ECO DATSUN PICK-UP 1977 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 424 of 537

Engine

Control

Fuel

Exhaust

Systems

I

Wipe

clean

all

the

contact

por

tions

of

tube

joints

allow

them

to

dry

thoroughly

2

Temporarily

mount

in

place

muffler

assembly

as

an

assembled

unit

on

the

vehicle

3

Insert

front

tube

until

it

touches

emboss

m

b

nlfrnnjj

mm

lJ

Ij

@L

J

FE263

Fig

FE

ll

Exhawt

tube

connection

4

Torque

nut

securing

the

male

and

female

tubes

at

the

connection

Tightening

torque

is

1

6

to

2

0

kg

m

12

to

14

ft

lb

5

Squeeze

approximately

5

CC

0

31

cu

in

of

sealant

into

injection

from

sealant

tube

See

Figure

FE

12

Sealant

tube

polyethylene

Injector

Fig

FE

IO

Exhaust

sealant

kit

Be

sure

to

place

cap

back

to

sealant

tube

since

sealant

will

dry

Approximately

5

cc

0

31

Cll

in

FE1l1

Fig

FE

12

Squeezing

sealant

to

injec

tor

6

Position

nozzle

of

injector

to

the

guide

and

press

it

there

firmly

Inject

sealant

slowly

until

sealant

begins

to

flow

out

of

the

slit

of

tube

This

indicates

that

the

bead

requires

no

further

sealant

Excessive

sealant

can

cause

a

clogged

tube

See

Figure

FE

13

After

injecting

wash

injector

thoroughly

in

clean

water

to

remove

all

traces

of

sealant

FE191

Fig

FE

13

Injecting

sealant

FE

9

7

Start

engine

and

let

it

idle

slowly

for

ten

minutes

minimum

to

hilfden

sealant

with

the

heat

of

exhaust

gas

8

Check

the

condition

of

sealant

before

driving

the

vehicle

It

is

also

essential

that

the

vehicle

should

not

be

accelerated

sharply

for

20

to

30

minutes

subsequent

to

this

operation

Noles

a

The

sealant

should

be

used

within

guaranty

term

indicated

on

the

kit

case

b

Exposure

of

sealant

to

the

skin

may

cause

a

rash

Wash

sealant

off

the

skin

with

water

c

Do

not

keep

the

sealant

tube

in

a

place

where

the

ambient

tempera

ture

is

above

400C

I040F

A

sealant

hardened

above

4QoC

I040F

cannot

be

used

The

most

suitable

storage

temperature

is

from

15

to

350C

59

to

950F

If

sealant

becomes

hardened

because

of

low

temperatures

wann

the

sealant

tube

with

lukewarm

water

until

the

sealant

is

softened

Do

not

warm

tube

at

a

temperature

over

400C

1040F

for

a

long

time

d

Thoroughly

read

the

instruction

sheet

furnished

with

the

kit

before

using

the

sealant

i

Page 426 of 537

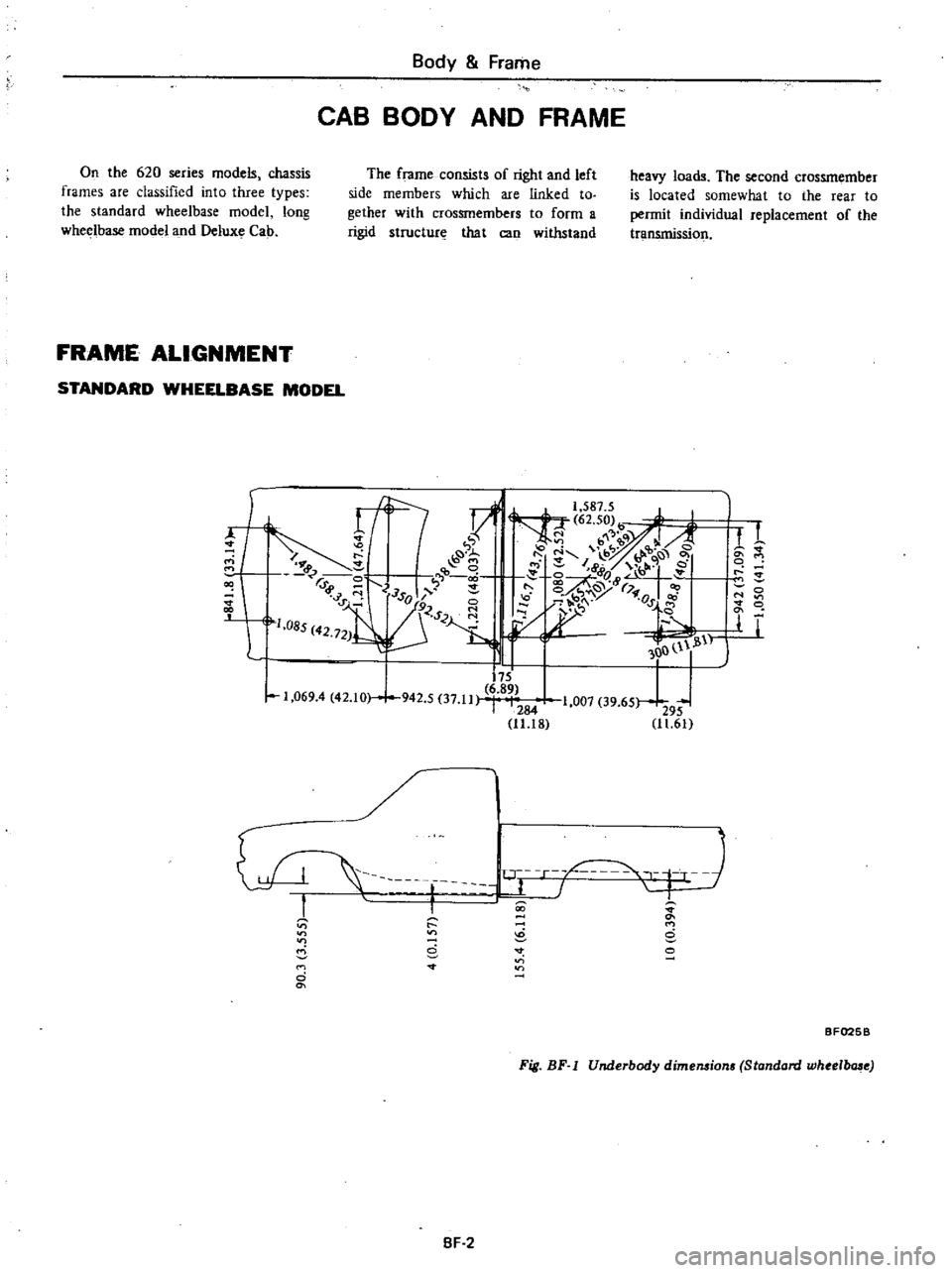

Body

Frame

CAB

BODY

AND

FRAME

On

the

620

series

models

chassis

frames

are

classified

into

three

types

the

standard

wheelbase

model

long

wheelbase

model

and

Deluxe

Cab

The

frame

consists

of

right

and

left

side

members

which

are

linked

to

gether

with

crossmembers

to

form

a

rigid

structure

that

can

withstand

heavy

loads

The

second

crossmember

is

located

somewhat

to

the

rear

to

permit

individual

replacement

of

the

transmissiol

FRAME

ALIGNMENT

STANDARD

WHEELBASE

MODEL

f

r1

1

587

5

J

I

1

X

62

50

I

b

q

J

A

1

7

I

b

9

9

8

I

1

e

t

r

0

ij

e

6

rd

r

r

1sol

1

1

9ClS

1

085

42

721

Cl

H

1

I

11

OO

l

1

i11

175

6

89

1

069

4

42

10

942

5

37

11

1007

39

65

I

284

295

11

18

11

61

00

d

M

o

8

r

r

c

8

o

r

T

L

BF025B

Fig

BF

I

Underbody

dime1l8ion

Standard

whee

b

e

SF

2

Page 434 of 537

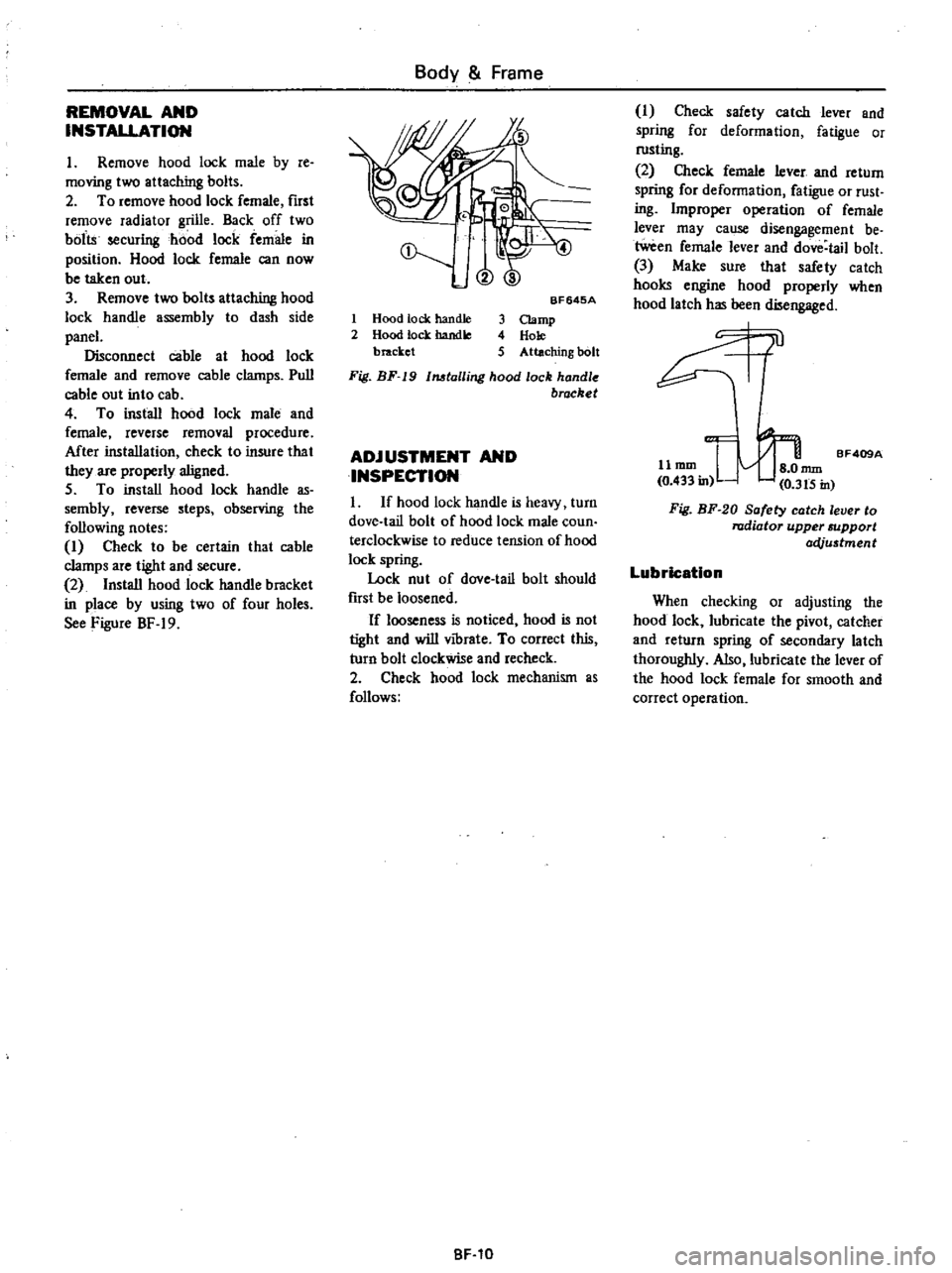

REMOVAL

AND

INSTALLATION

I

Remove

hood

lock

male

by

re

moving

two

attaching

bolts

2

To

remove

hood

lock

female

first

remove

radiator

grille

Back

off

two

bolts

securing

hood

lock

female

in

position

Hood

lock

female

can

now

be

taken

out

3

Remove

two

bolts

attaching

hood

lock

handle

assembly

to

dash

side

paneL

Disconnect

cable

at

hood

lock

female

and

remove

cable

clamps

Pull

cable

out

into

cab

4

To

install

hood

lock

male

and

female

reverse

removal

procedure

Mter

installation

check

to

insure

that

they

are

properly

aligned

5

To

install

hood

lock

handle

as

sembly

reverse

steps

observing

the

following

notes

I

Check

to

be

certain

that

cable

clamps

are

tight

and

secure

2

Install

hood

lock

handle

bracket

in

place

by

using

two

of

four

holes

See

Figure

BF

19

Body

Frame

@

1

Hood

tock

handle

2

Hood

lock

handle

bracket

BF645A

3

Clamp

4

Hole

5

Attaching

bolt

Fig

BF

19

1MtalIing

hood

lock

handle

brocket

ADJUSTMENT

AND

INSPECTION

I

If

hood

lock

handle

is

heavy

turn

dove

tail

bolt

of

hood

lock

male

coun

terclockwise

to

reduce

tension

of

hood

lock

spring

Lock

nut

of

dove

tail

bolt

should

fust

be

loosened

If

looseness

is

noticed

hood

is

not

tight

and

will

vibrate

To

correct

this

turn

bolt

clockwise

and

recheck

2

Check

hood

lock

mechanism

as

follows

BF

10

I

Check

safety

catch

lever

and

spring

for

deformation

fatigue

or

rusting

2

Check

female

lever

and

return

spring

for

deformation

fatigue

or

rust

ing

Improper

operation

of

female

lever

may

cause

disengagement

be

tween

female

lever

and

dove

tail

bolt

3

Make

sure

that

safety

catch

hooks

engine

hood

properly

when

hood

latch

has

been

disengaged

0l

11

mm

I

nun

BF409A

0

433

in

0

3t5

in

Fig

BF

20

Safety

catch

lever

to

radiator

upper

support

acVu5tment

Lubrication

When

checking

or

adjusting

the

hood

lock

lubricate

the

pivot

catcher

and

return

spring

of

secondary

latch

thoroughly

Also

lubricate

the

lever

of

the

hood

lock

female

for

smooth

and

correct

operation

Page 442 of 537

Body

Frame

INTERIOR

TRIM

AND

CENTER

CONSOLE

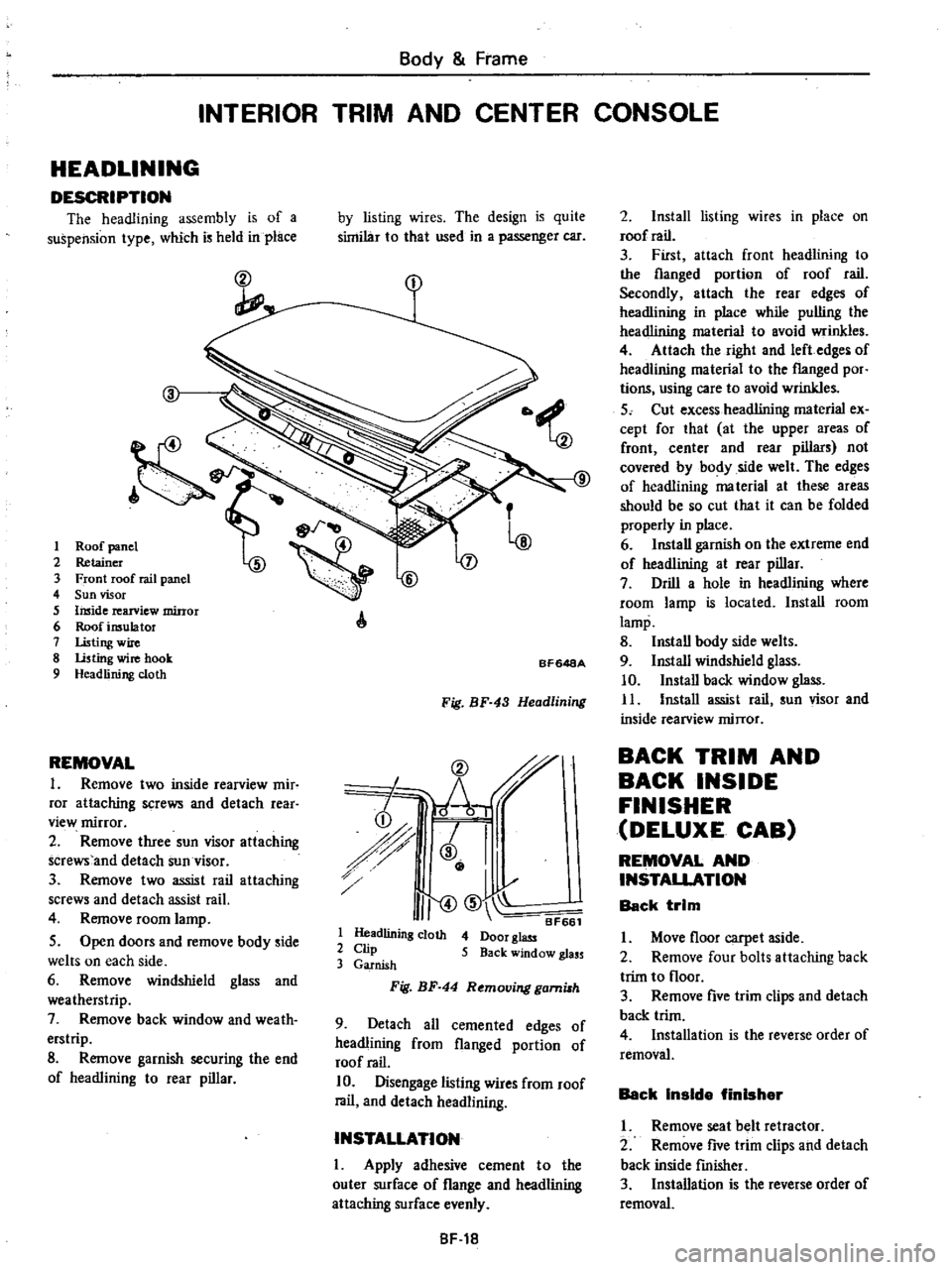

HEADLINING

DESCRIPTION

The

headlining

assembly

is

of

a

suspension

type

which

is

held

in

place

ct

I

2

3

4

5

6

7

8

9

REMOVAL

1

Remove

two

inside

rearview

mir

ror

attaching

screws

and

detach

rear

view

mirror

2

Remove

three

sun

visor

attaching

screws

and

detach

sun

visor

3

Remove

two

assist

rail

attaching

screws

and

detach

assist

rail

4

Remove

room

lamp

5

Open

doors

and

remove

body

side

welts

on

each

side

6

Remove

windshield

glass

and

weatherstrip

7

Remove

back

window

and

weath

erstrip

8

Remove

garnish

securing

the

end

of

headlining

to

rear

pillar

by

listing

wires

The

design

is

quite

similar

to

that

used

in

a

passenger

car

A

BF648A

Fig

BF

43

Headlining

CD

r

h

i

r

J

I

I

I

II

CID

BF661

1

Headlining

cloth

4

Door

glass

2

Clip

5

Back

window

glass

3

Garnish

Fig

BF

44

Removing

gami8h

9

Detach

all

cemented

edges

of

headlining

from

flanged

portion

of

roof

rail

10

Disengage

listing

wires

from

roof

rail

and

detach

headlining

INSTALLATION

I

Apply

adhesive

cement

to

the

outer

surface

of

flange

and

headlining

attaching

surface

evenly

8F

18

2

Install

listing

wires

in

place

on

roof

rail

3

First

attach

front

headlining

to

the

flanged

portion

of

roof

rail

Secondly

attach

the

rear

edges

of

headlining

in

place

while

pulling

the

headlining

material

to

avoid

wrinkles

4

Attach

the

right

and

left

edges

of

headlining

material

to

the

flanged

por

tions

using

care

to

avoid

wrinkles

5

Cut

excess

headlining

material

ex

cept

for

that

at

the

upper

areas

of

front

center

and

rear

pillars

not

covered

by

body

side

welt

The

edges

of

headlining

ma

terial

at

these

areas

should

be

so

cut

that

it

can

be

folded

properly

in

place

6

Install

garnish

on

the

extreme

end

of

headlining

at

rear

pillar

7

Drill

a

hole

in

headlining

where

room

lamp

is

located

Install

room

lamp

8

Install

body

side

welts

9

Install

windshield

glass

10

Install

back

window

glass

11

Install

assist

rail

sun

visor

and

inside

rearview

mirror

BACK

TRIM

AND

BACK

INSIDE

FINISHER

DELUXE

CAB

REMOVAL

AND

INSTALLATION

Back

trim

I

Move

floor

carpet

aside

2

Remove

four

bolts

attaching

back

trim

to

floor

3

Remove

five

trim

clips

and

detach

back

trim

4

Installation

is

the

reverse

order

of

removal

Back

Inside

finisher

I

Remove

seat

belt

retractor

2

Remove

five

trim

clips

and

detach

back

inside

fmisher

3

Installation

is

the

reverse

order

of

removal

Page 447 of 537

DESCRIPTION

Cables

are

covered

with

color

coded

vinyl

for

easy

identification

In

the

wiring

diagram

colors

are

indicated

by

one

or

two

alphabetical

letters

It

is

recommended

that

the

battery

be

disconnected

before

performing

any

electrical

service

other

than

bulb

or

fuse

replacement

In

addition

to

fuses

a

fusible

link

has

been

installed

to

protect

wiring

The

fusible

link

functions

almost

the

same

as

a

fuse

though

its

eharac

teristics

are

slightly

different

than

normal

fuses

CABLE

COLORS

Cable

colors

are

indicated

by

one

or

two

alphabetical

letters

B

Black

Be

Brown

G

Green

L

Blue

Lg

Light

green

R

Red

W

White

Y

Yellow

The

main

cable

is

generally

coded

with

a

single

color

The

others

are

coded

with

a

two

tone

color

as

follows

BW

Black

with

white

stripe

gR

Light

green

with

red

stripe

INSPECTION

Inspect

all

electrical

circuits

refer

ring

to

wiring

or

circuit

diagrams

Circuits

should

be

tested

for

conti

nuity

or

short

circuit

with

a

conven

tional

test

lamp

or

low

reading

volt

meter

Before

inspection

of

circuit

ensure

that

I

Each

electrical

component

part

or

cable

is

securely

fastened

to

its

con

nector

or

terminal

2

Each

connection

is

firmly

in

place

and

free

from

rust

and

dirt

3

No

cable

covering

shows

any

evidence

of

cracks

deterioration

or

other

damage

4

Each

terminal

is

at

a

safe

distance

away

from

any

adjacent

metal

parts

5

Each

cable

is

fastened

to

its

proper

connector

or

terminal

Body

Electrical

System

BODY

ELECTRICAL

WIRING

6

Each

grounding

bolt

is

firmly

pbnted

7

Wiring

is

kept

away

from

any

adjacent

parts

with

sharp

edges

or

high

temperature

parts

such

as

exhaust

pipe

8

Wiring

is

kept

away

from

any

rotating

or

working

parts

fan

pulley

fan

belt

etc

9

Cables

between

ftxed

portions

and

moving

parts

are

long

enough

to

withstand

shocks

and

vibratory

forces

Notes

a

Before

starting

to

inspect

and

repair

any

part

of

electrical

system

or

other

parts

which

may

lead

to

a

short

circuit

disconnect

cables

at

battery

terminals

as

follows

Disconnect

cable

at

negative

terminal

and

then

disconnect

cable

at

positive

terminal

Before

connecting

cables

to

battery

terminal

be

sure

to

clean

terminals

with

a

rag

Fasten

cable

at

positive

terminal

and

then

ground

cable

at

negative

terminal

Apply

grease

to

top

of

these

terminals

to

prevent

rust

from

developing

on

them

b

Never

use

a

screwdriver

or

senrice

tool

to

conduct

a

continuity

test

Use

test

leads

c

Never

ground

an

open

circuit

or

circuits

under

no

load

Use

a

test

lamp

12V

3W

or

circuit

tester

as

a

load

FUSE

AND

FUSIBLE

LINK

DESCRIPTION

The

fuse

and

fusible

link

are

protec

tive

devices

used

in

an

electrical

cir

cuit

When

current

increases

beyond

rated

amperage

fusible

metal

melts

and

the

circuit

is

broken

BE

2

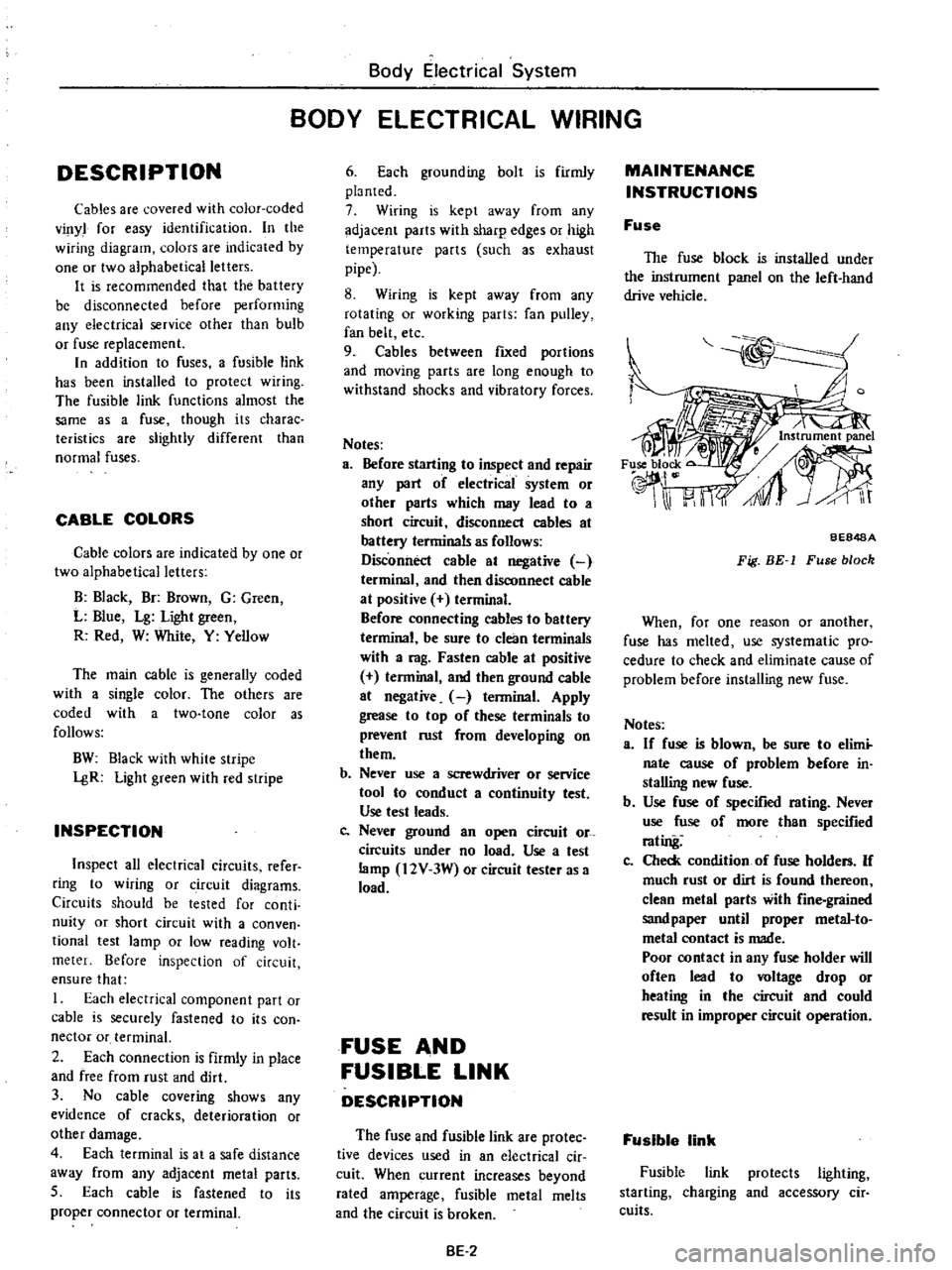

MAINTENANCE

INSTRUCTIONS

Fuse

The

fuse

block

is

installed

under

the

instrument

panel

on

the

left

hand

drive

vehicle

BE848A

Fig

BE

1

Fuse

block

When

for

one

reason

or

another

fuse

has

melted

use

systematic

pro

cedure

to

check

and

eliminate

cause

of

problem

before

installing

new

fuse

Notes

a

If

fuse

is

blown

be

sure

to

elimi

nate

cause

of

problem

before

in

stalling

new

fuse

b

Use

fuse

of

specified

rating

Never

use

fuse

of

more

than

specified

rating

Co

Check

condition

of

fuse

holders

If

much

rust

or

dirt

is

found

thereon

clean

metal

parts

with

fine

grained

sandpaper

until

proper

metal

to

metal

contact

is

made

Poor

contact

in

any

fuse

holder

will

often

lead

to

voltage

drop

or

heating

in

the

circuit

and

could

result

in

improper

circuit

operation

Fusible

link

Fusible

link

protects

lighting

starting

charging

and

accessory

cir

cuits

Page 461 of 537

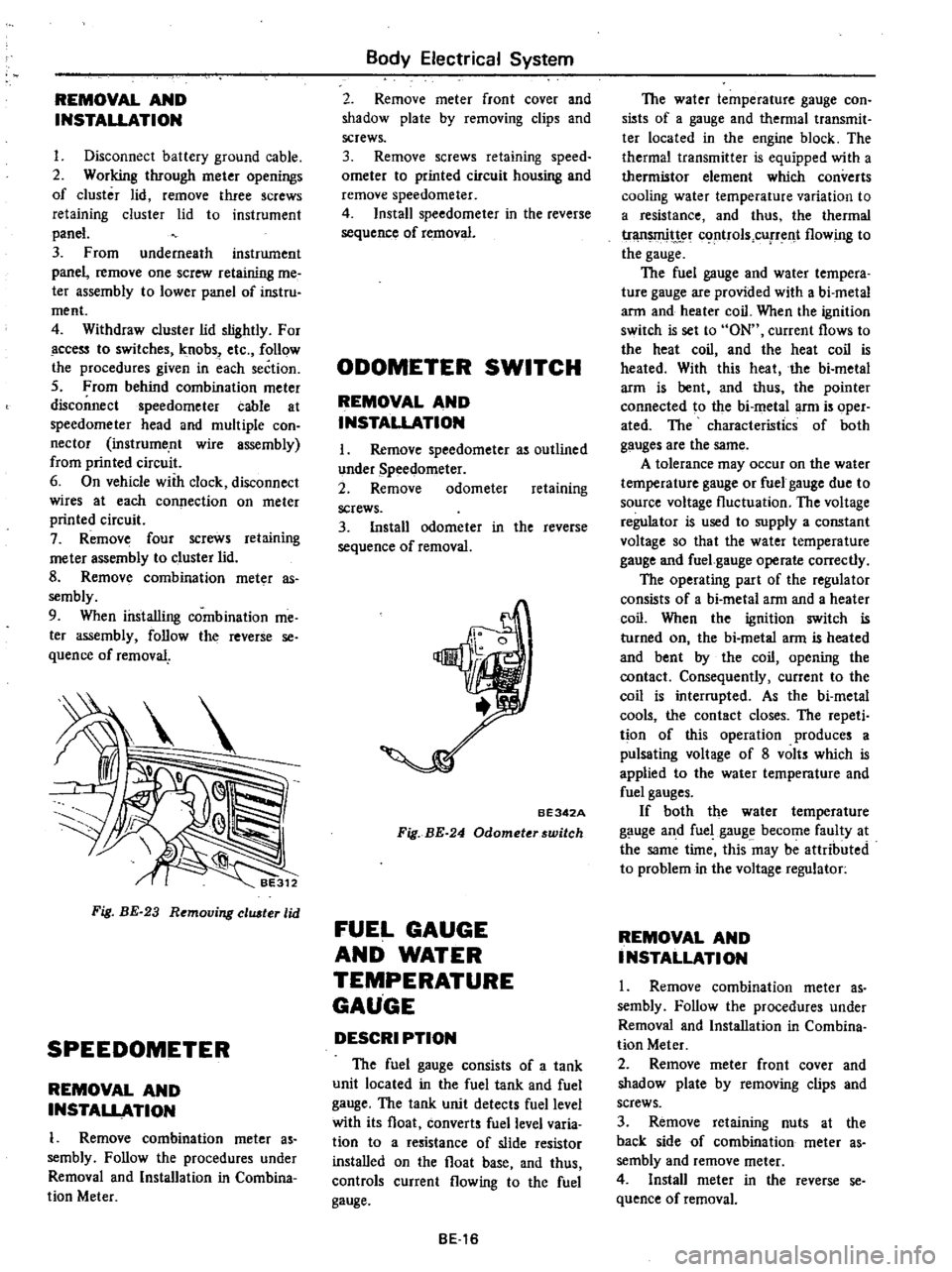

REMOVAL

AND

INSTALLATION

I

Disconnect

battery

ground

cable

2

Working

through

meter

openings

of

cluster

lid

remove

three

screws

retaining

cluster

lid

to

instrument

panel

3

From

underneath

instrument

panel

remove

one

screw

retaining

me

ter

assembly

to

lower

panel

of

instru

ment

4

Withdraw

cluster

lid

slightly

For

ccess

to

switches

knobs

etc

follow

the

procedures

given

in

each

section

5

From

behind

combination

meter

disconnect

speedometer

cable

at

speedometer

head

and

multiple

con

nector

instrume

nt

wire

assembly

from

printed

circuit

6

On

vehicle

with

clock

disconnect

wires

at

each

connection

on

meter

printed

circuit

7

Remove

four

screws

retaining

me

ter

assembly

to

cluster

lid

8

Remov

combination

meter

as

sembly

9

When

installing

combination

me

ter

assembly

follow

the

reverse

se

quence

of

removal

Fig

BE

23

Removing

eluster

lid

SPEEDOMETER

REMOVAL

AND

INSTALLATION

1

Remove

combination

meter

as

sembly

Follow

the

procedures

under

Removal

and

Installation

in

Combina

tion

Meter

Body

Electrical

System

2

Remove

meter

front

cover

and

shadow

plate

by

removing

clips

and

screws

3

Remove

screws

retaining

speed

ometer

to

printed

circuit

housing

and

remove

speedometer

4

Install

speedometer

in

the

reverse

sequence

of

removal

ODOMETER

SWITCH

REMOVAL

AND

INSTALLATION

I

Remove

speedometer

as

outlined

under

Speedometer

2

Remove

odometer

retaining

screws

3

Install

odometer

in

the

reverse

sequence

of

removal

BE342A

Fig

BE

24

Odometerswitch

FUEL

GAUGE

AND

WATER

TEMPERATURE

GAUGE

DESCRI

PTION

The

fuel

gauge

consists

of

a

tank

unit

located

in

the

fuel

tank

and

fuel

gauge

The

tank

unit

detects

fuel

level

with

its

float

converts

fuel

level

varia

tion

to

a

resistance

of

slide

resistor

installed

on

the

float

base

and

thus

controls

current

flowing

to

the

fuel

gauge

BE16

The

water

temperature

gauge

con

sists

of

a

gauge

and

thermal

transmit

ter

located

in

the

engine

block

The

thermal

transmitter

is

equipped

with

a

thermistor

element

which

converts

cooling

water

temperature

variation

to

a

resistance

and

thus

the

thermal

tr

t

c

rtrols

cUfTent

flowing

to

the

gauge

The

fuel

gauge

and

water

tempera

ture

gauge

are

provided

with

a

bi

metal

arm

and

heater

coil

When

the

ignition

switch

is

set

to

ON

current

flows

to

the

heat

coil

and

the

heat

coil

is

heated

With

this

heat

the

bi

metal

arm

is

bent

and

thus

the

pointer

connected

to

the

bi

metal

arm

is

oper

ated

The

characteristics

of

both

gauges

are

the

same

A

tolerance

may

occur

on

the

water

temperature

gauge

or

fuel

gauge

due

to

source

voltage

fluctuation

The

voltage

regulator

is

used

to

supply

a

constant

voltage

so

that

the

water

temperature

gauge

and

fuel

gauge

operate

correctly

The

operating

part

of

the

regulator

consists

of

a

bi

metal

arm

and

a

heater

coil

When

the

ignition

switch

is

turned

on

the

bi

metal

arm

is

heated

and

bent

by

the

coil

opening

the

contact

Consequently

current

to

the

coil

is

interrupted

As

the

bi

metal

cools

the

contact

closes

The

repeti

tion

of

this

operation

produces

a

pulsating

voltage

of

8

volts

which

is

applied

to

the

water

temperature

and

fuel

gauges

If

both

the

water

temperature

gauge

and

fuel

gauge

become

faulty

at

the

same

time

this

may

be

attributed

to

problem

in

the

voltage

regulator

REMOVAL

AND

INSTALLATION

1

Remove

combination

meter

as

sembly

Follow

the

procedures

under

Removal

and

Installation

in

Combina

tion

Meter

2

Remove

meter

front

cover

and

shadow

plate

by

removing

clips

and

screws

3

Remove

retaining

nuts

at

the

back

side

of

combination

meter

as

sembly

and

remove

meter

4

Install

meter

in

the

reverse

se

quence

of

removal

Page 464 of 537

Condition

Inaccurate

speedometer

indication

Inaccurate

odometer

operation

Body

Electrical

System

Probable

cause

Inoperative

speedometer

Improperly

meshed

second

and

third

gear

worn

gears

Faulty

feeding

due

to

deformed

odometer

and

pinion

carrier

WATER

TEMPERATURE

AND

FUEL

GAUGES

Condition

Both

water

temperature

gauge

and

fuel

gauge

do

not

operate

Both

water

temperature

gauge

and

fuel

gauge

indicate

inaccurately

Water

temperature

gauge

Water

temperature

gauge

does

not

operate

Gauge

indicates

only

maximum

temperature

Water

temperature

gauge

does

not

operate

accurately

Probable

cause

Burnt

fuse

Inoperative

gauge

voltage

regulator

Inoperative

gauge

voltage

regulator

Gauge

pointer

fluctuates

excessively

Loose

of

poor

connection

Gauge

pointer

fluctuates

slightly

Correct

conn

Faulty

thermal

transmitter

or

loose

terminal

connection

When

thermal

transmitter

yellow

white

wire

is

grounded

gauge

pointer

fluctuates

Faulty

water

temperature

gauge

Open

circuit

Faulty

thermal

transmitter

Gauge

pointer

returns

to

original

position

when

ignition

switch

is

turned

off

Faulty

water

temperature

gauge

Gauge

pointer

indicates

maximum

tempera

ture

even

after

ignition

switch

is

turned

off

Faulty

water

temperature

gauge

Faulty

thermal

transmitter

Loose

or

poor

connection

BE

19

Corrective

action

Replace

Replace

speedometer

Replace

speedometer

Corrective

action

Correct

cause

and

replace

fuse

Replace

water

temperature

gauge

Replace

water

temperature

gauge

Correct

connector

contact

Replace

thermal

transmitter

or

correct

terminal

connection

Replace

wtater

temperature

gauge

Replace

thermal

transmitter

Replace

water

temperature

gauge

Connect

a

usn

resistance

between

ther

mal

transmitter

yellow

white

wire

and

ground

When

gauge

indicates

approximately

500C

i220F

gauge

is

serviceable

Correct

gauge

terminal

contact

Page 468 of 537

Body

Electrical

System

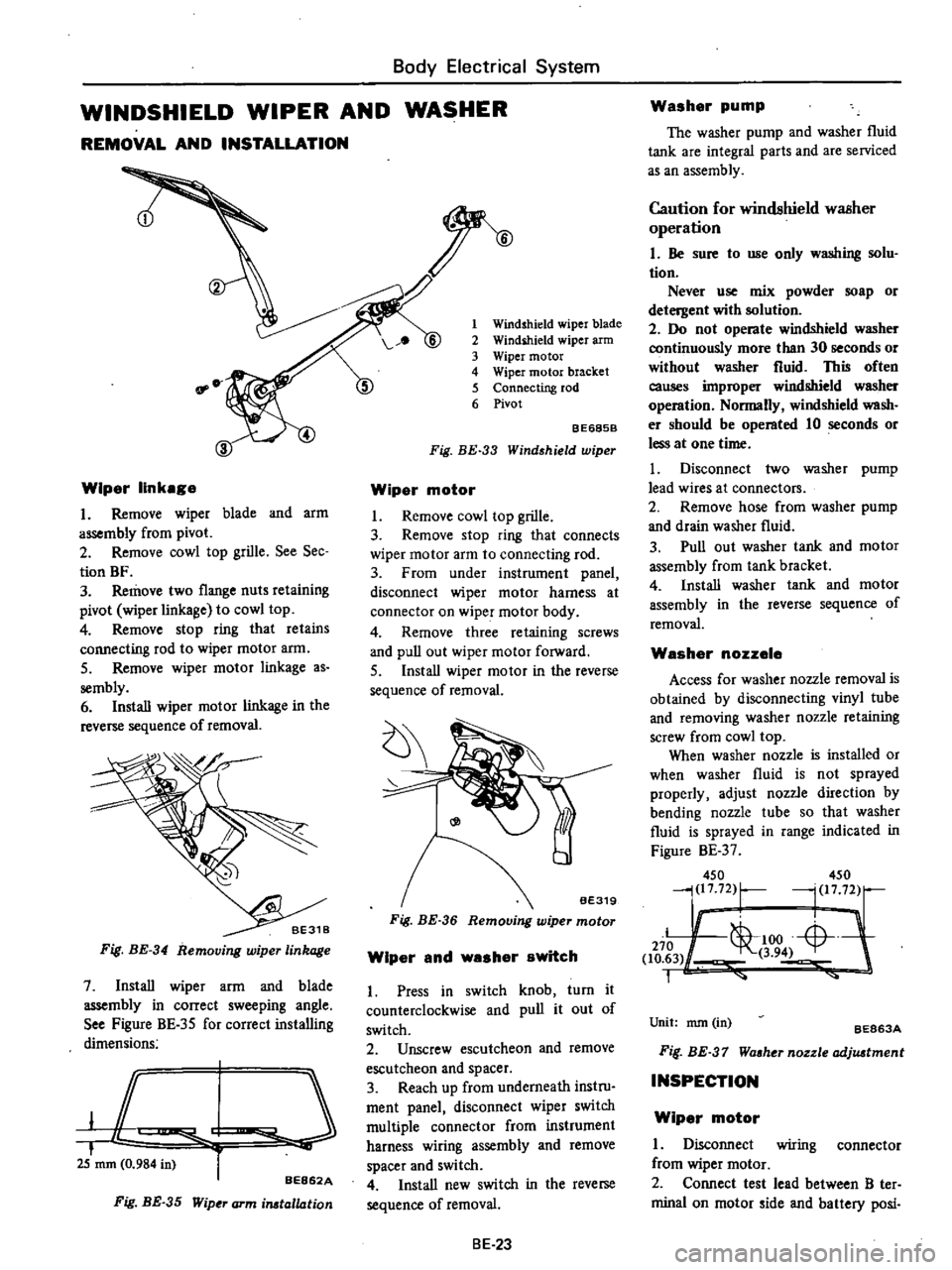

WINDSHIELD

WIPER

AND

WASHER

REMOVAL

AND

INSTALLATION

Wiper

linkage

I

Remove

wiper

blade

and

arm

assembly

from

pivot

2

Remove

cowl

top

grille

See

Sec

tion

BF

3

Remove

two

flange

nuts

retaining

pivot

wiper

linka

e

to

cowl

top

4

Remove

stop

ring

that

retains

connecting

rod

to

wiper

motor

arm

5

Remove

wiper

motor

linkage

as

sembly

6

Install

wiper

motor

linkage

in

the

reverse

sequence

of

removal

Fig

BE

34

Removing

wiper

linkage

7

Install

wiper

arm

and

blade

assembly

in

correct

sweeping

angle

See

Figure

BE

35

for

correct

installing

dimensions

JC

I

i

25

mm

0

984

in

r

BE862A

Fig

BE

35

Wip

J

arm

irutallation

1

Windshield

wiper

blade

2

Windihield

wiper

arm

3

Wiper

motor

4

Wiper

motor

bracket

5

Connecting

rod

6

Pivot

BE685B

Fig

BE

33

Wind

hield

wiper

Wiper

motor

I

Remove

cowl

top

grille

3

Remove

stop

ring

that

connects

wiper

motor

arm

to

connecting

rod

3

From

under

instrument

panel

disconnect

wiper

motor

harness

at

connector

on

wiper

motor

body

4

Remove

three

retaining

screws

and

pull

out

wiper

motor

forward

5

Install

wiper

motor

in

the

reverse

sequence

of

removal

Fig

BE

36

Wiper

and

washer

switch

1

Press

in

switch

knob

turn

it

counterclockwise

and

pull

it

out

of

switch

2

Unscrew

escutcheon

and

remove

escutcheon

and

spacer

3

Reach

up

from

underneath

instru

ment

panel

disconnect

wiper

switch

multiple

connector

from

instrument

harness

wiring

assembly

and

remove

spacer

and

switch

4

Install

new

switch

in

the

reverse

sequence

of

removal

BE

23

Washer

pump

The

washer

pump

and

washer

fluid

tank

are

integral

parts

and

are

serviced

as

an

assembly

Caution

for

windshield

waBher

operation

I

Be

sure

to

use

only

washing

solu

tion

Never

use

mix

powder

soap

or

detergent

with

solution

2

Do

not

operate

windshield

washer

continuously

more

than

30

seconds

or

without

washer

fluid

This

often

causes

improper

windshield

washer

operation

Normally

windshield

wash

er

should

be

operated

10

seconds

or

less

at

one

time

I

Disconnect

two

washer

pump

lead

wires

at

connectors

2

Remove

hose

from

washer

pump

and

drain

washer

fluid

3

Pull

out

washer

tank

and

motor

assembly

from

tank

bracket

4

Install

washer

tank

and

motor

assembly

in

the

reverse

sequence

of

removal

Washer

nozzele

Access

for

washer

nozzle

removal

is

obtained

by

disconnecting

vinyl

tube

and

removing

washer

nozzle

retaining

screw

from

cowl

top

When

washer

nozzle

is

installed

or

when

washer

fluid

is

not

sprayed

properly

adjust

nozzle

direction

by

bending

nozzle

tube

so

that

washer

fluid

is

sprayed

in

range

indicated

in

Figure

BE

37

450

450

j217

72

r

l

1772

Ii

L

1

00

Li

L

J

270

1

to

63

3

94

1

Unit

nun

in

BE863A

Fif

BE

37

Waaher

nozzle

adjuatment

INSPECTION

Wiper

motor

I

Disconnect

wiring

connector

from

wiper

motor

2

Connect

test

lead

between

B

ter

minal

on

motor

ide

and

battery

posi

Page 476 of 537

SEAT

BELT

WARNING

SYSTEM

DESCRIPTION

Except

Canada

When

the

ignition

switch

is

turned

to

the

ON

position

the

warning

lamp

comes

on

and

remains

on

for

4

to

8

seconds

The

warning

buzzer

sounds

for

4

to

8

seconds

intermittent

ly

if

the

driver

s

seat

belt

is

not

fastened

properly

The

seat

belt

warning

system

con

sists

of

a

driver

s

belt

switch

a

warning

buzzer

a

warning

lamp

a

timer

unit

and

an

ignition

switch

For

Canada

When

the

ignition

switch

is

turned

Body

Electrical

System

to

the

ON

position

the

warning

lamp

comes

on

and

the

warning

buz

zer

sounds

if

the

driver

s

seat

belt

is

not

fastened

properly

The

seat

belt

warning

system

con

sists

of

a

driver

s

belt

switch

a

warning

buzzer

a

warning

lamp

and

an

igni

tion

switch

REMOVAL

AND

INSTALLATION

Ignition

switch

Refer

to

page

BE

22

for

Removal

and

Installation

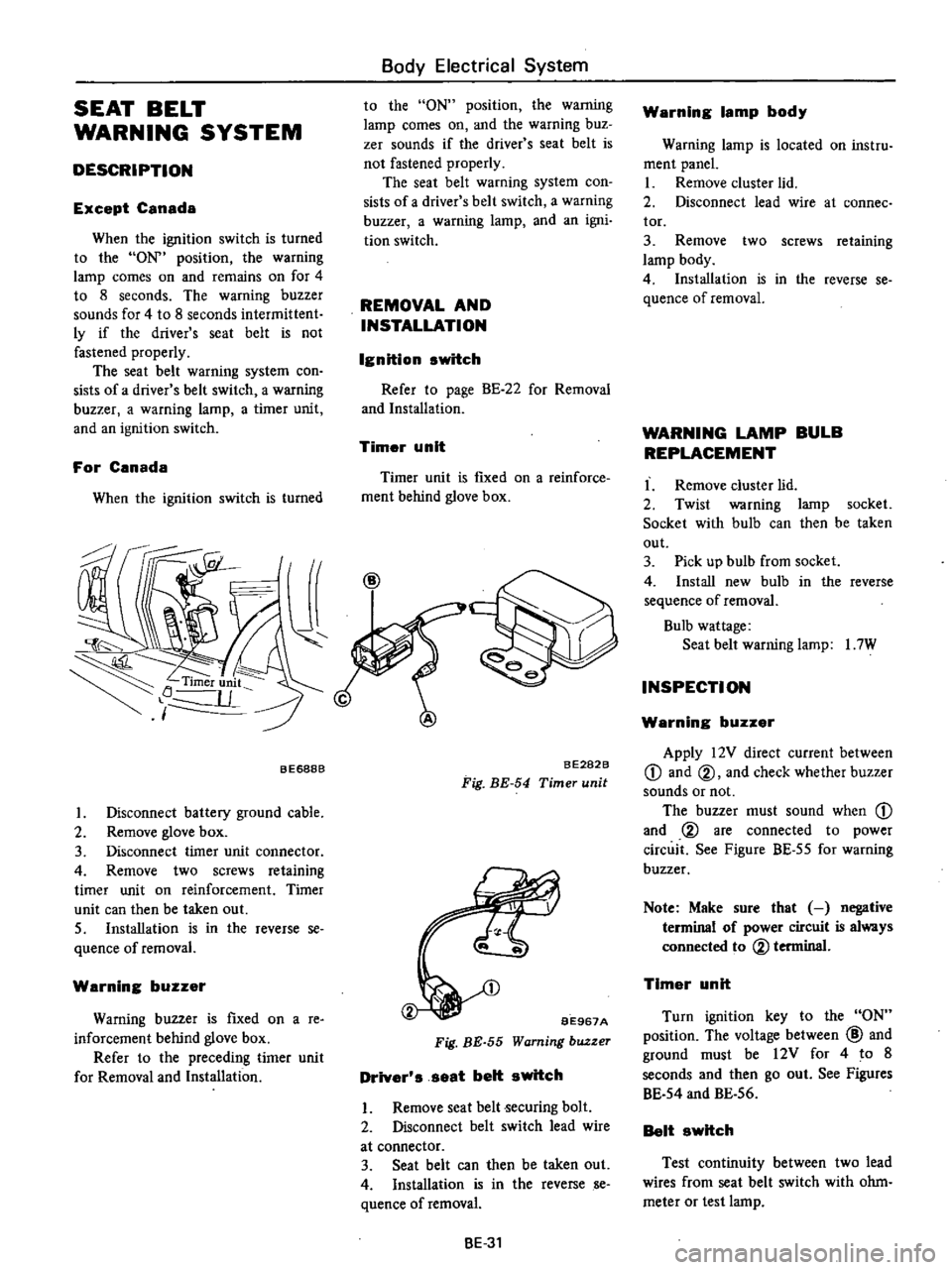

Timer

unit

Timer

unit

is

fIXed

on

a

reinforce

ment

behind

glove

box

BE688B

I

Disconnect

battery

ground

cable

2

Remove

glove

box

3

Disconnect

timer

unit

connector

4

Remove

two

screws

retaining

timer

unit

on

reinforcement

Timer

unit

can

then

be

taken

out

S

Installation

is

in

the

reverse

se

quence

of

removal

Warning

buzzer

Warning

buzzer

is

fIxed

on

a

re

inforcement

behind

glove

box

Refer

to

the

preceding

timer

unit

for

Removal

and

Installation

BE282B

Fig

BE

54

Timer

unit

BE967A

Fig

BE

55

Warning

buzzer

Driver

s

seat

belt

switch

I

Remove

seat

belt

ecuring

bolt

2

Disconnect

belt

switch

lead

wire

at

connector

3

Seat

belt

can

then

be

taken

out

4

Installation

is

in

the

reverse

se

quence

ofremoval

BE

31

Warning

lamp

body

Warning

lamp

is

located

on

instru

ment

panel

I

Remove

cluster

lid

2

Disconnect

lead

wire

at

connee

tor

3

Remove

two

screws

retaining

lamp

body

4

Installation

is

in

the

reverse

se

quence

of

removal

WARNING

LAMP

BULB

REPLACEMENT

I

Remove

cluster

lid

2

Twist

warning

lamp

socket

Socket

with

bulb

can

then

be

taken

out

3

Pick

up

bulb

from

socket

4

Install

new

bulb

in

the

reverse

sequence

of

removal

Bulb

wattage

Seat

belt

warning

lamp

I

7W

INSPECTION

Warning

buzzer

Apply

12V

direct

current

between

CD

and

@

and

check

whether

buzzer

sounds

or

not

The

buzzer

must

sound

when

CD

and

@

are

connected

to

power

circuit

See

Figure

BE

55

for

warning

buzzer

Note

Make

sure

that

negative

terminal

of

power

circuit

is

always

connected

to

@

terminal

Timer

unit

Turn

ignition

key

to

the

ON

position

The

voltage

between

@

and

ground

must

be

12V

for

4

to

8

seconds

and

then

go

out

See

Figures

BE

54

and

BE

56

Belt

switch

Test

continuity

between

two

lead

wires

from

seat

belt

switch

with

ohm

meter

or

test

lamp

Page 480 of 537

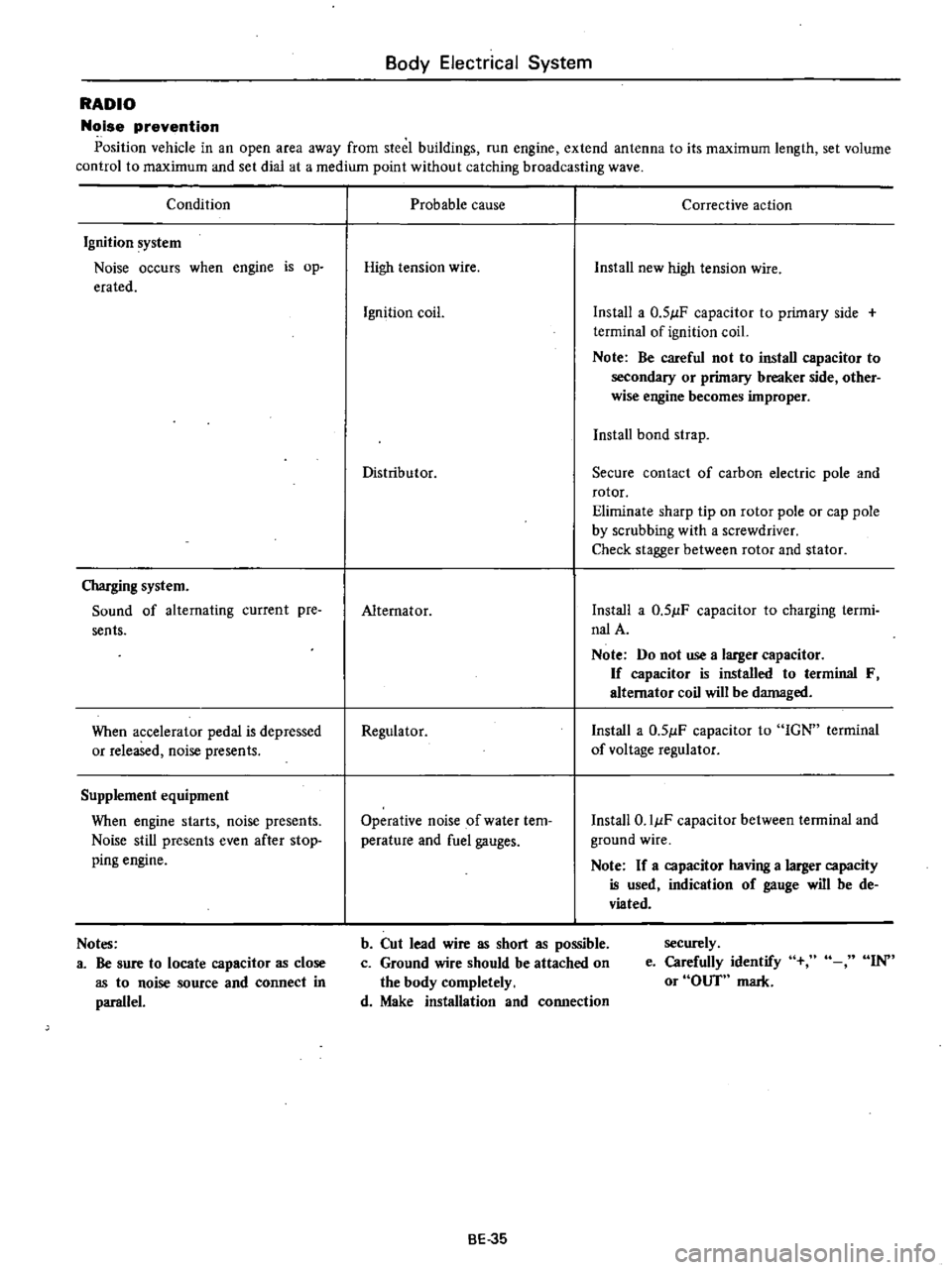

Body

Electrical

System

RADIO

Noise

prevention

Position

vehicle

in

an

open

area

away

from

steel

buildings

run

engine

extend

antenna

to

its

maximum

length

set

volume

control

to

maximum

and

set

dial

at

a

medium

point

without

catching

broadcasting

wave

Condition

Ignition

system

Noise

occurs

when

engine

is

op

erated

Charging

system

Sound

of

alternating

current

pre

sents

When

accelerator

pedal

is

depressed

or

released

noise

presents

Supplement

equipment

When

engine

starts

noise

presents

Noise

still

presents

even

after

stop

ping

engine

Notes

a

Be

sure

to

locate

capacitor

as

close

as

to

noise

source

and

connect

in

parallel

Probable

cause

Corrective

action

High

tension

wire

Install

new

high

tension

wire

Ignition

coil

Install

a

0

51lF

capacitor

to

primary

side

terminal

of

ignition

coil

Note

Be

careful

not

to

install

capacitor

to

secondary

or

primary

breaker

side

other

wise

engine

becomes

improper

Install

bond

strap

Distributor

Secure

contact

of

carbon

electric

pole

and

rotor

Eliminate

sharp

tip

on

rotor

pole

or

cap

pole

by

scrubbing

with

a

screwdriver

Check

stagger

between

rotor

and

stator

Alternator

Install

a

0

51lF

capacitor

to

charging

termi

nalA

Note

Do

not

use

a

larger

capacitor

If

capacitor

is

installed

to

terminal

F

alternator

coil

will

be

damaged

Regulator

Install

a

0

51lF

capacitor

to

IGN

terminal

of

voltage

regulator

Operative

noise

of

water

tem

perature

and

fuel

gauges

Install

O

IIlF

capacitor

between

terminal

and

ground

wire

Note

If

a

capacitor

having

a

larger

capacity

is

used

indication

of

gauge

will

be

de

viated

b

Cut

lead

wire

as

short

as

possible

c

Ground

wire

should

be

attached

on

the

body

completely

d

Make

installation

and

connection

securely

e

Carefully

identify

or

OUT

mark

IN

BE

35