light DATSUN PICK-UP 1977 Workshop Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 314 of 537

Using

the

tester

check

the

two

black

yellow

BY

wires

from

the

in

hibitor

switch

in

the

ranges

N

and

I

and

the

tw

re

d

black

RBj

wir

s

in

the

range

R

for

continuity

Turn

range

select

lever

in

both

directions

from

each

lever

set

position

and

check

each

continuity

range

It

is

normal

if

the

electricity

is

on

while

the

lever

is

within

an

angle

of

about

30

on

both

sides

from

each

lever

set

line

How

ever

if

its

continl

ity

range

is

obvious

ly

unequal

on

both

sides

adjustment

is

required

If

any

malfunction

is

found

un

screw

the

fastening

nut

of

the

range

selector

lever

and

two

fastening

bolts

of

the

switch

body

and

then

remove

the

machine

screw

under

the

switch

body

Adjust

the

manual

shaft

correct

ly

to

the

position

N

by

means

of

the

selector

lever

When

the

slot

of

the

shaft

becomes

vertical

the

detent

works

to

position

the

shaft

correctly

with

a

clicking

sound

MSlVe

the

switch

slightly

asj

Je

so

that

the

screw

hole

will

be

aligned

with

the

pin

hole

of

the

internal

rotor

combined

with

the

manual

shaft

and

check

their

alignment

by

inserting

a

1

5

mm

0

059

in

diameter

pin

into

the

holes

If

the

alignment

is

correct

fasten

the

switch

body

with

the

bolts

pull

out

the

pin

tighten

up

the

screw

in

the

hole

and

fasten

the

selector

lever

as

before

Check

the

continuity

again

with

the

tester

If

the

malfunc

tion

still

remains

replace

the

inhibitor

switch

Chcck

whether

the

reverse

lamp

and

the

starter

motor

operate

normal

ly

in

these

ranges

If

Ihere

is

any

lrouble

first

check

the

linkage

If

no

fault

is

found

in

the

linkage

check

the

inhibitor

switch

Separate

the

manual

lever

from

Ihe

remote

control

selector

rod

and

turn

the

range

selcct

lever

to

N

Note

In

the

position

N

the

slot

of

the

manual

shaft

is

vertical

STALL

TEST

The

purpose

of

this

test

is

to

check

the

transmission

and

engine

for

trou

ble

by

measuring

the

maximum

num

bers

of

revolutions

of

the

engine

while

Automatic

Transmission

vehicle

is

held

in

a

stalled

condition

The

carburctor

is

in

full

throttle

opera

tion

with

the

selector

lever

in

ranges

f

2

and

I

respectively

Com

pare

the

measured

results

with

the

slandard

values

Components

to

be

tested

and

test

items

I

Clutches

brake

and

band

in

trans

mission

for

slipping

2

Torque

converter

for

proper

fune

tioning

3

Engine

for

overall

properly

STALL

TEST

PROCEDURES

Before

Icsting

c

heck

the

engine

oil

and

torque

converter

oil

warm

up

the

engine

cooling

water

to

suitable

tem

perature

by

running

at

1

200

rpm

with

the

selector

lever

in

the

range

P

for

several

minutes

Warm

up

the

torque

converter

oil

to

suitable

temperature

6010

1000C

140

to

2l20F

I

Mount

the

engine

tachometer

at

a

location

that

allows

good

visibility

fro

the

dri

er

s

seat

and

put

a

mark

on

specified

revolutions

on

the

meter

2

Secure

the

front

and

rear

wheels

with

chocks

and

apply

the

hand

brake

Be

sure

to

depress

the

brake

pedal

fumly

with

the

left

foot

before

de

pressing

the

accelerator

pedal

3

Throw

the

selector

lever

into

the

range

1

4

Slowly

depress

the

accelerator

pedal

until

the

throttle

valvc

is

fully

opened

Quickly

read

and

record

the

engine

revolution

when

the

engine

begins

to

rotate

steadily

and

then

release

the

accelerator

pedal

5

Shift

the

selector

lever

to

N

and

operate

the

engine

at

approxi

mately

1

200

rpm

for

more

than

one

minute

to

cool

down

the

torque

con

ver

ter

oil

and

coolant

6

Make

similar

stall

tests

in

ranges

2

I

and

RIO

Note

The

stall

test

operation

as

speci

f

d

in

item

4

should

be

I

l3de

wiihin

five

seconds

If

it

takes

too

long

the

oil

deteriorates

an

the

clutches

brake

and

band

are

ad

versely

affected

Sufficient

cooling

time

should

be

given

between

each

AT

5O

test

for

the

four

ranges

0

2

I

and

R

JUDGEMENT

High

stall

revolution

more

than

standard

revolution

If

the

engine

revolution

in

stall

condition

is

higher

than

the

standard

values

it

indicates

that

one

or

more

clutches

in

the

transmission

are

slipping

and

therefore

no

further

test

is

required

For

the

following

abnormalities

the

respective

causes

are

presumed

High

rpm

in

all

ranges

low

Iine

pressure

High

rpm

in

D

2

and

I

and

normal

rpm

in

R

Rear

clutch

slipping

High

rpm

in

0

and

normal

rpm

in

I

clutch

slipping

High

rpm

in

R

only

Front

clutch

or

low

and

reverse

brake

slipping

To

determine

which

is

slipping

front

clutch

or

low

and

reverse

brake

a

road

test

is

nceded

If

whilc

coasting

after

starting

with

the

lever

in

1

range

engine

braking

does

not

work

properly

the

low

and

reverse

brake

is

slipping

Otherwise

the

front

clutch

is

slipping

Slipping

of

the

band

brake

is

diffi

cult

to

ascertain

However

if

it

occurs

with

the

lever

in

2

range

engine

revolution

increases

Jp

to

thesarne

level

as

in

I

strange

It

is

impossible

to

check

it

in

the

stall

test

2

and

One

way

2

Standard

stall

revolution

If

the

engine

revolution

in

stall

condition

is

within

the

standard

values

the

control

elements

are

nor

mally

operating

in

the

ranges

0

2

I

and

R

Also

tIle

engine

and

one

way

clutch

of

the

torque

converter

are

normal

in

performance

and

operation

The

one

way

clutch

of

the

torque

converter

however

sometimes

sticks

This

is

determined

in

the

road

test

3

Lower

stall

revolution

than

stand

ard

revolution

If

the

engine

revolution

in

stall

condition

is

lower

than

the

standard

Page 331 of 537

PROPELLER

SHAFT

DIFFERENTIAL

CARRIER

Watch

for

oil

leakage

from

trans

mission

end

Notes

a

Remove

propeller

shaft

carefully

so

as

not

to

damage

spline

sleeve

yoke

and

rear

oil

seal

b

Plug

up

the

opening

in

the

rear

of

rear

extension

housing

to

prevent

oil

from

flowing

out

To

install

reverse

the

foregoing

removal

procedure

1

Align

propeller

shaft

with

com

panion

flange

using

reference

marks

prescribed

in

removal

procedure

and

assemble

with

bolts

Tightening

torque

2

4

to

3

3

kg

m

17

to

24

ft

Ib

2

Insert

bolts

through

the

holes

of

center

beariug

bracket

and

torque

nuts

to

retain

center

bearing

on

cross

member

Tightening

torque

1

6

to

2

2

kg

m

12

to

16

ft

Ib

DISASSEMBLY

AND

ASSEMBLY

Primarily

do

not

disassemble

pro

peller

shaft

because

it

is

balanced

as

an

assembly

However

check

propeller

shaft

with

journal

for

movement

When

journal

does

not

move

smoothly

dis

assemble

1

Mark

propeller

shaft

and

journal

so

that

the

original

combination

can

be

restored

at

assembly

2

Remove

snap

ring

with

a

standard

screwdriver

3

Lightly

tap

base

of

yoke

with

a

hammer

and

withdraw

bearing

race

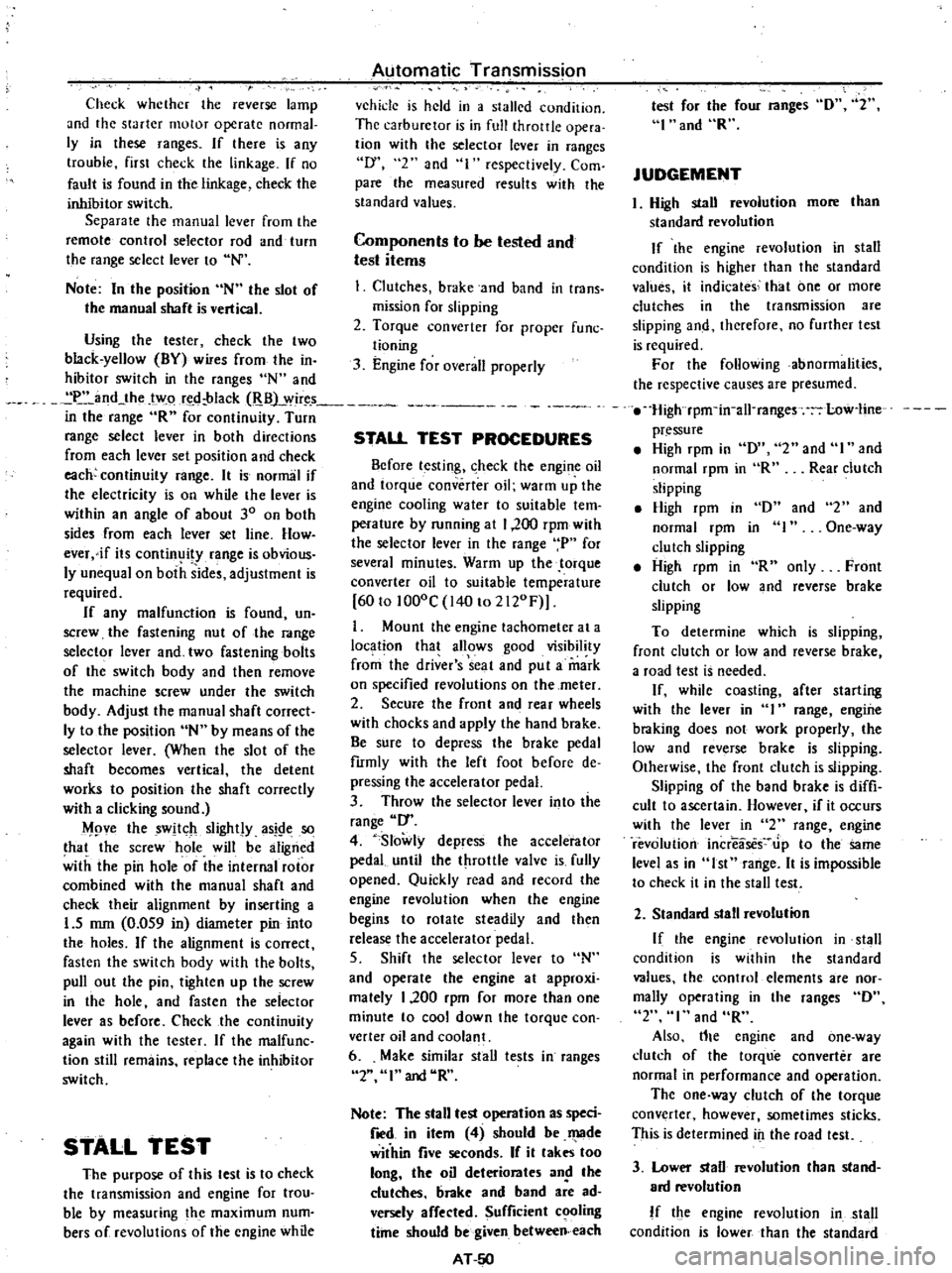

See

Figure

PD

4

PDOO5

Fig

PD

4

Remo

i

bearing

Note

When

removing

journal

from

yoke

be

careful

not

to

damage

journal

and

yoke

bole

When

disassembling

and

repairing

center

bearing

are

required

the

follow

ing

procedures

are

applied

1

Put

match

marks

on

flange

and

front

propeller

shaft

Remove

bolts

connecting

flange

yoke

to

companion

flange

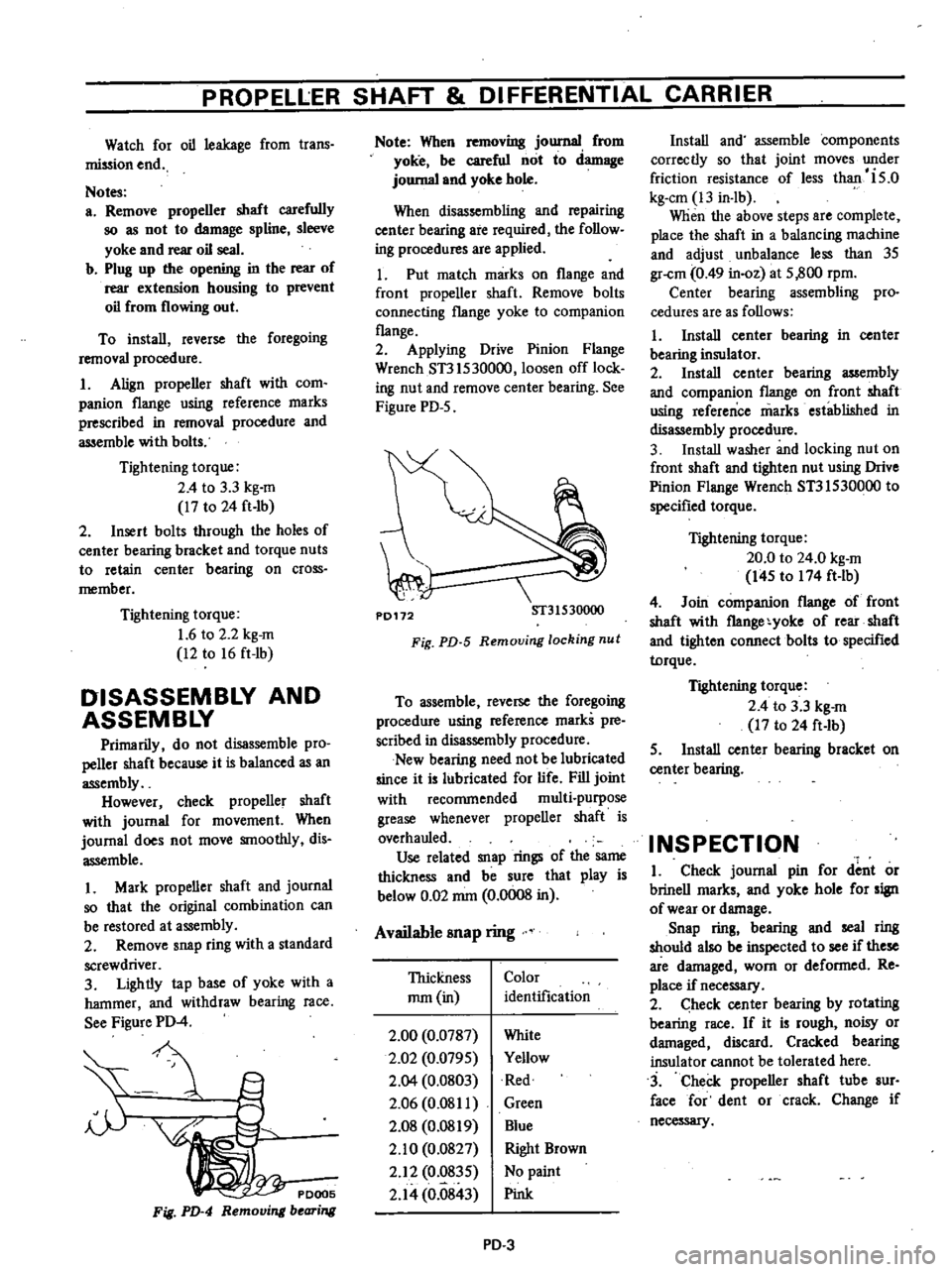

2

Applying

Drive

Pinion

Flange

Wrench

ST3lS30000

loosen

off

lock

ing

nut

and

remove

center

bearing

See

Figure

PD

5

P0172

ST31530000

Fig

PD

5

Remouing

locking

nut

To

assemble

reverse

the

foregoing

procedure

using

reference

marks

pre

scribed

in

disassembly

procedure

New

bearing

need

not

be

lubricated

since

it

is

lubricated

for

life

Fill

joint

with

recommended

multi

purpose

grease

whenever

propeller

shaft

is

overhauled

Use

related

snap

rings

of

the

same

thickness

and

be

sure

that

play

is

below

0

02

mm

0

0008

in

Available

snap

ring

Thickness

mm

in

Color

identification

2

00

0

0787

2

02

0

079S

2

Q4

0

0803

2

06

0

08

II

2

08

0

0819

2

10

0

0827

2

12

0

83S

2

14

0

0843

White

Yellow

Red

Green

Blue

Right

Brown

No

paint

Pink

PD

3

Install

and

assemble

components

correctly

so

that

joint

moves

under

friction

resistance

of

less

than

is

o

kg

em

13

in

lb

When

the

above

steps

are

complete

place

the

shaft

in

a

balancing

machine

and

adjust

unbalance

less

than

3S

gr

cm

0

49

in

oz

at

S

800

rpm

Center

bearing

assembling

pro

cedures

are

as

follows

I

Install

center

bearing

in

center

bearing

insulator

2

Install

center

bearing

assembly

and

companion

flange

on

front

shaft

usiug

reference

marks

established

in

disassembly

procedure

3

Install

washer

and

locking

nut

on

front

shaft

and

tighten

nut

using

Drive

Pinion

Flange

Wrench

ST3IS30000

to

specified

torque

Tightening

torque

20

0

to

24

0

kg

m

I4S

to

174

ft

lb

4

Join

companion

flange

of

front

shaft

with

f1ange

yoke

of

rear

shaft

and

tighten

connect

bolts

to

specified

torque

Tightening

torque

2

4

to

3

3

kg

m

17

to

24

ft

Ib

S

Install

center

bearing

bracket

on

center

bearing

INSPECTION

I

Check

journal

pin

for

dent

or

brinell

marks

and

yoke

hole

for

sign

of

wear

or

damage

Snap

ring

bearing

and

seal

ring

should

also

be

inspected

to

see

if

these

are

damaged

worn

or

deformed

Re

place

if

necessary

2

heck

center

bearing

by

rotating

bearing

race

If

it

is

rough

noisy

or

damaged

discard

Cracked

bearing

insulator

cannot

be

tolerated

here

3

Check

propeller

shaft

tube

sur

face

for

dent

or

crack

Change

if

necessary

Page 340 of 537

PROPELLER

SHAFf

DIFFERENTIAL

CARR

IER

Ex

2

A

0

B

3

C

I

0

0

E

0

20

mOl

F

0

17

mOl

H

2

Left

side

T

I

A

C

D

H

x

om

0

17S

E

0

I

0

2

x

0

01

0

I7S

0

20

0

I

0

2

x

0

01

0

17S

0

20

3

Om

0

17S

0

20

0

03

0

17S

0

20

O

34S

mrn

The

correct

shinjs

are

O

OS

plus

0

10

plus

0

20

mrn

thick

Right

side

T2

B

D

H

xO

0l

O

ISO

F

3

0

2

x

om

O

ISO

0

17

3

0

2

x

om

0

150

0

17

S

x

0

01

0

ISO

0

I7

O

OS

0

1S0

0

17

0

37

mrn

The

correct

shims

are

0

07

plus

0

1

0

plus

0

20

mm

thick

Note

If

w1ues

signifying

A

B

C

0

and

H

are

not

given

regard

them

as

zero

and

compute

Aft

assembly

check

to

see

that

preload

and

backlash

are

correct

If

not

readjust

Side

bearing

adjusting

shim

Thickness

mm

in

O

OS

0

0020

0

07

0

0028

0

1

0

0

0039

0

20

0

0079

0

50

0

0197

2

Fit

determined

side

bearing

adjusting

shim

on

differential

case

and

press

fit

left

and

right

side

bearing

inner

races

on

it

using

Side

Bearing

Drift

ST33230000

and

Adapter

ST33061000

3

Install

differential

case

assembly

into

gear

carrie

tapping

with

a

rubber

mallet

4

Align

mark

on

bearing

cap

with

that

on

gear

carrier

and

install

bearing

cap

on

carrier

And

tight

n

bolts

to

specified

torque

Tightening

torque

4

0

to

S

O

kg

m

29

to

36

fHb

S

Measure

ring

gear

to

drive

pinion

backlash

If

backlash

is

too

small

remove

shims

from

left

side

and

add

them

to

right

side

To

reduce

backlash

remove

shims

from

right

side

and

add

them

to

left

side

Backlash

O

1S

to

0

20

mrn

0

00S9

to

0

0079

in

Fig

PD

22

Mccuuring

back1aah

6

At

the

same

time

check

side

bearing

preload

Bearing

preload

should

read

12

0

to

20

0

kg

cm

10

to

17

in

lb

of

rotating

torque

3

S

to

S

8

kg

7

7

to

12

8

Ib

at

ring

gear

bolt

hole

PD

12

If

preload

does

not

accord

with

this

specification

adjust

it

with

side

bear

ing

shims

7

Check

and

adjust

the

tooth

con

tact

pattern

of

ring

gear

and

drive

pinion

I

Thoroughly

clean

ring

and

drive

pinion

gear

teeth

2

Paint

ring

gear

teeth

lightly

and

evenly

with

a

mixture

of

ferric

oxide

and

gear

oil

to

produce

a

contact

pattern

3

Rotate

pinion

through

several

revolutions

in

the

forward

and

reverse

directions

until

a

defmite

contact

pat

tern

is

developed

on

ring

gear

4

When

contact

pattern

is

incor

rect

readjust

thickness

of

adjusting

washer

S

Incorrect

contact

pattern

of

teeth

can

be

adjusted

in

the

following

manner

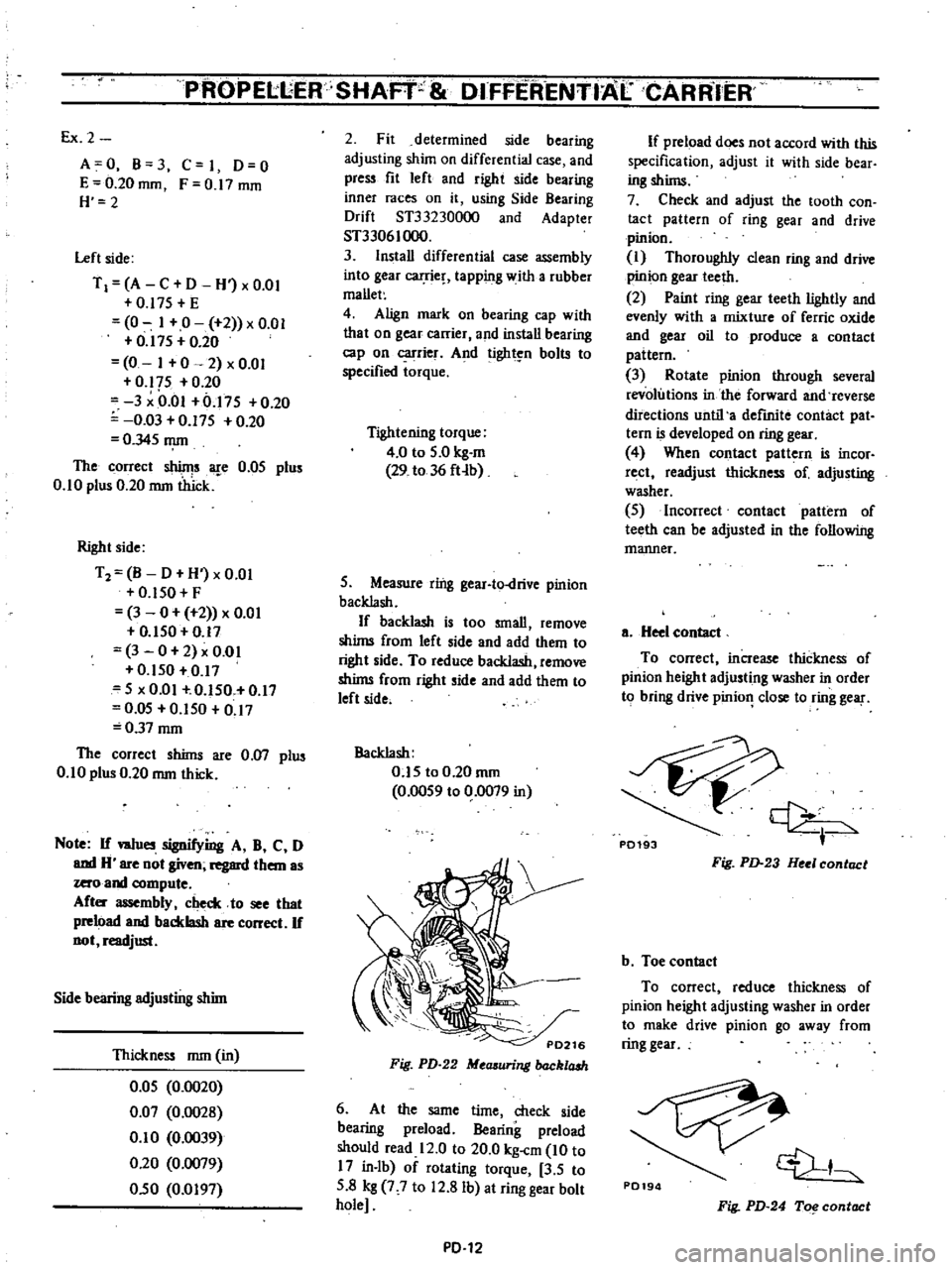

a

Heel

contact

To

correct

increase

thickness

of

pinion

height

adjusting

washer

in

order

to

bring

drive

pinio

close

to

ring

gear

P0193

Fig

PD

23

Hul

contact

b

Toe

contact

To

correct

reduce

thickness

of

pinion

height

adjusting

washer

in

order

to

make

drive

pinion

go

away

from

ring

gear

P0194

1

Fig

PD

24

To

contact

Page 352 of 537

The

design

of

the

front

suspension

adopts

the

independent

double

wishbone

type

suspension

used

the

torsion

bar

spring

Both

the

upper

and

lower

links

are

installed

on

the

bracket

which

is

welded

on

the

frame

A

1d

the

above

links

swing

to

allow

the

knuckle

spindle

to

move

freely

in

a

vertical

dimension

The

top

and

bottom

of

the

knuckle

spindle

support

are

connected

to

the

upper

link

through

rubber

bushing

and

to

the

lower

lick

through

screw

bushing

The

tension

rod

held

by

the

brack

ets

on

the

chassis

frame

and

lower

lick

wiih

rubber

bushings

bears

the

force

of

fore

and

aft

direction

The

front

end

of

the

torsion

bar

spring

is

installed

to

the

torque

arm

which

attaches

to

the

lower

link

The

opposite

end

is

installed

to

the

spring

anchor

that

secures

to

chassis

frame

firmly

The

both

ends

of

the

torsion

bar

spring

are

serrated

The

shock

absorber

is

double

action

telescopic

hydraulic

type

The

upper

stem

is

attached

to

the

bracket

of

the

chassis

frame

The

lower

insulated

bracket

is

bolted

to

the

lower

lick

The

bumper

rubber

secured

to

the

bracket

Of

the

frame

limits

the

verti

cal

motion

of

the

suspension

lick

The

knuckle

spindle

is

connecied

to

the

k

ufkle

spindle

arm

by

the

king

pin

The

king

pin

bushings

are

fitted

to

the

upper

and

lower

arm

portIOns

of

the

knuckle

spindle

and

seals

are

provided

at

the

portions

mentioned

to

keep

water

and

dirt

from

enteri

g

The

knuckle

arm

is

connected

to

the

lower

end

of

the

knuckle

spindle

to

transmit

ttLe

movement

of

the

steering

wheel

to

the

knuckle

spindle

The

wheel

hub

is

supported

by

two

taper

roller

bearings

on

the

knuckle

spindle

Tlie

brake

drum

and

wheel

are

secured

to

ihe

hub

by

the

hub

bolts

Front

Axle

Front

Suspension

FRONT

AXLE

REMOVAL

AND

INSTALLATION

Removal

I

Jack

up

and

support

vehicle

on

the

stands

at

the

frame

in

a

safe

manner

2

Remove

front

wheel

3

Re

ove

brake

hose

together

with

connector

from

wheel

cylinder

4

Remove

brake

drum

S

Remove

hub

cap

and

then

remove

cotter

pin

adjusting

cap

and

spindle

nut

from

knuckle

spindle

6

Remove

wheel

hub

outer

and

inner

wheel

bearings

bearing

washer

and

grease

seal

from

knuckle

spindle

7

Remove

brake

disc

assembly

from

the

flange

of

knuckle

spindle

8

Remove

knuckle

arm

from

knuckle

spindle

9

Remove

king

pin

lock

bolt

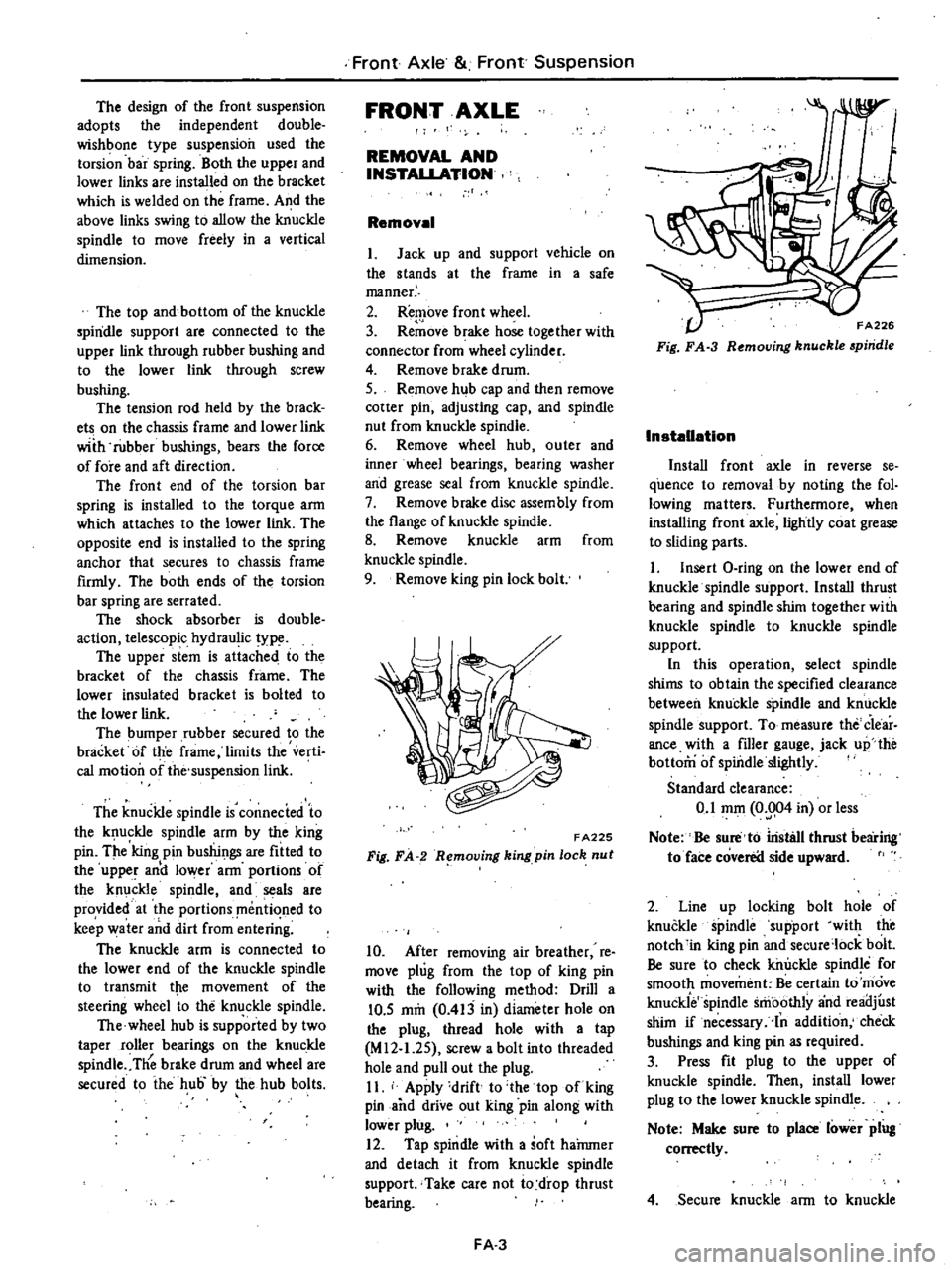

FA225

Fig

FA

R

mol1ing

king

pin

loch

nut

10

After

removing

air

breather

re

move

plug

from

the

top

of

king

pin

with

the

following

method

Drill

a

10

5

mm

0

413

in

diameter

hole

on

the

plug

thread

hole

with

a

tap

M

12

1

2S

screw

a

bolt

into

threaded

hole

and

pull

out

the

plug

II

Apply

drift

to

the

top

of

king

pin

and

drive

out

king

pin

along

with

lower

plug

12

Tap

spindle

with

a

soft

haJnmer

and

detach

it

from

knuckle

spindle

support

Take

care

not

io

drop

thrust

bearing

FA

3

FA226

Fig

FA

3

R

moving

knuckle

piridle

Installation

Install

front

axle

in

reverse

se

quence

to

removal

by

noting

the

fol

lowing

matters

Furthermore

when

installing

front

axle

lightly

coat

grease

to

sliding

parts

I

Insert

O

ring

on

the

lower

end

of

knuckle

spindle

support

Install

thrust

bearing

and

spindle

shim

together

with

knuckle

spindle

to

knuckle

spindle

support

In

this

operation

select

spindle

shims

to

obtain

the

specified

clearance

between

knuckle

spindle

and

knuckle

spindle

support

To

measure

the

Clear

ance

with

a

filler

gauge

jack

up

the

bottom

of

spindle

slightly

Standard

clearance

0

1

mOl

0

004

in

or

less

Note

Be

sure

to

iristsll

thrust

bearing

to

face

coverea

side

upward

2

Line

up

locking

bolt

hole

of

knuckle

spindle

support

with

the

notch

in

king

pin

and

secure

lock

bolt

Be

sure

to

check

killJckle

spindle

for

smooth

movement

Be

certain

to

move

knuckie

spindle

smoothly

and

reailjust

shim

if

necessary

In

addition

check

bushings

and

king

pin

as

required

3

Press

fit

plug

to

the

upper

of

knuckle

spindle

Then

install

lower

plug

to

the

lower

knuckle

spindle

Note

Make

sure

to

place

lower

plug

conectly

4

Secure

knuckle

arm

to

knuckle

Page 354 of 537

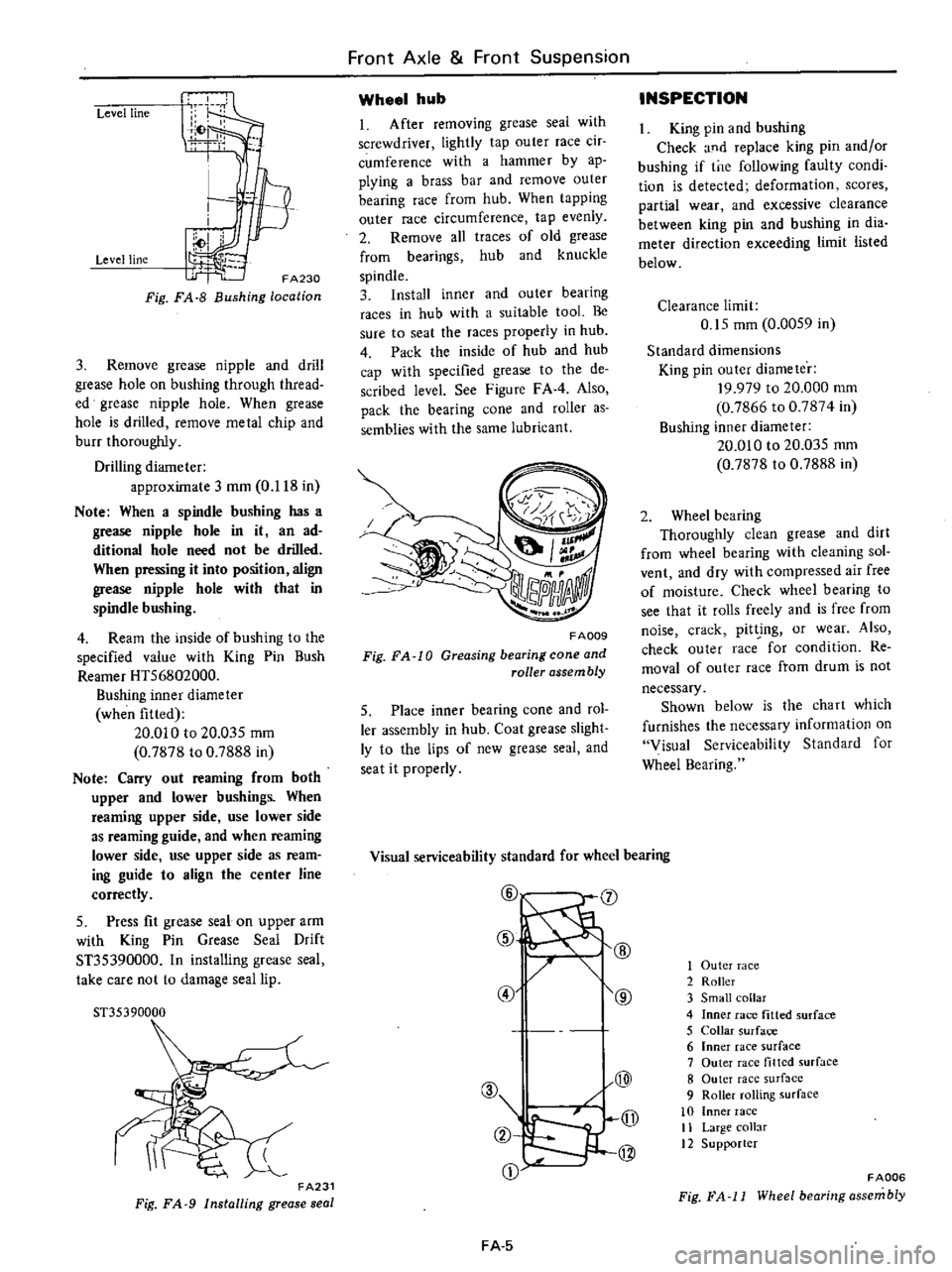

Level

line

Level

line

FA230

Fig

FA

8

Bushing

location

3

Remove

grease

nipple

and

drill

grease

hole

on

bushing

through

thread

ed

grease

nipple

hole

When

grease

hole

is

drilled

remove

metal

chip

and

burr

thoroughly

Drilling

diameter

approximate

3

mOl

0

118

in

Note

When

a

spindle

bushing

has

a

grease

nipple

hole

in

it

an

ad

ditional

hole

need

not

be

drilled

When

pressing

it

into

position

align

grease

nipple

hole

with

that

in

spindle

bushing

4

Ream

the

inside

of

bushing

to

the

specified

value

with

King

Pin

Bush

Reamer

HT56802000

Bushing

inner

diameter

when

fitted

20

010

to

20

03S

mOl

0

7878

to

0

7888

in

Note

Carry

out

reaming

from

both

upper

and

lower

bushings

When

reaming

upper

side

use

lower

side

as

reaming

guide

and

when

reaming

lower

side

use

upper

side

as

ream

ing

guide

to

align

the

center

line

correctly

5

Press

fit

grease

seal

on

upper

arm

with

King

Pin

Grease

Seal

Drift

ST35390000

In

installing

grease

seal

take

care

not

to

damage

seal

lip

51

35390000

FA231

Fig

FA

9

Installing

grease

seal

Front

Axle

Front

Suspension

Wheel

hub

1

After

removing

grease

seal

with

screwdriver

lightly

tap

outer

race

cir

cumference

with

a

hammer

by

ap

plying

a

brass

bar

and

remove

outer

bearing

race

from

hub

When

tapping

outer

race

circumference

tap

evenly

2

Remove

all

traces

of

old

grease

from

bearings

hub

and

knuckle

spindle

3

Install

inner

and

outer

bearing

races

in

hub

with

a

suitable

tool

Be

sure

to

seat

the

races

properly

in

hub

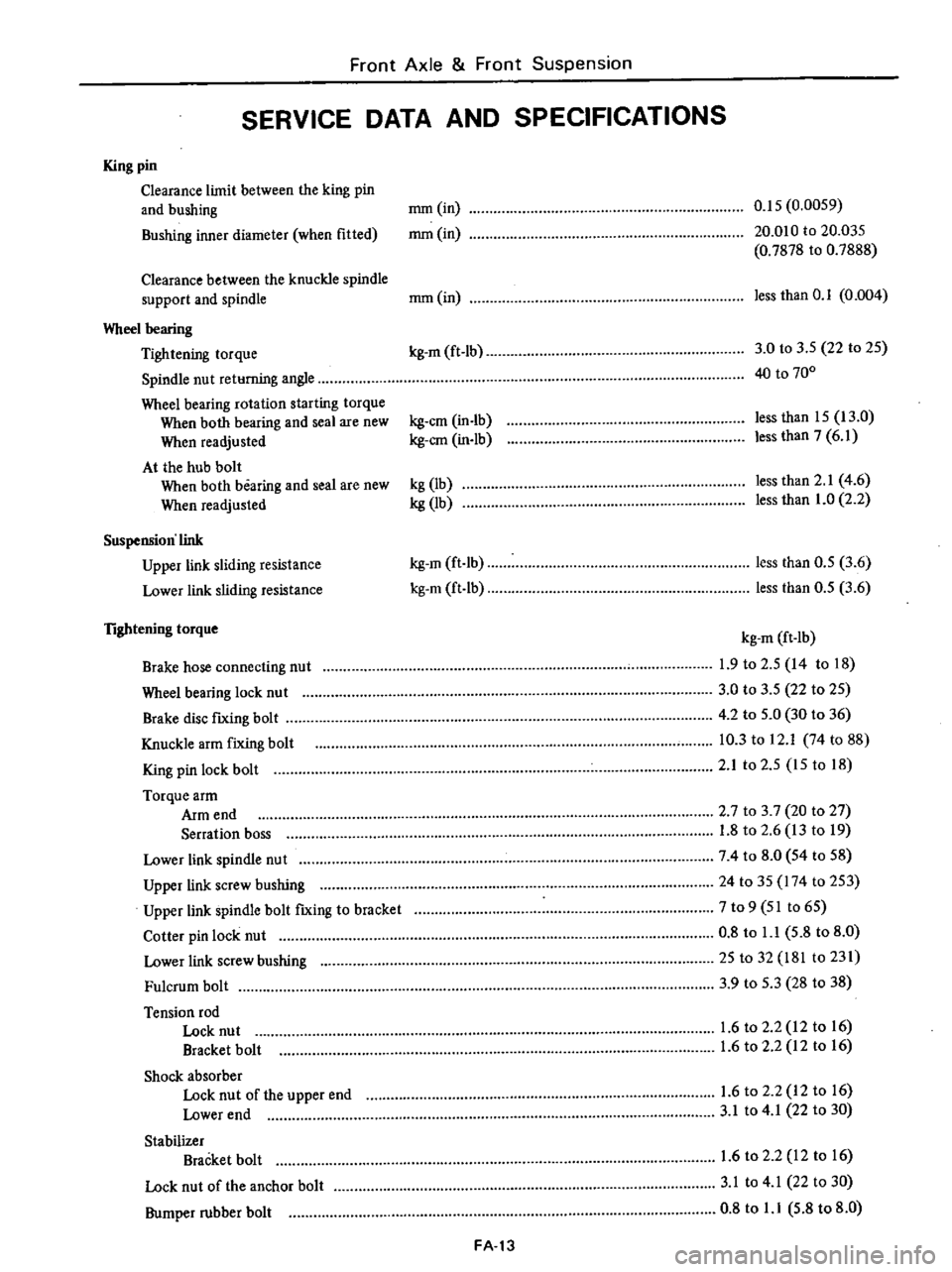

4

Pack

the

inside

of

hub

and

hub

cap

with

specified

grease

to

the

de

scribed

level

See

Figure

FAA

Also

pack

the

bearing

cone

and

roller

as

semblies

with

the

same

lubricant

FA009

Fig

FA

10

Greasing

bearing

cone

and

roller

assembly

5

Place

inner

bearing

cone

and

rol

ler

assembly

in

hub

Coat

grease

slight

ly

to

the

lips

of

new

grease

seal

and

seat

it

properly

INSPECTION

King

pin

and

bushing

Check

and

replace

king

pin

andlor

bushing

if

tne

following

faulty

condi

tion

is

detected

deformation

scores

partial

wear

and

excessive

clearance

between

king

pin

and

bushing

in

dia

meter

direction

exceeding

limit

listed

below

Clearance

limit

0

15

mOl

0

00S9

in

Standard

dimensions

King

pin

outer

diameter

19

979

to

20

000

mm

0

7866

to

0

7874

in

Bushing

inner

diameter

20

010

to

20

035

mOl

0

7878

to

0

7888

in

2

Wheel

bearing

ThorougWy

clean

grease

and

dirt

from

wheel

bearing

with

cleaning

sol

vent

and

dry

with

compressed

air

free

of

moisture

Check

wheel

bearing

to

see

that

it

rolls

freely

and

is

free

from

noise

crack

pit

ing

or

wear

Also

check

outer

race

for

condition

Re

moval

of

outer

race

from

drum

is

not

necessary

Shown

below

is

the

cha

rt

which

furnishes

the

necessary

information

on

Visual

Serviceability

Standard

for

Wheel

Bearing

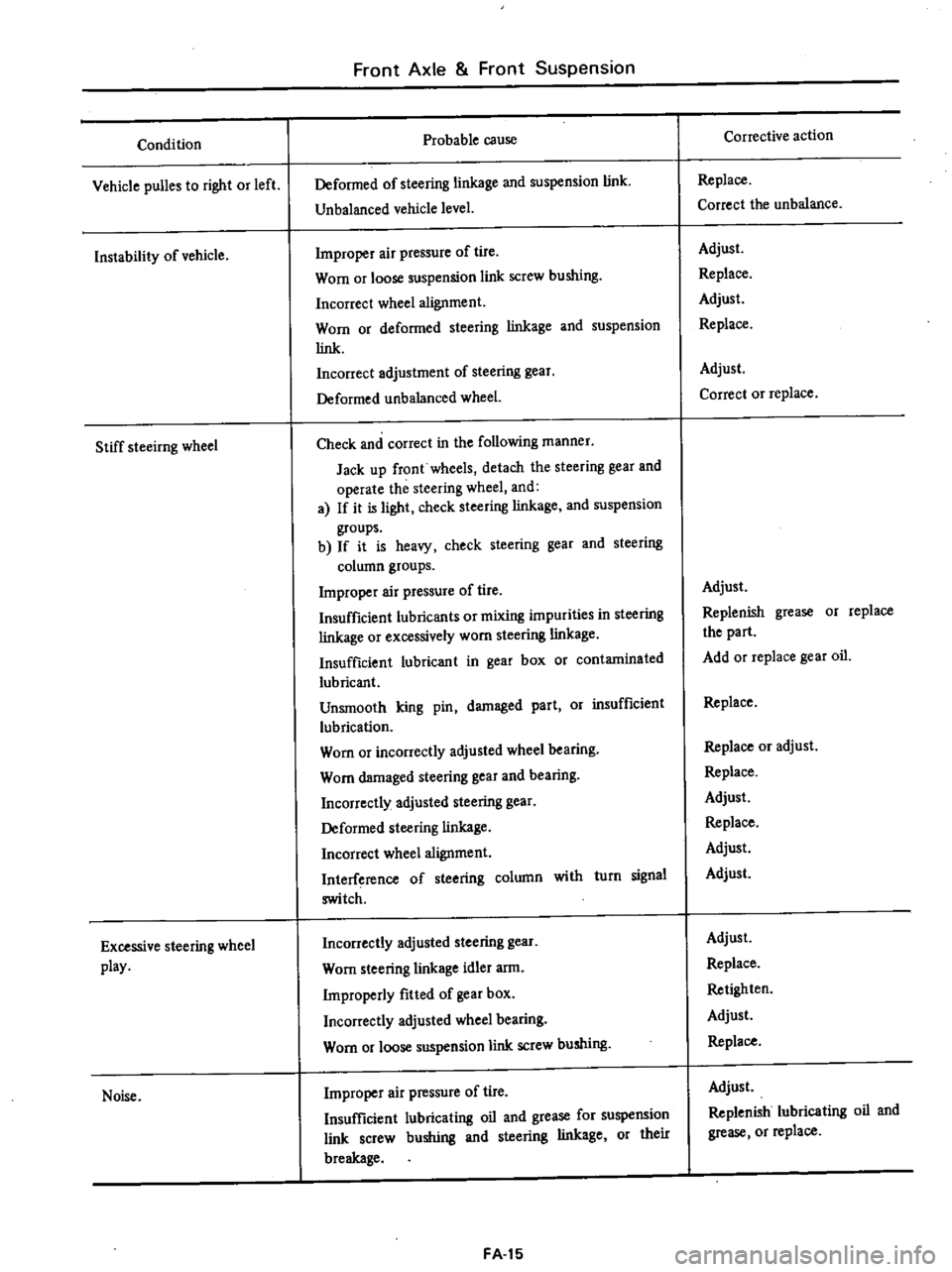

Visual

serviceability

standard

for

wheel

bearing

@

J

@

@

@

@

@

A

Q

jJ

2

@

CD

FA

5

1

Outer

race

2

Roller

3

Small

collar

4

Inner

race

fitted

surface

5

Collar

surface

6

Inner

race

surface

7

Outer

race

tilted

surface

8

Outer

race

surf

lcc

9

Roller

rolling

surface

10

Inner

race

11

Large

collar

12

Supporter

FADD6

Fig

FA

11

Wheel

bearing

assembly

Page 356 of 537

Components

Rust

Discoloring

Race

and

roller

u

u

e

2

2

0

3

0

t

c

6

6

6

Fig

h

The

wheel

bearing

is

serv

iceable

if

discoloring

can

be

removed

with

solvent

or

by

polishing

f

a

Inner

race

flaking

t

d

Cracked

roller

iT

t

j

t

11

1

1

t

t

I

l

1

t

F

1ll

JJ

J

t

I

1

ollf

oe

c

g

Recess

on

foDer

Front

Axle

Front

Suspension

Cause

Temperature

increased

during

operation

lowers

when

the

bearing

stops

moisture

inside

the

bearing

is

condensed

becoming

fine

drips

and

the

grease

is

moistened

The

bearing

has

been

placed

in

a

highly

moistened

place

for

a

long

period

of

time

Intrusion

of

moisture

chemicals

etc

or

the

bearing

is

touched

with

bare

hand

and

no

rustproof

action

has

been

taken

Slight

discoloring

may

become

like

oxidized

oil

stain

due

to

grease

In

the

most

cases

this

occurs

when

preliminary

pressure

is

too

high

I

I

I

1

v

i

n

dJ

b

RoUer

flaking

c

Cracked

inner

race

c

f

J

Jt

v

l

e

Recess

on

inner

race

f

Recess

on

outer

race

h

Rust

outer

race

F

A007

Fig

FA

12

Defective

conditions

of

bearing

FA

7

Page 362 of 537

Front

Axle

Front

Suspension

SERVICE

DATA

AND

SPECIFICATIONS

King

pin

Clearance

limit

between

the

king

pin

and

bushing

mm

in

0

15

0

0059

Bushing

inner

diameter

when

fitted

mm

in

20

010

to

20

035

0

7878

to

0

7888

Clearance

between

the

knuckle

spindle

support

and

spindle

mm

in

less

than

0

1

0

004

Wheel

bearing

Tightening

torque

kg

m

ft

Ib

3

0

to

3

S

22

to

2S

Spindle

nut

returning

angle

40

to

700

Wheel

bearing

rotation

starting

torque

When

both

bearing

and

seal

are

new

kg

em

in

Ib

less

than

IS

13

0

When

readjusted

kg

em

in

lb

less

than

7

6

1

At

the

hub

bolt

When

both

bearing

and

seal

are

new

kg

lb

less

than

2

1

4

6

When

readjusted

kg

lb

less

than

1

0

2

2

Suspension

link

Upper

link

sliding

resistance

kg

m

ft

Ib

less

than

O

S

3

6

Lower

link

sliding

resistance

kg

m

ft

lb

less

than

O

S

3

6

lightening

torque

kg

m

ft

Ib

Brake

hose

connecting

nut

1

9

to

2

S

14

to

18

Wheel

bearing

lock

nu

t

3

0

to

3

5

22

to

2S

Brake

disc

fIXing

bolt

4

2

to

S

O

30

to

36

Knuckle

arm

fixing

bolt

10

3

to

12

1

74

to

88

King

pin

lock

bolt

2

1

to

2

S

IS

to

18

Torque

arm

Arm

end

2

7

to

3

7

20

to

27

Serration

boss

1

8

to

2

6

13

to

19

Lower

link

spindle

nut

74

to

8

0

S4

to

58

Upper

link

screw

bushing

24

to

35

174

to

2S3

Upper

link

spindle

bolt

fIXing

to

bracket

7

to

9

51

to

6S

Cotter

pin

lock

nut

0

8

to

l

l

5

8

to

8

0

Lower

link

screw

bushing

25

to

32

181

to

231

Fulcrum

bolt

3

9

to

S

3

28

to

38

Tension

rod

Lock

nut

1

6

to

2

2

12

to

16

Bracket

bolt

1

6

to

2

2

12

to

16

Shock

absorber

Lock

nut

of

the

upper

end

1

6

to

2

2

12

to

16

Lower

end

3

1

to

4

1

22

to

30

Stabilizer

Bracket

bolt

1

6

to

2

2

12

to

16

Lock

nut

of

the

anchor

bolt

3

1

to

4

1

22

to

30

Bumper

rubber

bolt

0

8

to

l

l

5

8

to

8

0

FA

13

Page 364 of 537

Condition

Vehicle

puBes

to

right

or

left

Instability

of

vehicle

Stiff

steeirng

wheel

Excessive

steering

wheel

play

Noise

Front

Axle

Front

Suspension

Probable

cause

Deformed

of

steering

linkage

and

suspension

link

Unbalanced

vehicle

level

Improper

air

pressure

of

tire

Worn

or

loose

suspension

link

screw

bushing

Incorrect

wheel

alignment

Worn

or

deformed

steering

linkage

and

suspension

link

Incorrect

adjustment

of

steering

gear

Deformed

unbalanced

wheel

Check

and

correct

in

the

following

manner

Jack

up

front

wheels

detach

the

steering

gear

and

operate

the

steering

wheel

and

a

If

it

is

light

check

steering

linkage

and

suspension

groups

b

If

it

is

heavy

check

steering

gear

and

steering

column

groups

Improper

air

pressure

of

tire

Insufficient

lubricants

or

mixing

impurities

in

steering

linkage

or

excessively

worn

steering

linkage

Insufficient

lubricant

in

gear

box

or

contaminated

lubricant

Unsmooth

king

pin

damaged

part

Or

insufficient

lubrication

Worn

or

incorrectly

adjusted

wheel

bearing

Worn

damaged

steering

gear

and

bearing

Incorrectly

adjusted

steering

gear

Deformed

steering

linkage

Incorrect

wheel

alignment

Interference

of

steering

column

with

turn

signal

switch

Incorrectly

adjusted

steering

gear

Worn

steering

linkage

idler

arm

Improperly

fitted

of

gear

box

Incorrectly

adjusted

wheel

bearing

Worn

or

loose

suspension

link

screw

bushing

Improper

air

pressure

of

tire

Insufficient

lubricating

oil

and

grease

for

suspension

link

screw

bushing

and

steering

linkage

or

their

breakage

FA

15

Corrective

action

Replace

Correct

the

unbalance

Adjust

Replace

Adjust

Replace

Adjust

Correct

or

replace

Adjust

Replenish

grease

or

replace

the

part

Add

or

replace

gear

oil

Replace

Replace

or

adjust

Replace

Adjust

Replace

Adjust

Adjust

Adjust

Replace

Retighten

Adjust

Replace

Adjust

Replenish

lubricating

oil

and

grease

or

replace

Page 383 of 537

REMOVAL

1

Removing

flare

nuts

on

both

ends

and

clips

effects

the

removal

of

brake

tube

and

brake

hose

2

Rear

brake

hose

can

be

removed

by

disconnecting

the

tube

and

then

turning

round

the

hose

Note

When

removing

brake

tubes

and

hoses

use

Flare

Nut

Torque

Wrench

GG943IOOOO

Never

use

an

OpeD

end

or

an

adjust

able

wrench

INSPECTION

1

Examine

all

hoses

for

swell

rubbing

marks

or

ozone

cracking

re

placing

those

found

with

any

of

above

badly

beyond

use

Also

inspect

end

fittings

and

be

sure

that

no

fluid

leak

through

staked

end

has

taken

place

replace

if

necessary

Hose

with

badly

rusted

fitting

should

also

be

replaced

with

a

new

one

2

Clean

all

tubes

to

remove

dust

and

dirt

with

isopropyl

alcohol

check

ing

for

collapse

wear

cracking

swell

or

rusting

Replace

if

foun

d

with

any

of

wove

Use

care

not

to

damage

brake

tubes

while

operation

Check

if

tubes

are

clamped

secure

ly

Mter

all

brake

lines

have

been

installed

retighten

aU

connections

if

necessary

to

assist

in

obtaining

correct

torque

In

retightening

at

front

wheel

cylinder

first

remove

hose

clamp

and

loosen

flare

nut

on

opposite

side

to

avoid

twisting

hose

Hold

pedal

as

far

downward

as

possible

80

kg

176

lb

or

more

examining

evidence

as

to

whether

fluid

is

leaking

through

brake

lines

or

con

nections

Leakage

in

any

manner

can

not

be

permitted

here

In

case

fluid

leaks

tightening

to

specified

torque

tighten

additionally

up

to

2

5

kg

m

J

8

ft

lb

Under

no

circumstances

should

not

be

tightened

over

2

5

kg

m

18

ft

Ib

torque

since

this

elongates

end

fitting

making

it

impossible

to

reuse

brake

tube

Under

no

circumstances

should

rear

brake

hose

and

3

way

connector

be

retightened

over

specified

torques

In

Brake

System

stead

replace

copper

washer

with

a

new

one

after

checking

for

sign

of

damage

on

seating

surface

Never

reuse

an

old

copper

washer

INSTALLATION

Brake

hose

Front

brake

hose

In

installing

brake

hose

first

jack

up

vehicle

to

take

off

the

weight

of

vehicle

from

wheels

so

that

suspension

is

in

rebound

Steering

wheel

should

also

be

kept

in

straight

ahead

position

To

connect

brake

line

first

connect

brake

hose

to

wheel

cylinder

with

the

specified

torque

Tightening

torque

1

7

to

2

0

kg

m

12

to

14

ft

Ib

Then

secure

brake

hose

to

the

bracket

with

lock

plate

so

as

not

to

twist

or

abnormally

bend

the

hose

Note

After

connecting

brake

hose

at

both

eiuIs

pay

keen

attention

not

to

twist

the

hose

when

additional

tightening

is

required

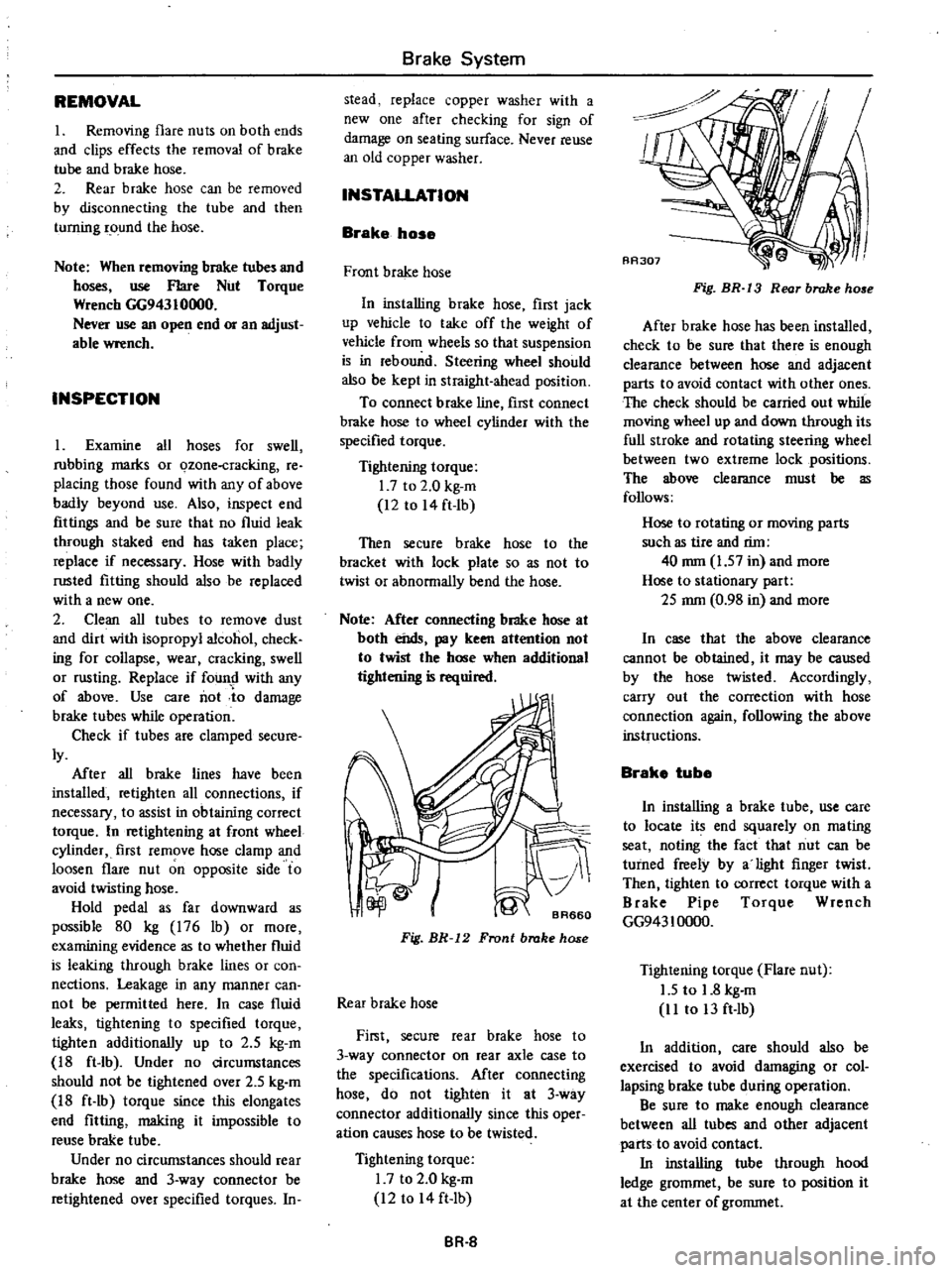

Fig

BR

12

Front

brake

hose

Rear

brake

hose

First

secure

rear

brake

hose

to

3

way

connector

on

rear

axle

case

to

the

specifications

Mter

connecting

hose

do

not

tighten

it

at

3

way

connector

additionally

since

this

oper

ation

causes

hose

to

be

twisted

Tightening

torque

I

7

to

2

0

kg

m

12

to

14

ft

Ib

BR

8

Fig

BR

13

Rear

brake

ho

e

After

brake

hose

has

been

installed

check

to

be

sure

that

there

is

enough

clearance

between

hose

and

adjacent

parts

to

avoid

contact

with

other

ones

The

check

should

be

carried

out

while

moving

wheel

up

and

down

through

its

full

stroke

and

rotating

steering

wheel

between

two

extreme

lock

positions

The

wow

clearance

must

be

as

follows

Hose

to

rotating

or

mOving

parts

such

as

tire

and

rim

40

mm

1

57

in

and

more

Hose

to

stationary

part

2S

mm

0

98

in

and

more

In

case

that

the

above

clearance

cannot

be

obtained

it

may

be

caused

by

the

hose

twisted

Accordingly

carry

out

the

correction

with

hose

connection

again

following

the

above

instructions

Brake

tube

In

installing

a

brake

tube

use

care

to

locate

its

end

squarely

on

mating

seat

noting

the

fact

that

nut

can

be

turned

freely

by

a

light

finger

twist

Then

tighten

to

correct

torque

with

a

Brake

Pipe

Torque

Wrench

GG943

10000

Tightening

torque

Flare

nut

1

5

to

1

8

kg

m

11

to

13

ft

Ib

In

addition

care

should

also

be

exercised

to

avoid

damaging

or

col

lapsing

brake

tube

during

operation

Be

sure

to

make

enough

clearance

between

all

tubes

and

other

adjacent

parts

to

avoid

contact

In

installing

tube

through

hood

ledge

grommet

be

sure

to

position

it

at

the

center

of

grommet

Page 384 of 537

After

connecting

brake

tube

be

sure

to

check

the

clearance

to

prevent

from

damage

The

clearance

at

the

following

portions

must

be

specified

distance

or

more

Tube

to

body

panel

and

frame

Over

5

mm

0

20

in

Tube

to

edge

of

each

panel

Over

10

mm

0

39

in

Tube

to

tube

Loop

pitch

OVer

5

mm

0

20

in

Between

front

tube

and

rear

tube

Over

9

mOl

0

35

in

Tube

to

moving

parts

Over

10

mm

0

39

in

Loop

tube

to

hood

ledge

panel

Over

10

mm

0

39

in

Notes

a

Brake

tubes

are

shaped

at

factory

to

secure

specified

clearance

and

may

not

require

reshaping

Discard

if

they

call

for

excessive

reshaping

b

In

reshaping

a

brake

tube

take

care

to

avoid

damaging

galvanization

or

collapsing

section

Mter

brake

lines

have

been

asssem

bled

check

to

make

sure

that

all

fittings

and

flare

nu

Is

ale

lightened

to

correct

torques

Tightenint

torque

Brake

tube

to

connector

I

Ston

kg

m

II

to

13

ft

Ib

Brake

tube

to

brake

hose

1

7

to

2

0

kg

m

12

to

14

ft

lb

Connector

and

clip

fixing

bolt

O

3S

to

O

4S

kg

m

2

5

to

3

3

ft

lb

3

way

connector

fixing

bolt

on

rear

axle

case

0

8

to

1

1

kg

m

6

to

8

ft

lb

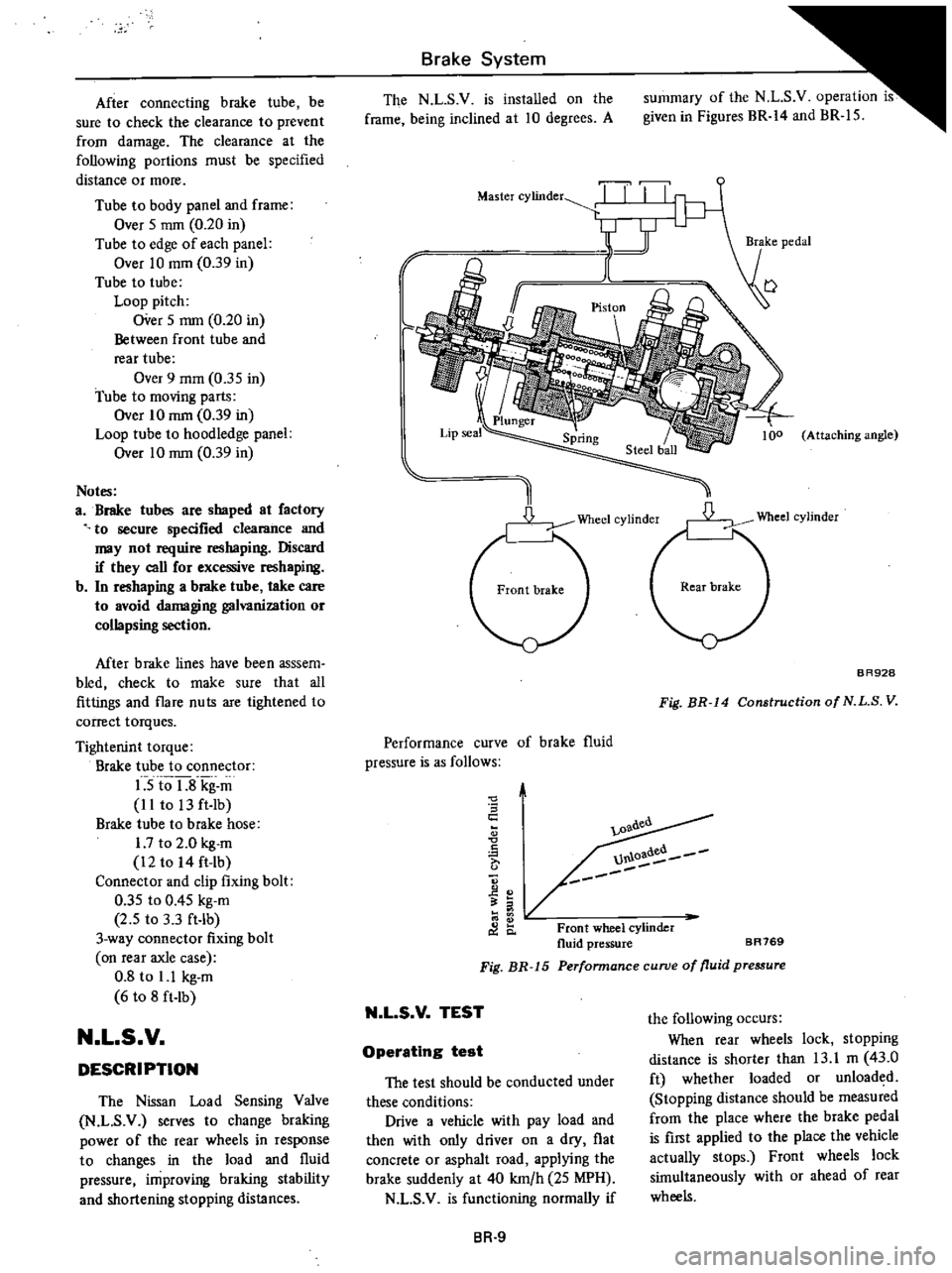

N

L

S

V

DESCRIPTION

The

Nissan

Load

Sensing

Valve

N

L

S

V

serves

to

change

braking

power

of

the

rear

wheels

in

response

to

changes

in

the

load

and

fluid

pressure

improving

braking

stability

and

shortening

stopping

distances

Brake

System

The

N

L

S

V

is

installed

on

the

frame

being

inclined

at

10

degrees

A

summary

of

the

N

L

S

v

operation

is

given

in

Figures

BR

14

and

BR

15

r

Master

cylinder

TI

II

I

y

1

J

I

l

Attaching

angle

D

Wheel

cylinder

BR928

Fig

BR

14

Construction

of

N

L

S

V

Performance

curve

of

brake

fluid

pressure

is

as

follows

0

S

c

A

0

C

o

l

0

oadea

U1U

Front

wheel

cylinder

fluid

pressure

BR769

Perfonnance

curve

of

fluid

pressure

Fig

BR

15

N

L

S

V

TEST

the

following

occurs

When

rear

wheels

lock

stopping

distance

is

shorter

than

13

1

m

43

0

ft

whether

loaded

or

unloaded

Stopping

distance

should

be

measured

from

the

place

where

the

brake

pedal

is

first

applied

to

the

place

the

vehicle

actually

stops

Front

wheels

lock

simultaneously

with

or

ahead

of

rear

wheels

Operating

test

The

test

should

be

conducted

under

these

conditions

Drive

a

vehicle

with

pay

load

and

then

with

only

driver

on

a

dry

flat

concrete

or

asphalt

road

applying

the

brake

suddenly

at

40

km

h

25

MPH

N

L

S

V

is

functioning

normally

if

BR

9