light DATSUN PICK-UP 1977 Workshop Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 252 of 537

TM757

Fig

MT

61

Removing

counterahaft

nut

Note

When

removing

mainshaft

as

sembly

loosen

mainshaft

nut

7

Draw

out

counter

overdrive

gear

and

bearing

from

countershaft

rear

end

by

using

a

suitable

gear

puller

See

Figure

MT

62

TM758

Fig

MT

62

Removing

count

r

overdriv

gear

and

bearing

8

Remove

counter

reverse

idler

gear

and

spacer

9

Remove

countershaft

by

lightly

tapping

the

rear

end

with

a

soft

hammer

Be

careful

not

to

drop

off

gear

shaft

10

Remove

reverse

idler

gear

snap

ring

TM759

Fig

MT

63

Removing

reverse

idler

gear

nap

ring

Manual

Transmission

II

Remove

reverse

idler

gear

12

Remove

snap

ring

of

mainshaft

end

bearing

Draw

out

bearing

using

Mainshaft

Rear

Bearing

Puller

KV32101330

Remove

other

snap

ring

of

mainshafl

end

bearing

See

Figure

MT

64

tw

KV32101330

TM160

Fig

MT

64

Removing

mai

haft

nd

bearing

13

Remove

mainshaft

nut

thrust

washer

mainshaft

reverse

gear

OD

synchronizer

and

overdrive

gear

14

Draw

out

mainshaft

gear

assem

bly

together

with

countershaft

by

lightly

tapping

the

rear

end

with

a

soft

hainmer

Me

holding

the

front

of

mainshaft

gear

assembly

by

hand

Be

careful

not

to

drop

off

gear

shaft

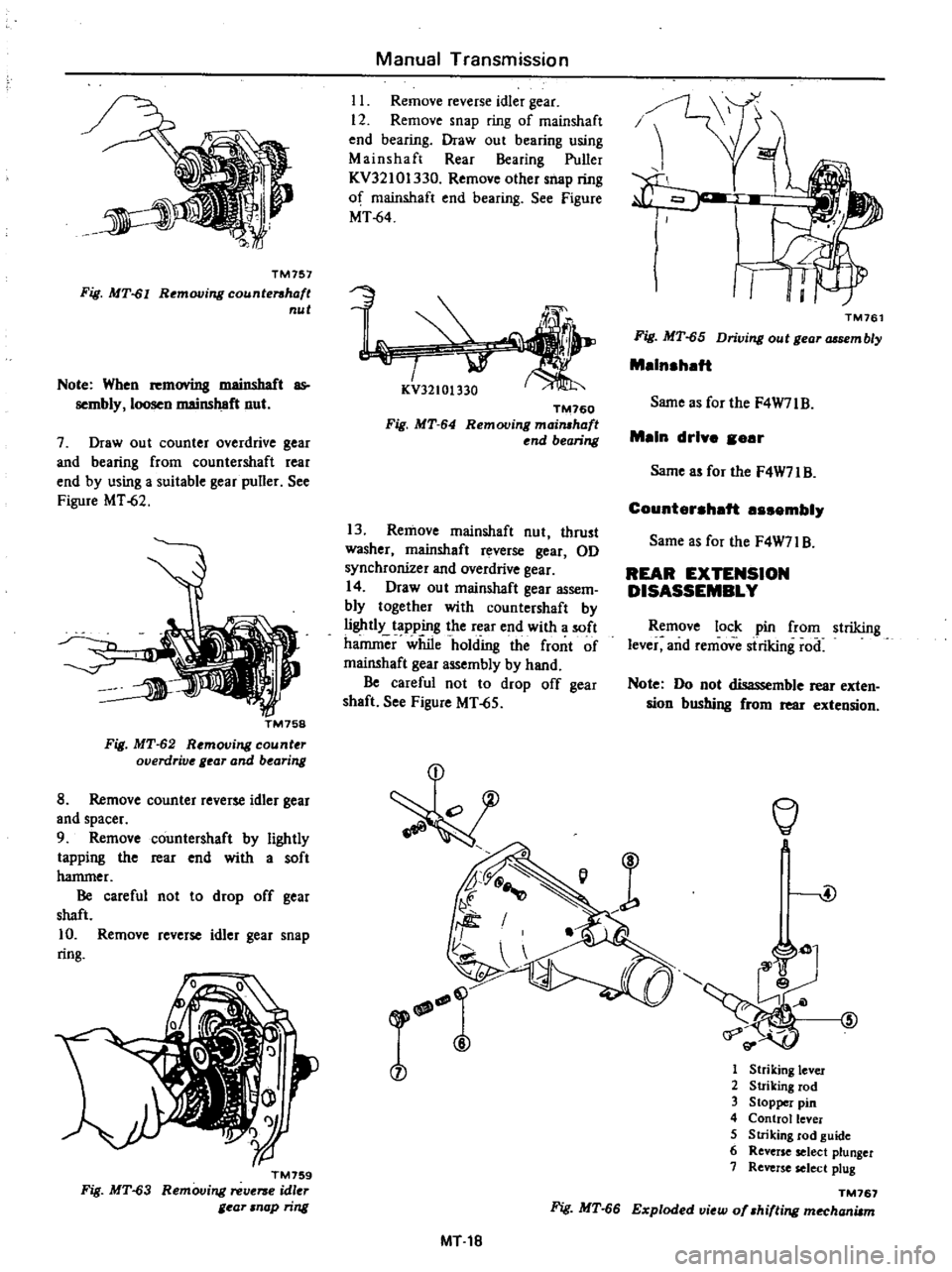

See

Figure

MT

65

k

r

IT

TM761

Fig

MT

65

Driving

out

gear

sembly

Malnahaft

Same

as

for

the

F4W7IB

Main

drive

ear

Same

as

for

the

F4W71

B

Counterahaft

aaaembly

Same

as

for

the

F4W7l

B

REAR

EXTENSION

DISASSEMBLY

Remove

lock

pin

from

striking

lever

and

remove

siriking

rod

Note

Do

not

disassemble

rear

exten

sion

bushing

from

rear

extension

J

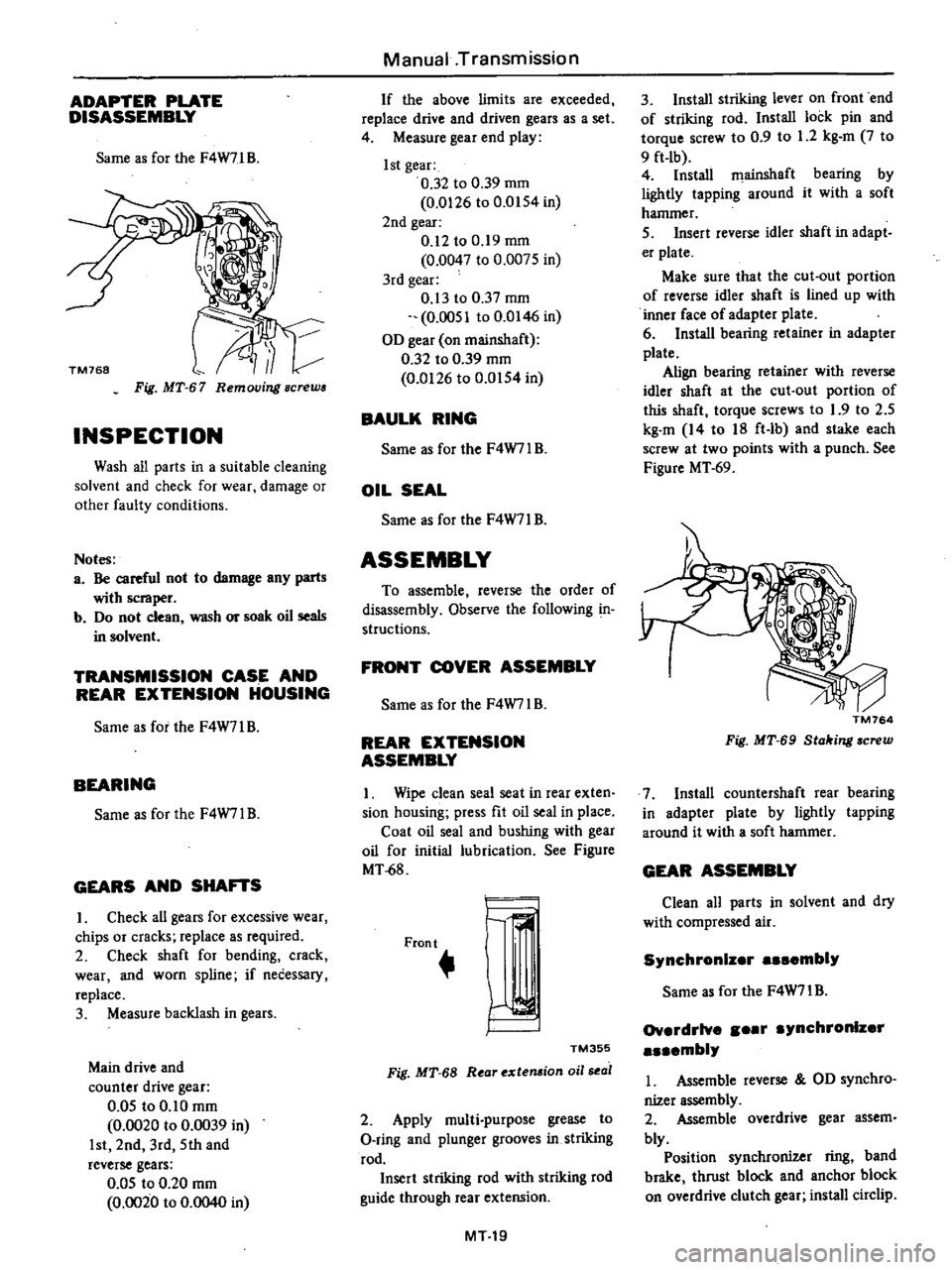

l

J

@

1

Striking

lever

2

Striking

rod

3

Stopper

pin

4

Control

lever

5

Striking

rod

guide

6

Reverse

select

plunger

7

Reverse

select

plug

TM767

Fig

MT

66

Exploded

view

of

shifting

mechanilm

MT1B

Page 253 of 537

ADAPTER

PLATE

DISASSEMBLY

Same

as

for

the

F4W71

B

Fig

MT

67

Removing

screws

INSPECTION

Wash

all

parts

in

a

suitable

cleaning

solvent

and

check

for

wear

damage

or

other

faulty

conditions

Notes

a

Be

careful

not

to

damage

any

parts

with

scraper

b

Do

not

clean

wash

or

soak

oil

seals

in

solvent

TRANSMISSION

CASE

AND

REAR

EXTENSION

HOUSING

Same

as

for

the

F4W71

B

BEARING

Same

as

for

the

F4W7l

B

GEARS

AND

SHA

S

I

Check

all

gears

for

excessive

wear

chips

or

cracks

replace

as

required

2

Check

shaft

for

bending

crack

wear

and

worn

spline

if

necessary

replace

3

Measure

backlash

in

gears

Main

drive

and

counter

drive

gear

0

05

to

0

10

mm

0

0020

to

0

0039

in

1st

2nd

3rd

5th

and

reverse

gears

0

05

to

0

20

mm

0

0020

to

0

0040

in

Manual

Transmission

If

the

above

limits

are

exceeded

replace

drive

and

driven

gears

as

a

set

4

Measure

gear

end

play

1st

gear

0

32

to

0

39

mm

0

0126

to

0

0154

in

2nd

gear

0

12

to

0

19

mm

0

0047

to

0

0075

in

3rd

gear

0

13

to

0

37

mm

0

0051

to

0

0146

in

OD

gear

on

mainshaft

0

32

to

0

39

mm

0

0126

to

0

0154

in

BAULK

RING

Same

as

for

the

F4W7IB

OIL

SEAL

Same

as

for

the

F4W71

B

ASSEMBLY

To

assemble

reverse

the

order

of

disassembly

Observe

the

following

in

structions

FRONT

COVER

ASSEMBLY

Same

as

for

the

F4W7l

B

REAR

EXTENSION

ASSEMBLY

I

Wipe

clean

seal

seat

in

rear

exten

sion

housing

press

fit

oil

seal

in

place

Coat

oil

seal

and

bushing

with

gear

oil

for

initial

lubrication

See

Figure

MT

68

Front

r

I

TM355

Fig

MT

68

R

ar

extemion

oil

sea

2

Apply

multi

purpose

grease

to

O

ring

and

plunger

grooves

in

striking

rod

Insert

striking

rod

with

striking

rod

guide

through

rear

extension

MT19

3

Install

striking

lever

on

front

end

of

striking

rod

Install

lock

pin

and

torque

screw

to

0

9

to

1

2

kg

m

7

to

9

ft

lb

4

Install

filainshaft

bearing

by

lightly

tapping

around

it

with

a

soft

hammer

5

Insert

reverse

idler

shaft

in

adapt

er

plate

Make

sure

that

the

cut

out

portion

of

reverse

idler

shaft

is

lined

up

with

inner

face

of

adapter

plate

6

Install

bearing

retainer

in

adapter

plate

Align

bearing

retainer

with

reverse

idler

shaft

at

the

cut

out

portion

of

this

shaft

torque

screws

to

1

9

to

2

5

kg

m

14

to

18

ft

lb

and

stake

each

screw

at

two

points

with

a

punch

See

Figure

MT

69

TM764

Fig

MT

69

Stahing

screw

7

Install

countershaft

rear

bearing

in

adapter

plate

by

lightly

tapping

around

it

with

a

soft

hammer

GEAR

ASSEMBLY

Clean

all

parts

in

solvent

and

dry

with

compressed

air

Synchronlz

r

embly

Same

as

for

the

F4W71

B

Ov

rdrlve

r

ynchronlz

r

mbly

I

Assemble

reverse

OD

synchro

nizer

assembly

2

Assemble

overdrive

gear

assem

bly

Position

synchronizer

ring

band

brake

thrust

block

and

anchor

block

on

overdrive

clutch

gear

install

circlip

Page 265 of 537

plate

The

parking

rod

pin

operates

the

rod

at

p

range

and

operates

the

mechanical

lock

system

The

above

described

manual

shaft

is

further

equipped

with

an

inhibitor

switch

A

rotor

inside

the

inhibitor

switch

rotates

in

response

to

each

range

When

tne

range

is

selected

at

p

or

N

the

rotor

closes

the

starter

magnet

circuit

so

that

the

engine

can

be

started

When

the

range

is

selected

at

R

the

rolor

closes

the

back

up

lamp

circuit

and

the

back

up

lamp

lights

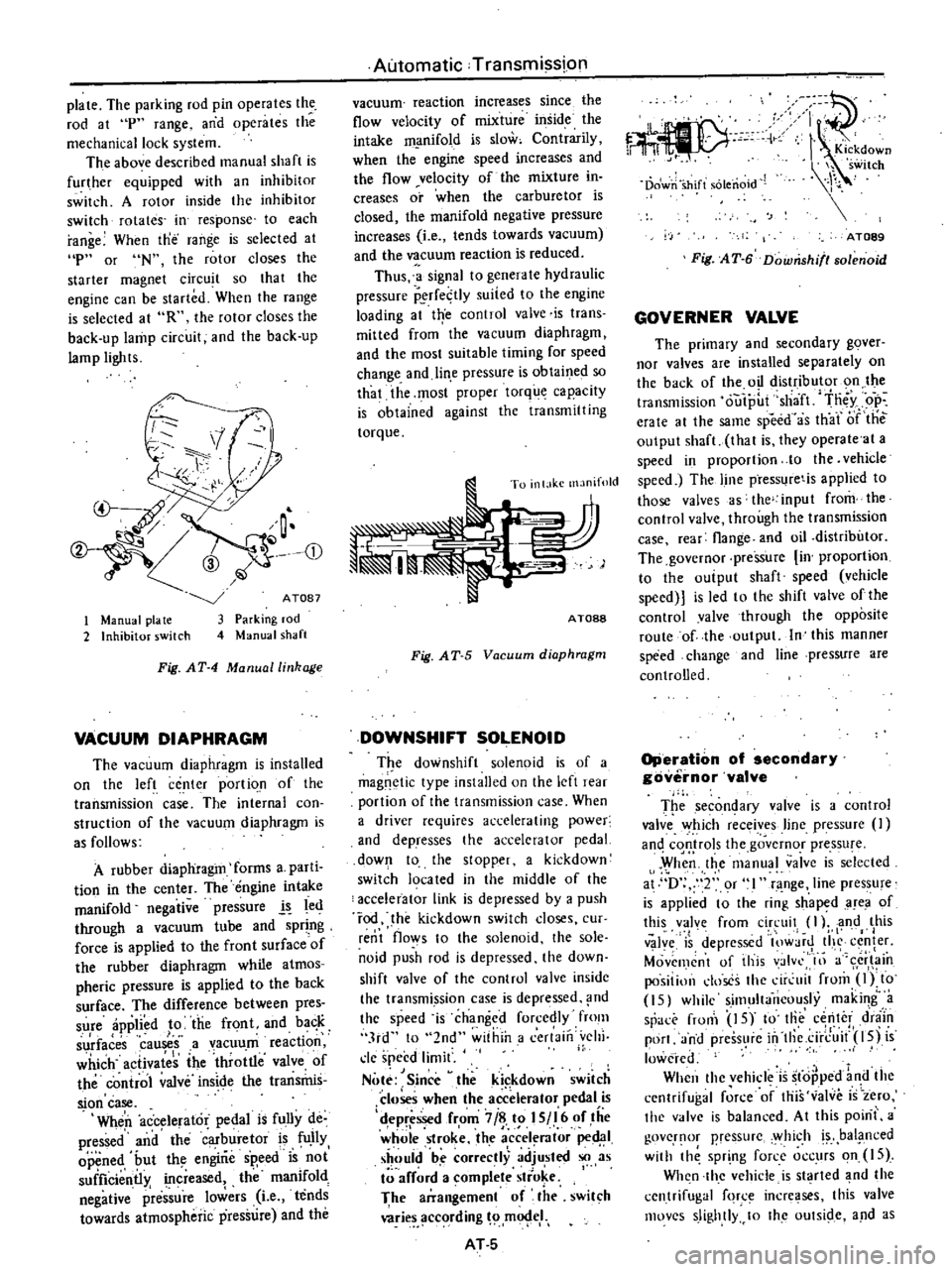

CD

1

Manual

pia

te

2

Inhibitor

switch

ATOB7

Parking

rod

Manual

shaft

Fig

AT

4

Manual

linkage

VACUUM

DIAPHRAGM

The

vacuum

diaphragm

is

installed

on

the

left

center

portio

n

of

the

transmission

case

The

internal

con

struction

of

the

vacuum

diaphragm

is

as

follows

A

rubber

diaphragm

forms

a

parti

tion

in

the

center

The

engine

intake

manifold

negative

pressure

l

led

through

a

vacuum

tube

and

spring

force

is

applied

to

the

front

surfaceof

the

rubber

diaphragm

while

atmos

pheric

pressure

is

applied

to

the

back

surface

The

difference

between

pres

sure

applied

to

the

front

and

ba

K

I

surfaces

causes

a

vacuum

reactIOn

which

activates

the

throttle

valve

of

the

control

valve

inside

the

transrhis

sion

case

Wheri

accelerator

pedal

is

fully

de

pressed

and

the

buretor

is

fU

IIy

opened

but

th

engirie

sp

eed

is

not

suificientl

increased

the

manifold

negative

plre

sure

lowers

Le

tends

towards

atmospheric

pressure

and

the

Automatic

Transmission

vacuum

reaction

increases

since

the

flow

velocity

of

mixture

inside

the

intake

m

mifold

is

slow

Contrarily

when

the

engine

speed

increases

and

the

flow

velocity

of

the

mixture

in

creases

or

when

the

carburetor

is

closed

the

manifold

negative

pressure

increases

Le

tends

towards

vacuum

and

the

vacuum

reaction

is

reduced

Thus

a

signal

to

genera

Ie

hydraulic

pressure

P

rfe

tly

suited

to

the

engine

loading

at

trye

control

valve

is

trans

mitted

from

the

vacuum

diaphragm

and

the

most

suitable

timing

for

speed

change

and

lin

e

pressure

is

obtaine

so

that

the

most

proper

torque

capacity

is

obtained

against

the

transmitting

torque

To

inl

lkc

manifold

AT088

Fig

AT

5

Vacuum

diaphragm

DOWNSHIFT

SOLENOID

T

e

downshift

solenoid

is

of

a

magnetic

type

installed

on

the

left

re

r

portion

of

the

transmission

case

When

a

driver

requires

accelerating

power

and

dePresses

the

accelerator

pedal

down

to

the

stopper

a

kickdown

switch

19ca

ted

in

the

middle

of

the

accelerator

link

is

depressed

by

a

push

rod

he

kickdown

switch

doses

cur

rent

flows

to

the

solenoid

the

sole

noid

push

rod

is

depressed

the

down

shift

valve

of

the

control

valvc

insidc

the

transmi

ssion

case

is

depressed

nd

the

speed

is

changed

forcedly

fmm

3rd

to

2nd

within

a

cerlaill

vehi

cle

speed

limit

Note

Since

theki

kdown

switch

closes

when

the

accelerator

pedal

is

d

epr

ssed

from

7

i

t

I

S

I

6

of

tiie

whole

stroke

the

a

ccel

rator

ped

1

should

be

correctly

adjusted

so

as

arf

rd

a

omplete

stro

e

I

The

arrangement

of

the

swit

h

wries

ccording

m

eI

AT

S

c

C

r

11

I

Kickdown

h

switch

Dowri

shift

solenoid

AT089

Fig

AT

6

Downshifl80lenoid

GOVERNER

VALVE

The

primary

and

secondary

gover

nor

valves

are

installed

separately

on

the

back

of

the

oil

distributor

on

the

transmission

outp

t

sha

ft

tn

y

op

erate

al

the

same

speed

as

th

ar

iJf

tile

output

shaft

thai

is

they

operate

at

a

speed

in

proportion

10

the

vehicle

speed

The

line

press

retis

applied

to

those

valves

s

the

input

from

the

control

valve

through

the

transmission

case

rear

flange

and

oil

distributor

The

governor

pressure

in

proportion

to

the

ouiput

shaft

speed

vehicle

speed

is

led

to

the

shift

valve

ofthe

control

valve

through

the

opposite

route

of

the

output

In

this

manner

speed

change

and

line

pressure

are

controlled

Operation

of

secondary

governor

valve

T

e

secon

ary

valve

is

a

contro

valve

Y

hich

receives

line

pressure

an

cqQ

rols

the

governor

pressu

e

When

the

manual

valve

is

selected

at

D

2

or

l

range

line

pressure

is

applied

t

the

ri

g

sh

aped

area

of

this

valve

from

circuit

I

l

and

this

I

v

Jy

is

depressed

lOW

jr

tI

c

fer

Movemcnt

of

this

valvl

III

a

cr

in

positillll

doses

the

dr

uit

from

Olto

15

while

simultaneously

making

a

sr

rronl

IS

to

Iii

center

d

niin

port

and

press

re

in

tllc

ci

rJ

it

l5j

is

lowered

When

thc

vehicle

is

stopped

1

d

the

cenlrifugal

force

of

this

valve

is

zero

the

v

lve

is

balanced

At

this

poini

a

govcr

lOr

pressurc

y

hich

bal

i1

nced

with

th

spr

ng

force

occurs

on

IS

Wh

n

thc

vehicle

is

st

rted

nd

the

centrifugal

fqr

incre

ses

this

valve

movcs

slightly

10

Ihc

oUlSide

and

as

Page 267 of 537

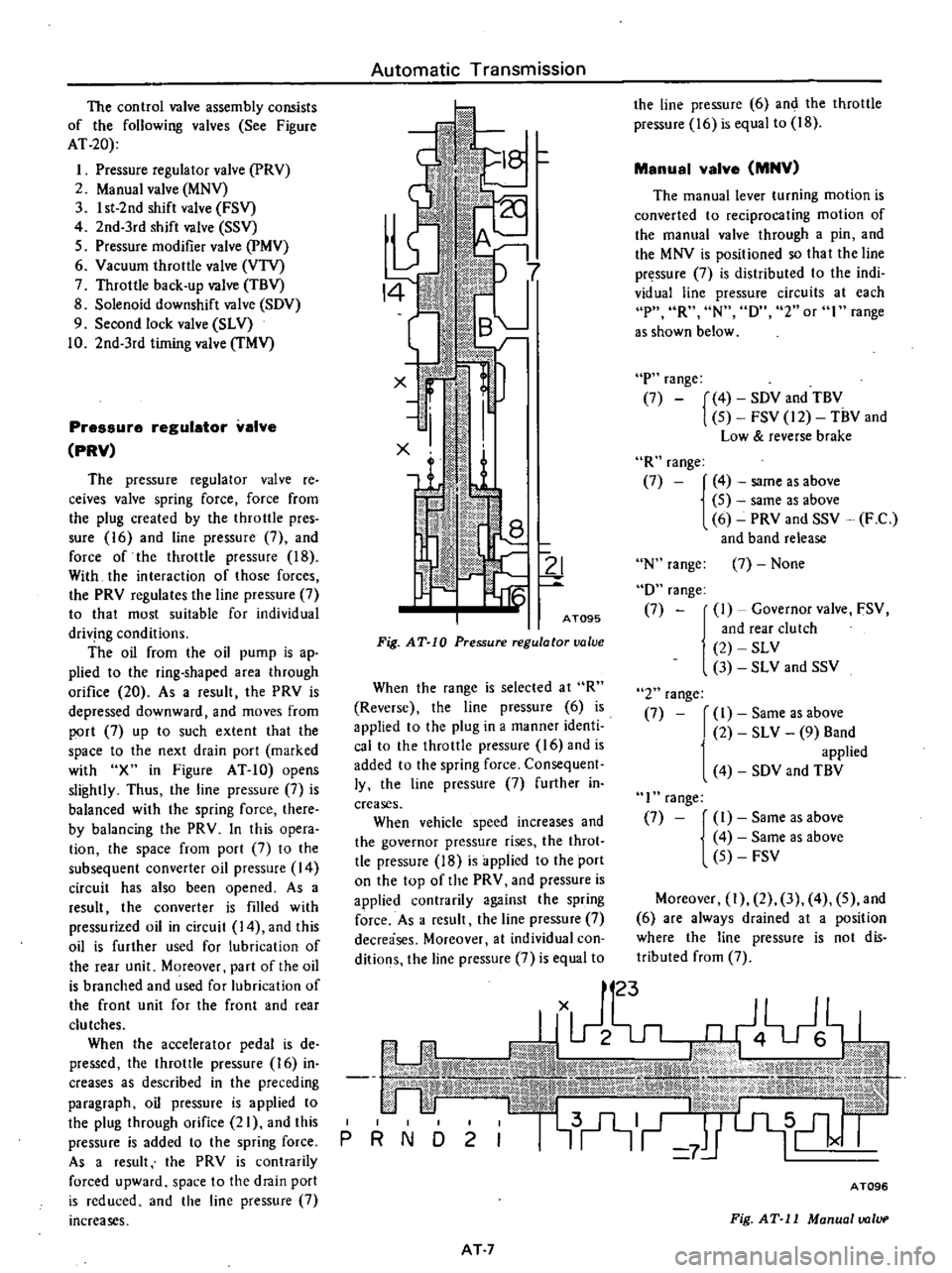

The

control

valve

assembly

consists

of

the

following

valves

See

Figure

AT

20

I

Pressure

regulator

valve

PRV

2

Manual

valve

MNV

3

I

st

2nd

shift

valve

FSV

4

2nd

3rd

shift

valve

SSV

5

Pressure

modifier

valve

PMV

6

Vacuum

throttle

valve

VTV

7

Throttle

back

up

valve

TBV

8

Solenoid

downshift

valve

SDV

9

Second

lock

valve

SL

V

10

2nd

3rd

timing

valve

TMV

Pressure

regulator

valve

PRV

The

pressure

regulator

valve

re

ceives

valve

spring

force

force

from

the

plug

created

by

the

throttle

pres

sure

16

and

line

pressure

7

and

force

of

the

throttle

pressure

18

With

the

interaction

of

those

forces

the

PRY

regulates

the

line

pressure

7

to

that

most

suitable

for

individual

driving

conditions

The

oil

from

the

oil

pump

is

ap

plied

to

the

ring

shaped

area

through

orifice

20

As

a

result

the

PRV

is

depressed

downward

and

moves

from

port

7

up

to

such

extent

that

the

space

to

the

next

drain

port

marked

with

X

in

Figure

AT

10

opens

slightly

Thus

the

line

pressure

7

is

balanced

with

the

spring

force

there

by

balancing

the

PRV

In

this

opera

tion

Ihe

space

from

port

7

to

the

subsequent

converter

oil

pressure

14

circuit

has

also

been

opened

As

a

result

the

converter

is

filled

with

pressurized

oil

in

circuit

14

and

this

oil

is

further

used

for

lubrication

of

the

rear

unit

Moreover

part

of

the

oil

is

branched

and

used

for

lubrication

of

the

front

unit

for

the

front

and

rear

clutches

When

Ihe

accelerator

pedal

is

de

presscd

the

throttle

pressure

16

in

creases

as

described

in

the

preceding

paragraph

oil

pressure

is

applied

to

the

plug

through

orifice

21

and

this

pressure

is

added

to

the

spring

force

As

a

result

the

PRV

is

contrarily

forced

upward

space

to

the

drain

port

is

reduced

and

Ihe

line

pressure

7

increases

Automatic

Transmission

11

AT095

Fig

AT

10

Pressure

regulator

ualue

When

the

range

is

selected

at

R

Reverse

the

line

pressure

6

is

applied

10

the

plug

in

a

manner

identi

caito

the

throttle

pressure

16

and

is

added

10

the

spring

force

Consequent

ly

the

line

pressure

7

further

in

creases

When

vehicle

speed

increases

and

the

governor

pressure

rises

the

theot

tle

pressure

18

is

applied

to

the

port

on

the

top

of

the

PRV

and

pressure

is

applied

contrarily

against

the

spring

force

As

a

result

the

line

pressure

7

decreases

Moreover

at

individual

con

ditions

the

line

pressure

7

is

equal

to

the

line

pressure

6

and

the

throttle

pressure

16

is

equal

to

18

Manual

valve

MNV

The

manual

lever

turning

motion

is

converted

to

reciprocating

motion

of

the

manual

valve

through

a

pin

and

the

MNV

is

positioned

so

that

the

line

pressure

7

is

distributed

to

the

indi

vidual

line

pressure

circuits

at

each

P

R

N

D

2

or

I

range

as

shown

below

P

range

7

4

SDV

and

TBV

5

FSV

12

TBV

and

Low

reverse

brake

R

range

7

4

same

as

above

5

same

as

above

6

PRY

and

SSV

F

C

and

band

release

N

range

D

range

7

7

None

I

Governor

valve

FSV

and

rear

clutch

2

SLY

3

SL

V

and

SSV

2

range

7

I

Same

as

above

2

SL

V

9

Band

applied

4

SDV

and

TBV

I

range

7

I

Same

as

above

4

Same

as

above

5

FSV

Moreover

1

2

3

4

5

and

6

are

always

drained

at

a

position

where

the

line

pressure

is

not

dis

tributed

from

7

u

JJX

g4Vhl

dIillillt

1

dlMIi

W

ld

IiIb

It

i

B

J

jd

l

tJj

fitMi

td

j

L@

x

x

j

j

P

R

N

17

l

AT7

AT096

Fig

AT

11

Manual

ualvp

Page 268 of 537

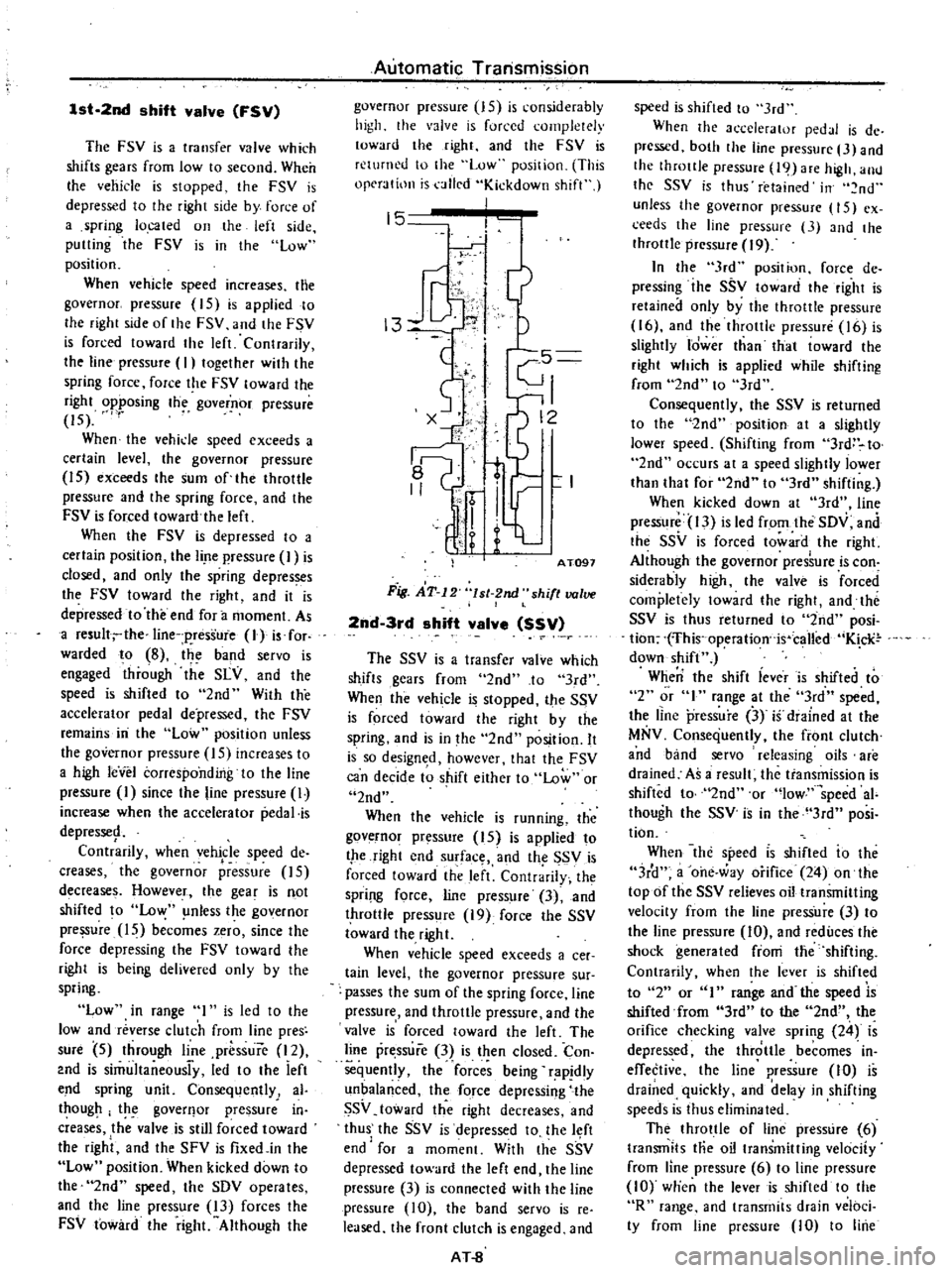

1st

2nd

shift

valve

FSV

The

FSV

is

a

transfer

valve

which

shifts

gears

from

low

to

second

When

Ihe

vehicle

is

stopped

the

FSV

is

depressed

to

the

right

side

by

force

of

a

spring

located

on

the

left

side

putting

the

FSV

is

in

the

low

position

When

vehicle

speed

increases

the

governor

pressure

15

is

applied

to

Ihe

right

side

of

the

FSV

and

the

FSV

is

forced

toward

the

left

Contrarily

the

line

pressure

I

togelher

with

the

spring

force

force

the

FSV

toward

the

right

opposing

the

governor

pressure

15

When

the

vehide

speed

exceeds

a

certain

level

the

governor

pressure

15

exceeds

the

sum

of

the

throttle

pressure

and

Ihe

spring

force

and

the

FSV

is

forced

toward

the

left

When

the

FSV

is

depressed

10

a

certain

position

the

lire

pressure

I

is

closed

and

only

the

spring

depresses

the

FSV

toward

the

right

and

it

is

depressed

to

the

end

for

a

moment

As

a

resull

the

line

p

ressure

lJ

is

for

warded

to

8

the

band

servo

is

engaged

through

the

SLY

and

the

speed

is

shifted

to

2nd

With

the

accelerator

pedal

depressed

the

FSV

remains

iIi

the

Low

position

unless

the

governor

pressure

IS

increases

to

a

high

leVel

corresponding

to

the

line

pressure

I

since

the

line

pressure

I

increase

when

the

accelerator

pedal

is

depresse9

Contrarily

when

vehicle

speed

de

creases

the

governor

pressure

15

decrease

Howeve

f

the

gear

is

not

shifted

to

Low

nless

the

governor

pressure

15

becomes

zero

since

the

force

depressing

the

FSV

toward

the

right

is

being

delivered

only

by

the

spring

Low

in

range

I

is

led

to

the

low

and

reverse

clutch

from

line

pres

sure

5

through

line

prbssure

12

2nd

is

simultaneousi

y

led

to

the

ieft

end

spring

unit

Consequently

al

thougp

the

goverflor

pressure

in

creases

the

valve

is

still

forced

toward

the

right

and

the

SFV

is

fixedjn

the

Low

position

When

kicked

down

to

the

2nd

speed

the

SDV

operates

and

the

line

pressure

13

forces

the

FSV

toward

the

right

Although

the

Automatic

Transmission

governor

pressure

15

is

considerably

high

the

valve

is

forced

completely

toward

the

right

and

the

FSV

is

returned

to

the

Low

position

This

operation

is

alled

Kickdown

shift

15

j

13

1

c5

I

0

t

r

I

I

q

1

AT091

Fig

AT

12

lsl

2nd

shift

valve

2nd

3rd

shift

valve

SSV

The

SSV

is

a

transfer

valve

which

shifts

gears

from

2nd

to

3rd

When

the

vehicle

is

stopped

the

SSV

is

forced

toward

the

right

by

the

spring

and

is

in

the

2nd

position

It

is

so

design

d

however

that

the

FSV

can

decide

to

shift

either

to

Low

or

2nd

When

the

vehicle

is

running

the

governor

pressure

15

is

applied

to

the

right

end

surface

and

th

SSV

is

forced

toward

the

left

Contrarily

the

Spri

l

force

line

pressure

3

and

throttle

press

re

19

force

the

SSV

toward

the

right

When

vehicle

speed

exceeds

a

cee

tain

level

the

governor

pressure

sur

passes

the

sum

of

the

spring

force

line

pressure

and

throttle

pressure

and

the

valve

is

forced

toward

the

left

The

line

pressure

3

is

then

closed

Con

sequently

the

forces

being

rapjdly

unbalanced

the

force

depressing

the

SSV

toward

the

right

decreases

and

thus

the

SSV

is

depressed

to

the

l

ft

end

for

a

moment

With

Ihe

SSV

depressed

toward

the

left

end

lhe

line

pressure

3

is

connected

with

the

line

pressure

10

the

band

servo

is

re

leased

the

front

clutch

is

engaged

and

AT

8

speed

is

shifted

to

3rd

When

the

accelerator

pedJI

is

de

prcssed

both

the

line

pressure

3

and

the

throttle

pressure

19

are

high

allll

the

SSV

is

thus

retained

in

nd

unless

the

governor

pressure

15

ex

ceeds

the

line

pressure

3

and

the

throttle

pressure

19

In

the

3rd

position

force

de

pressing

ihe

SSV

toward

the

right

is

retained

only

by

the

throttle

pressure

16

and

the

throttle

pressure

16

is

slightly

Idwer

than

that

toward

the

right

which

is

applied

while

shifting

from

2nd

to

3rd

Consequently

the

SSV

is

returned

to

the

2nd

position

at

a

slightly

lower

speed

Shifting

from

3rd

to

2nd

occurs

at

a

speed

slightly

lower

than

that

for

2nd

to

3rd

shifting

When

kicked

down

at

3rd

line

pressure

13

is

led

from

the

SDV

and

the

SSV

is

forced

toward

the

right

Although

the

governor

pres

ure

is

con

siderably

high

the

valve

is

forced

completely

loward

the

right

and

tht

SSV

is

thus

returned

to

2nd

posi

tion

fhis

operation

is

called

K

cli

down

shift

When

the

shift

iever

is

shifted

to

2

or

I

range

at

the

3rd

speed

the

line

pressure

3

if

diained

at

the

MNV

Consequently

the

front

clutch

and

band

servo

releasing

oils

are

drained

As

a

result

the

transmission

is

shifted

to

2nd

or

low

speed

ai

though

the

SSV

is

in

the

3rd

posi

tion

When

the

specd

IS

shifted

io

the

3r

1

a

one

way

orifice

24

on

the

topof

the

SSV

relieves

oil

transmitting

velocity

from

the

line

pressure

3

to

the

line

pressure

10

and

reduces

the

shock

generated

fioni

the

shifting

Contrarily

when

the

lever

is

shifted

to

2

or

I

range

and

the

speed

is

shifted

from

3rd

to

the

2nd

the

orifice

checking

valve

spring

24

is

depressed

the

throttle

becomes

in

effective

the

line

pressure

10

is

drained

quickly

and

delay

in

shifting

speeds

is

thus

eliminated

The

throttle

of

line

pressure

6

transmits

Hie

oil

transmitting

velocity

from

line

pressure

6

to

line

pressurc

10

wtien

the

lever

is

shifted

to

the

R

range

and

transmits

drain

veloci

ty

from

line

pressure

10

to

line

Page 269 of 537

3

Jit

f

ng

valve

24

1

3

L

l

r

I

Js

I

i

ilr

t

pressure

6

when

shif

ing

from

3rd

to

2nd

at

D

range

Thus

the

throttle

of

line

pressure

6

reduces

the

shock

generated

fro

shifting

A

plug

in

the

SSV

left

end

readjust

the

throttle

piessu

e

I

6

which

varies

depending

on

the

engine

throttle

con

dition

to

a

throttle

pressure

19

suiled

to

the

sp

ed

change

control

Moreover

the

plug

is

a

valve

which

applies

line

P

esspre

13

in

lieu

of

the

throttle

pressure

to

the

SSV

and

the

FSV

when

kickdowri

is

performed

When

the

throttle

pressure

16

is

applied

to

the

left

side

of

this

plug

and

the

plug

is

epressed

toward

the

right

a

slight

space

is

formed

from

the

throttle

pressure

6

10

19

A

throt

tIepressu

19

w

1iFh

is

lower

by

the

pressure

loss

equivalent

to

this

space

is

rH

1

Pressure

Odifier

valve

PMV

I

Compared

to

the

operating

pressure

required

in

starting

th

vehicle

the

ppwer

trimsinitting

capacity

of

the

clutch

that

is

required

operating

pres

sure

may

be

lower

when

the

vehicle

is

once

started

When

the

line

pressure

is

retained

at

a

high

level

up

to

a

high

vehicle

speed

shock

gerieraled

from

the

shirring

increases

arid

the

oil

pump

loss

also

jncrdases

In

order

to

prevent

his

the

t

lrott

le

pressure

must

be

l

hanged

over

with

the

operation

of

the

governor

pressure

15

to

reduce

Ihe

line

pressure

The

PMV

is

used

for

this

purposc

Automatic

Transmission

generated

the

piessure

loss

is

adde

d

to

the

spring

force

and

the

plug

is

lhus

forced

back

from

the

right

to

the

left

When

this

pressure

19

increases

ex

cessively

the

plug

is

further

depressed

toward

the

left

space

from

the

lhrot

tle

pressure

19

to

the

drain

circuit

13

increases

and

the

throttle

press

ure

19

decreases

Thus

the

plug

is

balanced

imd

the

throttle

pressure

19

is

reduced

to

Ii

certain

value

against

the

throttle

pressure

6

Wheri

performing

kickdowri

the

SDV

moves

a

high

line

pressure

is

led

to

the

circuit

19

from

the

line

pressure

circuit

13

which

had

been

drained

the

plug

is

forced

toward

the

left

and

circuit

19

becomes

equal

to

the

line

pressure

13

I

W

15

I

A

TOgS

Fig

iT

13

2nd

3rd

shift

vallJe

I

When

the

governor

pressuie

IS

which

is

applied

to

the

right

side

of

the

PMV

is

low

the

valve

is

forced

toward

the

right

by

the

throttle

ines

sure

16

applied

to

the

area

differ

ence

of

the

value

and

the

spring

foice

and

t

he

circuit

from

circuit

16

to

circuit

18

is

closed

However

when

vehicle

speed

increases

andl

the

gaver

nor

pressure

15

exceeds

a

certain

level

the

governor

pressure

toward

the

left

which

is

applied

to

the

right

side

exceeds

the

spring

force

and

the

throt

tle

pressure

16

toward

thc

right

the

valve

is

depressed

loward

the

lefi

and

the

throttle

pressure

is

led

from

circuit

AT

9

16

to

circuit

18

This

throttle

pressure

18

is

applied

to

the

top

of

the

PRV

and

the

force

of

the

line

pressure

source

7

is

reduced

Contra

rily

when

the

vehicle

speed

decreases

arid

the

governor

ipressure

15

de

creases

the

force

toward

the

fight

exceeds

ithe

governor

pressure

the

valve

is

forced

back

toward

the

right

and

the

throttle

pressure

18

is

drained

to

the

spring

unit

This

valve

is

sWitched

when

the

throttle

pressure

and

the

governor

pressure

are

high

or

when

tIiey

are

both

Tow

i

i

I

11

18

16

n

r

I

I

15

AT099

Fig

AT

14

Pre

ure

modifier

valve

Vacuum

thro

le

valve

VTV

The

vacuum

t

rottle

valve

is

a

regula

tor

valve

whiCh

uses

the

line

pressure

7

for

the

pressure

source

and

regulates

the

throttle

pressure

16

I

which

is

proportioned

t

the

force

of

the

vacuum

diaphragm

The

vacuum

dia

phragm

yories

depending

on

the

engine

throt

le

condition

negative

pressure

in

the

inta

e

line

When

the

line

pressure

7

is

ap

plied

to

the

bottom

through

the

valve

hole

and

the

v

a

ve

is

forced

upward

space

from

the

line

pressure

7

to

the

throttle

pressure

16

is

dosed

and

the

space

from

the

Ihrottle

pressure

16

to

the

drain

circuit

17

is

about

to

open

In

this

operation

the

throttle

pressure

16

becomes

lower

than

the

linep

s

ureY

btthe

p

e

sur

9

iv

alenl

of

the

loss

of

space

and

Ihe

force

depressing

tlie

rod

if

the

vaeuum

diaphragm

is

balanced

wit

Ii

thethrot

tie

pressure

16

a

pplied

upward

tOlthe

bottom

When

the

erigine

torque

is

high

Ihe

negative

pressure

in

the

intake

iirie

rises

tending

ioward

atmospheric

pressure

and

the

force

of

the

rod

to

depress

the

valve

increases

As

a

result

the

valve

is

depressed

downward

the

Page 298 of 537

Starter

should

be

brought

into

op

eration

only

when

selector

lever

is

in

P

and

N

positions

it

should

not

be

started

when

lever

is

in

D

2

I

and

R

positions

Back

up

lamp

should

also

light

when

selector

lever

is

placed

in

R

position

S

After

converter

is

installed

rotate

10

Check

level

of

oil

in

transmis

crankshaft

several

turns

and

check

to

be

sure

that

transmission

rotates

freely

sion

For

detailed

procedure

see

page

AT48

without

binding

6

Pour

recommended

automatic

II

Move

selector

lever

through

aU

positions

to

be

sure

that

transmission

transmission

fluid

up

to

correct

level

operates

correctly

through

oil

charge

pipe

verter

to

transmission

measure

dis

With

hand

brake

applied

rotate

tan

A

to

be

certain

that

they

are

7

Connect

manual

lever

to

shift

engine

at

idling

Without

disturbing

correctly

mbi

d

S

F

rod

Opeiationsliould

oecaTrie

f

bue

the

above

sclUng

ffiovTSelector

lever

AT

50

with

manual

and

selector

levers

in

through

N

to

D

to

2

to

I

Distance

A

N

and

to

R

A

slight

shock

should

be

More

than

21

5

mm

0

846

in

8

Connect

inhibitor

switch

wires

felt

by

hand

gripping

selector

each

time

transmission

is

shifted

Automatic

Transmission

4

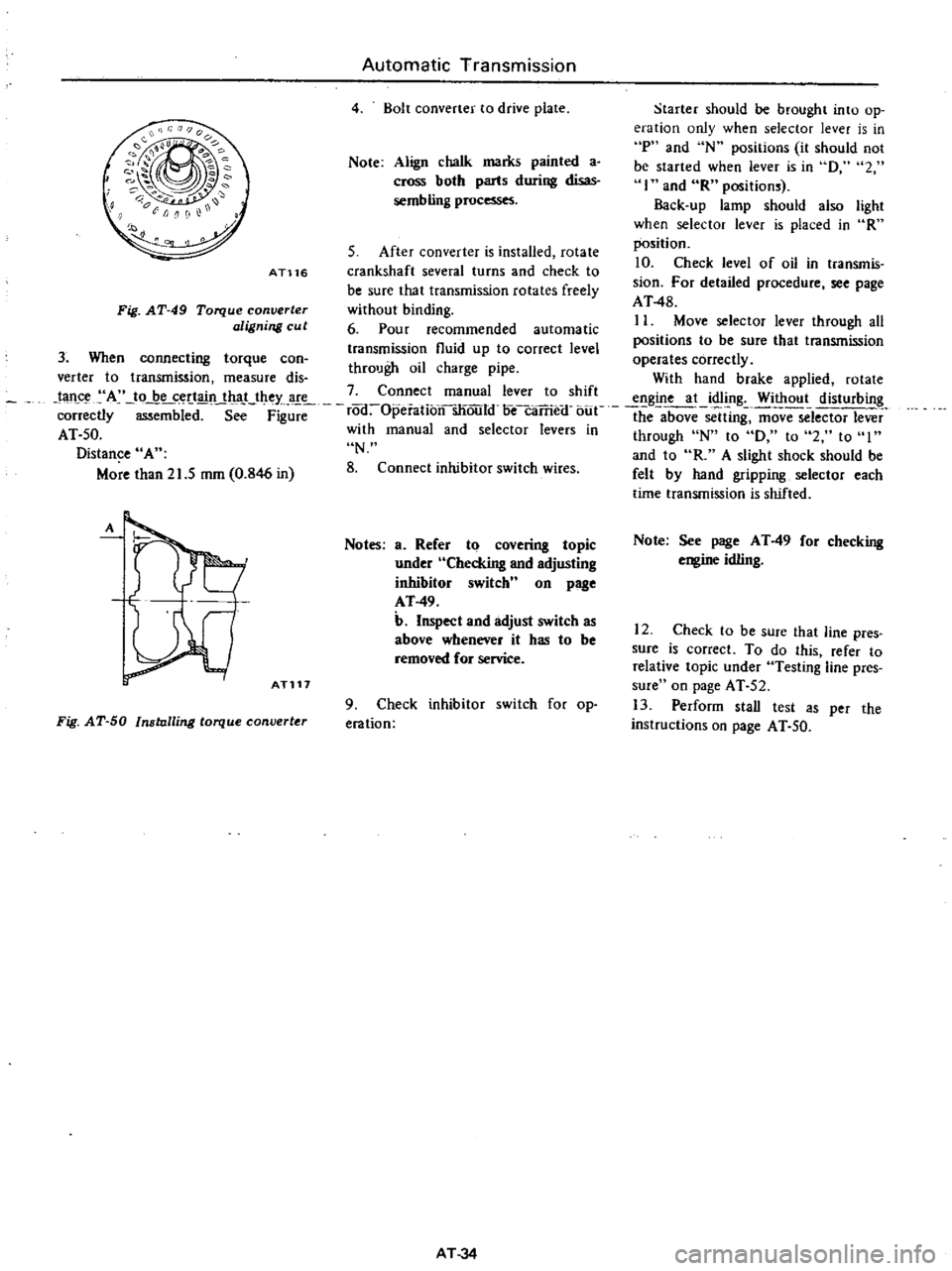

Bolt

converter

to

drive

plate

Note

Align

chalk

marks

painted

a

cross

both

parts

during

disas

sembling

processes

AT116

Fig

AT

49

Torque

converter

aligning

cu

t

3

When

connecting

torque

can

A

ATl17

Notes

a

Refer

to

covering

topic

under

Checking

and

adjusting

inhibitor

switch

n

on

page

AT

49

b

Inspect

and

adjust

switch

as

above

whenever

it

has

to

be

removed

for

service

Fig

AT

50

Installing

torque

converter

9

Check

inhibitor

switch

for

op

eration

AT

34

Note

See

page

AT

49

for

checking

engine

idling

12

Check

to

be

sure

that

line

pres

sure

is

correct

To

do

this

refer

to

relative

topic

under

Testing

line

pres

sure

on

page

AT

52

13

Perform

stall

test

as

per

the

instructions

on

page

AT

50

Page 307 of 537

Automatic

Transmission

i

r

11

I

@

@

j

A

T290

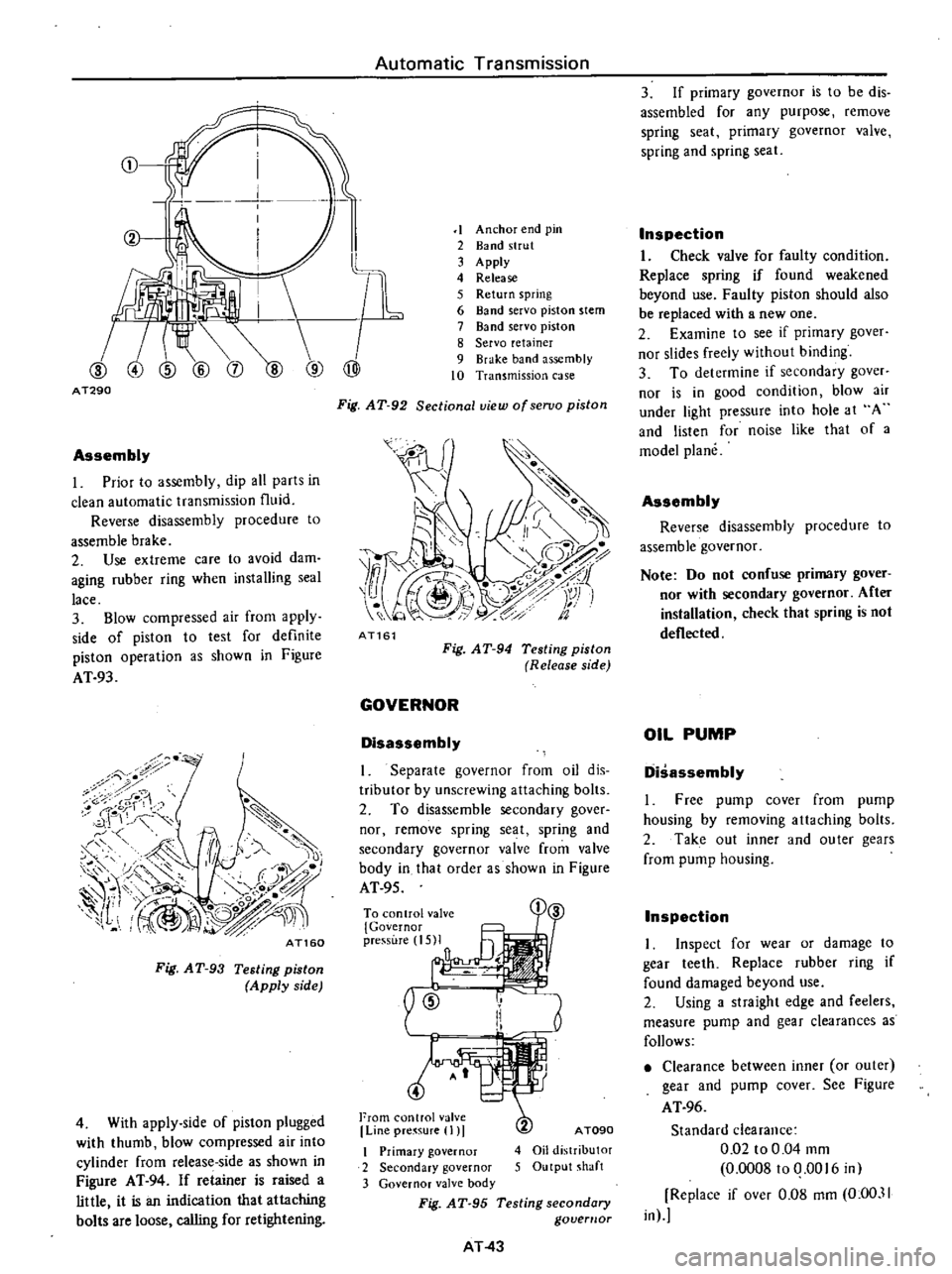

Assembly

I

Prior

to

assembly

dip

all

parts

in

clean

automatic

transmission

fluid

Reverse

disassembly

procedure

to

assemble

brake

2

Use

extreme

care

to

avoid

dam

aging

rubber

ring

when

installing

seal

lace

3

Blow

compressed

air

from

apply

side

of

piston

to

test

for

definite

piston

operation

as

shown

in

Figure

AT

93

7

i

8

ror

1

1

r

c

f

f

A

J

II

1

0

c

r

1

1

I

@

L

O

j

0

n

iJ

fl

IV

I

AT160

Fig

AT

93

Testing

piston

Apply

side

4

With

apply

side

of

piston

plugged

with

thumb

blow

compressed

air

into

cylinder

from

release

side

as

shown

in

Figure

AT

94

If

retainer

is

raised

a

little

it

is

an

indication

that

attaching

bolts

are

loose

calling

for

retightening

1

Anchor

end

pin

2

Band

strut

3

Apply

4

Release

5

Return

spring

6

Band

servo

piston

stem

7

Band

servo

piston

8

Servo

retainer

9

Brake

band

assembly

10

Transmission

case

Fig

AT

92

Sectional

view

ofseruo

piston

7

o

i

J

1S

I

z

1

Y

i

1

t

9

c

fa

AT161

Fig

AT

94

Testing

piston

Release

side

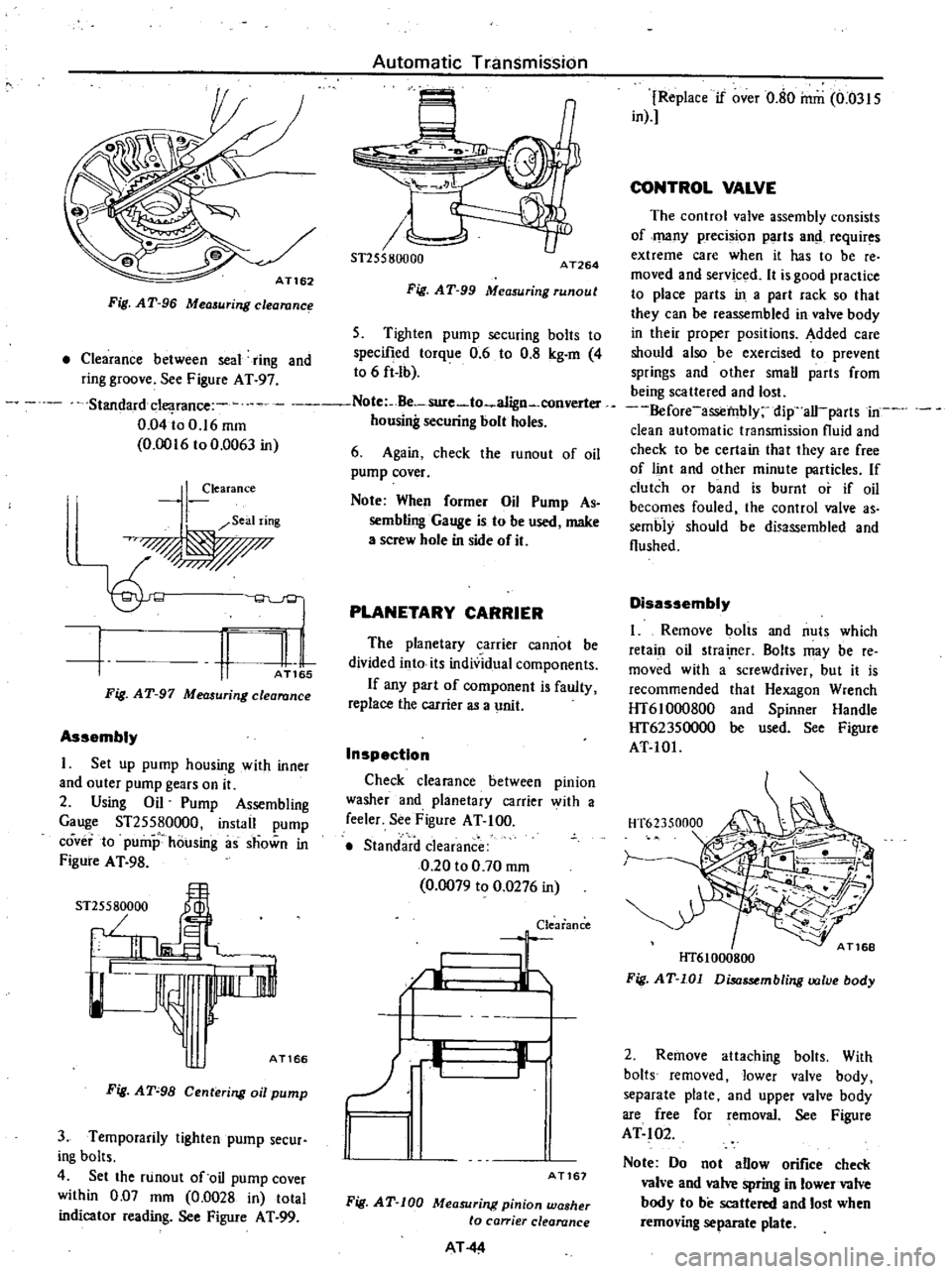

GOVERNOR

Disassembly

I

Separate

governor

from

oil

dis

tributor

by

unscrewing

attaching

bolts

2

To

disassemble

secondary

gover

nor

remove

spring

seat

spring

and

secondary

governor

valve

from

valve

body

in

that

order

as

shown

in

Figure

AT

95

To

control

val

i

1

3

5MI

n

ID

r

Ii

I

4

From

control

valve

Line

pre

sure

I

I

A

TOgO

4

Oil

distributor

5

Output

shaft

I

Primary

governor

2

Secondary

governor

3

Governor

valve

body

Fig

AT

95

Testing

secondary

govemor

AT

43

3

If

primary

governor

is

to

be

dis

assembled

for

any

purpose

remove

spring

seat

primary

governor

valve

spring

and

spring

seat

Inspection

I

Check

valve

for

faulty

condition

Replace

spring

if

found

weakened

beyond

use

Faulty

piston

should

also

be

replaced

with

a

new

one

2

Examine

to

see

if

primary

gover

nor

slides

freely

without

binding

3

To

determine

if

secondary

gaver

nor

is

in

good

condition

blow

air

under

light

pressure

into

hole

at

A

and

listen

for

noise

like

that

of

a

model

plane

Assembly

Reverse

disassembly

procedure

to

assemble

governor

Note

Do

not

confuse

primary

gover

nor

with

secondary

governor

After

installation

check

that

spring

is

not

deflected

OIL

PUMP

Disassembly

I

Free

pump

cover

from

pump

housing

by

removing

attaching

bolts

2

Take

out

inner

and

outer

gears

from

pump

housing

Inspection

I

Inspect

for

wear

or

damage

to

gear

teeth

Replace

rubber

ring

if

found

damaged

beyond

use

2

Using

a

straight

edge

and

feelers

measure

pump

and

gear

clearances

as

follows

Clearance

between

inner

or

outer

gear

and

pump

cover

See

Figure

AT

96

Standard

clearance

0

02

to

0

04

mm

0

0008100

0016

in

Replace

if

over

0

08

mm

0

00

11

in

Page 308 of 537

Fig

AT

96

Measuring

clearanc

Automatic

Transmission

6

u

ST255801JOO

AT264

Fig

AT

99

Measuring

runout

5

Tighten

pump

securing

bolts

to

specified

torque

0

6

to

0

8

kg

m

4

to

6

ft

Ib

Clearance

between

seal

ring

and

ring

groove

See

Figure

AT

97

Standarddearance

Note

Be

sure

to

a1ign

converter

0

04

io

0

16

mm

housing

securing

bolt

holes

0

0016

to

0

0063

in

6

Again

check

the

runout

of

oil

pump

cover

I

learance

Seal

ring

q

I

n

l

1

AT

5

Fig

AT

97

Measuring

clearance

Assembly

I

Set

up

pump

housing

with

inner

and

outer

pump

gears

on

it

2

Using

Oil

Pump

Assembling

Gauge

ST25580000

instail

pump

coverta

pump

housing

as

shown

in

Figure

A

T

98

ST

5

000

J

I

I

JL

AT166

Fig

AT

98

Centering

oil

pump

3

Temporarily

lighten

pump

secur

ing

bolts

4

Set

the

runout

of

oil

pump

cover

within

0

D7

mm

0

0028

in

total

indicator

reading

See

Figure

AT

99

Note

When

former

Oil

Pump

As

sembling

Gauge

is

to

be

used

make

a

screw

hole

in

side

of

it

PLANETARY

CARRIER

The

planetary

carrier

cannot

be

divided

into

its

individual

components

If

any

part

of

component

is

faulty

replace

the

carrier

as

a

unit

Inspection

Check

clearance

between

pinion

washer

and

planetary

carrier

with

a

feeler

See

Figure

AT

100

Standard

clearance

0

20

to

0

70

mm

0

0079

to

0

0276

in

Clearance

I

Jr

I

1

11

r

AT167

Fig

AT

100

Measuring

pinion

washer

to

ca

ier

clearance

AT

44

Replace

if

over

0

80

mm

0

0315

in

CONTROL

VALVE

The

control

valve

assembly

consists

of

many

preci

ion

parts

and

requir

s

extreme

care

when

it

has

to

be

reo

moved

and

serviced

It

is

good

practice

to

place

parts

in

a

part

rack

so

that

they

can

be

reassembled

in

valve

body

in

their

proper

positions

Added

care

should

also

be

exercised

to

prevent

springs

and

other

small

parts

from

being

scattered

and

lo

t

Before

assembly

dip

all

parts

in

clean

automatic

transmission

fluid

and

check

to

be

certain

that

they

are

free

of

lint

and

other

minute

particles

If

clutch

or

band

is

burnt

or

if

oil

becomes

fouled

the

control

valve

as

sembly

should

be

di

ssembled

and

flushed

Disassembly

I

Remove

bolts

and

nuts

which

retain

oil

trainer

Bolts

may

be

re

moved

with

a

screwdriver

but

it

is

recommended

that

Hexagon

Wrench

HT610oo800

and

Spinner

Handle

HT62350000

be

used

See

Figure

AT

101

HT61000800

Fig

AT

101

Disassembling

valve

body

2

Remove

attaching

bolts

With

bolts

removed

lower

valve

body

separate

plate

and

upper

valve

body

are

free

for

removal

See

Figure

AT

102

Note

Do

not

allow

orifice

check

vah

e

and

valve

spring

in

lower

valve

body

to

be

scattered

and

lost

when

removing

separate

plate

Page 313 of 537

In

these

cases

the

transmission

must

be

repaired

Notes

a

In

checking

oil

level

use

special

paper

cloth

to

handle

the

level

gauge

and

be

careful

not

to

let

the

scraps

of

paper

and

cloth

stick

to

the

gauge

b

Insert

the

gauge

fully

and

take

it

out

quickly

before

splashing

oil

adheres

to

the

gauge

Then

observe

the

level

c

Use

automatic

transmission

fluid

having

DEXRON

identifications

only

in

the

3N71B

automatic

trans

mission

d

Pay

attention

because

the

oil

to

be

used

differs

from

that

used

in

the

Nissan

Full

Automatic

TranSJTIis

sion

3N71A

Never

mix

the

oils

INSPECTION

AND

REPAIR

OF

OIL

LEAKAGE

When

oil

leakage

takes

place

the

portion

near

the

leakage

is

covered

with

oil

presenting

difficulty

in

detecting

the

spot

Therefore

the

places

where

oil

seals

and

gaskets

are

equipped

are

enumerated

below

11

Converter

housing

Rubber

ring

of

oil

pump

housing

Oil

seal

of

oil

pump

housing

Oil

seal

of

engine

crankshaft

Bolts

of

converter

housing

to

case

2

Trarismission

and

rear

extension

Junction

of

transm

ss

ion

and

rear

extension

J

Oil

cooler

tube

connectors

Oil

pan

Oil

pressure

inspection

holes

Refer

to

Figure

AT

il2

Mounting

portion

of

vacuum

dia

phragm

and

downshift

solenoid

Breather

and

oil

charging

pipe

Speedometer

pinion

sleeve

Oil

se

l

of

rear

extension

To

exactly

locate

the

place

of

oil

leaka

le

proceed

as

follows

Place

the

vehicle

in

a

pit

and

by

sampling

the

leaked

oil

determine

if

it

is

the

torque

converter

oil

The

torque

converter

oil

has

a

color

like

r

d

wine

So

it

is

easily

distinguished

from

engine

oil

or

gear

oil

Automatic

rransmission

Wipe

off

the

leaking

oil

and

dust

and

deiecl

the

spol

of

oil

eakage

l

se

nonflammable

organic

solve

t

s

ch

as

carbon

tetrachloride

for

wiping

Raise

the

oil

tcmperalure

by

op

erating

the

engine

and

shift

the

lever

to

D

to

increase

the

oil

pressure

The

spot

of

oil

lcakage

will

then

be

found

more

easily

Note

As

oil

leakage

from

the

breaih

er

does

not

take

place

except

when

running

at

high

speed

it

is

impos

sible

to

locate

this

leakage

with

vehicle

stationary

CHECKING

ENGINE

IDLING

REVOLUTION

The

engine

idling

revolution

should

be

properly

adjusted

If

the

engine

revolution

is

too

low

the

engine

does

not

operate

smoothly

and

if

too

high

a

strong

shock

or

creep

develops

when

changing

over

from

N

to

D

or

R

CHECKING

AND

ADJUSTING

KICK

DOWN

SWITCH

AND

DOWNSHIFT

SOLENOID

When

the

kickdown

operation

is

not

made

properly

or

the

speed

chang

ing

point

s

too

high

check

the

kick

down

switch

downshift

solenoid

and

wiring

between

them

When

the

igni

li

n

key

is

pqsitioned

a

t

the

I

st

stage

nd

the

accelerator

pedal

is

depressed

deeply

the

switch

contact

should

be

closed

and

the

solenoid

should

click

If

it

does

not

click

it

indicates

a

defect

Then

check

each

part

with

the

testing

instruments

See

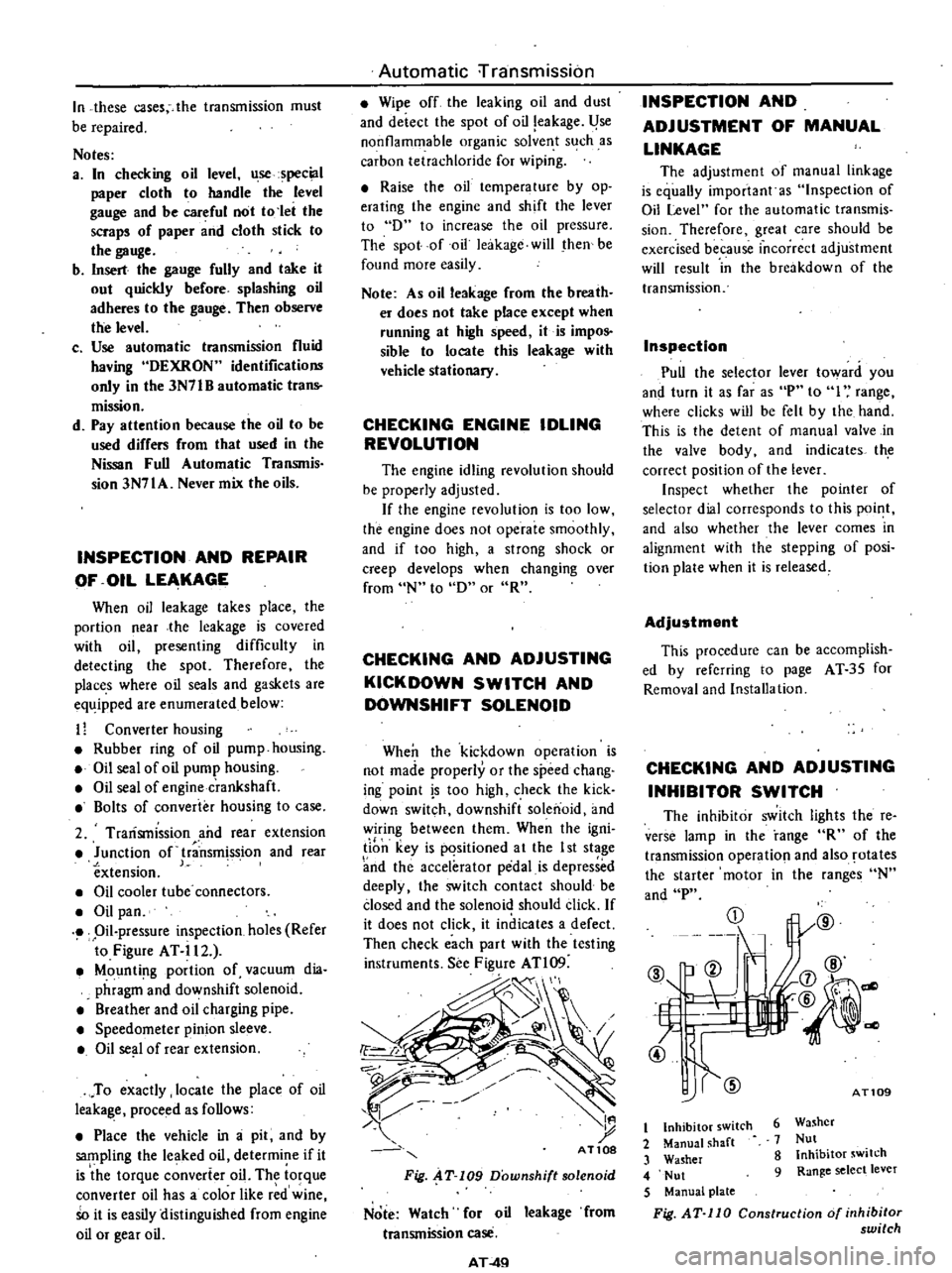

Figure

ATl09

d

I

t

AT10S

Fig

AT

109

Downshift

solenoid

Note

Watch

for

oil

leakage

from

transmission

case

AT

4Q

INSPECTION

AND

ADJUSTMENT

OF

MANUAL

LINKAGE

The

adjustmcnt

of

manual

linkage

is

equaUy

important

as

Inspection

of

Oil

Level

for

the

automatic

transmis

sion

Thereforc

great

care

should

be

exercised

because

incorrect

adjustment

will

rcsult

in

the

brcakdown

of

the

transmission

Inspection

Pull

the

selector

lever

toward

you

and

turn

it

as

far

as

P

to

I

range

wherc

clicks

will

be

felt

by

the

hand

This

is

the

detcnt

of

manual

valve

in

the

valve

body

and

indicates

th

correct

position

of

the

lever

Inspect

whether

the

pointer

of

selector

dial

corresponds

to

this

point

and

also

whether

the

lever

comes

in

alignment

with

the

stepping

of

posi

tion

plate

when

it

is

released

Adjustment

This

procedure

can

be

accomplish

ed

by

refcrring

to

page

AT

35

for

Removal

and

Installa

tion

CHECKING

AND

ADJUSTING

INHIBITOR

SWITCH

The

inhibitor

switch

lights

the

re

verse

lamp

in

the

range

R

of

the

transmission

operatio

l

and

also

rotates

the

starter

motor

in

the

ranges

N

and

P

CD

@

b

ell

If

L

t

7

4l

@

1l

j7

@

@

@

dl

AT109

6

Washer

7

Nut

8

Inhibitor

switch

9

Range

select

lever

t

Inhibitor

switch

2

Manual

shaft

3

Washer

4

Nut

5

Manual

plate

Fig

AT

110

Construction

of

inhibitor

switch