DATSUN PICK-UP 1977 Service Manual

Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 321 of 537

Automatic

Transmission

TROUBLE

SHOOTING

GUIDE

FOR

3N71B

AUTOMATIC

TRANSMISSION

Order

Test

item

Checking

Oil

level

gauge

2

Downshift

solenoid

3

Manuallinkage

L

4

Inhibitor

switch

5

Engine

idling

rpm

6

Vacuum

pressure

of

vacuum

pipe

7

Operation

in

each

range

8

Creep

of

vehicle

Stall

test

I

Oil

pressure

before

tesling

1

2

Stall

test

3

Oil

pressure

after

testing

Road

test

Slow

acceleration

I

st

2nd

2nd

3rd

2

Quick

acceleration

lst

2nd

2nd

3rd

3

Kick

down

operation

3rd

2nd

or

2nd

1st

Procedure

Check

gauge

for

oil

level

and

leakage

before

and

after

each

test

Check

for

sound

of

operating

solenoid

when

depressing

accelerator

pedal

fully

with

ignition

key

ON

Check

by

shifting

into

P

lR

IN

D

2

and

I

ranges

with

selector

lever

Check

whether

starter

operates

in

N

and

p

ranges

only

and

whether

reverse

lamp

operates

in

R

range

only

Check

whelher

idling

rpm

meet

standard

Check

whether

vacuum

pressure

is

more

than

450

mmHg

in

idling

and

whether

it

decreases

with

increasing

rpm

Check

whether

transmission

engages

positively

by

shifting

N

0

N

2

N

l

I

and

N

R

range

while

idling

with

brake

applied

Check

whether

there

is

any

creep

in

D

2

R

ranges

and

Measure

line

pressures

in

D

2

I

and

R

range

while

idling

Measure

engine

rpm

and

line

pressure

in

D

2

I

and

R

ranges

during

full

throttle

operati

n

Notes

a

Temperature

of

torque

converter

oil

used

in

test

should

be

from

600

to

1000C

1400

to

2120F

i

e

sufficiently

warmed

up

but

not

overheated

b

To

cool

oil

between

each

stall

test

for

D

2

I

and

R

ranges

idle

engine

i

e

rpm

at

about

1

200

rpm

for

more

than

1

minute

in

P

range

Measurement

time

must

not

be

more

than

5

seconds

Same

as

item

I

Check

vehide

speeds

and

engine

cpm

in

shifting

up

Ist

2nd

range

and

2nd

Jo3rd

range

while

running

with

lever

in

D

range

and

engine

vacuum

pressure

of

about

200

I11I1lHg

Same

as

item

1

above

except

with

engine

vacuum

pressure

of

0

mmHg

i

e

in

position

just

before

kickdown

Check

whether

the

kickdown

operates

and

measure

the

time

delays

while

running

at

30

40

50

60

70

km

h

18

25

30

37

43

MPH

in

D3

range

AT

57

Page 322 of 537

Automatic

Transmission

Order

Test

item

4

Shift

down

Dr

O2

0

5

Shift

down

DJ

12

1

6

Shift

down

DJ

2

7

Shift

up

I

12

8

Shift

up

or

down

when

start

iog

in

2

range

9

Parking

Others

Abnormal

shock

oil

leakage

Procedure

Check

vehicle

speeds

and

engine

rpm

in

shifting

down

from

3rd

2nd

I

st

sequentially

while

coasting

with

accelerater

pedal

released

in

D3

range

and

engine

vacuum

pressure

of

about

450

mmHg

Check

for

shifting

down

OJ

12

and

engine

braking

and

further

for

shifting

down

12

I

and

engine

braking

after

shifting

the

lever

into

I

range

with

the

accelerator

pedal

released

and

the

engine

vacuum

pressure

of

0

mmHg

while

driving

at

about

50

km

h

30

MPH

in

OJ

range

Check

for

quick

shifting

down

0

2

and

engine

biaking

after

shifting

the

lever

into

2

range

while

driving

at

about

50

km

h

30

MPH

in

OJ

range

Further

check

for

locking

of

the

transmission

in

2nd

gear

ratio

regardless

of

vehicle

speed

Check

for

failure

of

the

transmission

to

shift

up

during

acceleration

when

starting

in

I

range

Check

the

transmission

for

not

shifting

up

or

down

during

acceleration

or

deceleration

when

starting

in

2

rang

Confirm

that

vehicle

will

not

move

on

grade

when

shifting

to

P

range

Enter

into

record

conditions

observed

during

these

tests

such

as

gear

noise

abnormal

clutch

noise

and

acceleration

performance

AT

58

Page 323 of 537

Automatic

Transmission

SERVICE

DATA

AND

SPECIFICATIONS

General

specifications

AfT

Torque

converter

Type

Stall

torque

ratio

Symmetrica13

element

I

stage

2

phase

torque

converter

2

0

I

Transmission

Type

Control

elements

Multiple

disc

clutch

Band

brake

Multiple

disc

brake

One

way

clutch

Gear

ratio

1st

2nd

3rd

Reverse

3

speed

forward

and

one

speed

reverse

with

planetary

gear

train

2

I

I

I

2

458

1458

1

000

2

182

Selector

positions

P

Park

R

Reverse

N

Neutral

Transmission

is

placed

in

neutral

Output

shaft

is

fIXed

Engine

can

be

started

Backward

running

Transmission

is

in

neutral

Engine

can

be

started

Up

or

downshifts

automatically

to

and

from

I

st

2nd

and

top

Fixed

at

2nd

Fixed

at

low

or

downshifts

from

2nd

o

Drive

2

2nd

lock

I

Lock

up

Oil

pump

Type

Internally

intermeshing

involute

gear

pump

Number

of

pump

Oil

Automatic

transmission

fluid

DEXRON

type

5

5

liters

SUU

s

qt

4Ulmp

qt

Approximately

2

7

liters

2UU

s

qt

2XIrnp

qt

in

torque

converter

Controlled

by

measuring

the

nega

tive

pressure

of

intake

manifold

and

the

revolution

of

output

shaft

Forced

lubrication

by

an

oil

pump

Water

cooled

by

a

circulation

type

auxiliary

cooler

located

at

the

radiator

Capacity

Hydraulic

control

system

Lubrication

system

Cooling

system

AT

59

Page 324 of 537

Specifications

and

adjustment

AfT

Automatic

transmission

assembly

Model

code

number

Torque

converter

assembly

Stamped

mark

on

th

e

TiC

Front

clutch

Number

of

drive

plate

Number

of

driven

plates

Clearance

Thickness

of

retainin

g

plate

Rear

clutch

Number

of

drive

plates

Number

of

driven

plates

Clearance

Thickness

of

retaining

plate

Low

reverse

brake

Number

of

drive

plates

Number

f

driven

pla

es

Clearance

Thickness

of

retaining

plaie

Brake

band

Piston

size

Big

dia

S

all

dia

Control

valve

assembly

Stamped

mark

on

slraine

Governor

assembly

Stamped

mark

on

governor

body

Automatic

Transmission

mOl

in

mm

in

mOl

inJ

mOl

in

mOl

in

mOl

in

mOl

in

AT

60

X2402

16

B

3

3

1

6

to

1

8

0

063

to

0

071

10

6

0

417

10

8

0

42S

11

0

0

433

11

2

0

441

11

4

0

449

11

6

0

4S7

4

4

1

0

to

1

5

0

039

to

0

OS9

4

8

0

189

4

4

0

80

to

1

0S

0

0315

to

0

0413

11

8

0

46S

12

0

0

472

12

2

0

480

12

4

0

488

12

6

0

496

12

8

O

S04

64

2

S2

40

1

57

E

35

Page 325 of 537

Automatic

Transmission

Engine

Idling

and

stall

revolution

Idling

revolution

Stall

revolution

rpm

rpm

6S0

ai

0

position

2

000

to

2

200

TIghtening

torque

kg

m

ft

lb

Drive

plate

to

crankshaft

Drive

plate

to

torque

converter

Converter

housing

to

engine

Transmission

case

to

converter

housing

Transmission

case

to

rear

extension

Oil

pan

to

transmission

case

Servo

piston

retaine

T

to

transmission

case

Pislon

slem

when

adjuting

band

brake

Piston

stem

lock

nut

One

way

clutch

inner

race

to

transmission

case

Control

valve

body

to

transmission

case

Lower

valve

body

to

upper

valve

body

Side

plat

to

control

valve

body

Nut

for

control

valve

reamer

bolt

Oil

strainer

to

lower

valve

body

Governor

valve

body

to

oil

distribu

tor

Oil

pump

housing

to

oil

pump

cover

Inhibitor

switch

to

transmission

case

Manual

shaft

lock

nut

Oil

cooler

pipe

to

transmission

case

Test

plug

oil

pressure

inspection

hole

Support

actuator

parking

rod

inserting

position

to

rear

extension

I

Oil

charging

pipe

to

case

Dust

cover

to

converter

housing

Selector

range

lever

to

manual

shaft

14

0

to

16

0

101

to

116

4

0

to

5

0

29

to

36

4

0

to

S

O

29

10

36

4

S

to

5

5

33

to

40

2

0

to

S

14

to

18

O

S

to

0

7

4

to

S

O

S

to

0

7

4

to

S

1

2

to

1

5

9

to

11

1

5

to

4

0

I

I

to

29

1

3

to

1

8

9

to

13

0

5S

to

0

75

4

to

S

0

25

to

O

3S

2

to

3

0

25

to

0

35

2

to

3

O

S

to

0

7

4

to

S

0

25

to

0

35

2

to

3

D

S

100

7

4

to

5

0

6

to

0

8

4

to

6

0

5

to

0

7

4

toS

3

0

to

4

0

22

to

29

3

0

to

S

O

22

to

36

I

4to

2

1

10

to

IS

0

8

to

I

1

6

to

8

O

5S

to

0

7S

4

to

S

O

5S

to

0

75

4

to

S

3

0

to

4

0

22

to

29

Turn

back

two

turns

after

tightening

AT

61

Page 326 of 537

Automatic

Transmission

SPECIAL

SERVICE

TOOLS

No

Tool

number

tool

name

Description

For

use

on

Reference

page

or

Figure

No

Oil

pressure

gauge

set

3N71B

Fig

AT

11

2

and

3N71A

AfT

ST2S0SS001

Use

for

checking

hydraulic

pressure

SE119

2

ST07870000

Use

for

setting

transmission

3N71

B

Page

AT

36

AfT

Transmission

case

stand

SE120

3

ST2S850000

Use

for

removing

oil

pump

3N7IB

Fig

AT

S6

and

Sliding

hammers

3N71A

J

AfT

JIB

SE121

4

ST2S42000I

Use

for

assemblilJg

or

disassembling

front

and

rear

clutch

3N71B

Fig

AT

79

and

Fig

AT

86

Clutch

spring

3N7lA

compressor

AIT

SE

122

3N71B

Fig

AT

69

and

3N71A

AlT

Torque

wrench

Use

for

tightening

correct

torque

Max

torque

4

6

kg

m

0

33

ft

lb

Drive

angle

3

8

square

S

GG93010000

SE123

AT

62

Page 327 of 537

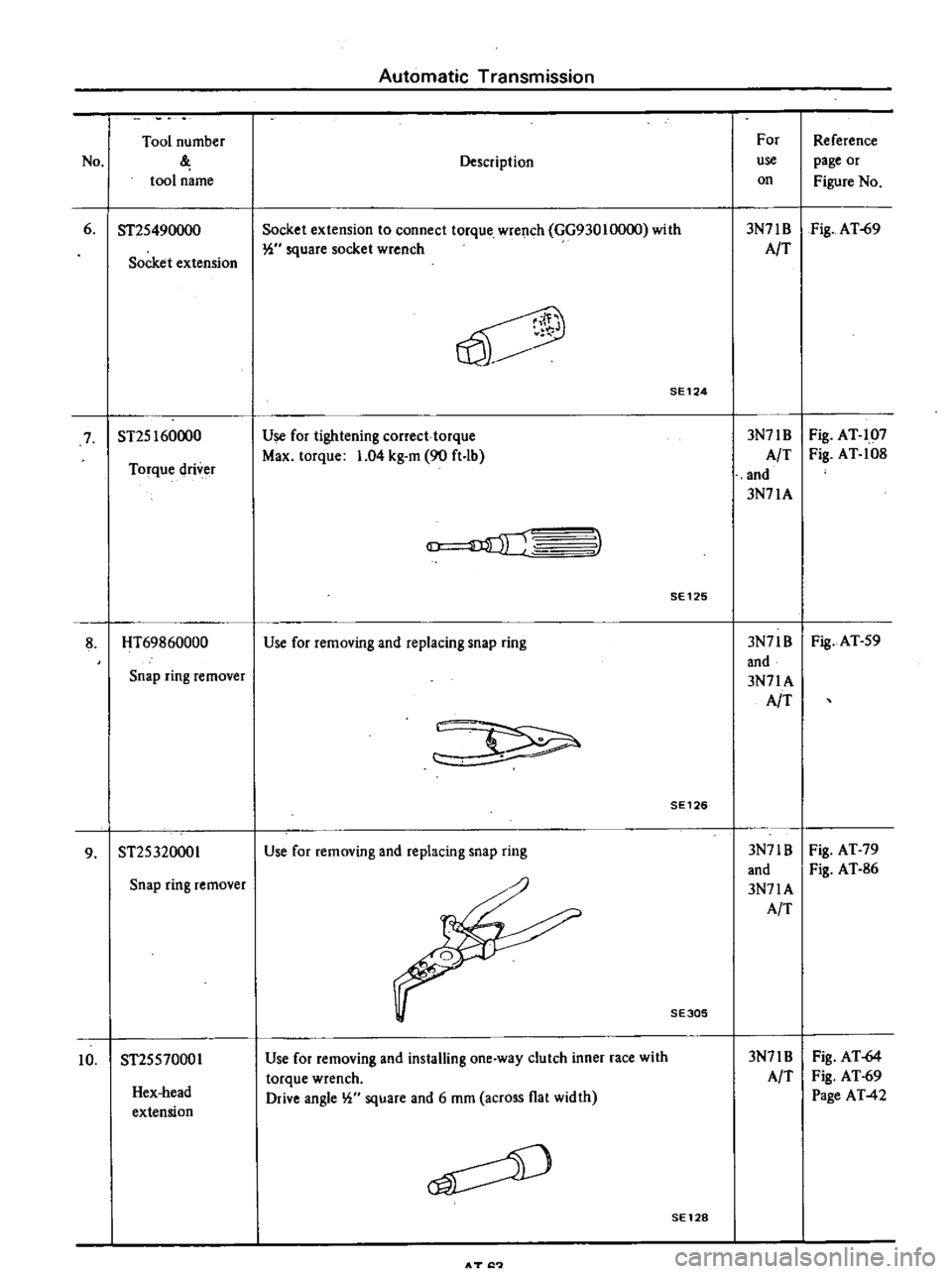

Automatic

Transmission

Tool

number

For

Reference

No

Description

use

page

or

tool

name

on

Figure

No

6

ST2S490000

Socket

extension

to

connect

torque

wrench

GG93010000

with

3N71B

Fig

AT

69

Socket

extension

W

square

socket

wrench

AIT

V

SE124

7

ST2S160000

Use

for

tightening

correct

torque

3N71B

Fig

AT

107

Torque

driver

Max

torque

1

04

kg

m

90

ft

lb

A

T

Fig

AT

108

and

3N71A

3

SE125

8

HT69860000

Use

for

removing

and

replacing

snap

ring

3N71B

Fig

AT

S9

and

Snap

ring

remover

3N71A

AIT

SE126

9

ST2S320001

Use

for

removing

and

replacing

snap

ring

3N71B

Fig

AT

79

and

Fig

AT

86

Snap

ring

remover

3N71A

AIT

SE305

Hex

head

extension

Use

for

removing

and

installing

one

way

clutch

inner

race

with

torque

wrench

Drive

angle

W

square

and

6

mOl

across

flat

width

3N71B

AIT

Fig

AT

64

Fig

AT

69

Page

AT

42

10

ST2SS70001

SE128

AT

I

Page 328 of 537

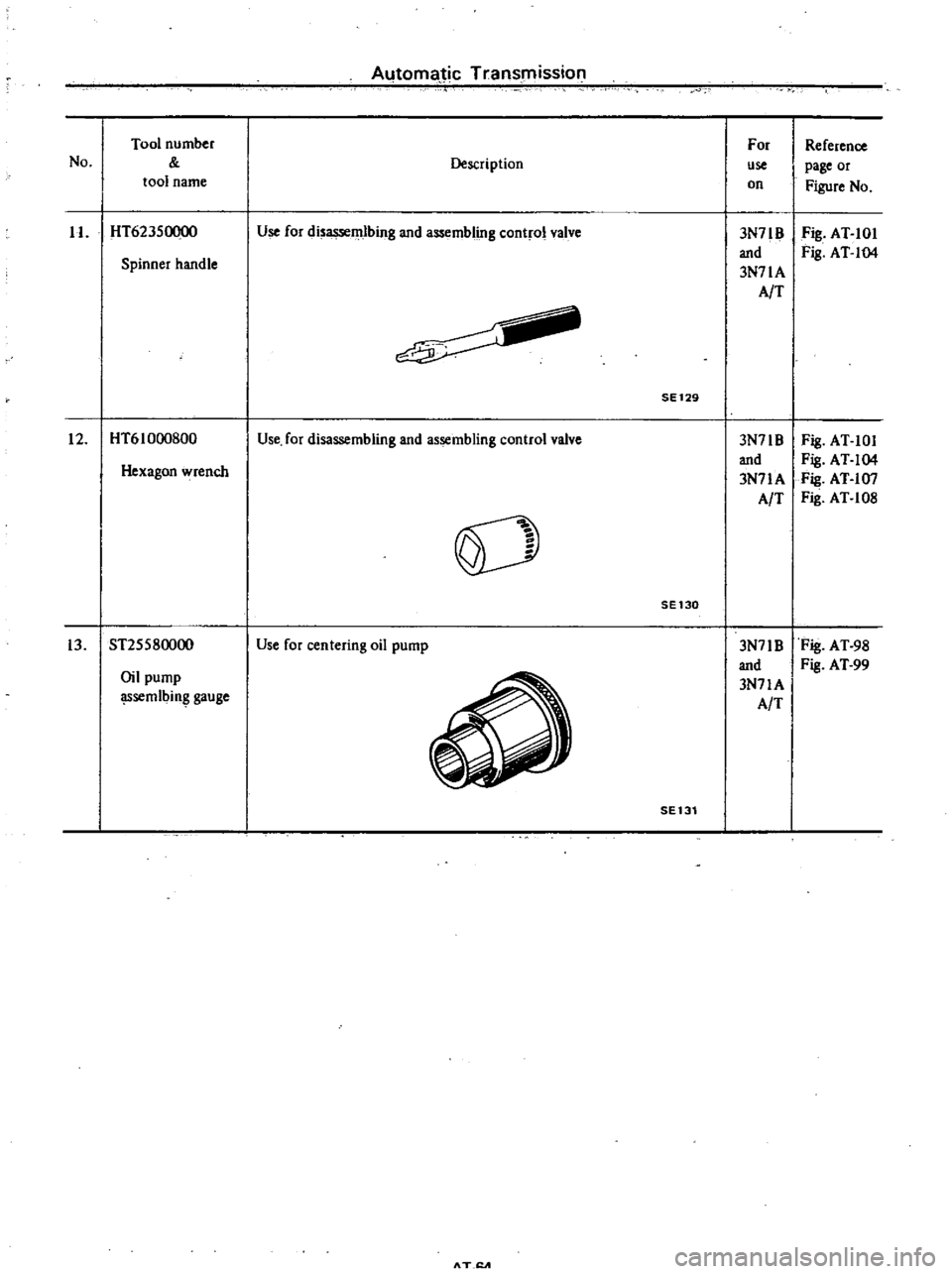

AutomaJic

Transmission

No

Tool

number

tool

name

Description

For

use

on

Reference

page

or

Figure

No

II

HT623S0Q00

Use

for

disassemlbing

and

assembling

control

valve

3N71B

and

3N71A

AIT

Fig

AT

IOI

Fig

AT

I04

Spinner

handle

SE129

12

HT61000800

Use

for

disassembling

and

assembling

control

valve

3N71B

Fig

AT

IOI

and

Fig

AT

104

Hexagon

wrench

3N71A

Fig

AT

I07

AIT

Fili

AT

108

0

SE130

13

ST2SS80000

Use

for

centering

oil

pump

3N71B

Fig

AT

98

and

Fig

A

T

99

Oil

pump

3N71A

l

Ssemlbing

gauge

AIT

SE131

AT

1l

A

Page 329 of 537

DATSUN

PICK

UP

MODEL

620

SERIES

I

NISSAN

I

NISSAN

MOTOR

CO

LTD

TOKYO

JAPAN

0

SECTION

PD

PROPELLER

SHAFT

DIFFERENTIAL

CARRIER

PROPELLER

SHAFT

AND

CENTER

BEARING

DIFFERENTIAL

CARRIER

TYPE

H19D

TROUBLE

DIAGNOSES

AND

CORRECTIONS

SERVICE

DATA

AND

I

SPECiFiCATIONS

PD

16

SPECIAL

SERVICE

TOOLS

PD

19

PD

2

f

PD

5

PD

14

Page 330 of 537

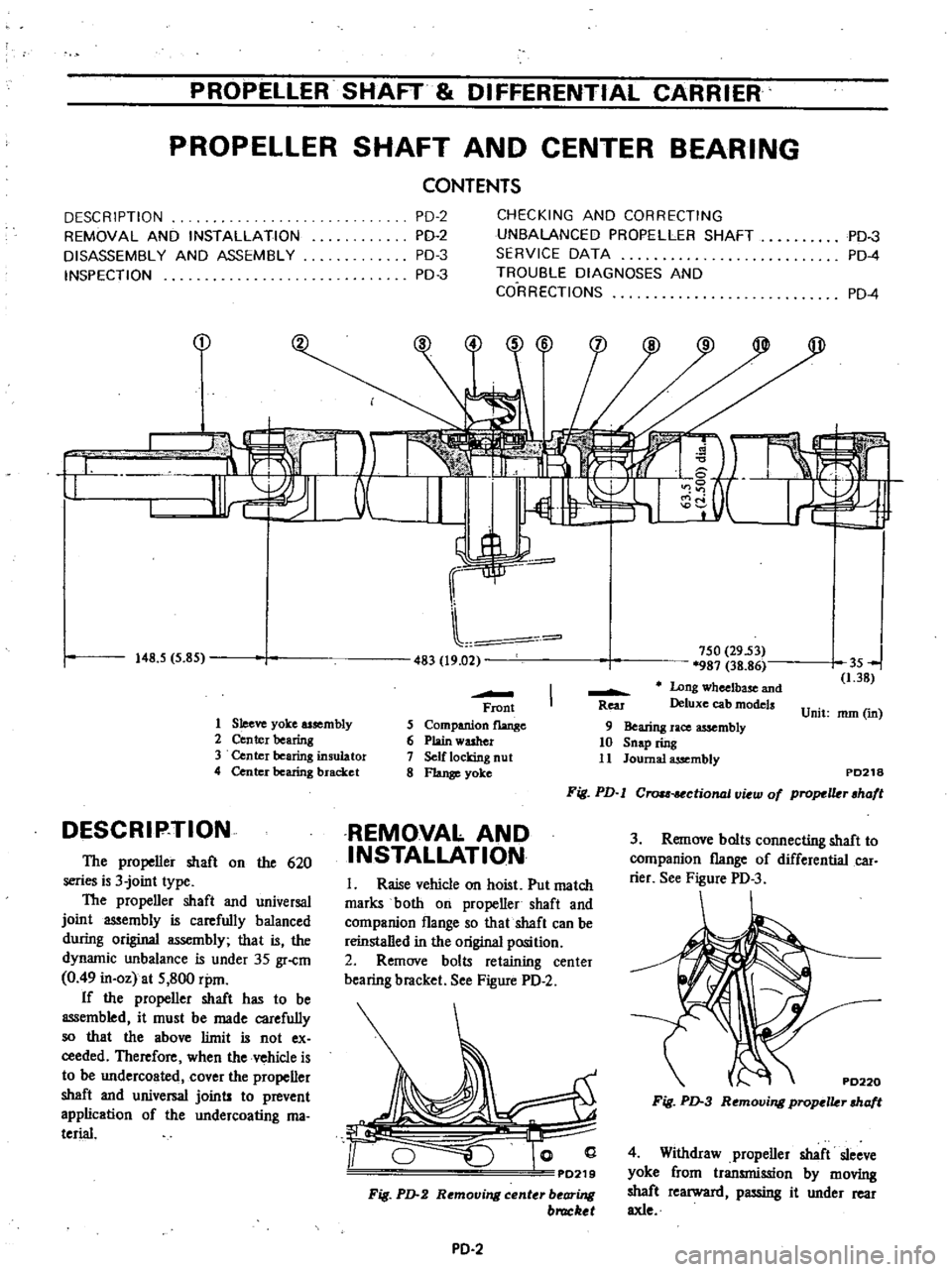

PROPElLER

SHAFT

DIFFERENTIAL

CARRIER

PROPELLER

SHAFT

AND

CENTER

BEARING

CONTENTS

DESCRIPTION

REMOVAL

AND

INSTALLATION

DISASSEMBLY

AND

ASSEMBLY

INSPECTION

i

t

I

tl

J

I

O

148

5

5

85

PD

2

PD

2

PD

3

PD

3

CHECKING

AND

CORRECTING

UNBALANCED

PROPELLER

SHAFT

SERVICE

DATA

TROUBLE

DIAGNOSES

AND

CORRECTIONS

PD

4

PD

3

PD

4

2

483

19

02

750

29

53

987

38

86

Long

wheelbase

and

Deluxe

cab

models

Unit

mm

in

35

1

38

Front

5

Companion

flange

6

Plain

washer

7

Self

locking

nut

8

Flange

yoke

Rea

1

Sleeve

yoke

assembly

2

Center

bearing

3

Center

bearing

insulator

4

Center

bearing

bracket

DESCRIP

TION

The

propeller

shaft

on

the

620

series

is

3

joint

type

The

propeller

shaft

and

universal

joint

assembly

is

carefully

balanced

during

original

assembly

that

is

the

dynamic

unbalance

is

under

35

gr

cm

0

49

in

oz

at

S

800

rpm

If

the

propeller

shaft

has

to

be

assembled

it

must

be

made

carefully

so

that

the

above

limit

is

not

ex

ceeded

Therefore

when

the

vehicle

is

to

be

undercoated

cover

the

propeller

shaft

and

universal

joints

to

prevent

application

of

the

undercoating

ma

terial

9

Bearing

race

assembly

10

Snap

ring

11

Journal

assembly

PD218

Fig

PD

l

Crou

ctional

v

w

of

propelkr

hafl

REMOVAL

AND

INSTALLATION

3

Remove

bolts

connecting

shaft

to

companion

flange

of

differential

car

rier

See

Figure

PD

3

I

Raise

vehicle

on

hoist

Put

match

marks

both

on

propeller

shaft

and

companion

flange

so

that

shaft

can

be

reinstalled

in

the

original

position

2

Remove

bolts

retaining

center

bearing

bracket

See

Figure

PD

2

PD220

Fig

PD

3

Removing

propclkr

cha

t

PD219

Fig

PD

2

Removing

center

bearing

bruckel

4

Withdraw

propeller

shaft

sleeve

yoke

from

transmission

by

moving

shaft

rearward

passing

it

under

rear

axle

PD

2