rear

shims

By

adding

a

shim

I

mm

0

039

in

at

front

side

caster

will

be

de

creased

by

33

At

the

same

time

camber

will

also

be

decreased

by

6

S

To

adjust

camber

add

or

remove

an

equal

amount

of

shims

to

front

and

rear

sides

By

adding

a

pack

of

shims

I

mOl

0

039

in

thick

at

both

sides

camber

will

be

decreased

by

13

Shims

are

available

in

I

mm

0

039

in

2

mOl

0

079

in

and

4

mOl

0

157

in

thickness

Front

Axle

Front

Suspension

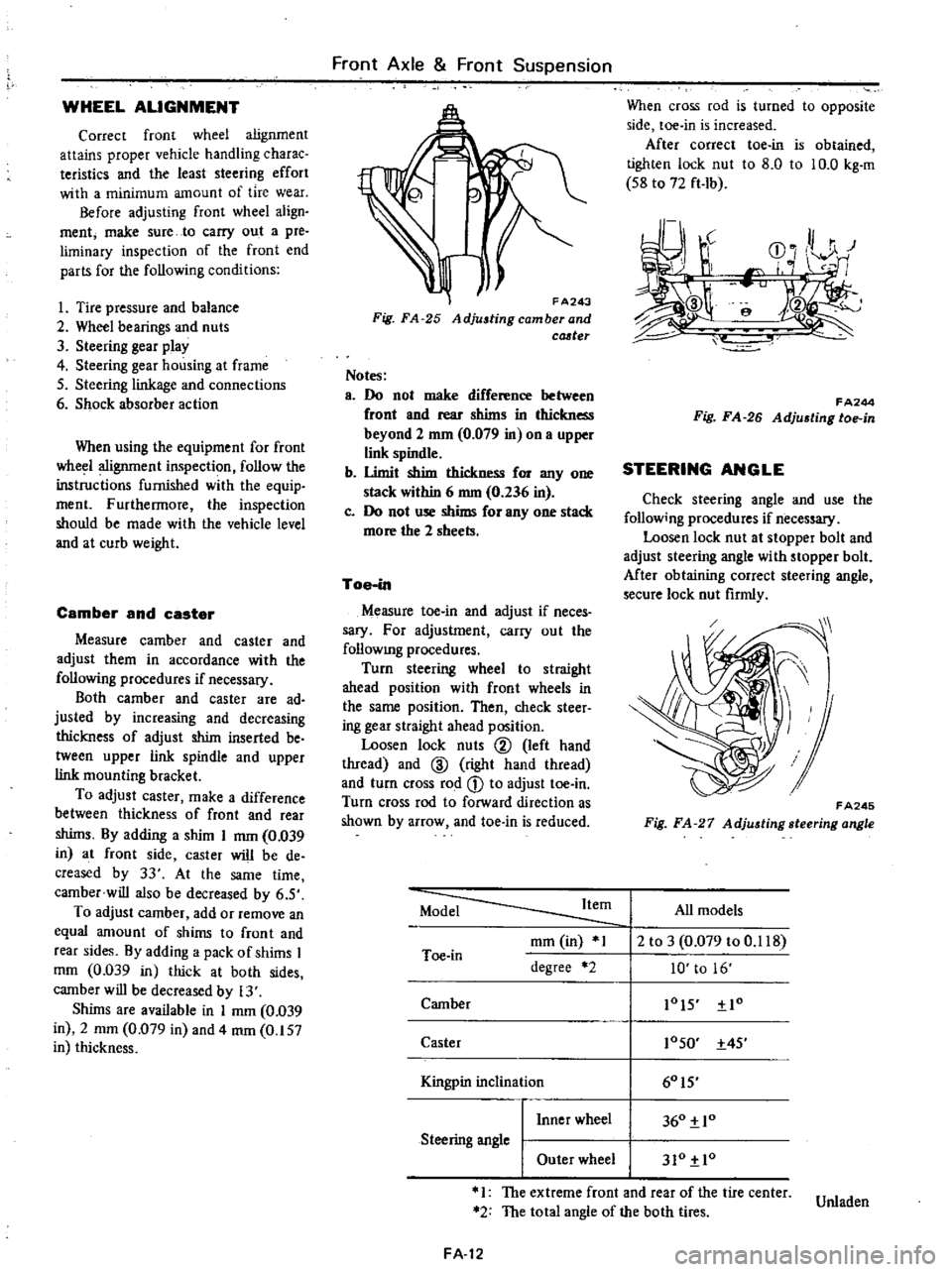

FA243

Fig

FA

25

Adjustingcamberand

cCJ

ter

Notes

a

Do

not

make

difference

between

front

and

rear

shims

in

thickness

beyond

2

mm

0

079

in

on

a

upper

link

spindle

b

Umit

shim

thickness

for

anyone

stack

within

6

nun

0

236

in

c

Do

not

use

shims

for

anyone

stack

more

the

2

sheets

Toe

in

Measure

toe

in

and

adjust

if

neces

sary

For

adjustment

carry

out

the

follOWIng

procedures

Turn

steering

wheel

to

straight

ahead

position

with

front

wheels

in

the

same

position

Then

check

steer

ing

gear

straight

ahead

position

Loosen

lock

nuts

@

left

hand

thread

and

ID

right

hand

thread

and

turn

cross

rod

CD

to

adjust

toe

in

Turn

cross

rod

to

forward

direction

as

shown

by

arrow

and

toe

in

is

reduced

When

cross

rod

is

turned

to

opposite

side

toe

in

is

increased

After

correct

toe

in

is

obtained

tighten

lock

nut

to

8

0

to

10

0

kg

m

S8

to

72

ft

Ib

r

J

r

CD

0

HI

r

I

e

f

FA244

Fig

FA

26

Adju6ting

toe

in

STEERING

ANGLE

Check

steering

angle

and

use

the

follow

ng

procedures

if

necessary

Loosen

lock

nut

at

stopper

bolt

and

adjust

steering

angle

with

stopper

bolt

Mter

obtaining

correct

steering

angle

secure

lock

nut

firmly

FA245

Fig

FA

27

Adjusting

steering

angle

Model

Item

All

models

mOl

in

1

2

to

3

0

079

to

0

118

Toe

in

degree

2

10

to

16

Camber

lOIS

Io

Caster

10SO

4S

I

60IS

Kingpin

inc

inal10n

I

Inner

wheel

360

10

Steering

angle

I

Outer

wheel

310

10

1

The

extreme

front

and

rear

of

the

tire

center

Unladen

2

The

total

angle

of

the

both

tires

FA

12

Page 363 of 537

Front

Axle

Front

Suspension

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

Vibration

shock

and

shimmy

ing

of

steering

wheeL

Vehicle

pulls

to

right

or

left

Probable

cause

Vibration

Too

much

backlash

of

steering

gear

wear

of

each

part

of

linkage

and

vibration

of

front

wheels

are

in

many

cases

transmitted

to

the

steering

wheel

This

is

Very

much

noticeable

when

traveJling

over

bad

roads

and

at

higher

speeds

Shock

When

the

front

wheels

are

travelling

over

bumpy

roads

the

play

of

the

steering

linkage

is

transmitted

to

the

steering

wheel

This

is

especially

noticeable

when

travelling

rough

road

Shimmy

Abnormal

vibrations

of

the

front

suspen

sion

group

and

the

whole

steering

linkage

which

occur

when

a

specific

speed

is

attained

Improper

air

pressure

of

tire

Unbalance

and

deformation

of

roadwheel

Unevenly

worn

tire

or

insufficient

tightening

Improperly

adjusted

or

worn

front

wheel

bearing

Faulty

wheel

alignment

Worn

or

loose

suspension

link

screw

bushing

Damaged

idler

arm

Insufficiently

tightened

steering

gear

housing

Worn

steering

linkage

Improper

steering

gear

adjustment

insufficient

back

lash

Faulty

shock

absorber

or

loose

installation

Unbalanced

vehicle

posture

When

driving

with

hands

off

the

steering

wheel

on

a

fiat

road

the

vehicle

gently

swerves

to

right

or

left

Note

A

faulty

rear

suspension

may

also

be

the

cause

of

this

condition

and

therefore

see

also

the

chapter

dealing

with

the

rear

suspension

Improper

air

pressure

of

tire

or

insufficient

tightening

of

wheel

nu

ts

Difference

in

height

of

right

and

left

tire

treads

Incorrect

adjustment

or

abrasion

of

front

wheel

bearing

Weakened

front

torsion

spring

or

deviation

from

standard

specification

Improper

wheel

alignment

Worn

or

loose

suspension

link

screw

bushing

FA

14

Corrective

action

Adjust

Correct

the

unbalance

or

re

place

Replace

or

tighten

Adjust

or

replace

Adjust

Replace

Replace

TIghten

Replace

ball

joint

Adjust

Replace

or

tighten

Adjust

Adjust

or

tighten

Replace

tires

Adjust

or

replace

Replace

Readjust

Replace

Page 374 of 537

Rear

Axle

Rear

Suspension

Spring

front

pin

Spring

shackle

Bearing

cage

fIXing

bolt

Wheel

bearing

lock

nut

Air

breather

Differential

gear

carrier

to

axle

case

nut

Propeller

shaft

flange

bolt

Drain

and

filler

plug

Bumper

rubber

fixing

bolt

Wheel

nut

kg

m

ft

lb

kg

m

ft

Ib

kg

en

ft

lb

kg

m

ft

Ib

kg

m

ft

Ib

kg

m

ft

Ib

kg

en

ft

Ib

kg

m

ft

Ib

kg

m

ft

Ib

kg

m

ft

lb

11

5

to

13

0

83

to

94

11

5

to

13

0

83

to

94

S

4

to

6

4

39

to

46

IS

to

20

108

to

l4S

0

7

to

0

9

S

I

to

6

S

17

to

2

7

12

to

20

2

0

to

2

7

14

to

20

6

to

10

43

to

72

1

6

to

2

2

12

to

16

8

to

9

S8

to

6S

TROUBLE

DIAGNOSES

AND

CORRECTIONS

When

rear

axle

and

suspension

is

suspected

of

being

noisy

it

is

advisable

to

make

a

thorough

test

to

determine

whether

the

noise

originates

in

the

tires

road

surface

exhaust

propeller

shaft

engine

transmission

universal

joint

wheel

bearings

or

suspension

Noise

which

originates

in

other

places

can

not

be

corrected

by

adjust

ment

or

replacement

of

parts

in

the

rear

axle

and

rear

suspension

In

case

of

oil

leak

first

check

if

there

is

any

damage

or

restriction

in

breather

Condition

Probable

cause

Noise

Loose

wheel

nuts

Loose

one

or

more

securing

bolts

Lack

of

lubricating

oil

or

grease

Faulty

shock

absorber

Incorrect

adjustment

of

rear

axle

shaft

end

play

Damaged

or

worn

wheel

bearing

Worn

spline

portion

of

rear

axle

shaft

Broken

leaf

spring

Loose

journal

connections

or

so

no

Wheel

and

tire

unbalance

Damaged

rubber

parts

such

as

leaf

spring

bush

shock

absorber

moun

ting

bush

Faulty

universal

joints

Instability

in

driving

Loose

wheel

nuts

Worn

shock

absorber

Worn

or

broken

leaf

spring

Oil

leakage

Damaged

or

restricted

air

breather

Damaged

oil

seal

in

rear

axle

case

or

differ

ential

carrier

Oil

leakage

from

between

the

differential

carrier

and

axle

case

RA

8

Corrective

action

Tighten

the

wheel

nuts

Tighten

the

bolts

to

the

specified

torque

Lubricate

as

required

Replace

the

shock

absorber

Adjust

the

rear

axle

shaft

end

play

Replace

wheel

bearing

Replace

if

necessary

Replace

leaf

spring

Tighten

to

the

given

torque

Balance

wheel

and

tire

Replace

the

required

parts

Adjust

or

replace

Tighten

to

the

given

torque

Replace

faulty

shock

absorber

Replace

leaf

spring

Clean

or

replace

air

breather

Replace

the

damaged

oil

seal

Tighten

to

the

specified

torque

or

replace

gasket

Page 402 of 537

DESCRIPTION

MAINTENANCE

AND

SERVICE

TIRE

INFLATION

TIRE

REPAIR

WHEEL

REPAIR

WEAR

DESCRIPTION

The

620

series

models

are

equipped

with

4lV

14

wheels

with

25

mOl

0

98

in

offset

All

tires

are

tubeless

Wheel

and

Tire

WHEEL

AND

TIRE

CONTENTS

WT2

WT

2

WT2

WT2

WT

2

WT

2

TIRE

ROTATION

CHANGING

TIRE

INSPECTION

WHEEL

BALANCE

WHEEL

AND

TIRE

Tire

size

Model

Tire

size

Wheel

size

All

models

6

00

I

4

6PR

Tubeless

4UJ

14

Tire

pressure

Unit

kgl

em

2

psi

Vehicle

speed

km

h

MPH

Under

Over

100

km

h

100

km

h

Model

60

MPH

60

MPH

Front

1

5

21

1

8

26

Unloaded

Rear

175

25

2

25

32

All

models

Front

1

5

21

1

8

26

Loaded

Rear

3

0

42

3

15

4S

Note

Tire

inflation

pressures

should

be

measured

when

tires

are

cold

MAINTENANCE

AND

SERVICE

TIRE

INFLATION

Correct

tire

pressure

is

very

im

portant

to

ease

of

steering

and

riding

comfort

This

also

reduces

driving

sound

to

a

minimum

resulting

in

longer

tire

life

that

is

overinflation

or

underinflation

promotes

wear

at

cen

ter

tread

or

shouider

of

tire

If

aU

tires

are

inspected

frequently

and

maintained

correct

tire

pressure

it

is

possible

to

detect

sharp

material

in

the

tread

Also

the

above

check

avoids

abnormal

wear

which

invites

serious

problem

If

tires

indicate

abnormal

or

uneven

wear

the

cause

of

problem

should

be

detected

and

eliminated

After

inflating

tires

leakage

in

valve

should

be

checked

Without

valve

caps

leakage

will

occur

due

to

dirt

and

water

resulting

in

underinflation

Ac

cordingly

whenever

tire

pressure

is

checked

be

sure

to

tighten

valve

caps

firmly

by

hand

WT

2

WT3

WT3

WTA

WTA

WT

4

TIRE

REPAIR

In

order

to

inspect

a

leak

apply

soapy

solution

to

tire

or

submerge

tire

and

wheei

in

the

water

after

inflating

tire

to

specified

pressure

Special

in

spection

for

leaks

should

be

carried

out

around

the

valve

wheel

rim

and

along

the

tread

Exercise

care

to

bead

and

rim

where

leakage

occurs

Wipe

out

water

from

area

which

leaks

air

bubbles

and

then

mark

the

place

with

chalk

After

removing

the

materials

which

caused

puncture

seal

the

point

When

repairing

the

puncture

use

the

tire

repair

kits

which

are

furnished

from

tire

dealers

following

the

instructions

provided

with

the

kits

In

case

that

a

puncture

becomes

large

or

there

is

any

other

damage

on

the

tire

fabric

repair

must

be

carried

out

by

authorized

tire

dealers

WHEEL

REPAIR

Inspect

the

wheel

rim

flange

for

bend

or

dents

The

flange

should

be

cleaned

by

a

wire

brush

when

rust

is

found

on

the

flange

Furthermore

if

excessive

pitting

occurs

on

the

rim

eliminate

it

with

a

file

WEAR

Missilgnment

When

the

front

wheels

align

in

excessive

toe

in

or

toe

out

condition

tires

scrape

the

tread

rubber

off

The

wear

of

tread

appears

feathered

edge

Page 403 of 537

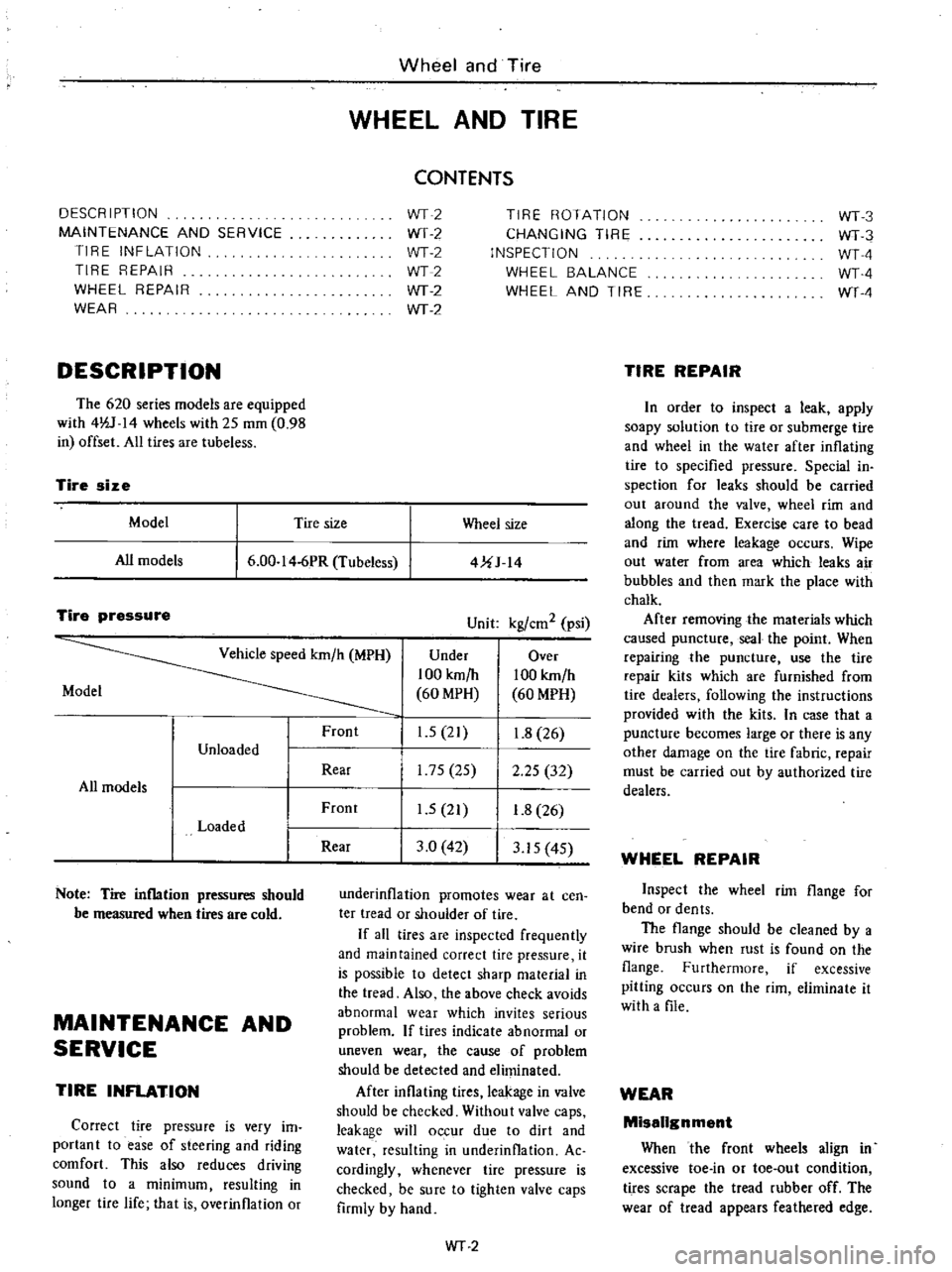

Center

This

wear

is

caused

by

overinflation

of

the

tire

The

inflation

pressure

must

be

kept

at

the

specified

value

Shoulder

The

wear

may

be

caused

by

under

inflation

incorrect

wheel

camber

or

continuous

high

speed

driving

on

curves

In

general

the

former

two

causes

are

common

Underinflation

wear

occurs

on

both

sides

of

treads

d

I

Ii

Toe

in

or

toe

out

wear

nf

I

Underinnation

wear

TIRE

ROTATION

Tires

wear

unevenly

and

become

unbalanced

according

to

running

dis

tance

Uneven

tire

wear

often

results

in

tire

noise

which

is

attributed

to

rear

axle

gears

bearing

etc

Meanwhile

the

front

tires

tend

to

wear

unevenly

because

of

improperly

aligned

front

wheel

Accordingly

to

equalize

tire

wear

it

is

necessary

to

rotate

tires

peri

odically

All

the

tires

including

the

spare

tire

are

of

the

same

type

Right

front

Right

rear

14

1

I

@

Spare

t

t

1

1

Left

front

Left

rear

Fig

WT

2

Tire

rotation

1

Wheel

and

Tire

and

on

the

other

hand

camber

causes

wear

only

on

one

side

of

treads

For

cornering

tread

wear

the

driver

must

operate

vehicle

slowing

down

on

curves

Uneven

Uneven

wear

is

caused

by

incorrect

camber

or

caster

malfunctioning

sus

pension

unbalanced

wheel

out

of

round

brake

drum

or

other

mechani

cal

conditions

To

repair

this

abnormal

wear

correct

the

above

faulty

parts

J

I

II

i

11

I

1

Overinllation

wear

1

I

I

t

Uneven

wear

WT007

Fig

WT

1

A

bnormal

tire

wear

The

spare

lire

has

a

different

brand

from

4

tires

on

the

vehicle

Right

front

Right

rear

I

@

Spare

x

J

r

Left

front

Left

rear

The

pare

tire

should

be

used

in

an

emergency

only

Fig

WT

3

Tire

rotation

2

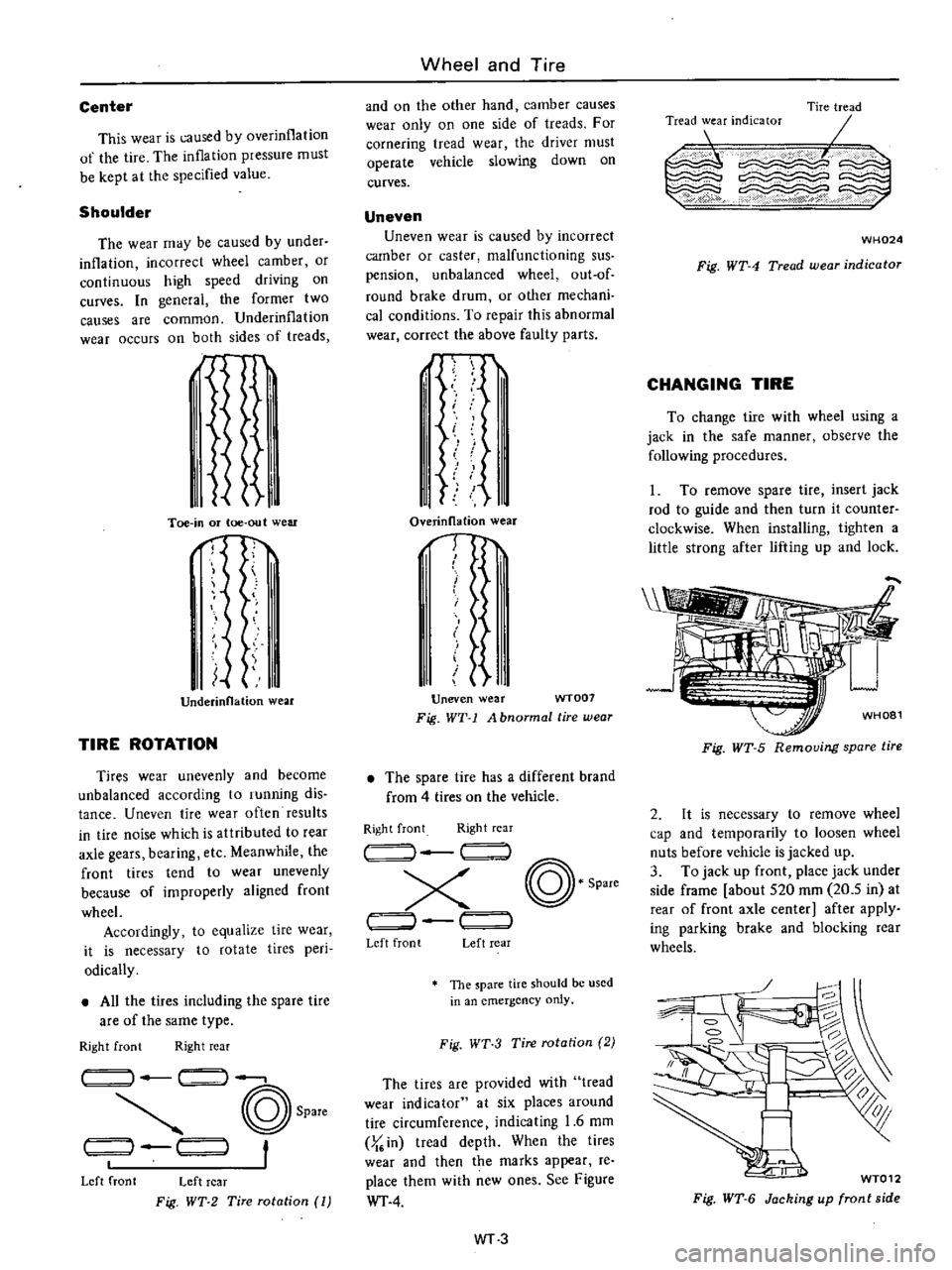

The

tires

are

provided

with

tread

wear

indicator

at

six

places

around

tire

circumference

indicating

1

6

mm

J

in

tread

depth

When

the

tires

wear

and

then

the

marks

appear

re

place

them

with

new

ones

See

Figure

WT

4

WT3

Tire

tread

0E

I

Tread

wear

indicator

c

WH024

Fig

WT

4

Tread

wear

indicator

CHANGING

TIRE

To

change

tire

with

wheel

using

a

jack

in

the

safe

manner

observe

the

following

procedures

1

To

remove

spare

tire

insert

jack

rod

to

guide

and

then

turn

it

counter

clockwise

When

installing

lighten

a

little

strong

after

lifting

up

and

lock

Fig

WT

5

Removing

spare

tire

2

It

is

necessary

to

remove

wheel

cap

and

temporarily

to

loosen

wheel

nuts

before

vehicle

is

jacked

up

3

To

jack

up

front

place

jack

under

side

frame

about

S20

mOl

20

5

in

at

rear

of

front

axle

center

after

apply

ing

parking

brake

and

blocking

rear

wheels

g

1

WT012

Fig

WT

6

Jacking

up

front

side

Page 414 of 537

STEERING

SYSTEM

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

Steering

wheel

moves

heavily

Steering

wheel

turns

but

sluggishly

Vehicle

pulls

to

one

side

Probable

cause

Wheel

alignment

out

of

specifications

or

air

pressure

in

tires

too

low

Steering

linkage

out

of

adjustment

Steering

column

out

of

alignment

Wheels

out

of

alignment

or

air

pressure

in

tires

too

low

Damaged

steering

linkage

Wheels

out

of

proper

alignment

Wheel

bearing

out

of

adjustment

Damaged

steering

linkage

ST

9

Corrective

action

Align

or

inflate

tires

to

correct

pressure

Adjust

and

see

relative

topic

under

Front

Suspension

Repair

Repair

or

inflate

tires

to

correct

air

pressure

Replace

and

see

relative

topic

under

Front

Suspension

Align

Adjust

Replace

and

see

relative

topic

under

Front

Suspension

Page 451 of 537

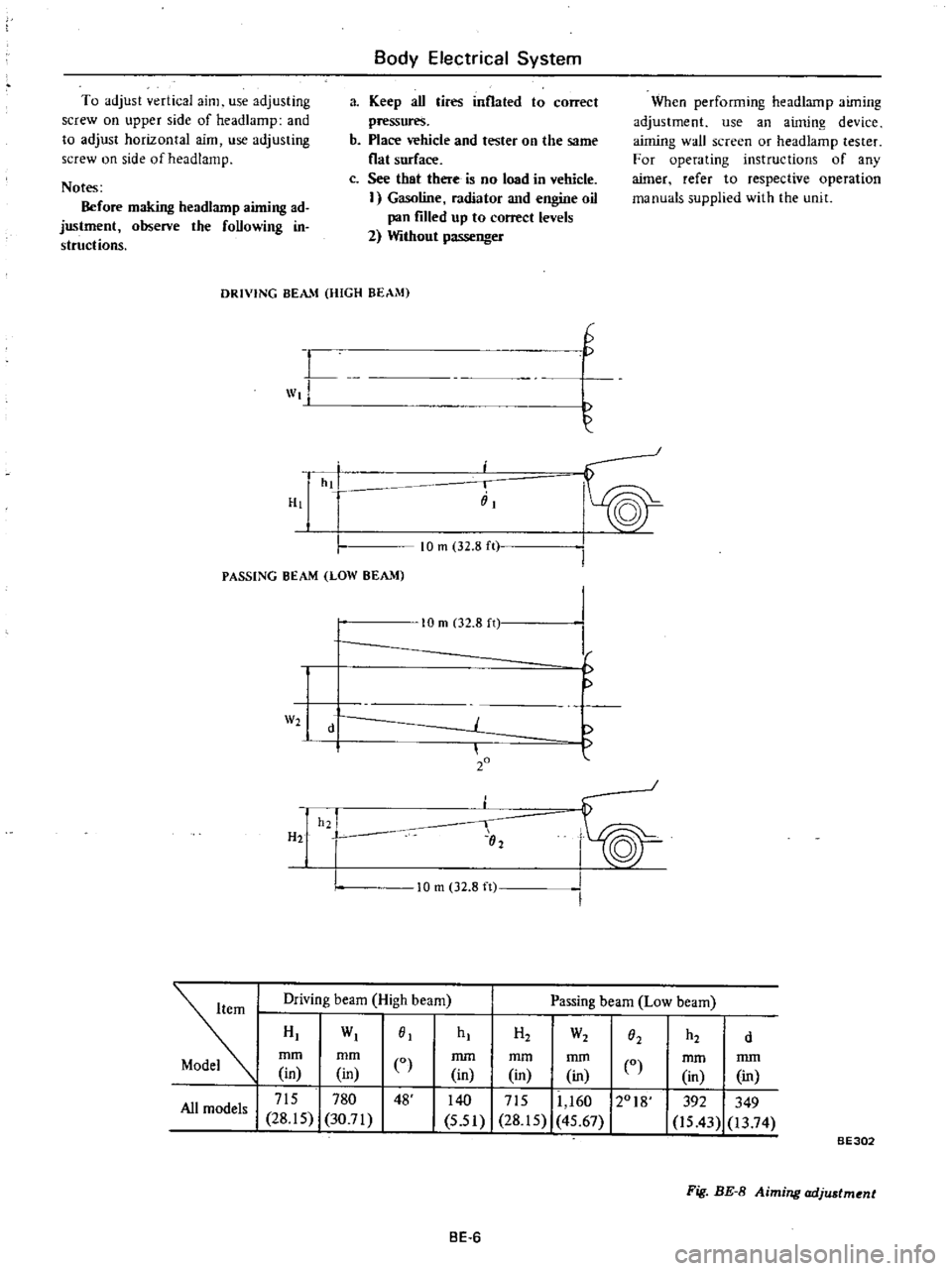

To

adjust

vertical

aim

use

adjusting

screw

on

upper

side

of

headlamp

and

to

adjust

horizontal

aim

use

adjusting

screw

on

side

of

head

lamp

Notes

Before

making

headlarnp

aiming

ad

justment

observe

the

foUowing

in

structions

Body

Electrical

System

a

Keep

aU

tires

inflated

to

correct

pressures

b

Place

vehicle

and

tester

on

the

same

flat

surface

c

See

that

there

is

no

load

in

vehicle

I

Gasoline

radiator

and

engine

oil

pan

filled

up

to

correct

levels

2

Without

passenger

When

performing

headlamp

aiming

adjustment

use

an

aiming

device

aiming

wall

screen

or

headlamp

tester

For

operating

instructions

of

any

aimer

refer

to

respective

operation

manuals

supplied

with

the

unit

DRIVING

BEAM

HIGH

BEAM

L

wt

H

G

hi

i

iiI

PASSING

BEAM

LOW

BEAM

10

m

32

8

ft

W2

H2

10

m

02

8

n

d

20

h2

I

02

I

I

f

10

m

32

8

ft

Driving

beam

High

beam

Passing

beam

Low

beam

HI

WI

01

mm

mm

CO

in

in

I

715

780

48

All

models

28

15

30

71

hI

H2

W2

h2

O2

d

mm

mm

mm

in

in

in

0

140

I

715

11

160

12018

5

51

28

15

45

67

mm

mm

in

in

392

349

is

43

13

74

BE302

Fig

BE

8

Aiming

adjustment

BE

6