stop start DATSUN PICK-UP 1977 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 26 of 537

Fresh

air

Blow

by

gas

CHECKING

VENTILATION

HOSE

1

Check

hoses

and

hose

connec

tions

for

leaks

2

Disconnect

all

hoses

and

blow

them

out

with

compressed

air

If

any

hose

cannot

be

free

of

obstructions

replace

Ensure

that

flame

arrester

is

surely

inserted

in

the

hose

between

air

cleaner

and

rocker

cover

CHECKING

EXHAUST

MANIFOLD

HEAT

CONTROL

VALVE

Run

engine

and

visually

check

counterweight

to

see

if

it

operates

properly

I

For

some

time

after

starting

engine

in

cold

weather

counterweight

turns

counterclockwise

until

it

comes

into

contact

with

stopper

pin

installed

to

exhaust

manifold

Counterweight

gradually

moves

down

clockwise

as

engine

warms

up

and

ambient

temperature

goes

higher

around

exhaust

manifold

2

When

engine

speed

is

increased

discharge

pressure

of

exhaust

gases

causes

counterweight

to

move

down

ward

clockwise

Engine

Tune

up

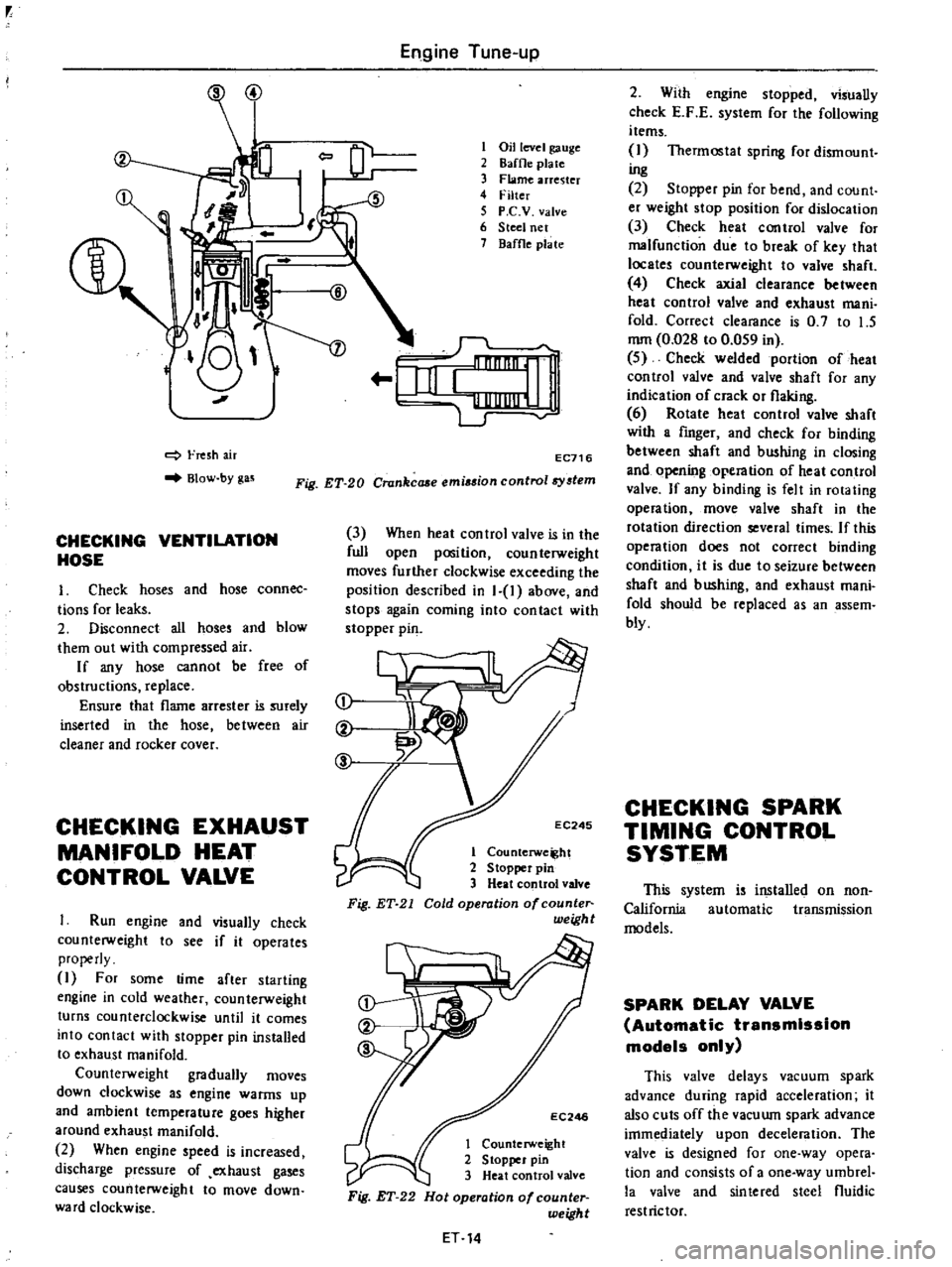

CoOl

1

Oil

level

gauge

2

8affle

pia

te

3

Flame

arrester

4

Filter

5

P

C

V

valve

6

Steel

net

7

Baffle

plate

1fiI

o

EC716

Fig

ET

20

Crankcaae

emi

ion

control8

tem

3

When

heat

control

valve

is

in

the

full

open

position

counterweight

moves

further

clockwise

exceeding

the

position

described

in

1

1

above

and

stops

again

coming

into

contact

with

stopper

pin

ct

t

C

EC245

1

Counterwe

ht

2

Stopper

pin

3

Heat

control

valve

Fig

ET

21

Cold

operation

of

counte

weigh

t

EC246

1

Counterweight

2

Stopper

pin

3

Heat

control

valve

Fig

ET

22

Hot

operation

of

counter

weight

ET

14

2

With

engine

stopped

visually

check

E

F

E

system

for

the

following

items

I

Thermostat

spring

for

dismount

ing

2

Stopper

pin

for

bend

and

count

er

weight

stop

position

for

dislocation

3

Check

heat

control

valve

for

malfunction

due

to

break

of

key

that

locates

counterweight

to

valve

shaft

4

Check

axial

clearance

between

heat

control

valve

and

exhaust

mani

fold

Correct

clearance

is

0

7

to

1

5

mm

0

028

to

0

059

in

5

Check

welded

portion

of

heat

control

valve

and

valve

shaft

for

any

indication

of

crack

or

flaking

6

Rotate

heat

control

valve

shaft

with

a

fmger

and

check

for

binding

between

shaft

and

bushing

in

closing

and

opening

operation

of

heat

control

valve

If

any

binding

is

felt

in

rotating

operation

move

valve

shaft

in

the

rotation

direction

several

times

If

this

operation

does

not

correct

binding

condition

it

is

due

to

seizure

between

shaft

and

bushing

and

exhaust

mani

fold

should

be

replaced

as

an

assem

bly

CHECKING

SPARK

TIMING

CONTROL

SYSTEM

This

system

is

installed

on

non

California

automatic

transmission

models

SPARK

DELAY

VALVE

Automatic

transmission

models

only

This

valve

delays

vacuum

spark

advance

during

rapid

acceleration

it

also

cuts

off

the

vacuwn

spark

advance

imme

iately

upon

deceleration

The

valve

is

designed

for

one

way

opera

tion

and

consists

of

a

one

way

umbrel

la

valve

and

sintered

steel

fluidic

restrictor

Page 28 of 537

Note

Vacuum

hose

position

R

R

side

of

Nissan

mark

on

the

top

of

sensor

for

intake

manifold

L

R

side

of

the

mark

is

for

vacuum

rootor

2

2

Vacuum

motor

I

With

engine

stopped

disconnect

fresh

air

duct

Place

a

mirror

at

the

end

of

air

cleaner

inlet

pipe

as

shown

and

check

to

see

if

air

control

valve

is

in

correct

position

EF213

Fig

ET

27

Impecting

lJalv

position

Air

control

valve

is

in

correct

posi

tion

if

its

under

hood

air

inlet

is

open

and

hot

air

inlet

is

closed

Check

air

control

valve

linkage

for

condition

2

Disconnect

vacuum

motor

inlet

vacuum

hose

and

connect

another

hose

to

the

inlet

to

apply

vacuum

to

vacuum

motor

Vacuum

can

be

ap

plied

by

breathing

in

the

hose

end

as

shown

Place

a

mirror

at

the

end

of

air

cleaner

inlet

pipe

and

check

to

see

if

air

control

valve

is

in

correct

position

Engine

Tune

up

EF217

Fig

ET

28

lmpecting

value

position

Correct

pC6ition

of

air

control

valve

is

the

reverse

of

paragraph

I

above

Air

control

valve

is

in

correct

position

if

under

hood

air

inlet

is

closed

and

hot

air

inlet

is

open

3

With

hot

air

inlet

is

open

posi

tion

as

descnbed

in

paragraph

2

above

pinch

vacuum

hose

with

fingers

and

cut

of

air

from

vacuum

hose

In

this

condition

check

that

air

control

valve

maintains

the

condition

de

scribed

in

step

2

for

more

than

30

seconds

and

that

hot

air

inlet

is

open

If

diaphragm

spring

actuates

the

air

control

valve

by

its

spring

force

to

open

under

hood

air

inlet

within

30

seconds

replace

vacuum

motor

as

an

assembly

since

this

may

be

resulted

from

air

leak

at

vacuum

motor

dia

phragm

2

3

Temperature

sensor

Check

temperature

sensor

for

func

tion

by

proceeding

as

follows

Be

sure

to

keep

engine

cold

before

starting

test

1

With

engine

off

check

air

control

valve

for

condition

In

this

case

under

hood

air

inlet

is

open

Use

a

mirror

for

inspection

as

2

2

1

above

2

Start

engine

and

keep

idling

Immediately

after

engine

starting

check

air

control

valve

for

correct

position

as

described

above

In

this

case

correct

position

of

air

control

valve

is

the

reverse

of

2

2

1

under

hood

air

inlet

is

closed

and

hot

air

inlet

is

open

ET

16

3

Check

that

air

control

valve

grad

ually

opens

to

under

hood

air

inlet

side

as

engine

warms

up

When

en

vironmental

temperature

around

tern

perature

sensor

is

low

spend

more

time

for

engine

warming

up

operation

to

facilitate

smooth

opera

tion

of

air

con

trol

valve

If

the

above

test

reveals

any

prob

lem

in

the

operation

of

air

control

valve

carry

out

the

following

test

4

Remove

air

cleaner

cover

Set

temperature

sensing

element

of

ther

mistor

or

thermometer

to

a

position

where

tempera

ture

around

sensor

can

be

measured

In

this

case

fix

wiring

of

thermistor

or

thermometer

on

the

bot

tom

surface

of

air

cleaner

with

adhe

sive

tape

in

such

a

manner

that

the

set

position

of

temperature

sensing

ele

ment

will

not

be

affected

by

airflow

Then

install

air

cleaner

cover

EF221

Fig

ET

29

Checking

temperotur

e

ensor

5

Carry

out

test

as

described

in

steps

I

2

and

3

above

When

air

control

valve

begins

to

open

to

under

hood

air

inlet

side

severa

minutes

after

engine

starting

read

the

indica

tion

of

thermistor

or

thermometer

If

reading

falls

within

the

working

tern

perature

range

of

temperature

sensor

the

sensor

is

normaL

If

reading

ex

ceeds

the

range

replace

the

sensor

with

new

one

Note

Before

replacing

temperature

sensor

check

idle

compensator

as

described

in

Section

EF

page

EF

8

Page 33 of 537

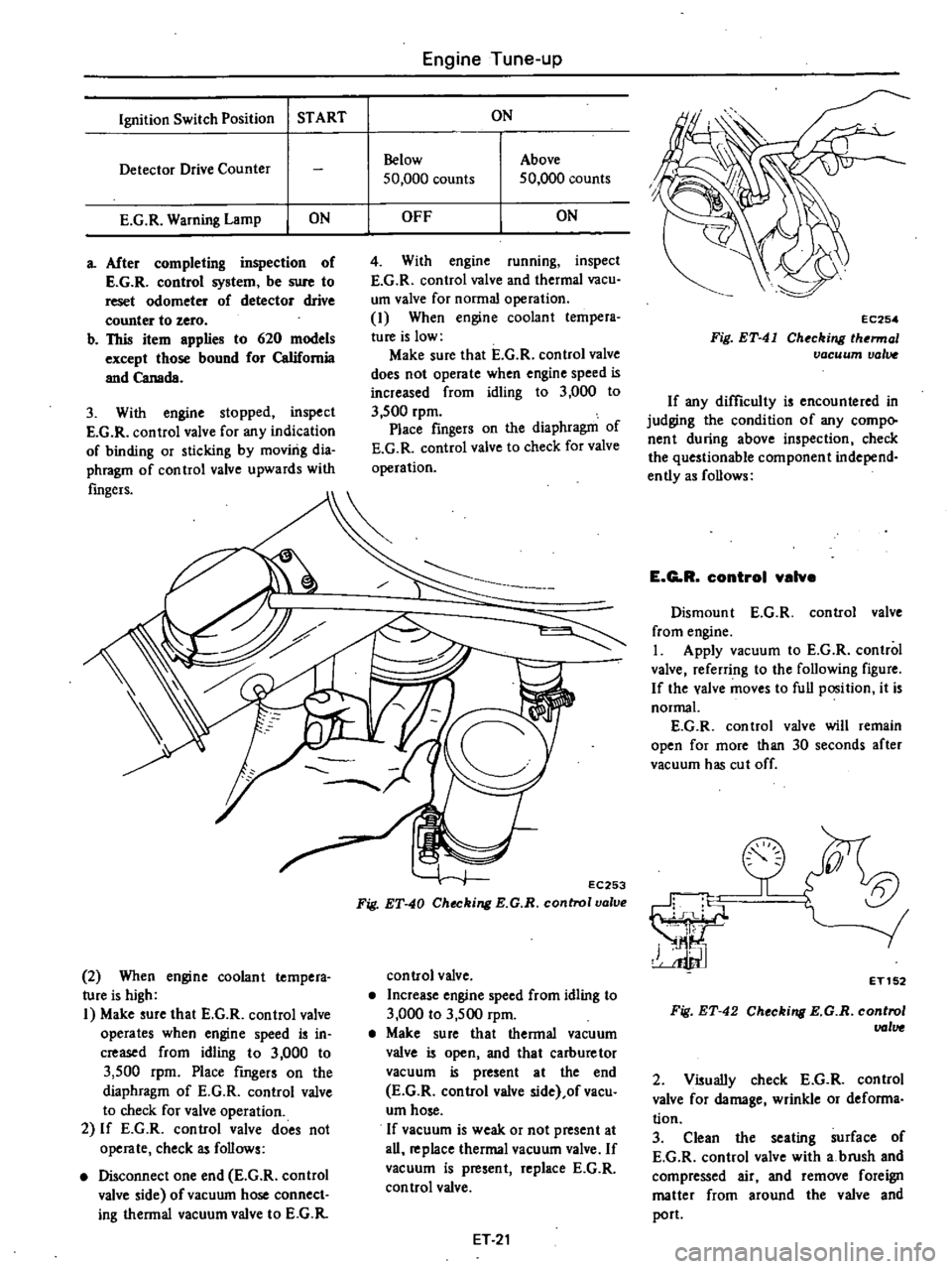

Ignition

Switch

Position

START

Detector

Drive

Counter

E

G

R

Warning

Lamp

ON

a

After

completing

inspection

of

E

G

R

control

system

be

sure

to

reset

odometer

of

detector

drive

counter

to

zero

b

This

item

applies

to

620

models

except

those

bound

for

California

and

Canada

3

With

engine

stopped

inspect

E

G

R

control

valve

for

any

indication

of

binding

or

sticking

by

movirig

dia

phragm

of

control

valve

upwards

with

fmgers

Engine

Tune

up

ON

Below

50

000

counts

Above

50

000

counts

OFF

ON

4

With

engine

running

inspect

E

G

R

control

valve

and

thermal

vacu

um

valve

for

normal

operation

I

When

engine

coolant

tempera

ture

is

low

Make

sure

that

E

G

R

control

valve

does

not

operate

when

engine

speed

is

increased

from

idling

to

3

000

to

3

500

rpm

Place

fingers

on

the

diaphragm

of

E

G

R

control

valve

to

check

for

valve

operation

2

When

engine

coolant

tempera

ture

is

high

I

Make

sure

that

E

G

R

control

valve

operates

when

engine

speed

is

in

creased

from

idling

to

3

000

to

3

500

rpm

Place

fingers

on

the

diaphragm

of

E

G

R

control

valve

to

check

for

valve

operation

2

If

E

G

R

control

valve

does

not

operate

check

as

follows

Disconnect

one

end

E

G

R

control

valve

side

ofvacuum

hose

connect

ing

thermal

vacuum

valve

to

E

G

R

EC253

Fig

ET

40

Checking

E

G

R

control

valve

control

valve

Increase

engine

speed

from

idling

to

3

000

to

3

500

rpm

Make

sure

that

thermal

vacuum

valve

is

open

and

that

carburetor

vacuum

is

present

at

the

end

E

G

R

control

valve

side

ofvacu

urn

hose

If

vacuum

is

weak

or

not

present

at

all

replace

thermal

vacuum

valve

If

vacuum

is

present

replace

E

G

R

con

trol

valve

ET

21

EC254

Fig

ET

41

Checking

thermal

vacuum

valw

If

any

difficulty

is

encountered

in

judging

the

condition

of

any

compo

nent

during

above

inspection

check

the

questionable

component

independ

ently

as

follows

E

G

R

control

valve

Dismount

E

G

R

control

valve

from

engine

I

Apply

vacuum

to

E

G

R

control

valve

referring

to

the

following

figure

If

the

valve

moves

to

full

position

it

is

normal

E

G

R

control

valve

will

remain

open

for

more

than

30

seconds

after

vacuum

has

cut

off

0

r11

hC

J

ET152

Fig

ET

42

Checking

E

G

R

control

VGlve

2

Visually

check

E

G

R

control

valve

for

damage

wrinkle

or

deforma

tion

3

Clean

the

seating

surface

of

E

G

R

control

valve

with

a

brush

and

compressed

air

and

remove

foreign

matter

from

around

the

valve

and

port

Page 102 of 537

r

AIR

CLEANER

1

Loosen

bolts

securing

air

cleaner

to

air

cleaner

bracket

2

Loosen

air

cleaner

lock

bolt

and

remove

air

cleaner

from

carburetor

Disconnect

the

following

hoses

when

dismounting

air

cleaner

Under

hood

air

inlet

hose

Hot

air

inlet

hose

Vacuum

hose

Sensor

to

intake

manifold

Vacuum

hose

Sensor

to

vacuum

motor

Vacuum

hose

Idle

compensator

to

intake

manifold

Hose

Air

pump

to

air

cleaner

Hose

AB

valve

to

air

cleaner

Hose

Carburetor

to

air

cleaner

Blow

by

hose

Air

cleaner

to

rocker

cover

Hose

Air

control

vaive

to

air

cleaner

California

models

only

3

To

install

reverse

the

removal

procedure

INSPECTION

1

AIR

CLEANER

ELEMENT

Viscous

paper

type

air

cleaner

ele

ment

does

not

require

any

cleaning

operation

until

it

is

replaced

periodi

cally

Brushing

or

blasting

operation

will

cause

clogging

and

result

in

enrich

ment

of

carburetor

mixture

and

should

never

be

conducted

For

reo

placement

interval

of

air

cleaner

ele

ment

refer

to

Maintenance

Sched

ule

2

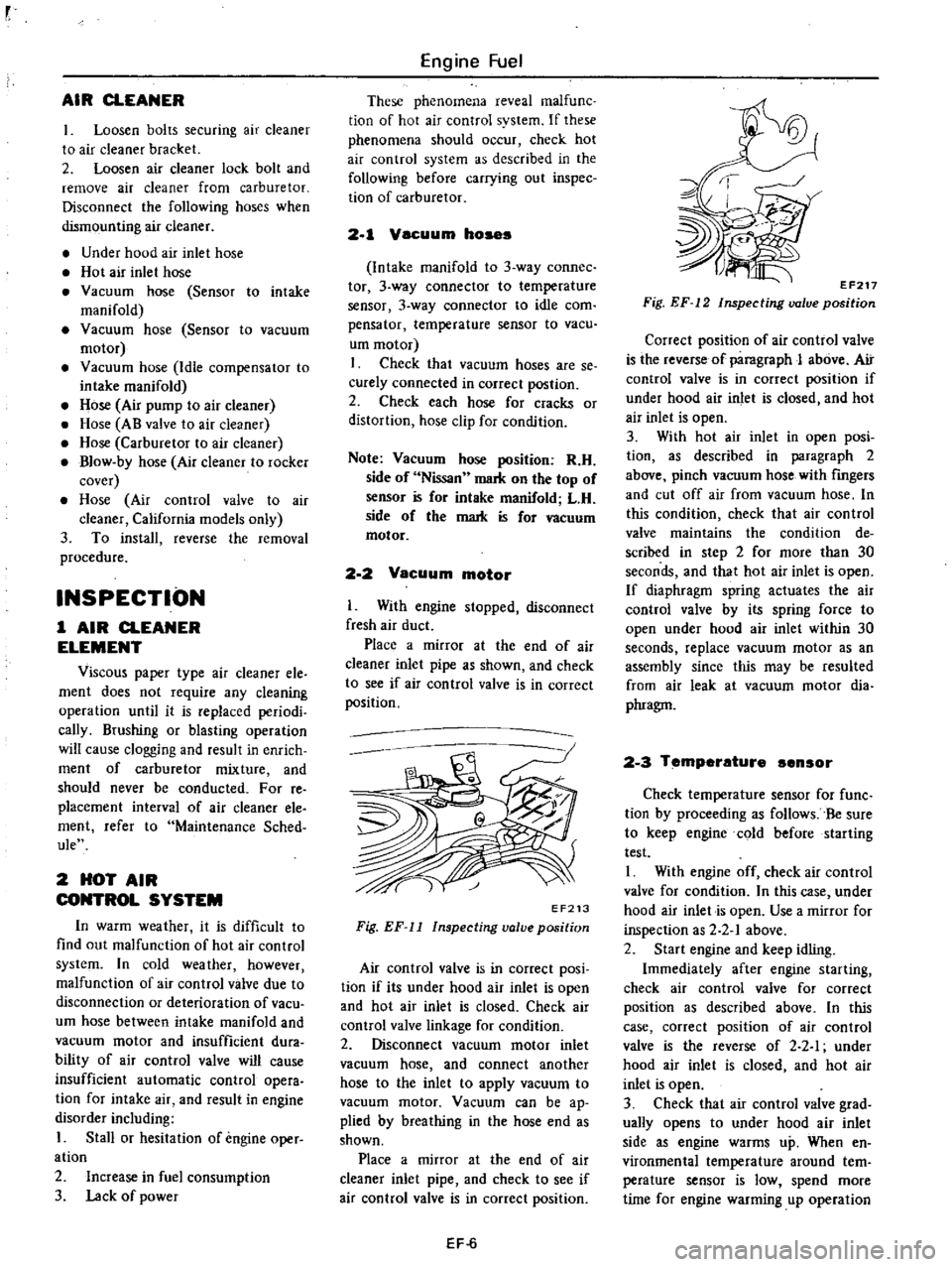

HOT

AIR

CONTROL

SYSTEM

In

warm

weather

it

is

difficult

to

find

out

malfunction

of

hot

air

control

system

In

cold

wea

thee

however

malfunction

of

air

control

valve

due

to

disconnection

or

deterioration

of

vacu

um

hose

between

intake

manifold

and

vacuum

motor

and

insufficient

dura

bility

of

air

control

valve

will

cause

insufficient

automatic

control

opera

tion

for

intake

air

and

result

in

engine

disorder

including

I

Stall

or

hesitation

of

engine

oper

ation

2

Increase

in

fuel

consumption

3

uck

of

power

Engine

Fuel

These

phenomena

reveal

malfunc

tion

of

hot

air

control

system

If

these

phenomena

should

occur

check

hot

air

control

system

as

described

in

the

following

before

carrying

out

inspec

tion

of

carburetor

2

1

Vacuum

hose

Intake

manifold

to

3

way

connec

tor

3

way

connector

to

temperature

sensor

3

way

connector

to

idle

com

pensator

temperature

sensor

to

vacu

um

motor

I

Check

that

vacuum

hoses

are

se

curely

connected

in

correct

postion

2

Check

each

hose

for

cracks

or

distortion

hose

clip

for

condition

Note

Vacuum

hose

position

R

H

side

of

Nissan

mark

on

the

top

of

sensor

is

for

intake

manifold

L

U

side

of

the

mark

is

for

vacuum

motor

2

2

Vacuum

motor

I

With

engine

stopped

disconnect

fresh

air

duct

Place

a

mirror

at

the

end

of

air

cleaner

inlet

pipe

as

shown

and

check

to

see

if

air

con

trol

valve

is

in

correct

position

EF213

Fig

EF

11

Inspecting

valve

position

Air

control

valve

is

in

correct

posi

tion

if

its

under

hood

air

inlet

is

open

and

hot

air

inlet

is

closed

Check

air

control

valve

linkage

for

condition

2

Disconnect

vacuum

motor

inlet

vacuum

hose

and

connect

another

hose

to

the

inlet

to

apply

vacuum

to

vacuum

motor

Vacuum

can

be

ap

plied

by

breathing

in

the

hose

end

as

shown

Place

a

mirror

at

the

end

of

air

cleaner

inlet

pipe

and

check

to

see

if

air

control

valve

is

in

correct

position

EF

6

EF217

Fig

EF

12

Inspecting

valve

position

Correct

position

of

air

control

valve

is

the

reverse

of

paragraph

J

above

Air

control

valve

is

in

correct

position

if

under

hood

air

inlet

is

closed

and

hot

air

inlet

is

open

3

With

hot

air

inlet

in

open

posi

tion

as

described

in

paragraph

2

above

pinch

vacuum

hose

with

fingers

and

cut

off

air

from

vacuum

hose

In

this

condition

check

that

air

control

valve

maintains

the

condition

de

scribed

in

step

2

for

more

than

30

seconds

and

that

hot

air

inlet

is

open

If

diaphragm

spring

actuates

the

air

control

valve

by

its

spring

force

to

open

under

hood

air

inlet

within

30

seconds

replace

vacuum

motor

as

an

assembly

since

this

may

be

resulted

from

air

leak

at

vacuum

motor

dia

phragm

2

3

Temperature

ensor

Check

temperature

sensor

for

func

tion

by

proceeding

as

follows

Be

sure

to

keep

engine

cold

before

starting

test

I

With

engine

off

check

air

control

valve

for

condition

In

this

case

under

hood

air

inlet

is

open

Use

a

mirror

for

inspection

as

2

2

1

above

2

Start

engine

and

keep

idling

Immediately

after

engine

starting

check

air

control

valve

for

correct

position

as

described

above

In

this

case

correct

position

of

air

control

valve

is

the

reverse

of

2

2

I

under

hood

air

inlet

is

closed

and

hot

air

inlet

is

open

3

Check

that

air

control

valve

grad

ually

opens

to

under

hood

air

inlet

side

as

engine

warms

up

When

en

vironmental

temperature

around

tern

perature

sensor

is

low

spend

more

time

for

engine

warming

up

operation

Page 108 of 537

854

co

in

in

one

minute

or

less

If

no

gasoline

or

only

a

little

flows

from

open

end

of

pipe

with

pump

operated

or

if

pump

does

not

work

perform

the

following

diagnosis

Notes

3

Do

not

connect

battery

in

reverse

polarity

which

if

left

for

a

long

time

would

damage

transitor

circuit

and

disable

pump

Engine

Fuel

b

Do

not

let

fall

pump

as

it

may

damage

electronic

components

c

Do

not

apply

overvoitage

max

l

8Y

Overvoltage

starting

by

quick

charge

or

tage

running

would

deteriorate

or

damage

elec

tronic

components

Fuel

pressure

maximum

0

32

kg

cm

4

6

psi

REMOVAL

AND

INSTALLATION

Flom

fuel

tank

Electric

fuel

pump

is

installed

on

bracket

with

two

bolts

This

bracket

is

located

on

R

H

side

member

adjacent

to

fuel

tank

I

Remove

inlet

hose

from

fuel

pump

Also

remove

outlet

hose

run

ning

to

engine

Receive

fuel

remaining

in

fuel

hose

in

a

suitable

container

2

Disconnect

harness

at

connector

3

Remove

bolts

securing

fuel

pump

to

bracket

and

detach

fuel

pump

4

Installation

is

the

reverse

order

of

removal

9

@

1

Cover

2

Magnet

3

Cover

gasket

4

Filter

5

Gasket

6

Spring

retainer

7

Washer

8

O

ring

9

Inlet

valve

10

Retutn

PIing

11

Plunger

12

Plunger

cylinder

13

Body

To

carburetor

1

Elecuic

fuel

pump

2

Mounting

bracket

3

Fuel

mter

EF72D

Fig

EF

23

Electric

fuel

pump

DISASSEMBLY

Do

not

disassemble

unless

pump

is

faulty

I

Remove

cover

with

wrench

and

take

out

cover

gasket

magnet

and

filter

from

pump

body

2

When

removing

plunger

take

out

spring

retainer

from

plunger

tube

3

Then

take

out

washer

O

ring

inlet

valve

return

spring

and

plunger

from

tube

Note

Do

not

disassemble

electronic

components

If

n

replace

with

new

ones

6

EF721

Fig

EF

24

Exploded

view

of

electric

fuel

pump

EF

12

ASSEMBLY

I

Before

assembly

clean

all

parts

with

gasoline

and

compressed

air

com

pletely

Notes

a

If

gask

t

an

d

fdterare

faulty

r

place

b

Clean

magnet

and

cover

for

fault

c

Take

care

not

to

defonn

thin

tube

d

Assemble

plunger

return

spring

inlet

valve

O

ring

washer

and

set

spring

retainer

in

that

order

e

Assemble

filter

gasket

and

cover

with

f

Tighten

cover

with

wrench

to

the

stopper

If

component

parts

are

dirty

after

disassembly

clean

as

follows

Wash

fIlter

and

strainer

with

clean

gasoline

and

blow

with

compressed

air

When

cleaning

parts

check

fllter

for

fault

If

faulty

replace

Wash

plunger

plunger

cylinder

and

inlet

valve

with

clean

gasoline

and

blow

dust

off

with

compressed

air

2

Check

c

v

m

lI

parts

for

wear

or

damage

If

they

are

found

faulty

replace

them

3

Insert

plunger

assembly

into

plunger

cylinder

of

body

and

apply

electric

current

to

it

Move

the

assembly

up

and

down

If

the

assembly

does

not

move

it

shows

that

the

electric

uuit

is

faulty

and

it

must

be

replaced

Page 120 of 537

ELECTRIC

AUTOMATIC

CHOKE

Checklna

automatic

choke

heater

circuit

with

function

test

connector

Caution

Do

not

altach

test

leads

of

a

circuit

tester

to

those

other

than

designated

Refer

to

figure

Ef

43

I

With

engine

not

running

check

for

continuity

between

A

and

B

as

shown

in

figure

Ef

43

If

continuity

exists

heater

is

func

tioning

properly

If

continuity

d

s

not

exist

check

for

disconnected

connector

or

open

P

T

e

heater

circuit

2

With

engine

running

at

idle

check

for

presence

of

voltage

across

A

and

B

as

shown

in

figure

EF

43

If

voltmeter

reading

is

12

volts

d

c

heater

circuit

is

functioning

properly

If

vohmeter

reading

is

zero

check

for

disconnected

connector

open

circuit

or

faulty

automatic

choke

relay

3

Replace

faulty

parts

J

j

N

j

EF710

1

ignition

key

2

Automatic

choke

relay

Engine

stop

OFF

Engine

start

ON

3

Automatic

choke

heateI

4

Function

test

connector

5

Altema

tor

Fig

EF

43

Checking

oulomalic

choke

heater

circuit

with

fu

nc

non

led

connector

Engine

Fuel

Automatic

choke

I

Before

starting

engine

fully

de

press

al

celerator

pedaJ

to

ensure

that

choke

valve

doses

properly

Push

choke

valve

with

a

finger

and

heck

for

binding

3

Check

0

be

sure

that

bi

rnetal

cover

index

mark

is

set

at

the

cen

leT

of

choke

housing

index

mark

a

s

shown

in

Figure

EF

44

Note

Do

not

set

b

metal

cover

index

mark

at

any

position

except

the

center

of

choke

housing

index

marl

tE

jL

J

Thermostat

cover

Bi

metal

chamber

2

Thermostat

housing

3

Groove

ET034

Fig

EF

44

Bi

metol

tting

4

Check

automatic

choke

heater

source

wiring

for

proper

connection

then

start

engine

5

After

warming

up

the

engine

see

that

choke

valve

is

fully

open

6

If

automatic

choke

heater

source

wiring

is

normal

and

choke

valve

does

not

operate

after

warm

up

replace

hi

metal

co

t

er

Automatic

choke

relay

I

Remove

automatic

choke

relay

Auto

choke

heater

relay

EF278

Fig

EF

45

Location

of

automatic

choke

relay

EF

24

2

Make

an

operational

check

of

automatic

choke

relay

as

shown

in

Figure

EF

46

Apply

2

volts

d

c

across

termi

nals

I

and

3

to

ensure

that

i

ontinuity

exists

between

terminals

2

and

4

Check

t

lal

continuity

does

not

exist

between

terminals

2

and

4

when

no

voltage

is

applied

across

them

If

results

satisfies

the

above

automatic

choke

relay

is

functioning

properly

if

not

replace

choke

relay

1

2

3

y

4

EF723

Fig

EF

46

Checking

automatic

choke

relay

Automatic

choke

heater

I

Measure

resistance

of

choke

heater

as

shown

in

figure

EF

47

spe

ified

re

s

an

ce

is

3

7

to

8

9

ohms

F

EF261

Fig

EF

47

Automatic

choke

heater

check

2

If

measured

value

is

not

within

the

specification

replace

bi

metal

cover

INTERLOCK

OPENING

OF

PRIMARY

AND

SECONDARY

THROTnE

VALVE

Figure

EF

48

shows

primary

throt

tie

valve

opened

SO

When

primary

throtlle

valve

is

opened

50

the

adjust

plate

integrated

with

throttle

valve

is

in

contact

with

return

plate

at

A

Page 121 of 537

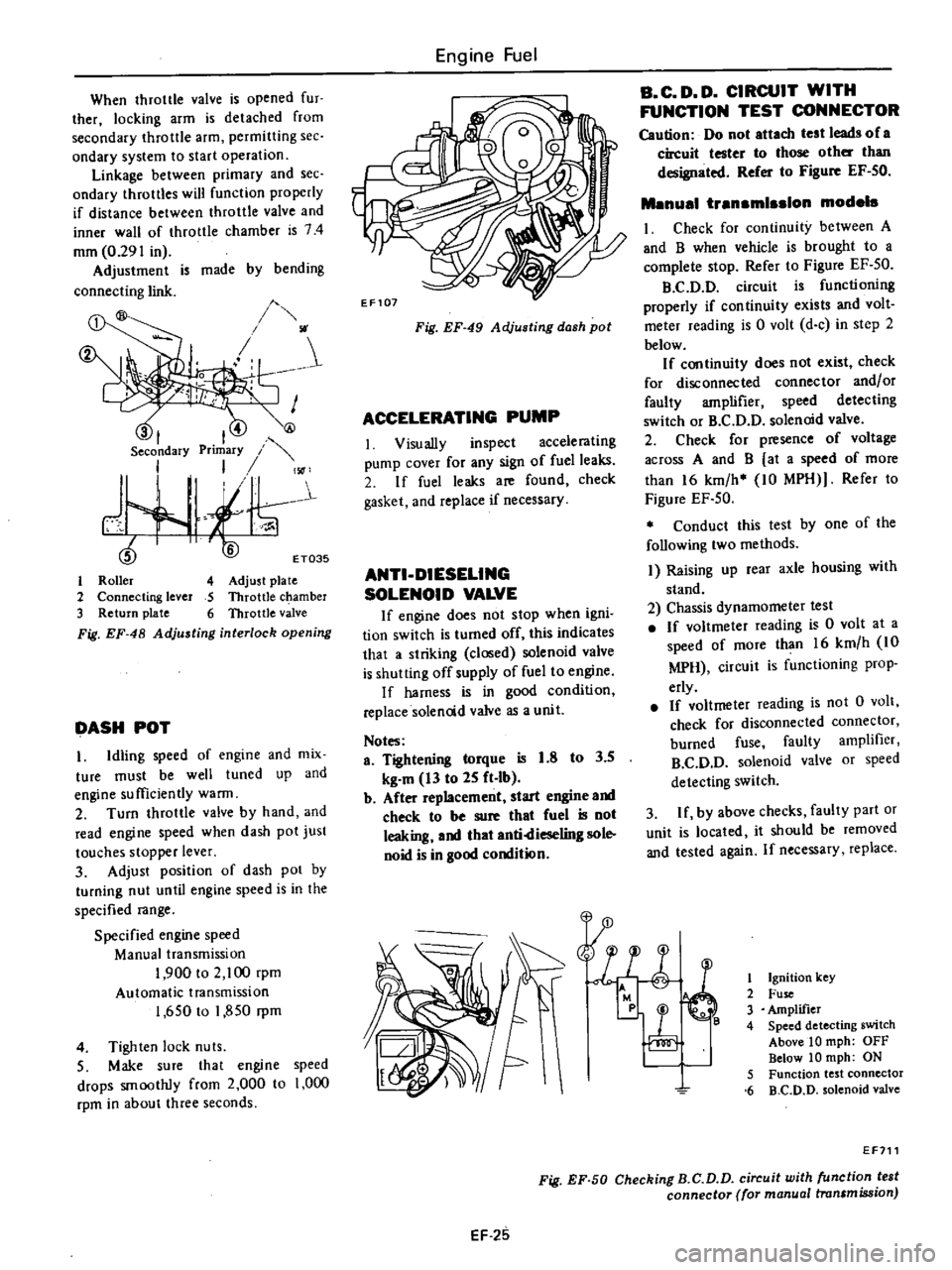

When

throttle

valve

is

opened

fur

ther

locking

arm

is

detached

from

secondary

throttle

arm

permitting

see

ondary

system

to

start

operation

Linkage

between

primary

and

see

ondary

throttles

will

function

properly

if

distance

between

throttle

valve

and

inner

wall

of

throttle

chamber

is

74

mm

0

291

in

Adjustment

is

made

by

bending

connecting

link

I

L

l

1

4

CAl

Secondary

prm

ary

I

Jl

I

7

t

@

1

Roller

4

Adjust

plate

2

Connecting

lever

5

Throttle

c

amber

3

Return

plate

6

Throttle

valve

Fig

EF

48

Adjusting

interlock

opening

DASH

POT

1

Idling

speed

of

engine

and

mix

ture

must

be

well

tuned

up

and

engine

sufficiently

warm

2

Turn

throttle

valve

by

hand

and

read

engine

speed

when

dash

pot

just

touches

stopper

lever

3

Adjust

position

of

dash

pot

by

turning

nut

until

engine

speed

is

in

the

specified

range

Specified

engine

speed

Manual

transmission

1

900

to

2

100

rpm

Automatic

transmission

1

650

to

1

850

rpm

4

Tighten

lock

nuts

5

Make

sure

that

engine

speed

drops

smoothly

from

2

000

to

1

000

rpm

in

about

three

seconds

Engine

Fuel

Fig

EF

49

Adjusting

dash

pot

ACCELERATING

PUMP

I

Visually

inspect

accelerating

pump

cover

for

any

sign

of

fuel

leaks

2

If

fuel

leaks

are

found

check

gasket

and

replace

if

necessary

ANTI

DIESELING

SOLENOID

VALVE

If

engine

does

not

stop

when

igni

tion

switch

is

turned

off

this

indicates

that

a

striking

closed

solenoid

valve

is

shutting

off

supply

of

fuel

to

engine

If

harness

is

in

good

condition

replace

solencid

valve

as

a

unit

Notes

a

Tightening

torque

is

1

8

to

3

5

kg

m

13

to

25

ft

Ib

b

After

replacement

star

engine

and

check

to

be

sure

that

fuel

is

not

leaking

and

that

anti

dieseling

sol

noid

is

in

good

condition

B

C

D

D

CIRCUIT

WITH

FUNCTION

TEST

CONNECTOR

Caution

Do

not

attach

test

leads

of

a

circuit

tester

to

those

other

than

designated

Refer

to

Figure

EF

50

Menuel

trensmlsslon

models

I

Check

for

continuity

between

A

and

B

when

vehicle

is

brought

to

a

complete

stop

Refer

to

Figure

EF

50

B

C

D

D

circuit

is

functioning

properly

if

continuity

exists

and

volt

meter

reading

is

0

volt

d

c

in

step

2

below

If

continuity

does

not

exist

check

for

disconnected

connector

and

or

faulty

amplifier

speed

detecting

switch

or

B

C

D

D

solenoid

valve

2

Check

for

presence

of

voltage

across

A

and

B

at

a

speed

of

more

than

16

km

h

10

MPH

Refer

to

Figure

EF

50

Conduct

this

test

by

one

of

the

following

two

methods

I

Raising

up

rear

axle

housing

with

stand

2

Chassis

dynamometer

test

If

voltmeter

reading

is

0

volt

at

a

speed

of

more

than

16

km

h

10

MPH

circuit

is

functioning

prop

erly

If

voltmeter

reading

is

not

0

volt

check

for

disconnected

connector

burned

fuse

faulty

amplifier

B

C

D

D

solenoid

valve

or

speed

detecting

switch

3

If

by

above

checks

faulty

part

or

unit

is

located

it

should

be

removed

and

tested

again

If

necessary

replace

1

P4

11

0

8

l

1

Ignition

Icey

2

Fuse

3

Amplifier

4

Speed

detecting

switch

Above

10

mph

OFF

Below

10

mph

ON

5

Function

test

connector

6

B

C

D

D

solenoid

valve

EF711

Fig

EF

50

Checking

B

C

D

D

circuit

with

function

test

connector

for

manual

transmission

EF

25

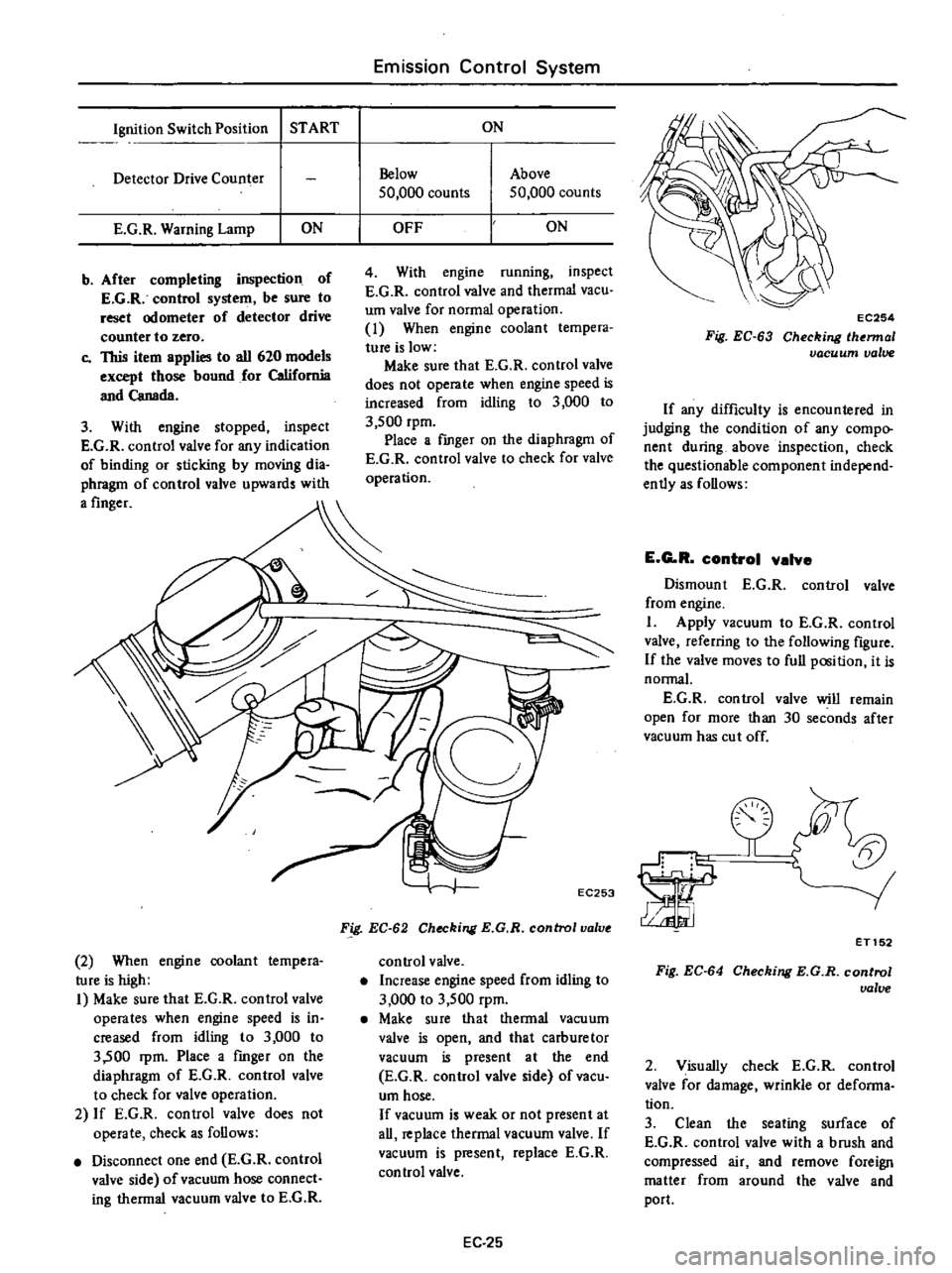

Page 158 of 537

Ignition

Switch

Position

START

Detector

Drive

Counter

E

G

R

Warning

Lamp

ON

b

After

completing

inspection

of

E

G

R

control

system

be

sure

to

reset

odometer

of

detector

drive

counter

to

zero

c

This

item

applies

to

all

620

models

except

those

bound

for

California

and

Canada

3

With

engine

stopped

inspect

E

G

R

control

valve

for

any

indication

of

binding

or

sticking

by

moving

dia

phragm

of

control

valve

upwards

with

a

finger

2

When

engine

coolant

tempera

ture

is

high

I

Make

sure

that

E

G

R

control

valve

operates

when

engine

speed

is

in

creased

from

idling

to

3

000

to

3

500

rpm

Place

a

fmger

on

the

diaphragm

of

E

G

R

control

valve

to

check

for

valve

operation

2

If

E

G

R

control

valve

does

not

operate

check

as

follows

Disconnect

one

end

E

G

R

control

valve

side

of

vacuum

hose

connect

ing

thermal

vacuum

valve

to

E

G

R

Emission

Control

System

ON

Below

50

000

counts

Above

50

000

counts

OFF

ON

4

With

engine

running

inspect

E

G

R

control

valve

and

thermal

vacuo

um

valve

for

normal

operation

1

When

engine

coolant

tempera

ture

is

low

Make

sure

that

E

G

R

control

valve

does

not

operate

when

engine

speed

is

increased

from

idling

to

3

000

to

3

500

rpm

Place

a

fmger

on

the

diaphragm

of

E

G

R

control

valve

to

check

for

valve

operation

EC253

Fig

EC

62

Checking

E

G

R

control

valve

control

valve

Increase

engine

speed

from

idling

to

3

000

to

3

500

rpm

Make

su

re

that

thermal

vacu

um

valve

is

open

and

that

carburetor

vacuum

is

present

at

the

end

E

G

R

control

valve

side

of

vacu

um

hose

If

vacuum

is

weak

or

not

present

at

all

replace

thermal

vacuum

valve

If

vacuum

is

present

replace

E

G

R

control

valve

EC

25

EC254

Fig

EC

63

Checking

lhermal

vacuum

valve

If

any

difficulty

is

encountered

in

judging

the

condition

of

any

compo

nent

during

above

inspection

check

the

questionable

component

independ

ently

as

follows

E

G

R

control

valve

Dismount

E

G

R

control

valve

from

engine

I

Apply

vacuum

to

E

G

R

control

valve

referring

to

the

following

figure

If

the

valve

moves

to

full

position

it

is

normal

E

G

R

control

valve

will

remain

open

for

more

than

30

seconds

after

vacuum

has

cut

off

la

ET152

Fig

EC

64

Checking

E

G

R

control

ualue

2

Visually

check

E

G

R

control

valve

for

damage

wrinkle

or

defonna

tion

3

Clean

the

seating

surface

of

E

G

R

control

valve

with

a

brush

and

compressed

air

and

remove

foreign

matter

from

around

the

valve

and

port

Page 173 of 537

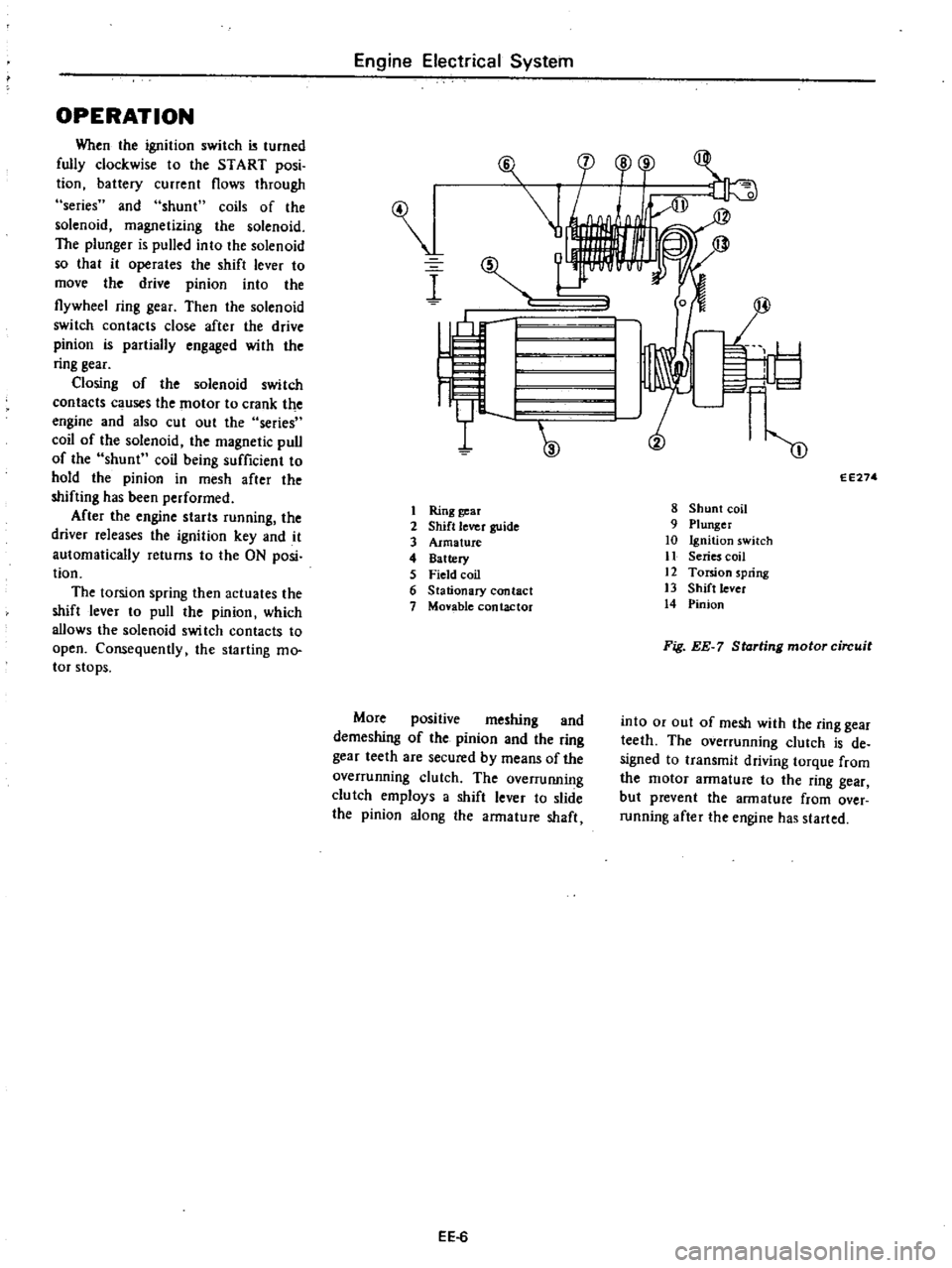

OPERATION

When

the

ignition

switch

turned

fully

clockwise

to

the

START

posi

tion

battery

current

flows

through

series

and

shunt

coils

of

the

solenoid

magnetizing

the

solenoid

The

plunger

is

pulled

into

the

solenoid

so

that

it

operates

the

shift

lever

to

move

the

drive

pinion

into

the

flywheel

ring

gear

Then

the

solenoid

switch

contacts

close

after

the

drive

pinion

is

partially

engaged

with

the

ring

gear

Closing

of

the

solenoid

switch

contacts

c

uses

the

motor

to

crank

the

engine

and

also

cut

out

the

series

coil

of

the

solenoid

the

magnetic

pull

of

the

shunt

coil

being

sufficient

to

hold

the

pinion

in

mesh

after

the

shifting

has

been

performed

After

the

engine

starts

running

the

driver

releases

the

ignition

key

and

it

automatically

returns

to

the

ON

posi

tion

The

torsion

spring

then

actuates

the

shift

lever

to

pull

the

pinion

which

allows

the

solenoid

swi

tch

contacts

to

open

Consequently

the

starting

mo

tor

stops

Engine

Electrical

System

I

I

Ring

gear

2

Shift

lever

guide

3

Armature

4

Battery

5

Field

coil

6

Stationary

contact

7

Monble

contactor

More

positive

meshing

and

demeshing

of

the

pinion

and

the

ring

gear

teeth

are

secured

by

means

of

the

overrunning

clutch

The

overruIUling

clutch

employs

a

shift

lever

to

slide

the

pinion

along

the

armature

shaft

EE

6

F

l

cp

o

r

1

I

I

W

m

EE274

8

Shunt

coil

9

Plunger

10

Ignition

switch

11

Series

coil

12

Torsion

spring

13

Shift

lever

14

Pinion

Fig

EE

7

Starting

motor

circuit

into

or

out

of

mesh

with

the

ring

gear

teeth

The

overrunning

clutch

is

de

signed

to

transmit

driving

torque

from

the

motor

armature

to

the

ring

gear

but

prevent

the

armature

from

over

running

after

the

engine

has

started

Page 174 of 537

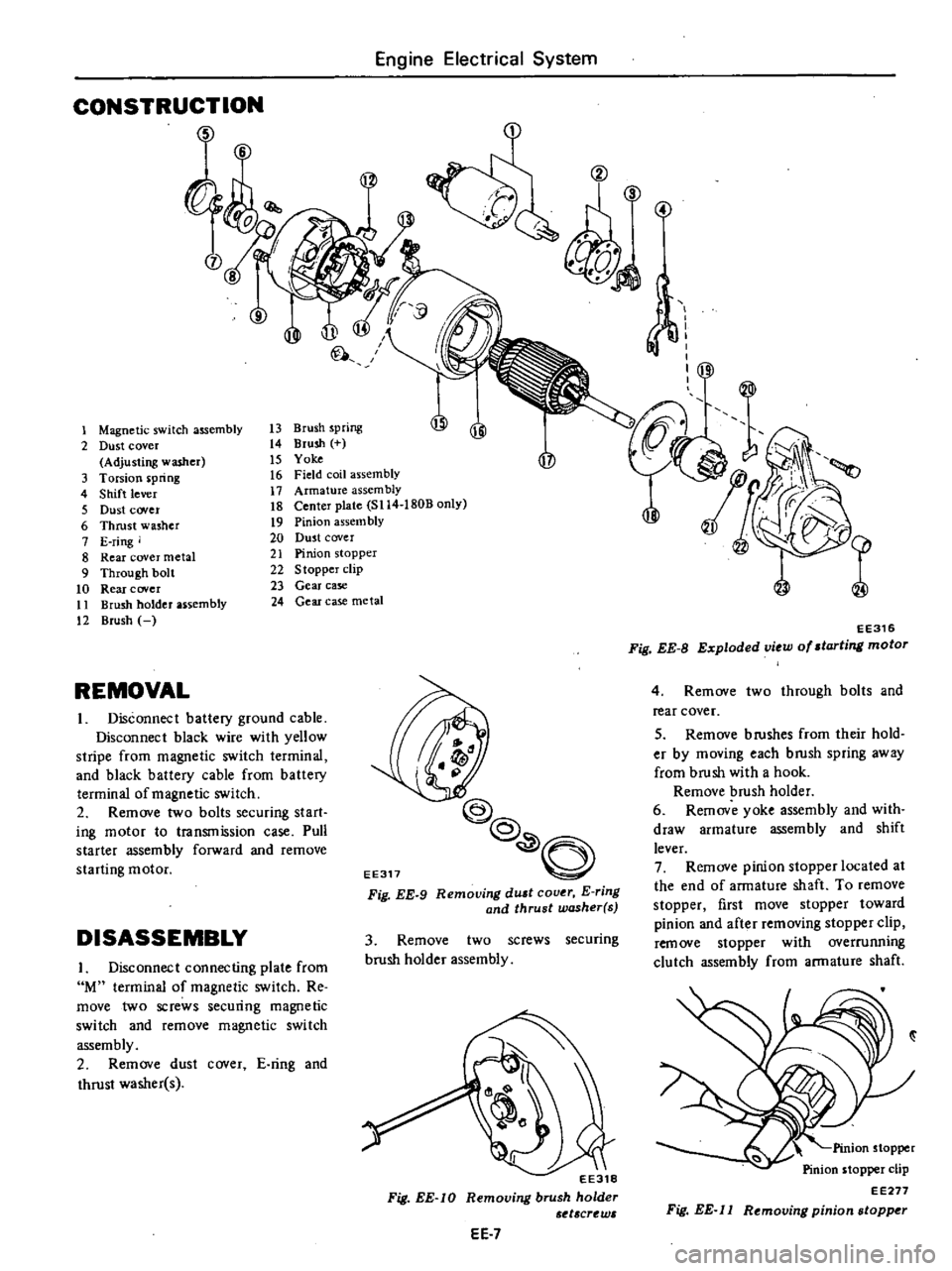

CONSTRUCTION

O

o

8

w

il

Engine

Electrical

System

V

1

Magnetic

switch

assembly

13

Brush

spring

jj

JI

2

Dust

cover

t4

Brush

Adjusting

washer

15

Yoke

P

3

Torsion

pring

t6

Field

coil

assembly

4

Shift

lever

17

Armature

assembly

5

Dust

cover

18

Center

plate

SI14

1808

only

6

Thrust

washer

19

Pinion

assem

bly

7

E

ring

20

Dust

cover

8

Rear

cover

metal

21

Pinion

stopper

9

Through

bolt

22

Stopper

clip

10

Rear

cover

23

Gear

case

tl

Brush

holder

assembly

24

Gear

case

metal

12

Brush

REMOVAL

Disconnect

battery

ground

cable

Disconnect

black

wire

with

yellow

stripe

from

magnetic

switch

terminal

and

black

battery

cable

from

battery

terminal

of

magnetic

switch

2

Remove

two

bolts

securing

start

ing

motor

to

transmission

case

Pull

starter

assembly

forward

and

remove

starting

motor

DISASSEMBLY

I

Disconnect

connecting

plate

from

M

terminal

of

magnetic

switch

Re

move

two

screws

securing

magnetic

switch

and

remove

magnetic

switch

assembly

2

Remove

dust

cover

E

ring

and

thrust

washer

s

EE317

@

@

O

Fig

EE

9

Remouing

dUlt

cover

E

ring

and

thrust

washer

s

3

Remove

two

screws

securing

brush

holder

assembly

EE318

Fig

EE

IO

Removing

brush

holder

d

crt

w

EE

7

S

4

f

I

jl

I

EE316

Fig

EE

B

Exploded

view

of

starting

motor

4

Remove

two

through

bolts

and

rear

cover

5

Remove

b

rushes

from

their

hold

er

by

moving

each

brush

spring

away

from

brush

with

a

hook

Remove

brush

holder

6

Remov

yoke

assembly

and

with

draw

armature

assembly

and

shift

lever

7

Remove

pinion

stopper

located

at

the

end

of

armature

shaft

To

remove

stopper

first

move

stopper

toward

pinion

and

after

removing

stopper

clip

remove

stopper

with

overrunning

clutch

assembly

from

armature

shaft

Pinion

stopper

Pinion

stopper

clip

EE277

Fig

EE

l1

Removing

pinion

stopper