heater DATSUN PICK-UP 1977 User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 428 of 537

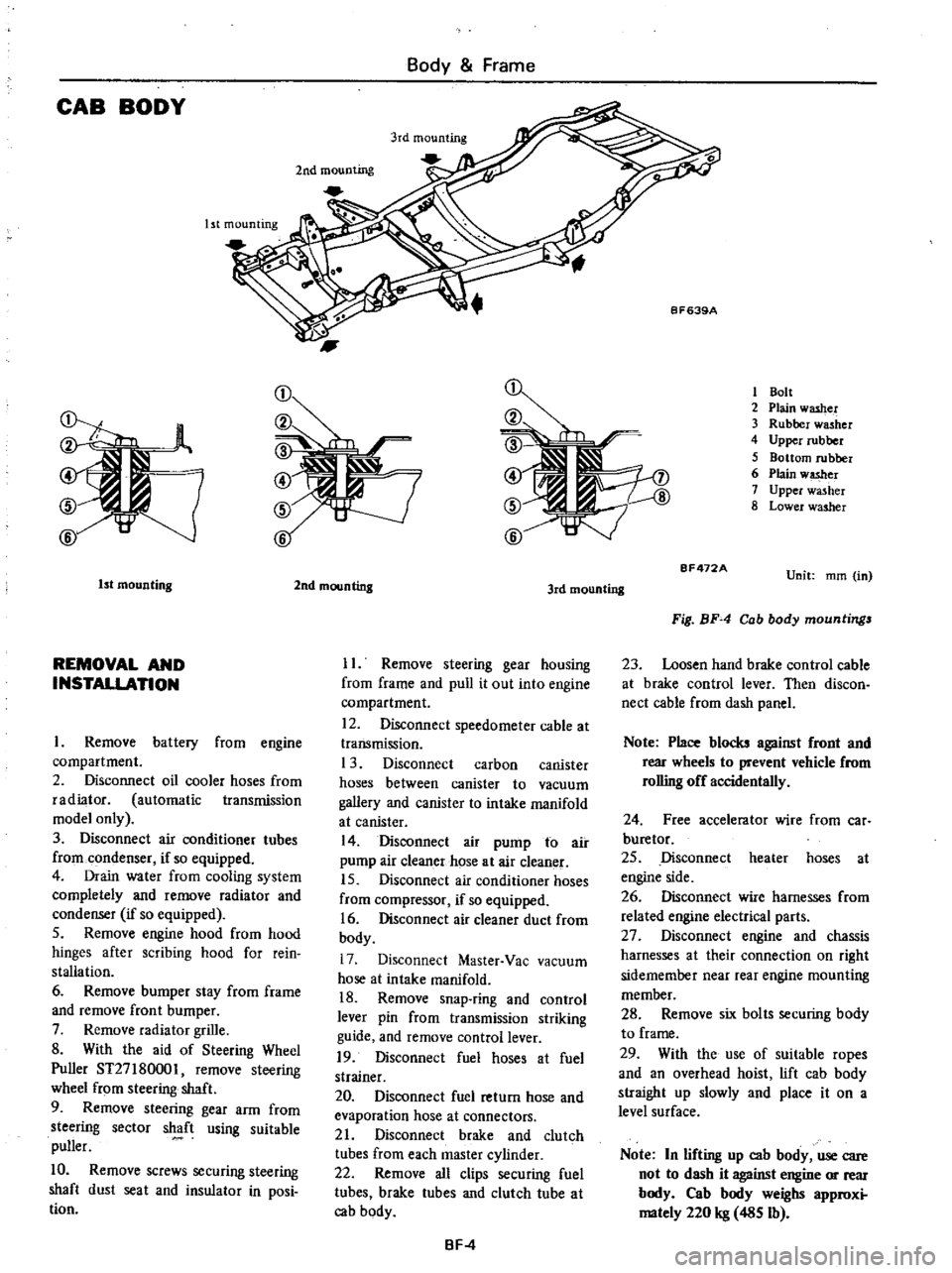

CAB

BODY

Body

Frame

Ist

mounting

2nd

mounting

1

Bolt

2

Plain

washer

3

Rubber

washer

4

Upper

rubber

5

Bottom

rubber

6

Plain

w

er

7

Upper

washer

8

Lower

washer

1st

mounting

REMOVAL

AND

INSTALLATION

Remove

battery

from

engine

compartment

2

Disconnect

oil

cooler

hoses

from

radiator

automatic

transmission

model

only

3

Disconnect

air

conditioner

tubes

from

condenser

if

so

equipped

4

Drain

water

from

cooling

system

completely

and

remove

radiator

and

condenser

if

so

equipped

5

Remove

engine

hood

from

hood

hinges

after

scribing

hood

for

rein

stallation

6

Remove

bumper

stay

from

frame

and

remove

front

bumper

7

Remove

radiator

grille

8

With

the

aid

of

Steering

Wheel

Puller

ST27

180001

remove

steering

wheel

from

steering

shaft

9

Remove

steering

gear

arm

from

steering

sector

shaft

using

suitable

puller

10

Remove

screws

securing

steering

shaft

dust

seat

and

insulator

in

posi

tion

2nd

mounting

3rd

mounting

II

Remove

steering

gear

housing

from

frame

and

pull

it

out

into

engine

compartment

12

Disconnect

speedometer

cable

at

transmission

1

3

Disconnect

carbon

canister

hoses

between

canister

to

vacuum

gallery

and

canister

to

intake

manifold

at

canister

14

Disconnect

air

pump

to

air

pump

air

cleaner

hose

at

air

cleaner

15

Disconnect

air

conditioner

hoses

from

compressor

if

so

equipped

16

Disconnect

air

cleaner

duct

from

body

17

Disconnect

Master

Vac

vacuum

hose

at

intake

manifold

18

Remove

snap

ring

and

control

lever

pin

from

transmission

striking

guide

and

remove

control

lever

19

Disconnect

fuel

hoses

at

fuel

strainer

20

Disconnect

fuel

return

hose

and

evaporation

hose

at

connectors

21

Disconnect

brake

and

clutch

tubes

from

each

master

cylinder

22

Remove

all

clips

securing

fuel

tubes

brake

tubes

and

clutch

tube

at

cab

body

BF

4

BF472A

Unit

mm

in

Fig

BF

4

Cab

body

mountings

23

Loosen

hand

brake

control

cable

at

brake

control

lever

Then

discon

nect

cable

from

dash

panel

Note

Place

blocks

against

front

and

rear

wheels

to

prevent

vehicle

from

rolling

off

accidentally

24

Free

accelerator

wire

from

car

buretor

25

Disconnect

heater

hoses

at

engine

side

26

Disconnect

wire

harnesses

from

related

engine

electrical

parts

27

Disconnect

engine

and

chassis

harnesses

at

their

connection

on

right

sidemember

near

rear

engine

mounting

member

28

Remove

six

bolts

securing

body

to

frame

29

With

the

use

of

suitable

ropes

and

an

overhead

hoist

lift

cab

body

straight

up

slowly

and

place

it

on

a

level

surface

Note

In

lifting

up

cab

body

use

care

not

to

dash

it

against

engine

or

rear

body

Cab

body

weighs

approxi

mately

220

kg

485

Ib

Page 441 of 537

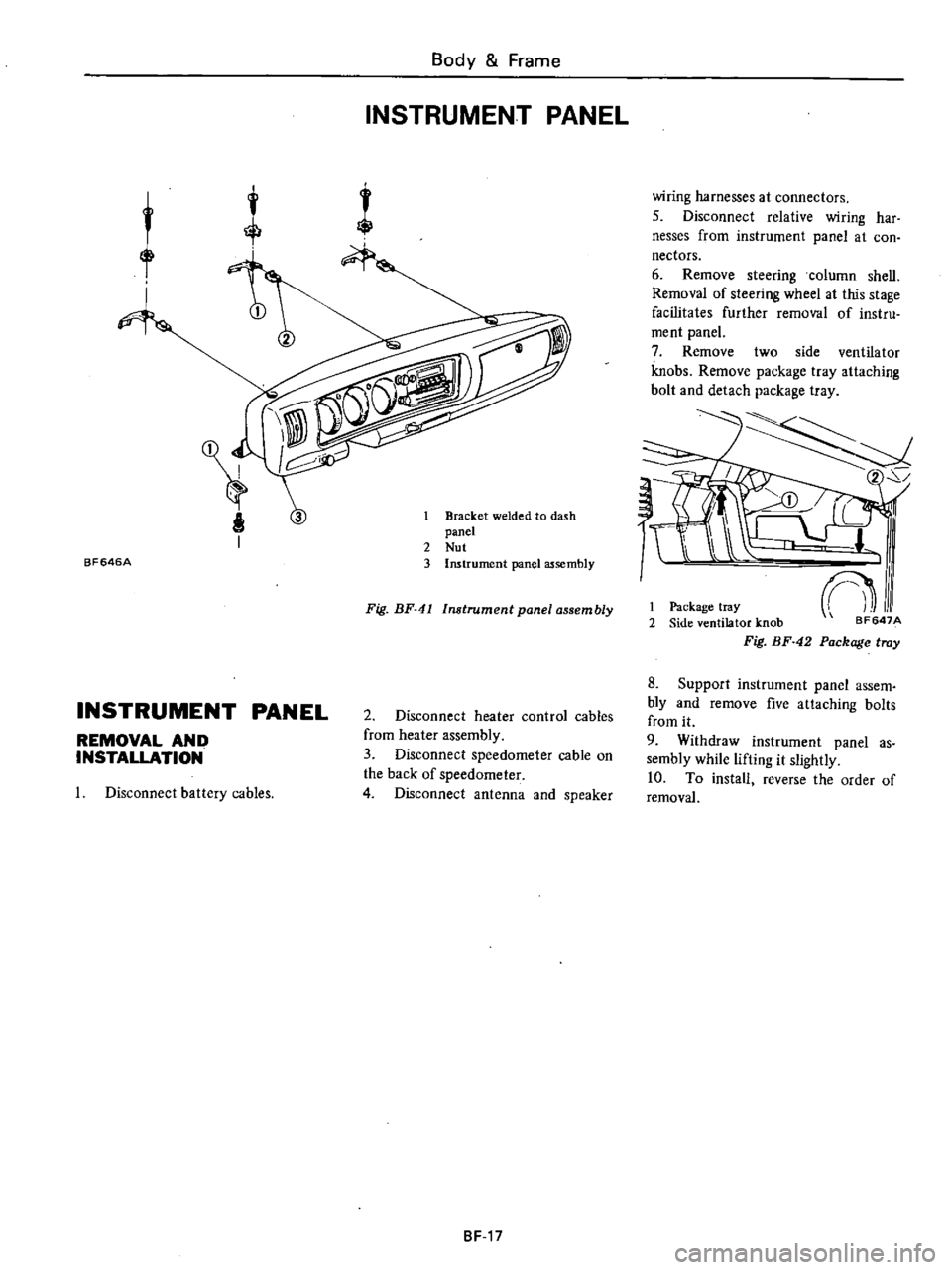

BF646A

Body

Frame

INSTRUMENT

PANEL

1

Bracket

welded

to

dash

panel

2

Nut

3

Instrument

panel

assembly

Fig

BF

41

Instrument

panel

assembly

INSTRUMENT

PANEL

REMOVAL

AND

INSTALLATION

2

Disconnect

heater

control

cables

from

heater

assembly

3

Disconnect

speedometer

cable

on

the

back

of

speedometer

4

Disconnect

antenna

and

speaker

Disconnect

battery

cables

8F

17

wiring

harnesses

at

connectors

5

Disconnect

relative

wiring

har

nesses

from

instrument

panel

at

con

nectors

6

Remove

steering

column

shell

Removal

of

steering

wheel

at

this

stage

facilitates

further

removal

of

instru

ment

panel

7

Remove

two

side

ventilator

knobs

Remove

package

tray

attaching

bolt

and

detach

package

tray

2

I

Package

tray

2

Side

ventilator

knob

Fig

BF

42

Package

tray

8

Support

instrument

panel

assem

bly

and

remove

five

attaching

bolts

from

it

9

Withdraw

instrument

panel

as

sembly

while

lifting

it

slightly

10

To

install

reverse

the

order

of

removal

Page 454 of 537

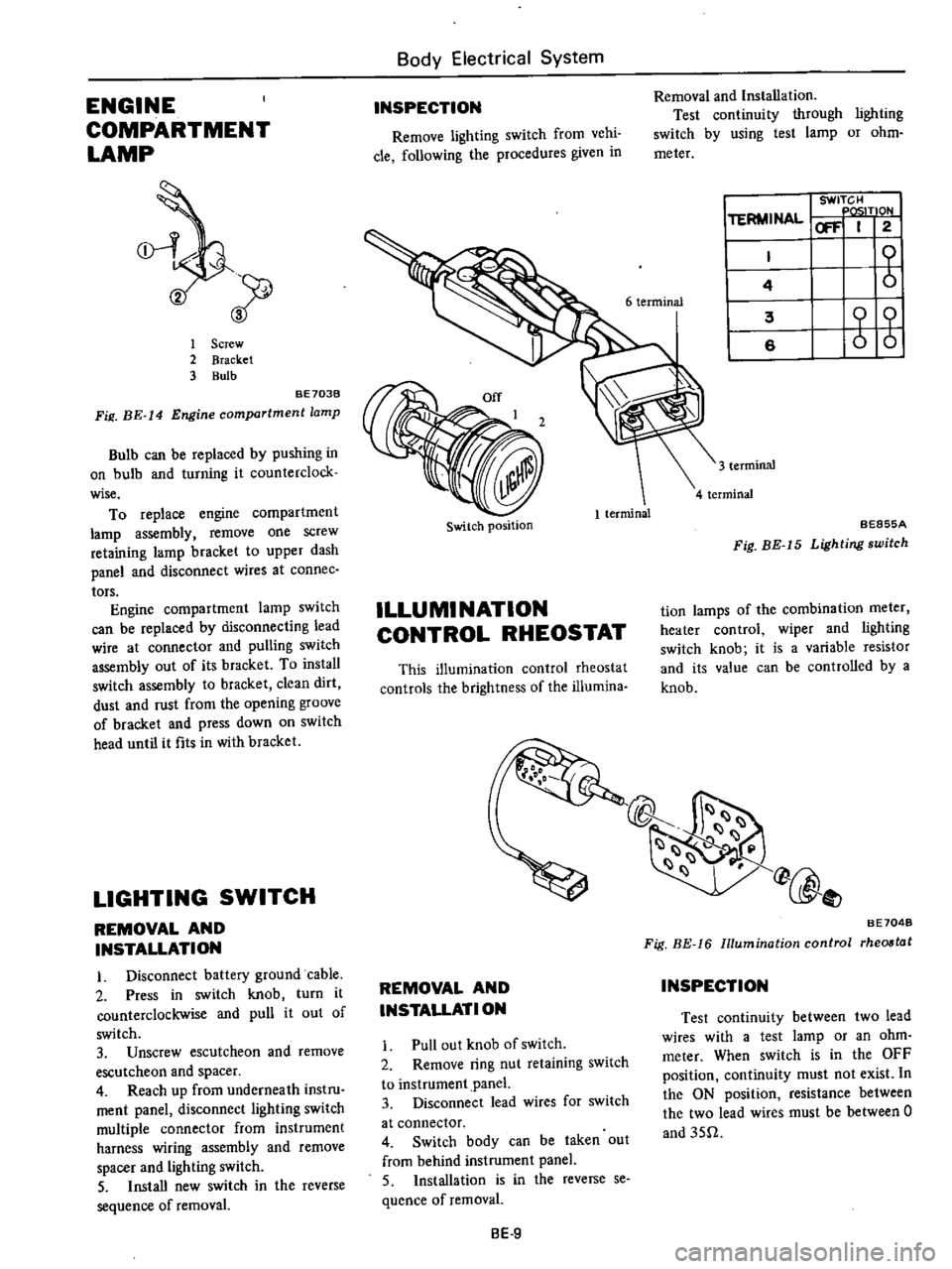

ENGINE

COMPARTMENT

LAMP

2

1

Screw

2

Bracket

3

Bulb

BE

7038

Fill

BE

14

Engine

compartment

lamp

Bulb

can

be

replaced

by

pushing

in

on

bulb

and

turning

it

counterclock

wise

To

replace

engine

compartment

lamp

assembly

remove

one

SCrew

retaining

lamp

bracket

to

upper

dash

panel

and

disconnect

wires

at

connee

tors

Engine

compartment

lamp

switch

can

be

replaced

by

disconnecting

lead

wire

at

connector

and

pulling

switch

assembly

out

of

its

bracket

To

install

switch

assembly

to

bracket

clean

dirt

dust

and

rust

from

the

opening

groove

of

bracket

and

press

down

on

switch

head

until

it

fits

in

with

bracket

LIGHTING

SWITCH

REMOVAL

AND

INSTALLATION

I

Disconnect

battery

ground

cable

2

Press

in

switch

knob

turn

it

counterclockwise

and

pull

it

out

of

switch

3

Unscrew

escutcheon

and

remove

escutcheon

and

spacer

4

Reach

up

from

underneath

instru

ment

panel

disconnect

lighting

switch

multiple

connector

from

instrument

harness

wiring

assembly

and

remove

spacer

and

lighting

switch

5

Install

new

switch

in

the

reverse

sequence

of

removal

Body

Electrical

System

INSPECTION

Remove

lighting

switch

from

vehi

cle

following

the

procedures

given

in

Switch

position

1

terminal

ILLUMINATION

CONTROL

RHEOSTAT

This

illumination

control

rheostat

controls

the

brightness

of

the

iliumina

Removal

and

Installation

Test

continuity

through

lighting

switch

by

using

test

lamp

or

ohm

meter

I

I

SWITCH

TERMINAL

P

T10N

ICI

F

2

I

I

b

I

4

I

I

6

terminal

I

3

I

6

3

terminal

4

terminal

BE855A

Fig

BE

15

Lighting

switch

tion

lamps

of

the

combination

meter

heater

control

wiper

and

lighting

switch

knob

it

is

a

variable

resistor

and

its

value

can

be

controlled

by

a

knob

REMOVAL

AND

INSTALLATION

I

Pull

out

knob

of

switch

2

Remove

ring

nut

retaining

switch

to

instrument

panel

3

Disconnect

lead

wires

for

switch

at

connector

4

Switch

body

can

be

taken

out

from

behind

instrument

panel

5

Installation

is

in

the

reverse

se

quence

of

removal

BE

9

0@

BE

7048

Fig

BE

16

Illumination

control

rhe08tat

INSPECTION

Test

continuity

between

two

lead

wires

with

a

test

lamp

or

an

ohm

meter

When

switch

is

in

the

OFF

position

continuity

must

not

exist

In

the

ON

position

resistance

between

the

two

lead

wires

must

be

between

0

and

3512

Page 457 of 537

Body

Electrical

System

BULB

SPECIFICATIONS

Item

Wattage

Candlepower

Headlamp

Inner

Outer

37

5W

37

5

S0W

Front

combination

lamp

Turn

signal

and

parking

lamp

23

8W

32

3C

Side

marker

lamp

Front

Rear

8W

4C

8W

4C

Rear

combination

lamp

Turn

signal

lamp

A

B

Tail

lamp

B

C

Stop

lamp

A

B

Back

up

lamp

D

A

23W

32C

B

23j8W

32j3C

C

8W

4C

D

23W

32C

7

SW

6C

License

plate

lamp

Engine

compartment

lamp

6W

Room

lamp

5W

Combination

meter

illurnina

tion

17W

iC

x3

Knob

illumination

lamp

3

4W

2C

Heater

control

illumination

lamp

3

4W

2C

TROUBLEDIAGNOSE

AND

CORRECTIONS

HEADLAMP

Condition

Headlarnps

do

not

light

for

both

high

and

low

beams

High

beam

cannot

be

switched

to

low

beam

or

vice

versa

Probable

cause

Burnt

fuse

Loose

connection

or

open

circuit

Faulty

lighting

switch

Faulty

dimmer

switch

Faulty

light

relay

No

ground

Faulty

dimmer

switch

Faulty

light

relay

BE12

Bulb

SAE

trade

number

4001

4002

1034

67

67

1073

1034

67

1073

89

161

158

158

Corrective

action

Correct

cause

and

replace

fuse

Check

wiring

and

or

repair

connection

Conduct

continuity

test

and

replace

if

neces

sary

Check

light

relay

for

proper

operation

and

replace

if

necessary

Clean

and

tighten

ground

terminal

Conduct

continuity

test

and

replace

if

neces

sary

Check

light

relay

for

proper

operation

and

replace

if

necessary

Page 461 of 537

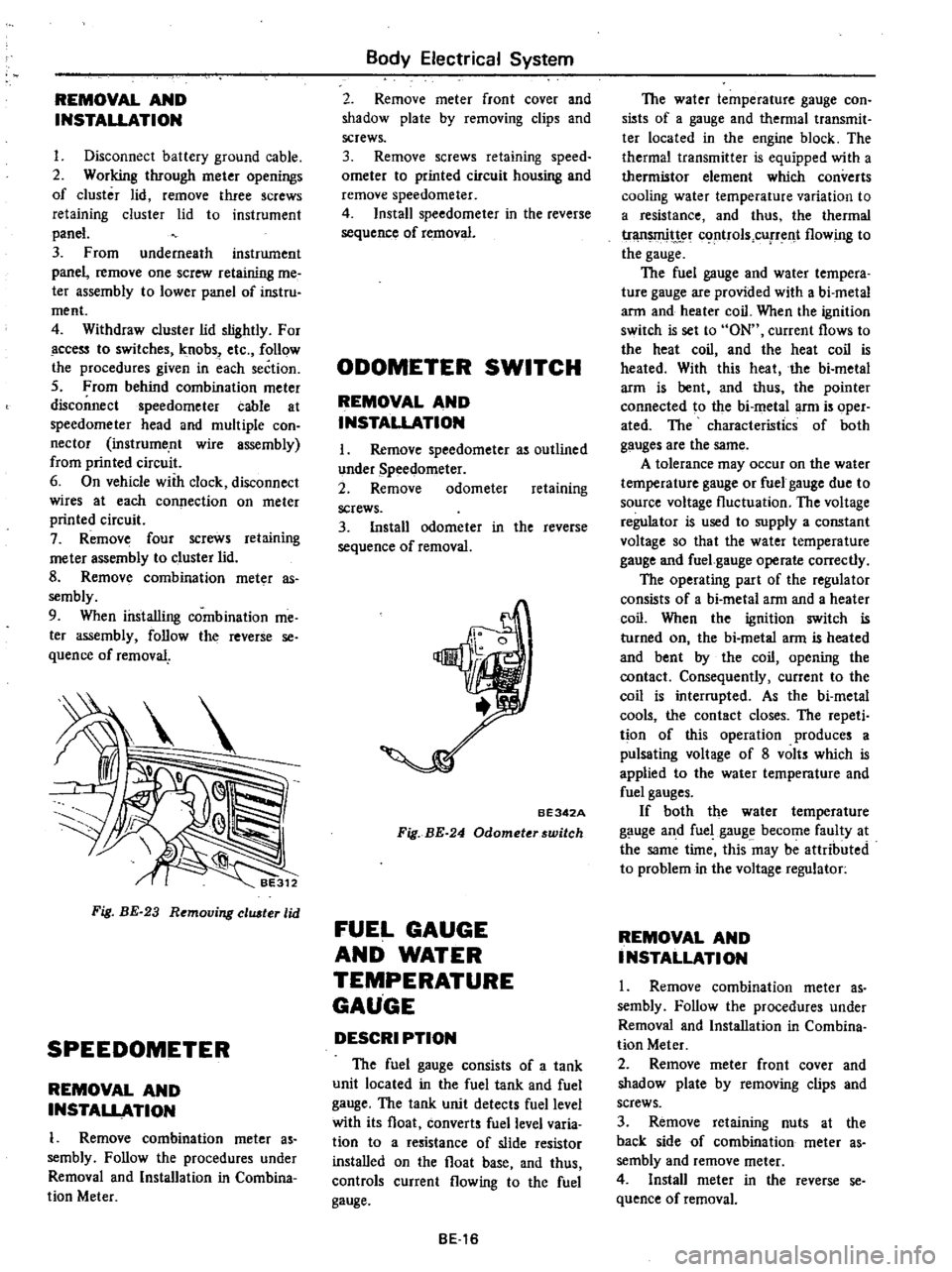

REMOVAL

AND

INSTALLATION

I

Disconnect

battery

ground

cable

2

Working

through

meter

openings

of

cluster

lid

remove

three

screws

retaining

cluster

lid

to

instrument

panel

3

From

underneath

instrument

panel

remove

one

screw

retaining

me

ter

assembly

to

lower

panel

of

instru

ment

4

Withdraw

cluster

lid

slightly

For

ccess

to

switches

knobs

etc

follow

the

procedures

given

in

each

section

5

From

behind

combination

meter

disconnect

speedometer

cable

at

speedometer

head

and

multiple

con

nector

instrume

nt

wire

assembly

from

printed

circuit

6

On

vehicle

with

clock

disconnect

wires

at

each

connection

on

meter

printed

circuit

7

Remove

four

screws

retaining

me

ter

assembly

to

cluster

lid

8

Remov

combination

meter

as

sembly

9

When

installing

combination

me

ter

assembly

follow

the

reverse

se

quence

of

removal

Fig

BE

23

Removing

eluster

lid

SPEEDOMETER

REMOVAL

AND

INSTALLATION

1

Remove

combination

meter

as

sembly

Follow

the

procedures

under

Removal

and

Installation

in

Combina

tion

Meter

Body

Electrical

System

2

Remove

meter

front

cover

and

shadow

plate

by

removing

clips

and

screws

3

Remove

screws

retaining

speed

ometer

to

printed

circuit

housing

and

remove

speedometer

4

Install

speedometer

in

the

reverse

sequence

of

removal

ODOMETER

SWITCH

REMOVAL

AND

INSTALLATION

I

Remove

speedometer

as

outlined

under

Speedometer

2

Remove

odometer

retaining

screws

3

Install

odometer

in

the

reverse

sequence

of

removal

BE342A

Fig

BE

24

Odometerswitch

FUEL

GAUGE

AND

WATER

TEMPERATURE

GAUGE

DESCRI

PTION

The

fuel

gauge

consists

of

a

tank

unit

located

in

the

fuel

tank

and

fuel

gauge

The

tank

unit

detects

fuel

level

with

its

float

converts

fuel

level

varia

tion

to

a

resistance

of

slide

resistor

installed

on

the

float

base

and

thus

controls

current

flowing

to

the

fuel

gauge

BE16

The

water

temperature

gauge

con

sists

of

a

gauge

and

thermal

transmit

ter

located

in

the

engine

block

The

thermal

transmitter

is

equipped

with

a

thermistor

element

which

converts

cooling

water

temperature

variation

to

a

resistance

and

thus

the

thermal

tr

t

c

rtrols

cUfTent

flowing

to

the

gauge

The

fuel

gauge

and

water

tempera

ture

gauge

are

provided

with

a

bi

metal

arm

and

heater

coil

When

the

ignition

switch

is

set

to

ON

current

flows

to

the

heat

coil

and

the

heat

coil

is

heated

With

this

heat

the

bi

metal

arm

is

bent

and

thus

the

pointer

connected

to

the

bi

metal

arm

is

oper

ated

The

characteristics

of

both

gauges

are

the

same

A

tolerance

may

occur

on

the

water

temperature

gauge

or

fuel

gauge

due

to

source

voltage

fluctuation

The

voltage

regulator

is

used

to

supply

a

constant

voltage

so

that

the

water

temperature

gauge

and

fuel

gauge

operate

correctly

The

operating

part

of

the

regulator

consists

of

a

bi

metal

arm

and

a

heater

coil

When

the

ignition

switch

is

turned

on

the

bi

metal

arm

is

heated

and

bent

by

the

coil

opening

the

contact

Consequently

current

to

the

coil

is

interrupted

As

the

bi

metal

cools

the

contact

closes

The

repeti

tion

of

this

operation

produces

a

pulsating

voltage

of

8

volts

which

is

applied

to

the

water

temperature

and

fuel

gauges

If

both

the

water

temperature

gauge

and

fuel

gauge

become

faulty

at

the

same

time

this

may

be

attributed

to

problem

in

the

voltage

regulator

REMOVAL

AND

INSTALLATION

1

Remove

combination

meter

as

sembly

Follow

the

procedures

under

Removal

and

Installation

in

Combina

tion

Meter

2

Remove

meter

front

cover

and

shadow

plate

by

removing

clips

and

screws

3

Remove

retaining

nuts

at

the

back

side

of

combination

meter

as

sembly

and

remove

meter

4

Install

meter

in

the

reverse

se

quence

of

removal

Page 466 of 537

Body

Electrical

System

ELECTRICAL

ACCESSORIES

CONTENTS

HORN

DESCRIPTION

REMOVAL

AND

INSTALLATION

IGNITION

SWITCH

REMOVAL

AND

INSTALLATION

INSPECTION

WINDSHIELD

WIPER

AND

WASHER

REMOVAL

AND

INSTALLATION

INSPECTION

RADIO

REMOVAL

AND

INSTALLATION

ADJUSTMENT

CLOCK

REMOVAL

I

NST

ALLA

TION

HEATER

DESCRIPTION

AIRFLOW

HEATER

UNIT

ASSEMBLY

BE

21

BE

21

BE

21

8E

n

BE

22

BE

22

BE

23

BE

23

BE

23

BE

25

BE

25

BE

25

BE

25

BE

25

BE

26

BE

26

BE

26

BE

28

BE

29

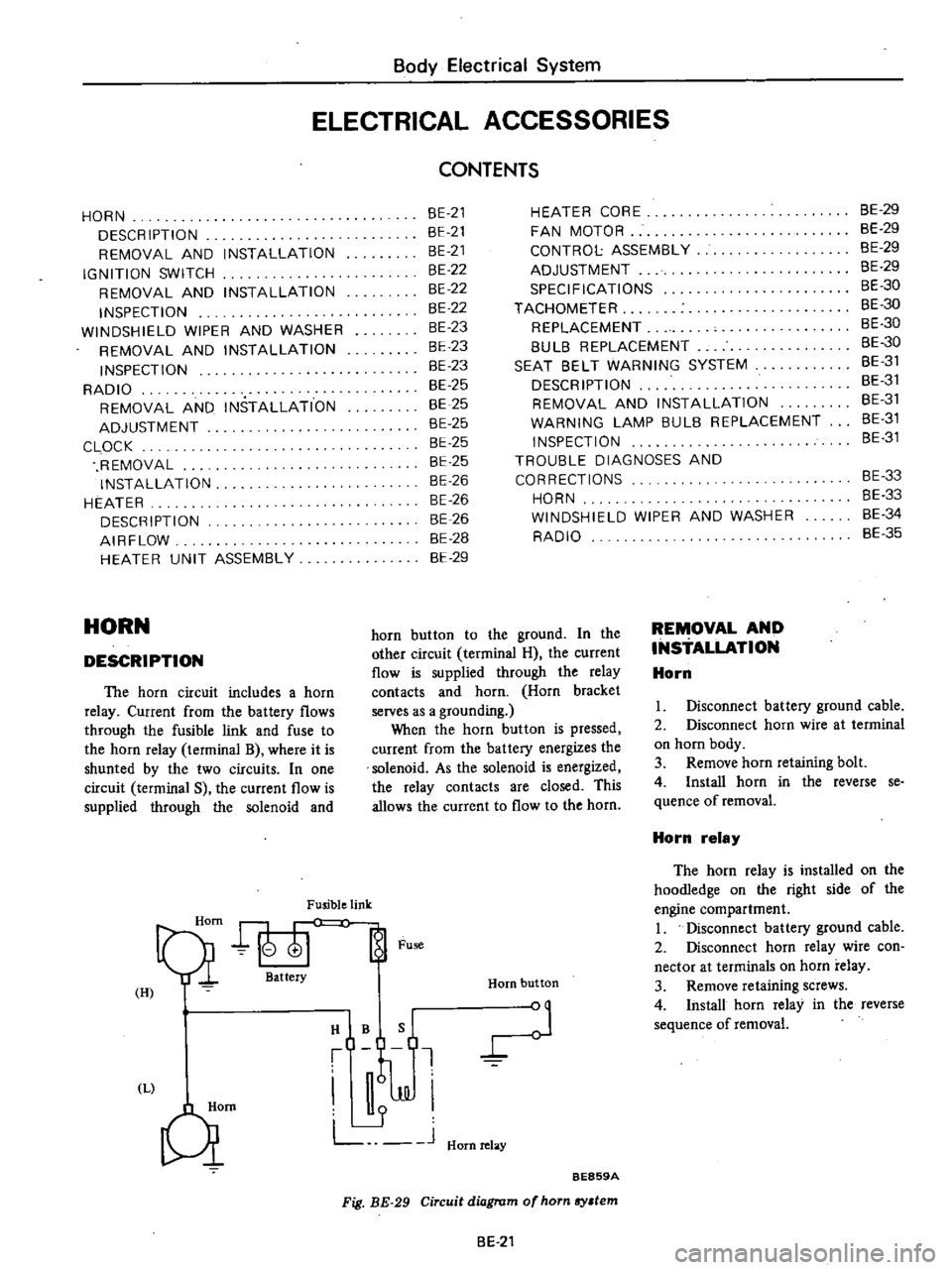

HORN

DESCRIPTION

The

horn

circuit

includes

a

horn

relay

Current

from

the

battery

flows

through

the

fusible

link

and

fuse

to

the

horn

relay

terminal

B

where

it

is

shunted

by

the

two

circuits

In

one

circuit

terminal

S

the

current

flow

is

supplied

through

the

solenoid

and

Fusible

link

Qi

att

Fu

H

I

HIBQ

t

J

JJI

L

J

Hornrelay

Qm

HEATER

CORE

FAN

MOTOR

CONTROL

ASSEMBLY

ADJUSTMENT

SPECIFICATIONS

TACHOMETER

REPLACEMENT

8UL8

REPLACEMENT

SEAT

8ELT

WARNING

SYSTEM

DESCRIPTION

REMOVAL

AND

INSTALLATION

WARNING

LAMP

BULB

REPLACEMENT

INSPECTION

TROUBLE

DIAGNOSES

AND

CORRECTIONS

HORN

WINDSHIELD

WIPER

AND

WASHER

RADIO

Horn

button

BE859A

Fig

BE

29

Circuit

diagram

of

horn

sy

tem

horn

button

to

the

ground

In

the

other

circuit

terminal

H

the

current

flow

is

supplied

through

the

relay

contacts

and

horn

Horn

bracket

serves

as

a

grounding

When

the

horn

button

is

pressed

current

from

the

battery

energizes

the

solenoid

As

the

solenoid

is

energized

the

relay

contacts

are

closed

This

allows

the

current

to

flow

to

the

horn

BE

21

REMOVAL

AND

INSTALLATION

Horn

8E

29

BE

29

BE

29

8E

29

BE

30

BE

30

BE

30

8E

30

8E

31

BE

31

BE

31

8E

31

8E

31

BE

33

8E

33

8E

34

BE

35

I

Disconnect

battery

ground

cable

2

Disconnect

horn

wire

at

terminal

on

horn

body

3

Remove

horn

retaining

bolt

4

Install

horn

in

the

reverse

se

quence

of

removal

Horn

relay

The

horn

relay

is

installed

on

the

hoodIedge

on

the

right

side

of

the

engine

compartment

I

Disconnect

battery

ground

cable

2

Disconnect

horn

relay

wire

con

nector

at

terminals

on

horn

relay

3

Remove

retaining

screws

4

Install

horn

relay

in

the

reverse

sequence

of

removal

Page 467 of 537

Body

Electrical

System

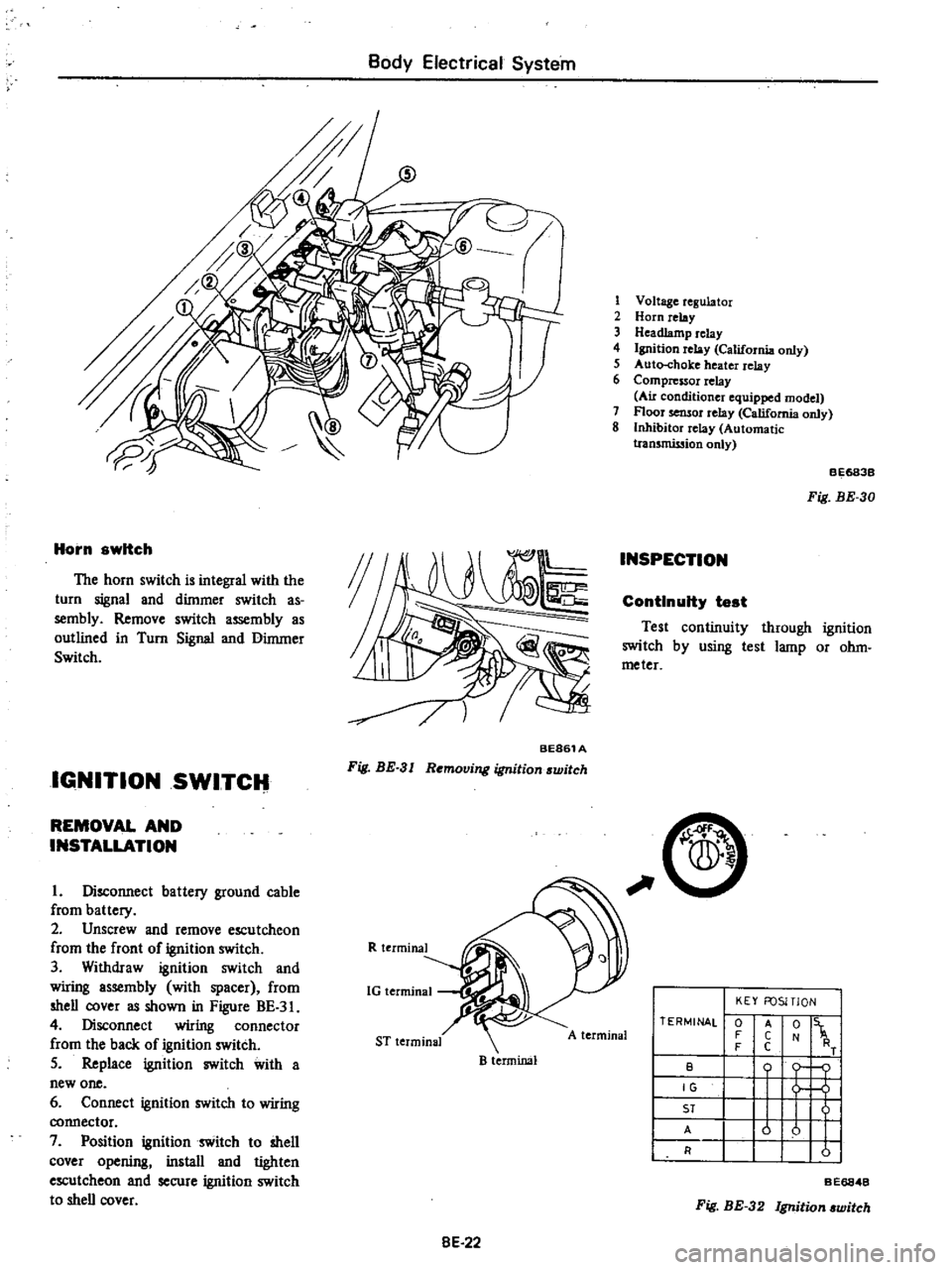

Horn

switch

The

horn

switch

is

integral

with

the

turn

signal

and

dimmer

switch

as

sembly

Remove

switch

assembly

as

outlined

in

Turn

Signal

and

Dimmer

Switch

IGNITION

SWITCH

BE861A

Fig

BE

3

I

Removing

ignition

switch

REMOVAL

AND

INSTALLATION

I

Disconnect

battery

ground

cable

from

battery

2

Unscrew

and

remove

escutcheon

from

the

front

of

ignition

switch

3

Withdraw

ignition

switch

and

wiring

assembly

with

spacer

from

shell

cover

as

shown

in

Figure

BE

3

4

Disconnect

wiring

connector

from

the

back

of

ignition

switch

5

Replace

ignition

switch

with

a

new

one

6

Connect

ignition

switch

to

wiring

connector

7

Position

ignition

switch

to

shell

cover

opening

install

and

tighten

escutcheon

and

secure

ignition

switch

to

shell

cover

R

terminal

1G

terminal

ST

terminal

B

terminal

8E

22

1

Voltage

regulator

2

Horn

relay

3

Headlamp

relay

4

Ignition

relay

California

only

5

Auto

choke

heater

relay

6

Compressor

relay

Au

conditioner

equipped

model

7

Floor

sensor

relay

California

only

8

Inhibitor

relay

Automatic

tran5mission

only

INSPECTION

BE683B

Fig

BE

30

ContInuity

test

Test

continuity

through

ignition

switch

by

using

test

lamp

or

ohm

meter

C

A

terminal

TERMINAL

0

F

F

B

IG

ST

A

R

KEY

FOSITlON

t

1

o

j

u

u

I

I

A

C

C

Fig

BE

32

Ignition

witch

BE6848

Page 471 of 537

INSTALLATION

I

Position

clock

to

cluster

lid

and

install

three

screws

2

Connect

three

wire

connectors

of

clock

to

each

connection

two

to

combination

meter

printed

circuit

one

to

instrument

h

ness

wiring

3

Install

cluster

lid

to

instrument

panel

4

Connect

battery

ground

cable

HEATER

DESCRIPTION

@

Body

Electrical

System

Fig

BE

44

Clock

1

Defroster

nozzle

L

U

2

Deflor

tcr

duct

L

R

3

Heater

control

4

Resistor

5

Heater

motor

6

Heater

case

7

Ventilator

knob

8

Heater

core

9

Conuol

cable

clip

10

Heater

cock

11

Defroster

duct

R

H

12

Defroster

nozzle

R

H

BE687B

Fig

BE

45

Heater

comtruction

BE

26

Page 472 of 537

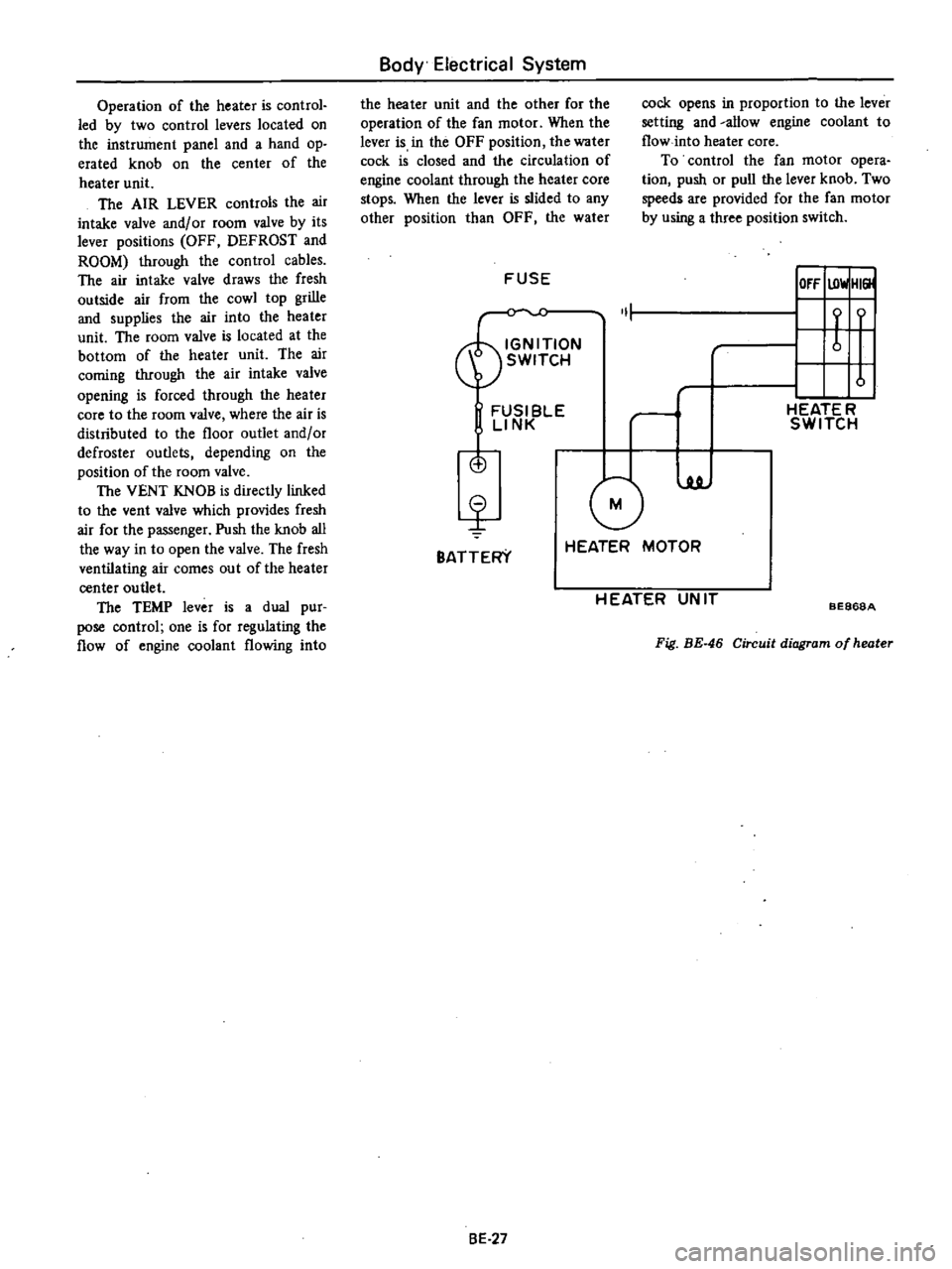

Operation

of

the

heater

is

control

led

by

two

control

levers

located

on

the

instrument

panel

and

a

hand

op

erated

knob

on

the

center

of

the

heater

unit

The

AIR

LEVER

controls

the

air

intake

valve

and

or

room

valve

by

its

lever

positions

OFF

DEFROST

and

ROOM

through

the

control

cables

The

air

intake

valve

draws

the

fresh

outside

air

from

the

cowl

top

grille

and

supplies

the

air

into

the

heater

unit

The

room

valve

is

located

at

the

bottom

of

the

heater

unit

The

air

coming

through

the

air

intake

valve

opening

is

forced

through

the

heater

core

to

the

room

valve

where

the

air

is

distributed

to

the

floor

outlet

and

or

defroster

outlets

depending

on

the

position

of

the

room

valve

The

VENT

KNOB

is

directly

linked

to

the

vent

valve

which

provides

fresh

air

for

the

passenger

Push

the

knob

all

the

way

in

to

open

the

valve

The

fresh

ventilating

air

comes

out

of

the

heater

center

outlet

The

TEMP

lever

is

a

dual

pur

pose

control

one

is

for

regulating

the

flow

of

engine

coolant

flowing

into

Body

Electrical

System

the

heater

unit

and

the

other

for

the

operation

of

the

fan

motor

When

the

lever

is

in

the

OFF

position

the

water

cock

is

closed

and

the

circulation

of

engine

coolant

through

the

heater

core

stops

When

the

lever

is

slided

to

any

other

position

than

OFF

the

water

cock

opens

in

proportion

to

the

lever

setting

and

allow

engine

coolant

to

flow

into

heater

core

To

control

the

fan

motor

opera

tion

push

or

pull

the

lever

knob

Two

speeds

are

provided

for

the

fan

motor

by

using

a

three

position

switch

FUSE

IOfF

UlwlHI

ON

1

t

f

SWITCH

u

FUSI

BlE

rl

HEATE

R

LINK

SWITCH

is

G

luJ

BATTERY

HEATER

MOTOR

H

EATER

UN

IT

BE868A

Fig

BE

46

Circuit

diagram

of

heater

8E

27

Page 473 of 537

Body

Electrical

System

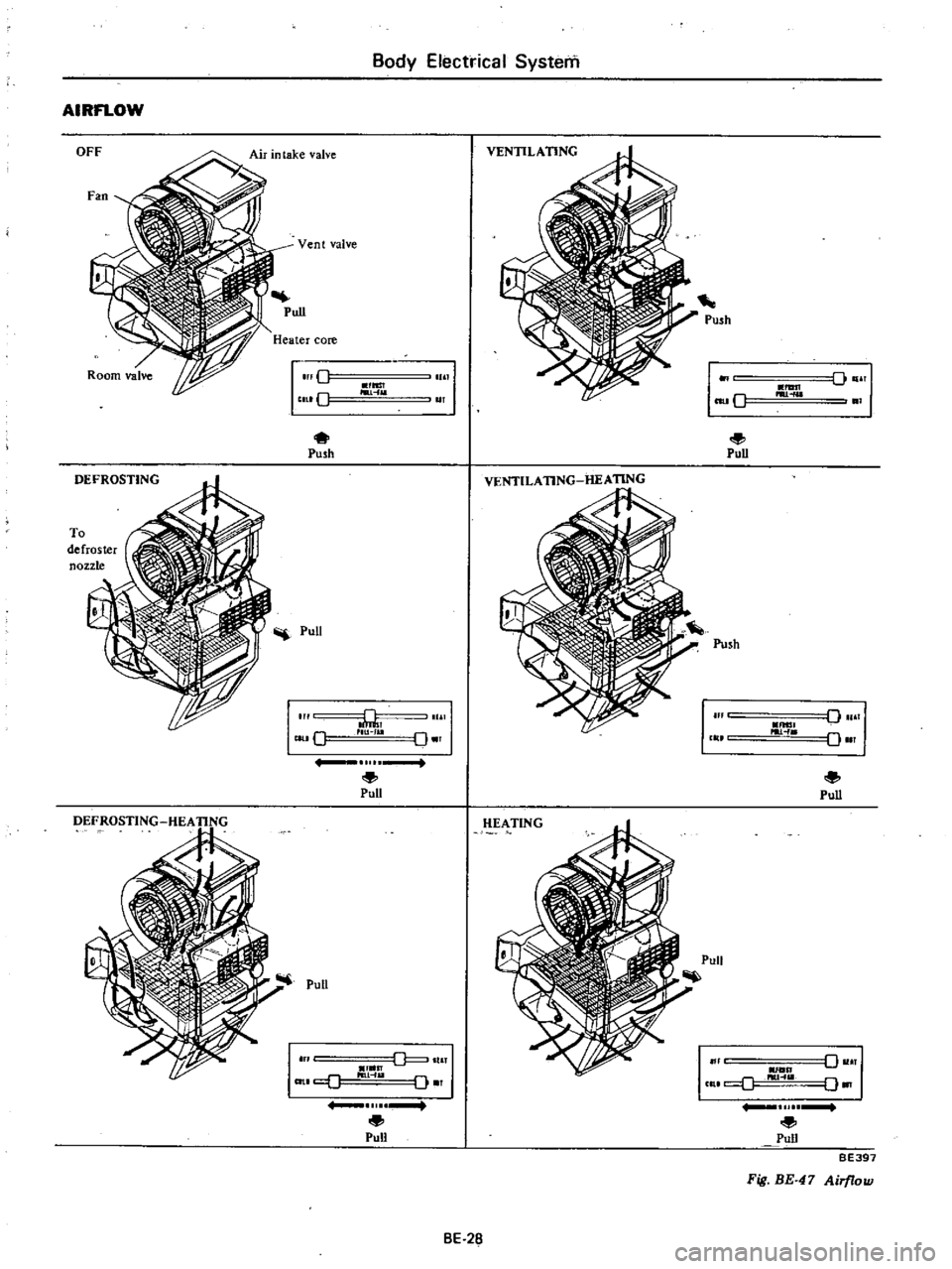

AIRFLOW

OFF

VENTILATING

Push

Vent

valve

Heater

core

c

n

e

NlL

fAl

u

c

J

u

IUl

g

Push

Pull

DEFROSTING

VENTILATING

HEATING

0

tTIlsl

IU

lI

D

WI

Push

Pull

g

IIt

J

L

I

I

Pull

Pull

DEFROSTING

HEATING

n

C

IU

n

HU

I

ff

UIUI

C

J

CIl

JIlT

Ill

Pull

J

11

Pull

BE397

Fig

BE

47

Airflow

8E

28